Patents

Literature

66results about How to "Reduce filter load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

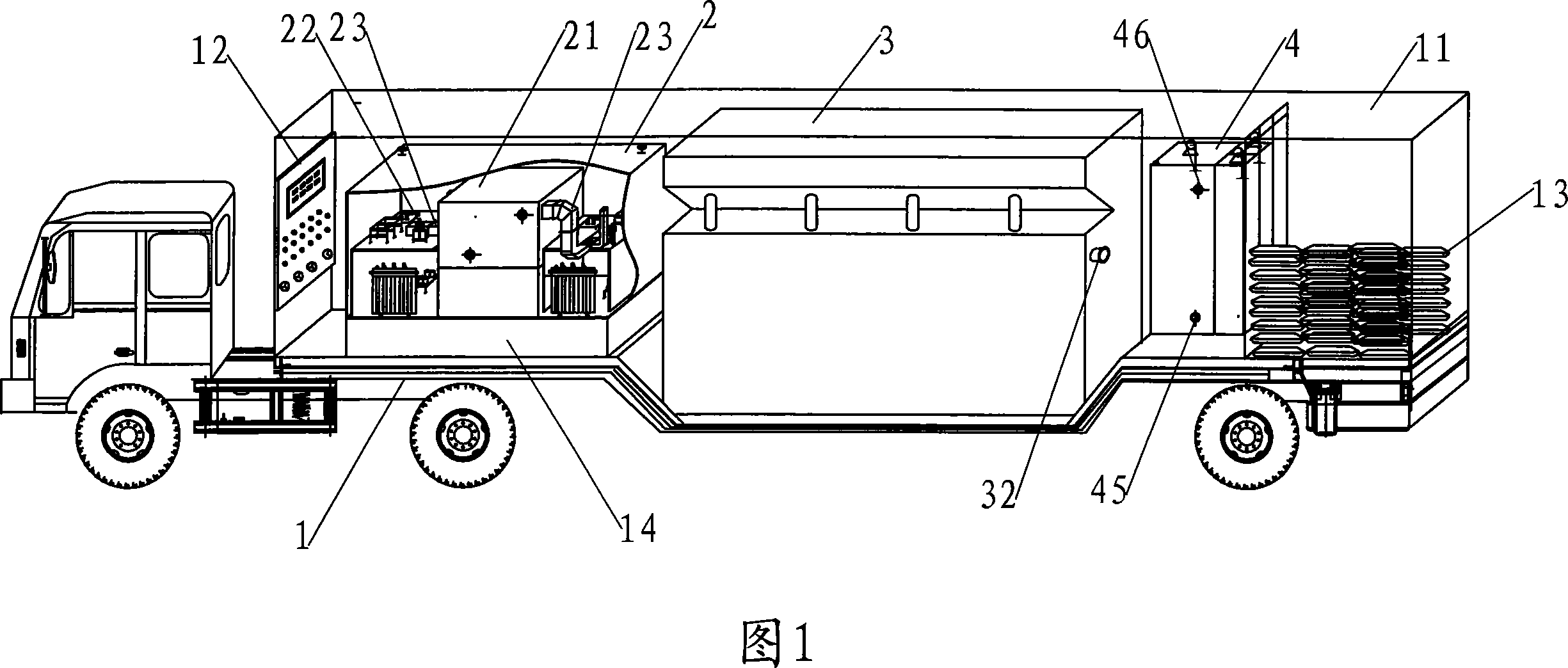

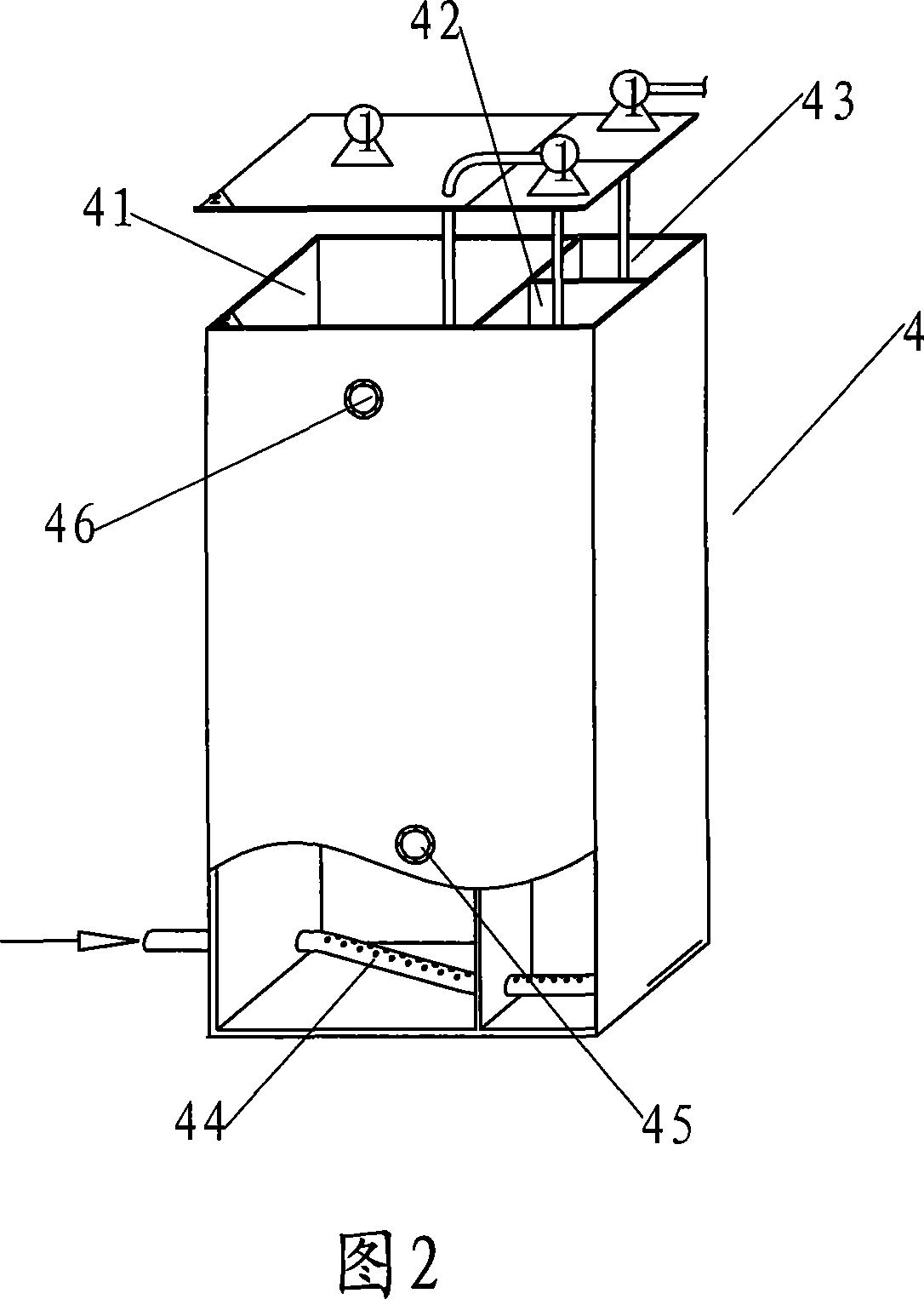

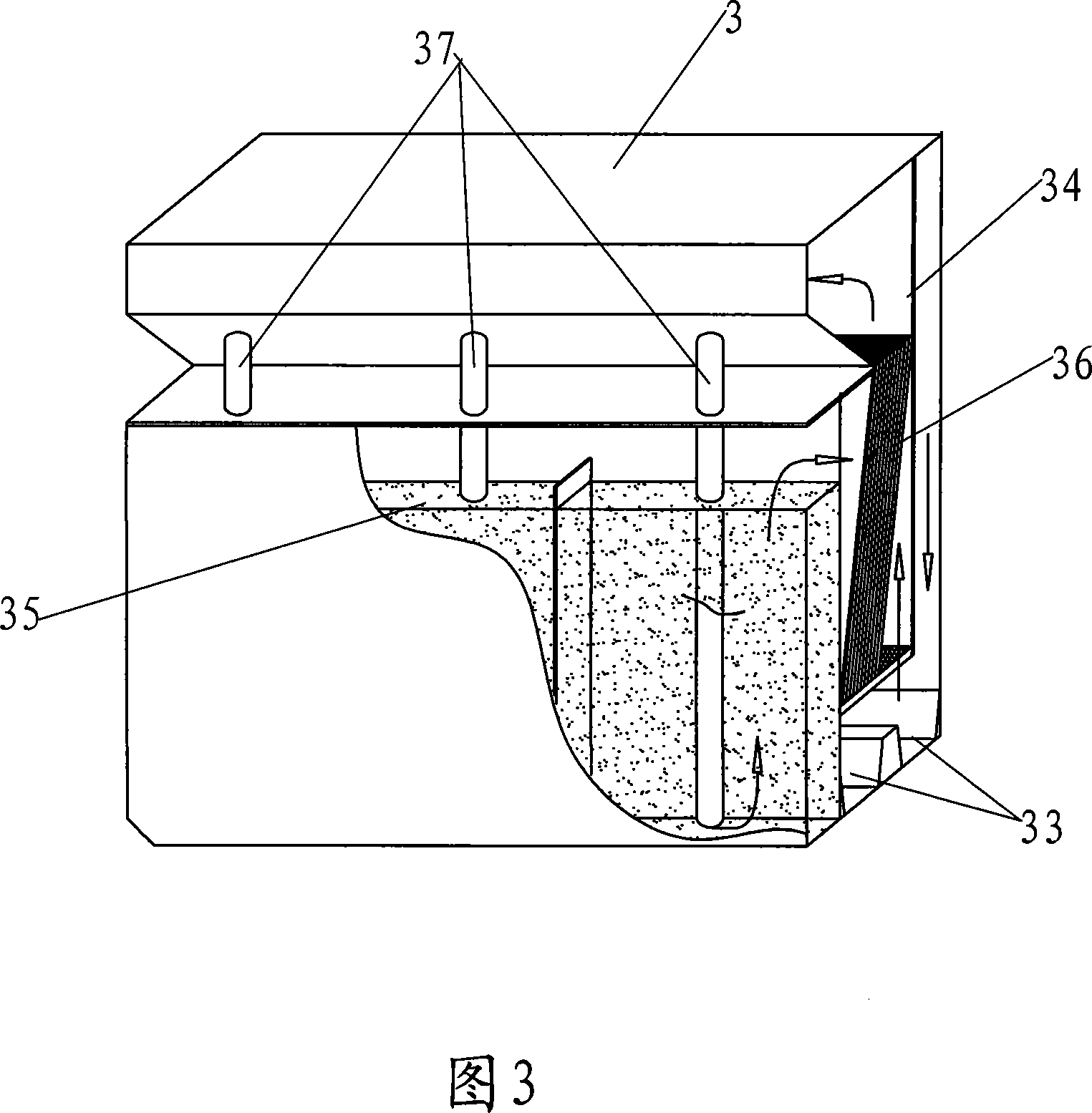

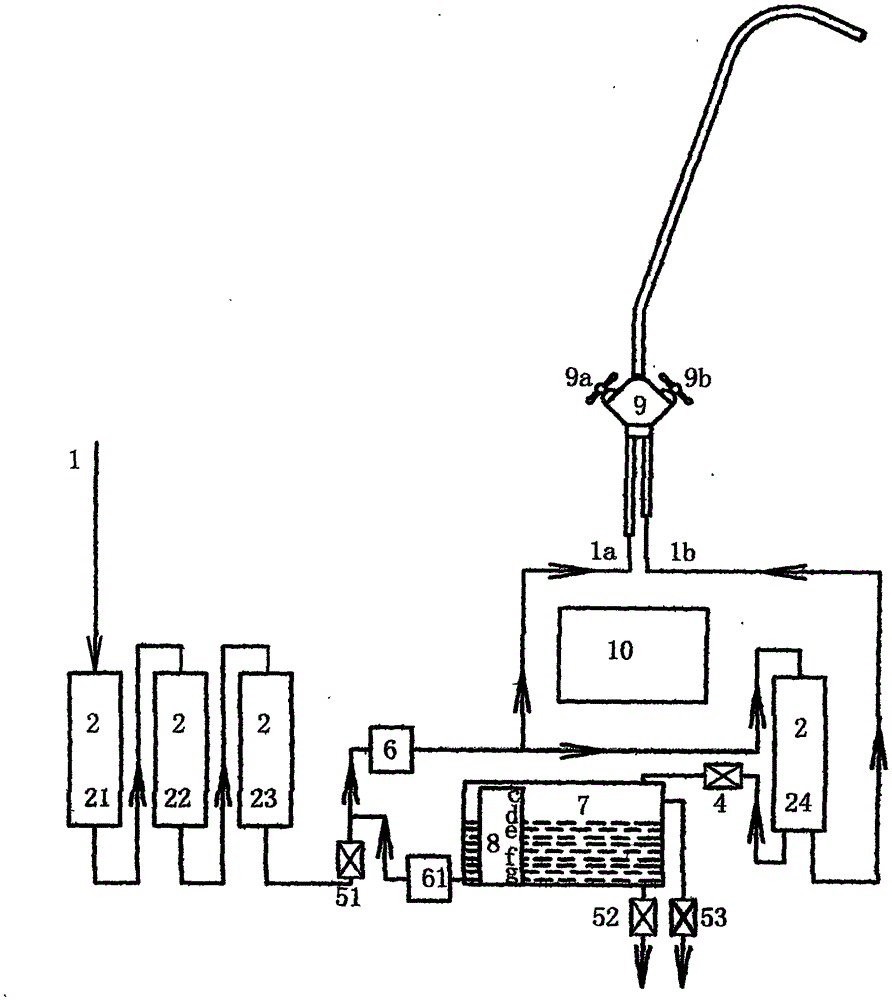

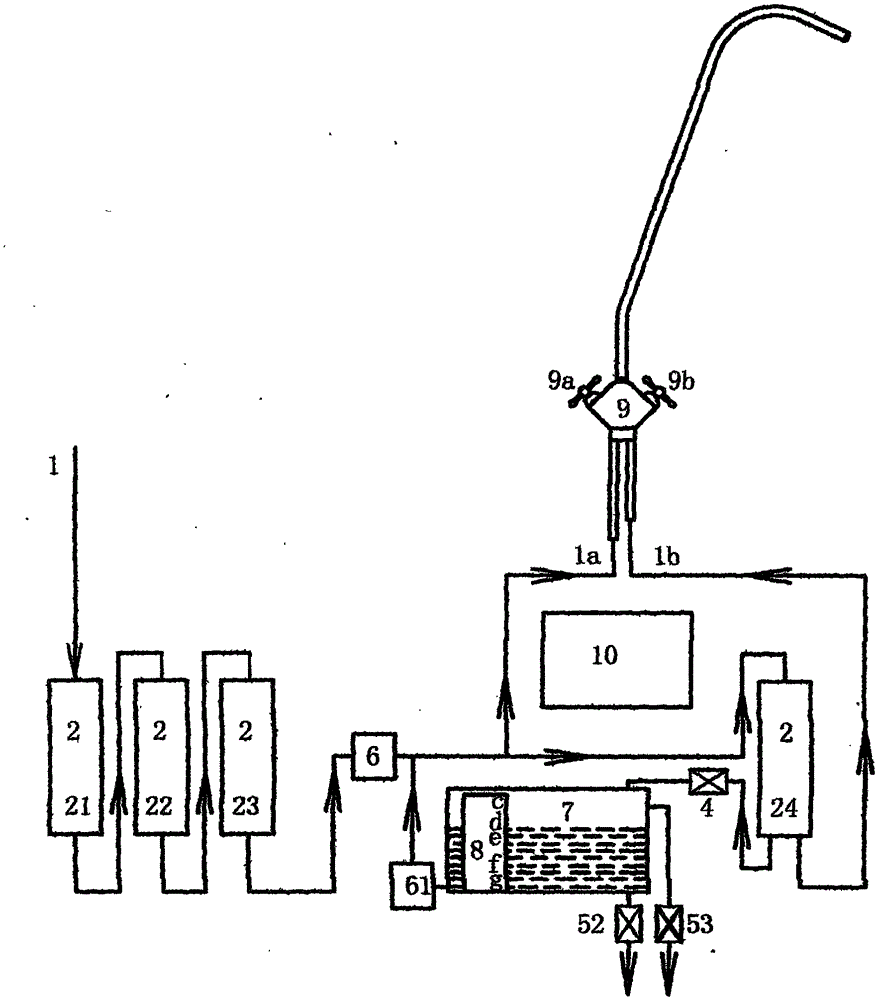

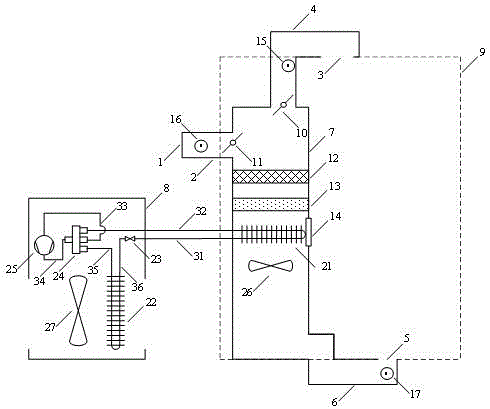

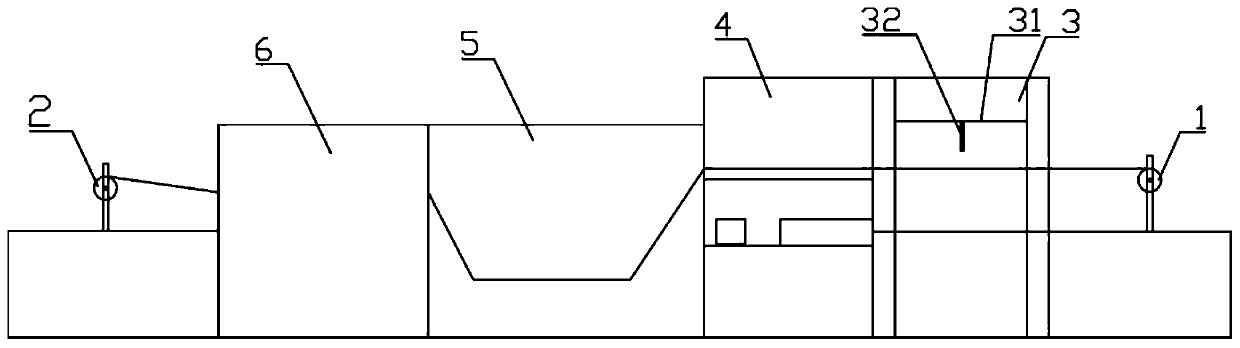

Mobile sewage treatment apparatus

ActiveCN101234794AImprove passabilityImprove processing efficiencyWater/sewage treatment by irradiationMicrowaveWater treatment system

The invention relates to a movable microwave emergency device for treating sewage, which comprises a carrier and a microwave sewage treatment system arranged on the carrier. The microwave sewage treatment system comprises a microwave reactor (2), a sedimentation filtering reactor (3) arranged on the lower part of the microwave reactor (2) and connected with the sewage outlet of the microwave reactor (2) through pipes, and a sensitizer arranged on the upper pipes of the microwave reactor (2) as well as an adding set (4) of other water treating agent. The movable microwave emergency device solves the technical issues that the current microwave sewage treatment system can not meet the requirement in terms of size for the vehicle and the utilization efficiency of the microwave is low. Particularly, the movable microwave emergency device is applicable to continuously treat the sewage generated by unexpected events and produced by enterprises with a little sewage producing quantity.

