Preparation of loaded bimetallic nano-catalyst

A bimetallic nano-catalyst technology, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, carbon-based compounds, etc., can solve the problems of low catalytic oxidation activity and achieve high catalytic activity, Simple preparation method and less catalyst loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

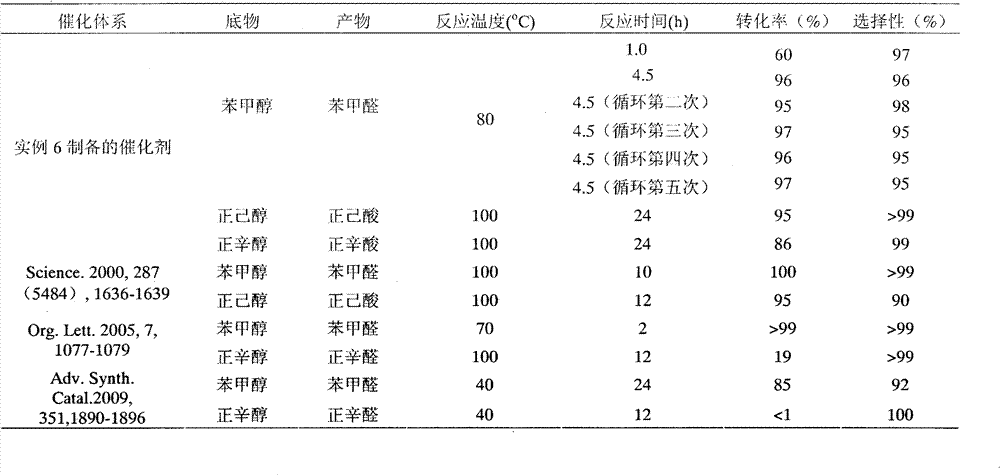

Examples

example 1

[0021] Example 1: Preparation of 0.5%Pd-0.6%Au / LDH catalyst

[0022] Step 1, the preparation of magnesium aluminum hydrotalcite: 0.03mol Mg(NO 3 ) 2 ·6H 2 O, 0.015mol Al(NO 3 ) 3 9H 2 O, 0.21mol urea, and 50mL deionized water were mixed evenly, and then slowly heated to 105°C under stirring. When the temperature began to exceed 90°C, urea began to decompose, and gas escaped from the solution continuously. After about 1 hour, the solution From clarification to turbidity, after a period of time, it becomes a slurry, which is maintained at 105°C for dynamic crystallization for 10 hours, followed by static crystallization for 20 hours. After the crystallization, filter with suction, wash with deionized water several times until the pH of the filtrate becomes neutral, and then dry at 60°C for 12 hours to obtain magnesium aluminum hydrotalcite (LDH).

[0023] The preparation of step 2, the palladium-gold bimetallic nanoparticle catalyst supported by magnesium aluminum hydrotal...

example 2

[0024] Example 2: Preparation of 0.5%Pd-0.8%Au / LDH catalyst

[0025] Step 1, the preparation of magnesium aluminum hydrotalcite: 0.03mol Mg(NO 3 ) 2 ·6H 2 O, 0.015mol Al(NO 3 ) 3 9H 2 O, 0.21mol urea, and 50mL deionized water were mixed evenly, and then slowly heated to 105°C under stirring. When the temperature began to exceed 90°C, urea began to decompose, and gas escaped from the solution continuously. After about 1 hour, the solution From clarification to turbidity, after a period of time, it becomes a slurry, which is maintained at 105°C for dynamic crystallization for 10 hours, followed by static crystallization for 20 hours. After the crystallization, filter with suction, wash with deionized water several times until the pH of the filtrate becomes neutral, and then dry at 60°C for 12 hours to obtain magnesium aluminum hydrotalcite (LDH).

[0026] The preparation of step 2, the palladium-gold bimetallic nanoparticle catalyst supported by magnesium aluminum hydrotal...

example 3

[0027] Example 3: Preparation of 0.5%Pd-1.0%Au / LDH catalyst

[0028] Step 1, the preparation of magnesium aluminum hydrotalcite: 0.03mol Mg(NO 3 ) 2 ·6H 2 O, 0.015mol Al(NO 3 ) 3 9H 2 O, 0.21mol urea, and 50mL deionized water were mixed evenly, and then slowly heated to 105°C under stirring. When the temperature began to exceed 90°C, urea began to decompose, and gas escaped from the solution continuously. After about 1 hour, the solution From clarification to turbidity, after a period of time, it becomes a slurry, which is maintained at 105°C for dynamic crystallization for 10 hours, followed by static crystallization for 20 hours. After the crystallization, filter with suction, wash with deionized water several times until the pH of the filtrate becomes neutral, and then dry at 60°C for 12 hours to obtain magnesium aluminum hydrotalcite (LDH).

[0029] The preparation of step 2, the palladium-gold bimetallic nanoparticle catalyst supported by magnesium aluminum hydrotal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com