Patents

Literature

72results about How to "Improve performance in soil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

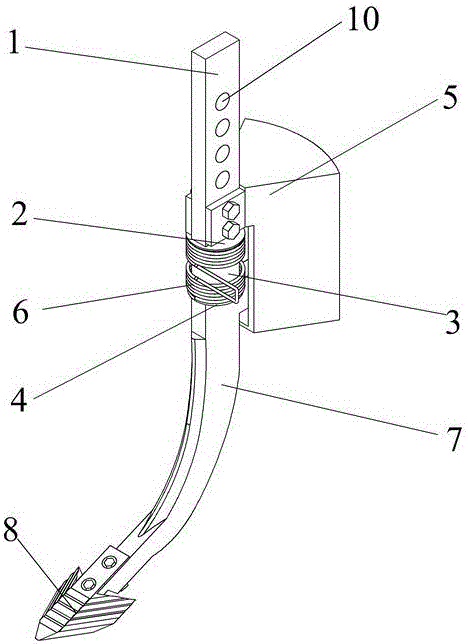

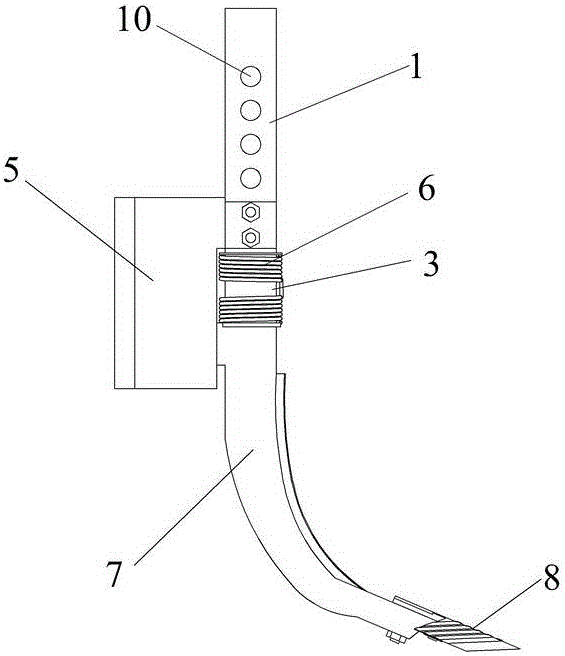

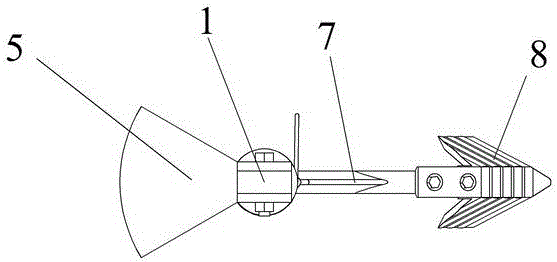

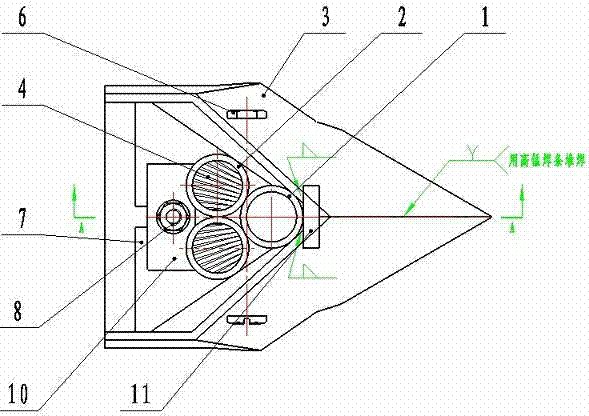

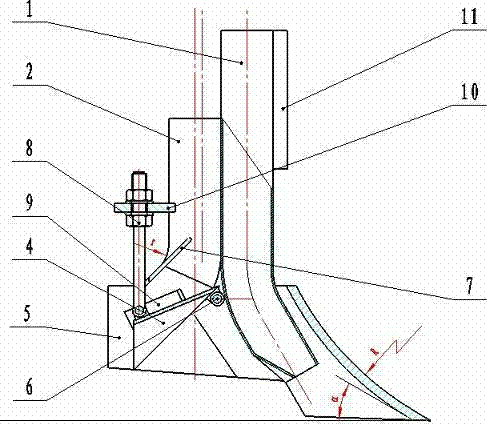

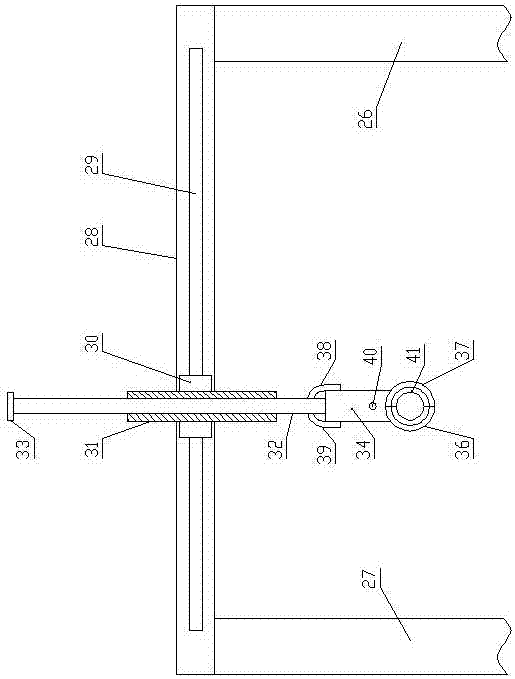

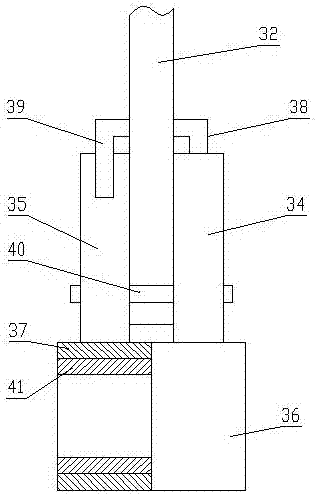

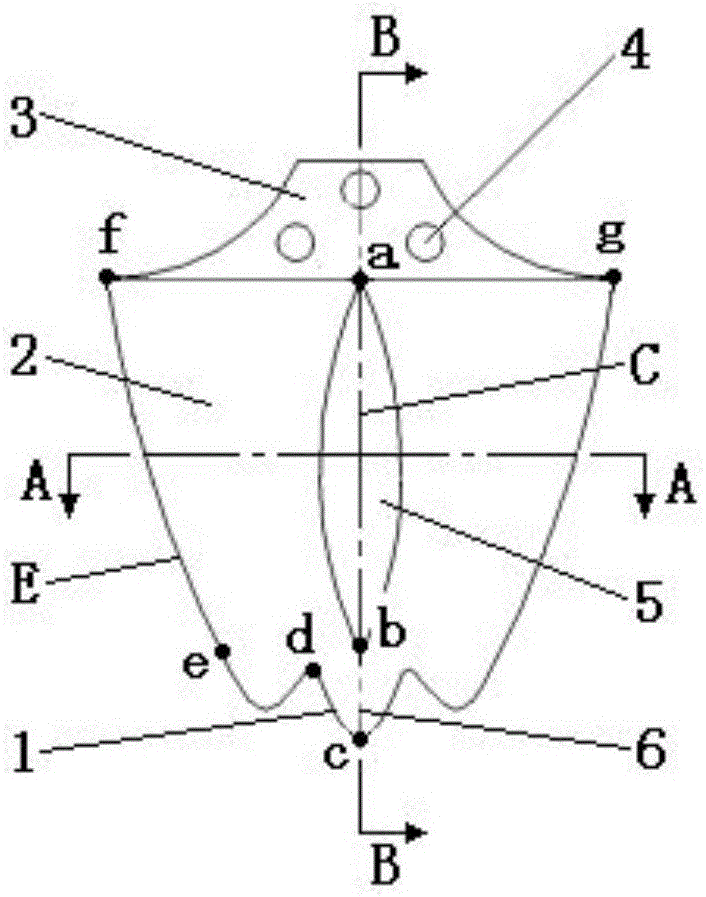

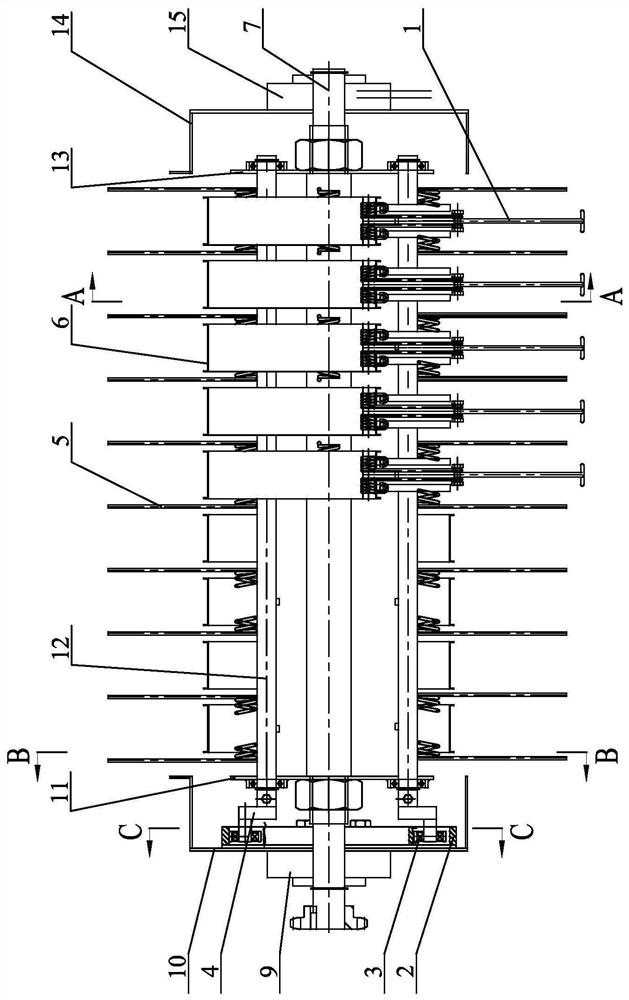

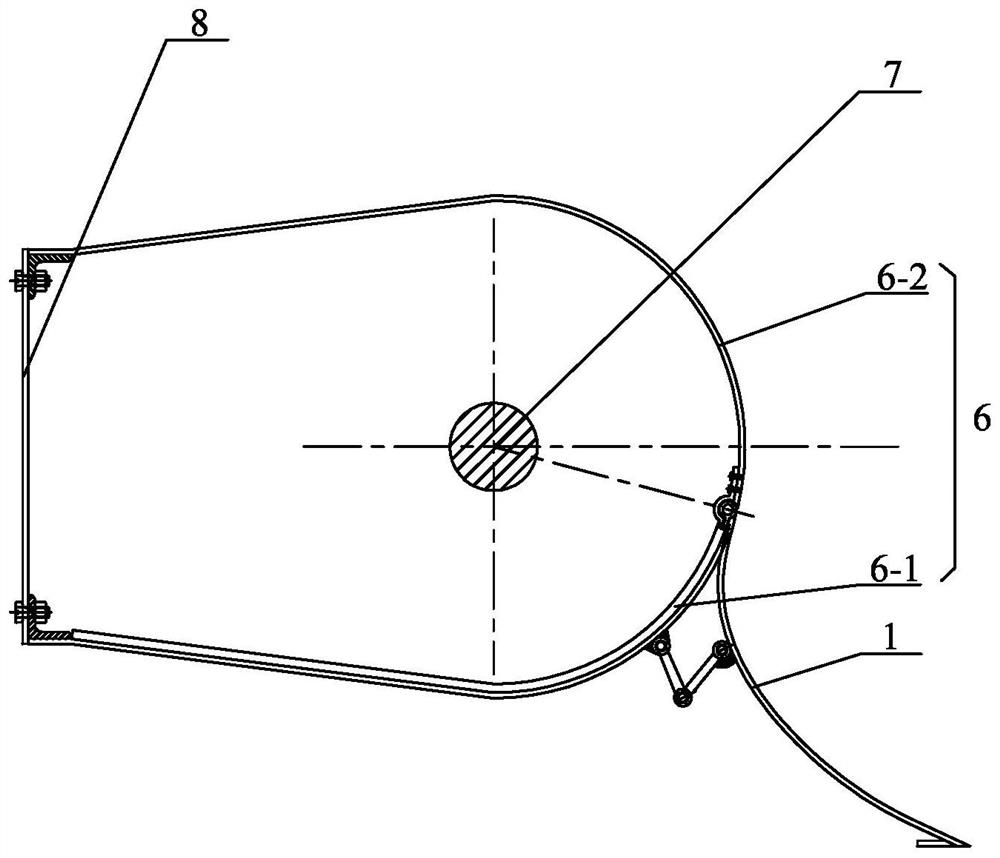

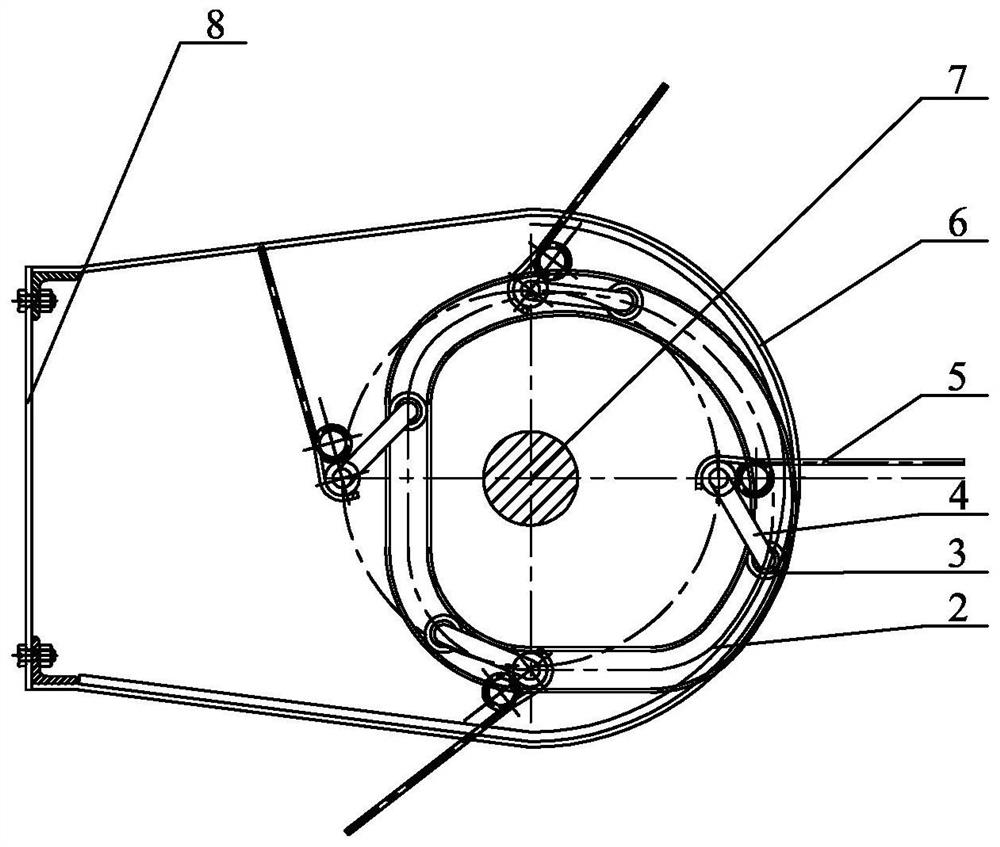

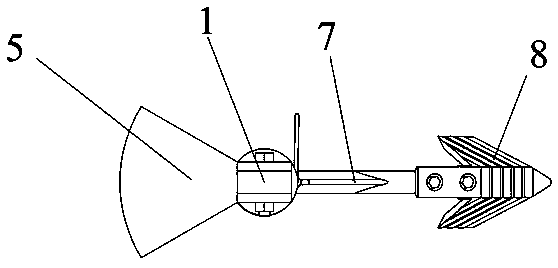

Subsoiler based on dynamic bionic principle

InactiveCN105874902AAchieve dynamic loosening effectImprove performance in soilPloughsEngineeringTorsion spring