Owner:孙宪彬

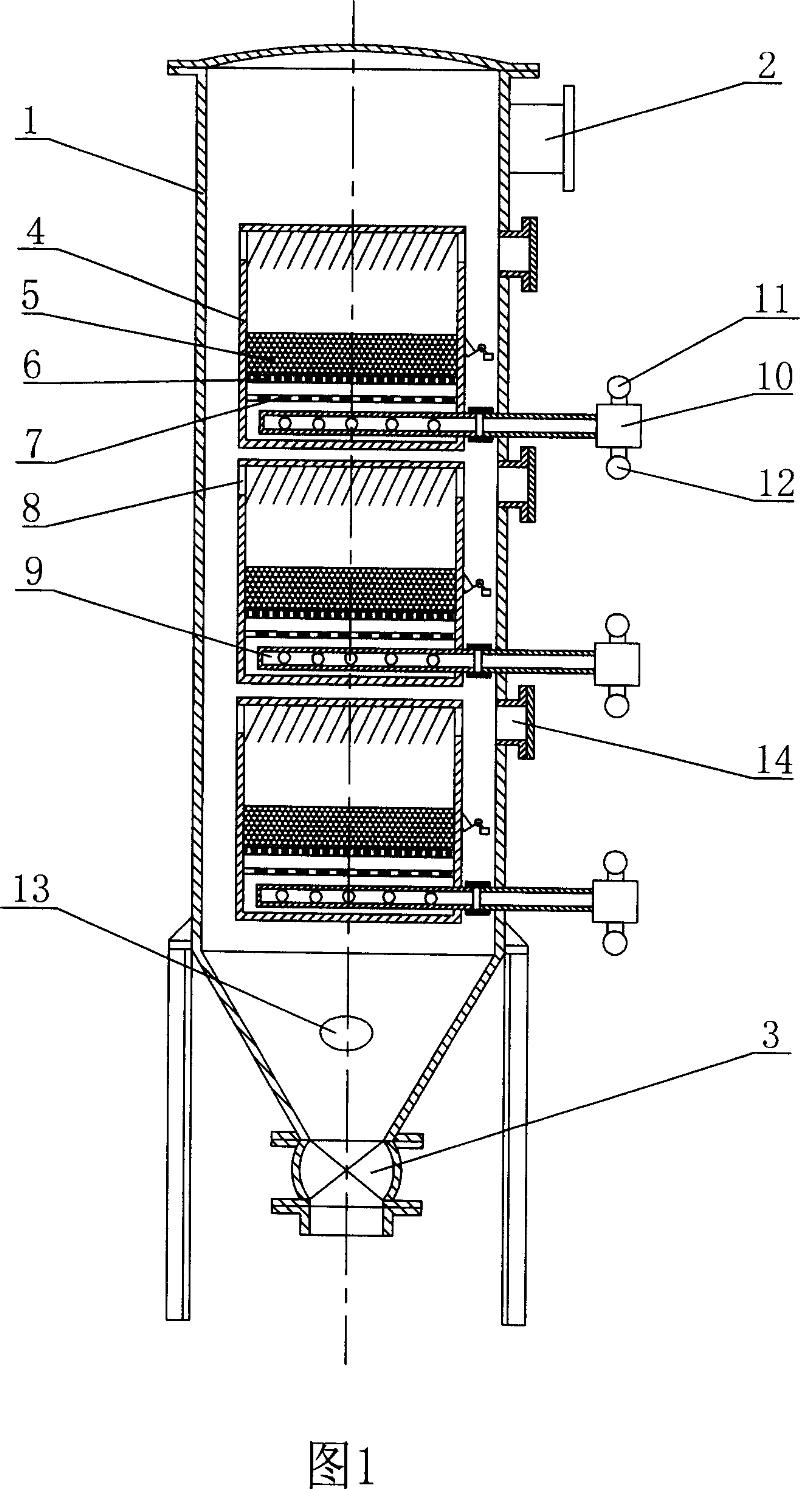

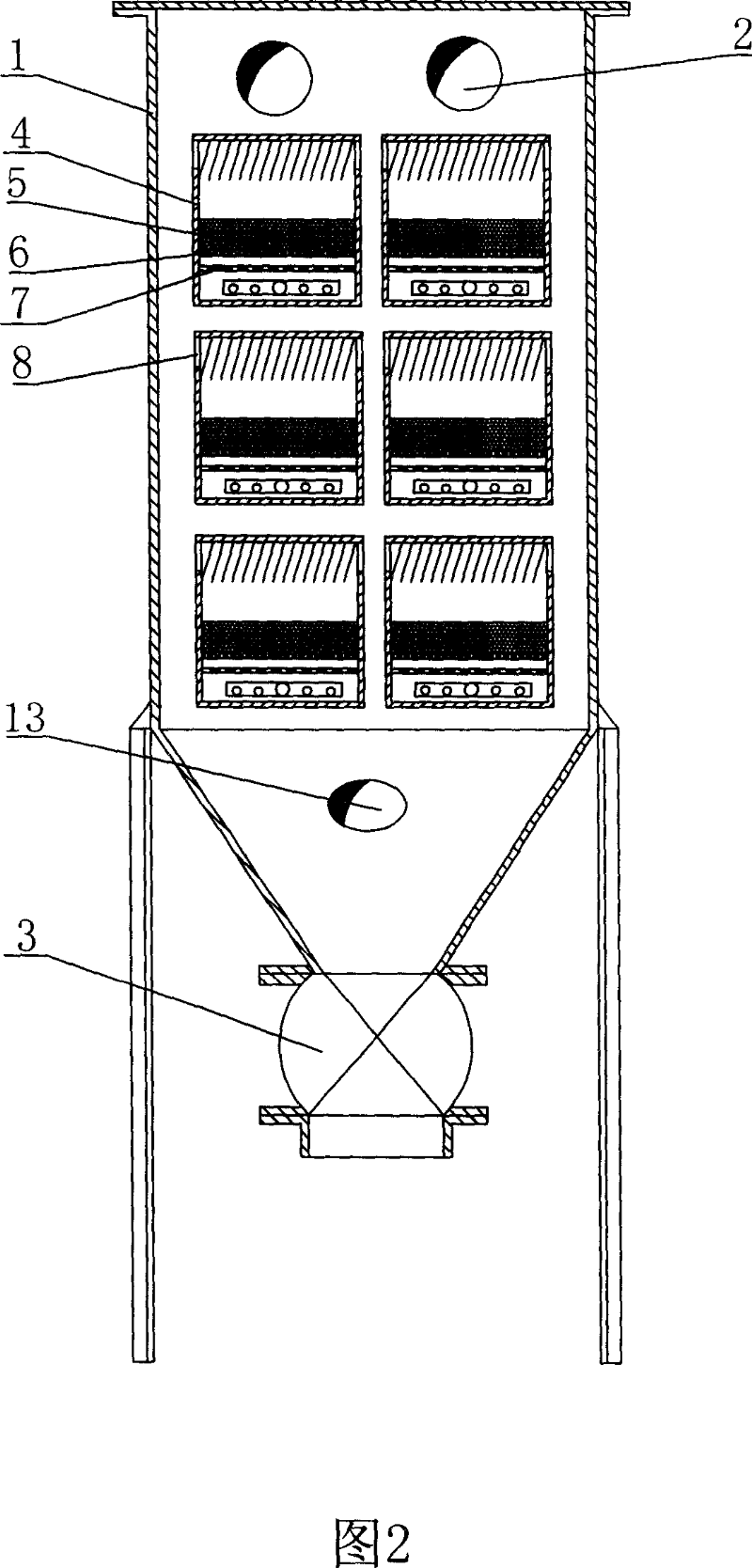

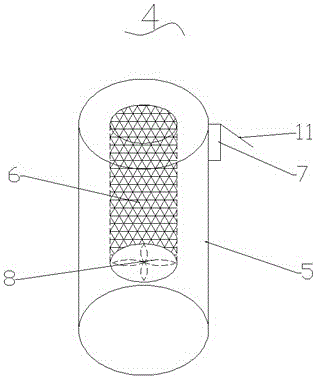

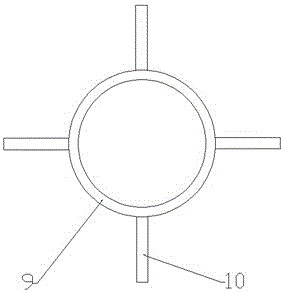

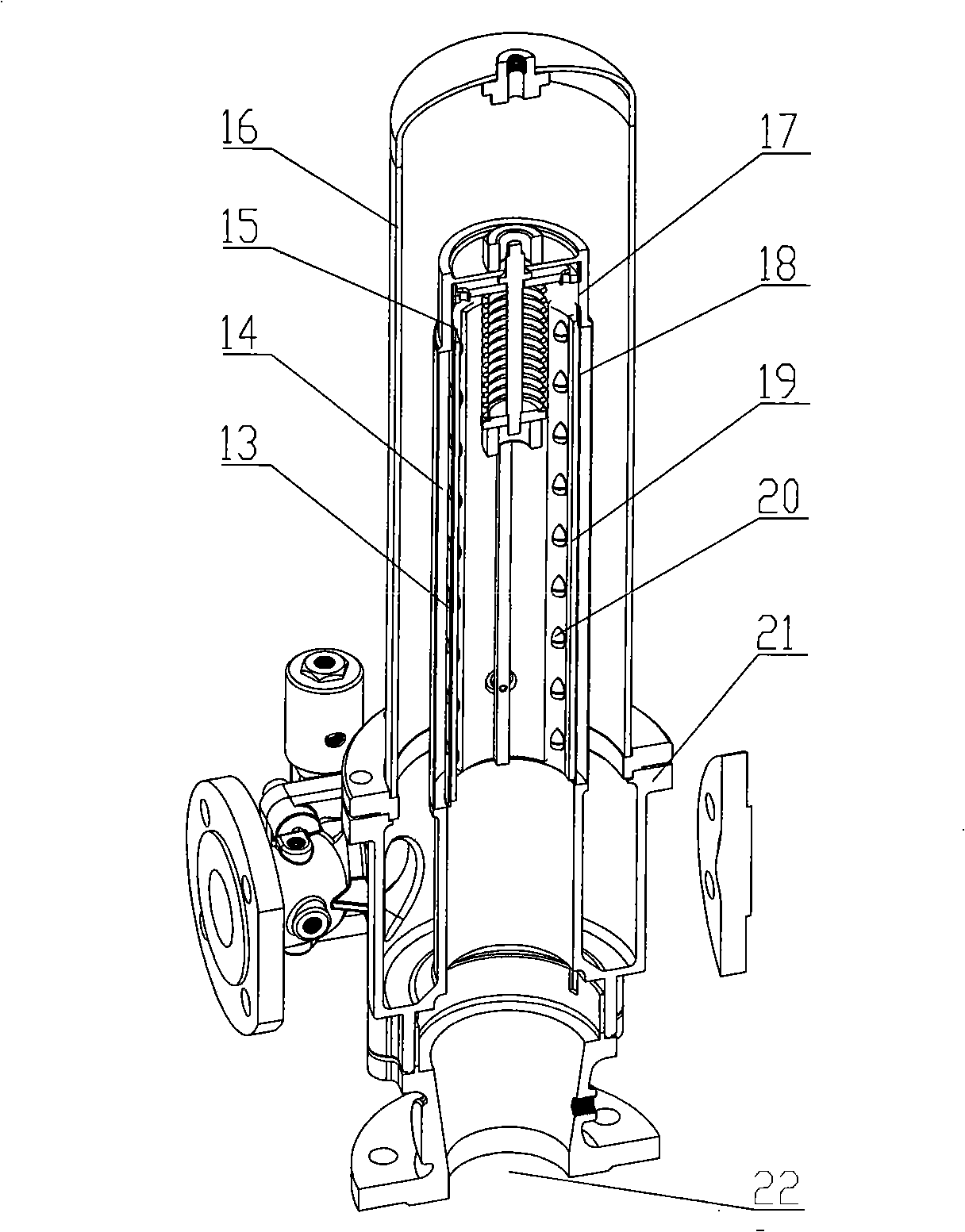

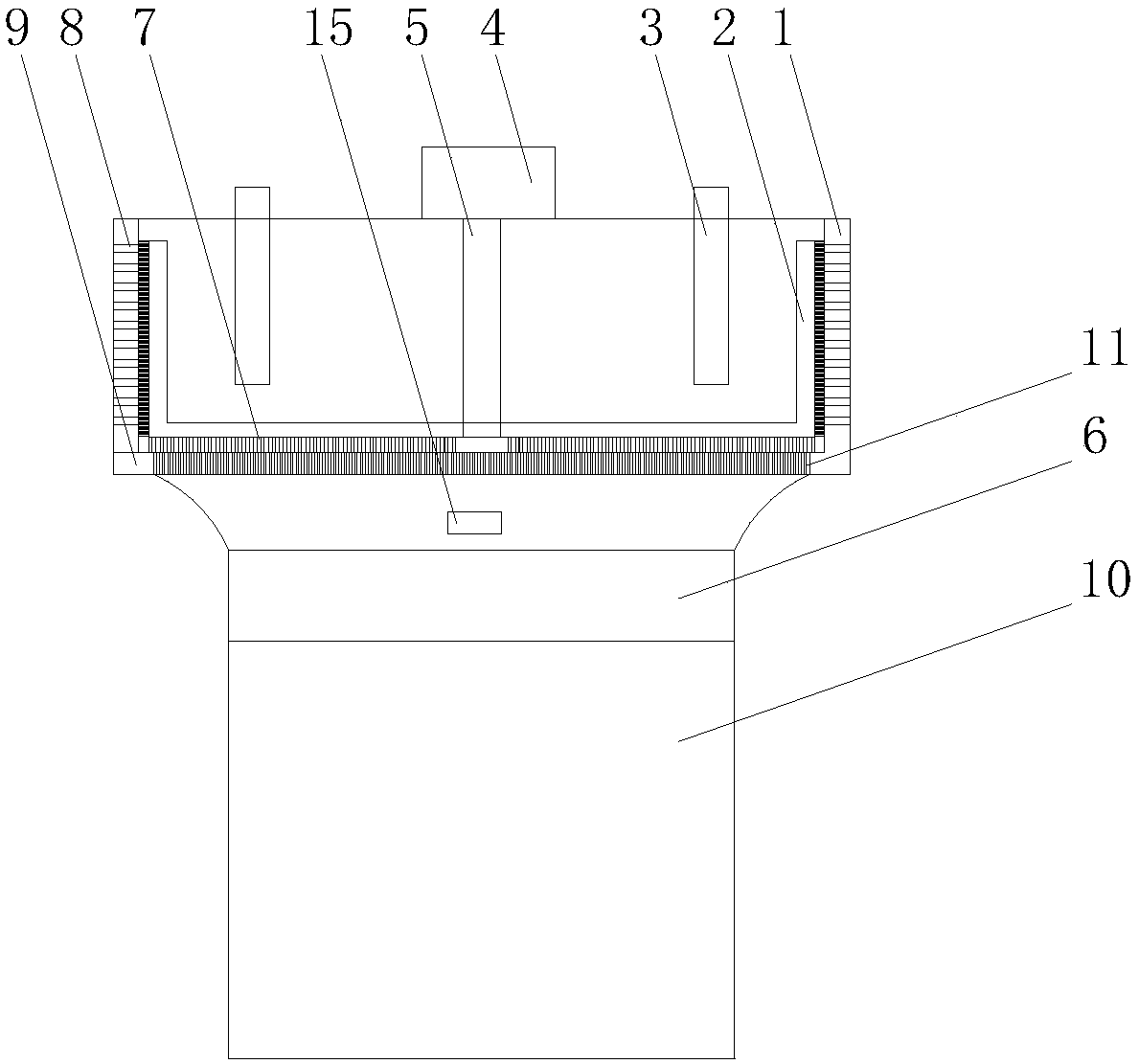

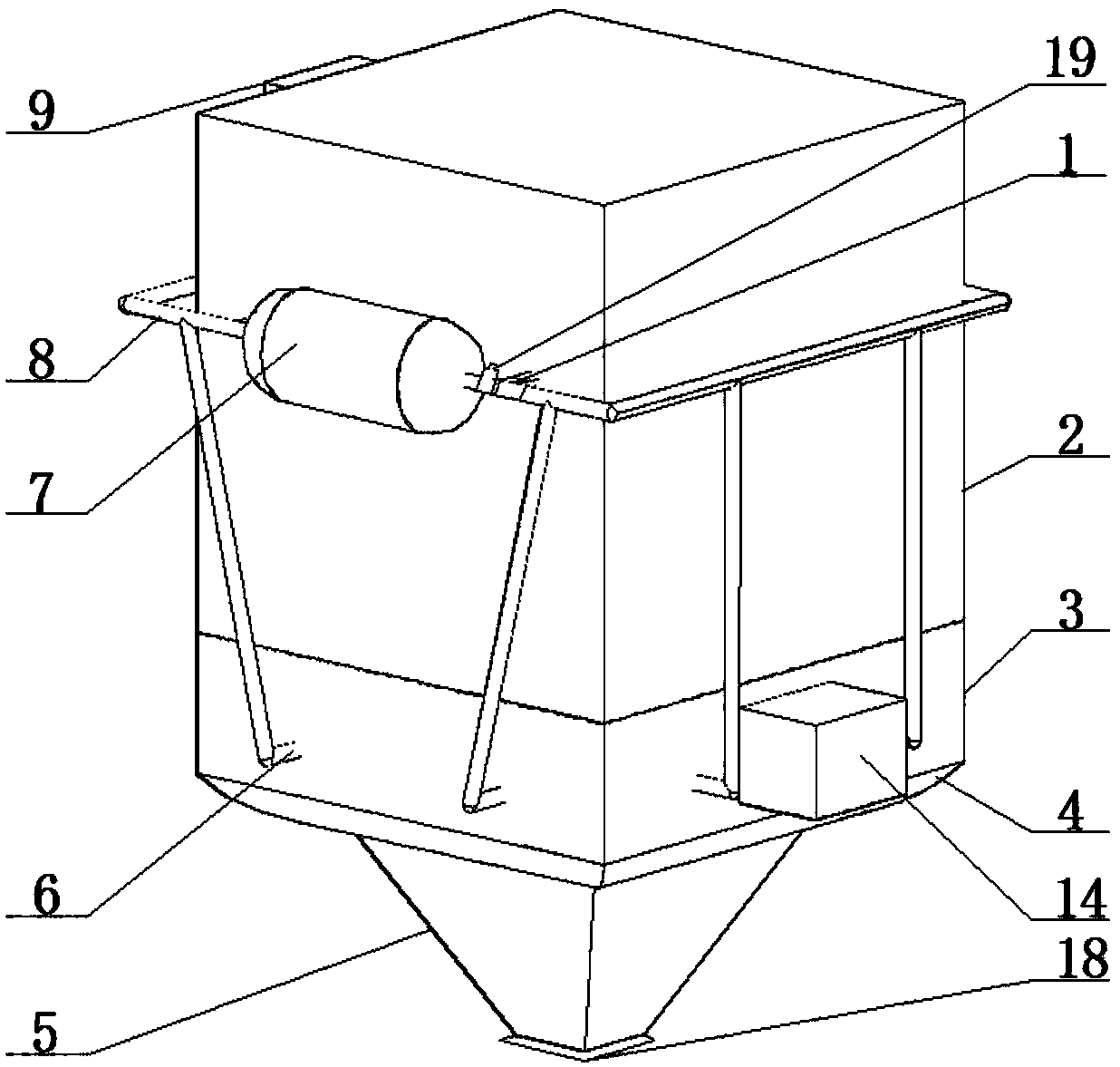

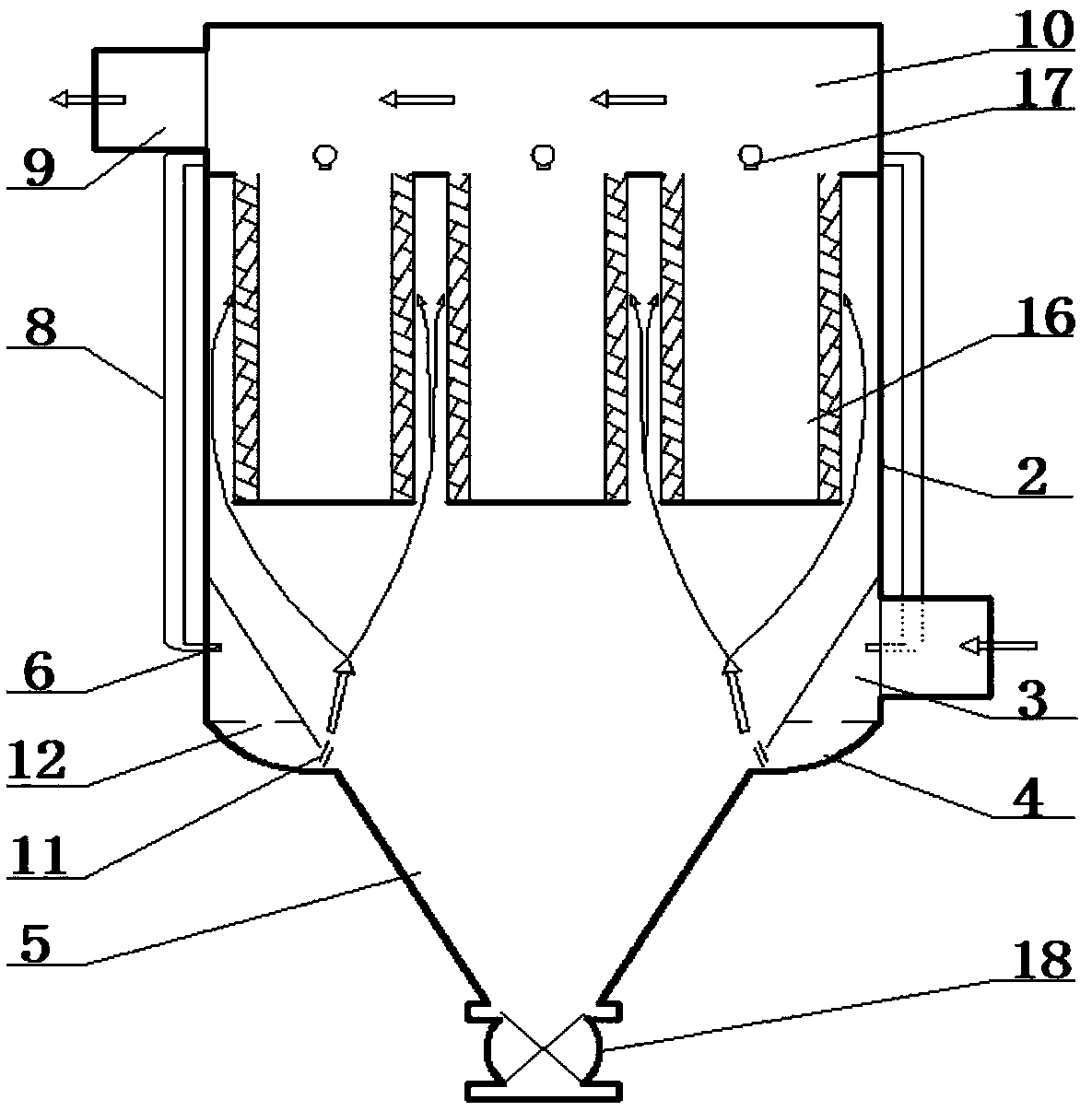

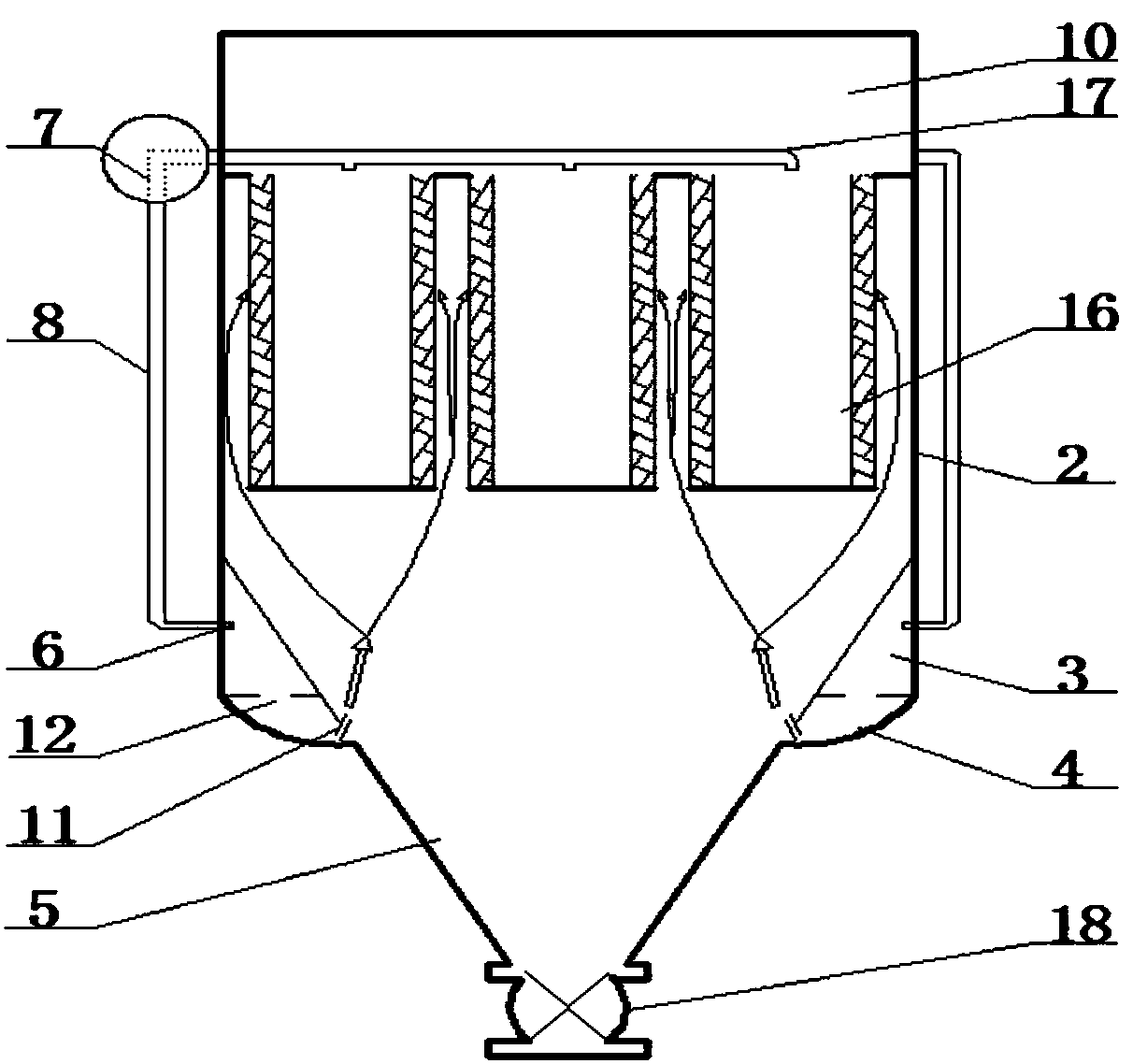

Granular-layer dust precipitator

InactiveCN101036846AReduce filter loadEven expansion and contractionDispersed particle filtrationThermal expansionEngineering

The invention discloses a particle bed filter dust-collector, comprising an outer shell and at least one layer filtering device arranged on the outer shell along height direction, wherein, the upper part of the outer shell is arranged with a dust inlet, and the lower part of the outer shell is arranged with a dust outlet, the filtering device is provided with a separate gas reversing device connected to a gas cleaning main pipe and a back-blowing gas main pipe, which is characterized in that the filtering device comprises at least one filtering unit, the filtering unit comprises an inner shell, on the inner shell are arranged an air port and an air pipe, and inside the inner shell are arranged a particle layer and a grid plate, wherein the air port is arranged above the particle layer, the air pipe is arranged below the particle layer, and the air pipe protruding from the outer shell in transverse direction is connected to the gas reversing device. The invention has the advantages that when filtering and removing dust, the inner shell is enclosed by hot air flow, thereby the every part of the inner shell has even flatulence due to heat and even shrinkage due to cold and is provided with good heat-deformation resistance performance, accordingly, the dust collector can be used in high temperature or temperature variation environment and has wide application range.

