Pull-type ditching system for combined direct seed machine

A traction type, direct seeding machine technology, applied in the direction of excavation/covering trenches, planting methods, sustainable manufacturing/processing, etc., can solve the problems of difficulty in guaranteeing the trench type, and the tractor power cannot be reasonably utilized, such as trenching resistance, etc. To achieve the effect of good effect, low ditching resistance and easy entry into the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

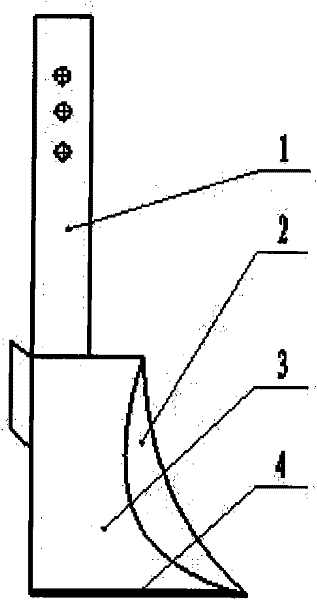

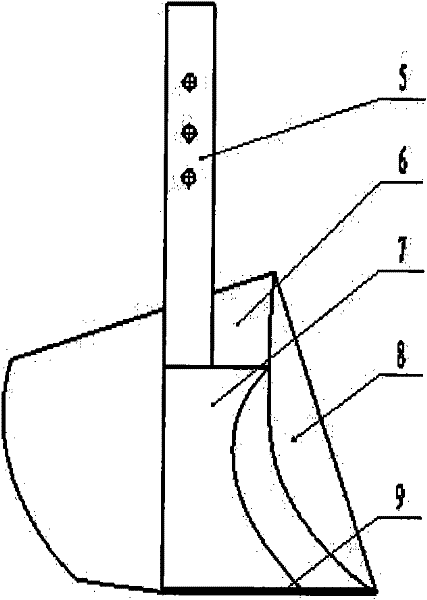

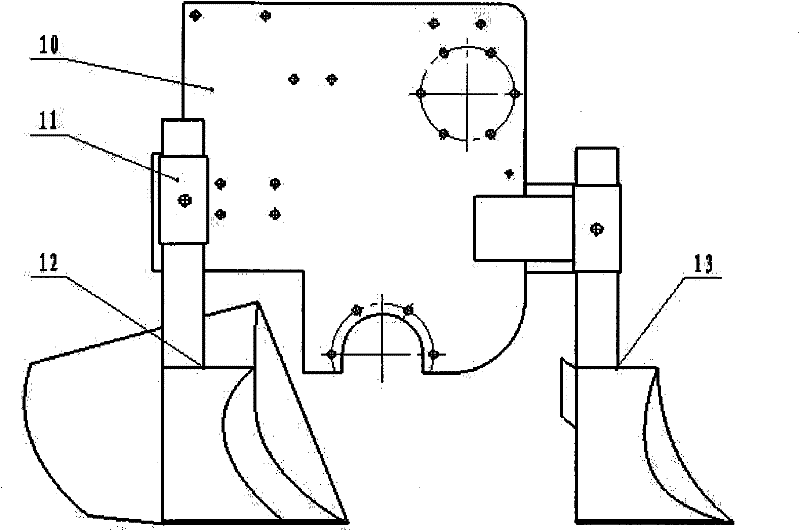

[0021] according to figure 1 , figure 2 , image 3 and Figure 4 It can be seen that in the traction type ditching system used in combination with the direct seeding machine of the present invention, two front plows (13) are symmetrically installed in front of the side plate of the seeder, and two front plows (13) are symmetrically installed behind the side plate of the seeder. The rear plow (12); the front plow (13) is a single-sided plowshare, with the plowshare face facing the forward direction, and it includes a welded front plow post (1), a front plow surface (2), a front plow The plow side plate (3) and the front plow bottom plate (4); the plow share surface of the rear plow (12) is at an angle of 30 degrees to the forward direction, and the rear plow (12) includes a welded one-piece rear plow column (5), rear plow plow face (6), rear plow dividing soil pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com