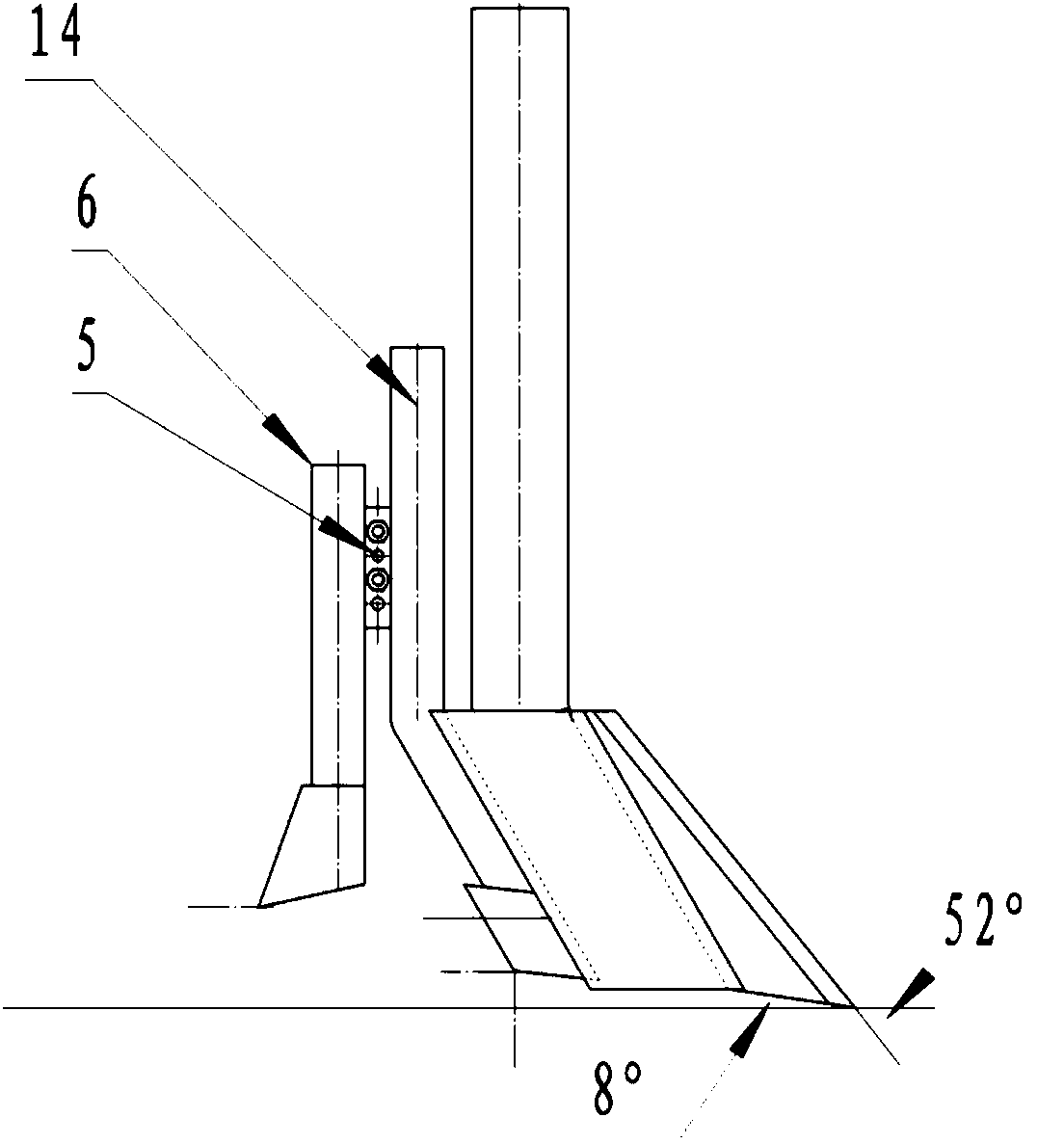

The invention discloses a subsoiler based on a dynamic bionic principle. The subsoiler comprises a subsoiler mounting handle, a limiting device, a bidirectional torsion spring, a subsoiler handle, a subsoiler tip and a pulley, wherein the subsoiler mounting handle and the subsoiler handle are mounted through a bearing, so that the subsoiler handle can be rotated at the bottom of the soil; the pulley is mounted at the rear end of the subsoiler handle, is in contact with the limiting device and is used for supplying a support force along a heading direction and limiting the rotating angle; the bidirectional torsion spring is mounted at the external end of the bearing, so that the rotating resetting of the subsoiler is realized and the dynamic operation effect is achieved; the subsoiler is optimized through bionic curve design, so that the improvement of the soil-breaking property is ensured; the dynamic bionic principle is designed and the moving form of the whole subsoiler is similar to the forms of the animals, such as, earthworm, mole cricket, and the like, in the moving process, so that the dynamic bionic motion is realized.

Owner:JILIN UNIV

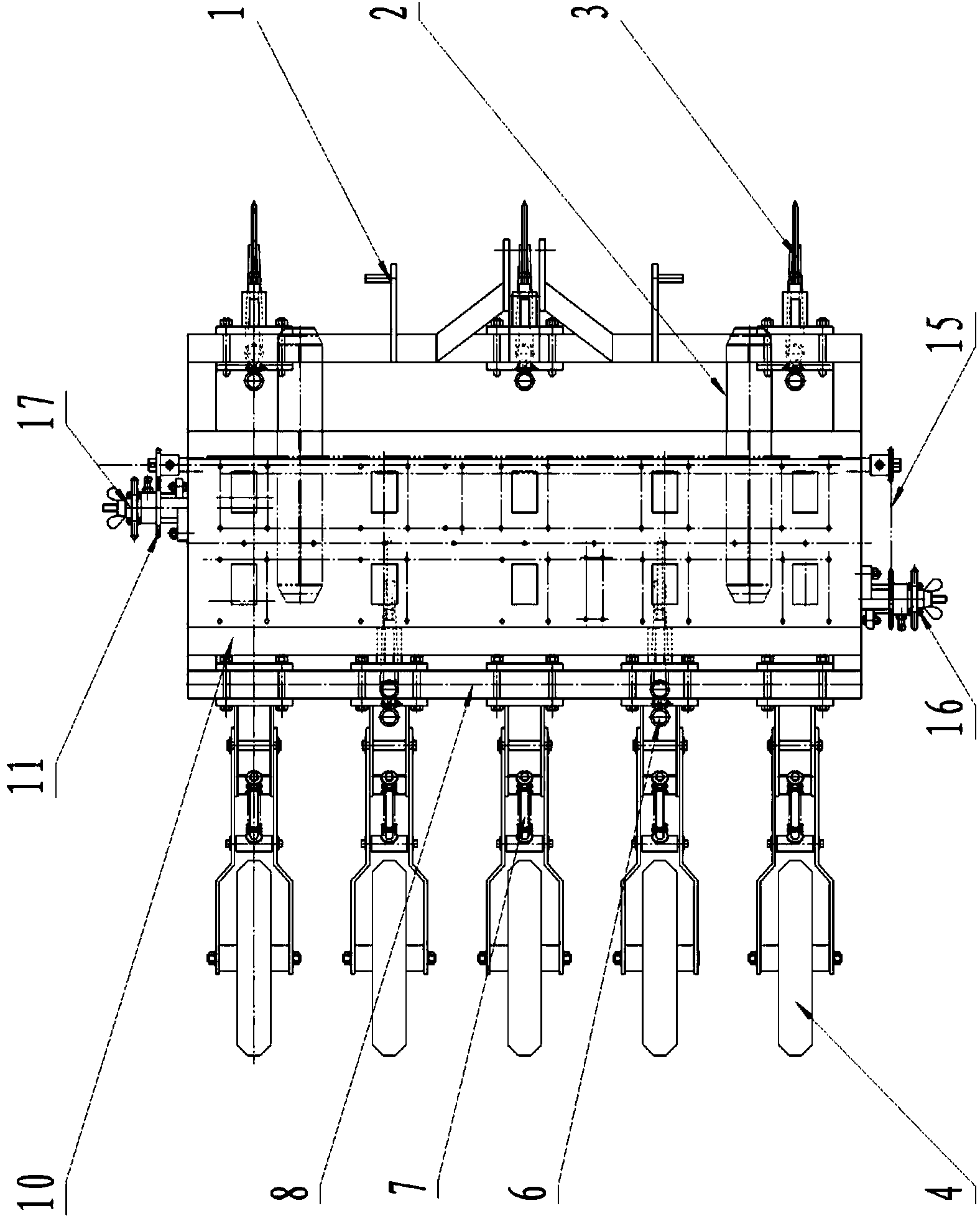

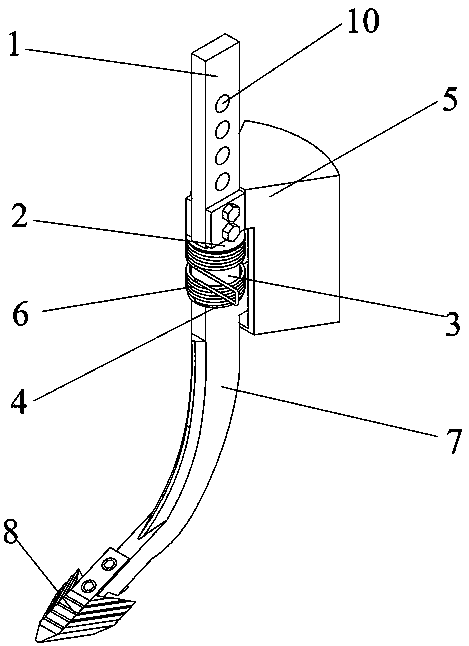

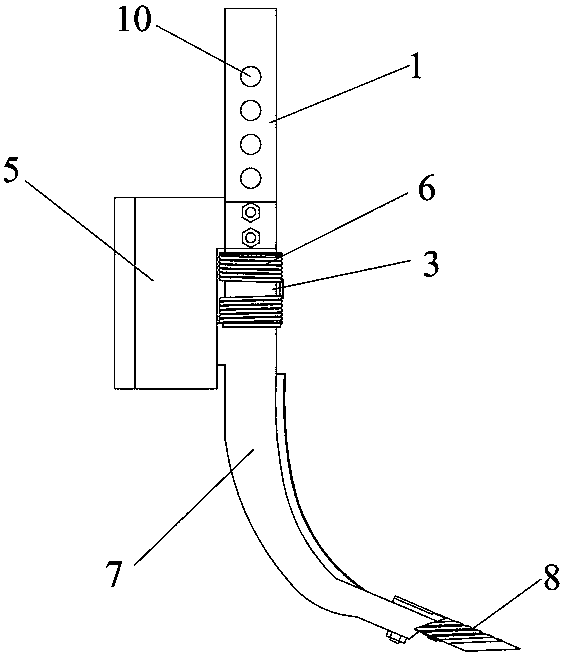

Combined type ditcher for wheat sowing

InactiveCN102388702AImprove performance in soilImprove ditching qualityPlantingFurrow making/coveringWedge angleBiology

The invention relates to a combined type ditcher for wheat sowing, and in particular relates to a compound ditcher which can realize wheat sowing based on uniform width, adjustability of the width in a certain range and separate applications of seeds and fertilizers. The ditcher is structurally characterized in that the penetrating wedge angle of a shovel body of the ditcher is 30 degrees; the curvature radius R of the soil breaking frontal line of the shovel body is 150-300mm; the width of the shovel body is 90-130mm; the width of the inner cavity is 80-120mm; the included angle between the lower edge of the shovel head part and the horizontal plane is 1-3 degrees and the included angle between the lower edge of the shovel body behind the orifice of a fertilizer pipe and the horizontal plane is 3-6 degrees, so the shovel body rises by 20-30mm relative to the shovel head; the fertilizer pipe of the ditch is arranged in front of seed pipes and is welded together with the inner cavity of the shovel body; the seed pipes are welded at the left and right sides of the fertilizer pipe; and the rear parts of side plates of the shovel body of the ditch, upper guard plates at the orifices of the seed pipes and a scatter plate form a wheat wide sowing device assembly.

