Patents

Literature

231results about How to "Less water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

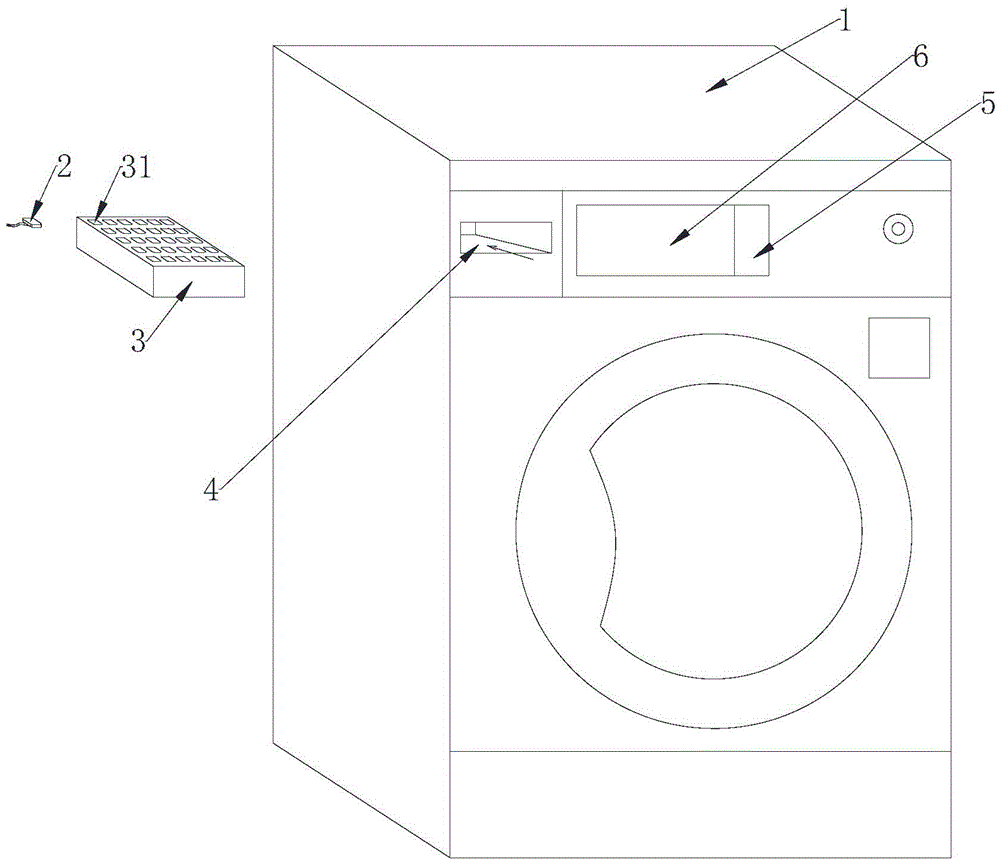

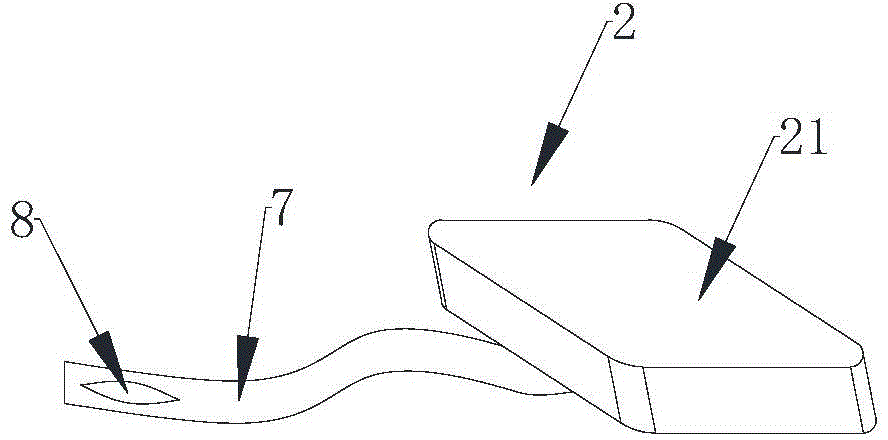

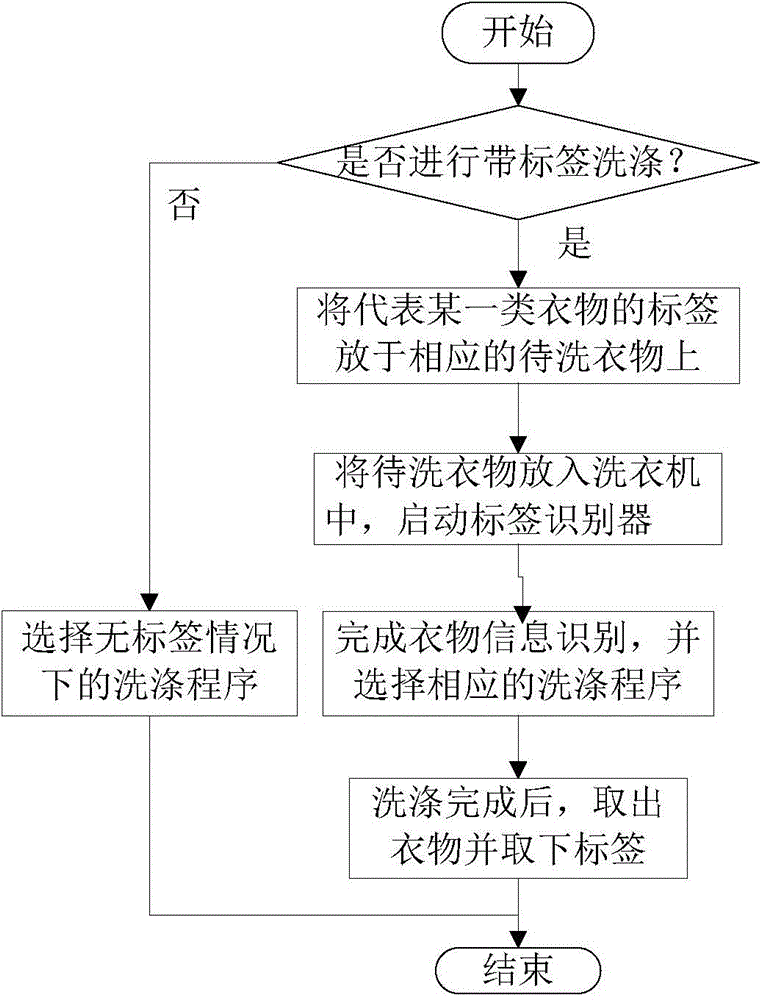

Washing machine with identification function and washing method

ActiveCN105401382ABetter wash ratioAchieve reuseOther washing machinesControl devices for washing apparatusRadio frequency signalMechanical engineering

The invention relates to a washing machine with an identification function and a washing method. The washing machine comprises a washing machine body and a clothes identification module, an RFID reader, and an RFID antenna. The clothes identification module comprises a plurality of RFID tags representing clothes classifications and / or materials. The RFID tags are placed on the washing machine body and can be separated from the washing machine body. In washing, the RFID tags are connected with to-be-washed clothes. After washing is finished, a user separates the RFID tags from the clothes and collects the RFID tags to the washing machine body. The RFID reader is used to read information of the RFID tags and transmit the information to a washing machine processor. The RFID antenna transmits radio-frequency signals among the tags and the reader. The washing machine solves problems that the RFID tags are not popularized on clothes and clothes intelligent identification cannot be realized. The method pushes intelligent identification of clothes which just remains in a theoretical research stage to a specific washing machine structure, so that intelligent identification of clothes without the RFID tags is realized. The washing machine realizes optimal washing ratio by minimum water consumption, minimum power consumption, and minimum detergent.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

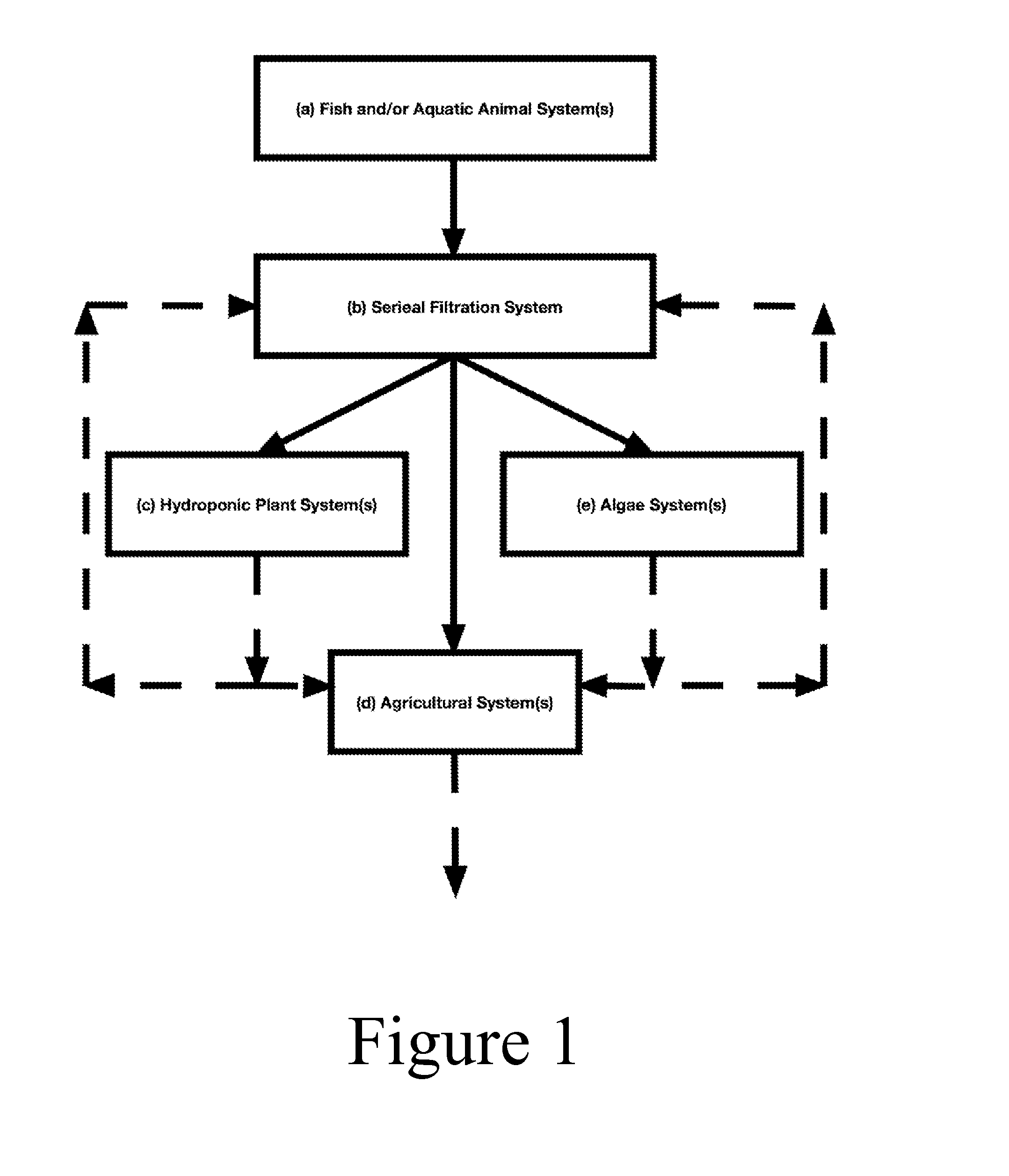

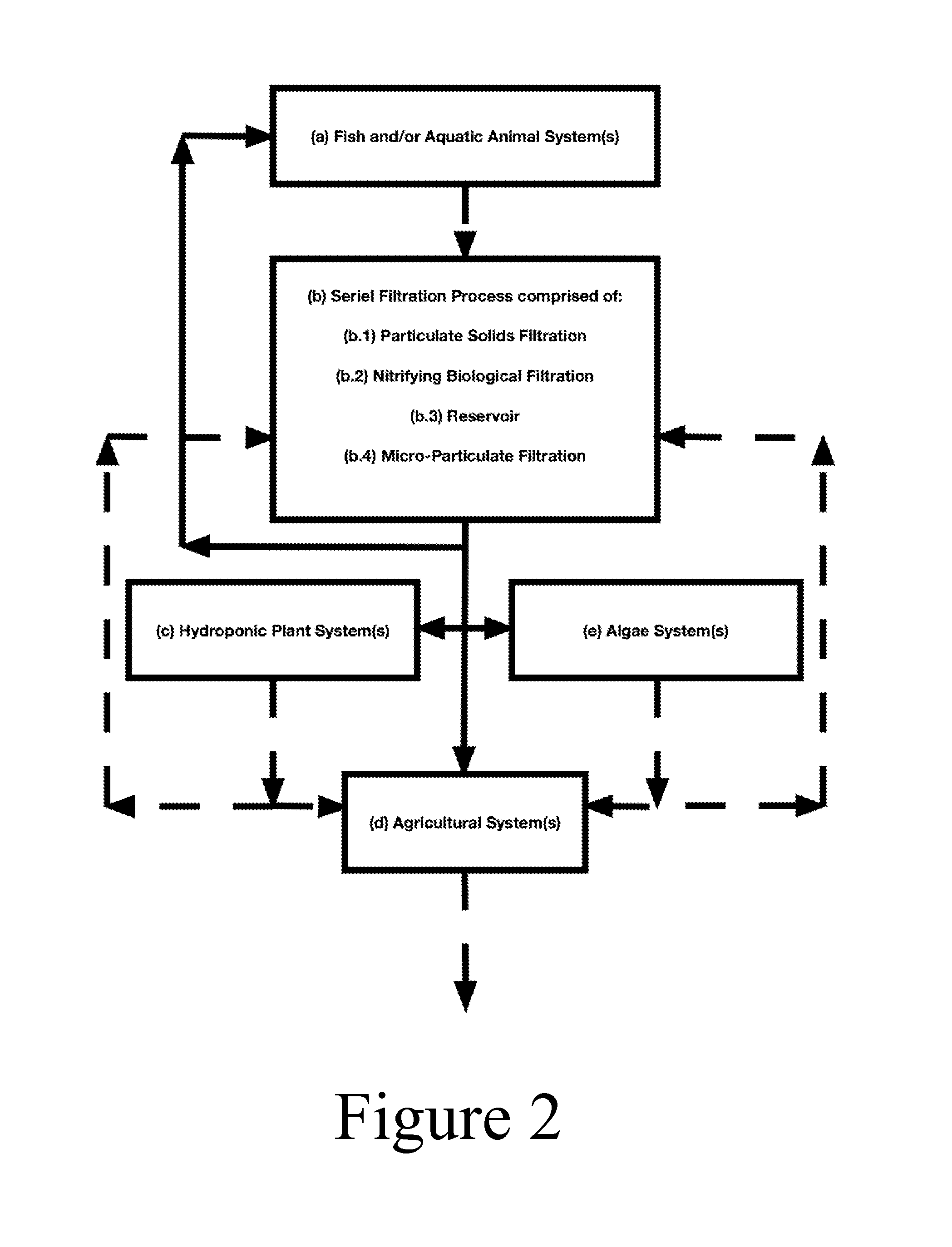

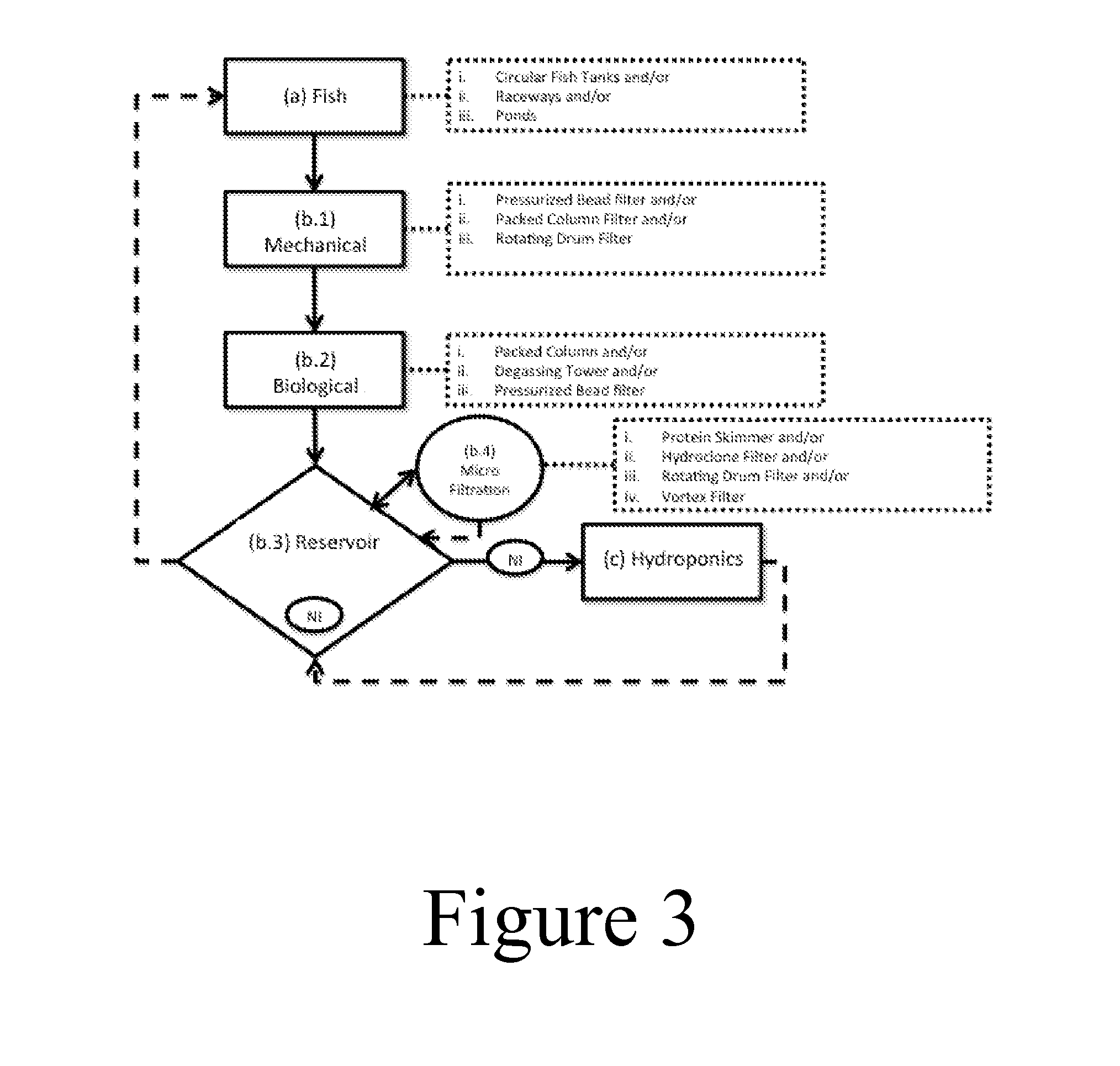

Integrated multi-trophic farming process

ActiveUS20150305313A1Less overall consumptionConserve waterIon-exchanger regenerationSingle direction vortexAquatic animalFresh water organism

The described invention is an integrated multi-trophic farming process and methods thereof that creates a linkage between aquaculture, hydroponics, agriculture, and algae production. The process and methods described herein enable one skilled in the art of aquaculture, agriculture, hydroponics, and / or algae production to integrate aquaculture practices with their respective industry. The process and methods described within are applied to freshwater, brackish, and / or saltwater aquaculture production systems. The processes and methods described herein enable one skilled in the art to produce fish and / or aquatic animals in conjunction with plant and / or algae crops with less consumption of water, feed, and / or fertilizers when compared to conventional open source farming practices such as but not limited to aquaculture, agriculture, and / or algae production