Owner:NINGBO UNIV

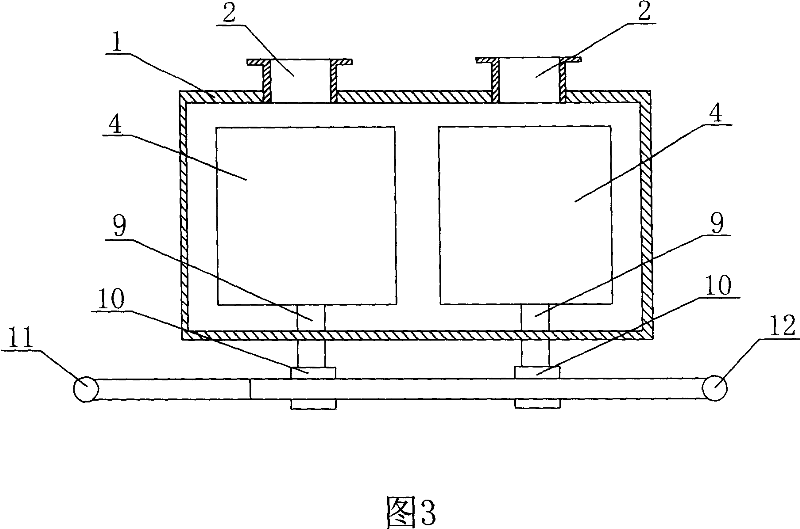

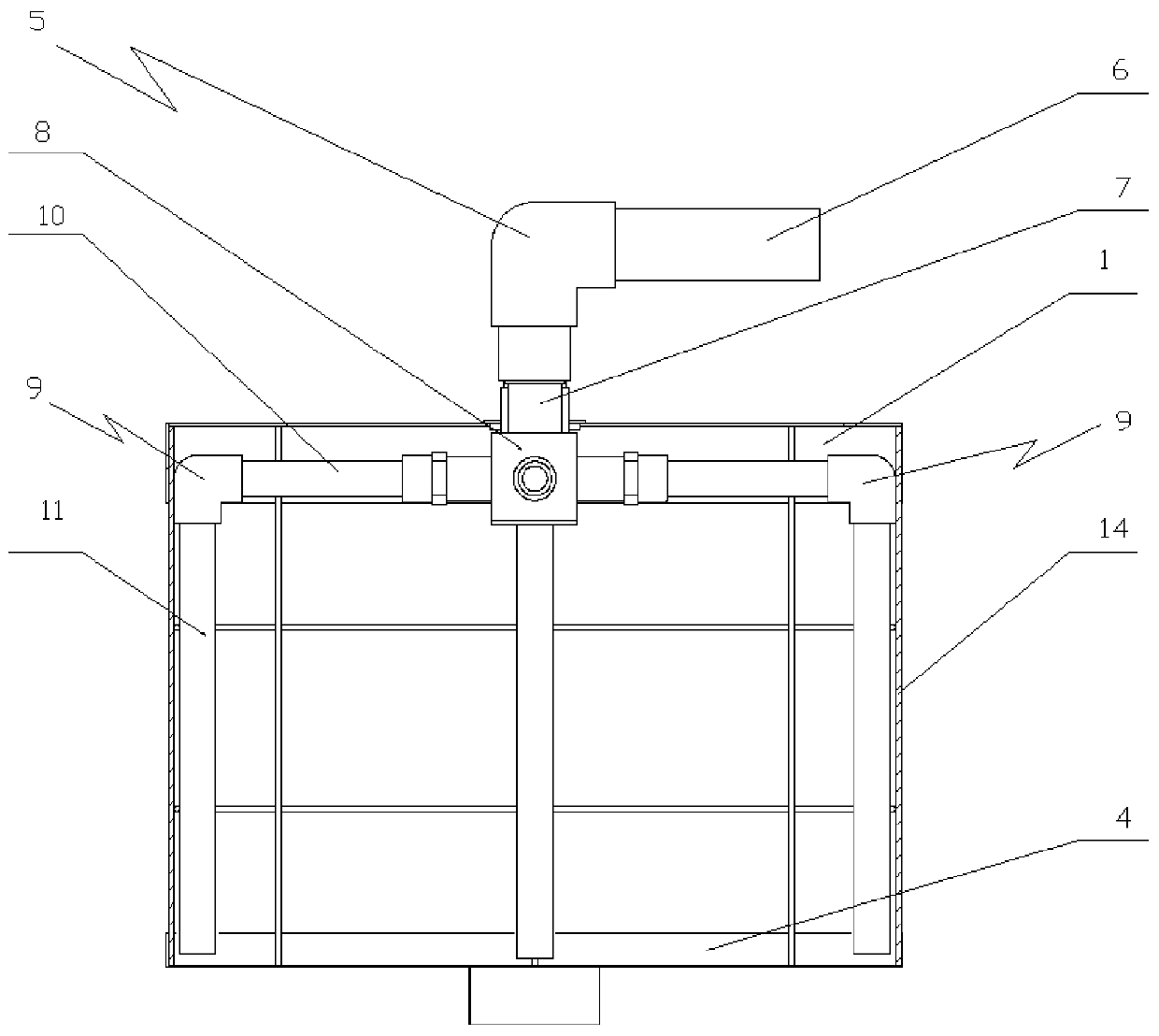

Turntable filter

InactiveCN103230697AUnattendedReduce filter loadMoving filtering element filtersAutomatic controlSprayer

The invention discloses a turntable filter which comprises a main framework, a core filtering system filtering net, a driving system, a backwash system and an automatic control system, wherein the main framework consists of a shell, a central water inlet pipe, a roller, a toothed gear, a rotating bearing, a central drum and a sealing piece; the driving system comprises a driving motor, a driving gear and a roller supporting wheel; and the backwash system comprises a reverse cleaning pump, a backwash sprayer, a flushing water pipe, a nozzle system, a sewage collecting groove and a blow-off line. Compared with the traditional process, the turntable filter has the advantages that the civil engineering such as a blowing room, a lifting pump room, a chlorination room, a clean-water reservoir and a settling pond are saved, the occupied area is small, and the occupied area of 10000-tonnage water is 15 square meters only and is only 1 / 7 to 1 / 6 of the area occupied by the traditional process, so that the maintenance and repair of the equipment are simple and convenient, the operating automation degree is quite high, special care is not required, and the labor intensity of workers and the maintenance cost are greatly reduced.

Owner:深圳市龙成科技有限公司

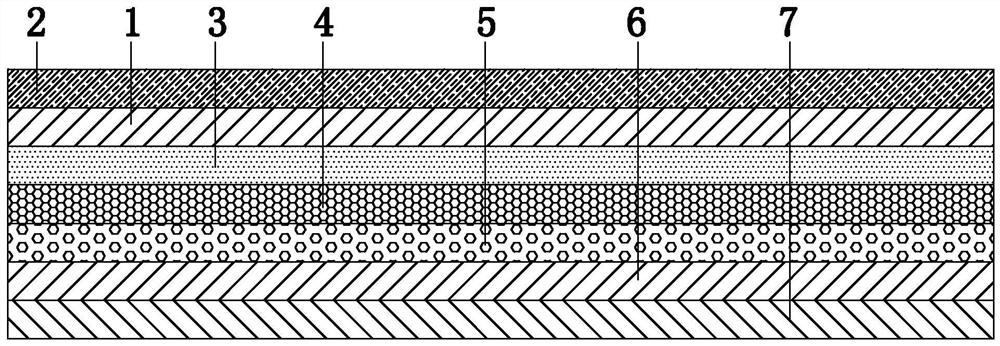

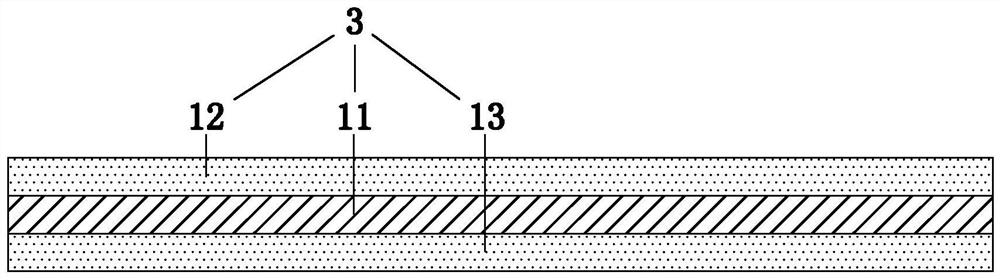

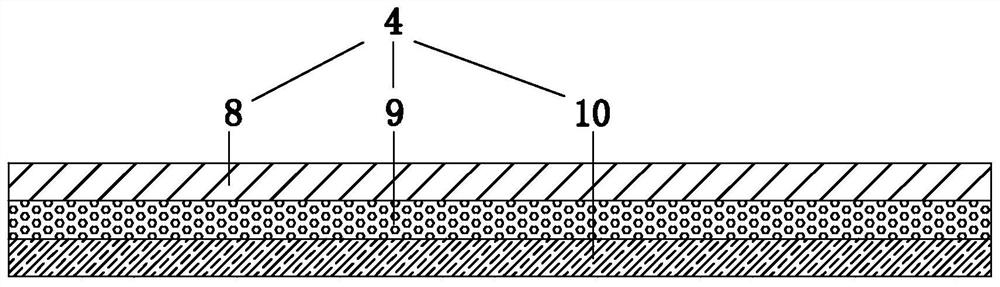

Non-woven fabric composite material for filter mask

PendingCN111775520AImprove antibacterial propertiesEffective waterproof protectionProtective equipmentSynthetic resin layered productsWoven fabric compositeNonwoven fabric

The invention discloses a non-woven fabric composite material for a filter mask. The material comprises an outer layer, a waterproof breathable layer is fixedly arranged on the outer layer; an antibacterial layer is fixedly arranged below the outer layer; wherein a filter layer is fixedly arranged below the antibacterial layer, an adsorption layer is fixedly arranged below the filter layer, an inner layer is fixedly arranged below the adsorption layer, a skin-friendly layer is fixedly arranged below the inner layer, the antibacterial layer comprises a built-in silver ion antibacterial fabric layer, and the built-in silver ion antibacterial fabric layer is coated with a porous nano titanium dioxide silver-loaded antibacterial agent coating. The composite material has the advantages that theantibacterial performance of the mask can be greatly improved, bacterium breeding is effectively prevented, the outer wall of the mask can be waterproof and breathable, inner side materials are effectively subjected to waterproof protection, a good adsorption effect is achieved, water vapor and peculiar smells on the inner side of the mask can be adsorbed, and the inner side of the mask can be kept dry.

Owner:福建省福杯满溢科技有限公司

Switching water production method for double-pump water purifier with discharged concentrated water recovery device

ActiveCN106565026ASimple structureHigh utilization rate of concentrated waterMultistage water/sewage treatmentNon-contaminated water treatmentFiltrationWater production

The invention discloses a switching water production method for a double-pump water purifier with a discharged concentrated water recovery device, and relates to the water treatment industry, in particular to filtration of drinking water. All front filter containers and a fine filter container with a water inlet, a water outlet and a concentrated water discharging outlet are sequentially connected in series in a filter channel, and a booster pump controlled by an electric control device is connected between the front filter containers and the fine filter container in series. The concentrated water discharging outlet of the fine filter container communicates with a concentrated water reservoir and is connected with the front filter channel through a return water pipeline. A return water pump in the return water pipeline is further included. The electric control device controls the return water pump to pump discharged concentrated water in the concentrated water reservoir in the water discharging process of the filter channel. A front filter channel control device is used for conveying water together with passing water in the front filter channel or supplying water with the passing water in the front filter channel alternately. When the discharged concentrated water in the concentrated water reservoir falls to a water level lower control limit, the electric control device controls the return water pump to be closed, and the front filter channel control device is turned to control the front filter channel to supply water.

Owner:杜也兵

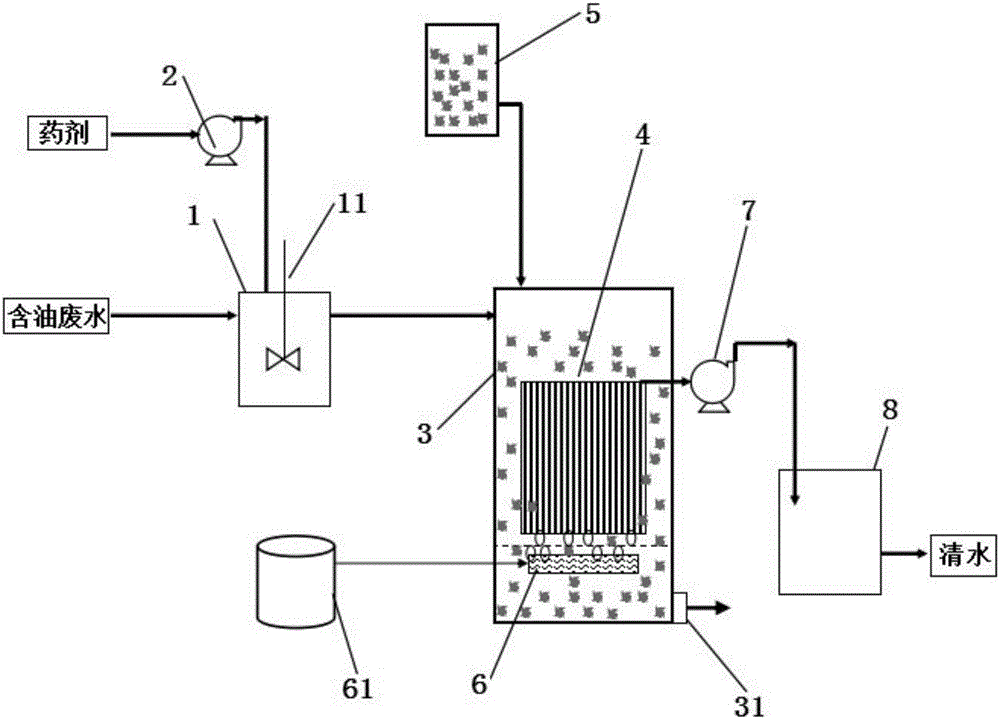

Oily wastewater treatment device and method

InactiveCN106630003AHigh temperature resistantWith acid and alkali corrosion resistanceFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisActivated carbonWater quality

The invention discloses an oily wastewater treatment device and method. The oily wastewater treatment device comprises a wastewater tank, a suction pump, a powdered activated carbon storage tank and a contact tank, wherein the contact tank comprises a tank body and a ceramic membrane module, the ceramic membrane module is installed in the tank body, the tank body is provided with a water inlet, a water outlet, a residue discharging port and a powder inlet, the wastewater tank is communicated with the water inlet, the suction pump is communicated with the water outlet, the residue discharging port is formed in the bottom of the tank body, and the powdered activated carbon storage tank is communicated with the powder inlet to add the powdered activated carbon to the tank body. The ceramic membrane module is a container structure formed by a ceramic membrane and provided with an outlet, the outlet is communicated with the water outlet, and the ceramic membrane is formed by integrally firing a supporting layer and an effective layer provided with pore channel. By the adoption of the oily wastewater treatment device and the method, the water quality requirement of reused wastewater of an oil field can be met, and the suspended matter content and oil content of output water and the median size of suspended matter can all meet the highest requirement for reinjected water of the oil yield.

Owner:深圳市康源环境纳米科技有限公司 +1

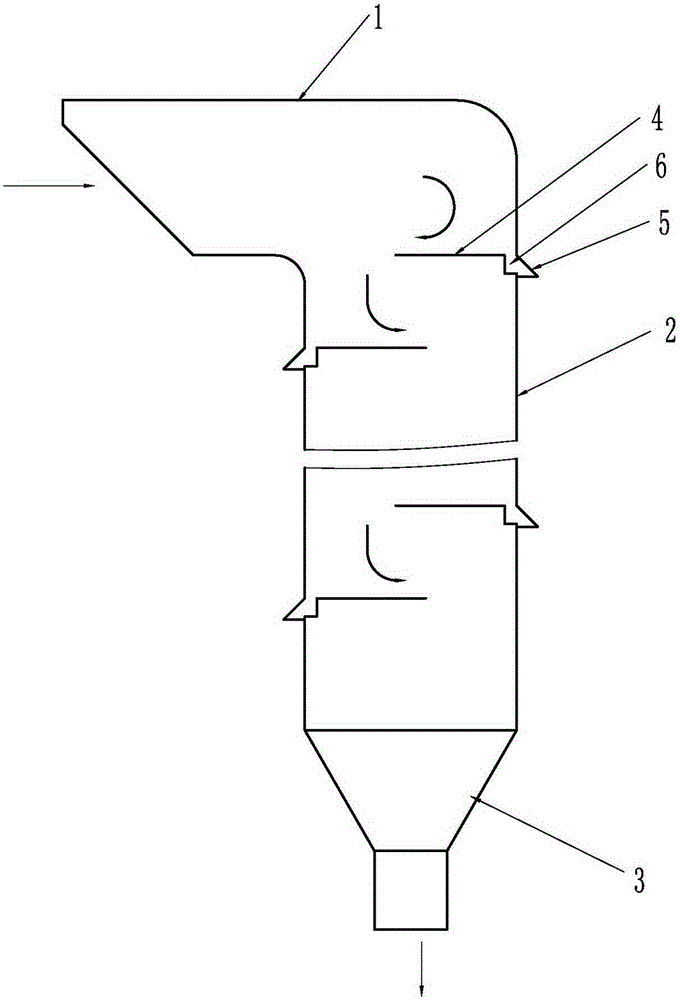

Cut-in multi-stage complex cyclone dust removal device

The invention discloses a cut-in multi-stage complex cyclone dust removal device which comprises a device body. The device body mainly comprises a flue gas inlet, gas outlets, an ash bucket and an ash outlet. A plurality of cyclone barrels are arranged at the inner bottom of the device body, and the rightmost cyclone barrel in a cyclone area is communicated with a pressurizing depression area through a pipeline. The top of the pressurizing depression area is provided with an electrostatic dust removal area in the device body, the pressurizing depression area and the electrostatic dust removal area are partitioned through a partition board which is provided with round openings, and abutting pressure plate is arranged above each round opening. A retractable device is fixedly connected to the lower surface of each abutting pressure plate and fixedly connected with the bottom of the pressurizing depression area. A plurality of electrostatic plates are arranged in the electrostatic dust removal area, a rotating shaft is vertically arranged in an adsorption area, and a plurality of adsorption wool yarns are fixedly connected to the rotating shaft by means of hot pressing. The cut-in multi-stage complex cyclone dust removal device is high in flue gas dust removal efficiency, staying time of flue gas in the device is long, and great dust removal effects are achieved.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

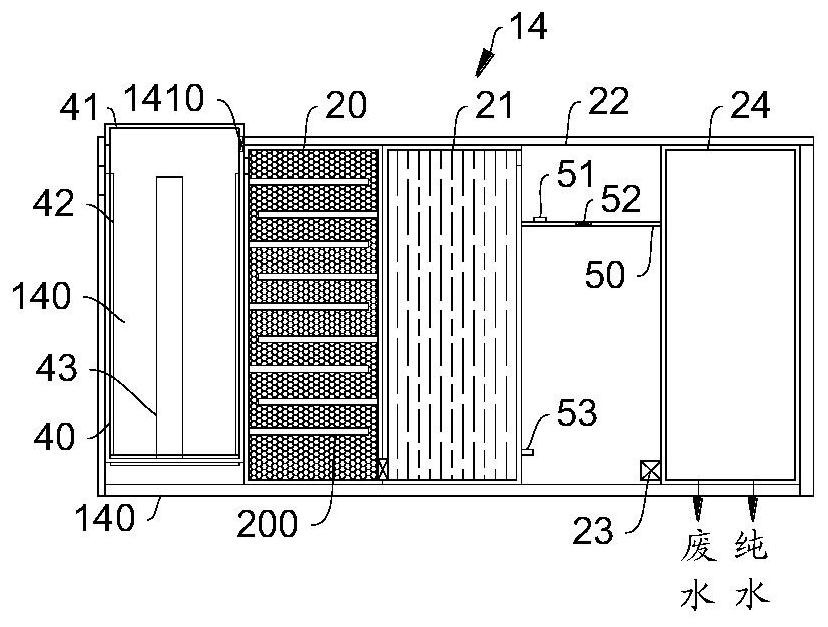

Replacing ventilation type haze-removing fresh air ventilator capable of switching fresh return air

InactiveCN106839185AAvoid self-circulationReduce heat and moisture processing energy consumptionMechanical apparatusSpace heating and ventilation safety systemsFiltrationFresh air

The invention discloses a replacing ventilation type haze-removing fresh air ventilator capable of switching fresh return air. The replacing ventilation type haze-removing fresh air ventilator capable of switching fresh return air comprises an internal machine and an external machine which are connected mutually; the internal machine is arranged in an air-conditioner room; a switchable air supply channel is adopted; air source can be selected autonomously according to the condition of the outdoor air; when the external air is in good condition, fresh air can serve as the air source; when the external air is in bad condition, the indoor return air is filtered to serve as the air source; a primary filter arranged in the internal machine performs primary filtration on volatile substances in the air and a PM2.5 efficient filter performs secondary filtration on the air, so that the purity of the air entering indoors is guaranteed; during layout design, an air return opening is formed in a ceiling and an air supply opening is formed in a floor, so that a replacing ventilation form from bottom to top is formed and self-circulation of vitiated air in the room is avoided.