Owner:SHANDONG UNIV OF TECH

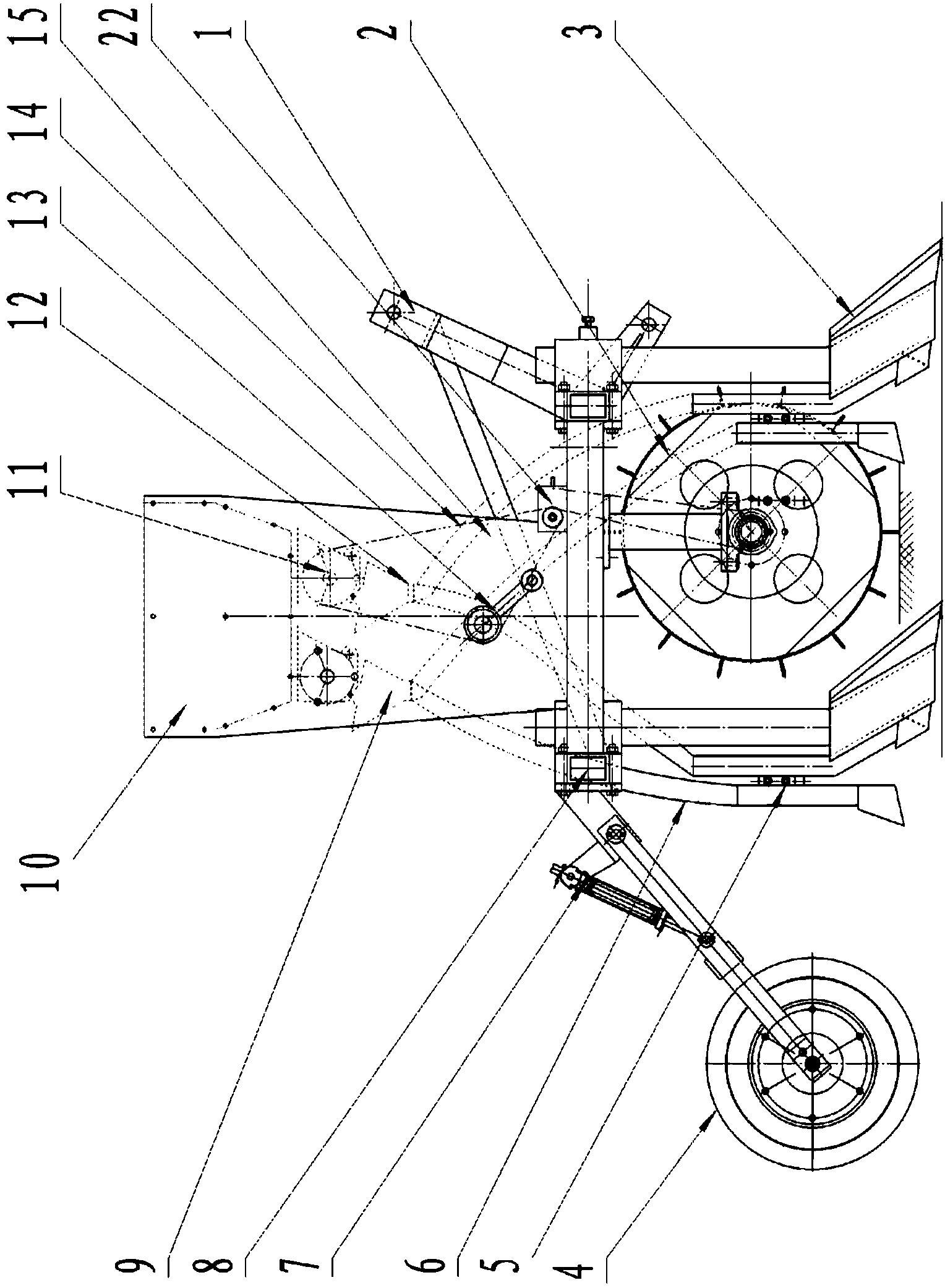

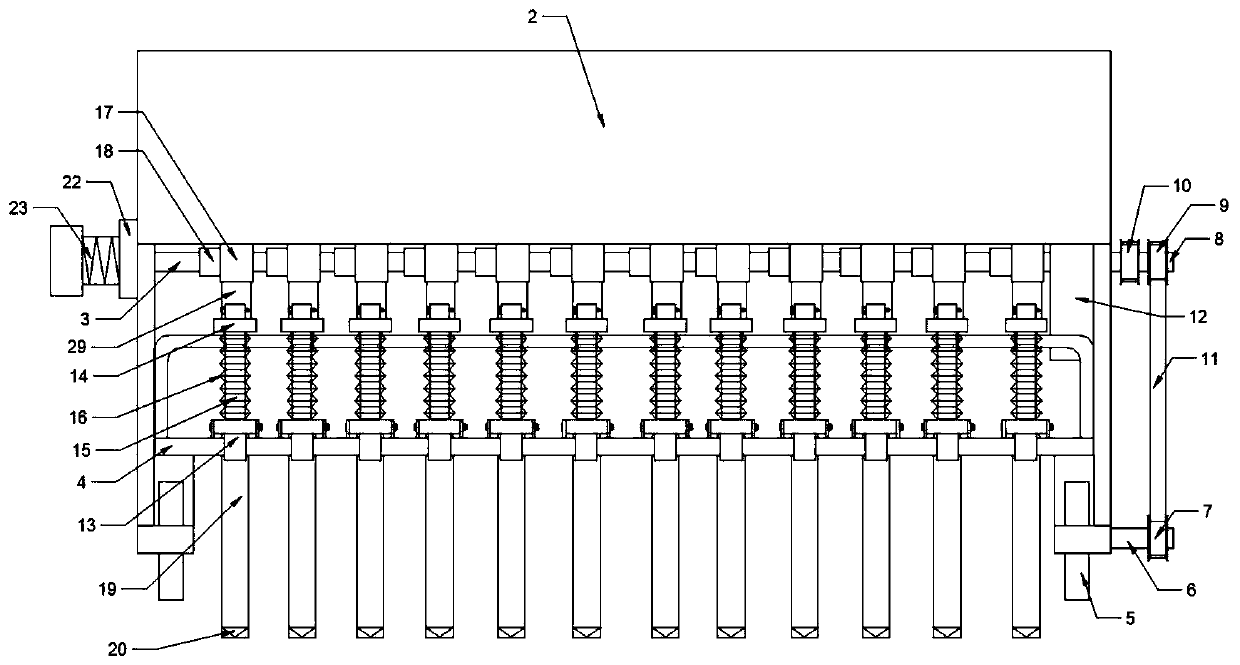

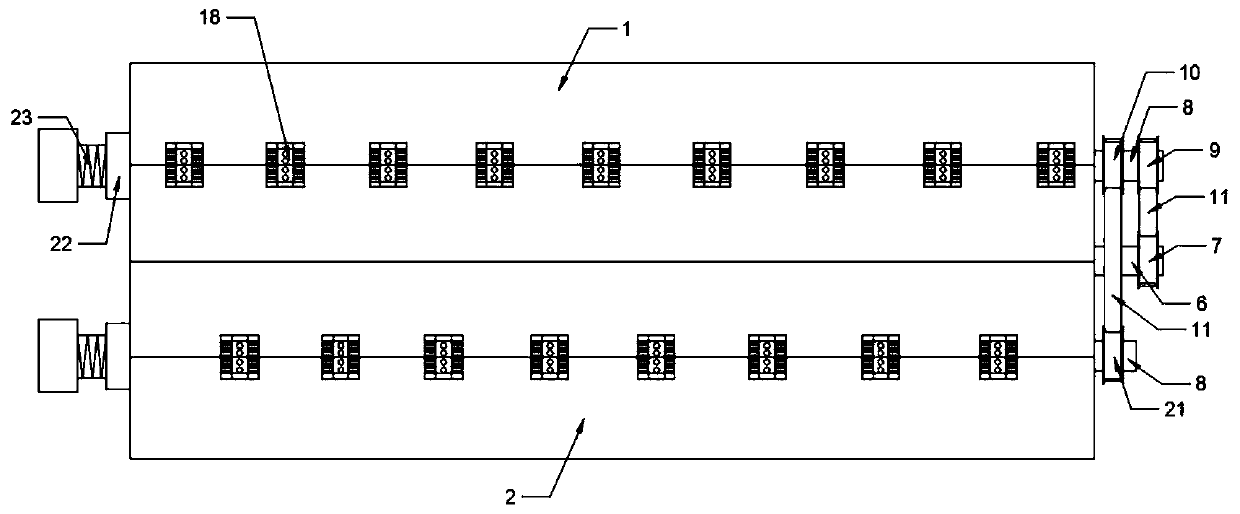

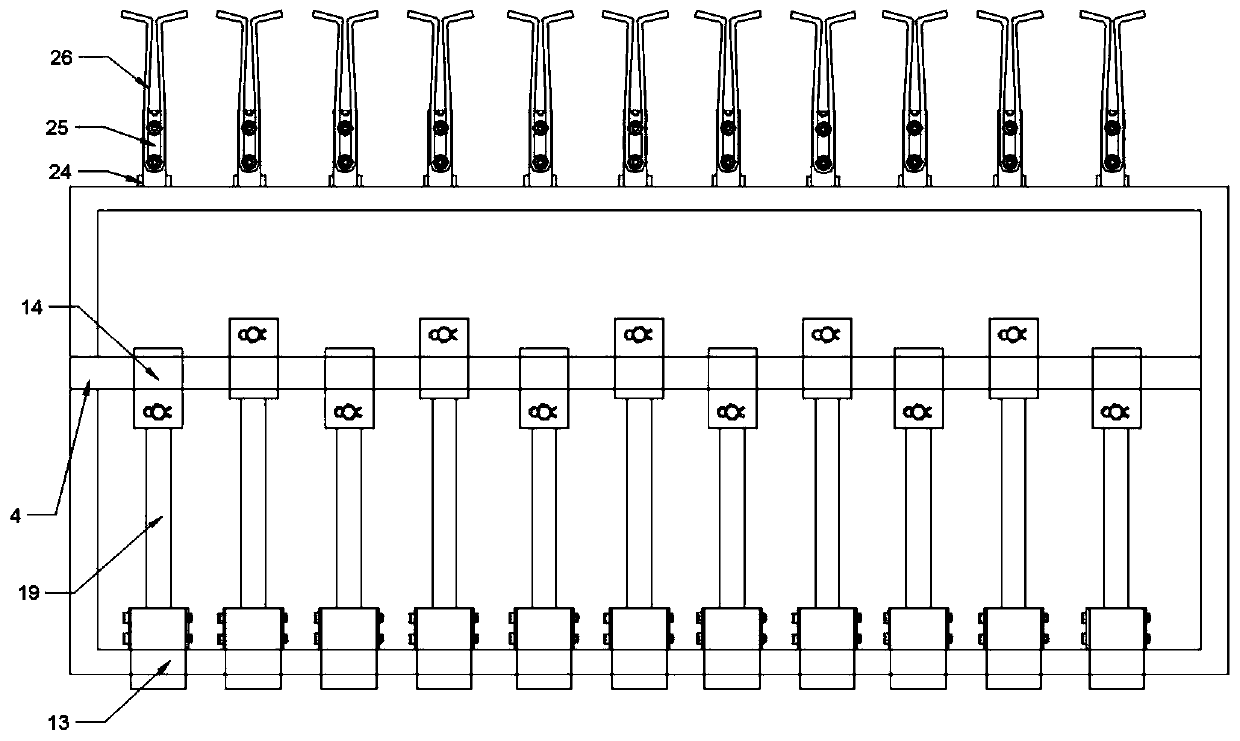

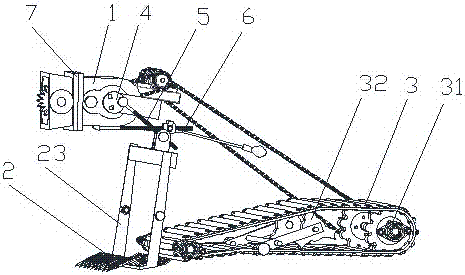

Coarse cereal seeding machine for no-tillage seeding

ActiveCN103444317ASimple structureSimple and fast operationPlantingFurrow making/coveringAgricultural engineeringSoil horizon

The invention discloses a coarse cereal seeding machine for no-tillage seeding. The coarse cereal seeding machine comprises a rack, a fertilizer apparatus, a seed sowing device, a seed manure box, a stubble breaking and ditching device, a suppression mechanism, ground wheels and transmission mechanisms. The machine adopts a stubble breaking, ditching, seed manure applying and seeding single body, a suppression wheel mechanism single body, a high ground clearance and large spacing transverse beam rack and the various transmission mechanisms for intensively changing speeds so as to realize stubble breaking and ditching, seed manure application, and semi-precision no-tillage seeding of wheat, corns, coarse cereals and small-grain pasture seeds. Particularly, the problems of crop stubble winding and blockage, hilling, mixed seed manure application, difficult burying of the ditching device, much disturbance to a soil layer, unevenness of a soil covered ground surface, large traction resistance and the like in the no-tillage seeding process are solved. The machine is simple in structure and easy to operate, has multiple purposes, is low in manufacturing cost and is suitable for specialized households of planting, and small and medium-sized farms to popularize and apply.

Owner:呼和浩特市得利新农机制造有限责任公司

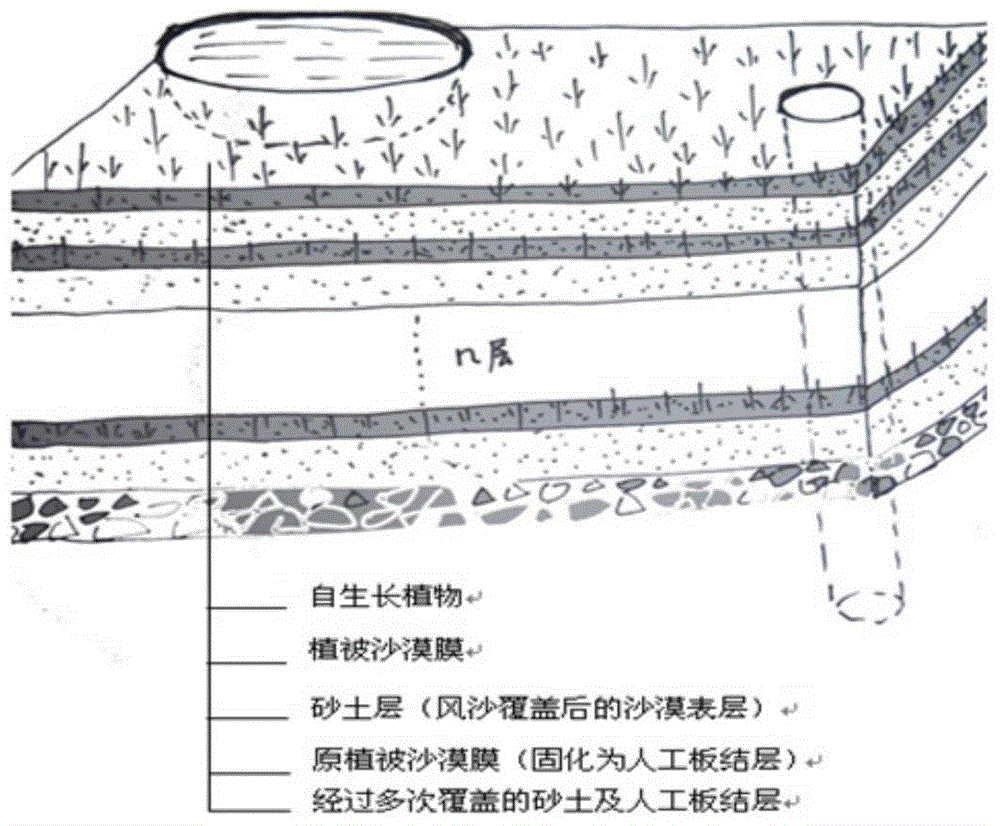

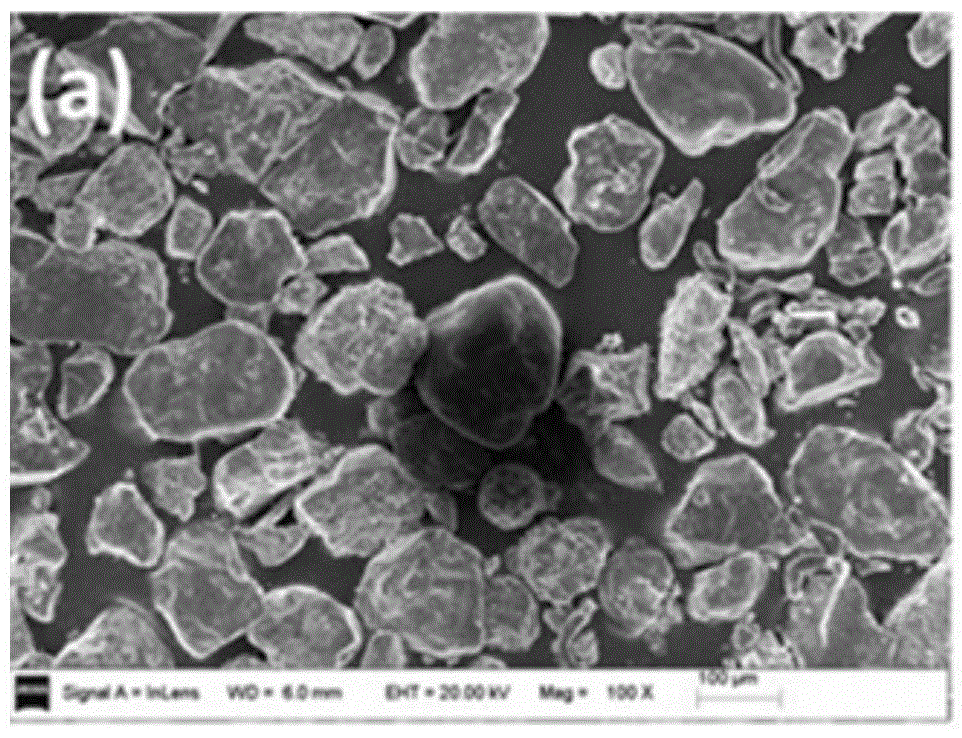

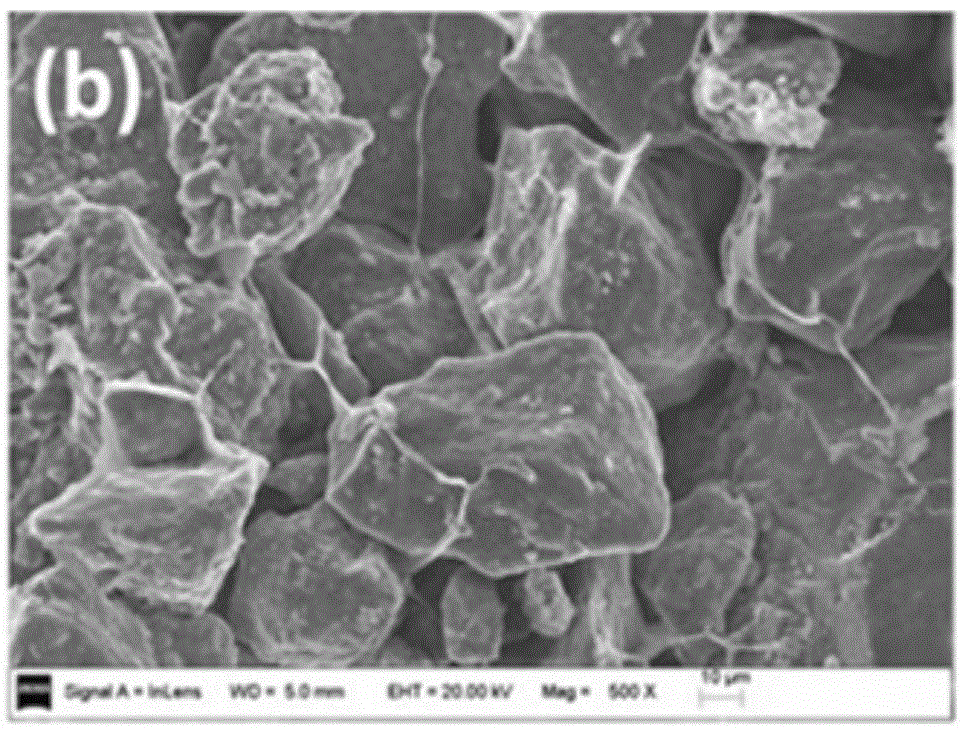

Water-retention and sand-fixing liquid mulching film and preparation method thereof

InactiveCN104804140AStrong water absorptionIncrease contactPlant protective coveringsCross-linkMoisture permeation

The invention relates to a water-retention and sand-fixing liquid mulching film and a preparation method thereof, and belongs to the technical field of agricultural production. The liquid mulching film comprises components in parts by weight as follows: 30-50 parts of ultrafine silica sol or nano-silica, 40-100 parts of carboxymethyl cellulose, 20-30 parts of N-isopropylacrylamide, 1-5 parts of ferrocene, 0.02-0.3 parts of a cross-linking agent and 0.4-1.2 parts of an initiator, wherein the solid content of the ultrafine silica sol is 10wt%-30wt%, and the particle size of silica is 1-100 nm. The liquid mulching film forms colloid easily with water, soil particles can be connected, structureless and dispersed sand soil is connected to form an elastic stable object, and a net-shaped film with good film performance and high strength is formed; one the one hand, surface pores of soil can be sealed, and soil moisture volatilization is blocked; on the other hand, moisture permeation is not inhibited, good water retention, soil moisture preservation and sand fixing functions are realized, and the performance of a desert and dry soil is improved effectively.

