Vibration mechanism of vibrating subsoiler

A technology of vibration mechanism and subsoiler, which is applied to agricultural machinery and implements, applications, plows, etc., can solve the problems of increasing subsoiling operation costs and fuel consumption, high-power tractors are bulky, and difficult to turn at the headlands, etc., to improve soil circulation. Permeability, increase soil water storage capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

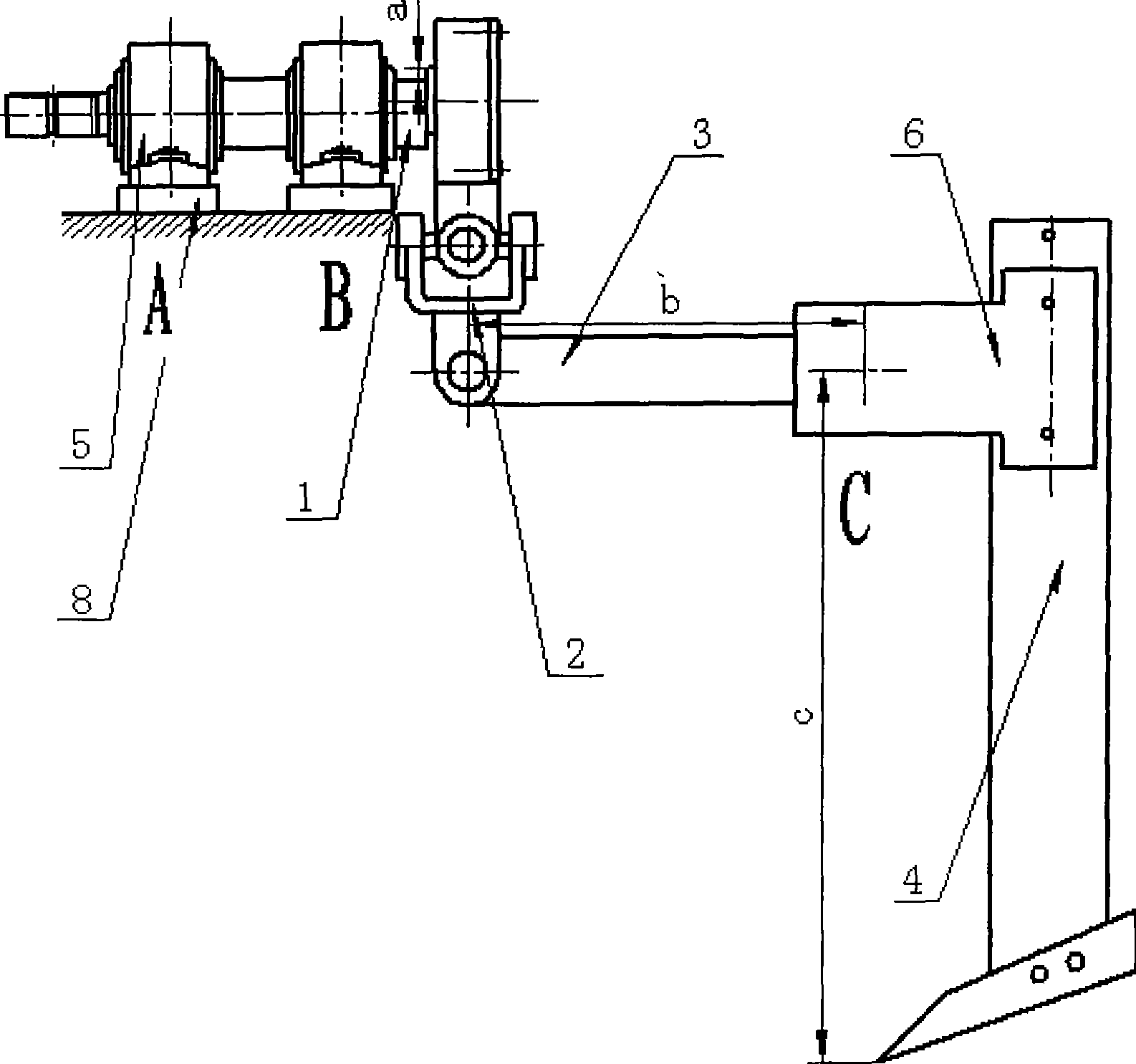

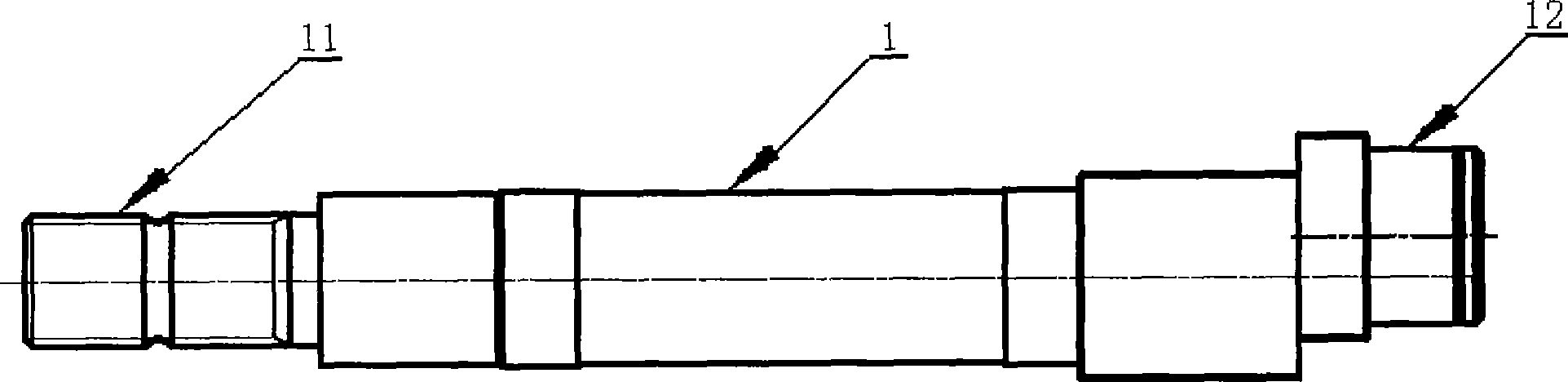

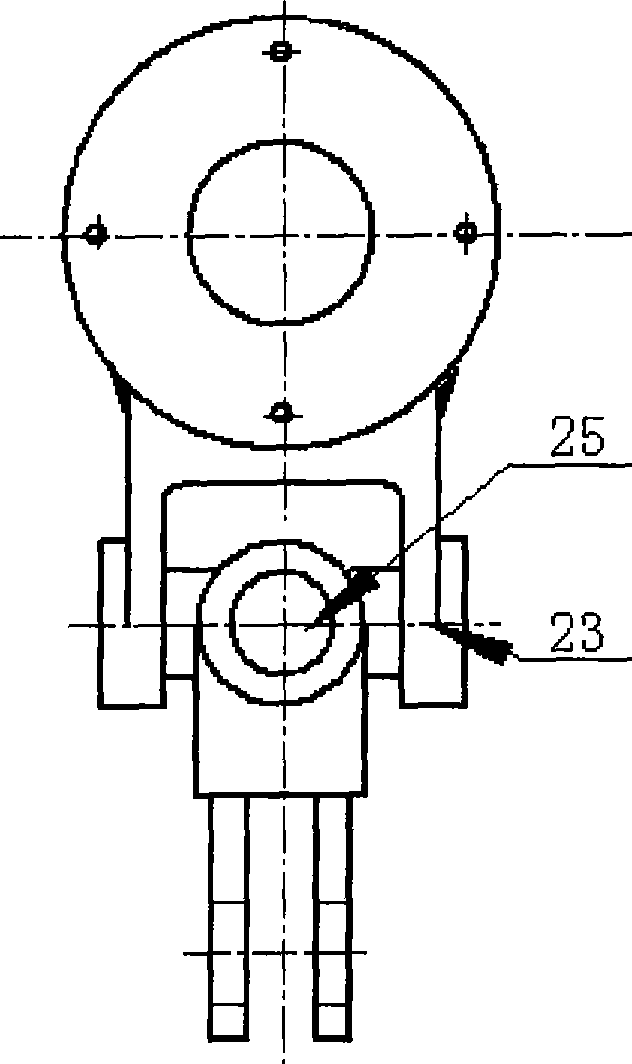

[0017] Such as figure 1 , 2 As shown, the present invention includes an eccentric shaft 1, an Oldham coupling 2, a lever 3 and a deep loosening blade 4. One end of the eccentric shaft 1 is a hexagonal spline shaft end 11 , and the other end is an eccentric shaft end 12 , and the eccentric shaft 1 is supported by two bearing seats 5 to form a cantilever shaft. The spline shaft end 11 of the eccentric shaft 1 is connected with the power output shaft of the tractor through a coupling, and the eccentric shaft end 12 of the eccentric shaft 1 is connected to the cross shaft coupling 2 through a bearing and a retaining spring. The lower end of the cross shaft coupling 2 is hinged on one end of the lever 3, and the other end of the lever 3 has a pair of outriggers 6, and a subsoiling shovel 4 is vertically fixed on each outrigger 6.

[0018] Such as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com