Shovel tooth and elastic tooth roller combined type peanut pickup device

A combined and roller technology, applied in the field of agricultural machinery, can solve the problems of increasing the peanut drop rate and loss rate, reducing the applicability and stability of the pickup device, and increasing the pickup height, so as to achieve a good lifting inclination and improve the service life. , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

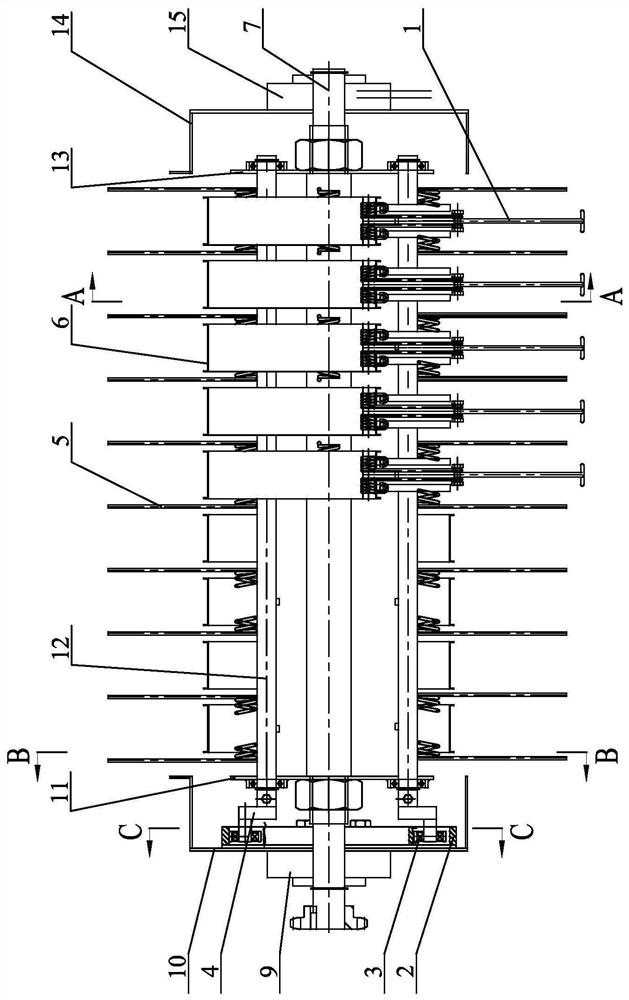

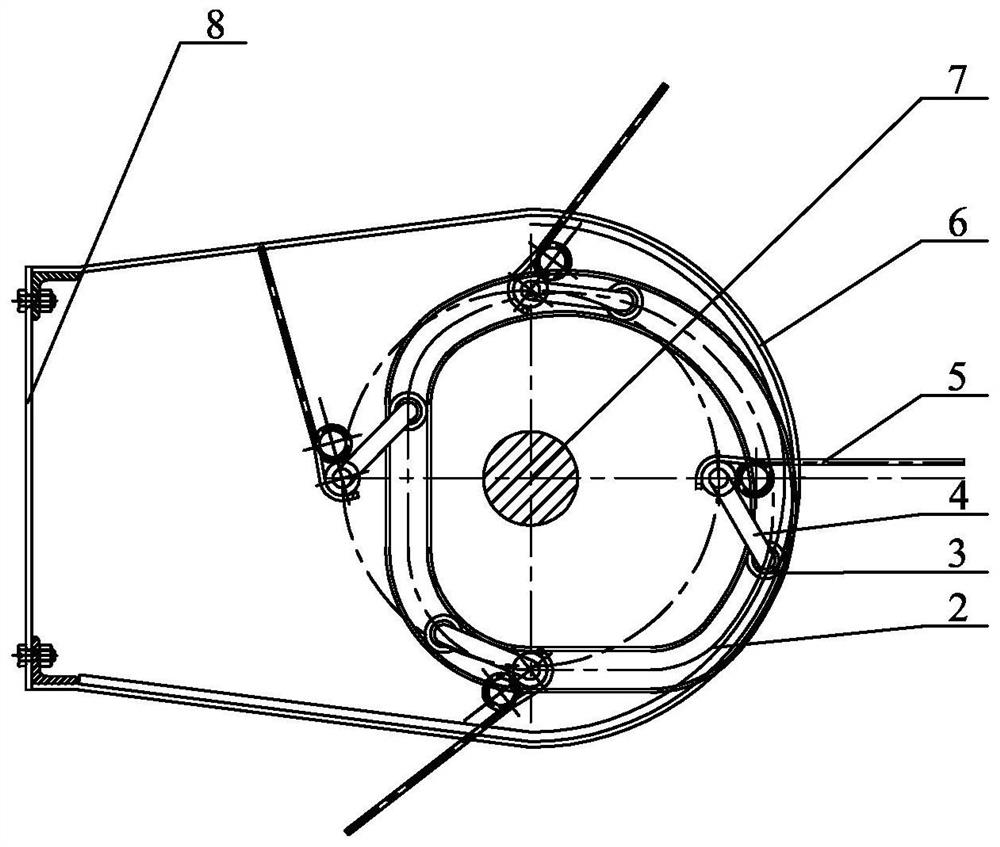

[0040] Embodiment 1: as figure 1 As shown, a kind of shovel tooth-elastic tooth drum combined peanut picking device of the present invention comprises picking up shovel teeth 1, a drum guard plate 6, a picking drum, a drum slideway 2 and a side plate, and the central axis 7 of the picking drum passes through two The left and right side plates 10 and 14 on the side are mounted on the left and right bearing housings 9 and 15 respectively, and the picking-up spring teeth 5 are evenly spaced on the spring-tooth shaft 12 of the pick-up drum, and rollers are arranged between the 5 adjacent pick-up spring teeth. Guard plate 6, at the front end of travel, arc-shaped pick-up shovel teeth 1 with the same structure are installed at the same position on each of the drum guard plates 6 to form a row of shovel teeth; Move forward, scoop up the peanut plants drying on the ground from the ground, make the peanut plants leave the ground and move up to a certain height along the arc-shaped shov...

