A construction method in which a rectangular enclosure pile and an enclosure structure double as a main structure

A technology of the main structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, excavation, etc., can solve the problems of difficult to guarantee the quality of piles, the influence of the surrounding environment, broken piles and mud inclusions, etc., to save the absolute construction period , The effect of improving construction speed and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing, implementation method of the present invention is described in detail:

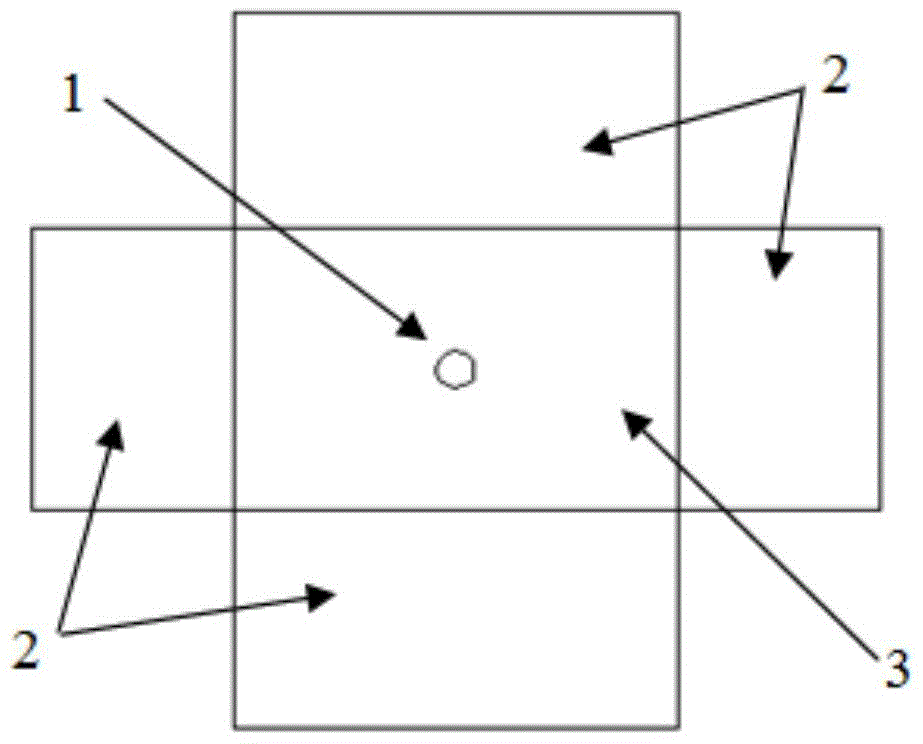

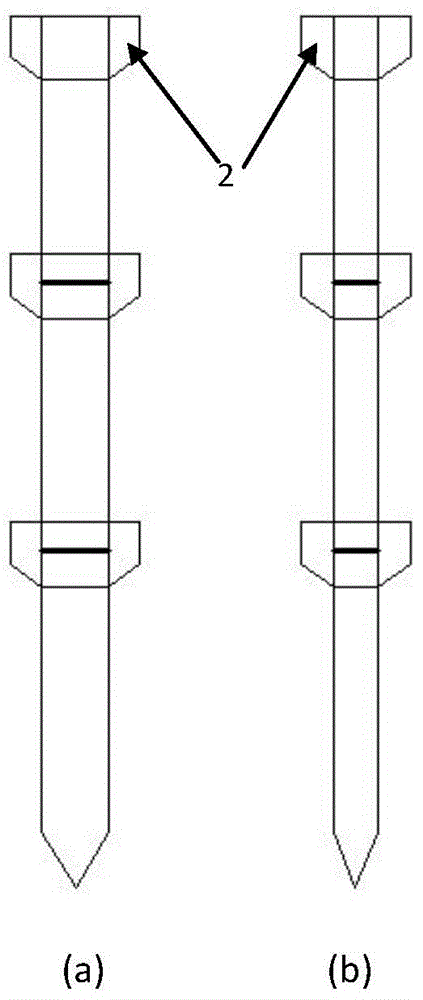

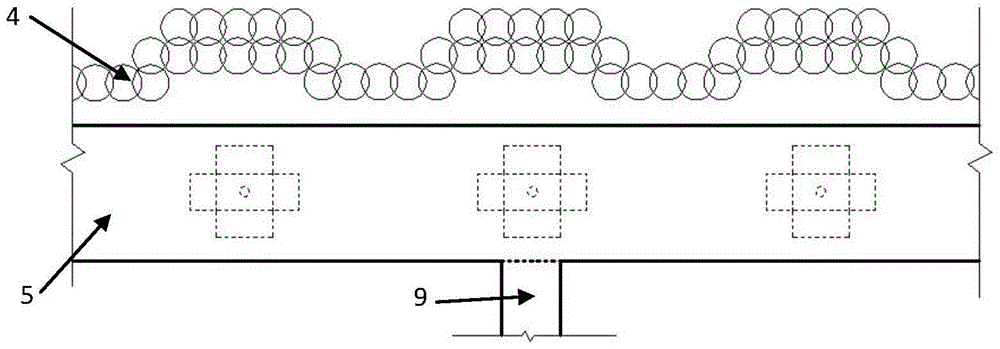

[0056] A rectangular enclosure pile, including a plurality of prefabricated rectangular piles 3 arranged according to set positions, connected by supporting members between adjacent piles; the rectangular pile is not only the enclosure structure of the foundation pit but also a building It is a part of the outer wall of the main structure of the underground space, and the horizontal and vertical components of the main structure of the building are also used as the horizontal support and vertical support of the foundation pit support.

[0057] The support includes a crown beam 5, a waist beam 8 and a partition wall 7, the crown beam is horizontally fixed on the top of the adjacent rectangular pile, and the waist beam is horizontally fixed on the corbel of the adjacent rectangular pile At 2, the crown beam and the waist beam are connected to the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com