Owner:NANTONG HUAXIN CENT AIR CONDITIONER +1

Filter

InactiveCN101352628AContinuously workingConstant pressureStationary filtering element filtersLine tubingFiltration

Owner:王克涛

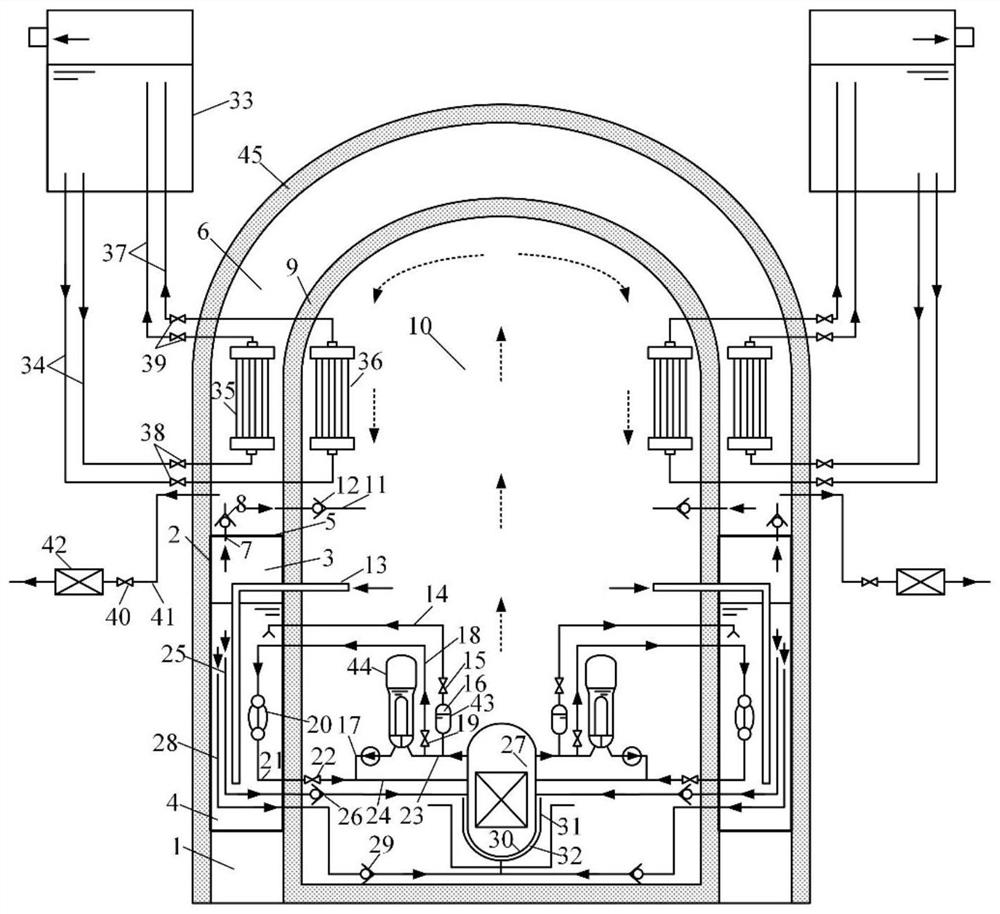

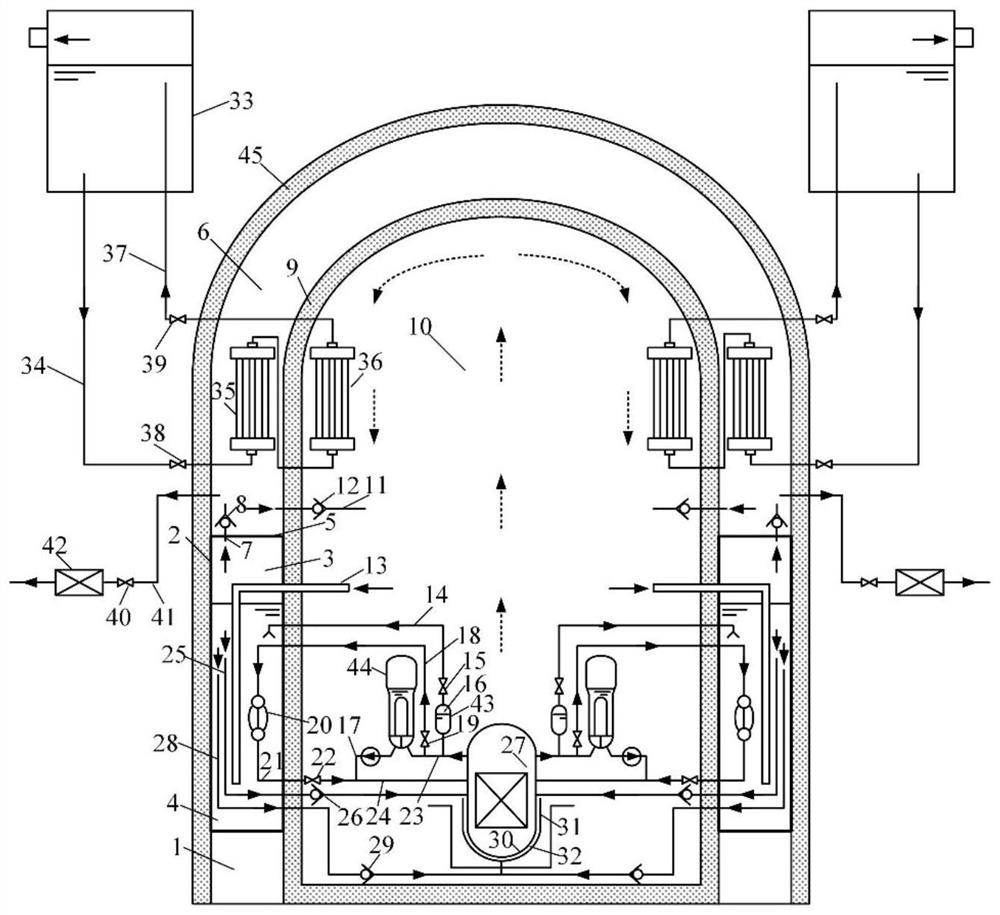

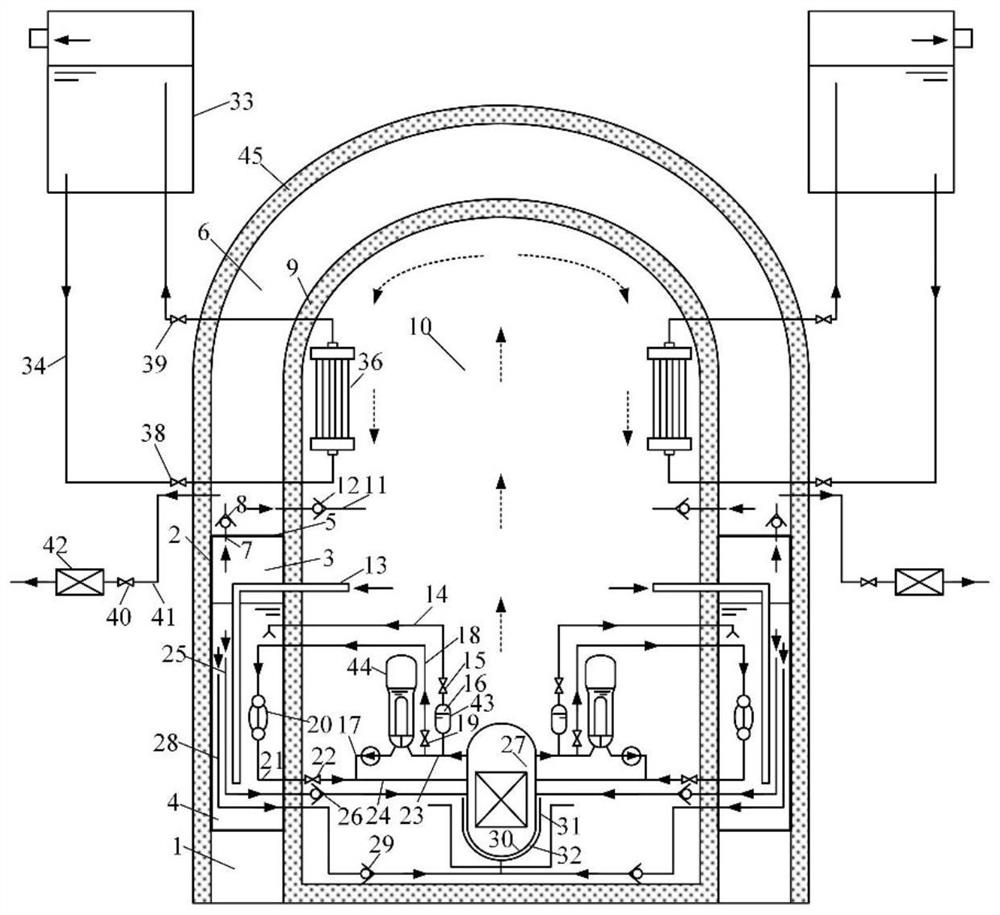

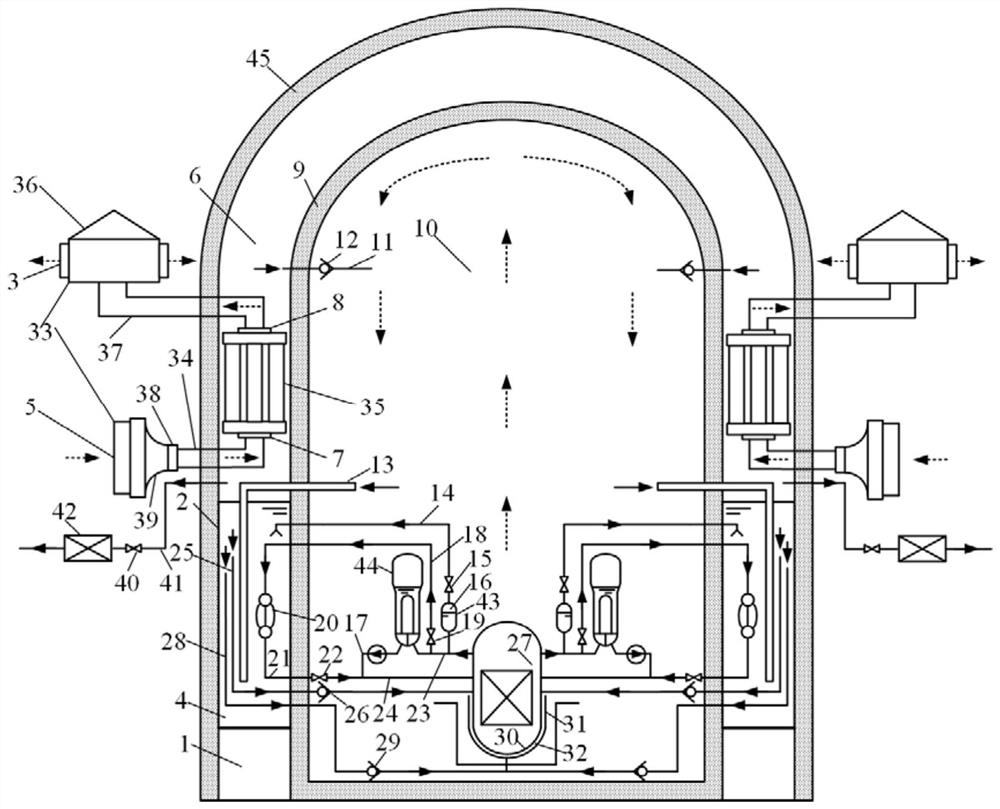

Passive combined heat removal system with integrated heat release trap

ActiveCN112071454ASystem layout is flexibleEnsure safetyNuclear energy generationCooling arrangementCorrosion resistantProcess engineering

The invention provides a passive combined heat removal system with an integrated heat release trap, which is characterized in that the integrated heat release trap is arranged at the middle lower partof a double-layer coagulation containment sandwich gas space, and is an annular water tank defined by a corrosion-resistant metal plate; at least one group of pipelines and one-way valves for communicating the integrated heat release trap with the internal gas space of the containment vessel are arranged on the top wall surface of the integrated heat release trap; and the integrated heat releasetrap is connected with a containment vessel quick pressure relief system, an automatic pressure relief system, a passive residual heat removal system, a passive low-pressure safety injection system, apassive reactor cavity water injection system and a filtering and discharging system. The arrangement of a reactor system of a nuclear power plant is simplified, the size of the containment is reduced, and a feasible scheme is provided for improving the economy and passive safety of an advanced nuclear power plant.

Owner:HARBIN ENG UNIV

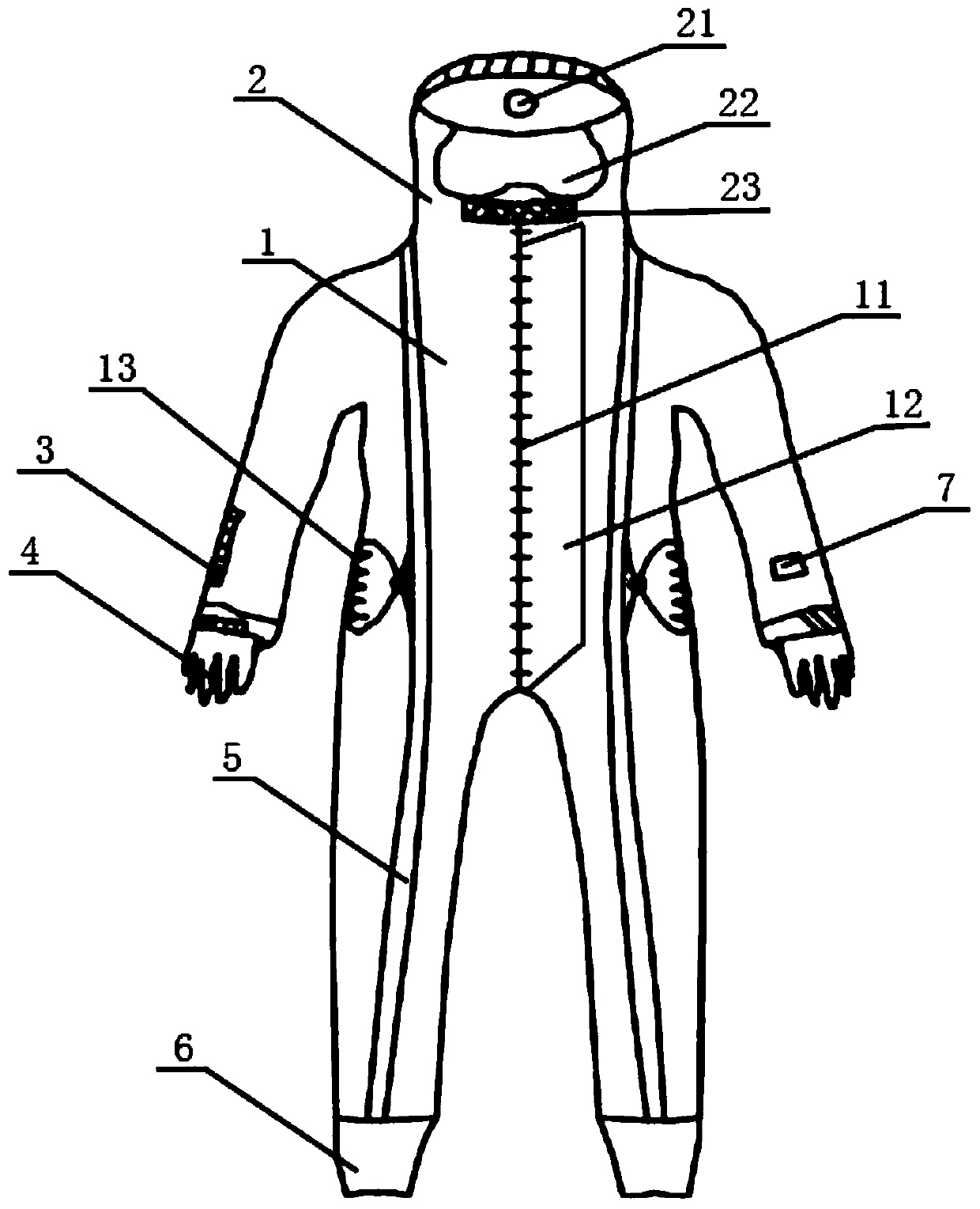

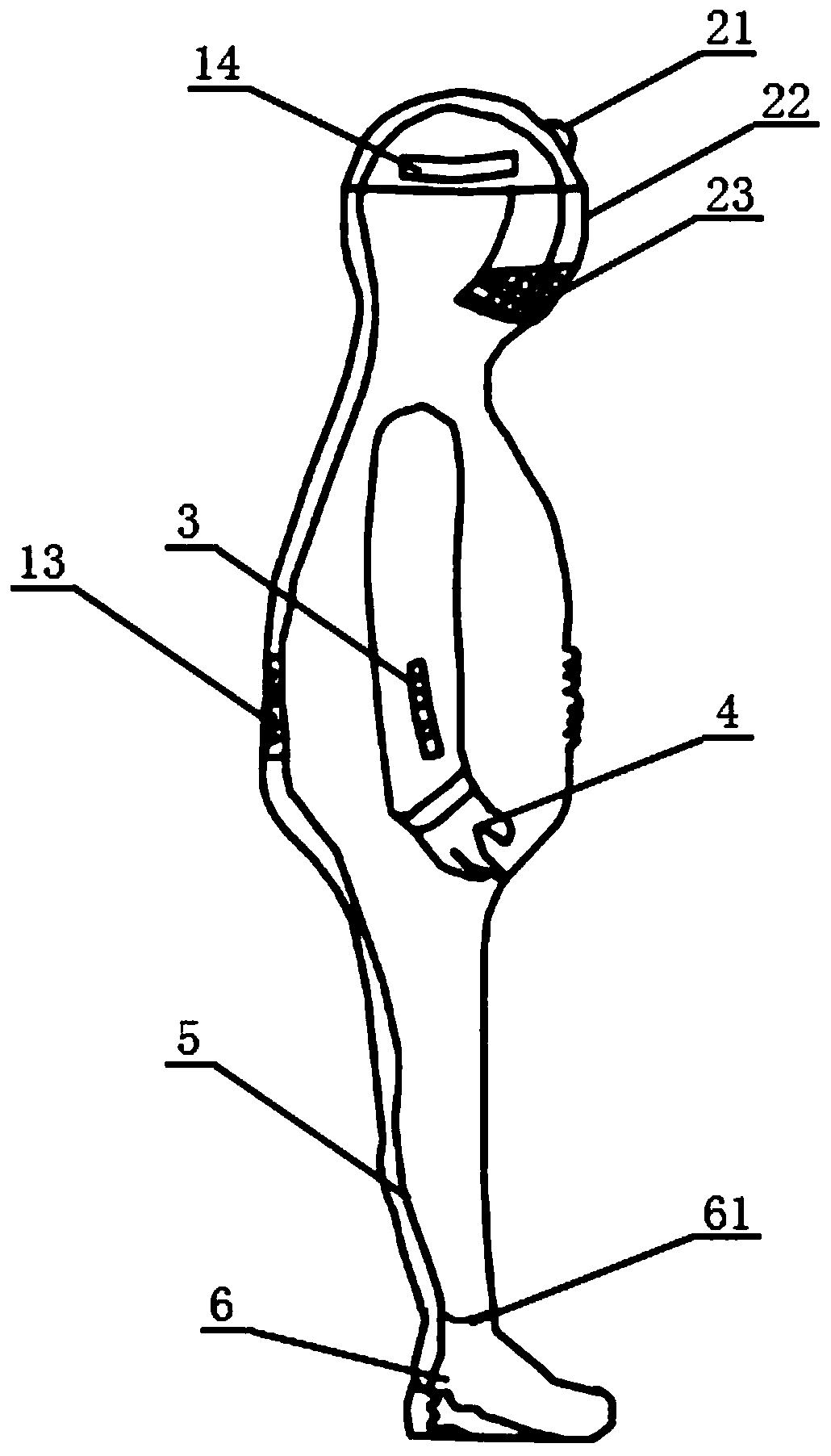

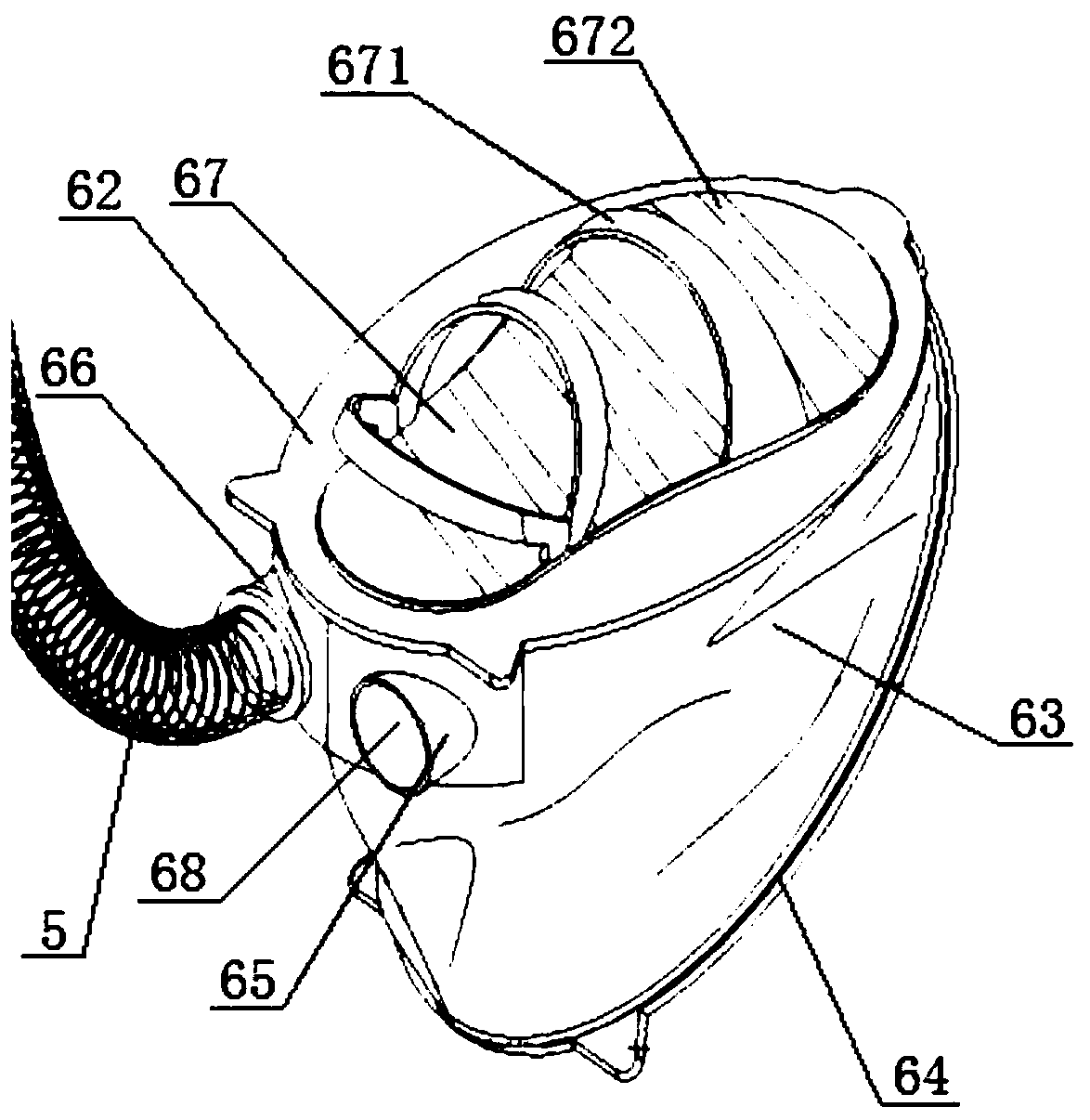

High-temperature-resistant air breathing clothing

PendingCN110721419AGuaranteed tightnessEasy to breatheChemical protectionHeat protectionInfrared thermometryGps navigation

The invention relates to high-temperature-resistant air breathing clothing. The high-temperature-resistant air breathing clothing comprises integrated heat-isolation clothing, wherein the integrated heat-isolation clothing comprises a protective coat and protective trousers, and protective sleeves are arranged at the two sides of the protective coat; a head ventilation face mask is connected withthe protective coat, protective gloves are connected with the protective sleeves, and a pedaled air supply device is connected with the protective trousers; an illumination lamp, a view window and a protective mouth mask are arranged on the head ventilation face mask; the pedaled air supply device comprises a top plate and a bottom plate which are hinged, the interiors of the top plate and the bottom plate are connected through a return spring, the peripheries are hermetically connected through a flame-retardant fabric layer structure, an air exhaust port and an air outlet port are formed in the flame-retardant fabric layer structure, and the air outlet port is connected with the protective mouth mask through an air supply hose; a pedal is arranged on the top plate, and a belt is arrangedon the pedal; and a GPS navigation locator and an infrared thermometer are arranged on the protective sleeves. The high-temperature-resistant air breathing clothing is capable of effectively solving the problems that an existing respirator adopts a closed cycle, and is high in operation difficulty, short in protective time, liable to be saturated, and high in pertinence to environment.