Owner:LICAMELE JASON

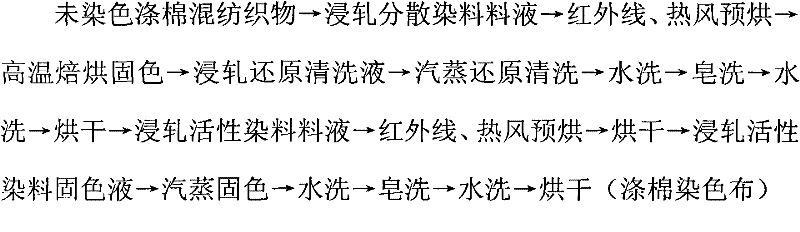

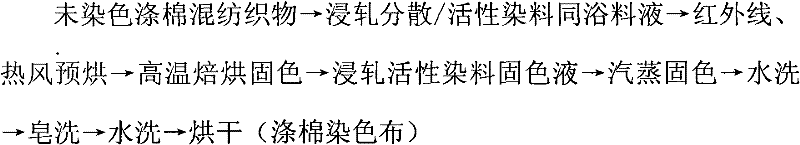

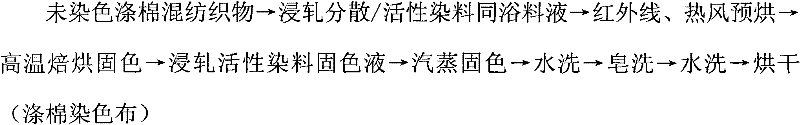

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

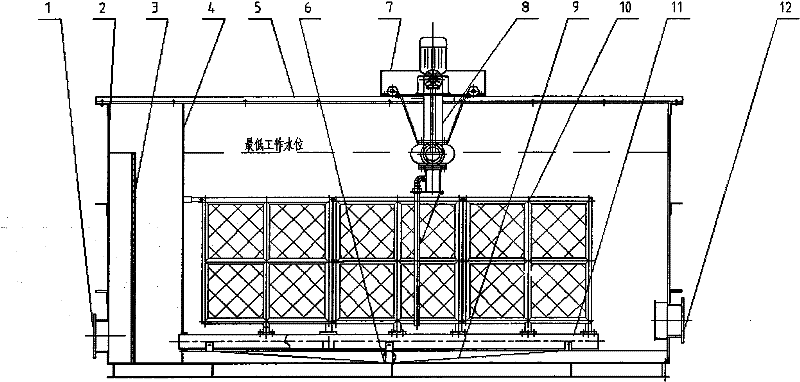

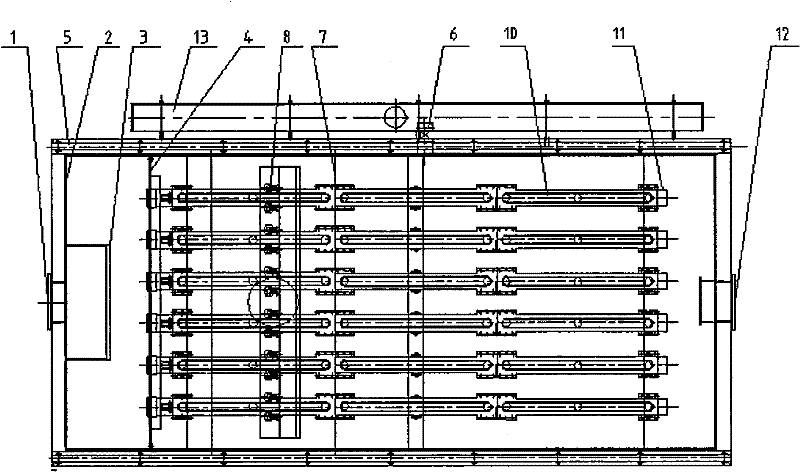

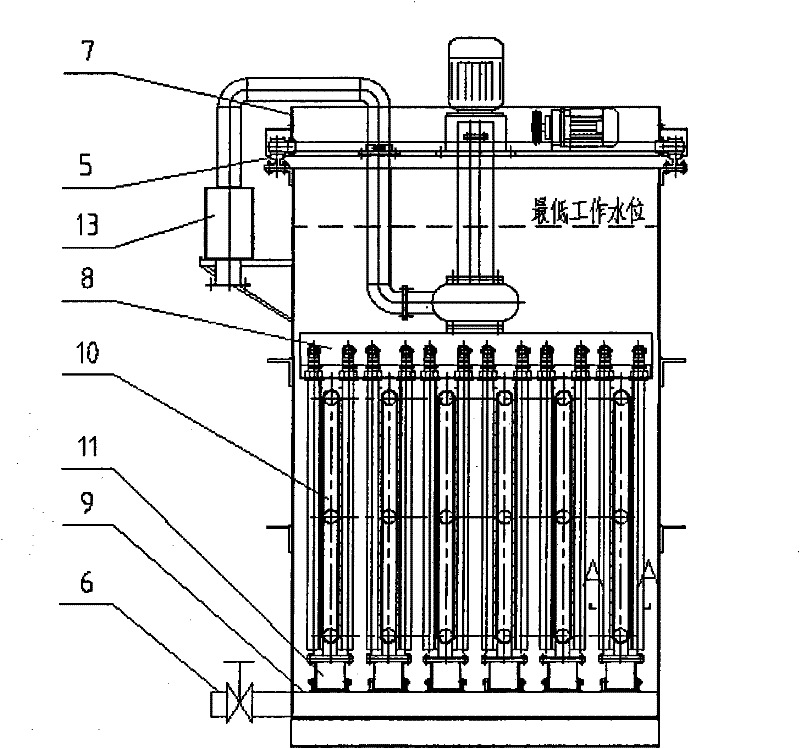

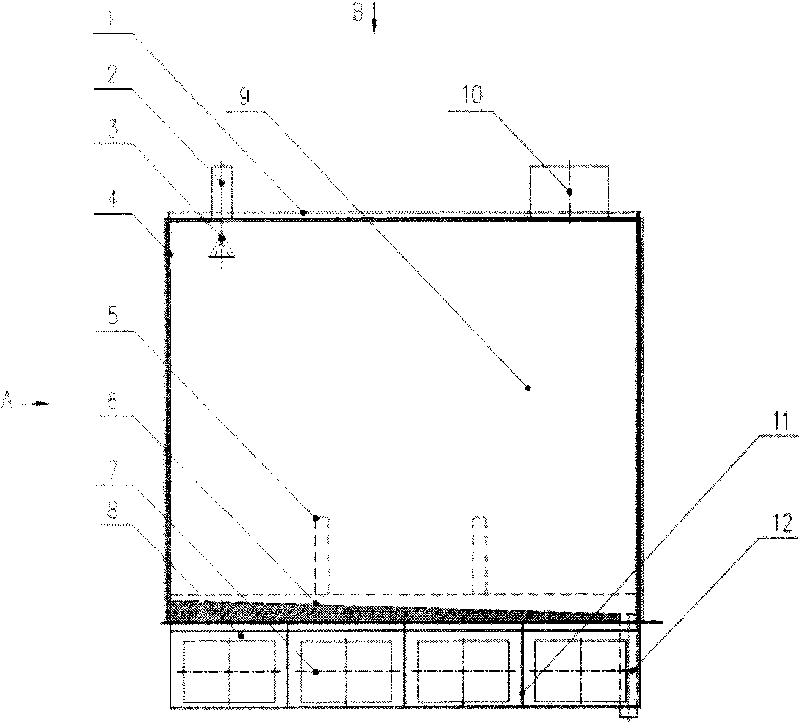

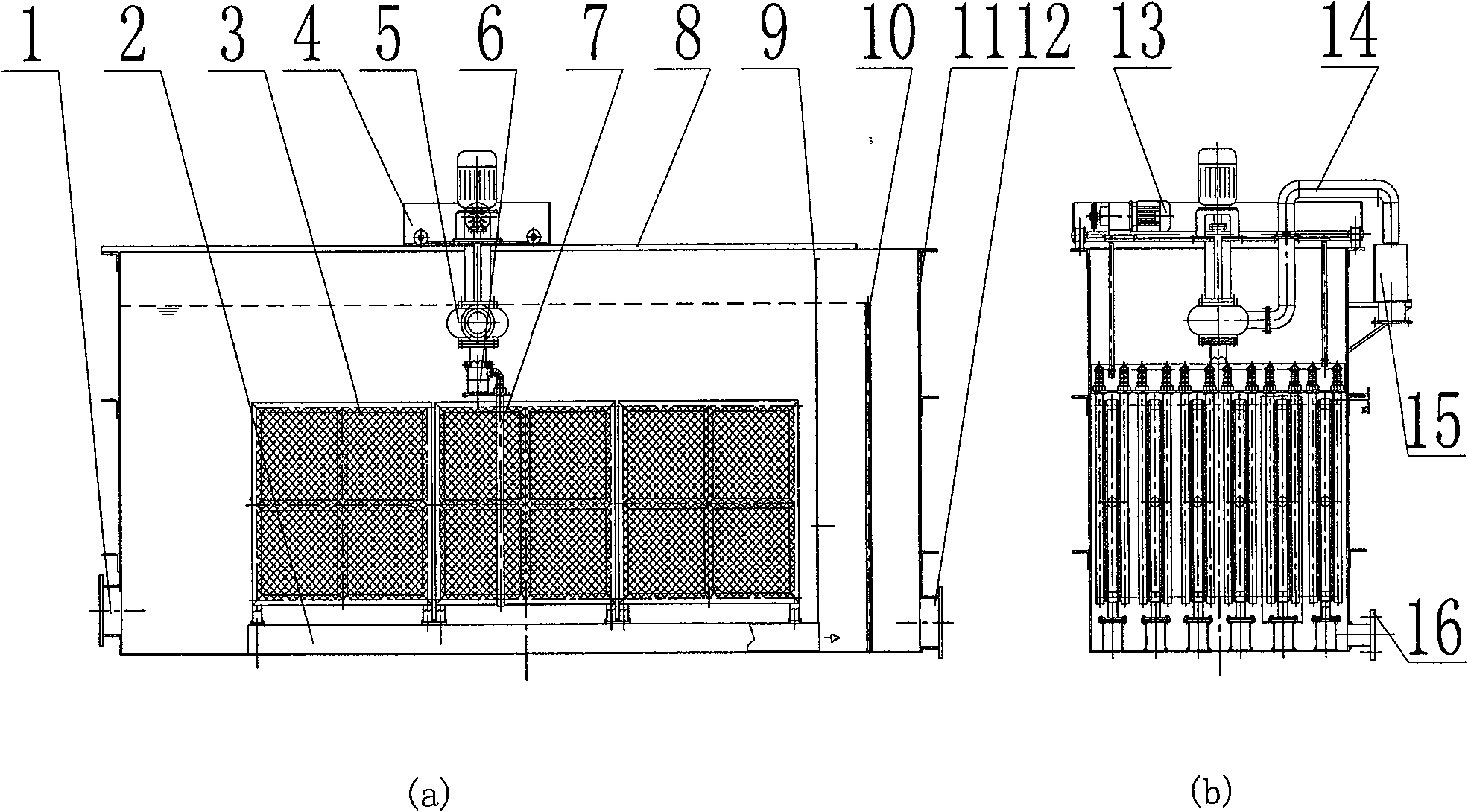

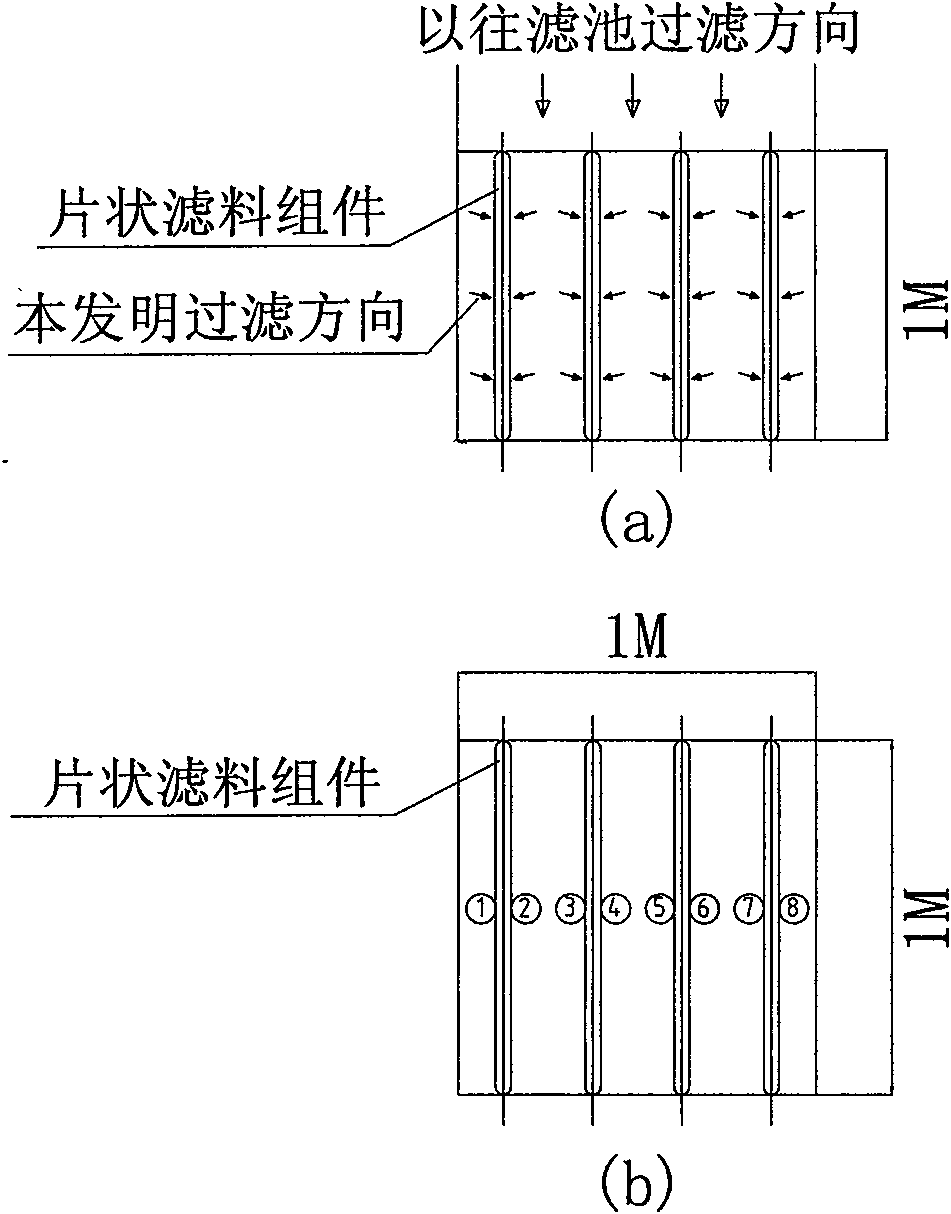

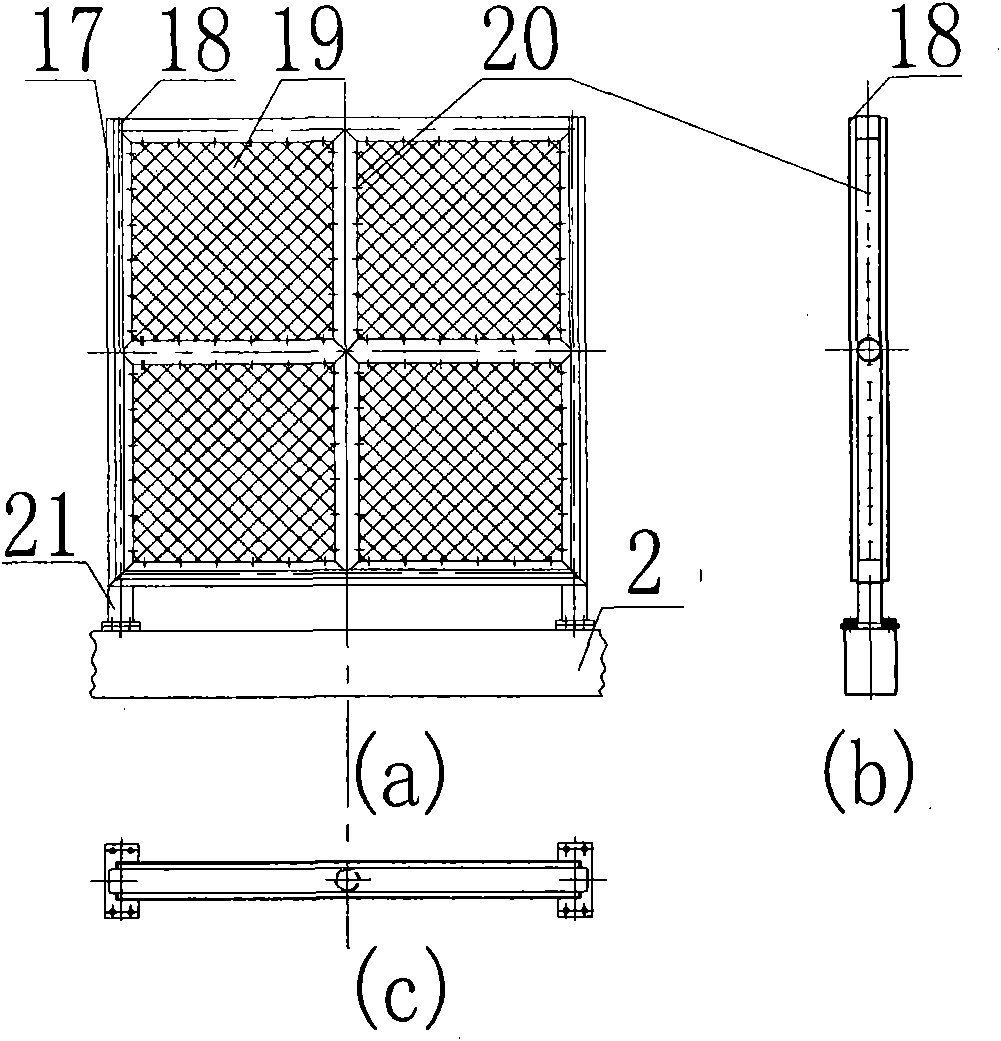

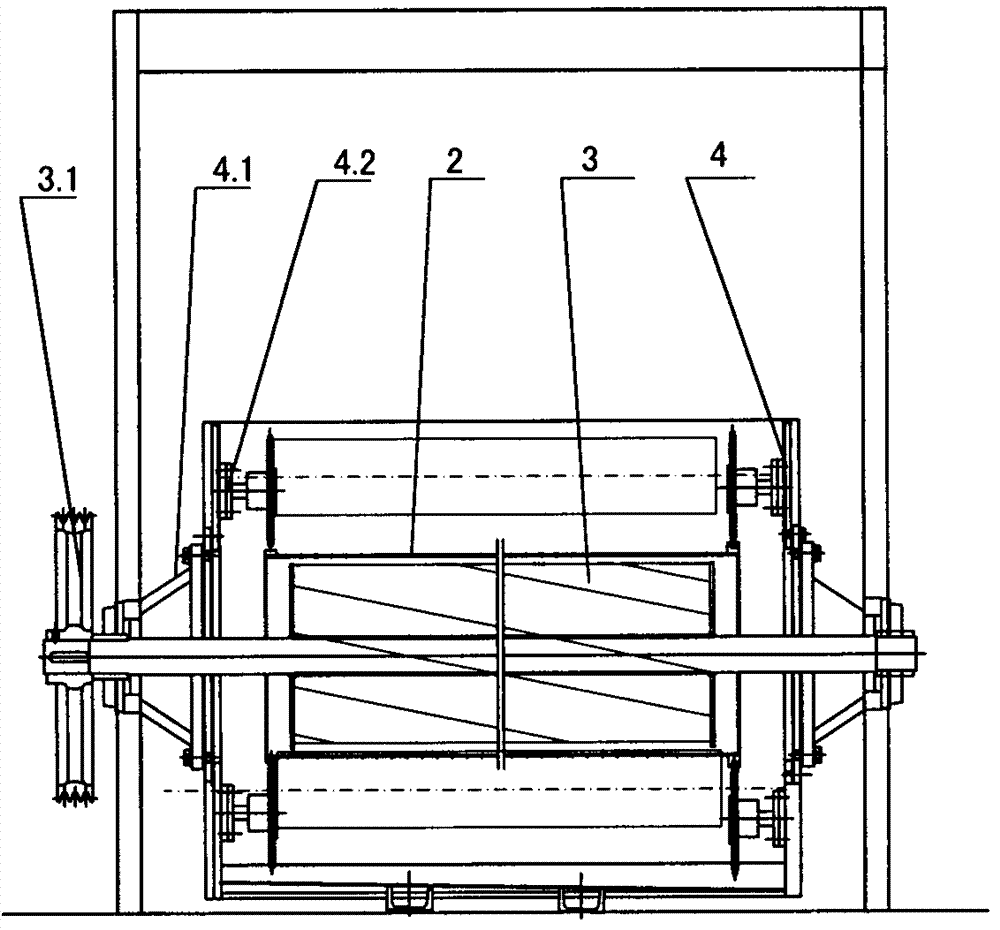

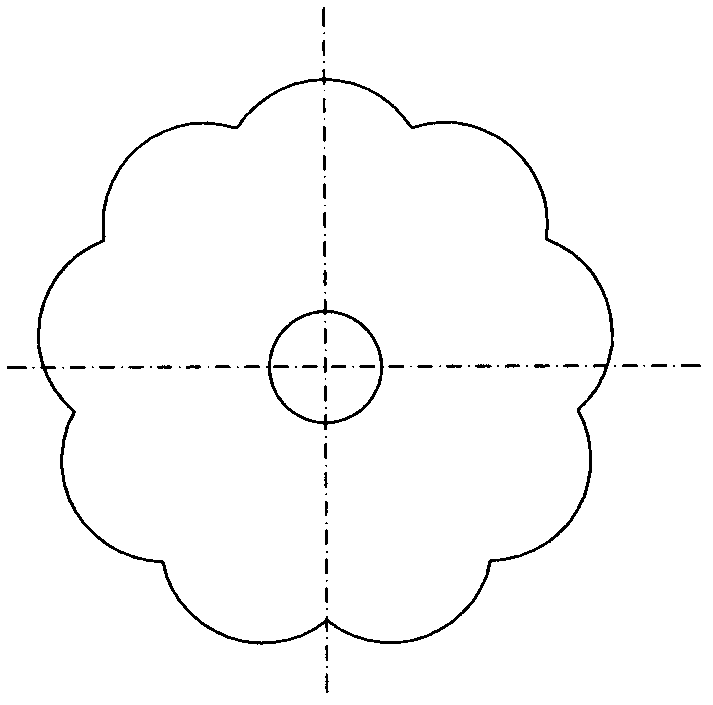

Vertical sheet filter

InactiveCN102343171AEliminate settingsLarge filter areaStationary filtering element filtersSludgeEngineering

The invention belongs to the technical field of water treatment, and specifically relates to a vertical sheet filter. The vertical sheet filter comprises a water outlet, a housing, an effluent weir, a side splitter, a guide rail, an emptying port, a dolly, a backwashing component, a filtering component, a water header, a water inlet and a sludge chamber. The water inlet, the water outlet and the emptying port are respectively arranged under the housing; the sheet filtering component is vertically arranged in the housing; the dolly is arranged on a dolly guide rail on top of the housing and can move on the guide rail; a dredge pump is fixed under the dolly; one end of a dredge tube is on two sides of the sheet filtering component, and the other end is connected to the dredge pump through a dredge header tube; and a spoil disposal plate with a certain gradient is arranged at the housing bottom. Because of usage of a light filter material and valve-free operation, the invention has characteristics of large filtering area, low filtering load, small backwashing water consumption, flexible system configuration, low energy consumption, small land occupation, simple operation and maintenance and high degree of automation, and can be combined with routine water treatment technology to realize a higher purifying efficiency.

