Filtering device with filter body adopting flaky filtering material

A filter device and filter body technology, applied in the field of water treatment, can solve the problems of shortened filtration cycle, large floor space, difficult filling and replacement, etc., and achieve the effects of improving space utilization, reducing floor space, and simple automatic control scheme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

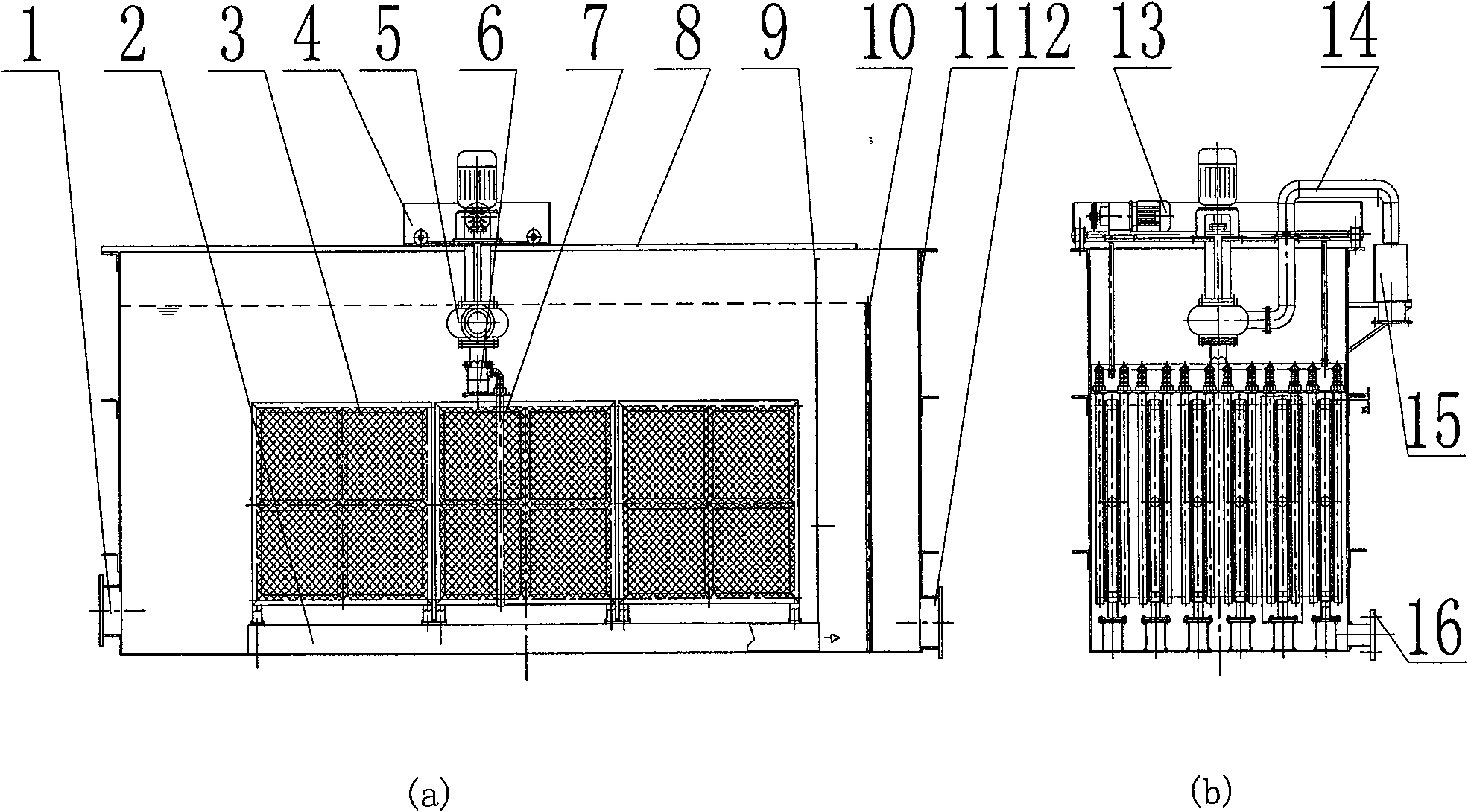

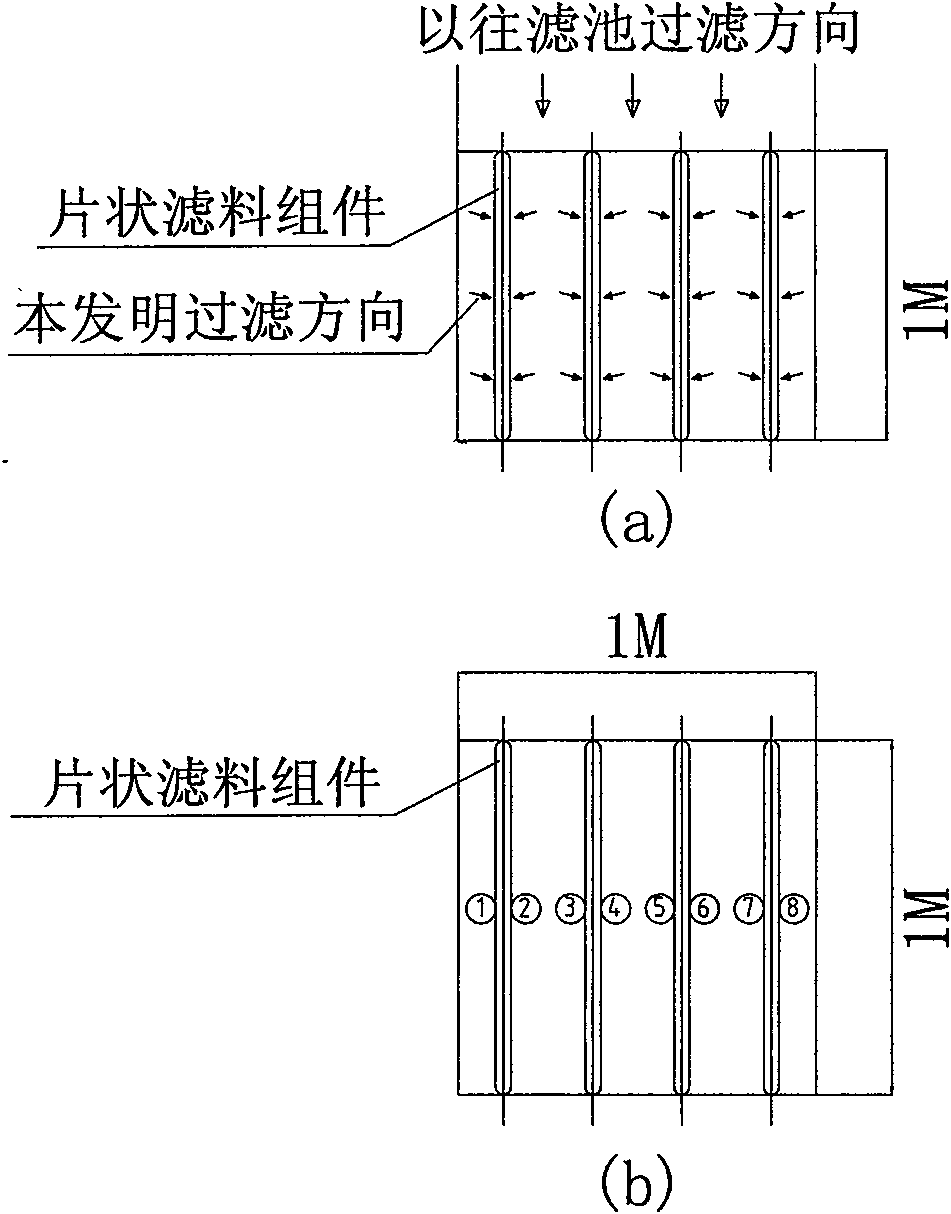