Owner:NANJING TECH UNIV

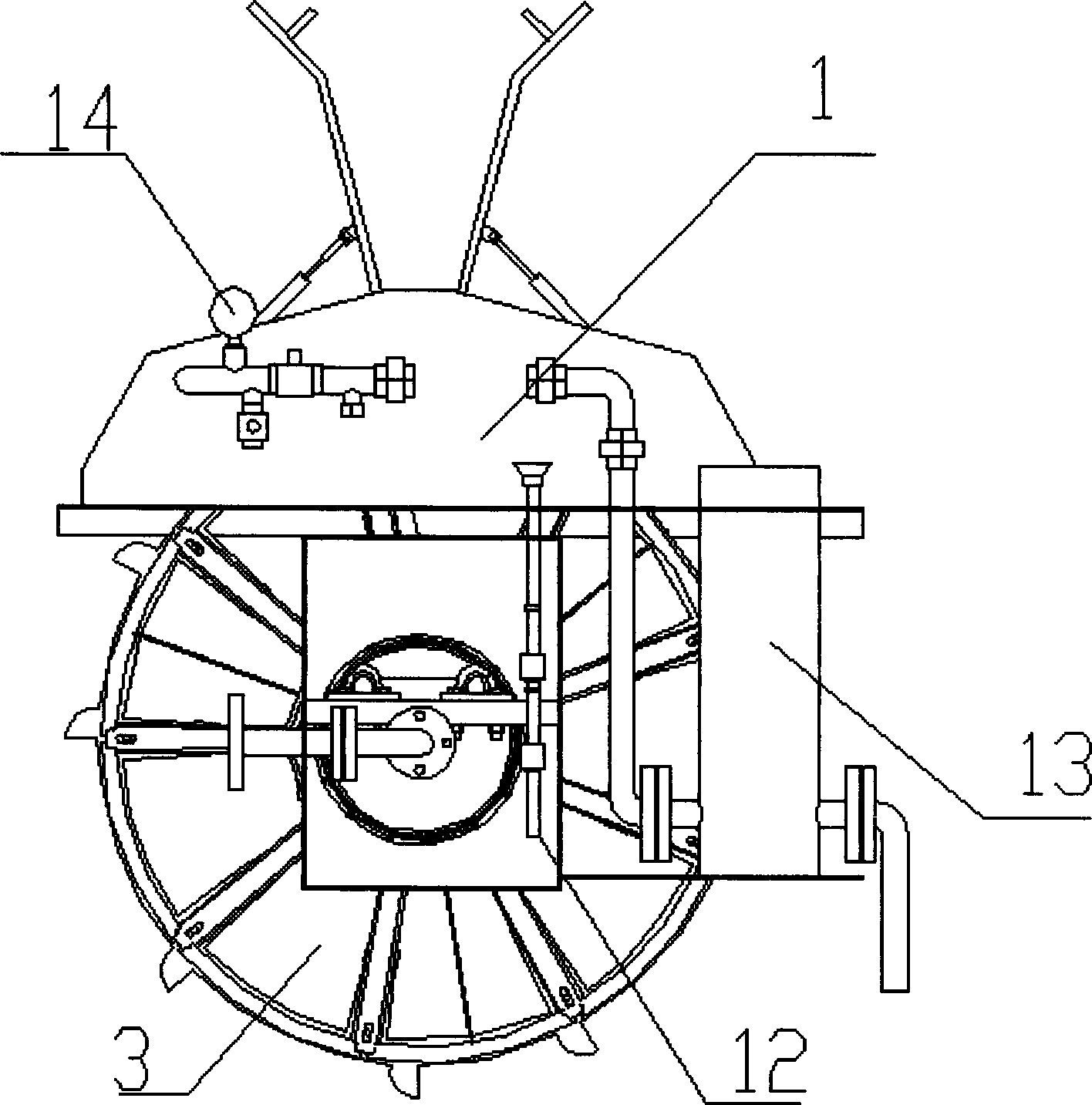

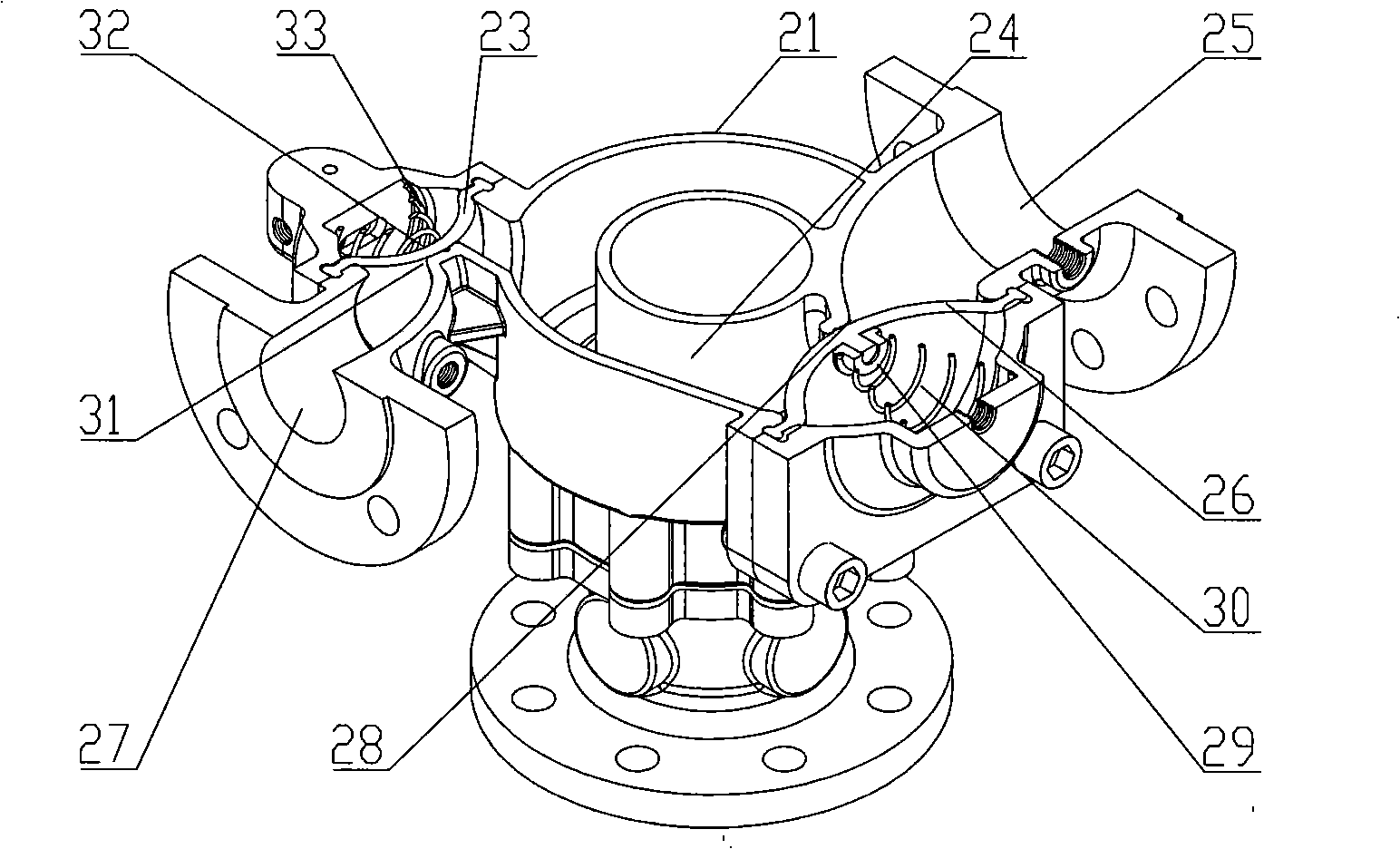

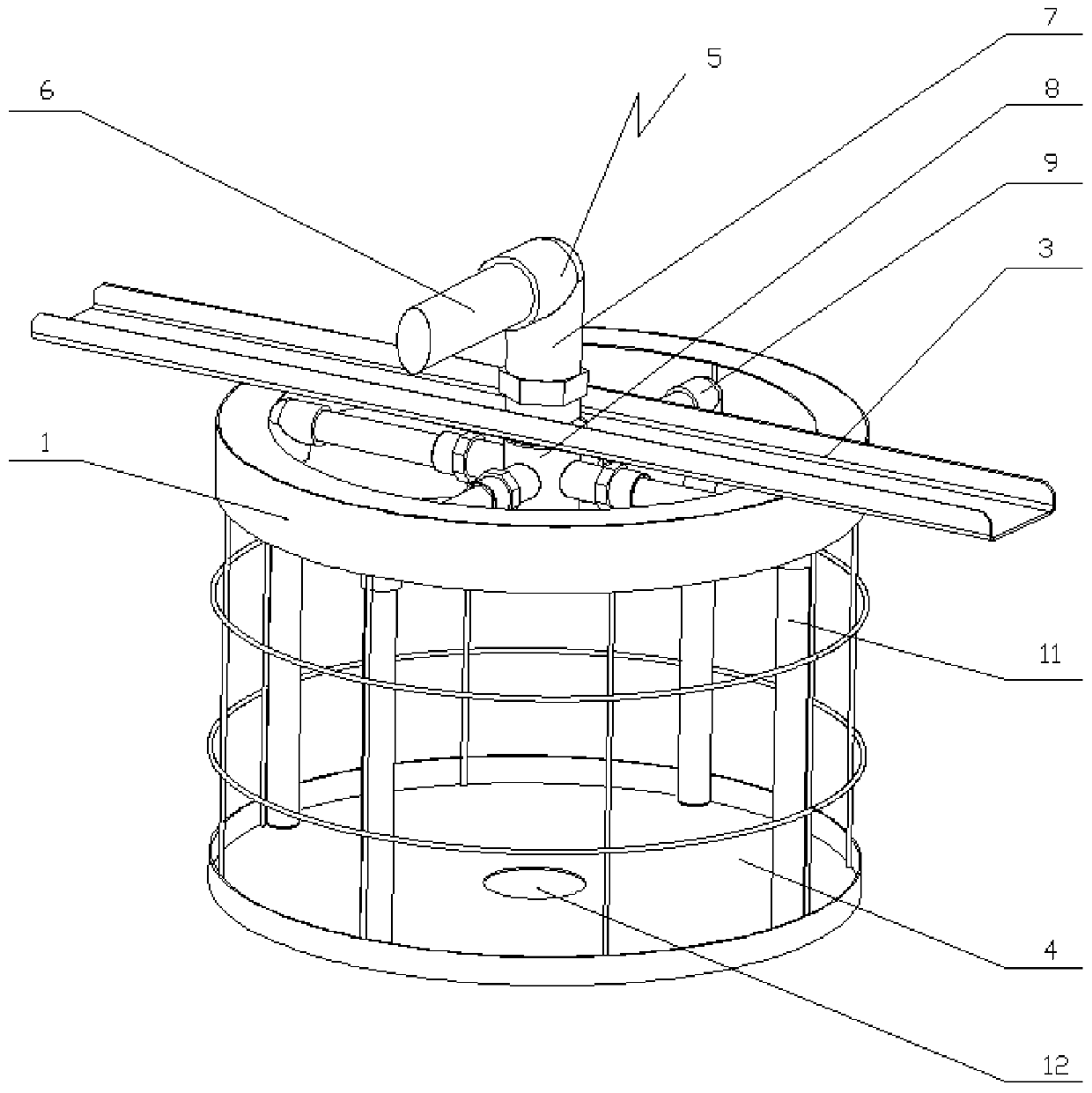

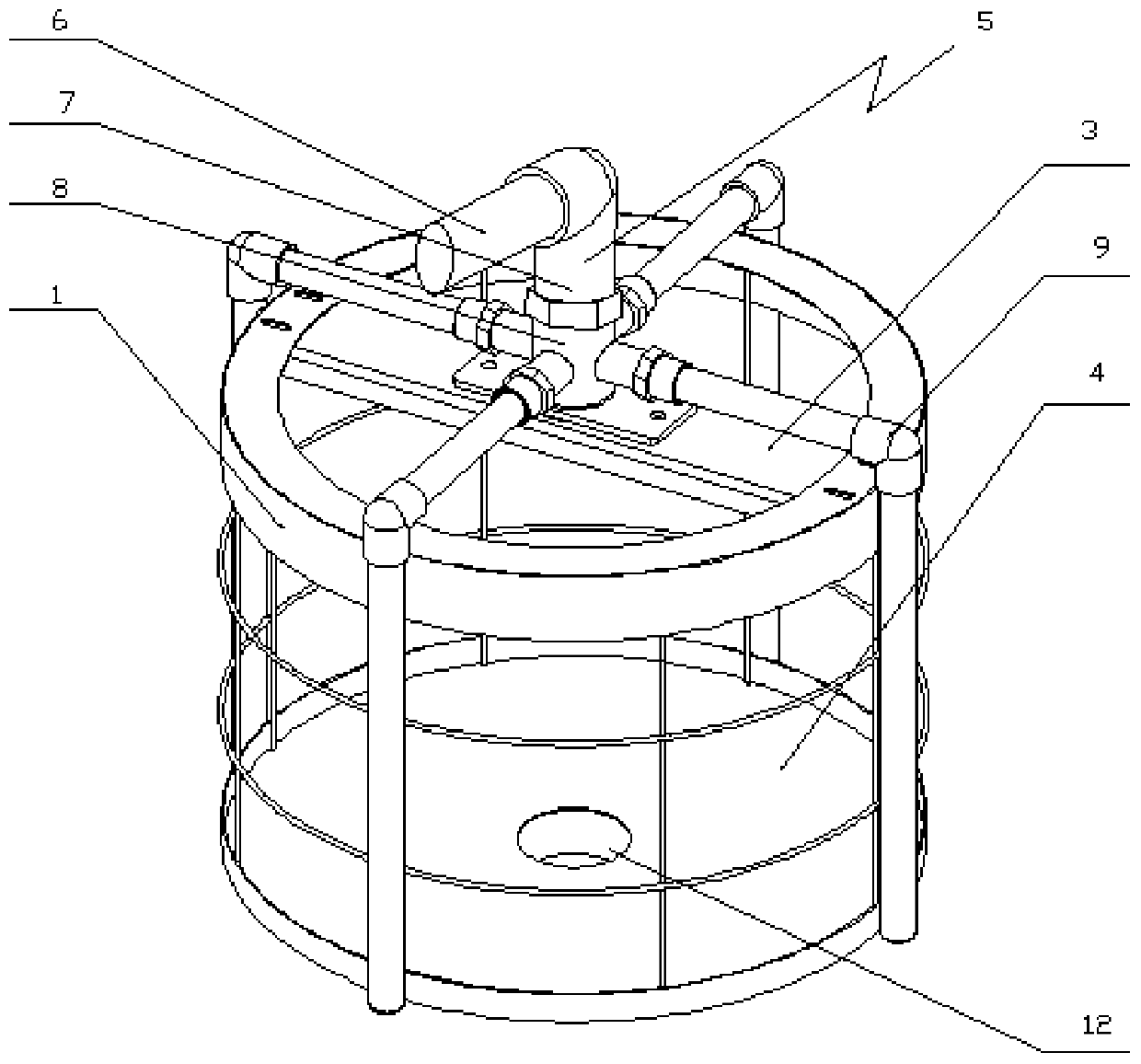

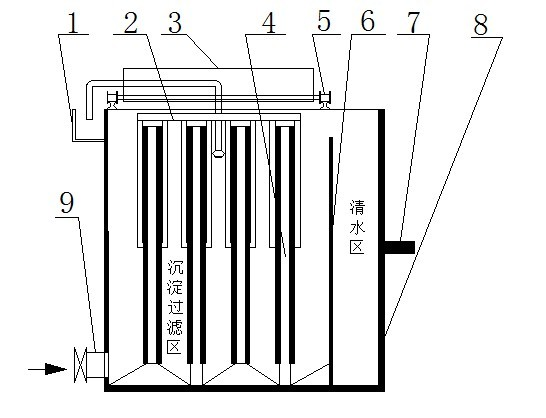

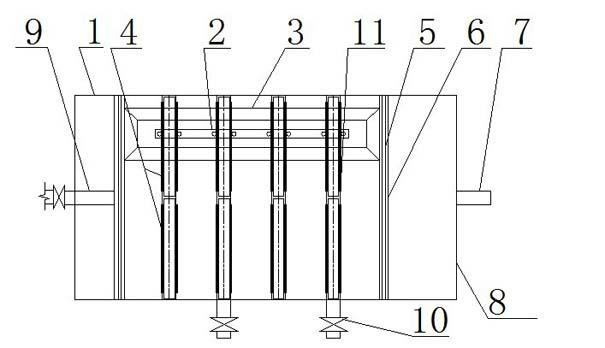

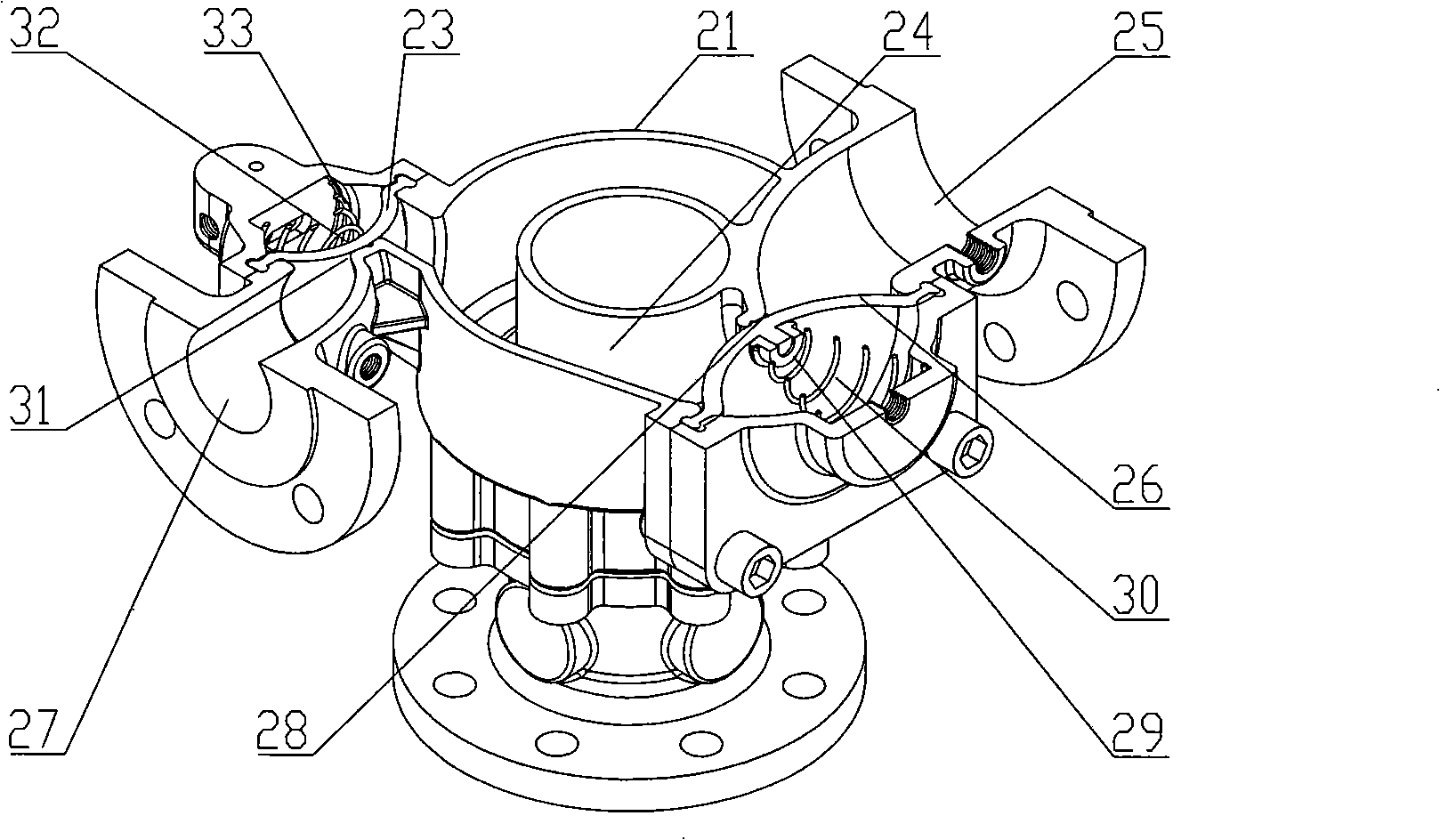

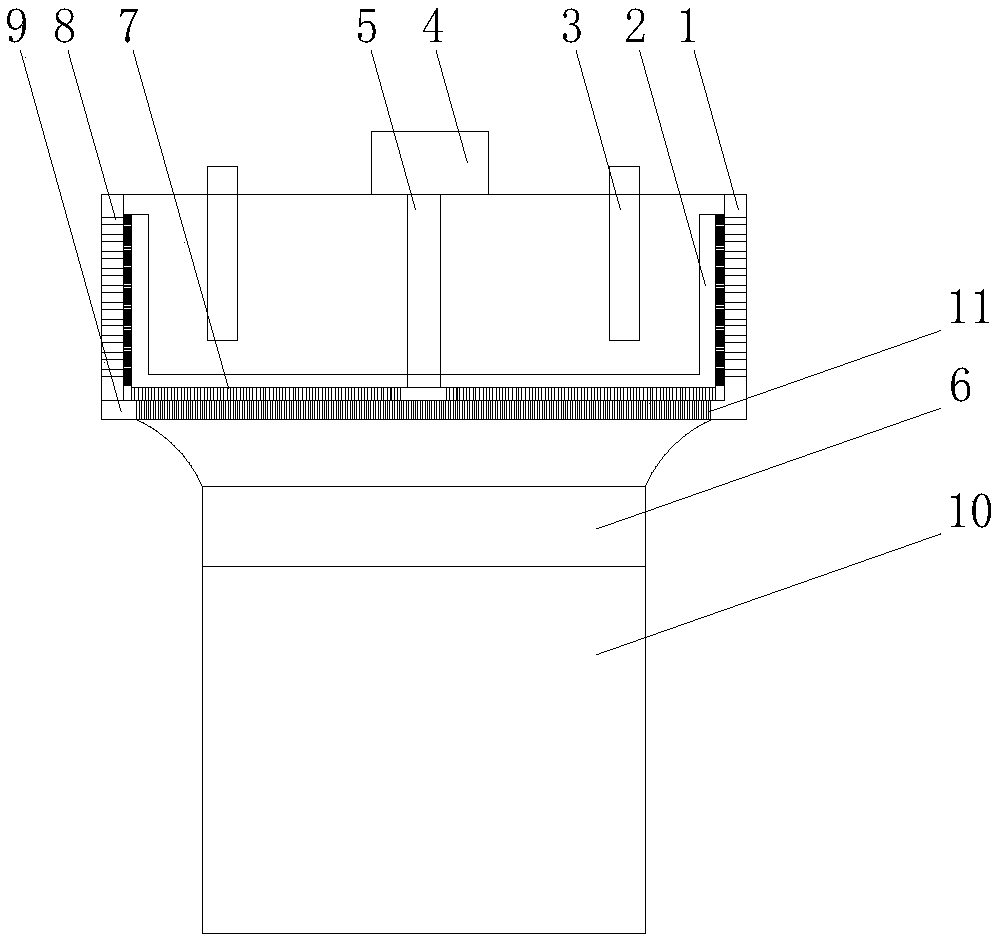

Microfiltration machine with backwashing device, and microfiltration and precipitation integration machine

PendingCN110201444ALarge filter areaSmall footprintFiltration circuitsStationary filtering element filtersWater pipePrecipitation

The invention discloses a microfiltration machine with a backwashing device. The microfiltration machine comprises a filter screen support frame with a filter screen, and the backwashing device, the backwashing device comprises a backwashing water inlet pipe and at least two backwashing water outlet pipes, the water outlet of the backwashing water inlet pipe is communicated with the upper ends ofthe backwashing water outlet pipes, the lower ends of the backwashing water outlet pipes are distributed along the circumference of the filter screen support frame, the filter screen is vertically arranged, and a rotating mechanism capable of automatically rotating the lower ends of the backwashing water outlet pipes around the filter screen support frame is provided between the backwashing wateroutlet pipes and the backwashing water inlet pipe. The microfiltration machine with the backwashing device has the advantages of low control system requirements, good filtering effect, good backwashing effect, and no influences on normal running. The invention also discloses a microfiltration and precipitation integration machine.