Owner:上海安鼎济水处理科技有限公司

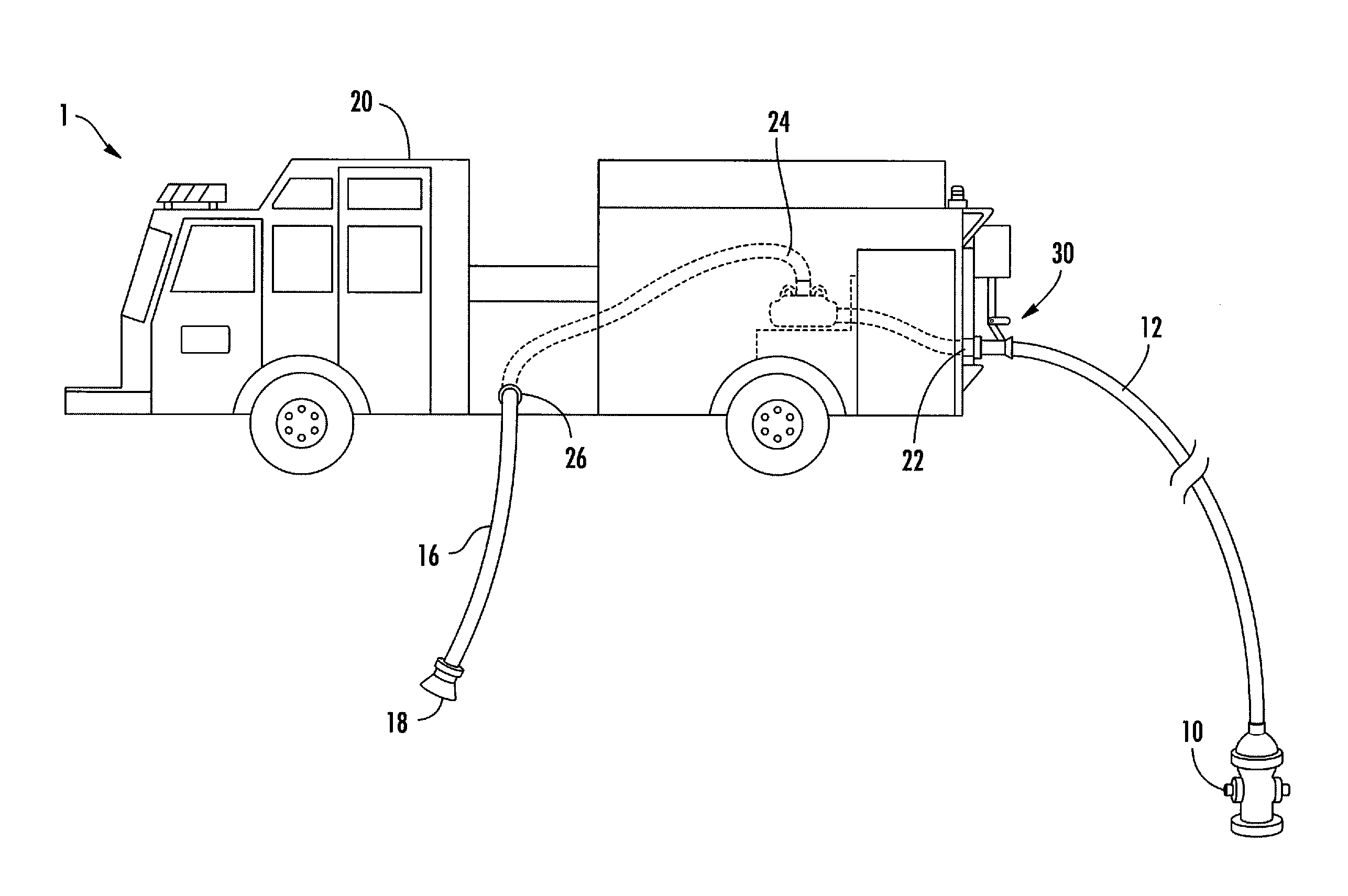

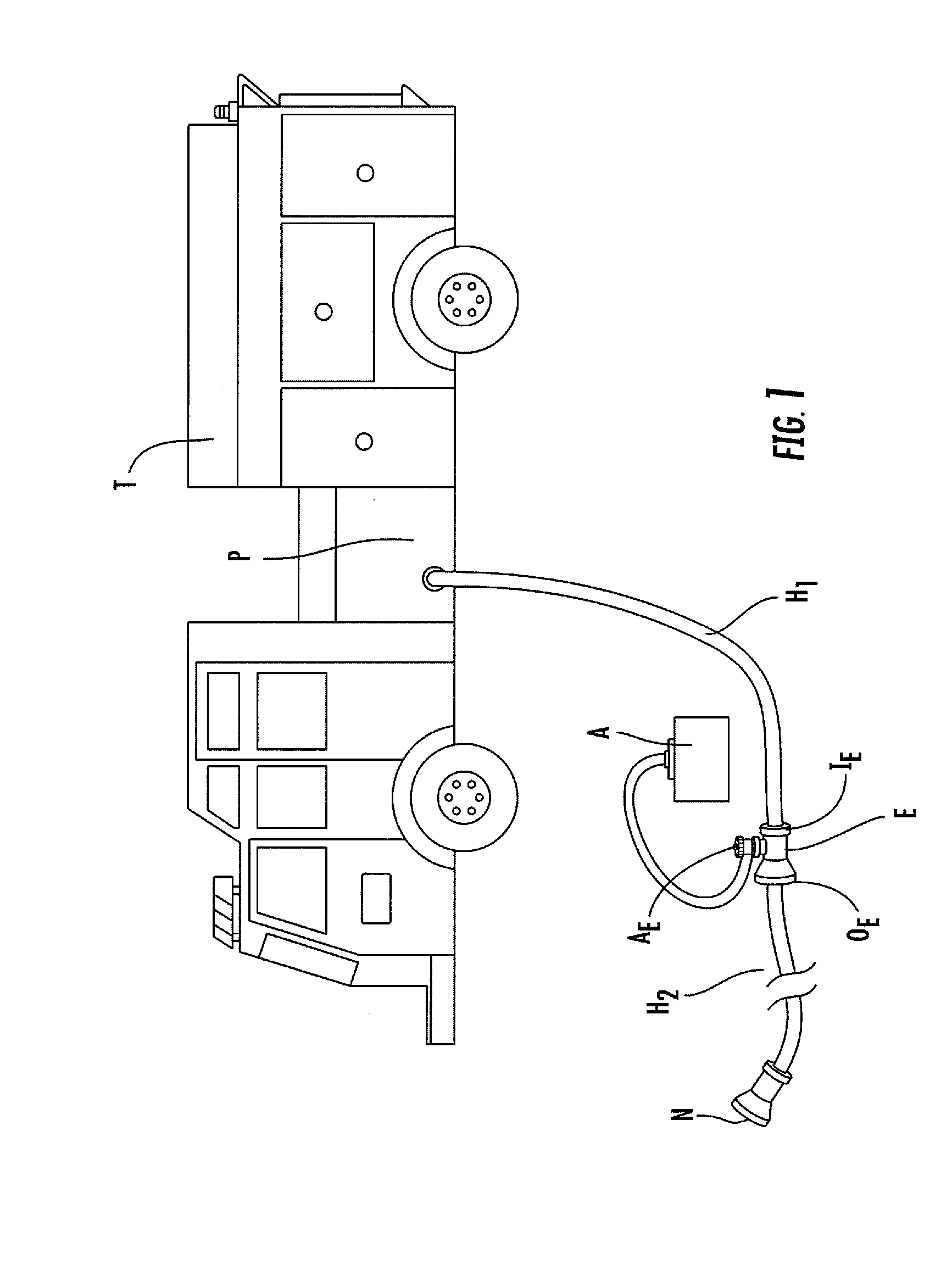

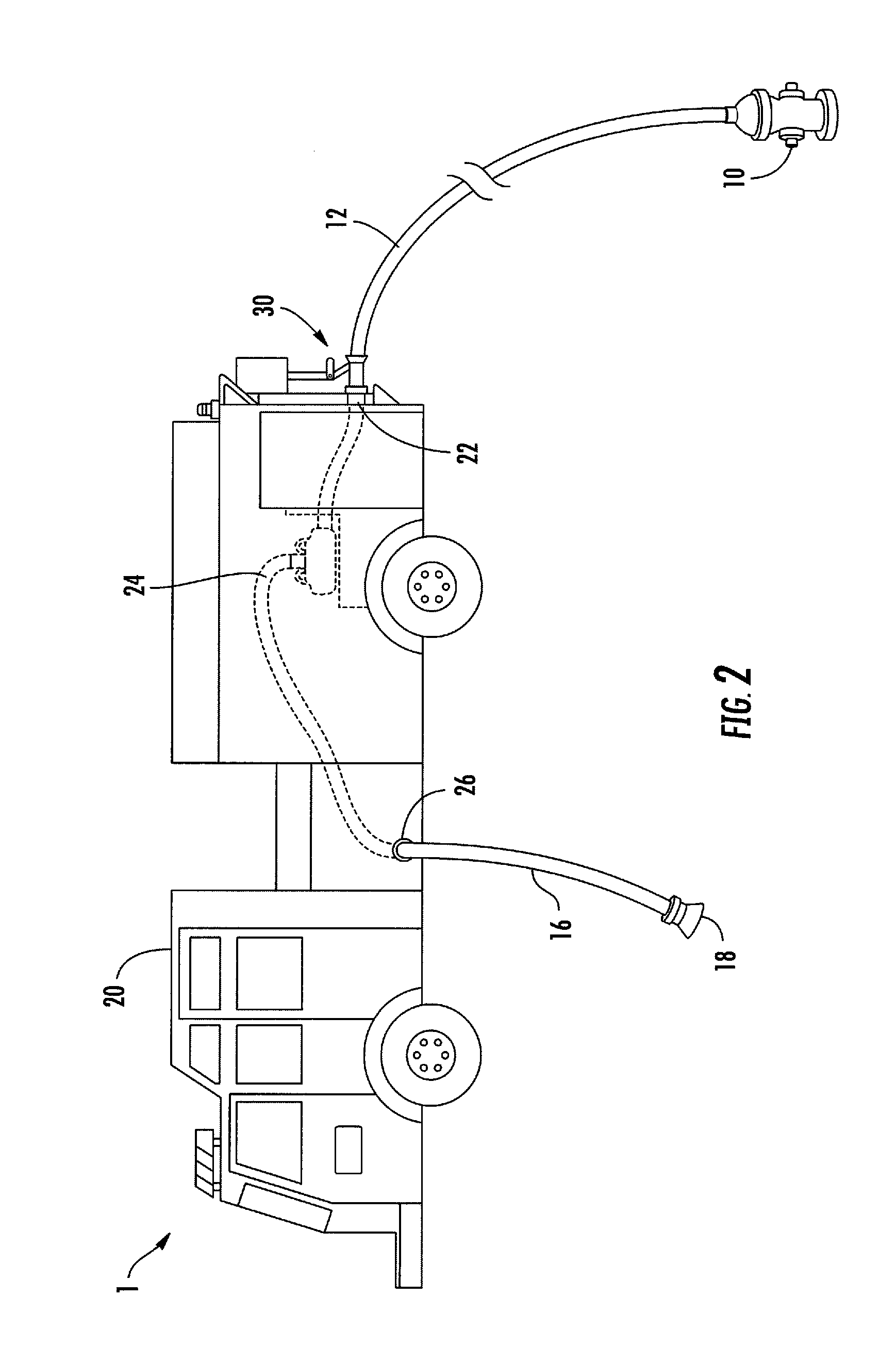

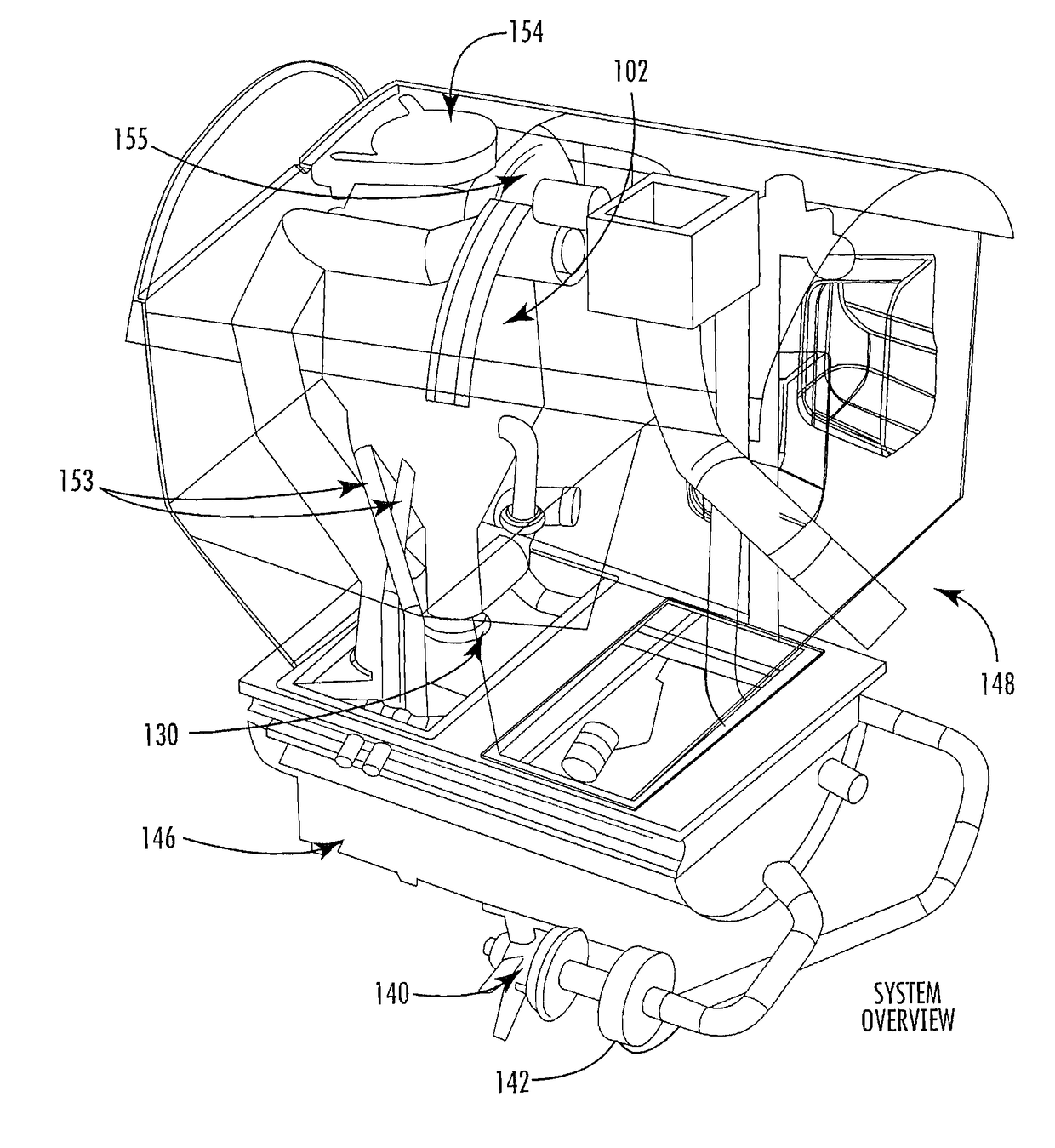

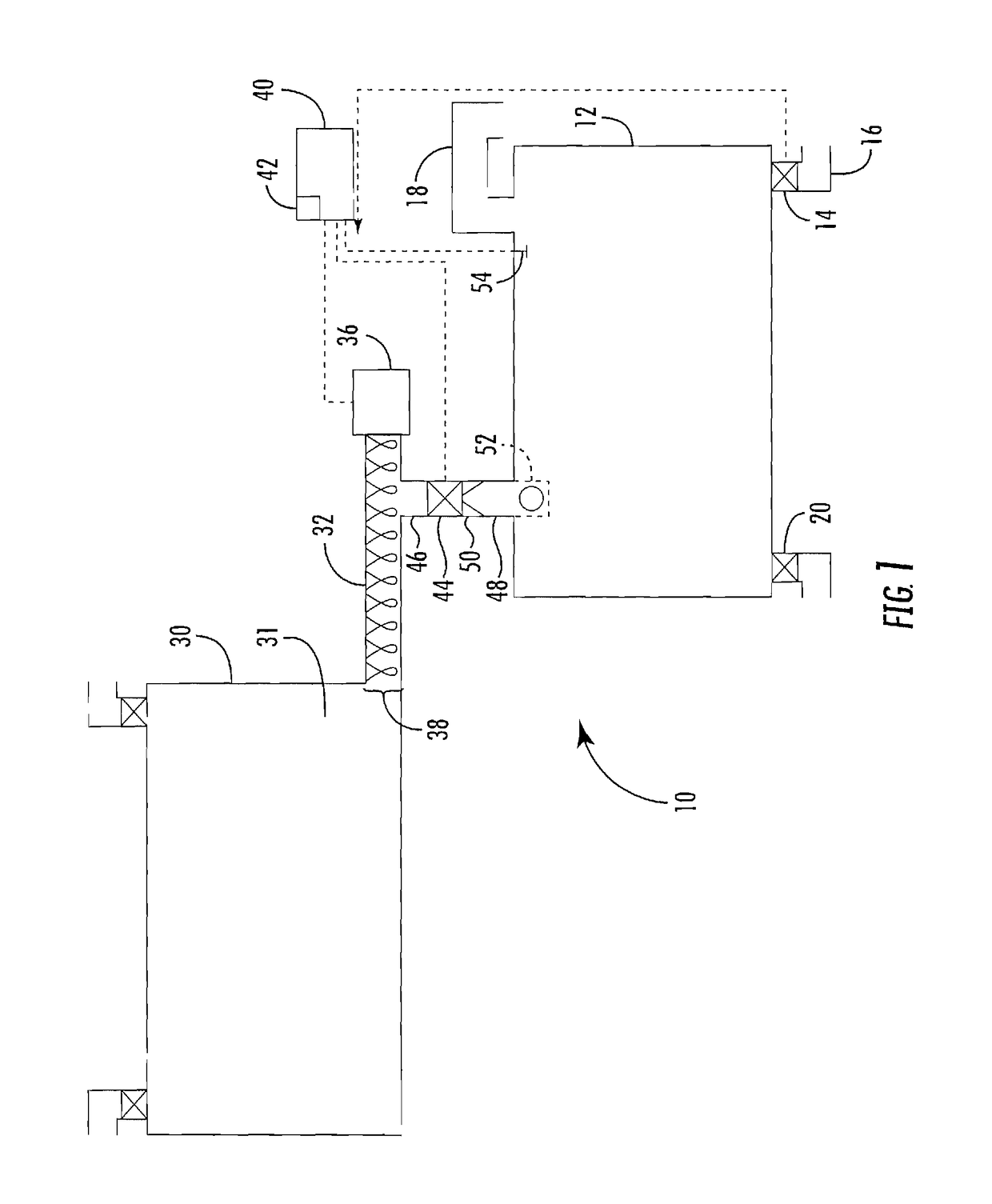

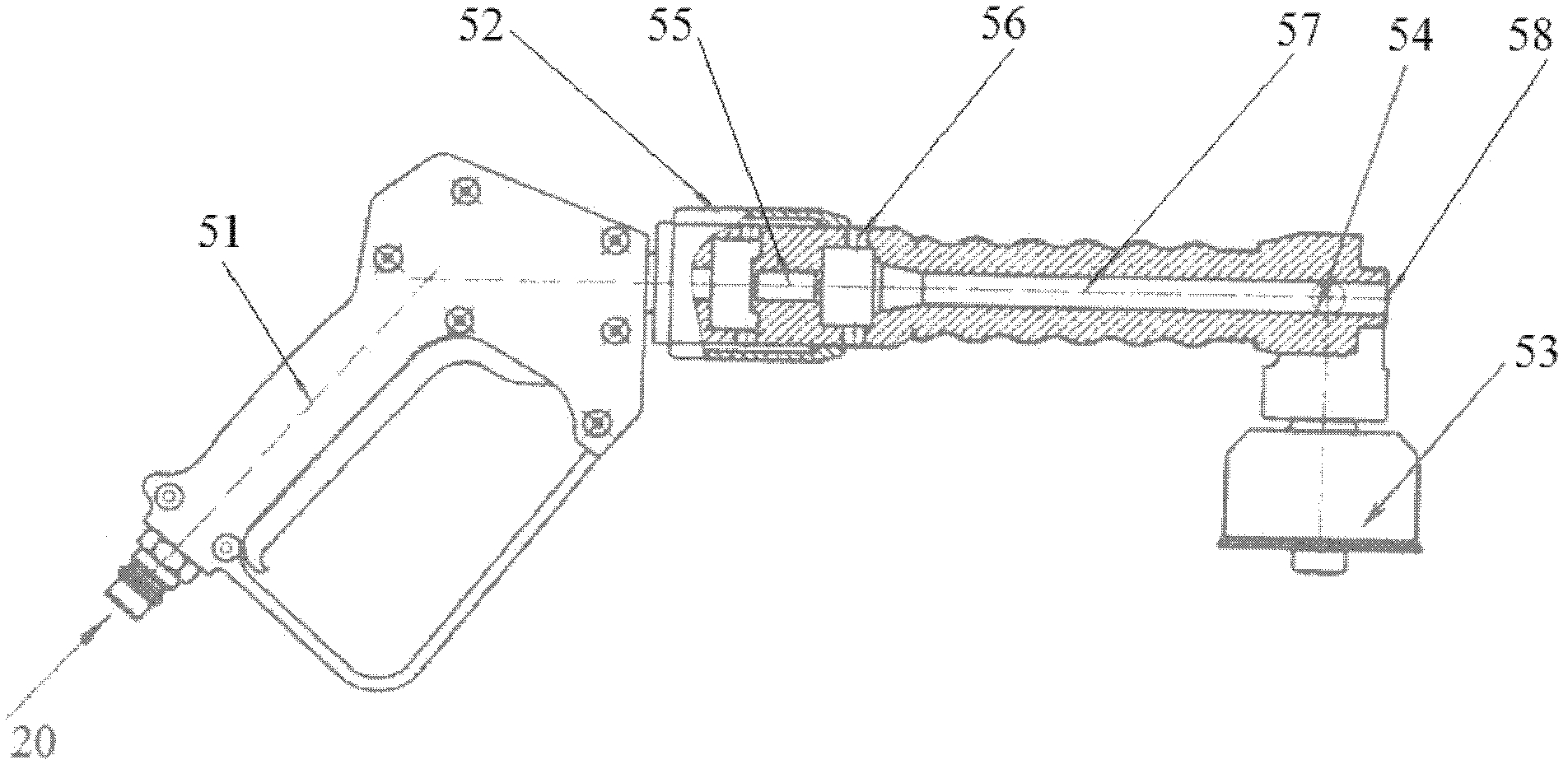

Method and apparatus for improving fire prevention and extinguishment

InactiveUS20090056957A1Quick controlLess water consumptionFlow mixersFire rescueWater sourceWater flow

The instant invention relates to an apparatus and method for fire extinguishment and retardation. The method comprises of a means for introducing polymeric material to a flow of water from an outside source before the flow of water enters a pumping unit within a mobile fire fighting apparatus, thereby forming a mixture of water and polymeric material. An eductor assemblage provides a means of introducing the polymeric material to the flow of water. The eductor assemblage comprises of a hopper and an eductor member. The hopper contains an amount of polymeric material, specifically super absorbent polymers. The eductor member comprises of an inlet connectable to the outside source of water, an outlet in fluid communication with the inlet and connected to the intake on a mobile fire fighting apparatus, and an additive inlet positioned between the inlet and outlet. The additive inlet is connected to the hopper and in fluid communication with the eductor member wherein a flow of the source of water from the inlet to outlet educts the super absorbent polymers through the additive inlet by venturi and flows into the eductor member forming a mixture for dispensing through the outlet onto combustible sources.

Owner:GEL TECH SOLUTIONS

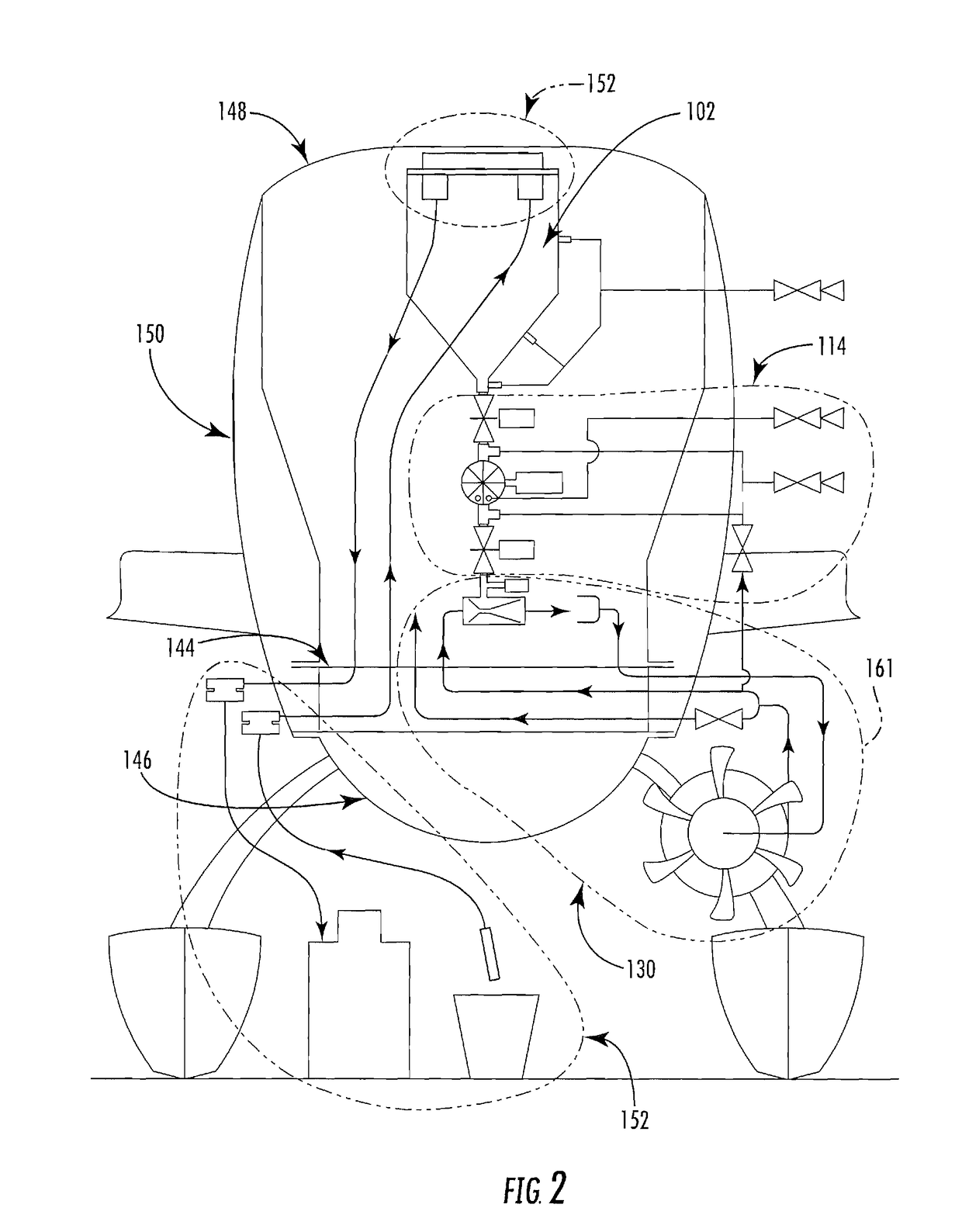

Amphibious aircraft fire fighting enhancement

ActiveUS20170072236A1Uniform measurementUniform flowAircraft componentsFire rescueAirplaneProperties of water

The instant invention relates to an apparatus and method for enhancing the fire extinguishing properties of water for use with fire fighting aircraft. The apparatus and method includes the steps of, and equipment for, transferring media into a holding tank in aircraft; filling a reservoir hopper with water in the aircraft; calculating the amount of media to be added to the reservoir; drawing the calculated amount of media into the reservoir to form an enhanced fire fighting admixture while the aircraft is in flight, wherein the admixture is offloaded by a controlled discharge for use in fighting forest fires.