Owner:JIAXING GUOXING NEW MATERIAL TECH CO LTD

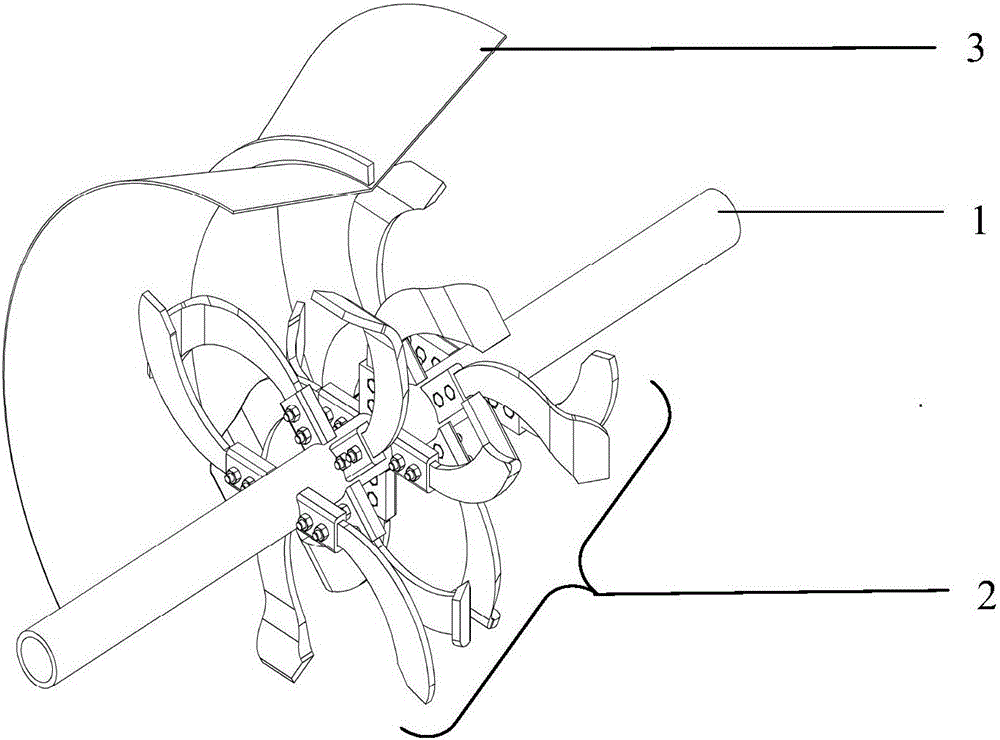

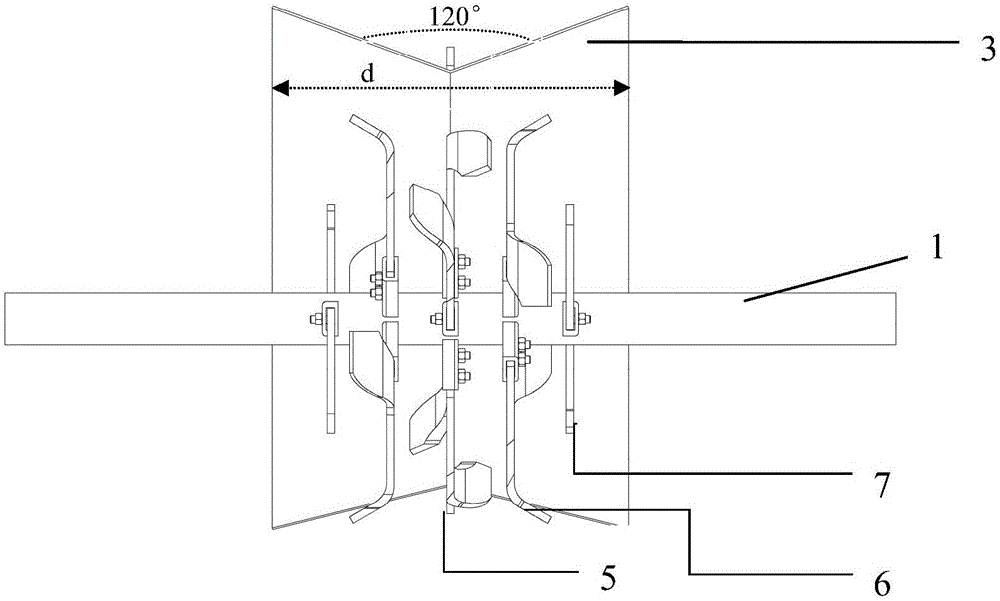

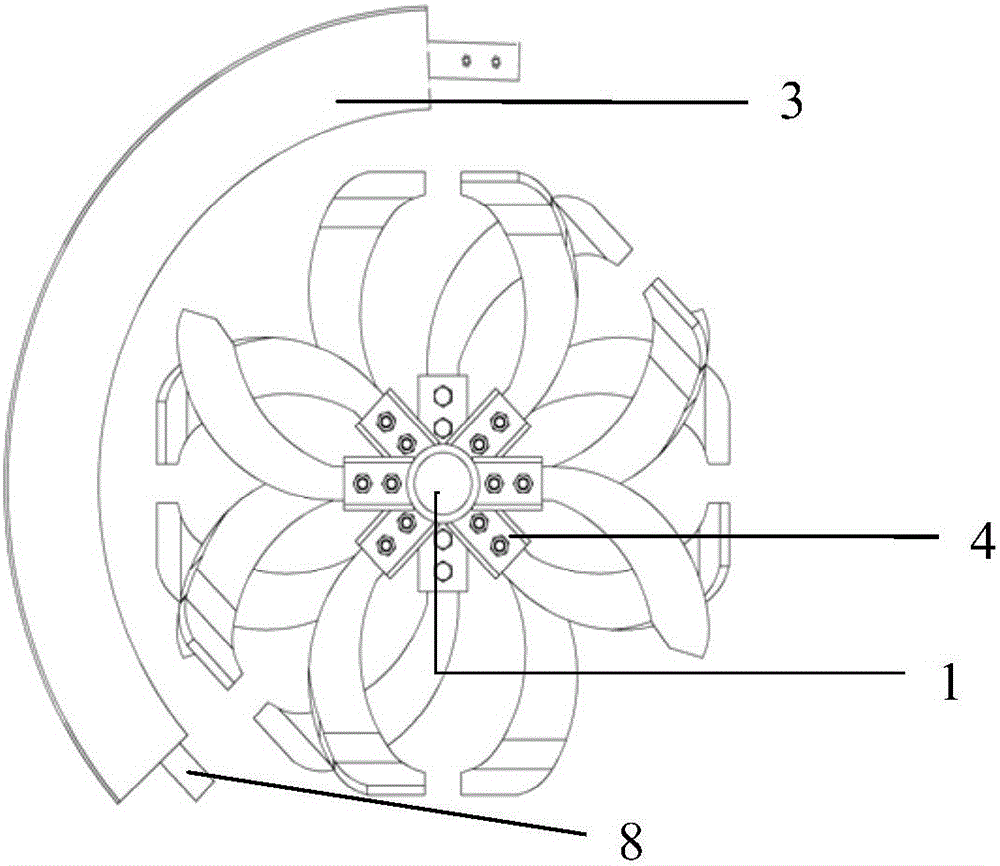

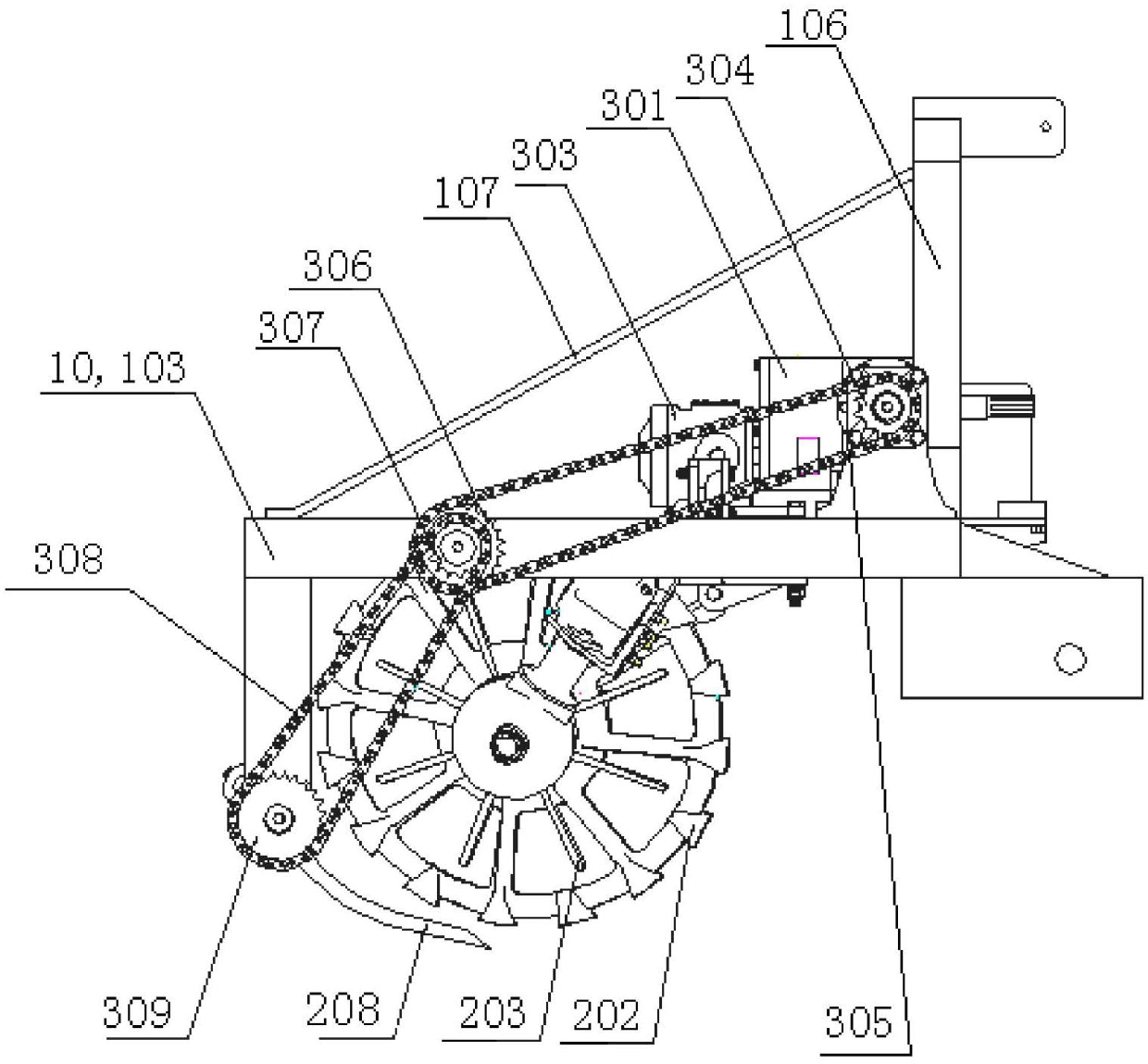

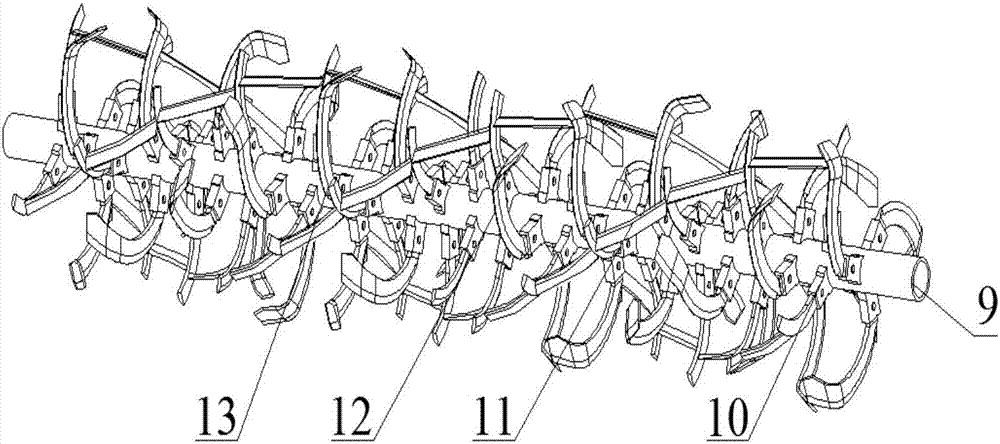

Pulverizing soil dispersal ditching device matched with rotary cultivator

A pulverizing soil dispersal ditching device matched with a rotary cultivator comprises a cutter shaft which is connected with a conveyer driven shaft of the rotary cultivator, a rotary tillage cutter head which is arranged on the cutter shaft and a soil separating board which is fixed on the rotary cultivator, and is characterized in that the rotary tillage cutter head comprises a first bent cutter head, a second bent cutter head and a straight cutter head; the first bent cutter head is arranged in the middle of the cutter head, the straight cutter head is symmetrically arranged on the cutter head with the first bent cutter head as the center, the second bent cutter head is arranged on the cutter head between the straight cutter head and the first bent cutter head, wherein the first bent cutter head, the second bent cutter head and the straight cutter head have the same diameter; a plurality of first right angled bent cutters provided with straight cutting edges are symmetrically arranged on the first bent cutter head with the axis of the cutter shaft as the center. By means of novel arrangement of the rotary tillage cutters, the ditching mode is changed, the soil pulverizing rate and the ditching rate are improved, and the ditching width can reach 20 cm-30 cm; the pulverizing soil dispersal ditching device is simple in structure, convenient to use in various rotary cultivators, low in cost, convenient to assemble and unassembled, and higher in ditching quality and efficiency.

Owner:HUNAN SOIL & FERTILIZER INST +1

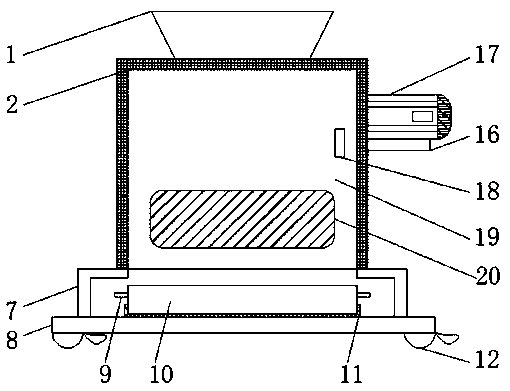

Cable twisting-releasing and surface cleaning movable trolley

The cable retractable and surface cleaning mobile vehicle includes a horizontal frame. The bottom of the horizontal frame is provided with walking wheels. The rotating shaft is arranged along the left and right horizontal directions. A cable tray is fixedly arranged on the rotating shaft. One end of the rotating shaft is connected with the power output shaft of the motor reducer. There is a gantry between the tops, and a sliding cleaning device for cleaning the cables is installed on the gantry; the invention is novel in design, and the cable retraction and cleaning are integrated, and the cables are all retracted and retracted in an electric way, which reduces the workload of workers. It is labor-intensive, improves work efficiency, does not require extra power for cleaning, and has a good effect on cleaning the dirt on the surface of the cable, ensuring that the cables wound on the cable drum are discharged neatly.

Owner:STATE GRID CORP OF CHINA +2

Beet digger

The invention relates to a beet digger, which is characterized by comprising a machine frame, a combined digging part and a driving system, wherein the machine frame comprises a first cross beam, a second cross beam, a third cross beam between the first and second cross beam, a first longitudinal beam and a second longitudinal beam; the combined digging part comprises a disc axle arm frame, one end of the disc axle arm frame is connected with the third cross beam, the other end of the disc axle arm frame is connected with two connecting shafts, and the other ends of the two connecting shafts are both connected with a disc; eccentric wheels are arranged below the longitudinal beams on the side of the first cross beam; the two eccentric wheels are connected by a first drive shaft which is provided with a digger blade positioned at a lower nonaligned place between the two discs; the driving system comprises a gear box arranged on the second cross beam, the input end of the gear box is connected with a power device, and the output end of the gear box is connected with a second drive shaft and a gear oil pump respectively; the second drive shaft drives the eccentric wheels to rotate through a chain wheel drive device; the input end of the gear oil pump is connected with an oil tank; the output end of the gear oil pump is connected with a hydraulic motor; and the power output end of the hydraulic motor is connected with one of the two discs.

Owner:CHINA AGRI UNIV

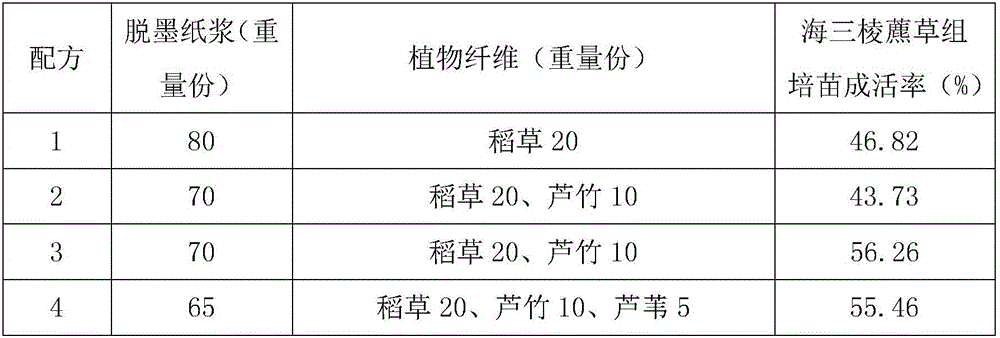

Degradable seedling raising holed tray and preparation method thereof

ActiveCN105724108AIt is resistant to salt and alkali decompositionNo pollution in the processCultivating equipmentsFiberAdhesive

The invention provides a degradable seedling raising holed tray.The degradable seedling raising holed tray is prepared from deinked pulp, plant fiber and an adhesive, wherein the mass ratio of the deinked pulp to the plant fiber to the adhesive is 60-80 to 20-40 to 0-2, and the plant fiber is selected from one or more of straw, bamboo reeds, reeds and wheat straw.The invention further provides a preparation method of the degradable seedling raising holed tray.Firstly, plant fiber raw materials are dried and then are smashed to reach 40-70 mesh; the deinked pulp, the plant fiber and the adhesive are mixed according to the mass ratio, are evenly stirred and are charged into a mold, pressing, molding and mold release are performed, and then drying is performed to reach 10-20% of water content, namely the finished product degradable seedling raising holed tray is obtained.The degradable seedling raising holed tray has a certain saline-alkaline resisting and decomposing role, is isolated from the outside at a seedling adapting stage and also has degradability, root systems can grow to penetrate through the holed tray after seedlings adapt to a salt marsh environment, and finally complete degradation is achieved.The degradable seedling raising holed tray improves the survival rate of transplanted tissue cultured seedlings and reduces the transplanting cost.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

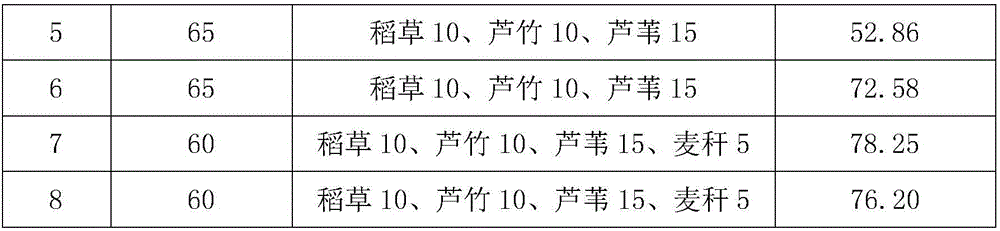

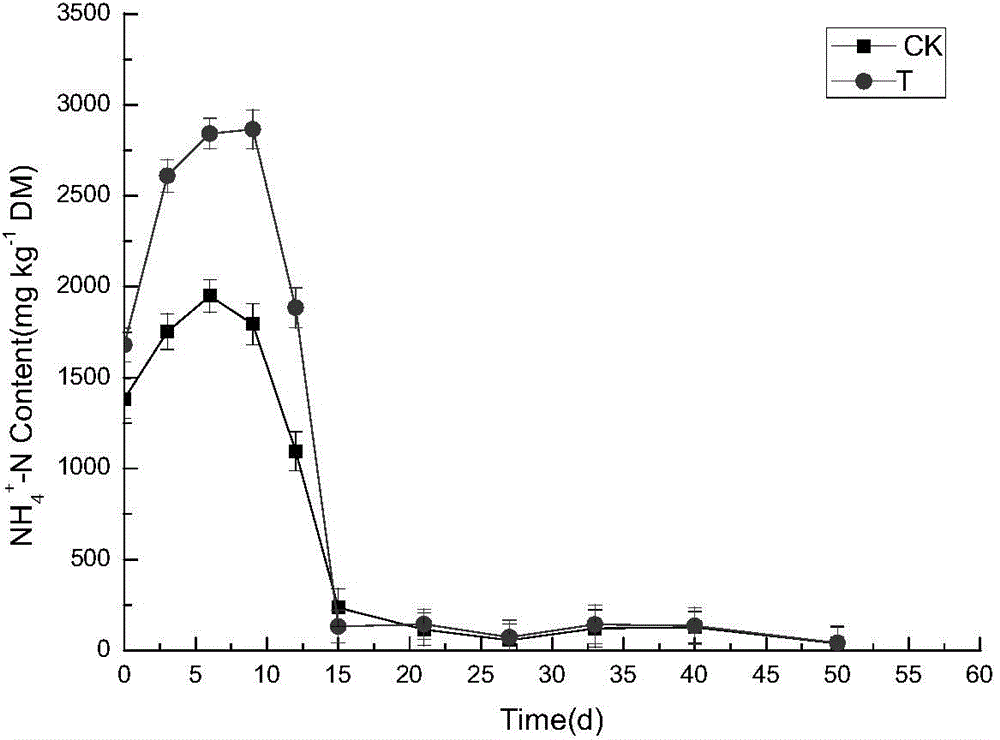

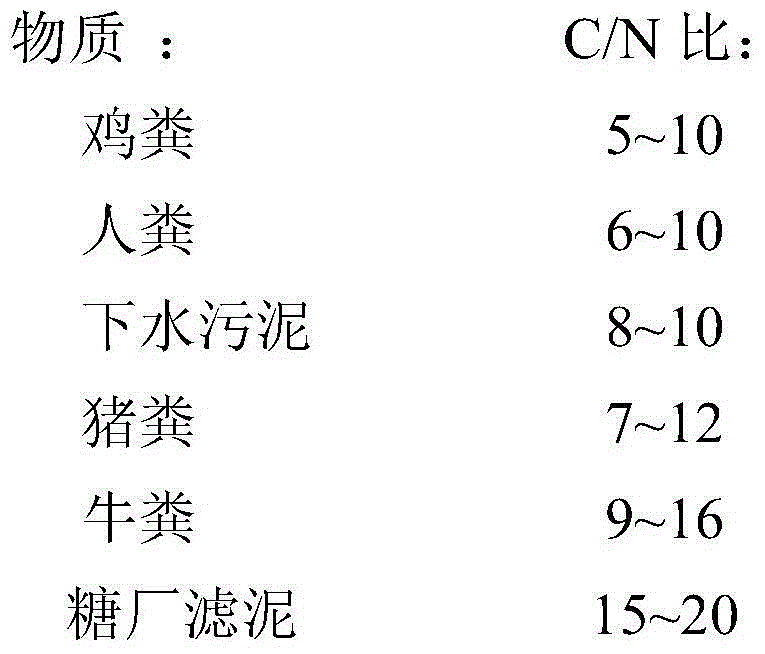

Fermenting method for organic solid wastes

InactiveCN104692848AGood fertilizer effectHigh ammonia nitrogen contentBio-organic fraction processingOrganic fertiliser preparationMoistureAmmonia nitrogen

The invention discloses a fermenting method for organic solid wastes. The fermenting method comprises the following operation steps: (1) getting organic solid wastes as raw materials, regulating a C / N ratio to be (20-35) to 1 and regulating the moisture content to be 55-70%; (2) mixing desulfurized gypsum with mass fraction of 5-15% in terms of wet weight of organic solid waste raw materials in the step (1) with the organic solid wastes obtained in the step (1) to form a pile body and ferment. In order to solve the problems that air is polluted by much ammonia nitrogen emission in a fermentation treatment process of the organic solid wastes in the prior art, and the fertilizer efficiency after fermentation is not good, the invention discloses the fermenting method for the organic solid wastes, which aims to improve the fertilizer efficiency after the fermentation while the ammonia nitrogen emission amount in the organic solid waste fermentation process is reduced.

