Buckwheat intertillage weeding machine

A weeding machine and buckwheat technology, which is applied in the fields of soil preparation machinery, agricultural machinery and implements, and applications, can solve the problems of large working resistance, low removal rate, and easy entanglement of grass, and achieves easy entry into the soil, increased removal rate, and unearthed Effortless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

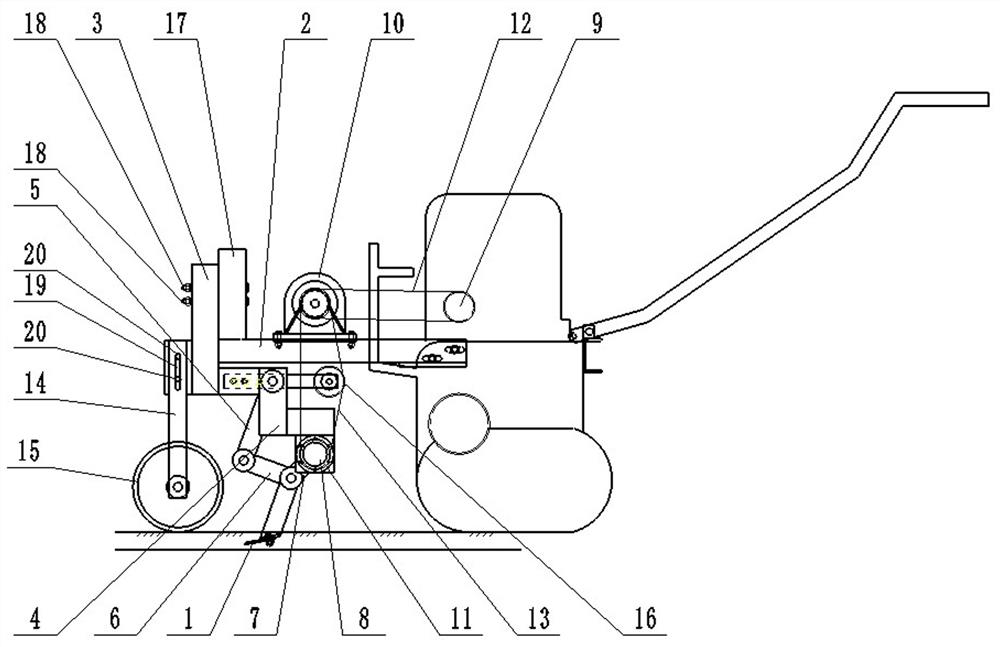

[0024] A kind of buckwheat cultivating and weeding machine, as attached figure 1 Shown, comprise walk-behind tractor and hoe knife 1, described walk-behind tractor comprises frame 2 and motor; A Z-shaped bracket 4 located below the frame 2 is fixed, and a crank-rocker mechanism is arranged on the Z-shaped bracket 4, and the motor is connected to the crank-rocker mechanism through a transmission mechanism;

[0025] as attached figure 1 As shown, the crank rocker mechanism includes a rocker 5 whose top end is hinged to the upper part of the Z-shaped bracket 4, and the bottom end of the rocker 5 is provided with an inverted L-shaped connecting rod 6 whose left end is hinged to it, and the hoe blade 1 is fixedly connected At the lower right end of the inverted L-shaped connecting rod 6; the upper right end of the inverted L-shaped connecting rod 6 is provided with a crank rod 7 located on its front side, one end of the crank rod 7 is hinged with the inverted L-shaped connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com