Owner:REGER MICHAEL L

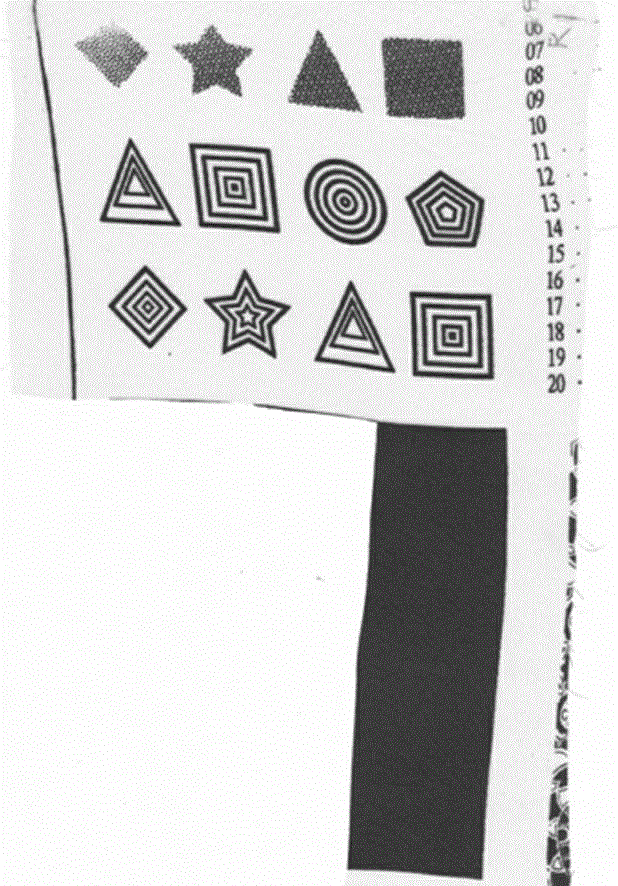

Slurry disperse dye and preparation method and appliance

The invention discloses a slurry disperse dye and a preparation method and an appliance, wherein the slurry disperse dye comprises liquid disperse dyes, functional prepolymers and synthetic thickeners, the synthetic thickeners and functional additives are added into the slurry disperse dye to prepare trace printing paste, and can complete printings of polyester fabrics on a common rotary screen printing machine or a screen printing machine, then printed polyester fabrics are prepared through a heat-setting stenter in 180 DEG C-210 DEG C for 45-120s. The slurry disperse dye has the advantages of short printing process when being used for polyester fabric printings, is soft in fabric handing, does not need post process, saves a lot of water and energy consumption, nearly does not have discharge amount of waste water, uses common equipment as process equipment, and is a green printing process technology.

Owner:SUZHOU UNIV

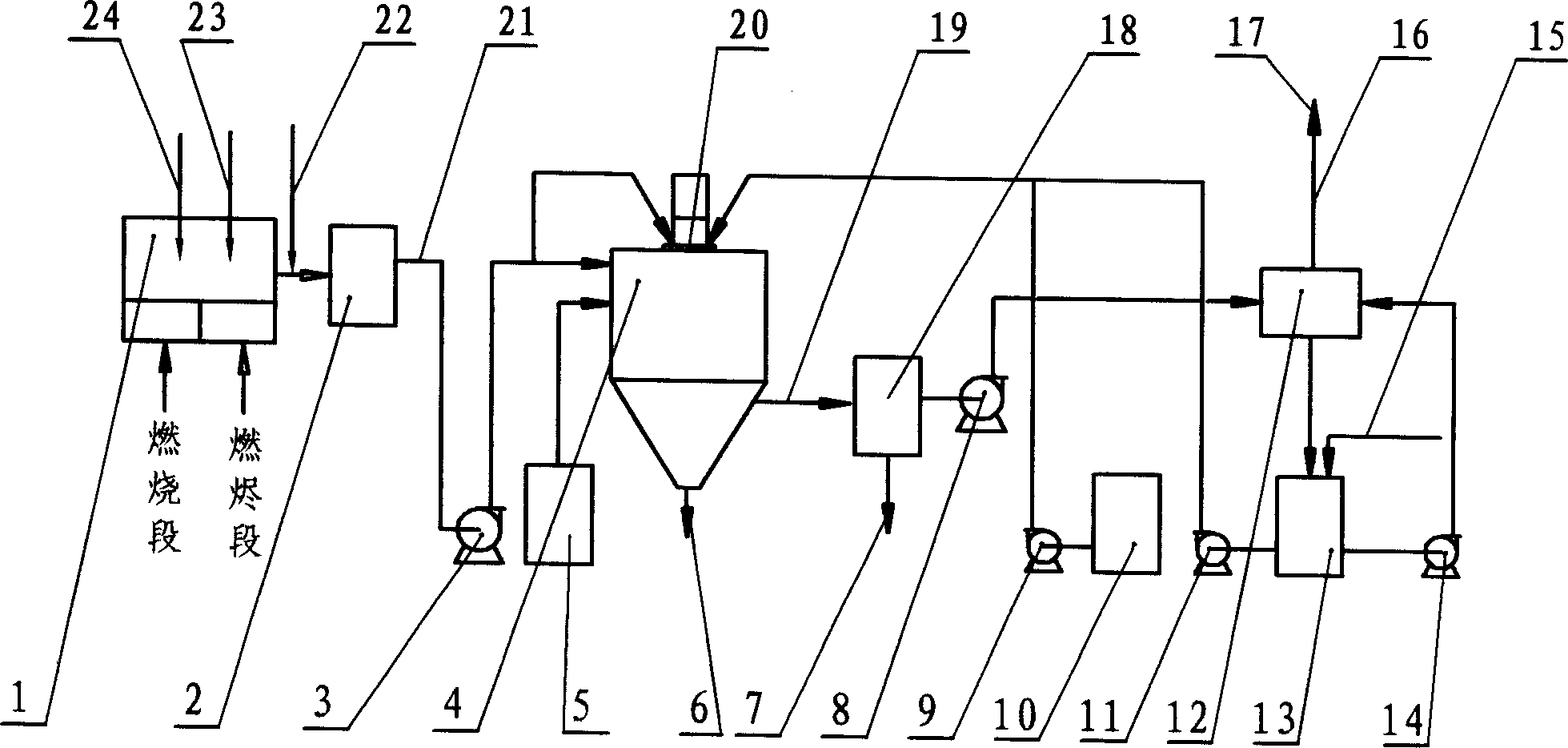

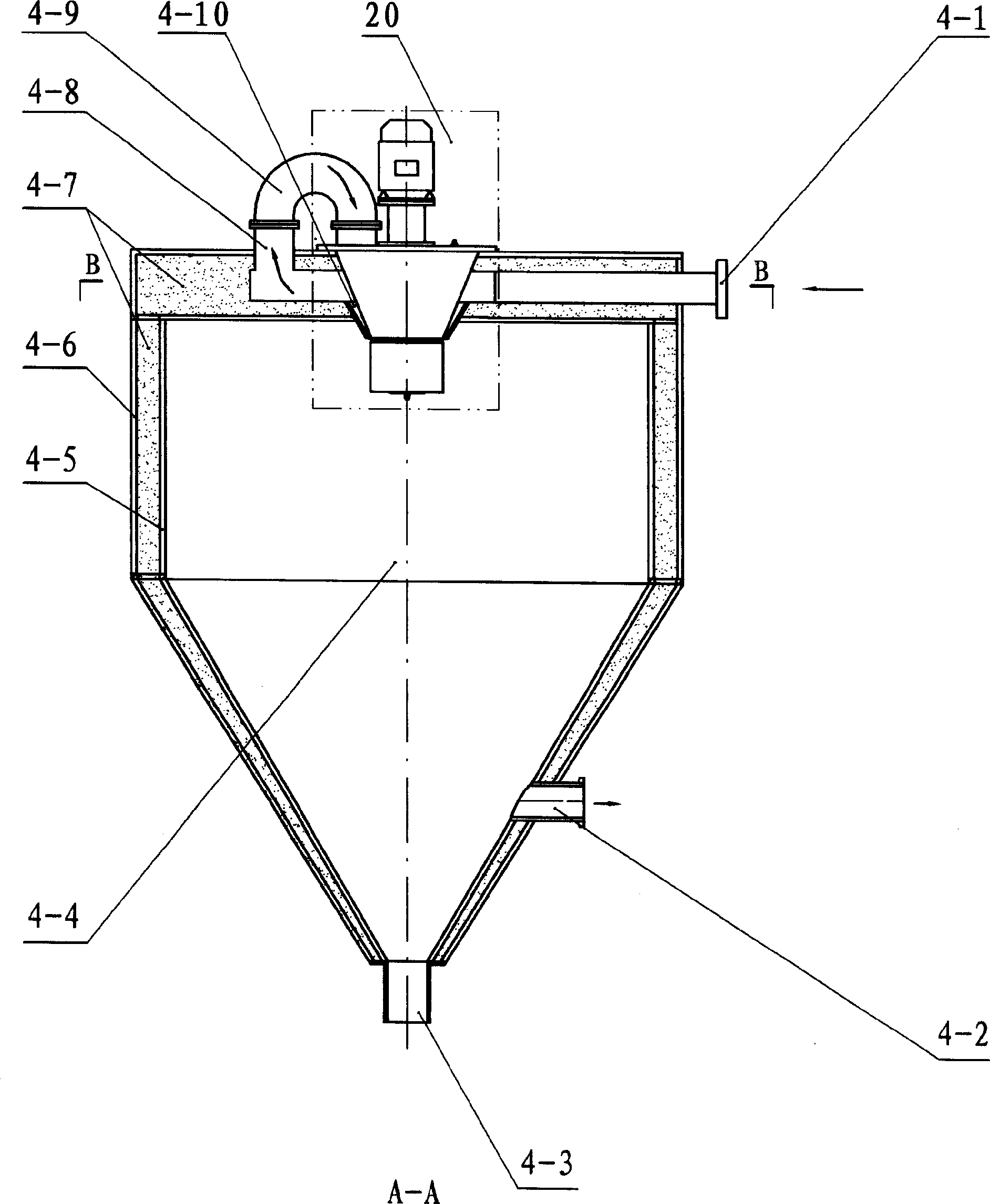

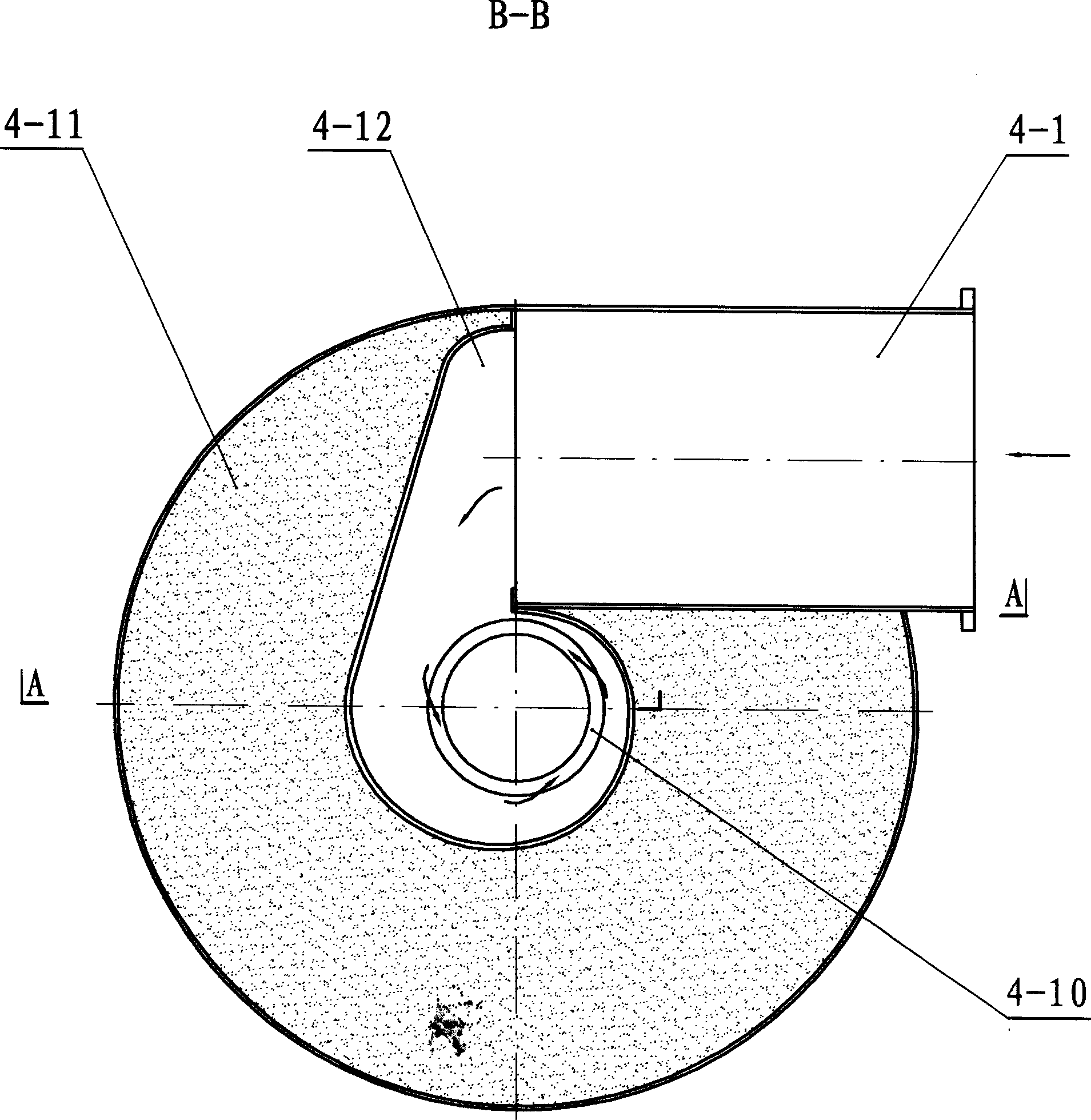

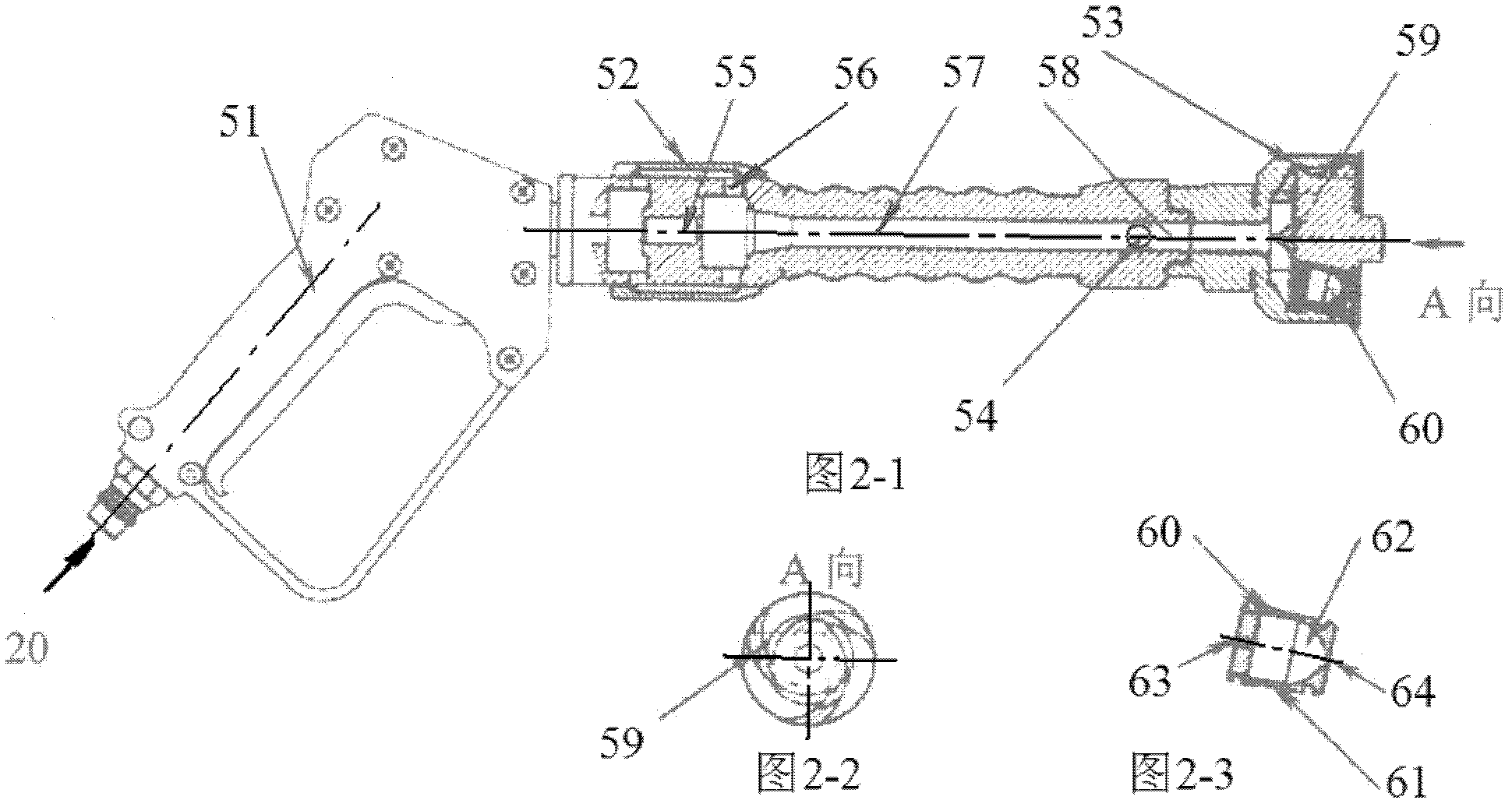

Smoke desucfuration denitrification dedust process and device

A process for desulfurizing, denitrifying and dusting the fume includes such steps as regulating the air supply of industrial furnace to decrease the generation of NOx, reversely spraying ammonia into combustion box, introducing oxygen to back smoke chamber, removing dust, reaction in centrifugally spraying drying tower to generate ammonium sulfate, separating, and washing in supergravitational washer. Its apparatus is composed of cyclone duster, draught fan, centrifugal spraying drying tower, oxygen generator, supergravitational washer and cyclone separator. Its advantages are high effect, low cost and no secondary pollution.