Owner:GUANGXI UNIV

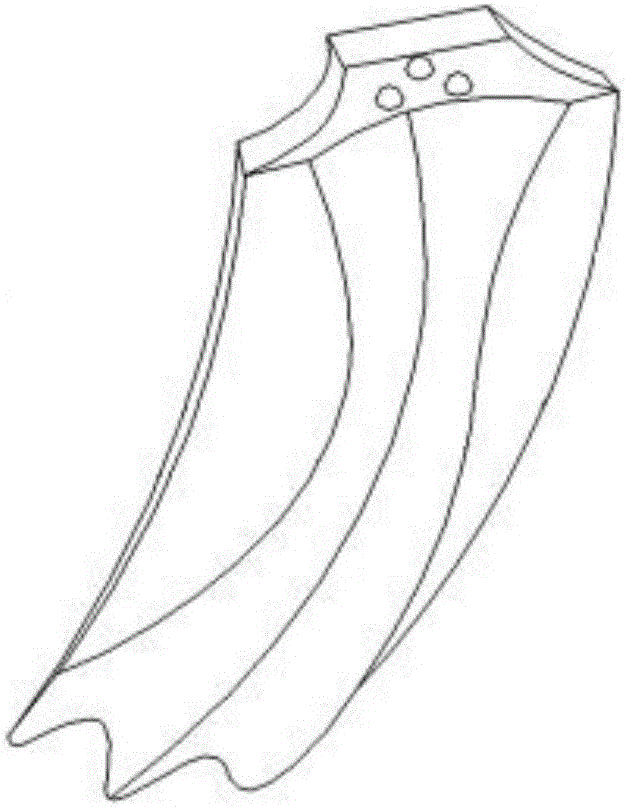

Bionic drag reduction potato harvester digging shovel

The invention discloses a bionic drag reduction potato harvester digging shovel, and belongs to the technical field of agricultural machinery. The bionic drag reduction potato harvester digging shovel is of an integrated structure comprising soil piercing shovel teeth, a soil contact shovel surface I, a shovel handle, a soil contact shovel surface II and a concave surface, a shovel body is arc-shaped, the soil contact shovel surface I and a convex surface are positioned in the front of the digging shovel, the soil contact shovel surface II and the concave surface are positioned at the back of the digging shovel, the convex surface is positioned in the middle of the soil contact shovel surface I, the concave surface is arranged in the middle of the soil contact shovel surface II, the soil piercing shovel teeth are positioned at the front end of the digging shovel, the shovel handle is positioned at the tail end of the digging shovel, the top end of the digging shovel is rectangular, transits to the bottom end by an arc and is fixedly connected with top ends of the soil contact shovel surface I and the soil contact shovel surface II, three triangular sunk screw holes are formed in the shovel handle, the soil piercing wedge angle alpha of the digging shovel ranges from 20 degrees to 45 degrees, and the clearance angle theta of a shovel edge with the soil piercing shovel teeth ranges from 3 degrees to 6 degrees. The digging shovel is high in applicability, the soil piercing capacity and drag reduction and desorption properties of the potato digging shovel can be remarkably improved, and the drag reduction property is improved by 30% or more as compared with a traditional potato digging shovel.

Owner:JILIN UNIV

Degradable seedling growing tray and preparing method thereof

InactiveCN107624612AAvoid damageThe effect is positive and obviousGrowth substratesCulture mediaFiberDecomposition

The invention discloses a degradable seedling growing tray and a preparing method thereof. The degradable seedling growing tray is prepared from, by weight, 75-85 parts of deinked pulp, 50-60 parts ofplant fiber, 0.5-1 part of straw leavening agent, 22-24 parts of modified starch, 4-6 parts of binder, 1-1.5 parts of releasing agent, 4-6 parts of nutritional agent, 0.8-1.2 parts of antibacterial agent, and 3-5 parts of waterproof thin film. The degradable seedling growing tray has a certain effect of resisting saline-alkaline decomposition, is isolated from the outside in a seedling adaptationperiod, and has degradability, after seedlings are adapted to a saltmarsh environment, root systems of the seedlings can penetrate through a hole tray, and finally the degradable seedling growing tray is completely decomposed. According to the degradable seedling growing tray and the preparing method thereof, the survival rate of tissue culture seedlings after transplanting is increased, and thetransplanting cost is lowered.