Embodiment 2

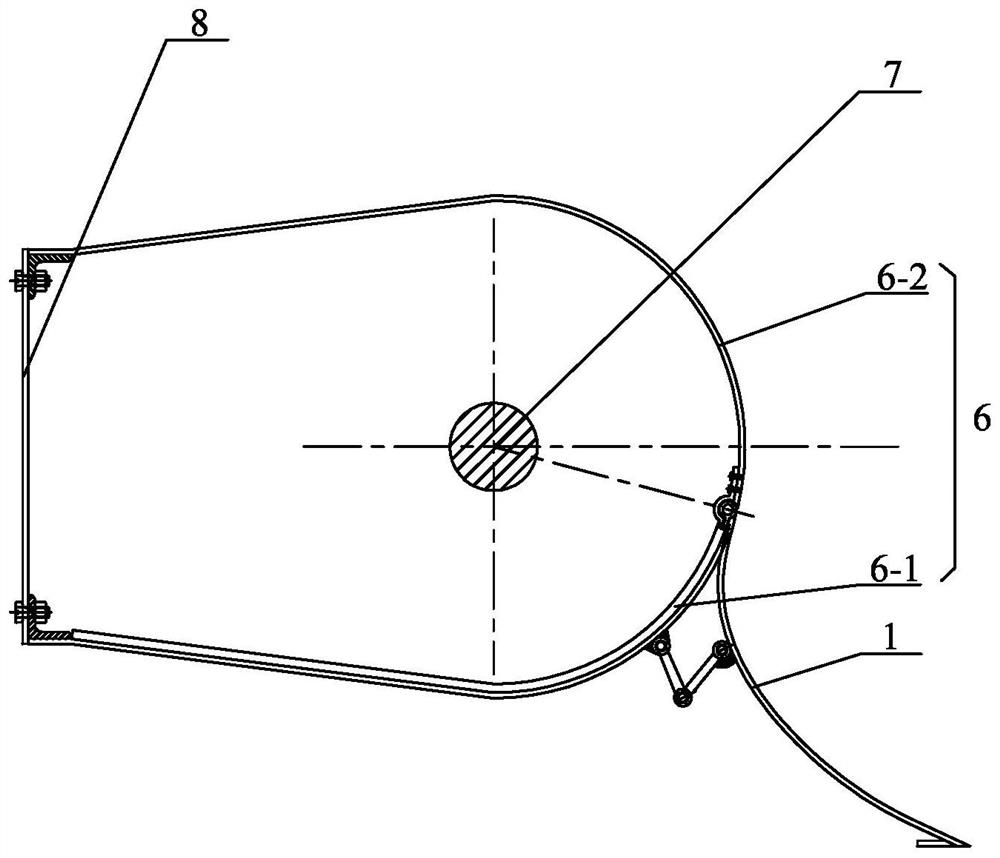

[0056] Such as figure 1 , Figure 4-Figure 7 , Figure 9 , Figure 10 As shown, when the angle θ between the installation tangent point (elastic hinge point) of the pick-up shovel tooth 1 and the guard plate is the same as that of the central axis and the ordinate of the central axis is 30°, the shovel tooth base circle radius R2 is 75mm, the corresponding central angle α2 is the fourth quadrant as the starting point, relative to the central angle of the starting point is a 97° segment involute, α 0 =60,α n = 157°; α 0 is the starting angle of the tooth involute, α n is the cut-off angle of the tooth involute.

[0057] The phase angles corresponding to the three stations of lifting, pushing and emptying are respectively β 1 ~β 3 , where the initial lift angle θ of the lift station 1 is 10-60°, the initial lift angle θ 1 is the angle between the pick-up tooth 5 and the Y-axis of the drum along the forward direction of the pick-up device, the three phase angles are β1=...

Embodiment 3

[0066] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the angle θ between the installation tangent point of the pick-up shovel teeth 1 and the guard plate 6 in this embodiment is the same as that of the central axis, and the y-coordinate of the central axis is 45°. °, the radius R2 of the shovel tooth base circle is 42mm, and the corresponding central angle α2 is based on the fourth quadrant as the starting point, relative to the starting point central angle is a 116° segment involute, α 0 =45,α n = 161°; α 0 is the starting angle of the tooth involute, α n is the cut-off angle of the tooth involute.

[0067] Lifting inclination angle θ described in this example 1 is 13°, and the three phase angles are β1=146°, β2=99°, and β3=115° clockwise.

[0068] Such as Figure 10 As shown, in this example: in the same section, O is the center of the central axis, and its coordinate system is (X, Y) as the basic coordinate system; O 1 for The center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com