Owner:重庆正和生物能源有限公司

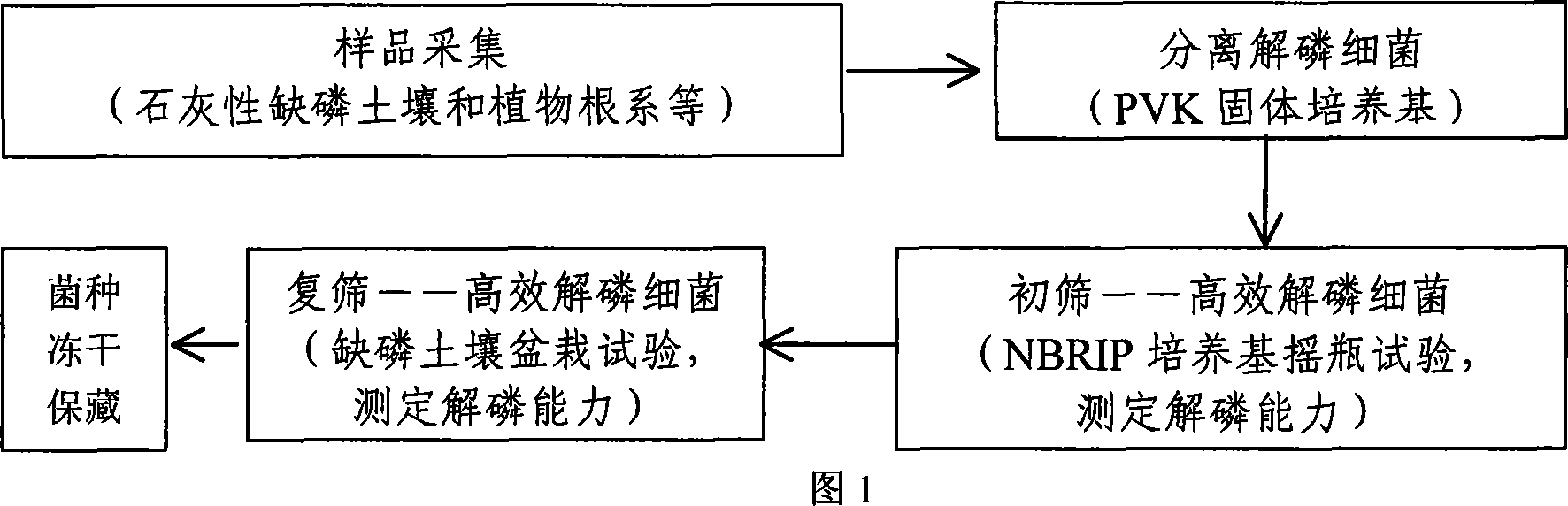

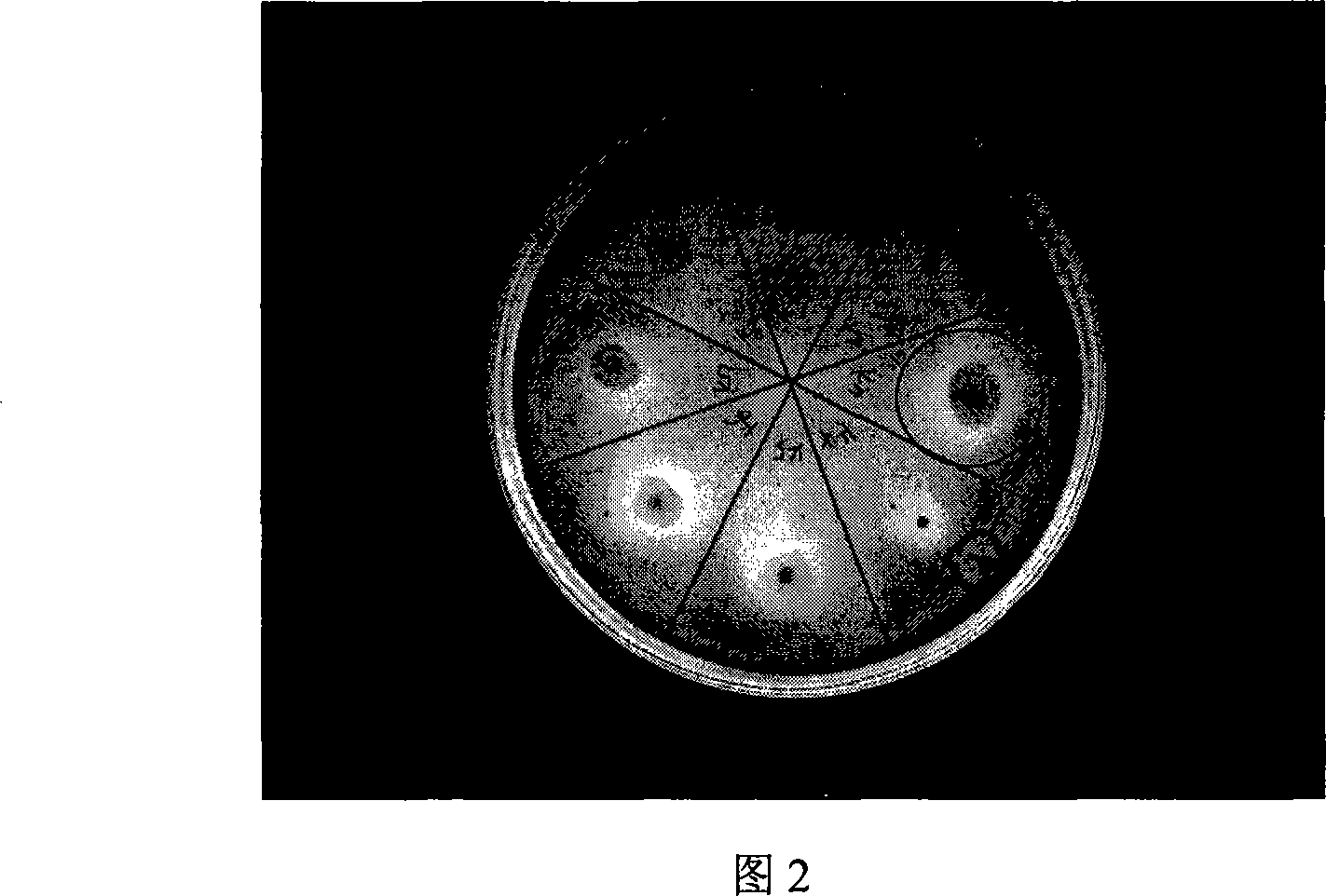

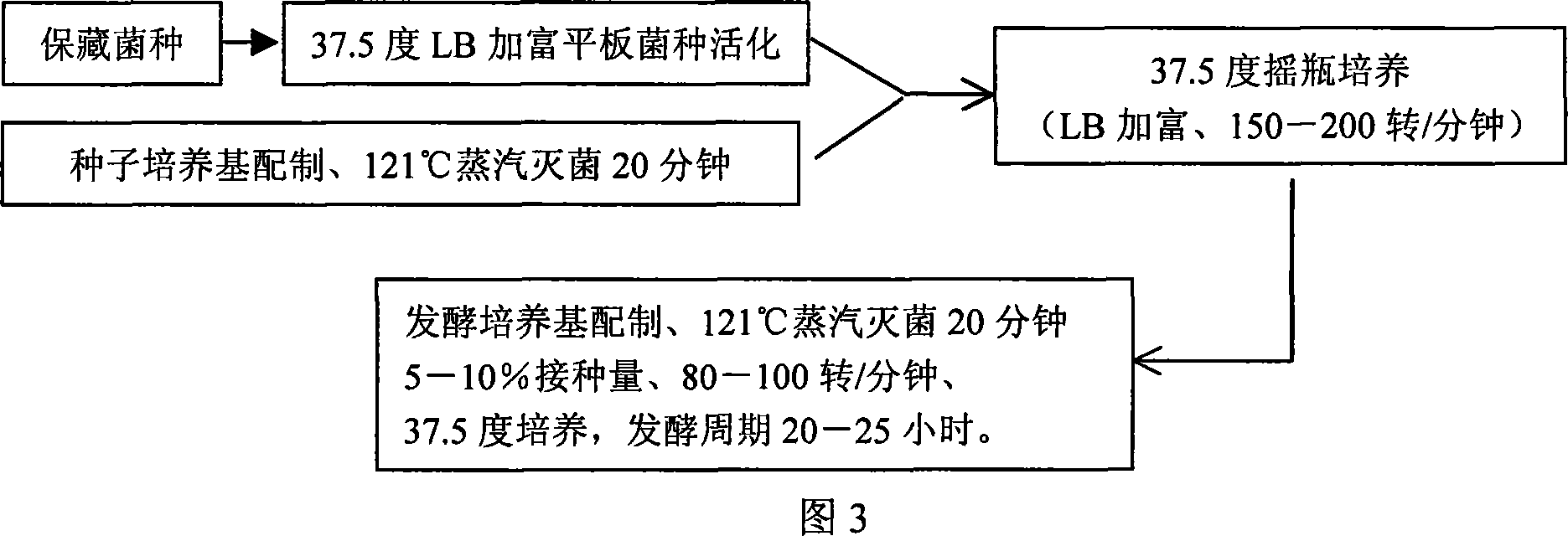

K3 bacterial strain capable of dissolving calcium phosphate in soil and organic microbial fertilizer therewith

ActiveCN101066897APhosphate dissolving effect is remarkableImprove the growing environmentMicroorganism based processesOrganic fertilisersTotal nitrogenBacterial strain

The present invention relates to agricultural production technology, and is especially one kind of K3 bacterial strain capable of dissolving calcium phosphate in soil and microbial fertilizer produced with the K3 bacterial strain. The bacterium strain with powerful calcium phosphate dissolving capacity is separated from limy soil, used in liquid fermentation, and mixed with specific organic carrier to produce phosphate decomposing microbial organic fertilizer, which contains phosphate decomposing microbes in 5x10<7> / g, total nitrogen in 4 wt%, total potassium in 1-2 wt%, total phosphorus in 1-2 wt% and organic matter in 35 wt%. Test shows that the phosphate decomposing microbial organic fertilizer can provide phosphorous nutrients in the effect similar to chemical phosphate fertilizer, and the phosphate decomposing bacterium can reach soluble phosphorus concentration in calcium phosphate solution up to 643 mg / l.

Owner:PENYAO ENVIRONMENTAL PROTECTION

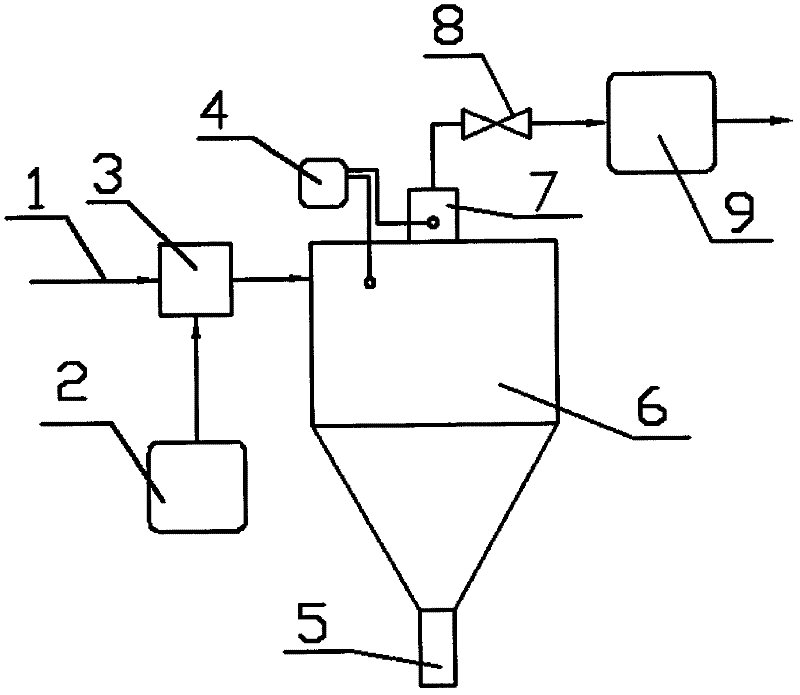

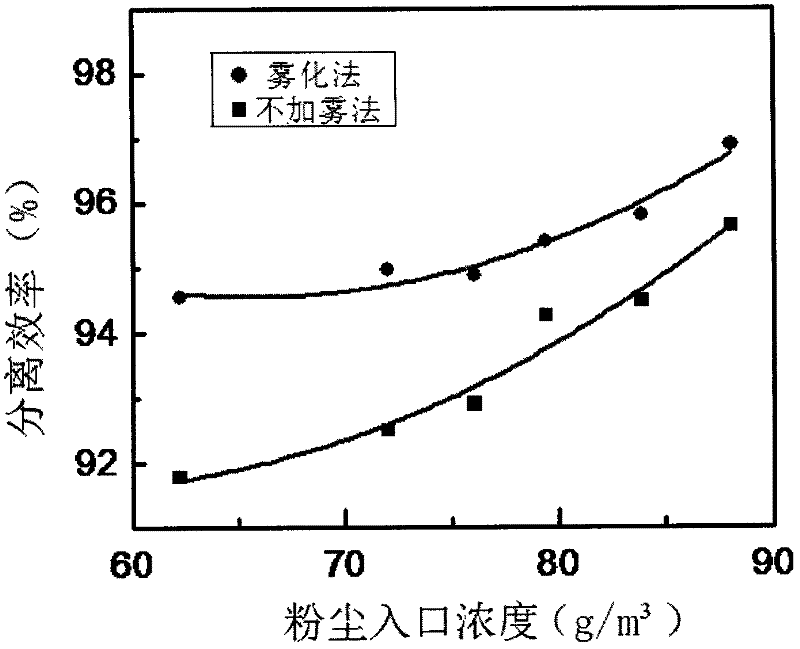

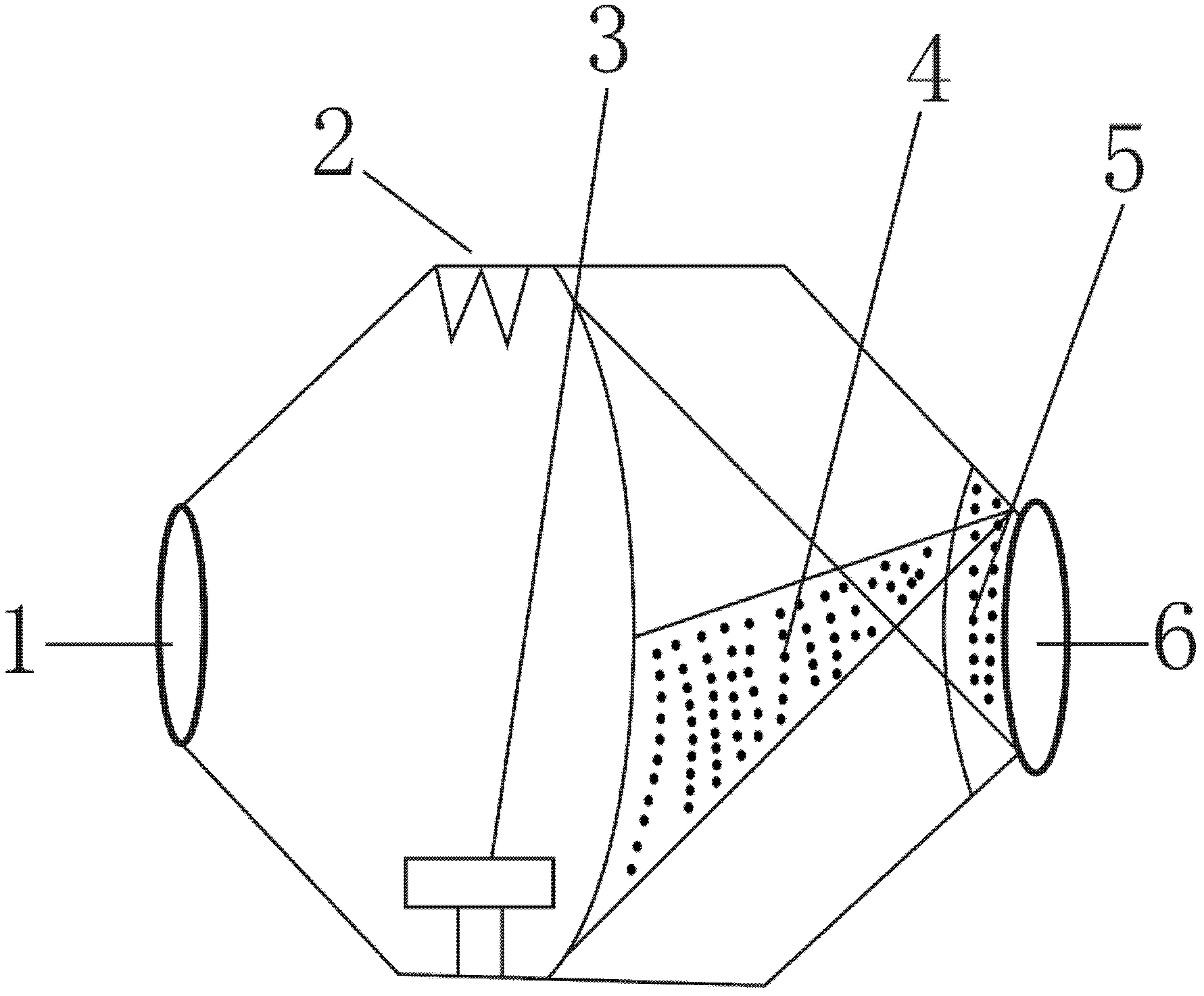

Dedusting device and dedusting method therefor

The invention discloses a dedusting device and a dedusting method therefor. The dedusting device is a cyclone dedusting device with a water atomization device. The dedusting device mainly comprises a cyclone dust collector and also comprises the water atomization device. A water mist outlet of the water atomization device is communicated with the interior of a mixing chamber. An upstream part of the mixing chamber is communicated with a waiting gas pipe. A downstream part of the mixing chamber is communicated with an air inlet of the cyclone dust collector. The water atomization device adopted by the invention is an electroacoustic transduction supersonic atomizing device, and sizes of liquid drops produced by the water atomization device are less than or equal to 5.0 micrometers.

Owner:LANZHOU UNIVERSITY

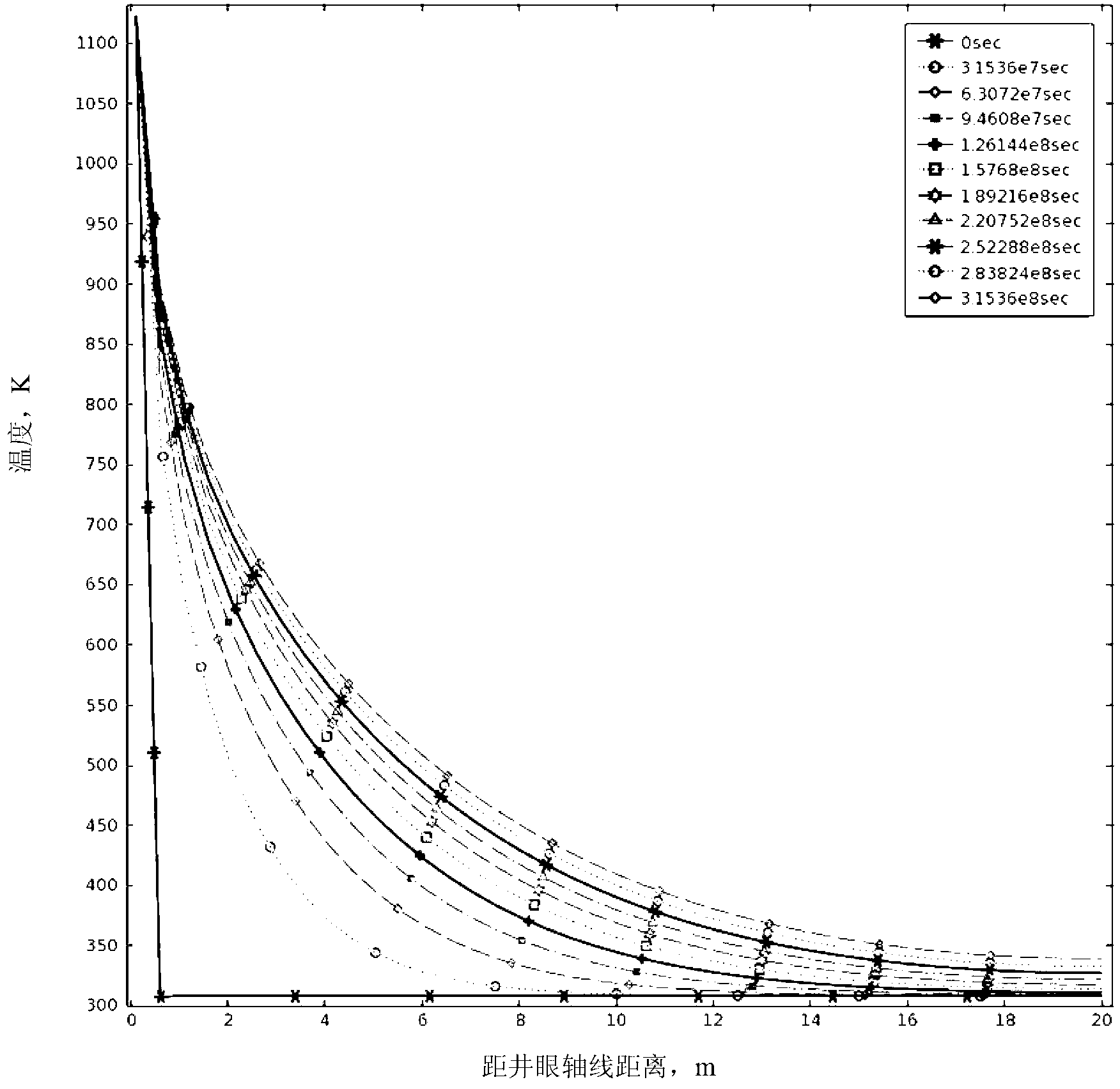

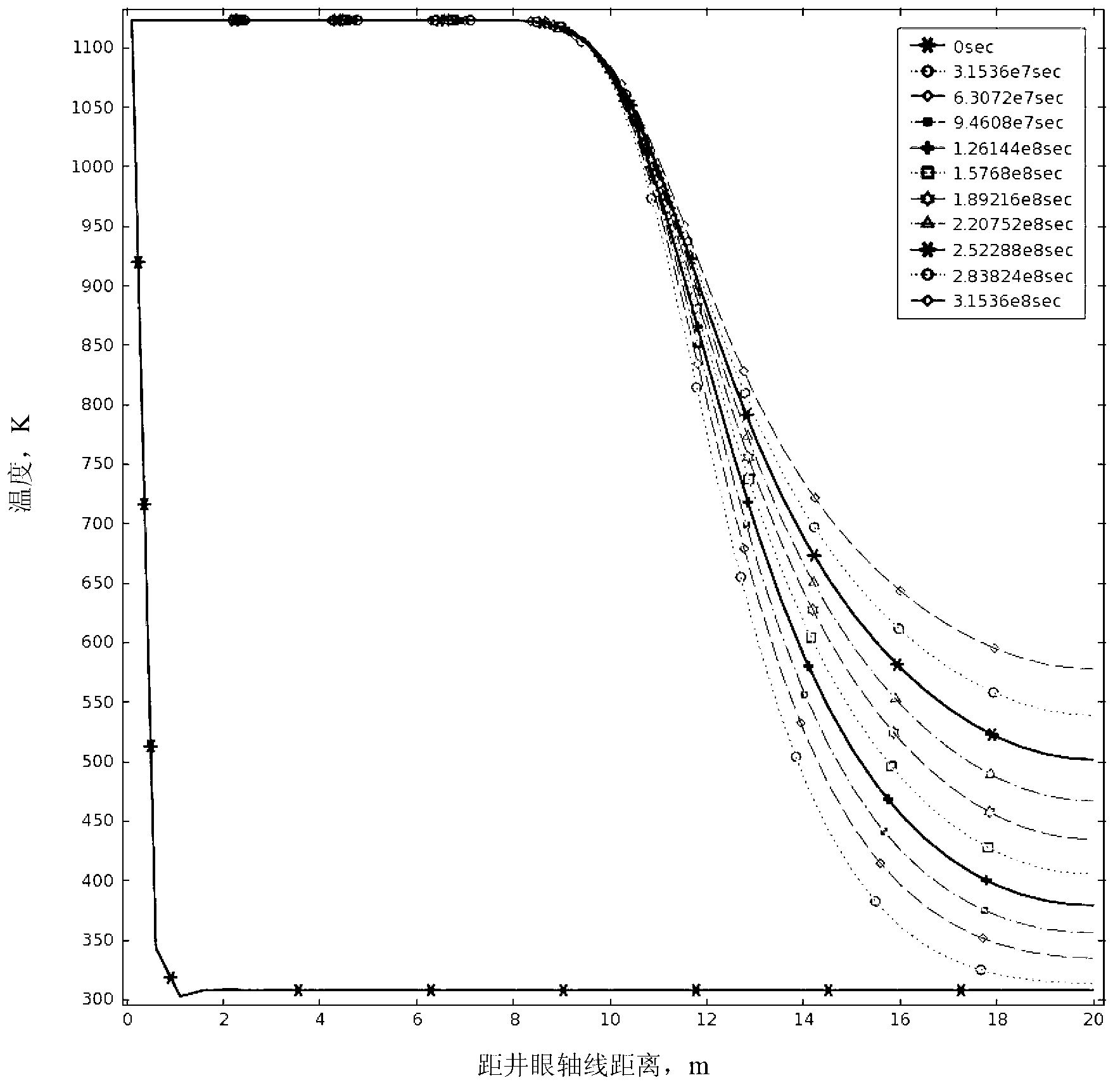

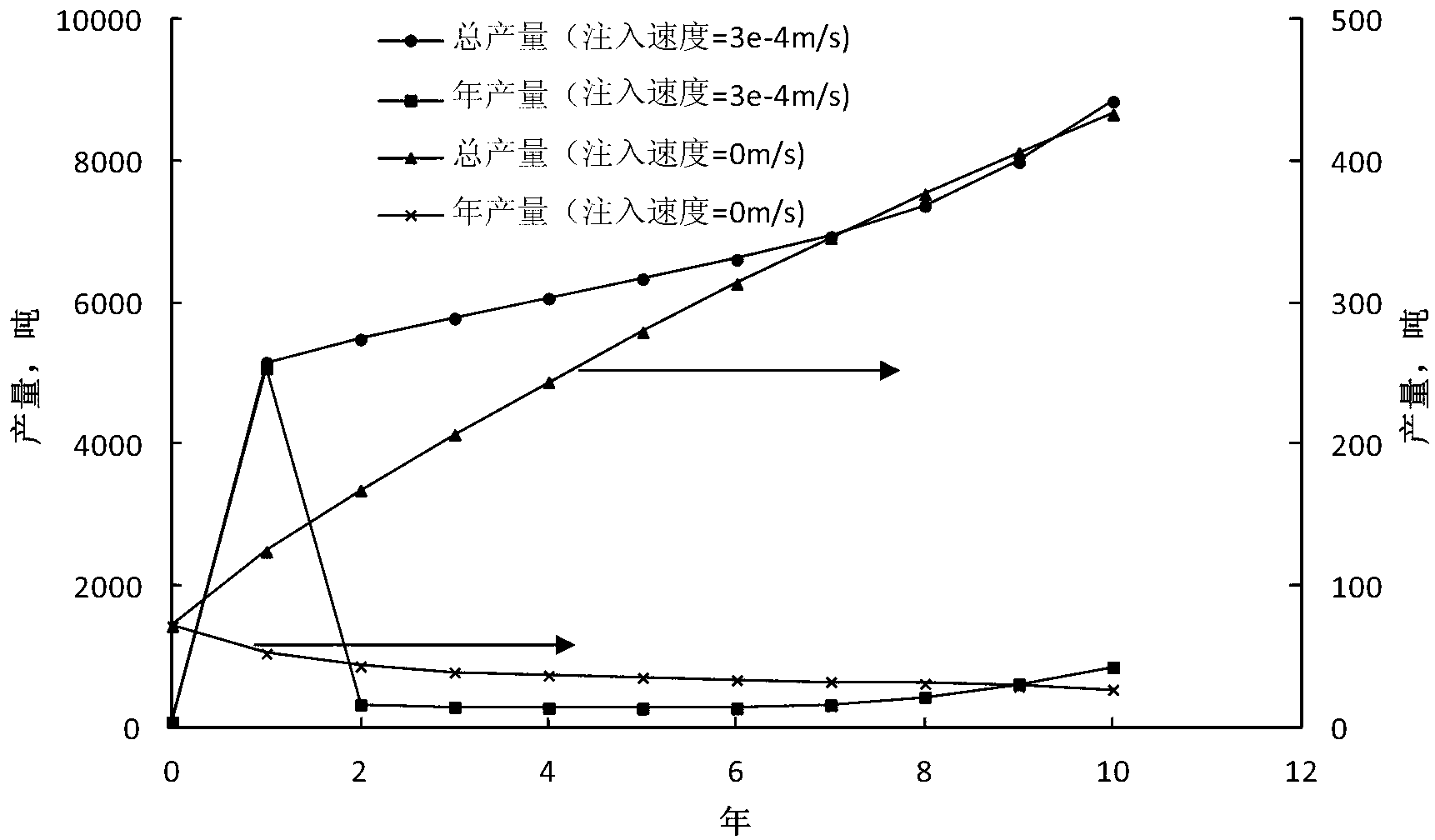

Oil shale in-situ mining method

The invention discloses an oil shale in-situ mining method and belongs to the field of oil shale mining. The method includes the following steps: arranging a pipe column communicated to a mined oil shale layer, and arranging a heater at the horizontal section of the oil shale layer; injecting water into the mined oil shale layer through the pipe column, and heating the injected water to be at a temperature not small than the thermal cracking temperature of oil shale through the heater to crack the oil shale; recovering shale oil and shale gas after cracking; injecting separated water (steam) into the underground oil shale for recycling. In-situ mining of the oil shale can be realized through water injection, heating and cracking, a wellhead steam generating device is not needed, and injection of hydrocarbon gas is not needed; the separated water (steam) is circularly injected, so that water consumption quantity is small, high temperature which is difficulty to reach on the ground can be reached, and generated heat can be used for heating a stratum in an in-situ manner; treatment of residues of the oil shale is not needed, so that small environment pollution, temperature controllability and low cost are realized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Solid fuel upgrading reaction device and process thereof

InactiveCN101717681ASimple processEasy to operateDrying solid materials with heatDrying gas arrangementsProcess engineeringProduct gas

The invention discloses a solid fuel upgrading reaction device and a process thereof. The device consists of a solid fuel crushing system, a fluid-bed solid fuel upgrading device, a ventilator, a thermal smoke furnace, a dust remover and the like. The process adopts fluid bed technology, uses a gas drying medium with certain temperature for keeping brown coal fed into the fluid-bed solid fuel upgrading device in a full fluid state and drying the brown coal, and meanwhile finishes the delivery of the brown coal from a feeding hole to a discharge hole. The process has the characteristics of simple process, convenient operation, low energy consumption, flexible control for moisture content of the dried solid fuel and broad granularity adaptability, and can implement large-scale production without large-scale mechanical equipment.