Owner:GUANGDONG ISUNGREEN TECH CO LTD

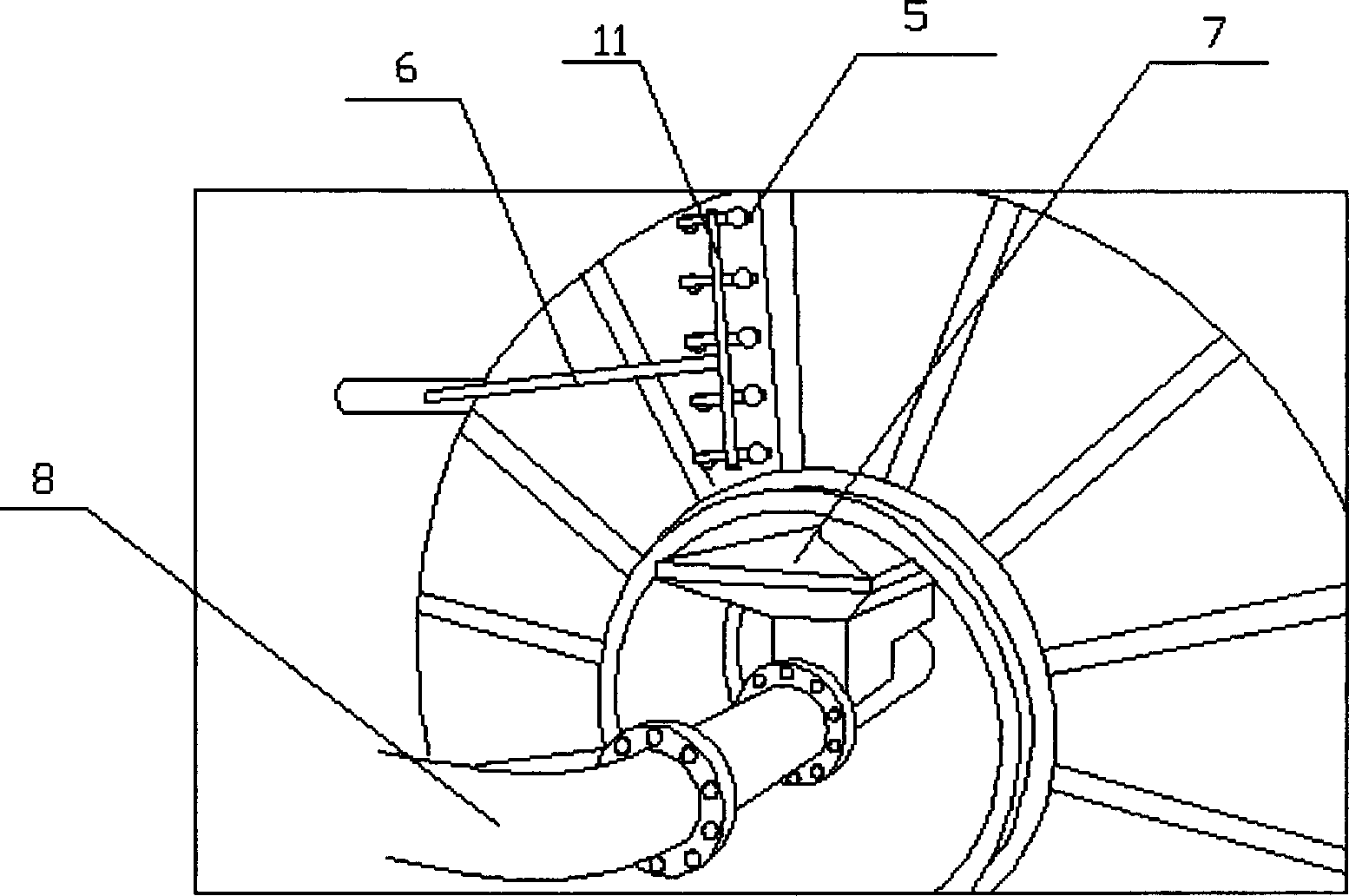

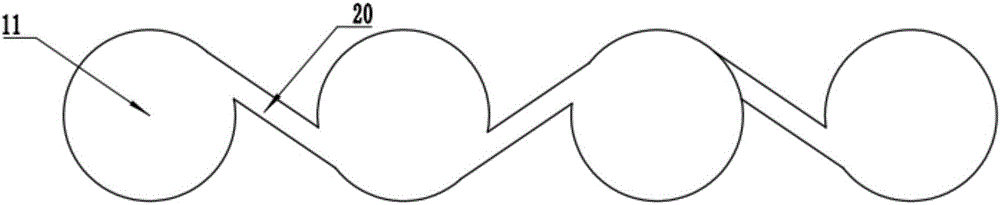

Circling type inlet air pre-filtering device

InactiveCN106555720AReduce filter loadReduce labor intensityMachines/enginesAir cleaners for fuelInlet channelAir filter

The invention provides a circling type inlet air pre-filtering device. The circling type inlet air pre-filtering device comprises an air inlet pipe. The air inlet pipe is formed by integrally connecting a transverse air inlet pipe body, a vertical air inlet pipe body and the installation end of an air filter. A plurality of baffles are arranged in the vertical air inlet pipe body at certain intervals in a mutually staggered manner in the vertical direction, so that a circling type air inlet channel is formed in the vertical air inlet pipe. A dust collecting disk is arranged on the outer wall of the vertical air inlet pipe body, and the dust collecting disk communicates with the bottoms of the baffles in the vertical air inlet pipe bodies. According to the circling type inlet air pre-filtering device, the circling type air inlet and dust removing idea is introduced to an external air inlet pipe path of the air filter, the pre-filtering effect is enhanced, the filtering load of the air filter is reduced, the maintenance period of a filter element of the air filter is prolonged, the filter element maintenance labor intensity of a driver is lowered, and the circling type inlet air pre-filtering device has relatively good economic applicability.

Owner:湖北申龙进气系统有限公司

Efficient de-dusting gas box type bag dust collector

The invention discloses an efficient de-dusting gas box type bag dust collector and belongs to the technical field of industrial de-dusting equipment. The efficient de-dusting gas box type bag dust collector comprises a box body and an ash bucket, wherein an air inlet pipe is arranged on the ash bucket; a centrifugal sedimentation device is arranged in the ash bucket and comprises an outer drum and an inner drum which are coaxially mounted; the axes of the outer drum and the inner drum are overlapped with the axis of the box body; the upper end of the outer drum is closed while the lower end of the outer drum is open; an air outlet is formed on the upper part of the side wall of the outer drum; the air inlet pipe passes through the upper end of the outer drum and is connected with the upper end of the inner drum; through holes are uniformly distributed in the circumferential wall of the inner drum; a centrifugal fan is arranged at the bottom of the inner drum; the lower end of the inner drum is higher than the lower end of the outer drum.

Owner:安徽续动环保科技有限公司

Rotary fabric filter

InactiveCN102657977AReduce lossesAvoid easy cloggingLoose filtering material filtersGravity filtersLight filterSystem configuration

The invention belongs to the technical field of water treatment, and particularly relates to a rotary fabric filter. The rotary fabric filter comprises a water outlet, a shell, a water outlet weir, a separating plate, guide tracks, vent nozzles, a trolley, a backwash component, filter material components, a water header, a water inlet and a sludge tank, wherein the water inlet, the water outlet and the vent nozzles are respectively disposed on the lower side of the shell, the platy filter material components are vertically mounted in the shell, the trolley is positioned on the trolley guide tracks on the top of the shell and can move on the trolley, a dredge pump is fixed to the lower side of the trolley, one end of each dredging tube is positioned on the corresponding side of the corresponding platy filter material component, the other end of each dredging tube is connected with the dredge pump by a dredge header, and a dredging inclined plate with a certain gradient is arranged at the bottom of the shell. As the rotary fabric filter is provided with light filter materials and is operated without a valve, the rotary fabric filter has the advantages of large filter area, low filter load, backwashing water consumption and energy consumption, flexibility in system configuration, small occupied area, simplicity in running and maintenance, high automation degree and the like, and has higher purification efficiency when used with conventional water treatment technology.

Owner:上海安鼎济水处理科技有限公司

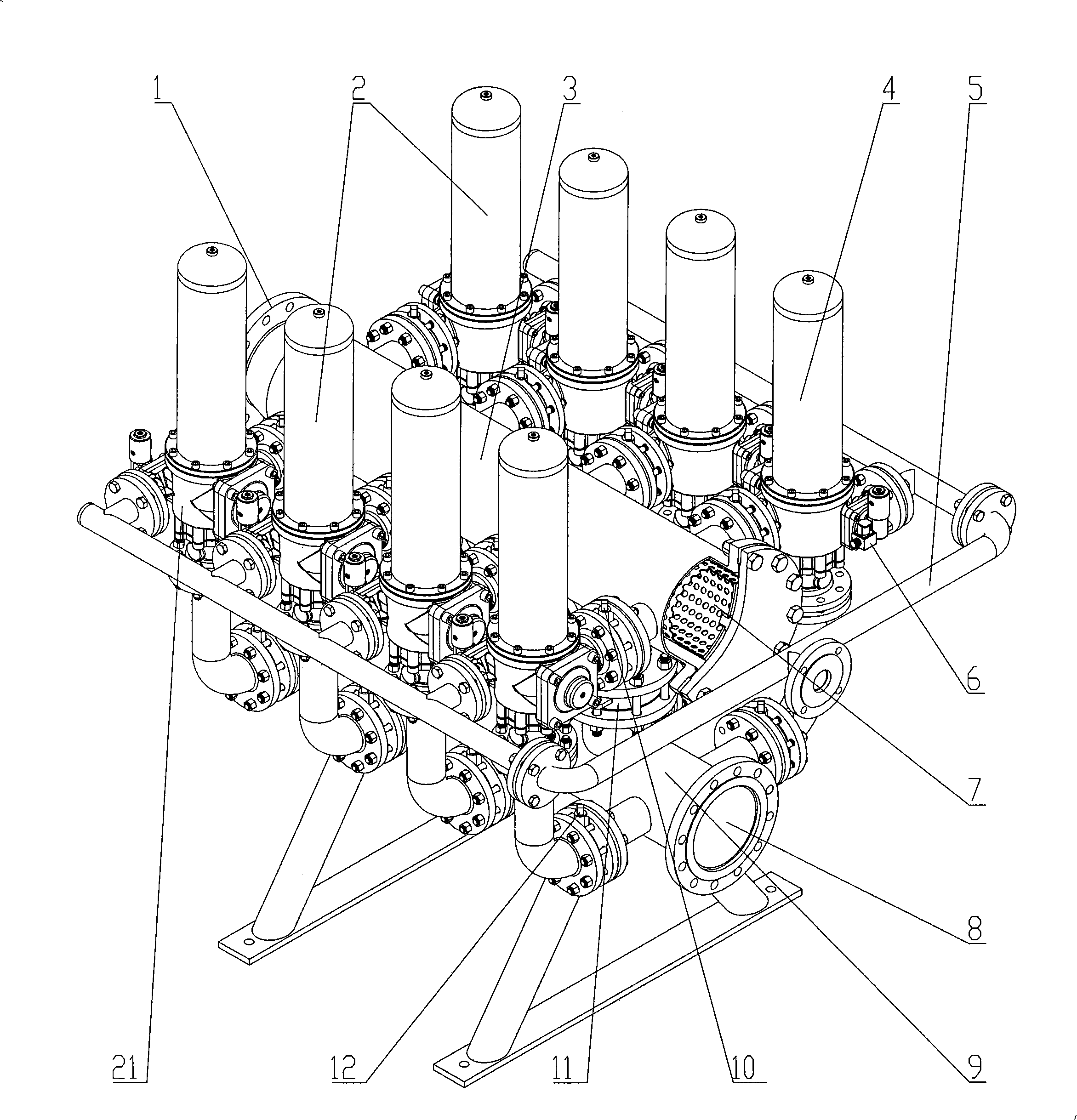

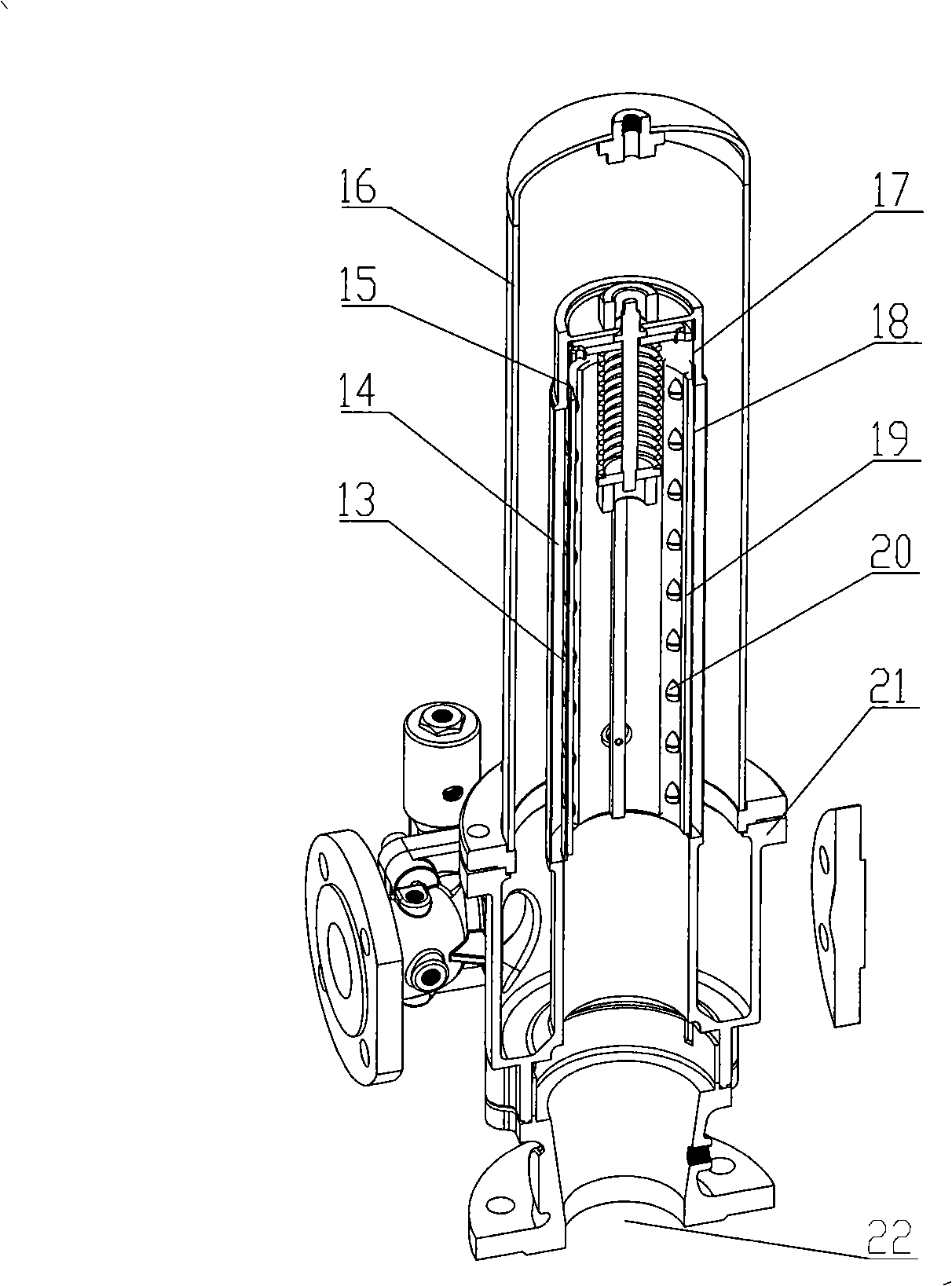

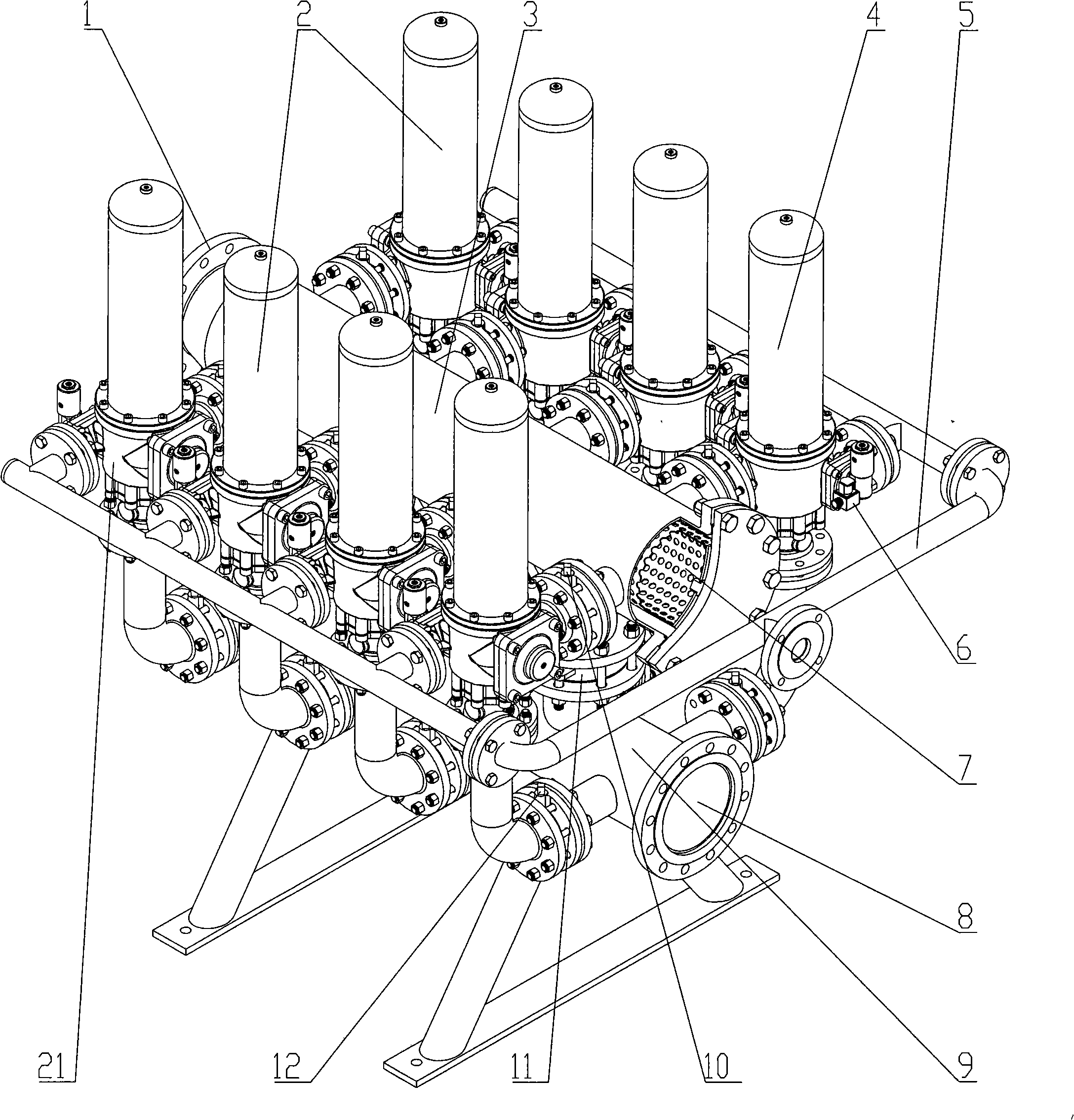

Filter

InactiveCN101352627AReduce filter loadReduce lossesStationary filtering element filtersFiltrationBiochemical engineering

The invention relates to a device which carries out the filtration on the fluid medium conveyed by the pipeline, in particular to a cleanable filter which can realize the hydrocyclone separation, surface interception and deep filtration of the impurity in the fluid medium at the same time. The filter is provided with a filter unit which consists of a filter unit shell and a valve body which are connected with each other; one side of the valve body is provided with a unit medium inlet and the other side thereof is provided with a sewage outlet; the internal side of the valve body is provided with a hydrocyclone passage; one side of the hydrocyclone passage is provided with a diaphragm valve port which is provided with an inlet diaphragm sheet; the other side of the hydrocyclone passage is provided with a sewage drainage diaphragm valve port which is provided with the sewage drainage port diaphragm sheet. Due to the design of the hydrocyclone passage, the device of the invention leads the medium to form the hydrocyclone when entering the filter unit, leads most impurities in the medium to be thrown towards the internal wall of the filter unit shell by the hydrocyclone centrifuging and be far away from a disc column, thus greatly lightening the filter load of the disc column and prolonging the service life of the filter.

