Separation and recovery apparatus for waste paper and plastic composite material, and method thereof

A composite material, separation and recycling technology, applied in the field of waste paper-plastic composite material separation and recycling devices, can solve the problems of increased recycling cost, high cost, large water consumption, etc., and achieves easy recycling and sorting, easy separation and recycling, water and energy consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

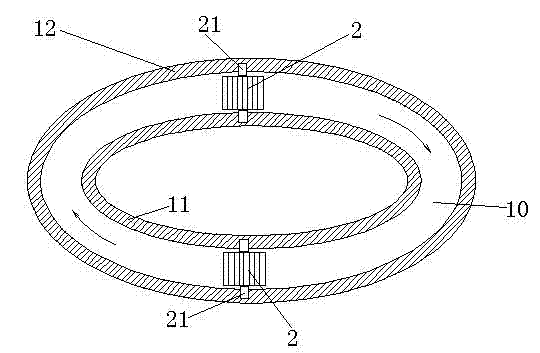

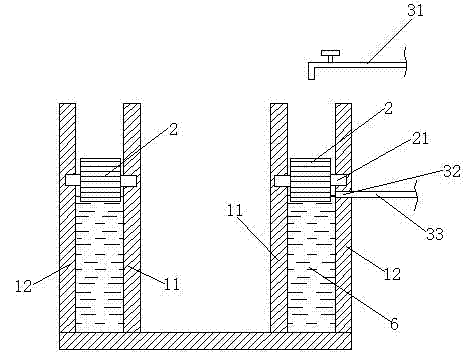

[0028] figure 1 , figure 2 , Figure 5 As shown, the waste paper-plastic composite material separation and recovery device includes an annular water tank, and its cavity 10 is annular. The annular water tank has an annular inner side wall 11 and an annular outer side wall 12. The annular water tank is equipped with two rollers 2, and the rotating shaft of each roller 21. The installation direction is the horizontal direction, and the surface of each roller is provided with convex teeth 22, and each roller is connected with a motor that drives it to rotate. The two ends of each roller shaft 21 are erected respectively on the annular inner wall 11 and the annular outer wall 12 of the water tank, that is, the two ends of each roller shaft are respectively erected on both sides of the tank cavity 10; the annular water tank is provided with a water supply pipe 31 and a slurry discharge The port 32 is connected with a slurry discharge pipe 33 to the slurry discharge port 32. Th...

Embodiment 2

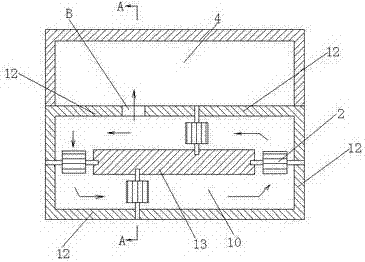

[0031] image 3 , Figure 4 , Figure 5 As shown, in this embodiment, the tank cavity of the annular water tank is annular, and the center of the water tank is an inner wall 13, and the surrounding sides of the inner wall form the inner surface of the annular water tank, and four rollers 2 are installed in the annular water tank. The two ends of each roller rotating shaft are erected on the tank inner wall 13 and the annular outer side wall 12 respectively. The slurry outlet of the annular water tank is the lowest point of the annular outer wall 12 elevation ( image 3 , Figure 4 The part indicated by B in the middle), so Figure 3, Figure 4 The part indicated by middle B forms a pulp outlet, and a pulp pool 4 is arranged next to the pulp outlet. When the height of the tank cavity water surface exceeds that shown in Figure 3, Figure 4 At the position indicated by middle B, the paper residue pulp naturally overflows and enters the CIMC stock tank 4. In order to prevent...

Embodiment 3

[0033] In the third embodiment, three pulp outlets are set at the same time, and the vertical elevations of each pulp outlet are different, wherein the vertical position of the uppermost pulp outlet is slightly lower than the vertical position of the roller shaft, and the bottom row The vertical position of the slurry port is located at the lower part of the annular outer wall, and the vertical position of the middle slurry discharge port is located at the middle part of the annular outer wall. In this way, different pulp outlets can be opened according to different shredded paper, for example, when the shredded paper is deposited in the water, the lower pulp outlet can be opened to facilitate the shredded paper to be discharged from the annular water tank; When the water tends to float upward, the upper pulp discharge port can be opened to facilitate the discharge of shredded paper residue into the annular water tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com