Owner:XIAN THERMAL POWER RES INST CO LTD

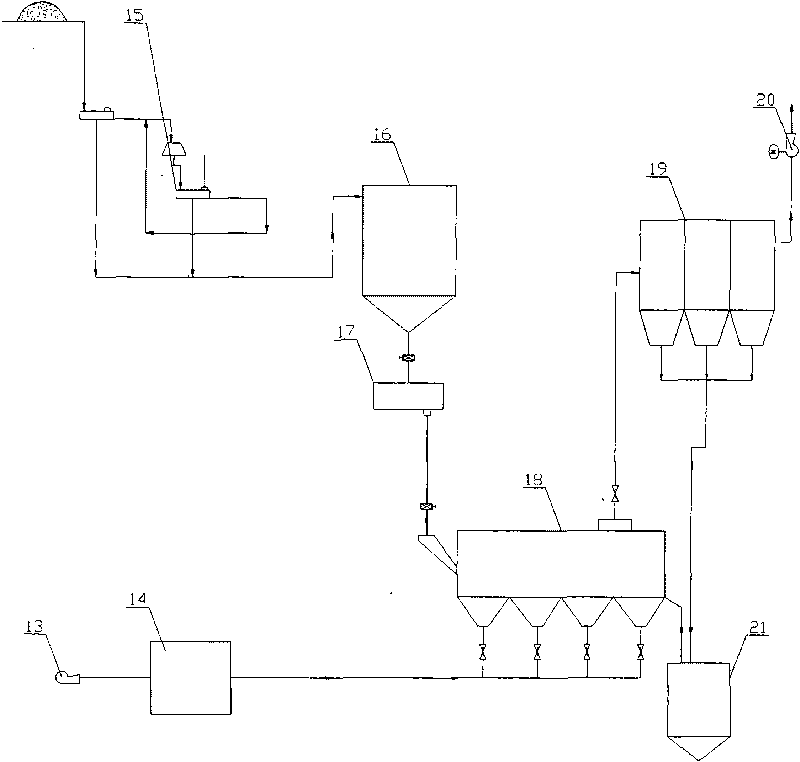

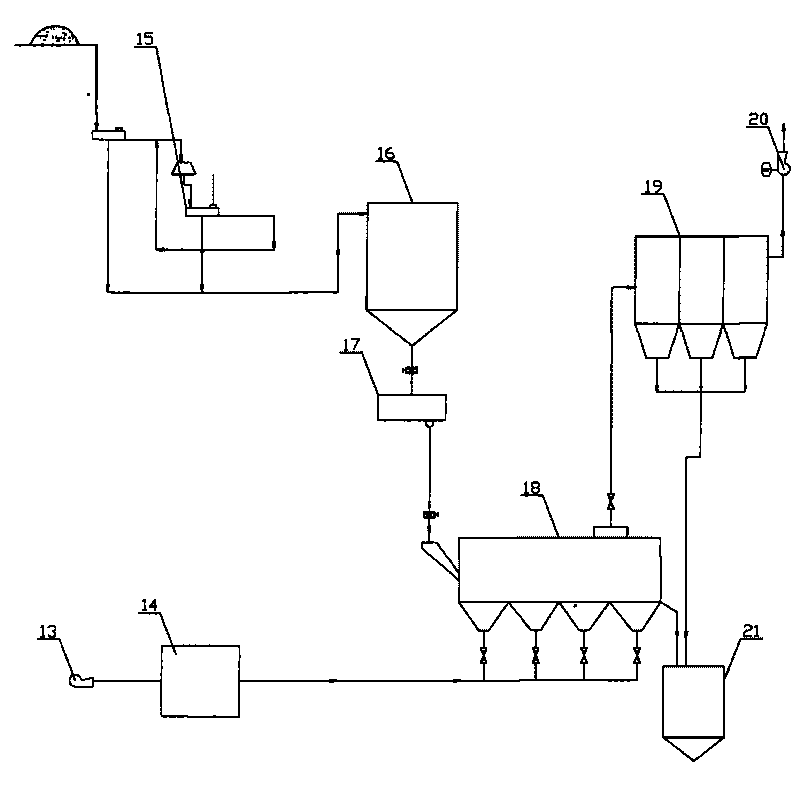

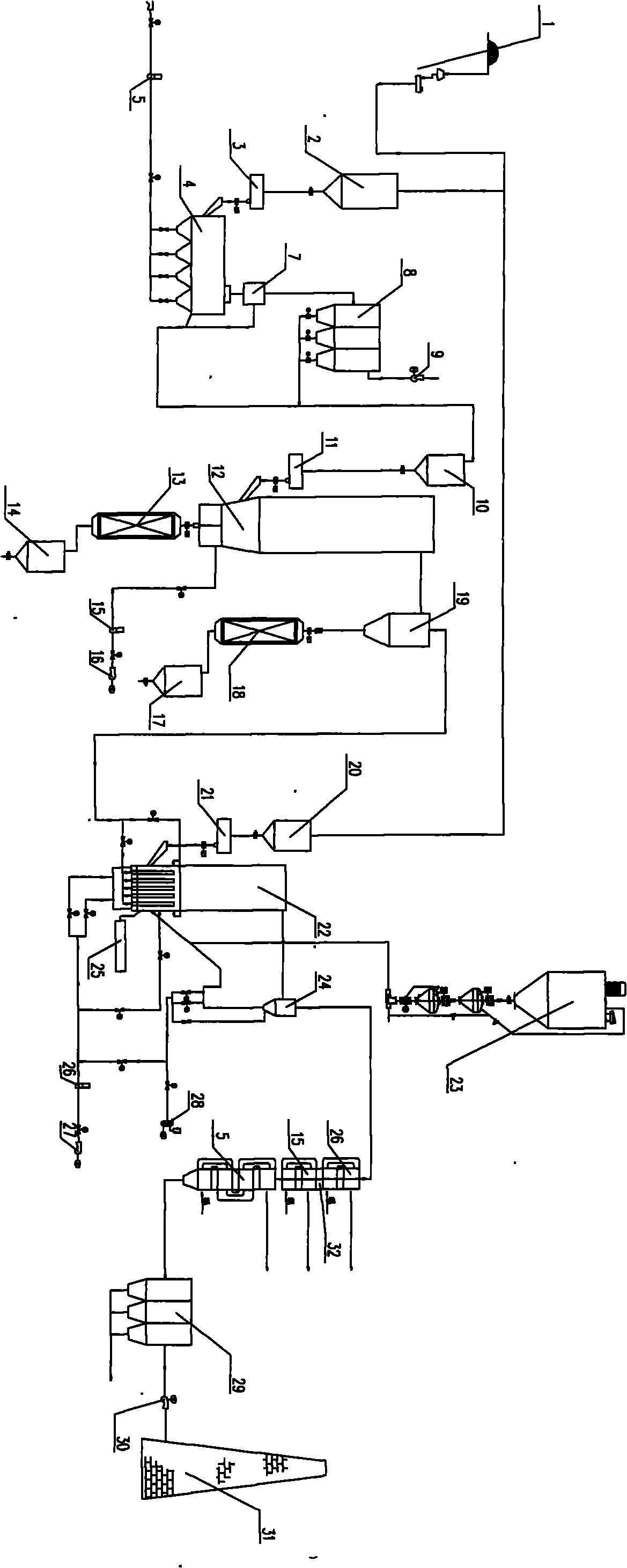

Integrated fluidized bed mild-gasification lignite upgrading system and technology

The invention discloses an integrated fluidized bed mild-gasification lignite upgrading system and integrated fluidized bed mild-gasification lignite upgrading technology. The lignite is subjected to pre-drying treatment by using high temperature air generated by a low-value gas-fired incinerator so as to remove part of moisture in the lignite; the lignite is delivered to a fluidized bed mild-gasification lignite upgrading reactor for partial gasification, destructive distillation and combustion reaction, wherein one part of heat generated in the reaction is used for maintaining the temperature in the reactor and the other part of heat is used for removing the moisture in the lignite; and the lignite upgraded by the fluidized bed mild-gasification lignite upgrading reactor is delivered to a finished product cooler for cooling and then delivered to a finished product warehouse, and the generated low-value gas is fed to a subsequent low-value gas-fired incinerator for burning. The system and the technology have the characteristics of simple process, convenient operation, low energy consumption, less pollutant discharge, and no waste water discharge.

Owner:XIAN THERMAL POWER RES INST CO LTD

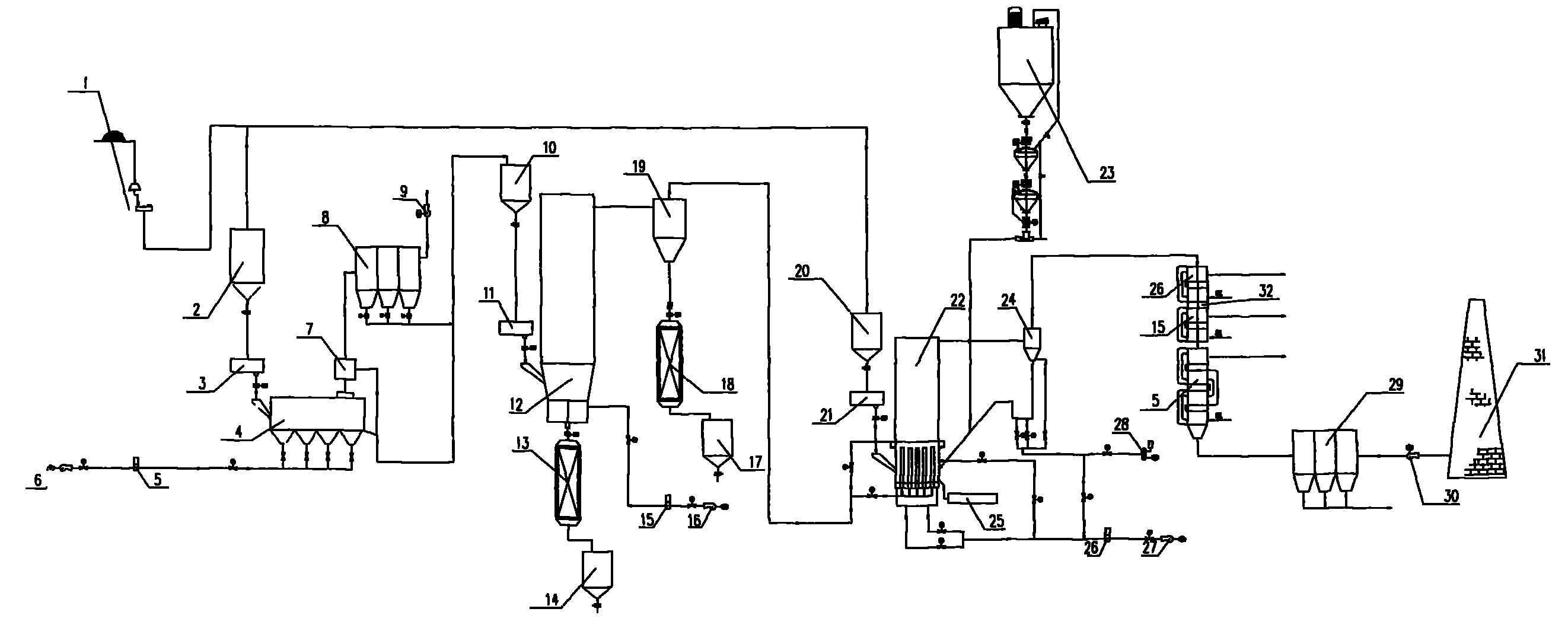

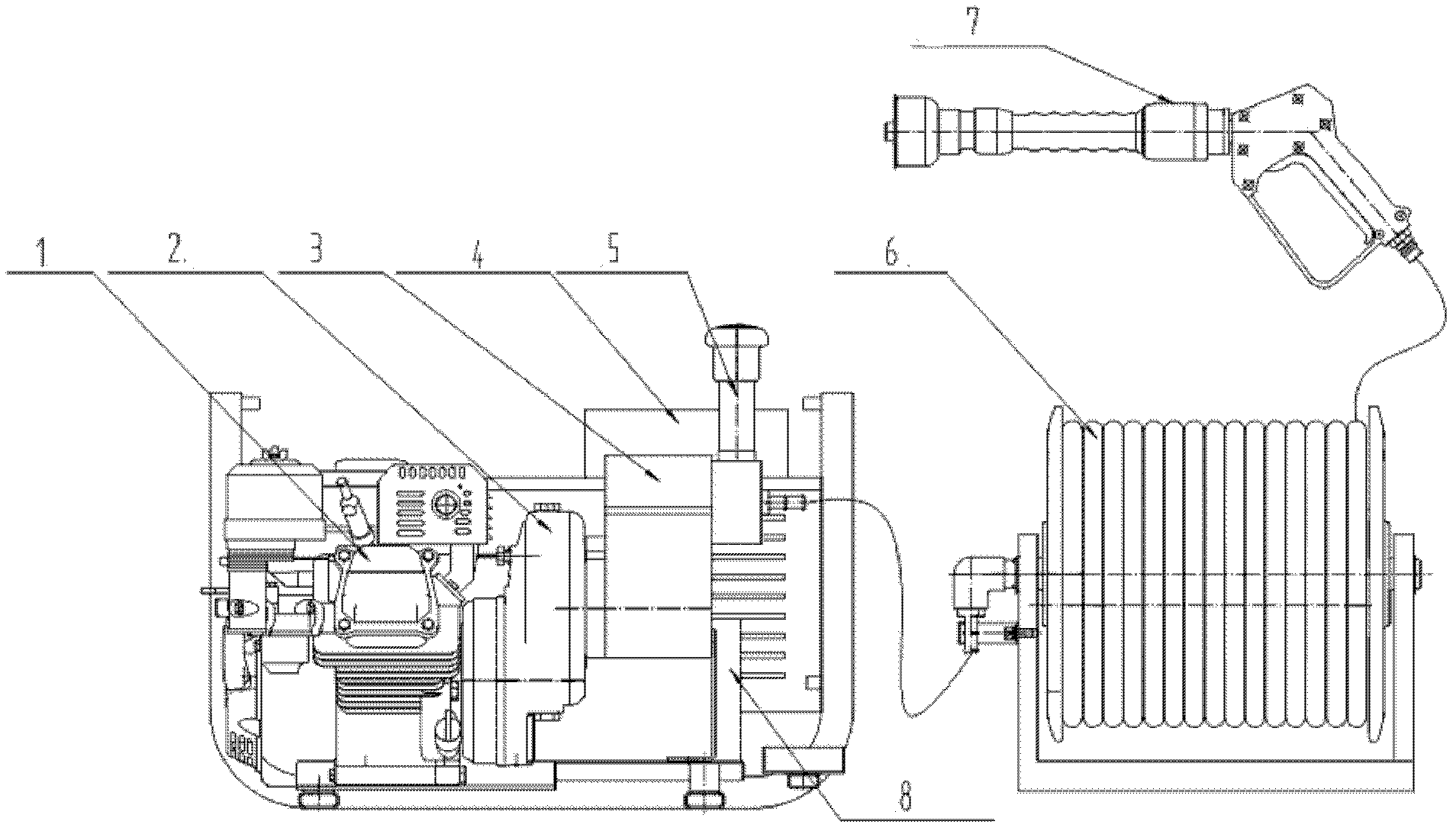

Automatic control clutch type water mist fire extinguishing device

InactiveCN102302834ARealize automatic controlReduce wasteFire rescueControllers with discontinuous output signalAutomatic controlAgricultural engineering

The invention belongs to the field of fire extinguishing and rescue equipment and provides an automatic control clutch type water mist fire extinguishing device. The automatic control clutch type water mist fire extinguishing device comprises an engine, a water pump, a pressure adjusting valve, a hose reel and a water mist spray gun and is characterized by also comprising a clutch type reduction box, an automatic control system and a foam adding system, wherein the engine is connected with the water pump through the clutch type reduction box; the pressure adjusting valve is arranged at a water outlet of the water pump; the hose reel is connected with the pressure adjusting valve; the water mist spray gun is connected with the hose reel; the automatic control system controls the engine and the foam adding system; and the foam adding system is connected with an inlet of the water pump. The automatic control clutch type water mist fire extinguishing device realizes automatic control of a machine set so as to realize unmanned management after the device is started, save unnecessary waste of fuel oil and water, effectively prolong service life of equipment and save labor.

Owner:TIANJIN TIMELYRAIN IND & TRADING

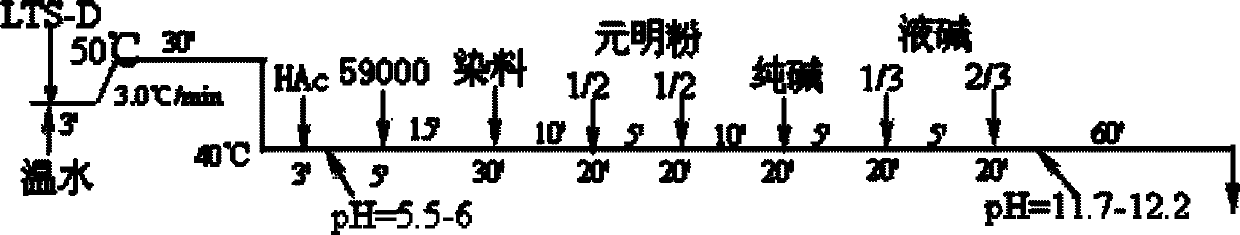

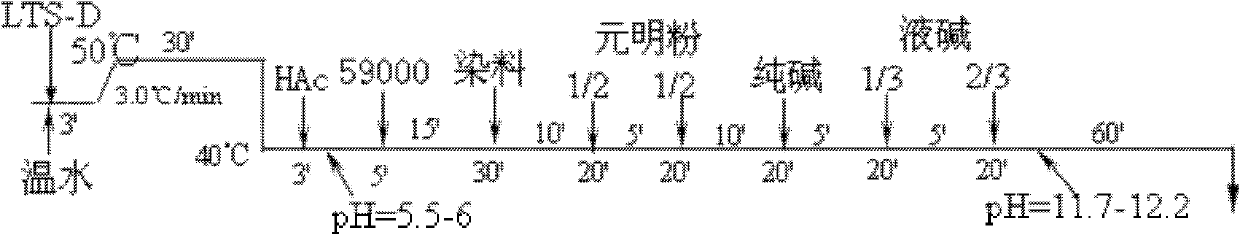

Low temperature dyeing technology for pure cotton fabrics

ActiveCN102561064AReduce consumptionReduce COD valueBiochemical fibre treatmentDyeing processSodium sulfateEnzyme

The invention relates to a low temperature dyeing technology for pure cotton fabrics. The technology which adopts low temperature preprocessing, polishing and low temperature dyeing one-bath process comprises the following steps: 1, carrying out low temperature preprocessing: adding a dyeing one-bath assistant to a dye solution, adjusting the temperature to 40-60DEG C, and continuously reacting for 15-30min; 2, polishing: adjusting the temperature to 35-60DEG C and the pH value to 5.5-6, adding a neutral polishing enzyme having a weight accounting for 0.2-0.5% of the weight of the fabrics, and continuously reacting for 15-20min; and 3, carrying out low temperature dyeing: adjusting the temperature to 35-45DEG C, sequentially adding a low temperature active dye, anhydrous sodium sulfate, soda ash and a caustic soda solution at a certain time interval, and reacting. The low temperature dyeing technology has the advantages of simple operation, small pollution, low energy consumption and the like.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Antago nistic fungus capable of preventing and treating continuous crops blight and its microbial organic fertilizer

InactiveCN1775035AHigh soluble carbonIncrease organic nitrogen contentBiocideBio-organic fraction processingContinuous croppingBiotechnology

The present invention relates to an antagonistic bacillus and microbial organic fertilizer produced by using said antagonistic bacillus for overcoming and eliminating continuous-cropping crop blight. Said invention utilizes a separation process to obtain the antagonistic bacillus which has obvious antagonistic action for blight fungus. The microbial organic fertilizer produced by mixing said antagonistic bacillus and organic farmyard manure is applied in the soil, then the antagonistic bacillus can be quickly reproduced, and the blight controlling rate can be up to above 80%.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Trace amount of printing paste and preparation method and application thereof

ActiveCN105113284AReduce water consumptionReduce sewage dischargeDyeing processPrepolymerEnergy consumption

The invention discloses a trace amount of printing paste and a preparation method and application thereof. The printing paste is composed of liquid disperse dyes, a function prepolymer, a synthetic thickener, a functional addition agent and water. The trace amount of prepared printing paste can finish printing of a polyester fabric on a conventional rotary screen printing machine or a screen printing machine; high-temperature processing is performed through a tentering heat setting machine, the temperature is 180-210 DEG C, the time is 45-120 seconds, and a polyester printing fabric is prepared. The printing paste is used for printing and is characterized in that the printing process is short, the fabric is soft in touch, afttertreatment is not needed, plenty of water resources are saved, plenty of energy consumption is reduced, and there is almost no waste water emission. Processing devices are all conventional devices, and the preparation method is a green printing processing technology.