Owner:桐城市申科塑业有限公司

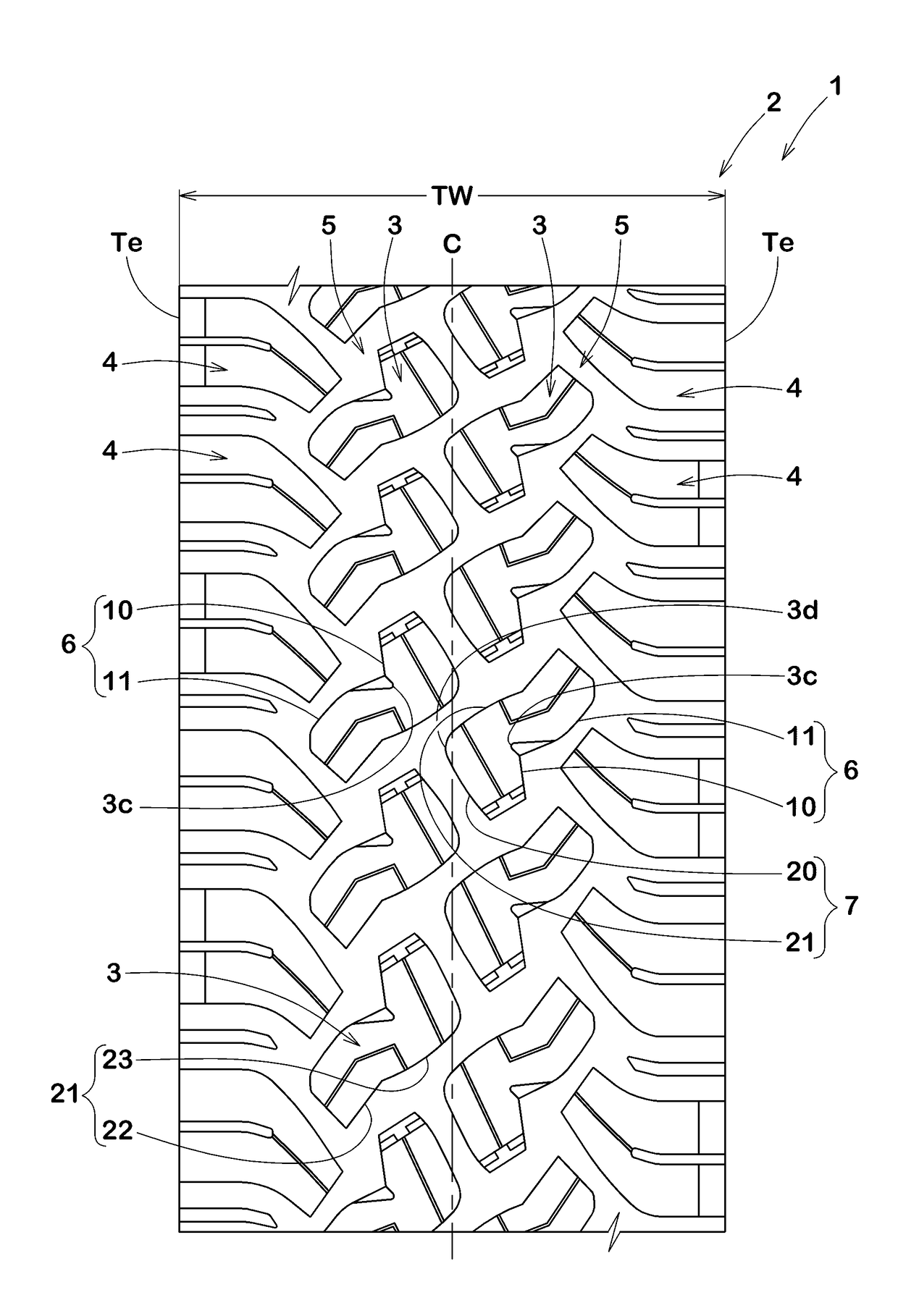

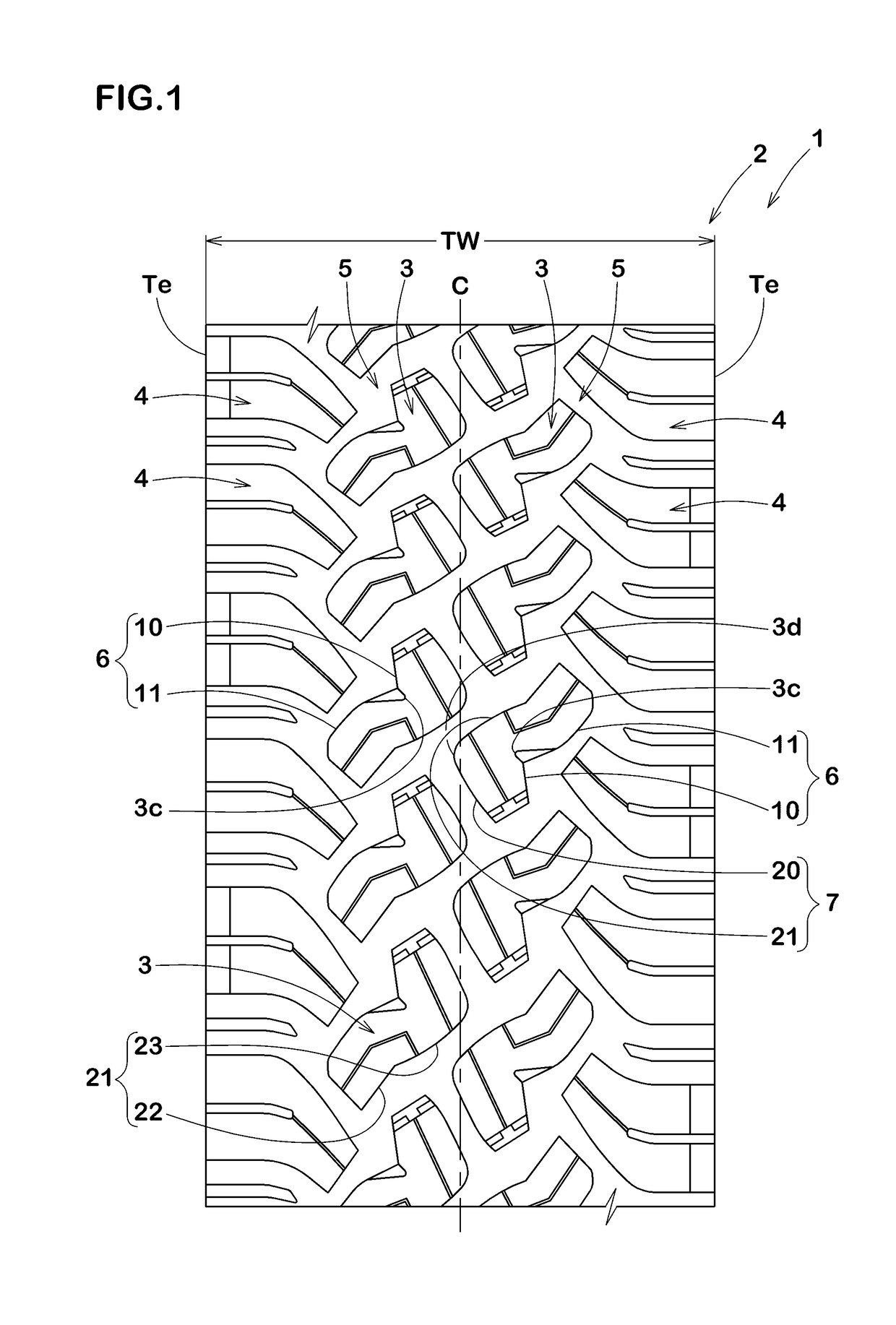

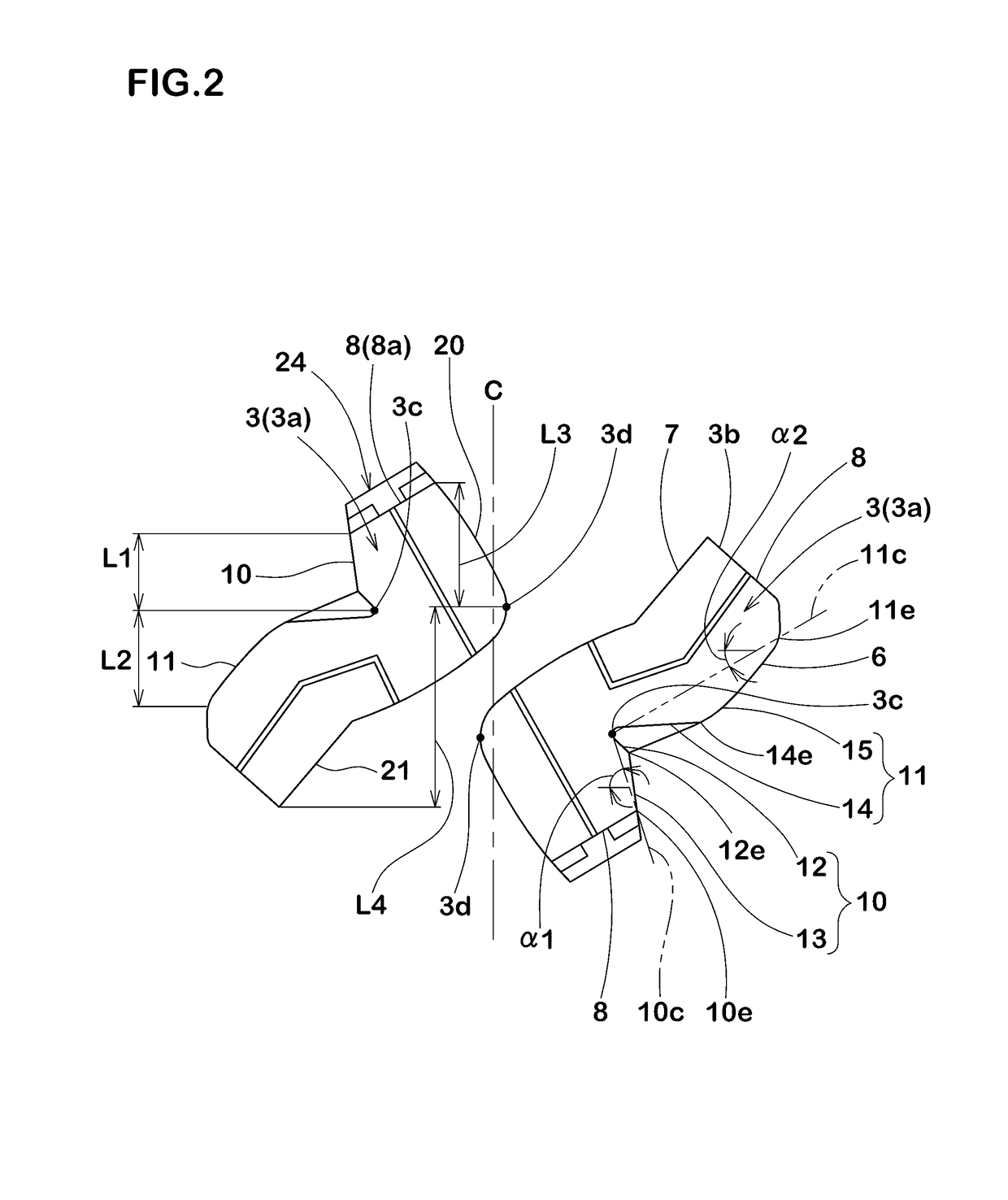

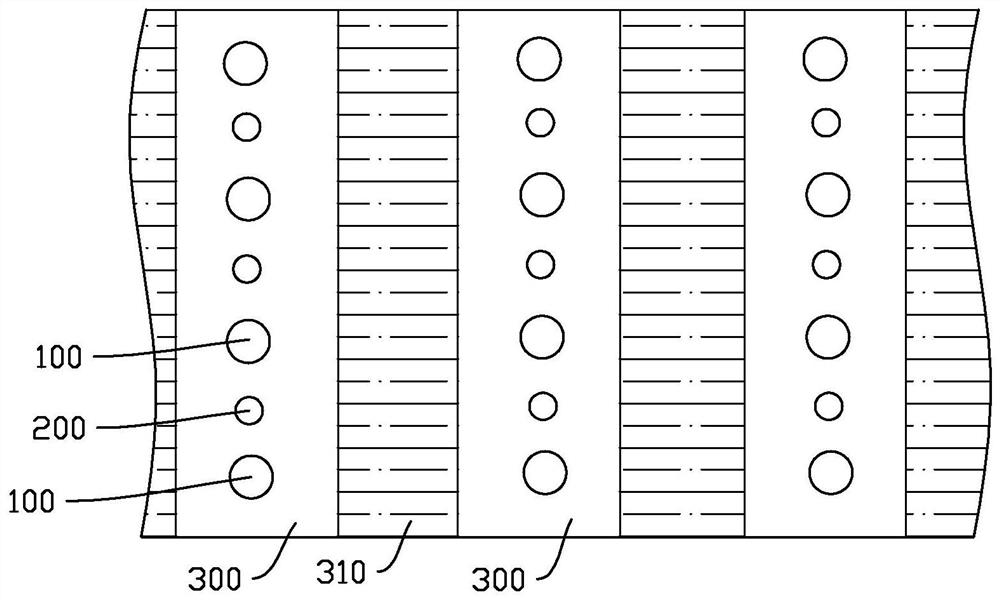

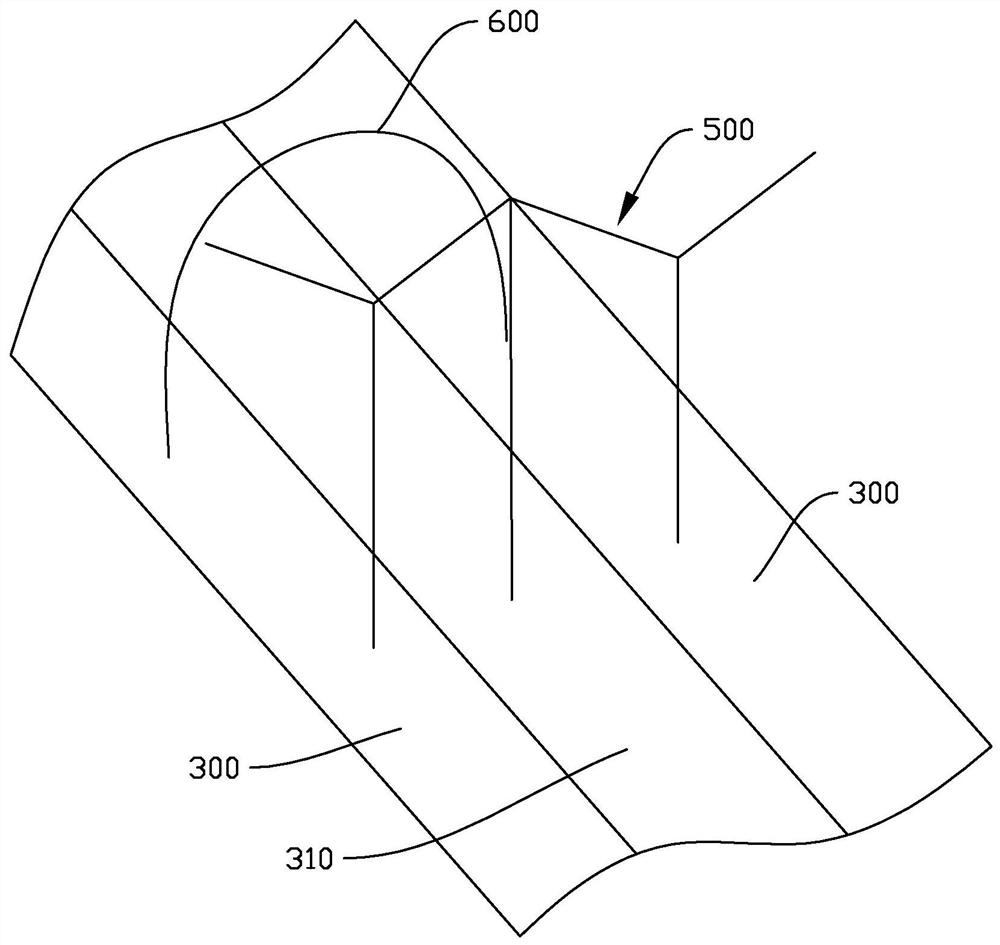

Pneumatic tire

ActiveUS20170120687A1Excellent mudExcellent dirt performanceOff-road vehicle tyresTyre tread bands/patternsGround contactEngineering

A pneumatic tire includes a tread portion provided with central blocks on both sides of a tire equator. Each of the central blocks includes a ground contact surface with an axially outer block edge and an outer block sidewall extending radially inwardly from the outer block edge. Each outer block edge includes a first inclined edge and a second inclined edge in an opposite inclination direction to the first inclined edge. The first inclined edge has an average angle of from 75 to 85 degrees and the second inclined edge has an average angle of from 30 to 50 degrees, with respect to the axial direction of the tire. Each outer block sidewall includes a middle portion and a pair of end portions, wherein the middle portion is inclined gently with respect to the end portions in relation to a radial direction of the tire.

Owner:SUMITOMO RUBBER IND LTD

Fertilizer synergist and preparation method thereof

InactiveCN104591843APrevent compactionRestorationMagnesium fertilisersAlkali orthophosphate fertiliserTrace element compositionTrichoderma sp.

The invention relates to a fertilizer synergist and a preparation method thereof. The fertilizer synergist contains, in percent by weight, 60-65% of humic acid, 25-30% of trace elements, and 5-15% of composite bacterial strains. The trace element composition is composed of the following raw materials in percent by weight based on the total weight of the race element composition: 10-20% of calcium sulfate, 10-20% of magnesium sulfate, 0.5-1.5% of borax, 2.5-4.5% of ferrous sulphate, 0.5-1.5% of manganese sulfate, 0.5-1.5% of zinc sulfate, 0.25-0.75% of copper sulphate, and 0.25-0.75% of ammonium molybdate. The composite bacterial strains is composed of the following raw materials in percent by weight based on the total weight of the composite bacterial strains: 30% of azotobacter, 25% of a phosphate-dissolving bacterium, 10% of actinomyces, 10% of potassium bacteria, 12% of ferment bacteria, and 13% of trichoderma spp. The fertilizer synergist is capable of obviously improving fertilizer utilization rate and absorption rate and improving soil fertility, and helps to substantially increase crop yield and improve economic benefit.

Owner:YANTAI NAKE ENVIRONMENTAL PROTECTION TECH

Improving and conditioning agent for soil of saline-alkali farmlands

InactiveCN104560052AImprove performance in soilIncrease productionAgriculture tools and machinesOther chemical processesSulfateZinc

The invention relates to a chemical reagent applied to soil and particularly relates to an improving and conditioning agent for soil of saline-alkali farmlands. The improving and conditioning agent comprises the following raw materials in parts by weight: 30-40 parts of desulfuration waste, 1-2 parts of aluminum sulfate, 0.001-0.01 part of zinc sulfate, 0.001-0.01 part of manganese sulfate, 0.1-0.5 part of urea, 0.1-0.3 part of a microbial fertilizer, 10-20 parts of grass carbon and 4-6 parts of straws. The improving and conditioning agent for the soil of the saline-alkali farmlands is low in cost and convenient to apply and has no toxic or side effect.

Owner:赵明贵

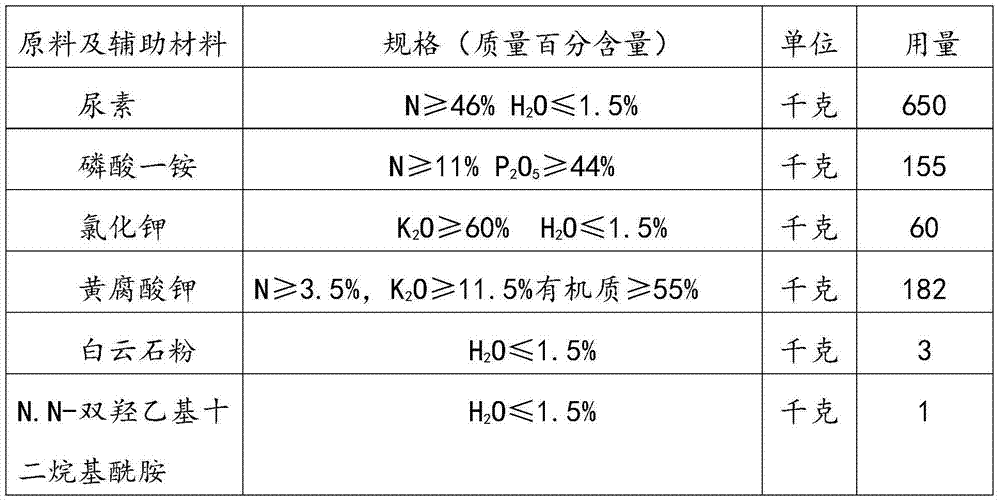

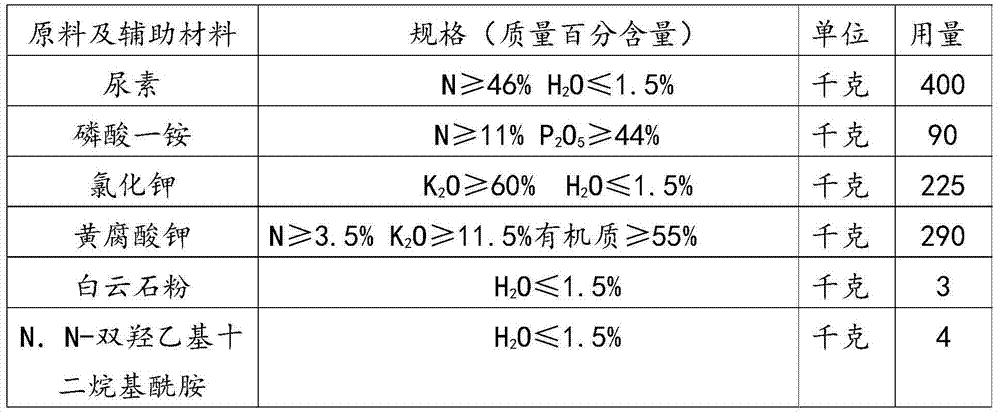

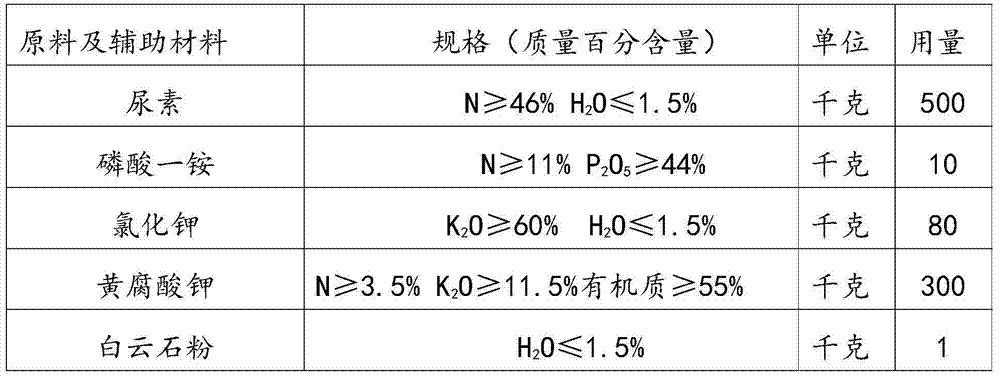

Compound fertilizer preparation method for improving utilization rate of phosphorus element

The invention relates to a compound fertilizer preparation method for improving the utilization rate of the phosphorus element. The method comprises the following steps: mixing molten urea or molten ammonium nitrate with a potash fertilizer and a filler to obtain a mixture; carrying out blending chelating on one or a mixture of more of potassium fulvate, ammonium humate and monoammonium phosphate and the mixture; defoaming the above blend-chelated product by a defoaming agent; sending the defoamed product to a high tower mixing tank, and carrying out high tower granulation; processing a composition comprising, by weight, 5 parts of guar gum, 3 parts of nonionic polyacrylamide and 2 parts of potassium polyacrylate to prepare a liquid with 10% of the composition, and uniformly sprinkling the surface of a granulated granular fertilizer with the liquid to wrap the fertilizer. The compound fertilizer adopting potassium fulvate or ammonium humate as an organic matter has the advantages of high content of nutrients, good dissolvability, low water content, reduction of the frequency of contact of phosphate radicals with metal ions, reduction of the curing probability of phosphorus, and improvement of the utilization rate of a phosphate fertilizer.

Owner:胡红辉

Organic fruit and vegetable nutrient soil and production method thereof

InactiveCN106336318AImprove breathabilityGood drainageAnimal corpse fertilisersSewage/sludge fertilisersSlagPotassium

The invention discloses an organic fruit and vegetable nutrient soil and a production method thereof. The organic fruit and vegetable nutrient soil comprises, by weight, 20-26 parts of crop straws, 12-18 parts of urea, 5-13 parts of stable manure, 5-10 parts of needle-leaved tree fallen leaves, 1-5 parts of oil cakes, 1-5 parts of coal slag, 3-8 parts of attapulgite clay, 5-10 parts of potassium chloride, 3-8 parts of sea mud, 1-3 parts of potassium sorbate, 3-8 parts of perlite, 1-5 parts of pig bone meal, 1-5 parts of tea saponin, 1-3 parts of vermiculite, 10-16 parts of EM strain and 45-52 parts of water. The production method comprises the following steps: mixing and uniformly stirring the crop straws, the stable manure, the needle-leaved tree fallen leaves, the oil cakes, the coal slag, the sea mud, potassium sorbate, perlite, the pig bone meal, the tea saponin, vermiculite, the EM strain and water, carrying out sealed fermentation, air-drying the obtained fermentation product, mixing the air-dried fermentation product with urea, the attapulgite clay and potassium chloride, and crushing the obtained mixture to obtain the organic fruit and vegetable nutrient soil. The organic fruit and vegetable nutrient soil has the advantages of comprehensive nutrition, seedling stage disease prevention, growth promotion, output increase, quality improvement, no pollution in the production process, and suitableness for industrial production.

Owner:FUYANG NORMAL UNIVERSITY

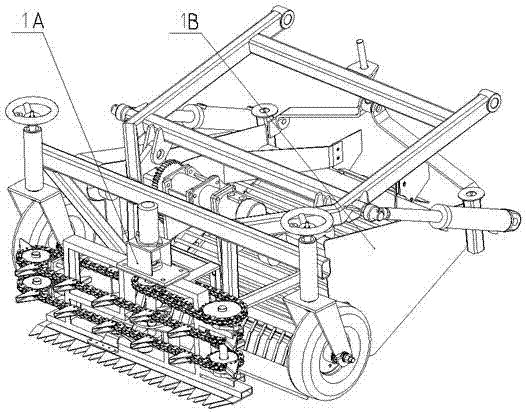

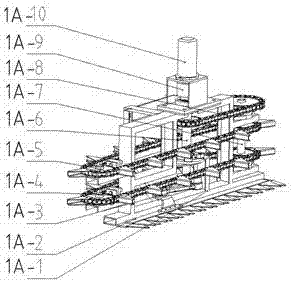

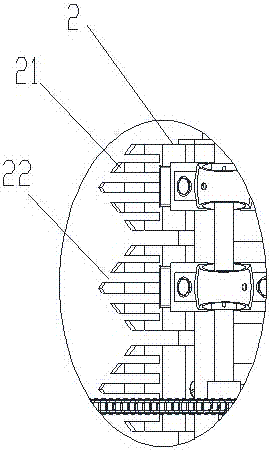

Shovel tooth and elastic tooth roller combined type peanut pickup device

ActiveCN112400478AEasy to pick upExtended service lifeHarvestersAgricultural engineeringStructural engineering

The invention discloses a shovel tooth and elastic tooth roller combined type peanut pickup device, and belongs to the technical field of agricultural machinery. The shovel tooth and elastic tooth roller combined type peanut pickup device comprises picking shovel teeth, roller protection plates, a picking roller, a roller sliding way and side plates; a center shaft of the picking roller penetratesthrough the side plates at the two sides to be installed on bearing pedestals, picking elastic teeth are evenly arranged on an elastic tooth shaft of the picking roller at intervals, and the roller protection plates are arranged between the adjacent picking elastic teeth; at the advancing front end of the pickup device, arc-shaped picking shovel teeth of the same structure are installed at the same position of each roller protection plate to form a row of shovel teeth; and the roller sliding way is fixedly installed in one side plate and is in sliding connection with the elastic tooth shaft on the picking roller. According to the pickup device, the peanut plants are shoveled up through the shovel teeth; the picking roller rotates along the roller sliding way, and the elastic teeth rotatearound the center shaft along with the roller and periodically and repeatedly swing due to the limitation of the roller sliding way, so that actions of lifting, pushing and returning to a station by the elastic teeth are realized; and the impact of the roller on a cam sliding way can be effectively reduced, large stress concentration is avoided, and the service life of the cam sliding way is prolonged.