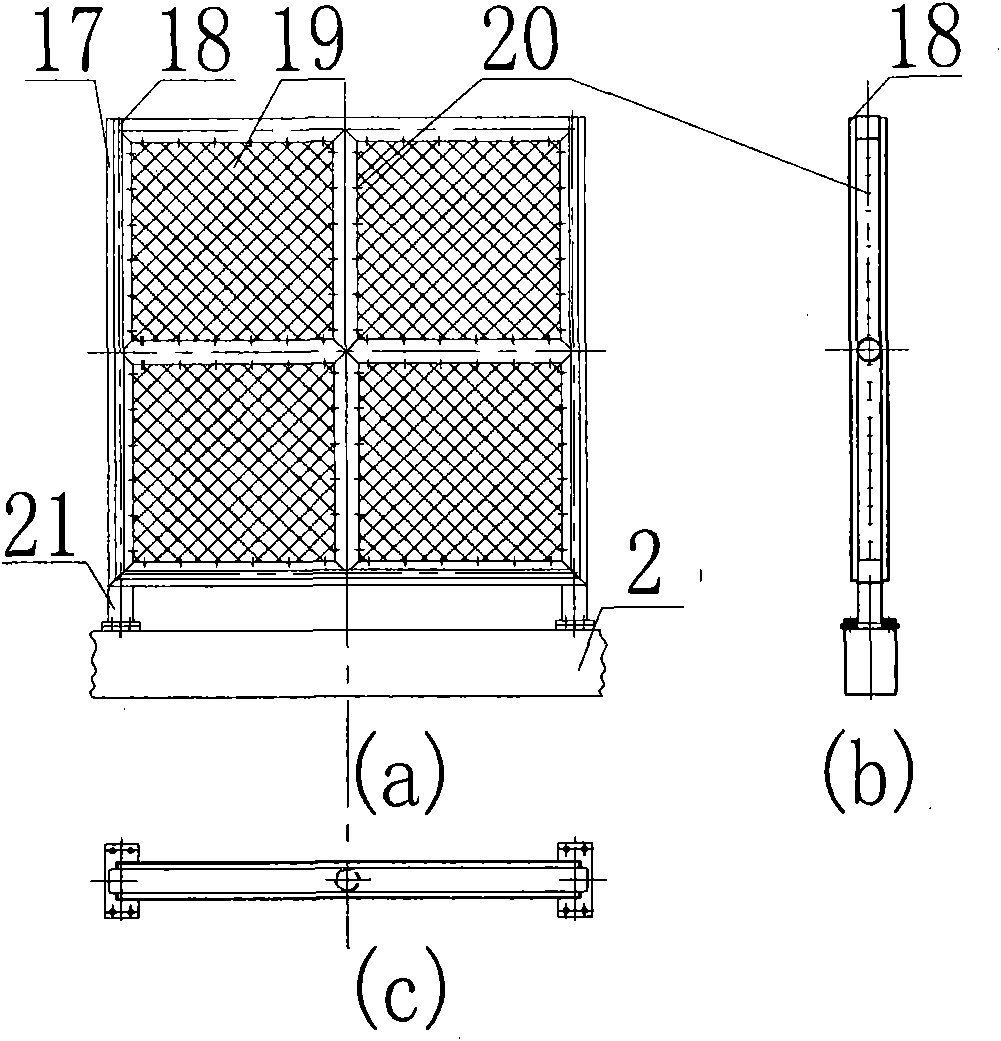

[0042] Embodiment 1: as figure 1 As shown, the raw water enters the casing 11 from the water inlet 1, and due to the blocking of the water outlet weir 10, the water level gradually rises until it submerges the sheet-shaped filter material assembly 3. After the water overflows, it enters the filtration stage. Raw water is filtered from the outside to the inside by the blanket-like braids on both sides of the filter material assembly 3 to be purified. The clean water flows to the outer side of the dividing plate 9 through the clean water outlet pipe 2, overflows from the water outlet weir 10, and is discharged to the clean water outlet 12. With the extension of the filtration time, the interception capacity of the filter material increases, and the filter resistance increases, which makes the water level in the shell rise. When it reaches a certain set height, it means that the filter material needs to be cleaned. At this time, the dredging pump 5 starts, and the trolley 4 beg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com