Owner:SUZHOU UNIV

Method for preparing lithium hydroxide from salt lake brine with high magnesium-lithium ratio

ActiveCN105177288AReduce utilizationLow costElectrolysis componentsProcess efficiency improvementHigh magnesiumCalcium hydroxide

The invention relates to the field of comprehensive utilization of salt lake resources, in particular to a method for preparing lithium hydroxide from salt lake brine with the high magnesium-lithium ratio. The method includes the steps that the salt lake brine with the high magnesium-lithium ratio serves as a raw material, and a certain amount of soluble trivalent metal salt is added; the magnesium-lithium ratio of the salt lake brine with the high magnesium-lithium ratio is reduced by synthesizing magnesium-based layered function materials so that magnesium and lithium in the salt lake brine with the high magnesium-lithium ratio can be separated; the magnesium in the brine is removed, and then the lithium hydroxide is prepared through lithium-rich hydrotalcite mother liquor. By means of the method for separating the magnesium from the lithium and preparing the lithium hydroxide, the technical problems that as for original methods, technologies are complex, cost is high, the use rate of magnesium resources and the use rate of lithium resources are low, and the magnesium-lithium separating effect is not ideal can be effectively solved, technological processes for preparing the lithium hydroxide are simplified, and cost is reduced; in addition, the waste magnesium resources can be sufficiently used; meanwhile, the cost of the magnesium-based function materials is reduced, higher-value utilization and comprehensive utilization of the salt lake magnesium resources, the salt lake lithium resources and salt lake boron resources are achieved, and good industrialization prospects are achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Tobacco stalk fiber substance as well as preparation method and application thereof

InactiveCN102475353AReduce damageHigh proportion of long fibersFibreboardTobacco preparationFiber bundlePapermaking

The invention provides a tobacco stalk fiber substance as well as a preparation method and an application thereof. The tobacco stalk fiber substance is obtained by the way that tobacco stalk is taken as a main raw material and biological degumming and extraction are carried out, the tobacco stalk fiber substance mainly comprises a single tobacco stalk fiber and a tobacco stalk fiber bundle (containing 2-20 single tobacco stalk fibers), and the average length of the fibers is 3-30mm. Production steps comprise processes such as burdening, biological degumming, defibering, fiber extracting and the like. The preparation method provided by the invention has the advantages of low degree of disruption to the fiber, high defibering degree, high long fiber ratio, low requirement on strength of mechanical equipment, low energy consumption and water consumption and no pollution discharge. The prepared fiber can be widely applied to tobacco sheet processing, papermaking, preparation of substrate used for soilless culture and the like.

Owner:朱大恒

Cement-free calcination-free shale pressing bearing brick and preparation thereof

InactiveCN101209909AImprove performance indicatorsLow costSolid waste managementEngineeringCalcination

The invention relates to a cement-free and baking-free shale suppression bearing brick and a manufacturing method thereof, which relates to a construction-used bearing brick and a manufacturing method thereof. Ordinary shale is used as main raw material and various 'wastes' are used as ingredients in the method; no open fire, waste gas, ash or waste water is produced in the manufacturing process which ensures low water and electricity consumption; various primary technical performances of a product are excellent. The method comprises steps that: (1) the materials are prepared according to following weight ratio: 40 to 50 percent of shale rock, 20 to 21 percent of auxiliary material, 4 to 6 percent of taillings powder, 7 to 9 percent of heavy calcium carbonate, 4 to 6 percent of gravel soil, 3 to 4 percent of alkali residue, 4 to 7 percent of construction waste, 5 to 6 percent of MSH polymerization condensate material especially used for shale and proper amount of water; (2) raw material treatment; the primary material and the auxiliary material are grinded; (3) ingredient stirring; (4) well-proportioned mixing and ageing; (5) mulling and plasticizing; (6) suppressing and forming; (7) steaming, pressing and solidification into finished product. The practice of the invention is environment friendly, and the quality of manufactured products is excellent, which reaches the standard of the bearing brick but has low cost and can be taken as the bearing brick for replacing a clay brick.

Owner:天津国威科技有限公司

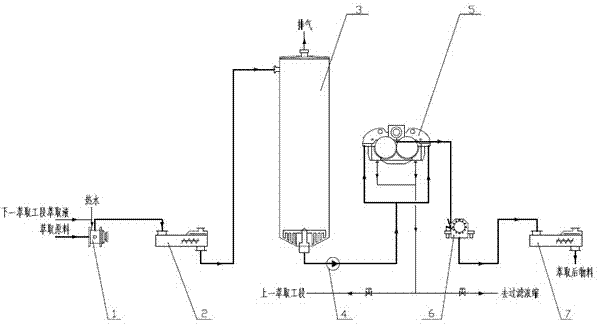

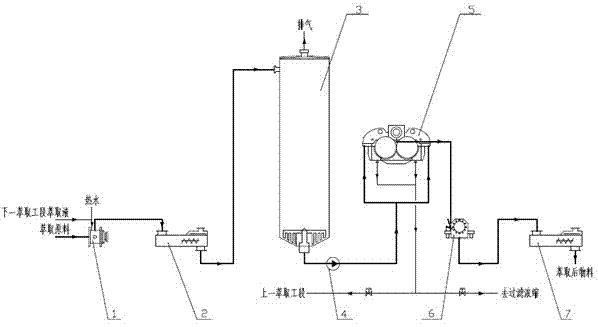

Continuous extraction method and device of papermaking reconstituted tobacco

ActiveCN102488319ARemain suspended on the surface of the liquidThere will be no suspension on the liquid surfaceTobacco treatmentScrew conveyorContinuous production

The invention discloses a continuous extraction method and device of papermaking reconstituted tobacco. The continuous extraction device of the papermaking reconstituted tobacco is characterized by comprising a mixer, a first spiral conveyor, a downflow extraction tower, a medium-consistency pulp pump, a press master, a fluffer and a second spiral conveyor, wherein the mixer, the first spiral conveyor, the downflow extraction tower and the medium-consistency pulp pump are orderly connected, a material discharge hole of the medium-consistency pulp pump is connected with a material feeding hole of the press master, a concentrated material discharge hole of the press master is connected with the fluffer, the fluffer is connected with the second spiral conveyor, a material discharge hole of the second spiral conveyor is connected to the next level of extraction section or pulping section, and an extract liquor discharge hole of the press master is connected to an extract liquor feeding hole of the mixer in a concentration section of the extract liquor or the last extraction section. The continuous extraction device of the papermaking reconstituted tobacco, disclosed by the invention, has the advantages of simple operation, good production flexibility, capability of continuously producing, low water consumption and high extraction rate.

Owner:CHINA HAISUM ENG

Full-automatic washing machine washing process

ActiveCN1544744AReduce the number of correctionsLess water consumptionControl devices for washing apparatusTextiles and paperProcess engineeringEngineering

The invention provides a washing program method of full-automatic washer, and its character: number of unbalanced times is accumulated in the whole course of the washing program. It eliminates the mode that existing techniques accumulate number of unbalanced times by using single rinsing program as a segment but accumulates number of unbalanced times by adopting the whole washing program as the basis of accumulation alarm, thus largely reducing unnecessary number of correction times, reducing unnecessary water consumption and shortening the washing delay time due to correction of unbalance.

Owner:HAIER GRP CORP +1

Separation and recovery apparatus for waste paper and plastic composite material, and method thereof

InactiveCN102357514AEasy to separate and recycleEasy to pick upSolid waste disposalPlastic recyclingElectric machineryWaste paper

The invention relates to a separation and recovery apparatus for a waste paper and plastic composite material. The apparatus comprises a circular water tank. The circular water tank is provided with a plurality of rollers. A rotation shaft installation direction of each roller is a horizontal direction. Both ends of the rotation shaft of each roller are respectively erected on both sides of the tank chamber. The surface of each roller is provided with convex teeth. The rollers are connected with a motor, wherein the motor drives the rollers to rotate. The invention further discloses a separation and recovery method for the waste paper and plastic composite material. The apparatus and the method of the present invention have the following advantages that: the cost is low, the energy consumption is low, the separation effect of the paper layer and the plastic layer is good, and the recovery is easily performed.

Owner:曾涛

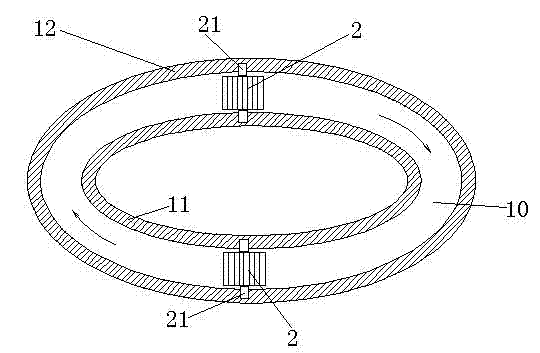

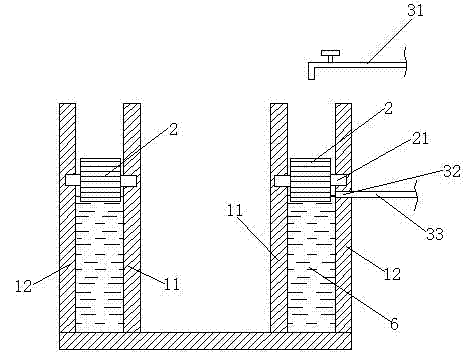

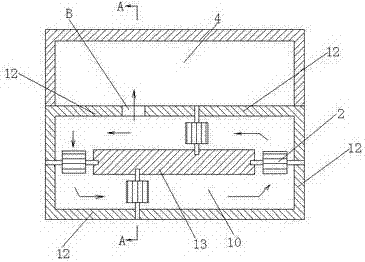

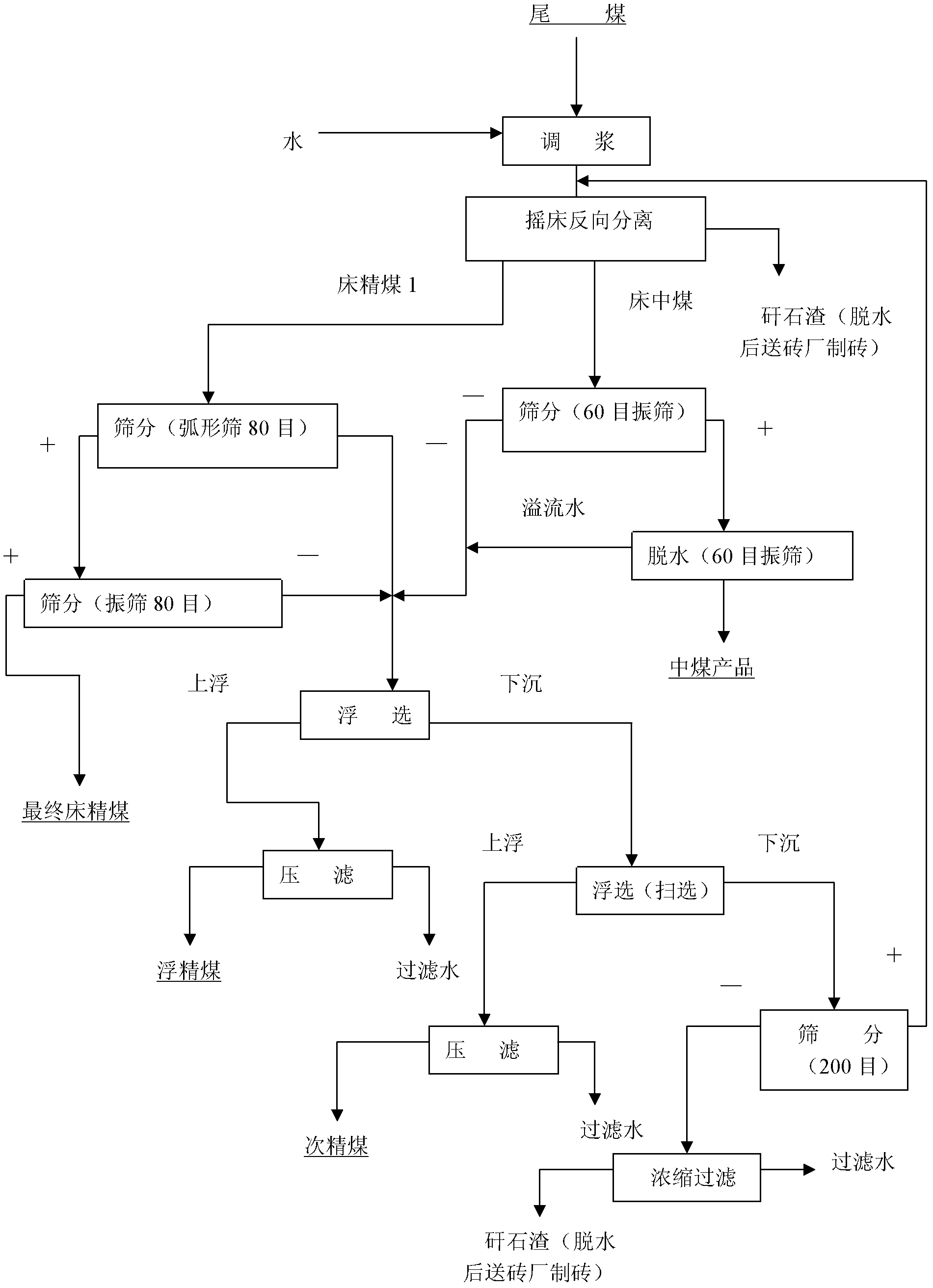

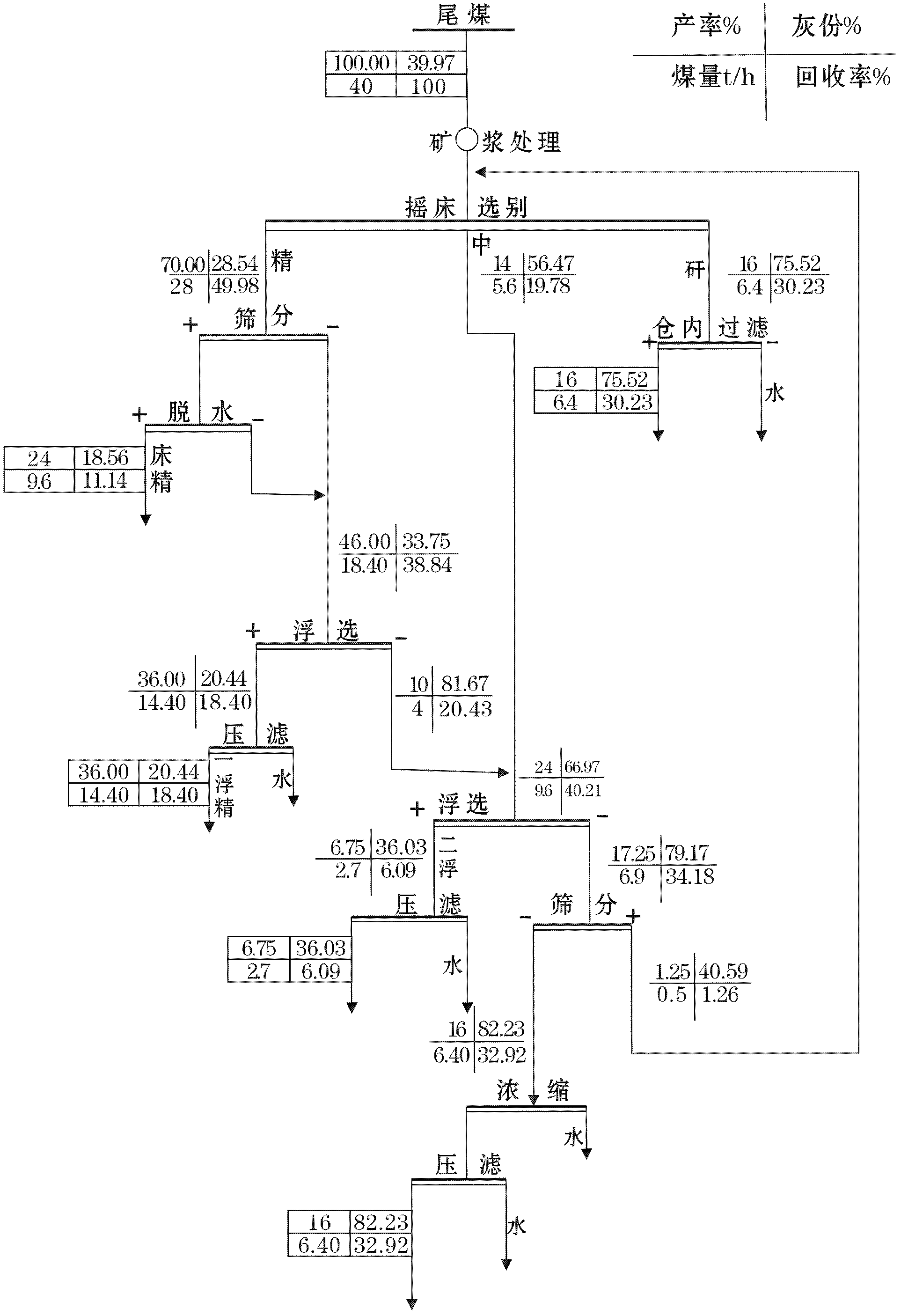

Technique for recycling cleaned coal from low-value gangue or tail coal of coal washery

The invention relates to a technique for recycling cleaned coal from low-value gangue or tail coal of a coal washery. The technique comprises the following steps of: crushing the gangue into powder with the grain size of 2mm, and dissociating coal from gangue mineral monomers; adding water into the powder or the tail coal of the coal washery to obtain ore pulp, carrying out reverse separation by virtue of a table concentrator, wherein light coal enters into a tailing slot to be prepared into a bed cleaned coal product, heavy gangue mineral enters into a concentrate slot to be prepared into gangue slag which can be used for making bricks, and an accretion body between the light coal and the heavy gangue mineral and a part of gangue mineral enter into a middling slot to be prepared into a bed midding coal product; screening the bed cleaned coal product to remove fine gangue component, dehydrating oversize products to obtain a final bed cleaned coal product; carrying out flotation separation on the bed middle coal product by adopting a flotation machine, and carrying out filter pressing on floating products to obtain a floating cleaned coal product, wherein a sink product is the gangue slag used for making bricks. By applying the technique provided by the invention, cleaned coal in the tail coal or gangue can be economically and reasonably recycled in a large scale, the reverse separation by using table concentrator is organically combined with certain flotation and the like, thus technological adaptability is high and technical index is good; coal gangue with ash content up to 62-72% can be processed into cleaned coal or secondary cleaned coal with the ash content of 27-40% only, technological process is simple and compact, operation cost is low, net profit created by each ton of the coal gangue is 50-80 yuan, no 'three wastes' pollution is produced, and the technique provided by the invention is safe and environmentally friendly.

Owner:高华

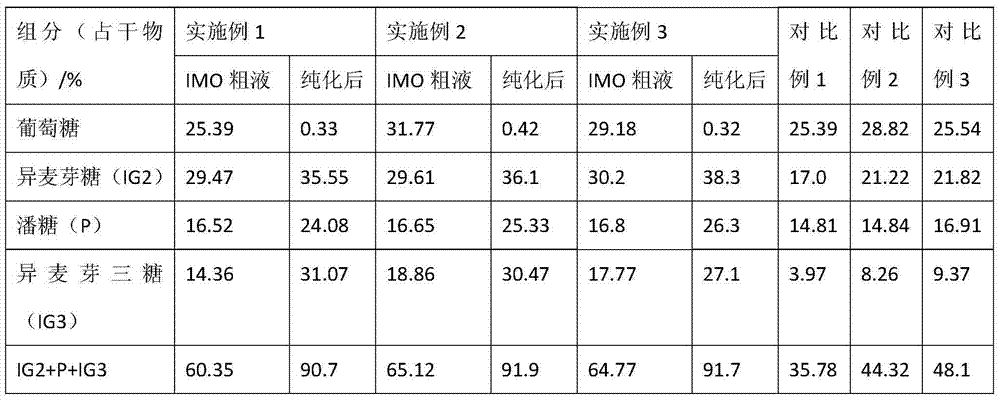

Method for producing high-functional-trisaccharide-content isomaltooligosaccharide by using immobilized cells

ActiveCN103484512AThe effect of low enzyme activityStable and efficient enzyme production environmentMicroorganism based processesOn/in organic carrierChromatographic separationIsomaltooligosaccharide

The invention relates to a method for producing high-functional-trisaccharide-content isomaltooligosaccharide by using immobilized cells. The method comprises the following steps: liquefying and saccharifying the raw material starch to obtain malt syrup; and preparing the high-functional-trisaccharide-content isomaltooligosaccharide by combining an immobilized Aspergillus niger cell technique and a simulated moving bed chromatographic separation technique. After the saccharified liquid is subjected to glycoside transformation by the immobilized cells, the total amount of the three functional components (isomaltose IG2, panose P and isomaltotriose IG3) is up to higher than 60%, the transformation ratio of the immobilized cell substrate is higher than that of the immobilized enzyme, and the indexes of the product are much higher than those of like products at home and abroad; after the chromatographic separation, the total amount of the three functional components can reach higher than 90%; and meanwhile, the method greatly shortens the reaction time, and is convenient to operate and suitable for large-scale continuous production.