Owner:JILIN AGRICULTURAL UNIV +2

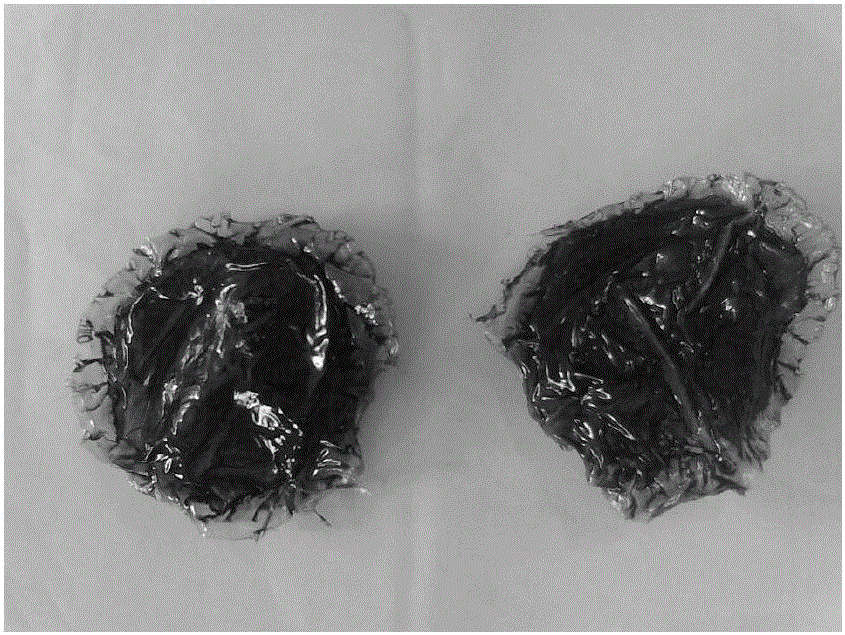

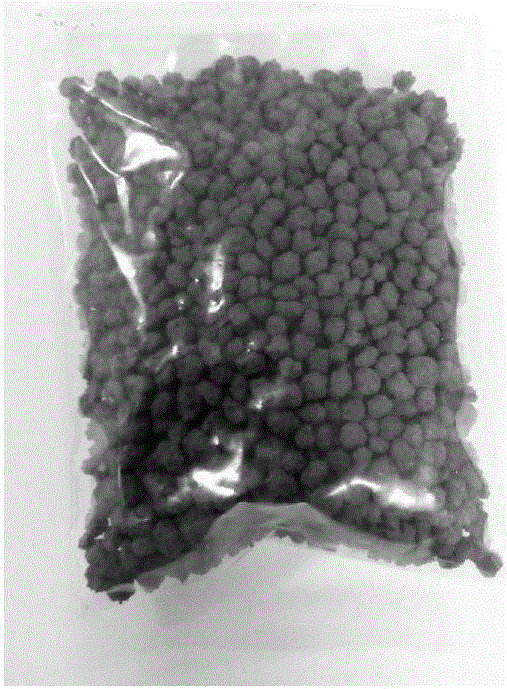

Method for preparing slow-release fertilizer coating from fermentation residues of wood fibers for ethanol production and application

ActiveCN106045703AImprove propertiesGood sustained release effectLayered/coated fertilisersFertilizer mixturesCelluloseFiber

The invention discloses a method for preparing a slow-release fertilizer coating from fermentation residues of wood fibers for ethanol production and an application. The fermentation residues of the wood fibers for ethanol production are used as a raw material for the first time for preparing the slow-release fertilizer coating which is environment-friendly, low in cost and simple and easy to produce on industrial scale, and slow-release fertilizer prepared from the slow-release fertilizer coating in combination with a fertilizer core has the advantages that the slow-release effect is optimum, the soil performance is improved, and the slow-release period is long.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

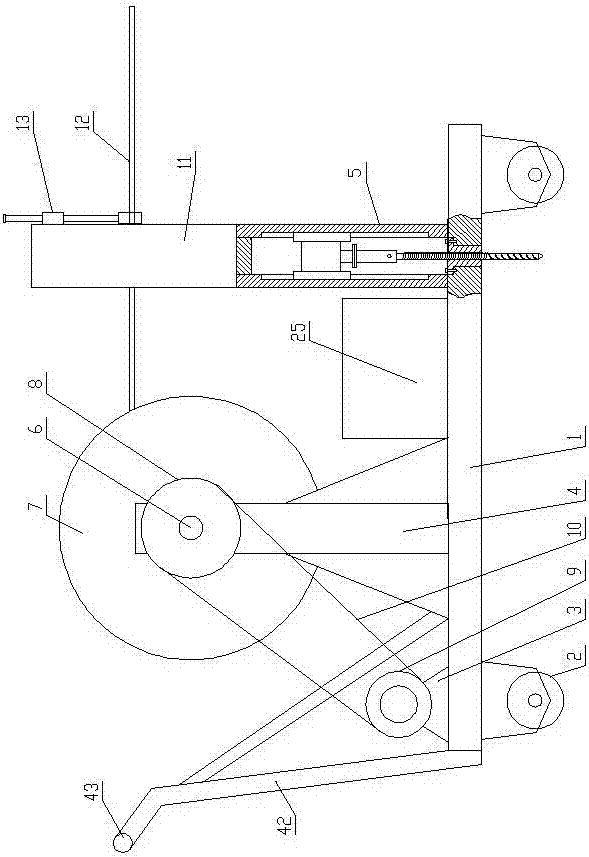

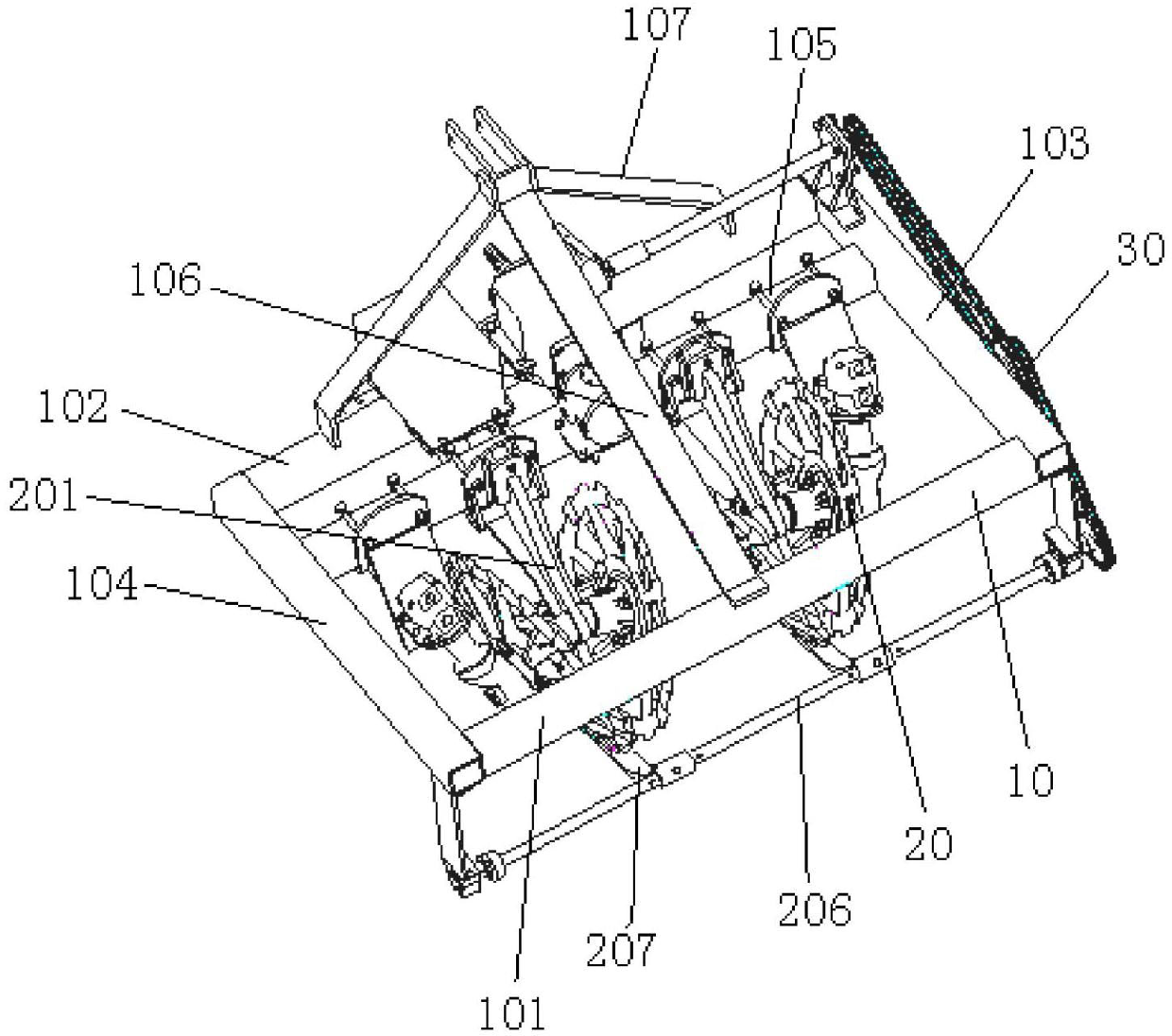

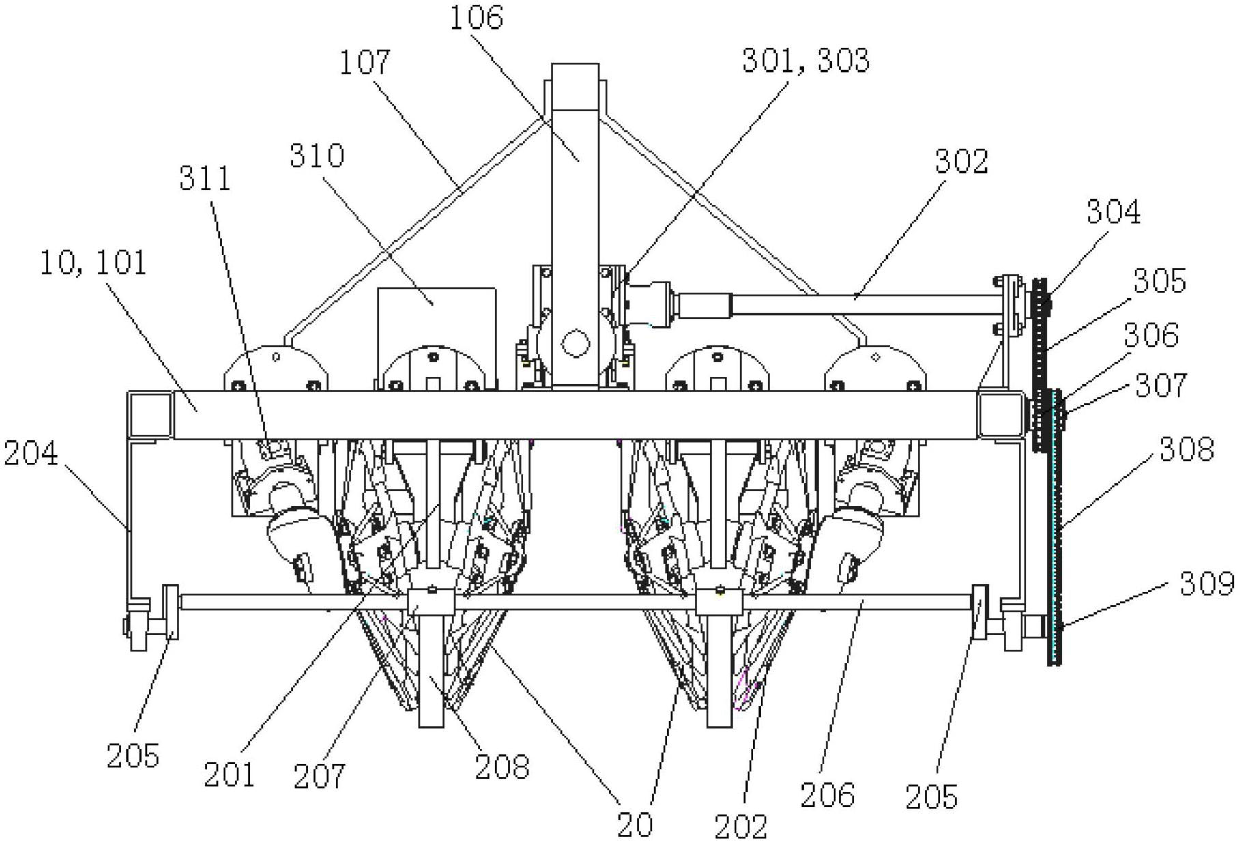

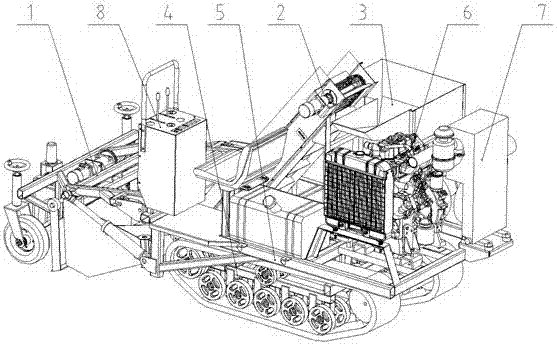

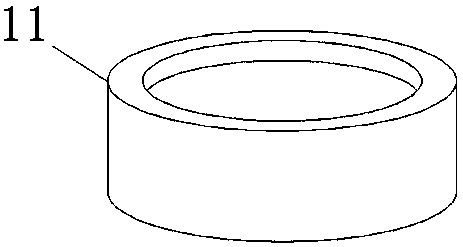

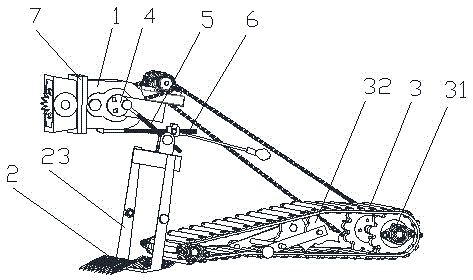

Self-propelled garlic combined harvester

The invention provides a self-propelled garlic combined harvester, which can complete the whole harvesting process including cutting, digging, conveying, soil clearing and collection of garlic. The self-propelled garlic combined harvester includes a self-propelled chassis, a rack arranged on the self-propelled chassis, a harvesting mechanism and an operation device which are positioned on the front of the rack, a conveying device which is positioned on the center of the rack and is used for conveying the harvested garlic to a collection box, and a power system positioned on the back of the rack. The harvesting mechanism is a non-line harvesting mechanism and includes a stem cutting device and a digging device, wherein the stem cutting device is positioned on the front of the digging device. The digging device includes a support, a harvesting motor arranged on the support, a driving shaft connected to an output end of the harvesting motor, a driven shaft connected to the driving shaft via a transmission unit, and a digging shovel arranged on the driven shaft via eccentric bearings, and wherein the digging shovel is connected to the rack via connection rods.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

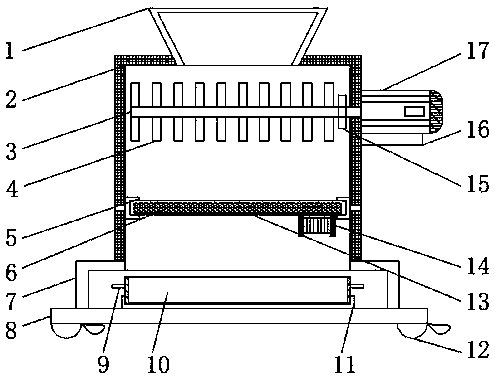

Earthworm harvester

The invention discloses an earthworm harvester, comprising a housing and a base. The upper surface of the housing is provided with a feed bucket; each side of the inner wall of the housing is providedwith a U-shaped clamp plate; a strainer mounting frame is arranged on the U-shaped clamp plates; a strainer is mounted on the strainer mounting frame; the lower surface of the strainer mounting frameis provided with a miniature vibrator; one side of the outer wall of the housing is provided with a support plate; the upper surface of the support plate is provided with a motor; an output shaft ofthe motor is passed through the housing and connected with a coupling; the other end of the coupling is provided with a rotary shaft that is positioned in the housing; the outer wall of the rotary shaft is provided with stirring blades; the lower surface of the housing is provided with a support post; the other end of the support post is provided with the base; each side of the outer wall of an earth receiving bucket is provided with a handle. With the series of structures, earthworms are exposed by breaking earth mass before the broken earth is collected; earthworm collecting efficiency is effectively improved, and nutrient soil is also effectively recycled.

Owner:江苏安禧生物科技有限公司

Compound microbial liquid drip irrigation fertilizer and preparation method thereof

InactiveCN102718579AReduce manufacturing costApplication method is simpleOrganic fertilisersAgricultural engineeringDrip irrigation

The invention discloses a fertilizer and a processing method thereof and particularly discloses a compound microbial liquid drip irrigation fertilizer and a preparation method thereof. The fertilizer is mainly obtained by taking yeast waste liquid as a raw material, adding sodium hypochlorite for sterilization and then adding streptomycs micuoflavus as a seed bacterium to carry out aerobic fermentation. The fertilizer takes the yeast waste liquid as the raw material of the microbial fertilizer and streptomycs micuoflavus as the seed bacterium, can decompose the matters which can not be decomposed by the previous yeasts, contains plenty of organic matters, amino acids and trace elements, is liquid, is low in production cost, is simple and practical to apply, can be directly sprayed, especially can be added to spray irrigation or drip irrigation water so as to be applied, is especially suitable for improvement of virgin soil and has the advantage of good soil improvement effect.