Owner:王克涛

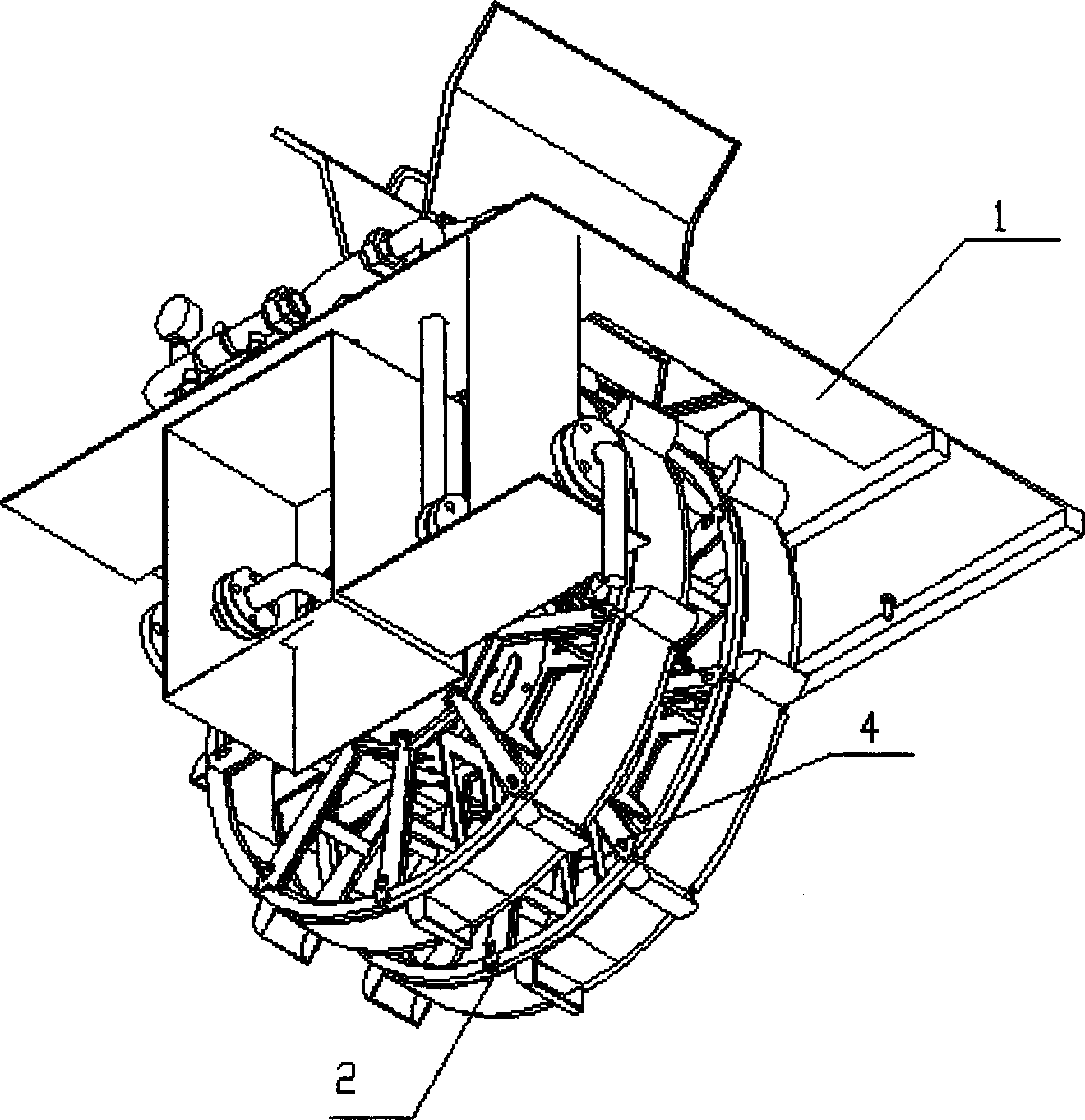

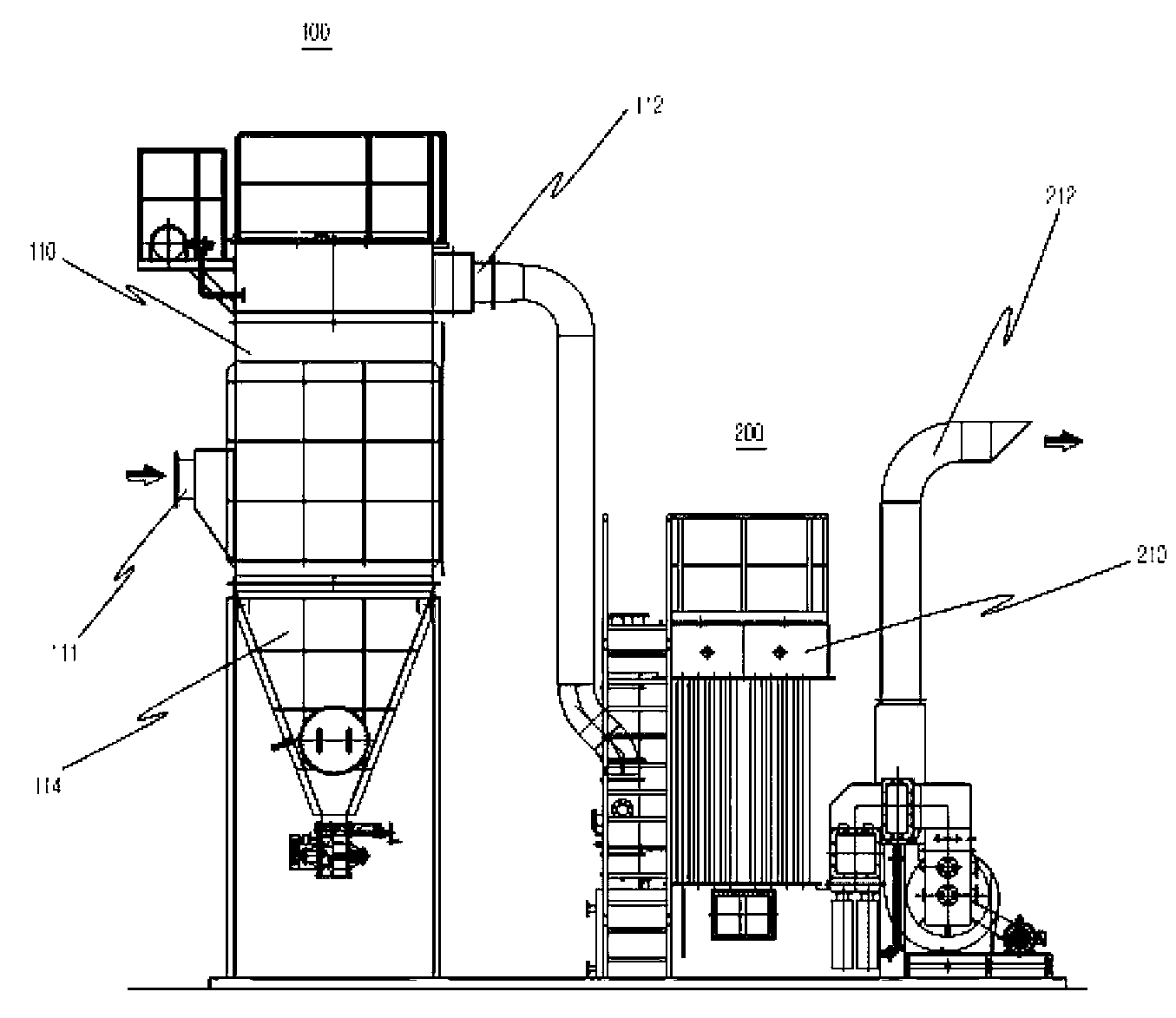

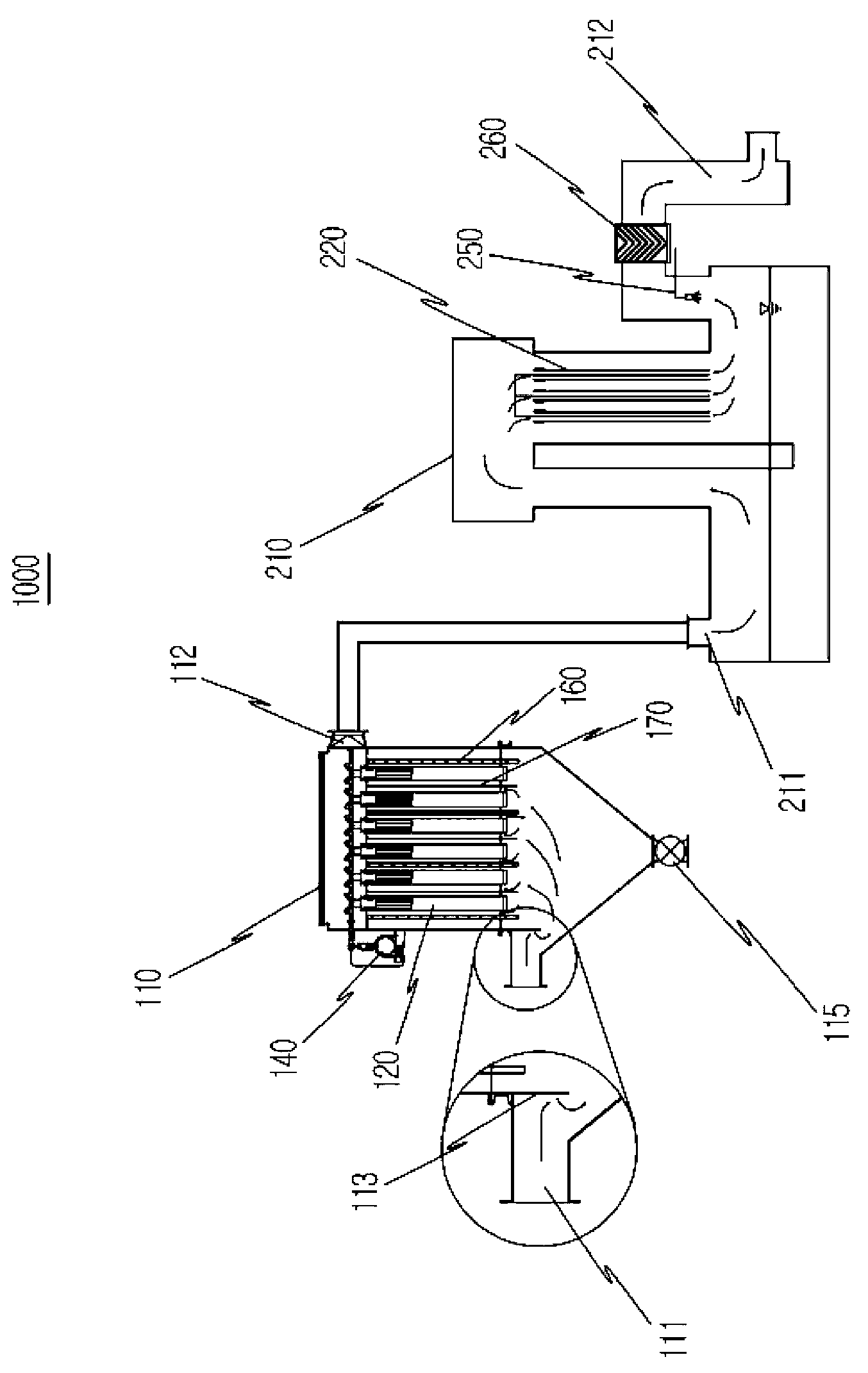

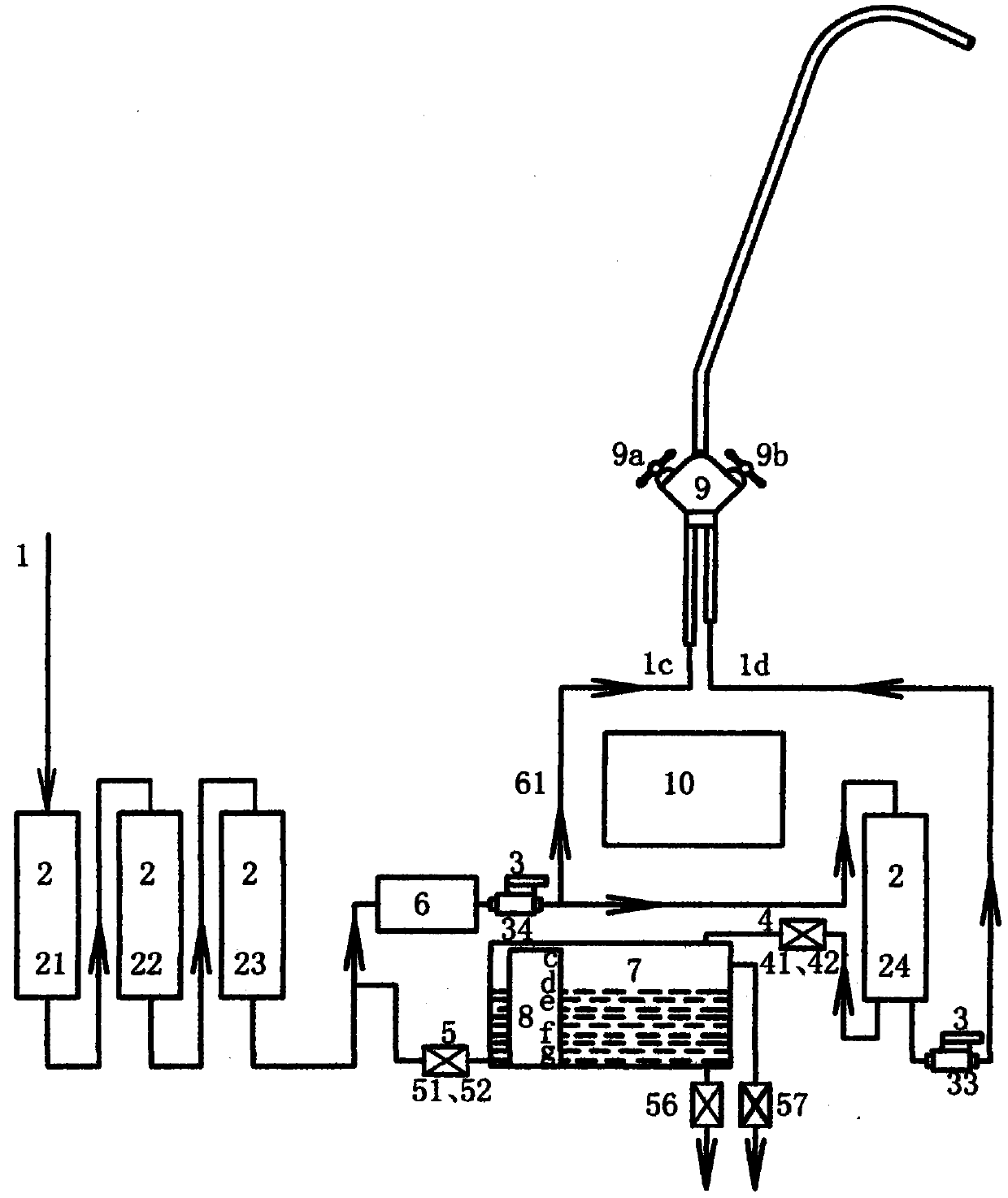

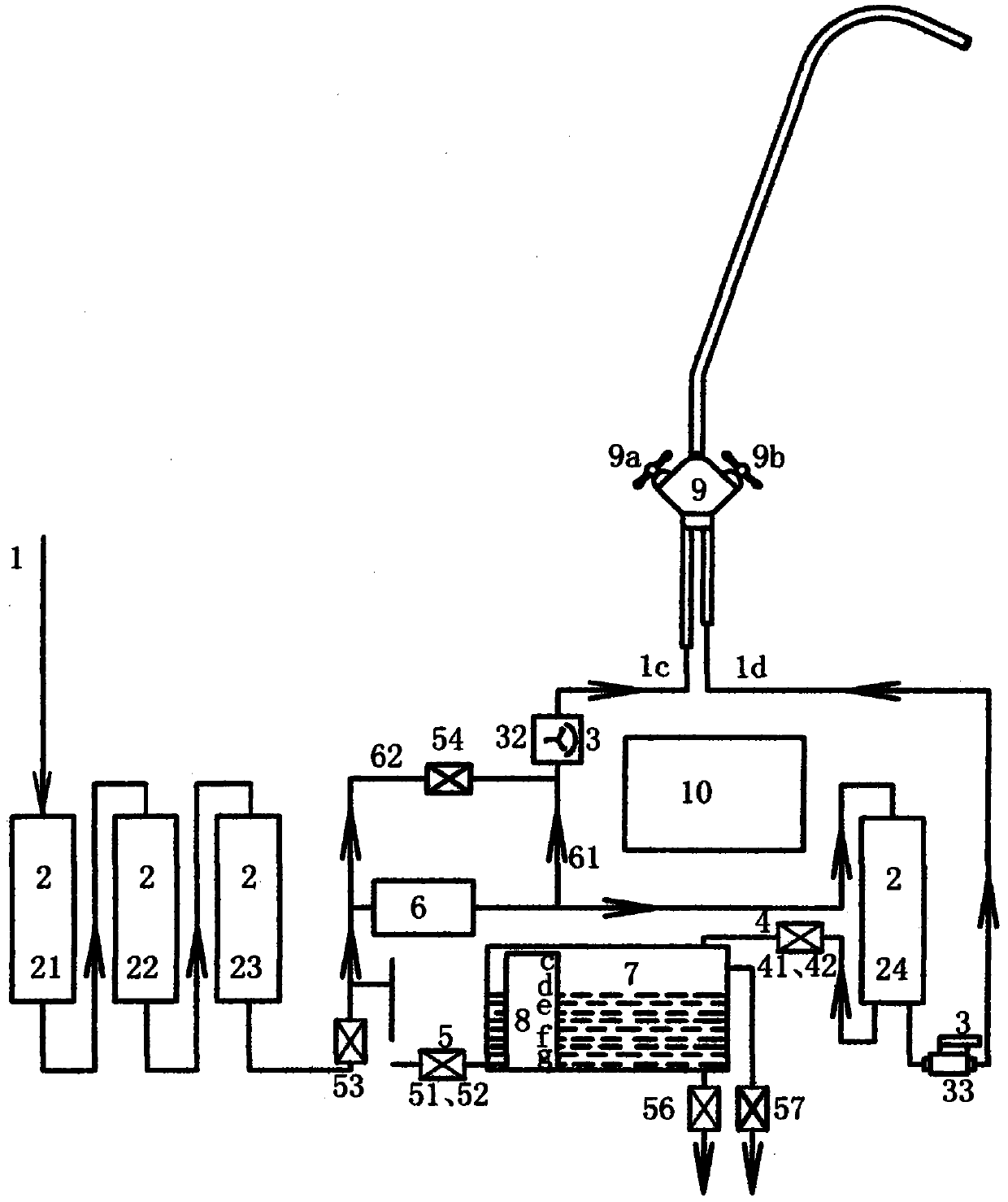

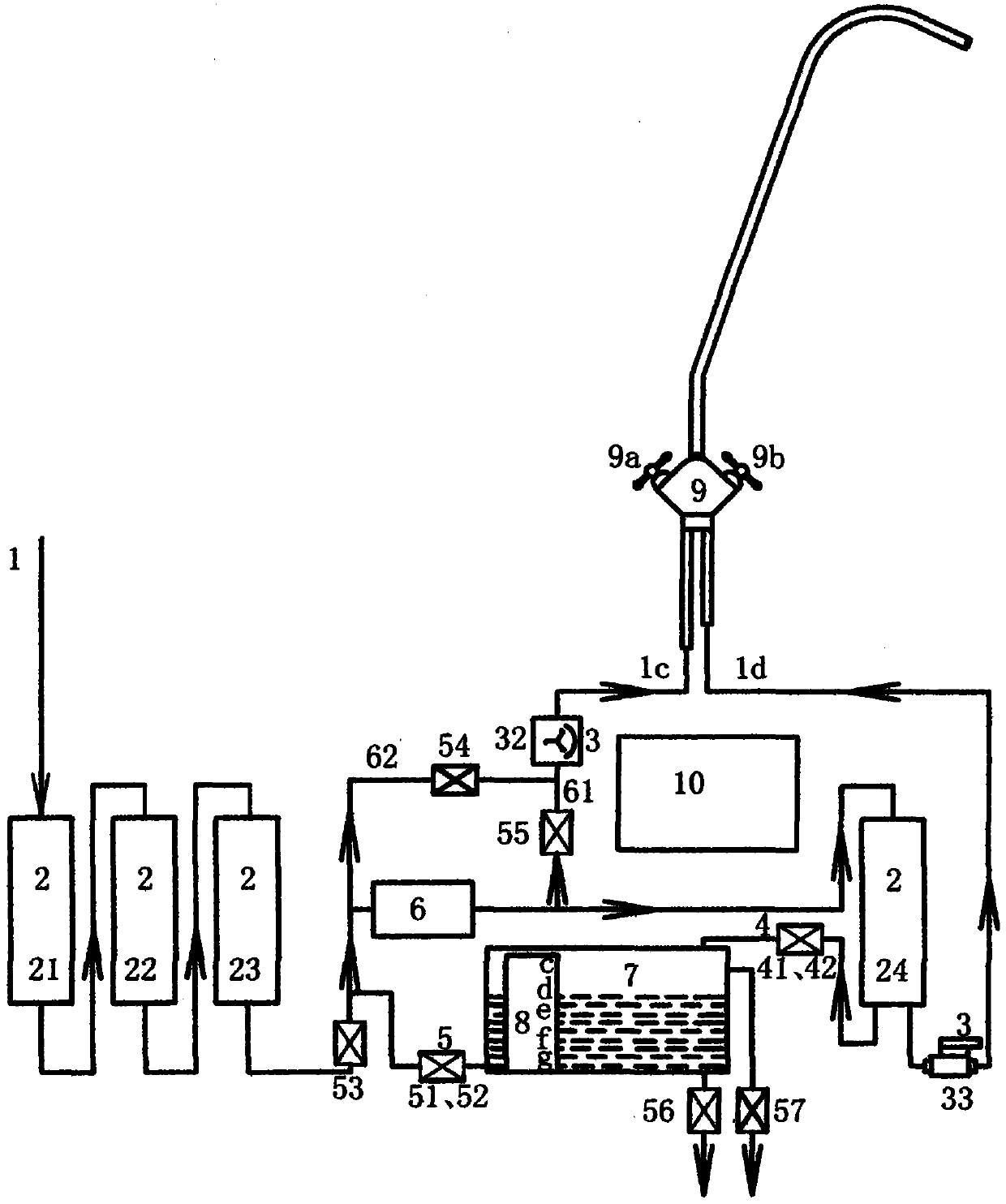

Simultaneous complex treatment apparatus for advanced treatment of mixed exhaust gas

InactiveCN103028299ASimultaneous processingReduce filter loadHuman health protectionCombination devicesEngineeringDust collector

The invention relates to a simultaneous complex treatment apparatus for advanced treatment of a mixed exhaust gas. The simultaneous complex treatment apparatus can perform dust collection, degradation, and elimination of PM, HAPs, SOx, and NOx, and more specifically, the invention relates to a simultaneous complex treatment apparatus for advanced treatment of a mixed exhaust gas, a filtering dust collector and a plasma discharger are arranged at the front part and the rear part of the apparatus, PM, HAPs, SOx, and NOx can be simultaneously treated, via a front panel and a nozzle of the filtering dust collector, filtering load of bag filters can be reduced, dust-eliminating efficiency can be improved, and service lifetime of the bag filters can be prolonged, a discharge electrode tube in the shape of a cylindrical tube is used, and an electrode bar is arranged at the central part, thereby increasing the reacting section of plasma and the residence time of introducing air.