Owner:BAOLINGBAO BIOLOGY

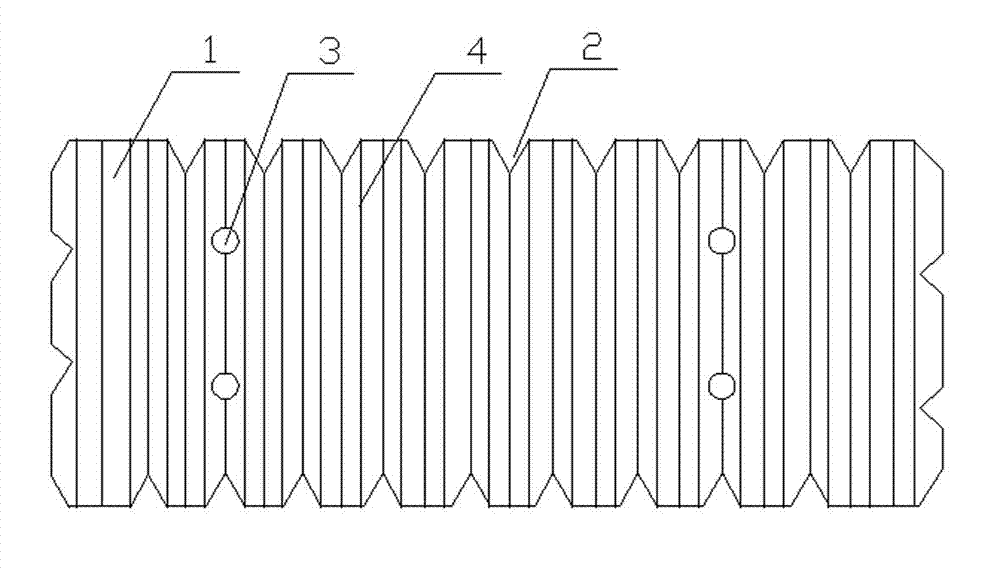

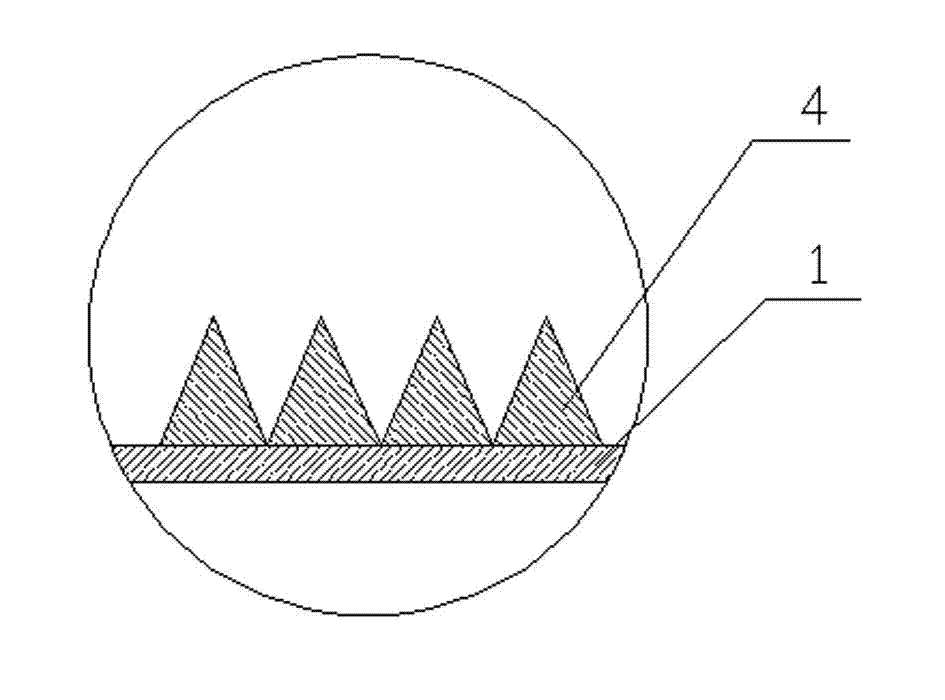

Filtering device with filter body adopting flaky filtering material

InactiveCN101658739ALess investmentSmall footprintStationary filtering element filtersLight filterSystem configuration

The invention belongs to the technical field of water treatment, in particular to a filtering device with a filter body adopting flaky filtering materials. The filtering device comprises a flaky filtering assembly, a dredging pipe, a dredging pump, a dolly, a dolly guide rail, a clapboard, an effluent weir and a shell, wherein a water inlet, a water outlet and a vent nozzle are arranged below theshell, the flaky filtering assembly is vertically arranged in the shell, a clear water outlet pipe is arranged at the bottom of the flaky filtering assembly, the effluent weir is vertically fixed at the water outlet near the shell, the clapboard is vertically fixed in the shell and positioned between the flaky filtering assembly and the effluent weir, the dolly guide rail is positioned at the topof the shell, the dolly is positioned on the dolly guide rail and can move on the dolly guide rail back and forth, the dredging pump is fixed below the dolly, one end of the dredging pipe is positioned at two sides of the flaky filtering material assembly, and the other end of the dredging pipe is connected with the dredging pump by a main dredging pipe. The invention adopts valve-free operationsand the light filtering materials, increases the filtering area, reduces the filtering load, has less backwashing water consumption and flexible system collocation and is convenient for increasing treating scale. The invention has the advantages of low energy consumption, small occupying area, simple operation and maintenance, and the like, and has higher purifying efficiency while in integrated application with the generate water treatment technology as well as wide application prospects.

Owner:TONGJI UNIV

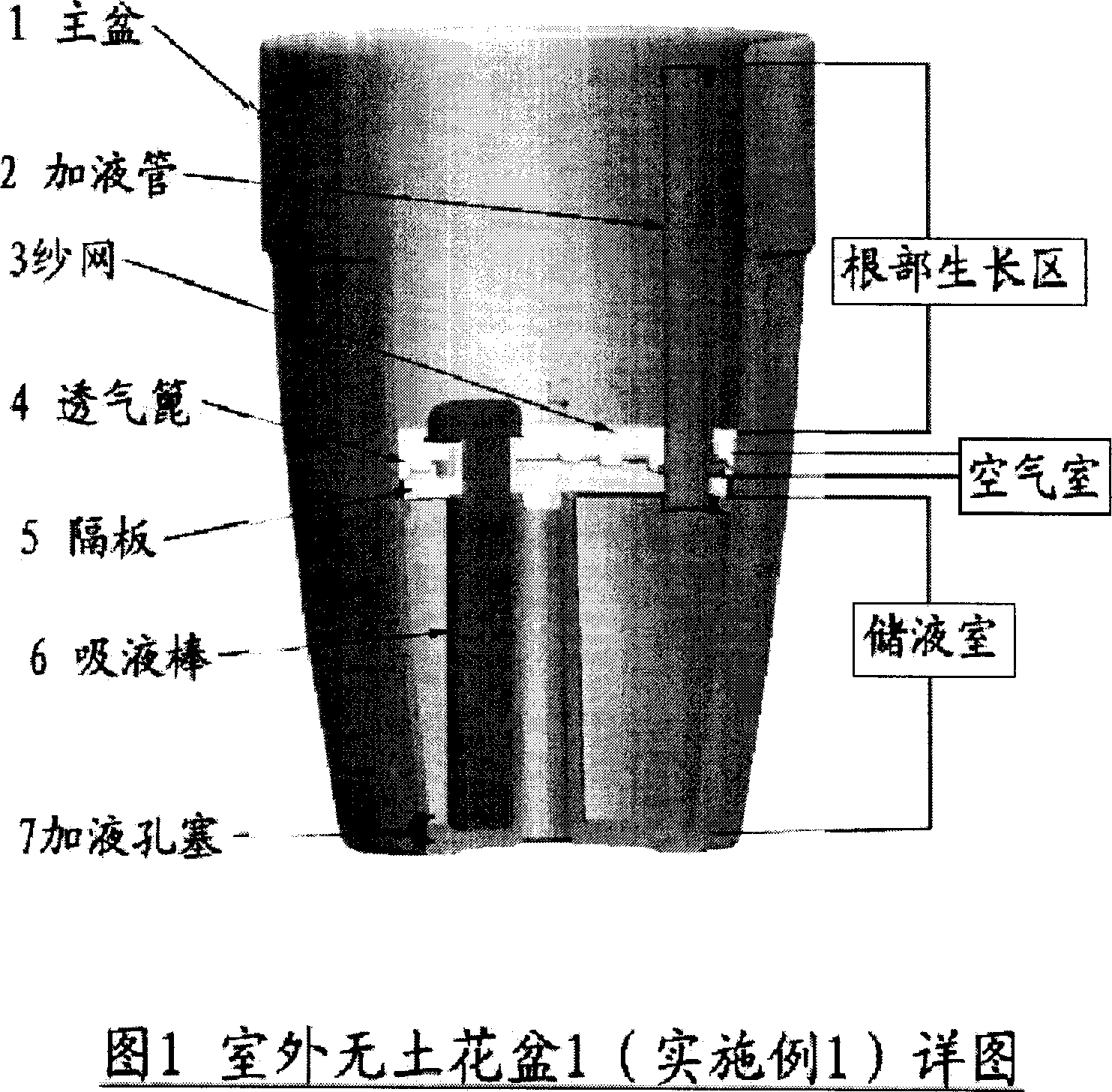

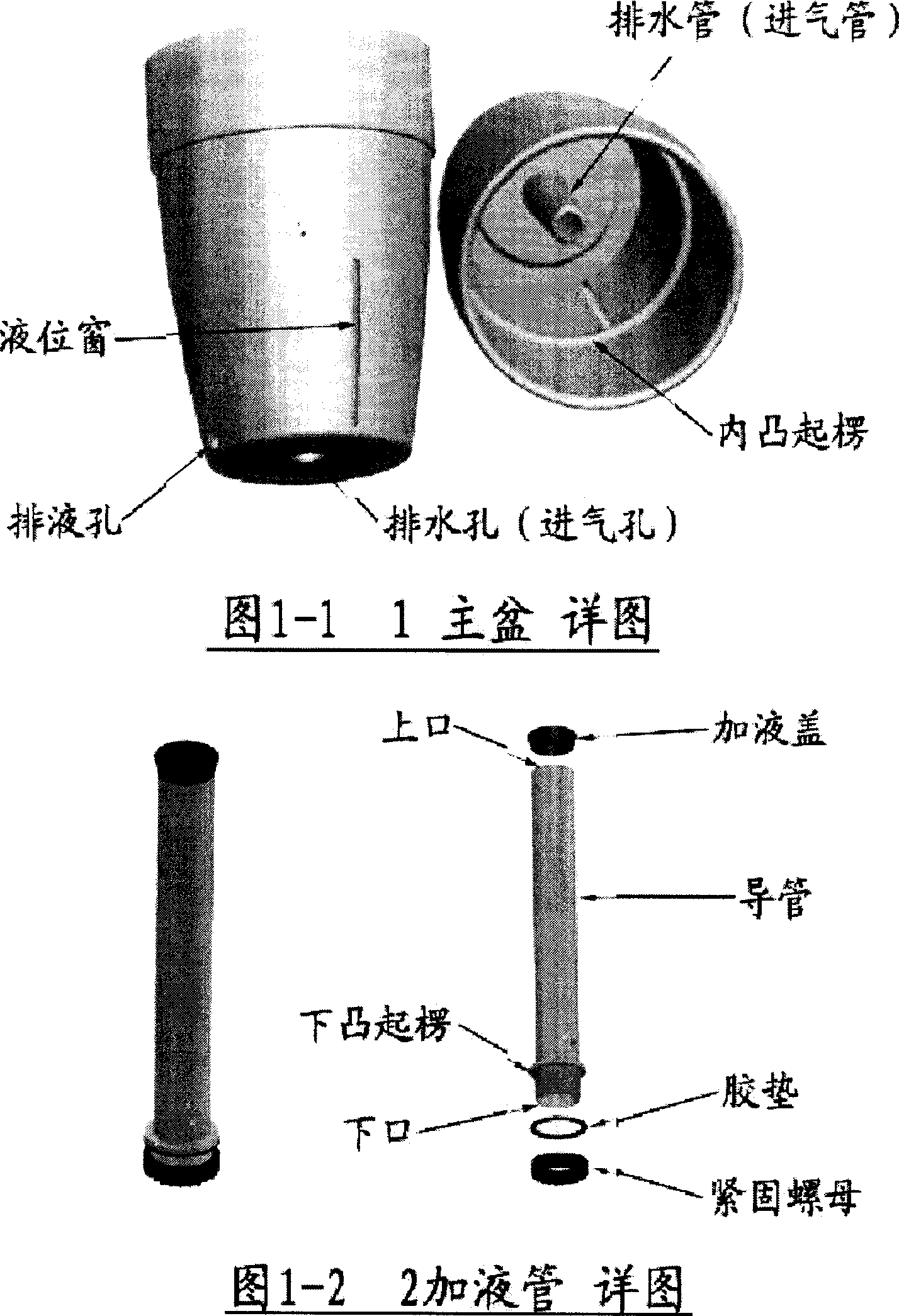

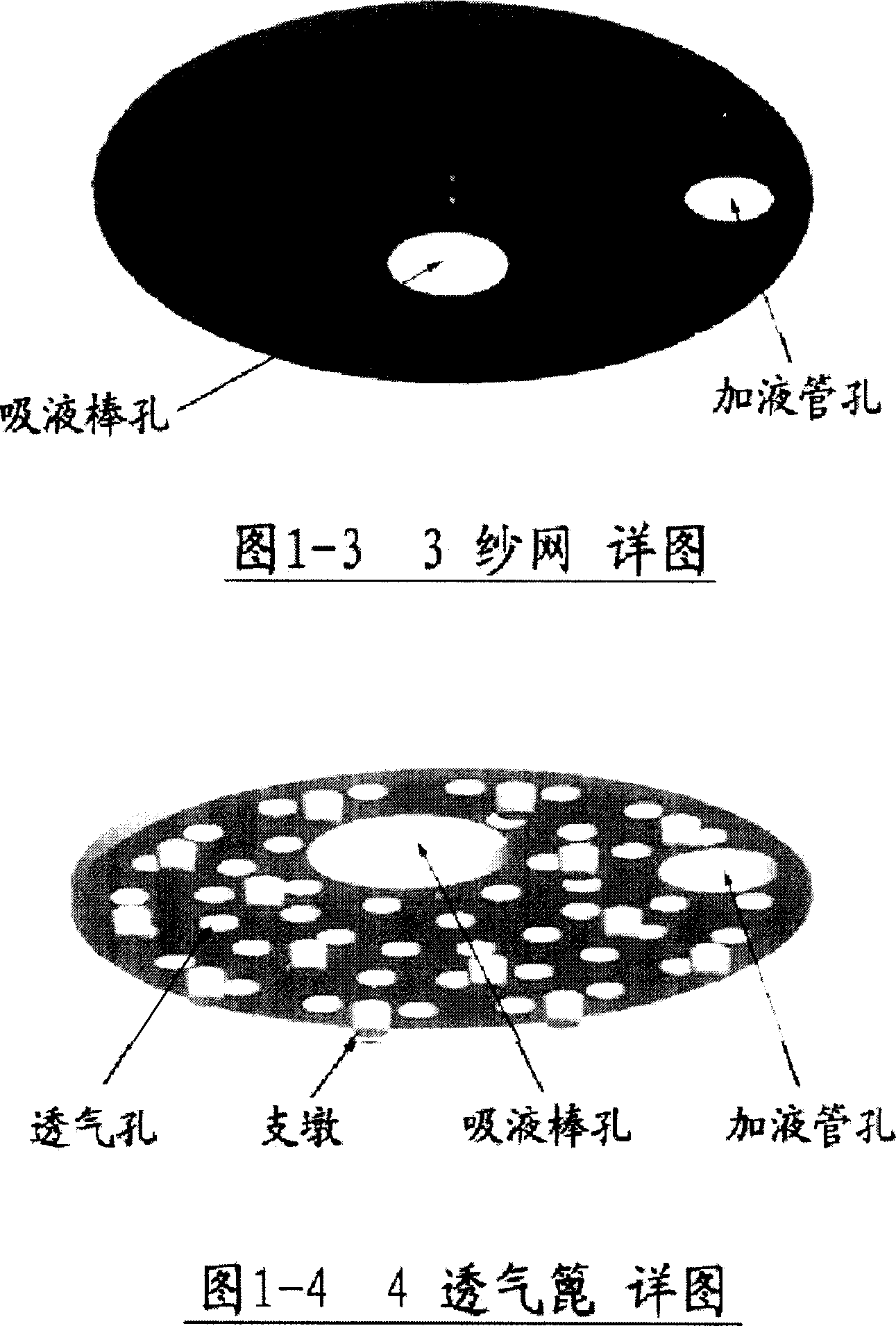

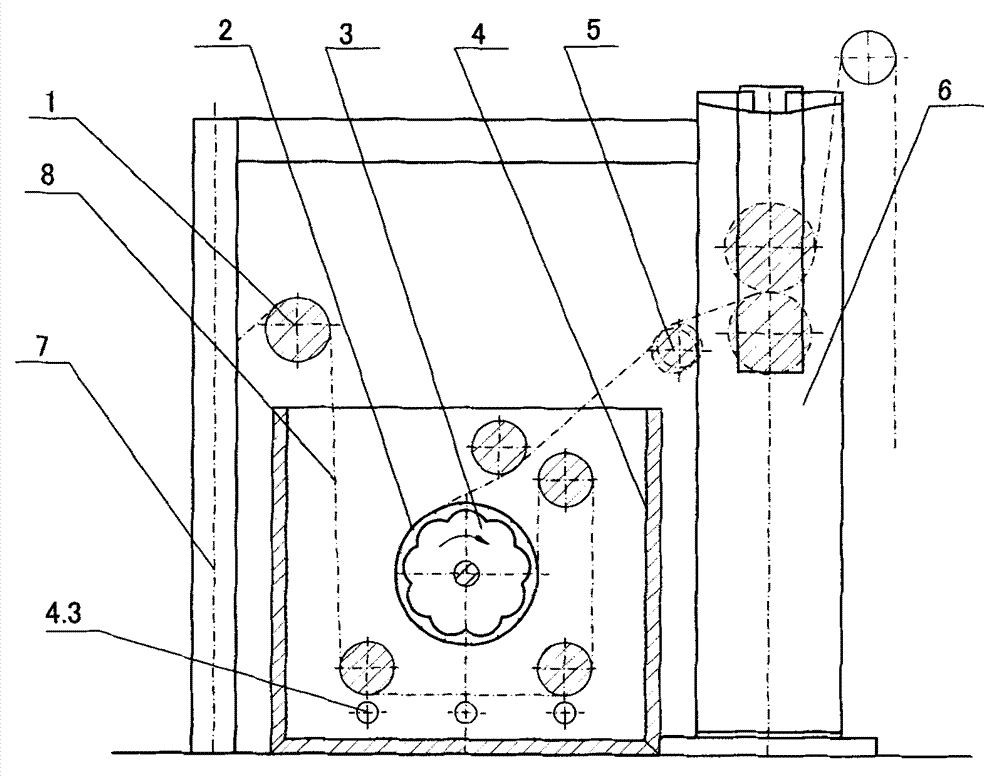

Multi-functional soilless flowerpot with large liquid storage reservoir

InactiveCN100998307AAvoid enteringAvoid root rotAgriculture gas emission reductionCultivating equipmentsRoot systemEngineering

A multifunctional soilless flowerpot with a big nutritive liquid storing chamber is composed of main pot divided into root growing region, air chamber and nutritive liquid storing chamber to provide nutritive liquid for 3 months, liquid filling tube, gauze net, air permeable grate, bulkheads, liquid sucking rod, liquid filling hole with plug, matrix and nutritive liquid.

Owner:佟振东

Producing method of sodium alginate with ultralow viscosity

The invention discloses a producing method of sodium alginate with ultralow viscosity. Kelp is soaked and homogenized, cellulose, protease and pectinase are added for enzymolysis, enzymatic hydrolysate is filtered out, and kelp dregs are obtained; dilute alkali is added into the kelp dregs for digestive treatment, a digestive fluid is diluted and filtered, H2O2 is added into an obtained alginate liquid for oxidative decoloration, and the mixture is filtered; a calcium chloride solution is added into an alginate clear liquid, so that sodium alginate is converted into calcium alginate fiber to be precipitated out; after calcium alginate is dehydrated and washed, an HCl solution is added to convert calcium alginate into alginic acid, then, NaOH is added, and the mixture is converted into a sodium alginate solution; ethyl alcohol is added to precipitate out sodium alginate, sodium alginate is dried at the temperature of 50-60 DEG C, and a sodium alginate product with the viscosity to be 10-50 mpa*s is obtained. The process is simple, less water is consumed, the degradation velocity is high, and severe conditions of high temperature, high pressure and the like are not required.

Owner:青岛福创环境科技有限公司

Oscillatory water current type water washing machine

InactiveCN102808297AImprove laundry qualityImprove decontamination abilityTextile treatment with treating outlet contectTextile treatment rollersWater flowPulp and paper industry

The invention discloses an oscillatory water current type water washing machine, which comprises a fabric guiding roll, an outer barrel, an inner shaft barrel, a water tank, a tensioning roll, an impregnating mangle and a frame. The frame is connected with the impregnating mangle to form a rectangular framework; the water tank is mounted in the frame; and the fabric guide roll and the tensioning roll are arranged inside and outside the water tank to form a water washing structure in a routine driving condition. The outer barrel and the inner shaft barrel which are coaxially sleeved are mounted at the middle part of the water tank; through holes are uniformly distributed on the wall of the outer barrel; concave-convex alternate ridges are uniformly distributed around the outer wall of the inner shaft barrel; two shaft ends of the inner shaft barrel stretch out from the middle parts of two end surfaces of the outer barrel to be matched with a shaft seat; and the inner shaft barrel forms a rotating structure driven by external power. In a rotation process, the volume of a section between the concave-convex ridges uniformly distributed around the outside of the inner shaft barrel and the inner wall of the outer barrel generates regular change, so that water current comes in and out from the through holes on the wall of the outer barrel alternately, and a washing effect is strengthened by oscillatory round-trip water current. According to the oscillatory water current type water washing machine, two washing structures are arranged in the same water tank in total; the weak washing transits to the strong washing; the washing quality is good; the efficiency is high; and the oscillatory water current type water washing machine is suitable to wash various grey fabrics.

Owner:泰州科世茂工程设备有限公司

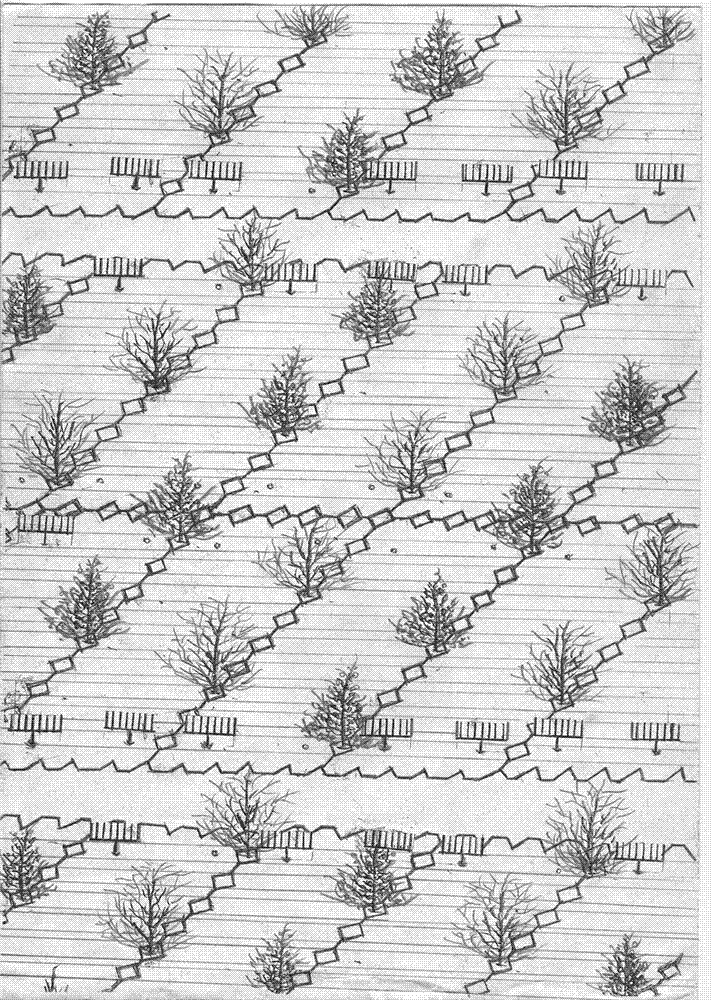

Irrigation-free sandbreak forest planting technique

ActiveCN102812837ALess water consumptionIncrease circulating waterClimate change adaptationWatering devicesEcological environmentEnvironmental geology

The invention relates to an irrigation-free sandbreak forest planting technique. The irrigation-free sandbreak forest planting technique is characterized in that in an arid desert area, according to a sandbreak forest construction plan, technical sand control facilities, sand control boards, are used for constructively covering a sand source to be forested in order to stop the movement of wind-blown sand in real time; and as the sand control boards are laid, a forest is synchronously and directly planted around the sand control boards. In the technique, the sand control boards have the functions of rainwater collection and water conservation, so that natural rainfall can be effectively stored, and therefore a rainwater-collecting cistern effect is generated. The technique can ensure that soil can keep desert plants in a suitable water-retaining state, the constructed sandbreak forest can survive and can be conserved without being irrigated, and the recovery of the ecology of the sandbreak area can be started in real time. The technique is the most effective, simplest, most reliable, most economical, able and cheapest engineering-biological measure in current measures for changing the natural ecological environments of deserts as soon as possible.

Owner:余绳鑫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com