Owner:寇建国

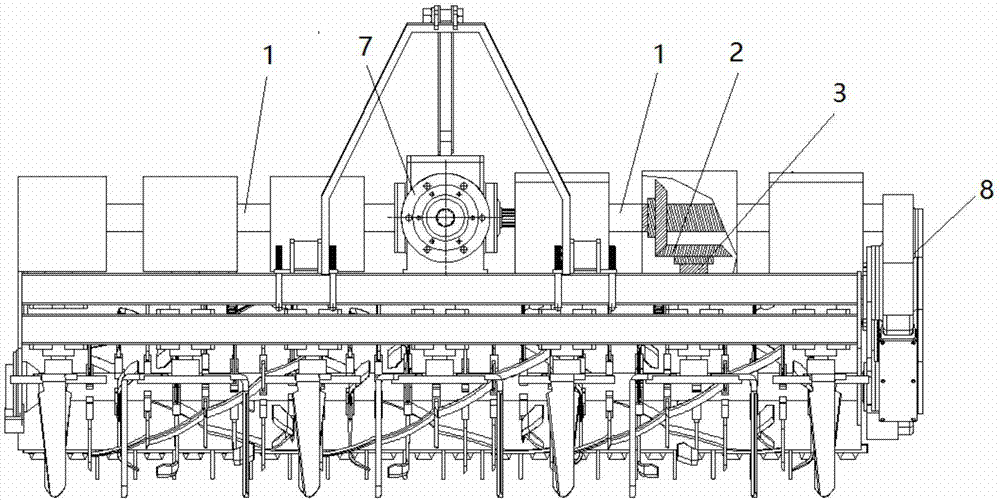

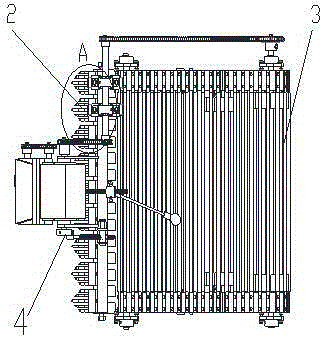

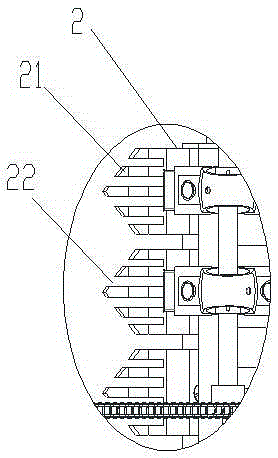

Vertical-horizontal combined dry land rotary cultivating, stubble cleaning and straw burying machine

InactiveCN106922278AReduce the difficulty of burying grassHigh coverage rateMowersAgricultural engineeringPower apparatus

The invention discloses a vertical-horizontal combined dry land rotary cultivating, stubble cleaning and straw burying machine and aims at solving the problems that an existing rotary cultivator is single in function, poor in transmission effect, relatively small in tilling depth during operation on dry land, large in resistance during straw burying, and low in operation efficiency. The vertical-horizontal combined dry land rotary cultivating, stubble cleaning and straw burying machine comprises a vertical rotary cultivating and stubble cleaning device arranged at the bottom of a front segment of a rack and a transmission device, wherein a power input end of the transmission device is connected with a power device of a tractor and a power output end of the transmission device is connected with the vertical rotary cultivating and stubble cleaning device. The vertical-horizontal combined dry land rotary cultivating, stubble cleaning and straw burying machine is characterized in that a horizontal rotary cultivating, stubble cleaning and straw burying device is arranged at the bottom of a rear segment of the rack; the power output end of the transmission device is connected with the horizontal rotary cultivating, stubble cleaning and straw burying device. The vertical-horizontal combined dry land rotary cultivating, stubble cleaning and straw burying machine is simple in structure, good in transmission effect, suitable for dry land operation and relatively small in tilling depth; the resistance on a blade during straw burying is reduced, the functions of rotary cultivation, soil crushing, stubble cutting and cleaning and straw burying can be completed once, the operation frequency of the machine is reduced and the farming efficiency is improved.

Owner:HUAZHONG AGRI UNIV

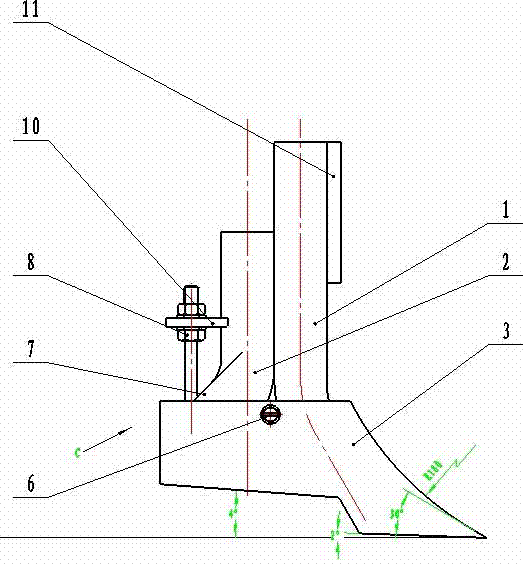

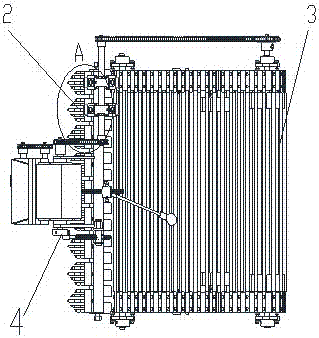

Potato digging and harvesting device

ActiveCN105230217AReduce the stress areaImprove the ability to penetrate into the soilDiggersAgricultural engineeringShovel

The invention provides a potato digging and harvesting device. The potato digging and harvesting device comprises a rack, a gearbox arranged on the rack, and a digging shovel for digging potatoes, wherein a connecting support is connected to the digging shovel; an eccentric wheel which makes eccentric motion under the effect of impetus is connected to the power output shaft of the gearbox; the connecting support is movably connected to a position which deviates from the circle center of the eccentric wheel, on the eccentric wheel, through a connecting threaded rod; when the eccentric wheel makes the eccentric motion, the digging shovel is driven to make circular motion, so that the soil to be dug is loosened; the digging shovel comprises a shovel body; a plurality of openings are formed at intervals in the shovel body to form grids, so that the force receiving area of the shovel body is reduced. The potato digging and harvesting device is provided with a grid-shaped shovel body, so that the force receiving area of the shovel body is reduced, the soil penetrating capability of the shovel body is improved, and the working efficiency is improved.

Owner:QINGDAO AGRI UNIV

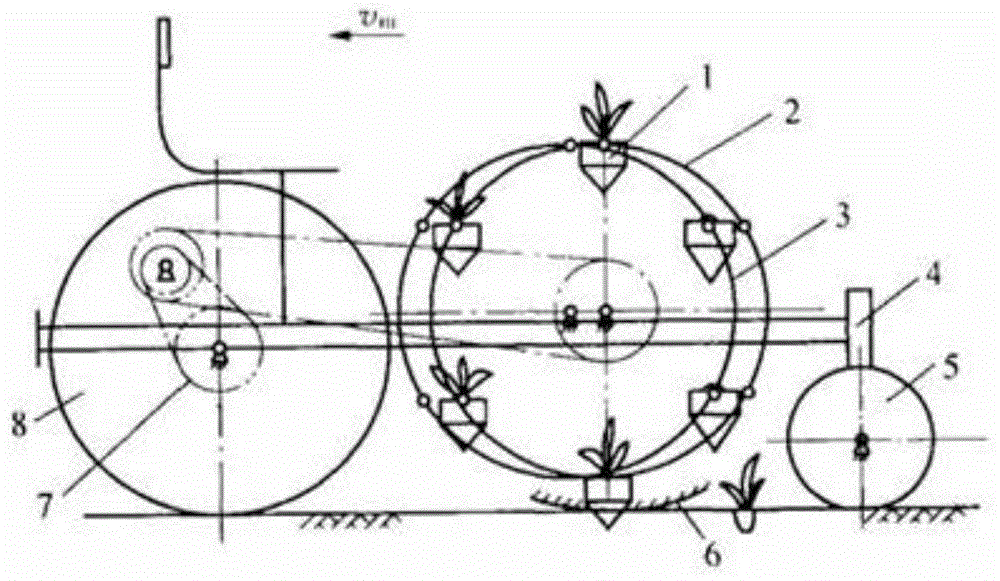

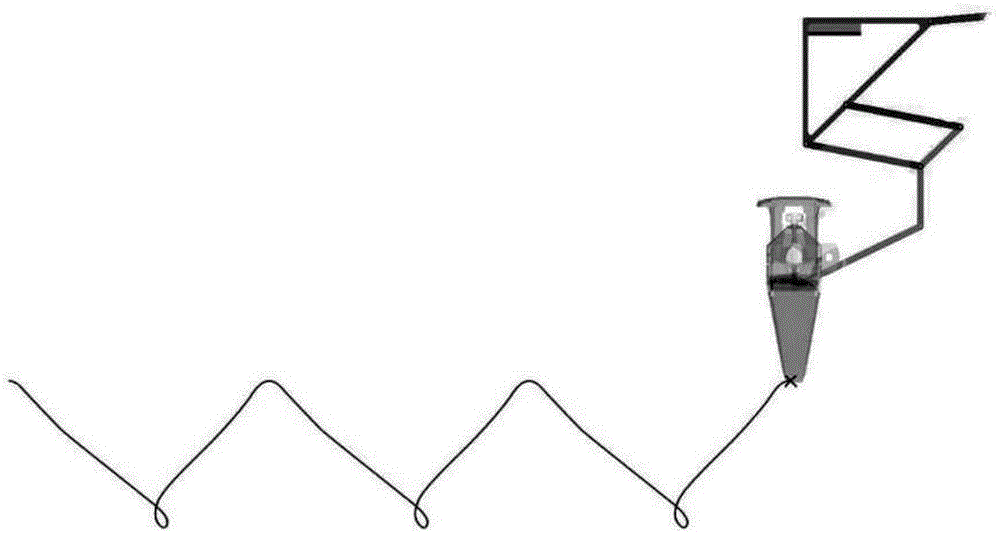

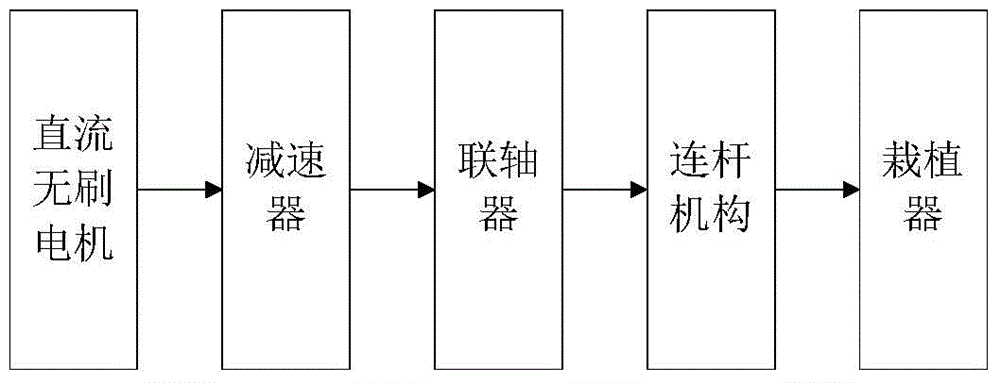

Hanging cup type planting device driving system based on DC brushless motor

ActiveCN104967369AImprove performance in soilImprove performanceSingle motor speed/torque controlElectronic commutatorsBrushless motorsMotor speed

The invention discloses a hanging cup type planting device driving system based on a DC brushless motor. A planting device is used for hole punching and seeding planting work in seeding transplanting. The hanging cup planting device based on the DC brushless motor comprises a controller module, a driver module, a storage battery power supply module, the DC brushless motor, a feedback module, a decelerator, a transmission mechanism and a hanging cup transplanting mechanism. The transmission mechanism transmits power and drives a crank rocker mechanism to move, and the put-in pot seeding is carried by a hanging cup when the crank rocker mechanism moves to the highest point; and soil dusting and hole punching are performed by the hanging cup when the crank rocker mechanism moves to the lowest point, and the pot seeding is put in the hole so that seeding planting work is completed. A driving control part is mainly composed of the controller, the DC brushless motor, the driver and the feedback module. The driving system can accurately control movement of the hanging cup via high-precision closed-loop control of motor speed and torque. According to the driving system, the hanging cup can be driven to stably complete planting movement according to the specific movement characteristics so that seeding planting frequency and reliability can be enhanced and short-planting-distance close transplanting work can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Profiling sowing machine and using method thereof

InactiveCN110326402AStable power deliveryEasy to adjust broadcast volumePlantingFurrow making/coveringAgricultural engineeringSowing

The invention discloses a profiling sowing machine and a using method thereof, and belongs to the technical field of agricultural mechanical equipment. The profiling sowing machine comprises a rack aswell as a first seed box and a second seed box which are arranged side by side, wherein rotating rods are arranged at the bottom ends of the first seed box and the second seed box; one end of each rotating rod is fixedly connected with a second connecting shaft; a first driven wheel and a second driven wheel are arranged on the second rotating shaft connected with the rotating rod at the lower end of the first seed box; a third driven wheel movably connected with the second driven wheel through a chain is arranged on the second connecting shaft connected with the rotating rod at the lower endof the second seed box; a plurality of land wheels are movably connected with the lower end of the rack through a rotating shaft, a first connecting shaft is connected onto the land wheels, a drivingwheel is arranged on the first connecting shaft, and a gearbox connected with the rotating rods and the second connecting shafts is arranged at the bottom end of the first seed box. By means of the land wheels, the chain, the driving wheel and multiple driven wheels, power transmission is realized and is stable, the sowing quantity is adjusted and controlled by the gearbox, the sowing quantity adjustment is convenient and fast, and sowing is more uniform.

Owner:宿州市信德机械股份有限公司

Production method of compound microorganism fertilizer

InactiveCN105272459AIncrease productionImprove qualityFertilizer mixturesDiseaseAzotobacter chroococcum

The invention discloses a production method of a compound microorganism fertilizer. The production method comprises steps as follows: an azotobacter chroococcum bacterial agent and a soil silicate bacterial agent in the weight ratio being 1: (0.5-1.5) are stirred and mixed in proportion; 2-8kg of flour and 10-40kg of clear water are taken and then stirred and mixed in the proportion being 1: (4-6), and a liquid culture medium is prepared; the stirred mixture is placed in the liquid culture medium and left to stand for 24 hours at the temperature of 10-30 DEG C, and the compound microorganism fertilizer is obtained. The source of soil nitrogen is increased; phosphorus and potassium which are difficult to dissolve are converted into a phosphorus and potassium compound which can be absorbed and used by crops, and the nutrition condition of the crops is improved. Microorganisms can generate a large amount of plant growth hormone in the breeding process to stimulate and adjust crop growth, accordingly, plants grow healthily and robustly, and absorption of nutritional elements is promoted; the disease resistance and drought resistance ability of the plants are enhanced, breeding of pathogenic microorganisms is inhibited, water absorption is increased, the use quantity of fertilizers is reduced, and the crop quality is improved.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Fruit tree cultivation method suitable for orchard landscapes

InactiveCN112075280ABeautiful sceneryImprove the ecosystemGrowth substratesCulture mediaFruit treeSeedling

The invention discloses a fruit tree cultivation method suitable for orchard landscapes, and belongs to the technical field of fruit tree cultivation. The method mainly comprises the following cultivation steps of preparing a garden plot, ploughing the garden plot, preparing a planting groove and paving planting soil; preparing a supporting structure, and mounting persimmon tree brackets and mulberry tree brackets in the garden plot; planting seedlings, selecting healthy persimmon tree seedlings and mulberry tree seedlings, and planting the seedlings in spring; and pruning persimmon trees andpruning mulberry trees. According to the method, the growth habits and appearance characteristics of the mulberry trees and the persimmon trees are combined, orchard field conditions are combined, traditional orchard planting and sightseeing tour are combined, a very comfortable and beautiful picking environment is provided for tourists, the picking sightseeing time is longer, and a new cultivation mode is created.

Owner:平湖市报本农业科技有限公司

Method for preparing slow-release fertilizer from lignocellulose ethanol fermentation residues

ActiveCN106083489ASignificantly synergistic beneficial effectsNo secondary pollutionCalcareous fertilisersAlkali orthophosphate fertiliserCelluloseSoil properties

The invention discloses a method for preparing a slow-release fertilizer from lignocellulose ethanol fermentation residues. A completely novel slow-release fertilizer can be prepared by using the method, the lignocellulose ethanol fermentation residues are taken as a raw material for a first time, and the slow-release fertilizer which is good in slow-release effects and improved in soil properties can be prepared. The method is simple and feasible in process, components of the slow-release fertilizer can be all degraded, and the slow-release fertilizer is applicable to ecological fertilization of agriculture and forestry.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

A subsoiling shovel based on the principle of dynamic bionics

InactiveCN105874902BAchieve dynamic loosening effectImprove performance in soilPloughsEngineeringTorsion spring

The invention discloses a subsoiler based on a dynamic bionic principle. The subsoiler comprises a subsoiler mounting handle, a limiting device, a bidirectional torsion spring, a subsoiler handle, a subsoiler tip and a pulley, wherein the subsoiler mounting handle and the subsoiler handle are mounted through a bearing, so that the subsoiler handle can be rotated at the bottom of the soil; the pulley is mounted at the rear end of the subsoiler handle, is in contact with the limiting device and is used for supplying a support force along a heading direction and limiting the rotating angle; the bidirectional torsion spring is mounted at the external end of the bearing, so that the rotating resetting of the subsoiler is realized and the dynamic operation effect is achieved; the subsoiler is optimized through bionic curve design, so that the improvement of the soil-breaking property is ensured; the dynamic bionic principle is designed and the moving form of the whole subsoiler is similar to the forms of the animals, such as, earthworm, mole cricket, and the like, in the moving process, so that the dynamic bionic motion is realized.

Owner:JILIN UNIV

Potato digging and harvesting device

ActiveCN105230217BReduce the stress areaImprove performance in soilDiggersAgricultural engineeringShovel

The invention provides a potato digging and harvesting device, which includes a frame, a gearbox arranged on the frame, and a digging shovel for digging potatoes. A connecting frame is connected to the digging shovel; a power output shaft of the gearbox is connected to a The eccentric wheel that moves eccentrically under the action of power, the part that deviates from the center of the eccentric wheel is connected with the connecting frame through the connecting screw. When the eccentric wheel moves eccentrically, it drives the excavating shovel to make a circular motion to loosen the soil to be excavated; the excavating shovel includes a shovel body , The shovel body is provided with a plurality of openings at intervals, forming a grid shape, so as to reduce the force-bearing area of the shovel body. The device reduces the force-bearing area of the shovel body by setting the grid-shaped shovel body, improves the soil penetration ability of the shovel body, and improves work efficiency.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com