Owner:ANSUNG PRECISION MACHINERY

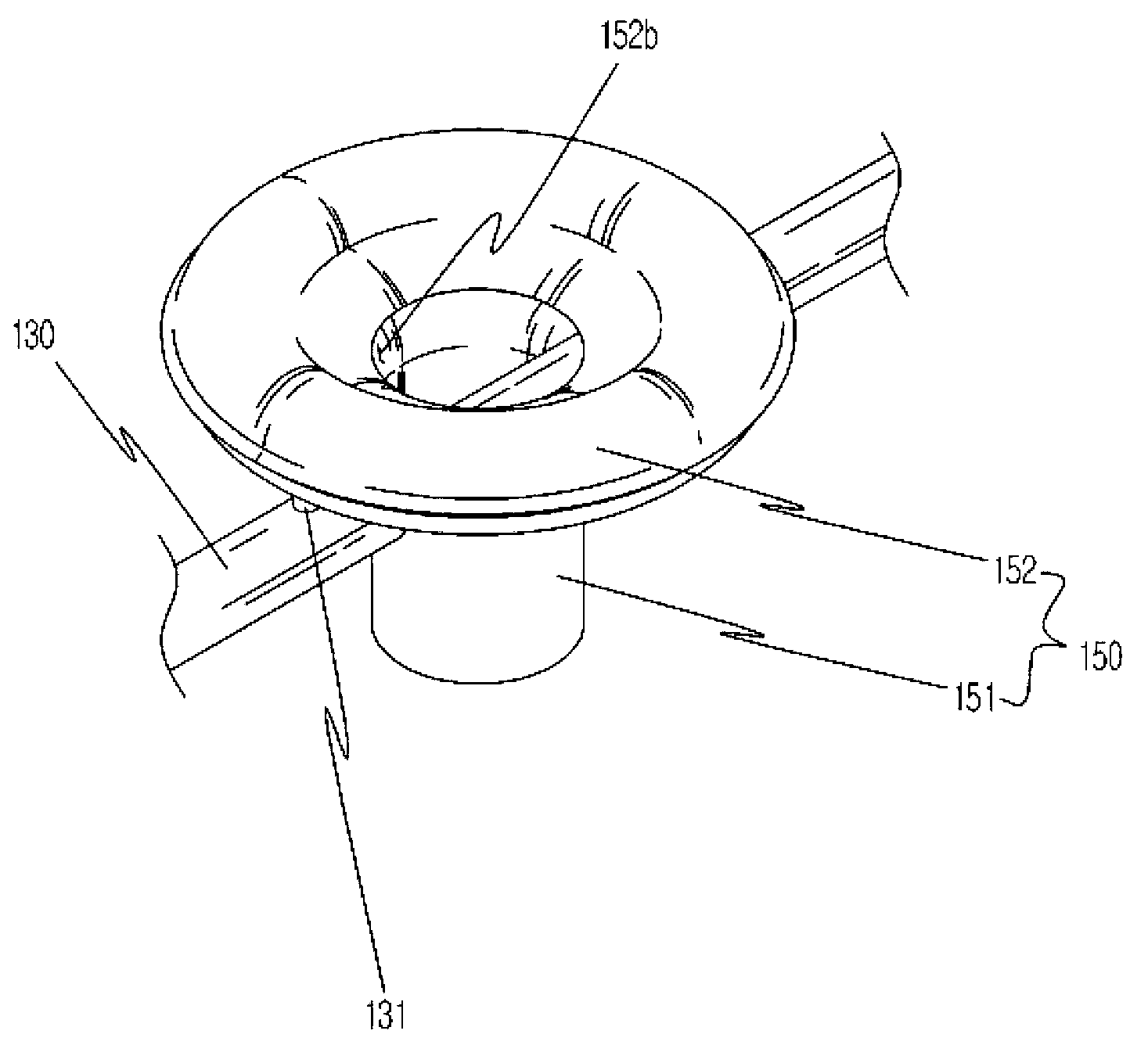

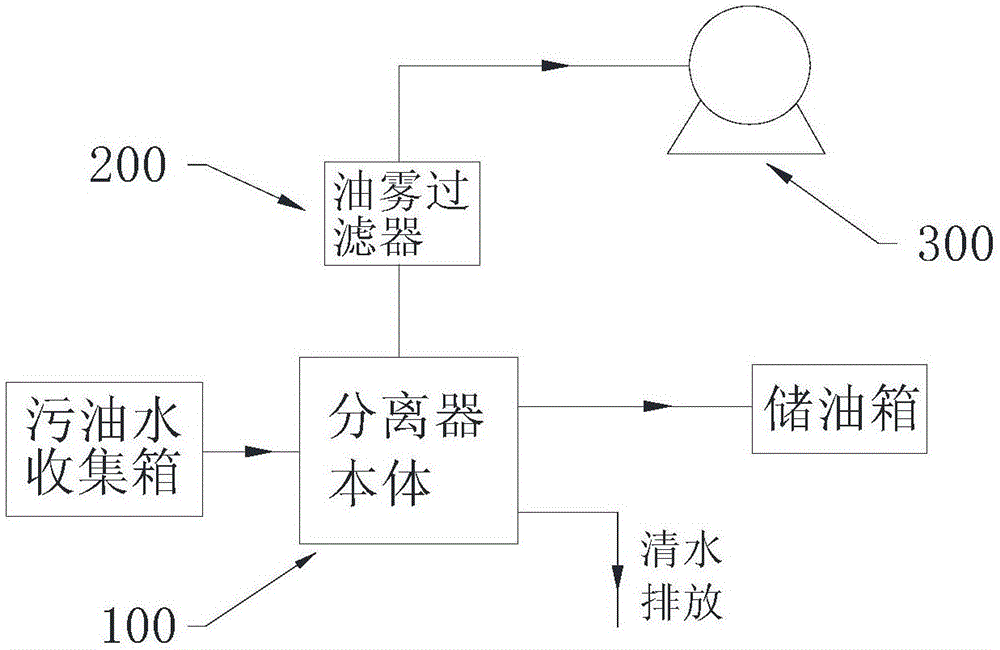

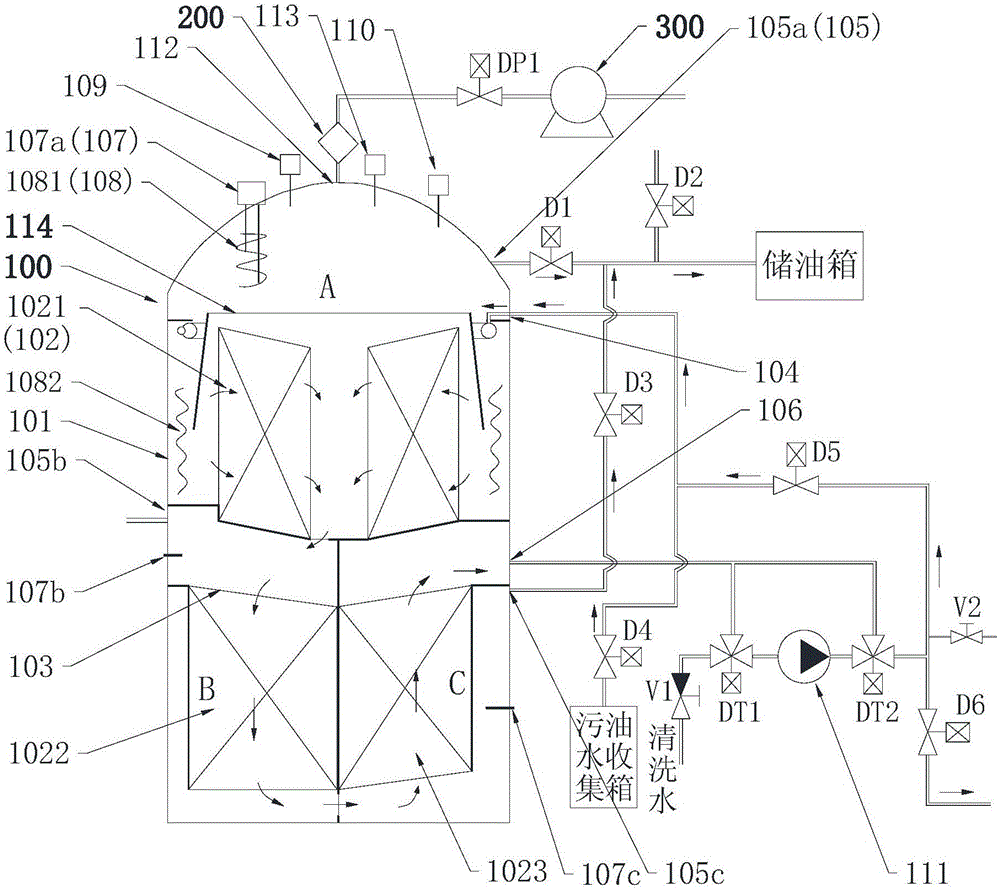

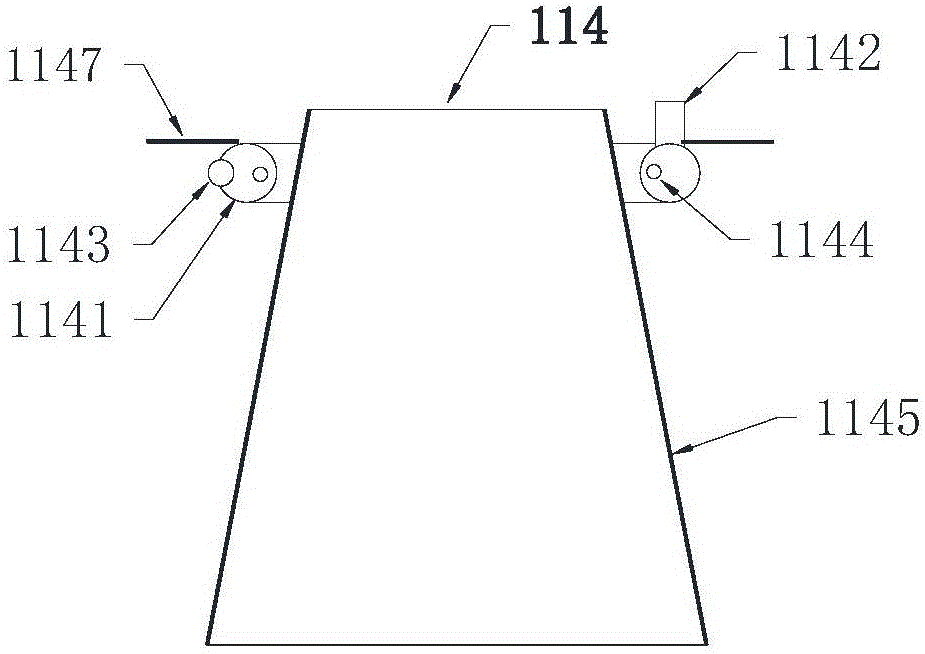

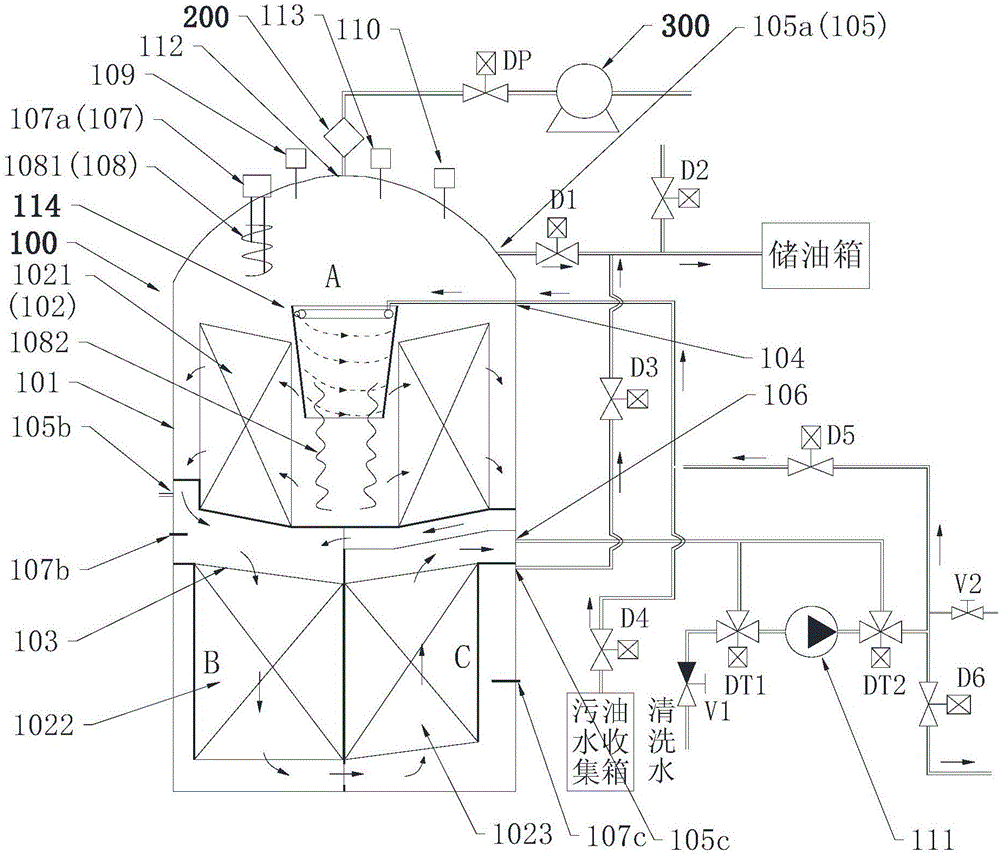

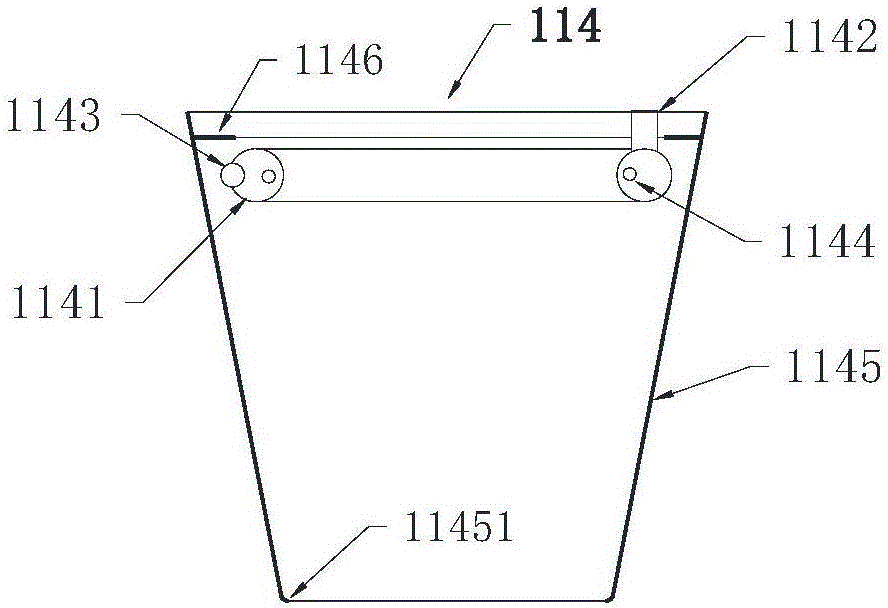

Dirty oil water separator with built-in flow restraining device

ActiveCN106582068AReduce oil contentReduce filter loadFatty/oily/floating substances removal devicesLiquid separationFiltrationOil water

The invention discloses a dirty oil water separator with a built-in flow restraining device; the dirty oil water separator comprises a separator body, the flow restraining device and a vacuum pump. The separator body is provided with an extraction port communicating with the vacuum pump and an input port for influx of dirty oil water, and the separator body is internally provided with a cylindrical first filter core arranged vertically and used for coarse filtration. The flow restraining device comprises an input part and at least two flow restraining parts which are connected with each other, the flow restraining parts are used for restraining the flowing-out direction of the dirty oil water, and output ports of the flow restraining parts are distributed along the consistent angle direction. The flow restraining device is assembled on the top side of the first filter core, and the output ports of the flow restraining parts are located between the first filter core and a shell body of the separator body. The flow restraining device is used for retaining the flow direction of the dirty oil water flowing to the first filter core, is used for oil and water pre-separation treatment of the dirty oil water and is used for timely removing dirty oil droplets gathered on the first filter core, so the filtration load of the filter core is reduced, oil-water separation is performed in vacuum conditions, and the separation effect and the separation efficiency of the separator are facilitated to be improved.

Owner:安徽百川源新型材料科技有限公司

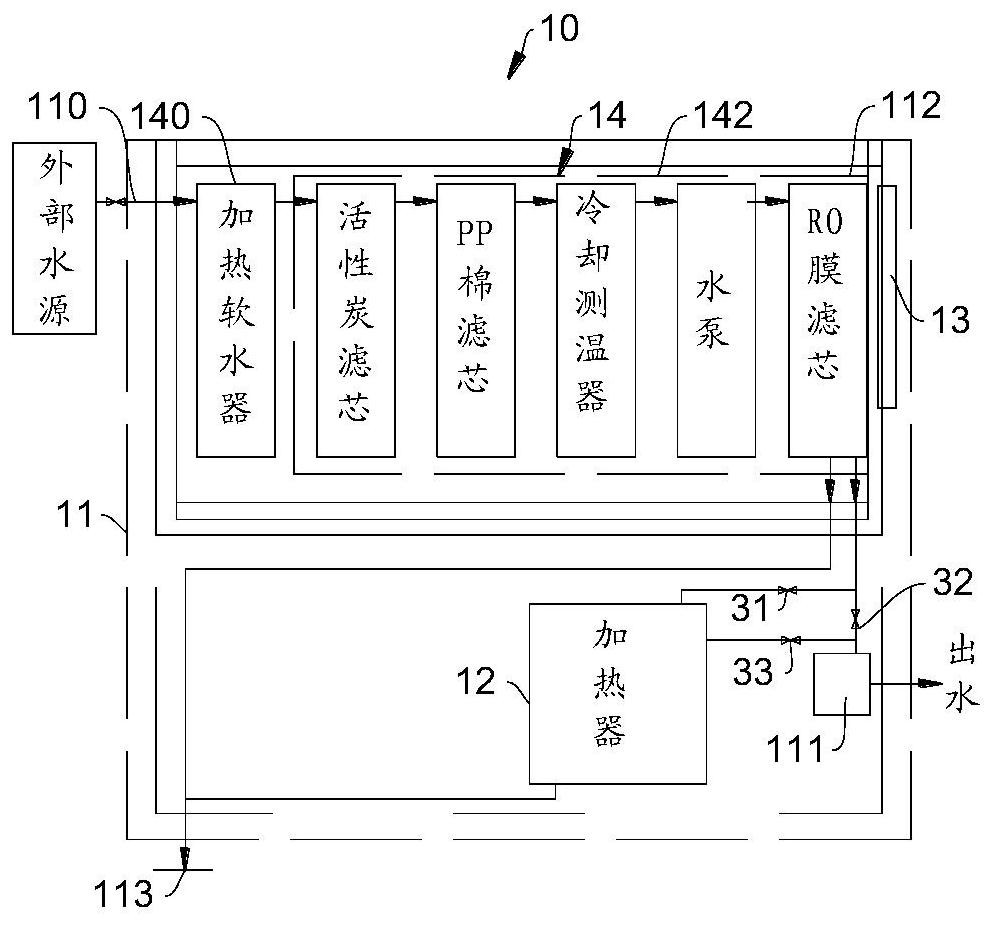

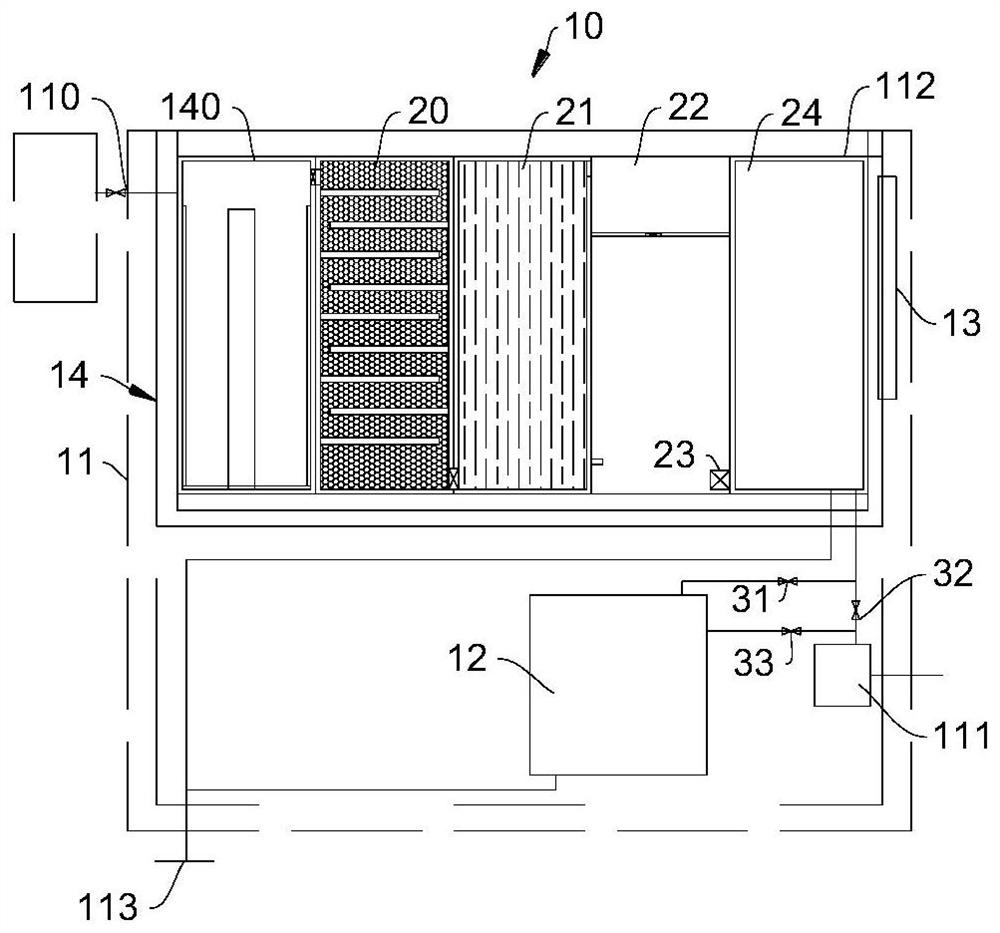

Instant heating purification type water dispenser

ActiveCN111887719AExtended service lifeReduce filter loadTreatment involving filtrationBeverage vesselsWater sourceSoft water

The invention discloses an instant heating purification type water dispenser. The instant heating purification type water dispenser comprises a machine shell, a heater, a controller and a heating water purifier; a water receiving opening is connected with an external water inlet so as to be connected with an external water source; water is heated to be boiled in a heating water softener, soft water is generated, and a water temperature signal is generated; the heating water softener is in communication connection with the controller and transmits the water temperature signal to the controller;a water suction pump is connected with a water inflow part and is in communication connection with the controller; and when the controller receives a water temperature signal meeting conditions, thecontroller controls the water suction pump to suck soft water into a composite filter element, so that the composite filter element can filter the soft water, and pure water can be generated; a wateroutflow part is connected with the heater and a water outflow nozzle through a valve structure so as to selectively convey the pure water to one of the heater and the water outflow nozzle through thevalve structure; the heater is used for heating the received pure water and conveying the heated pure water to the water outflow nozzle. The instant heating purification type water dispenser can be used independently, and is long in service life and low in maintenance cost.

Owner:湖南因思特电器有限责任公司

Time-limit-free passive combined heat removal system with integrated heat release trap

ActiveCN112053791AEnsure safetyOptimize layoutNuclear energy generationEmergency protection arrangementsNuclear plantThermodynamics

The invention provides a non-time-limit passive combined heat removal system with an integrated heat release trap, which is characterized in that the integrated heat release trap is arranged at the middle lower part of a double-layer coagulated containment sandwich gas space and is an annular water tank defined by a corrosion-resistant metal plate; at least one group of communicating pipelines andone-way valves leading to the internal air space of the containment are arranged on an inner-layer containment wall surface of the upper air space of a containment interlayer; the integrated heat release trap is connected with a containment vessel rapid pressure relief system, an automatic pressure relief system, a passive residual heat removal system, a passive low-pressure safety injection system, a passive reactor cavity water injection system and a filtering and discharging system, and the integrated heat release trap is used for simplifying the arrangement of a reactor system of a nuclear power plant, reducing the volume of a containment vessel and providing unlimited heat export for the containment vessel. A feasible scheme is provided for improving the economy and the passive safety of the advanced nuclear power plant.

Owner:HARBIN ENG UNIV

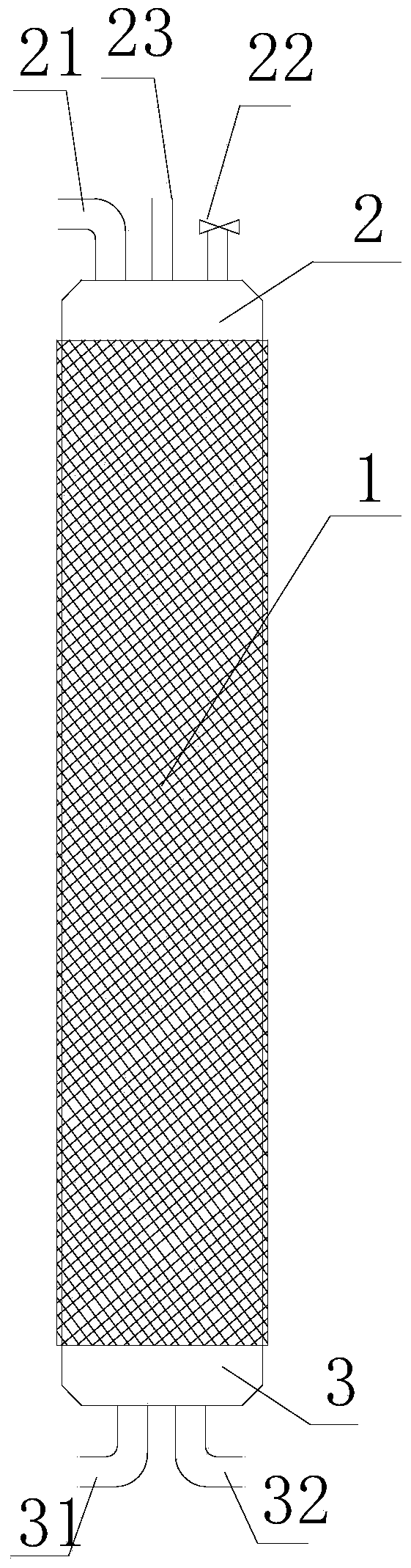

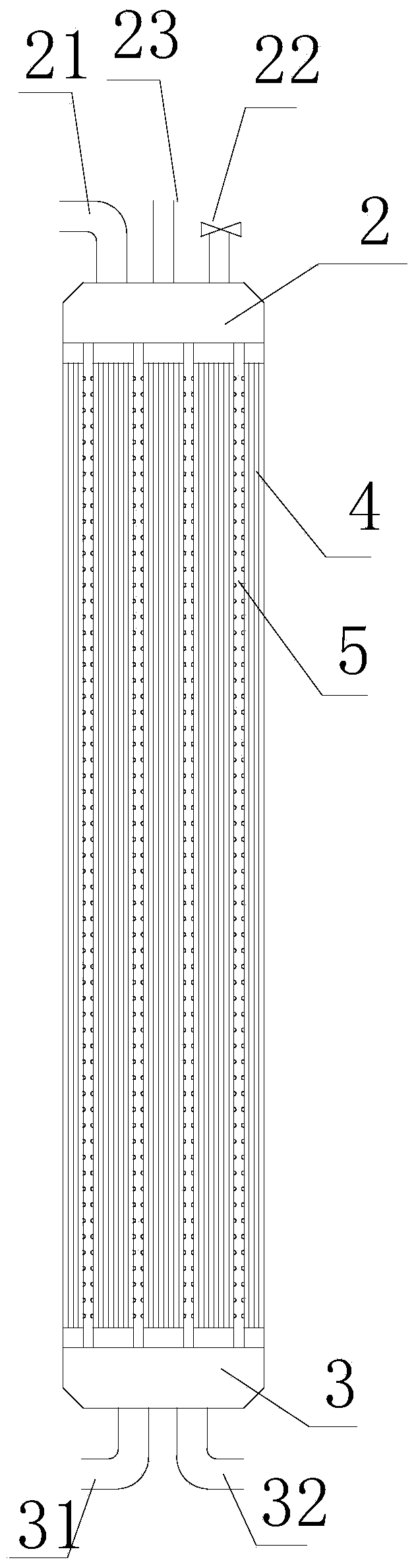

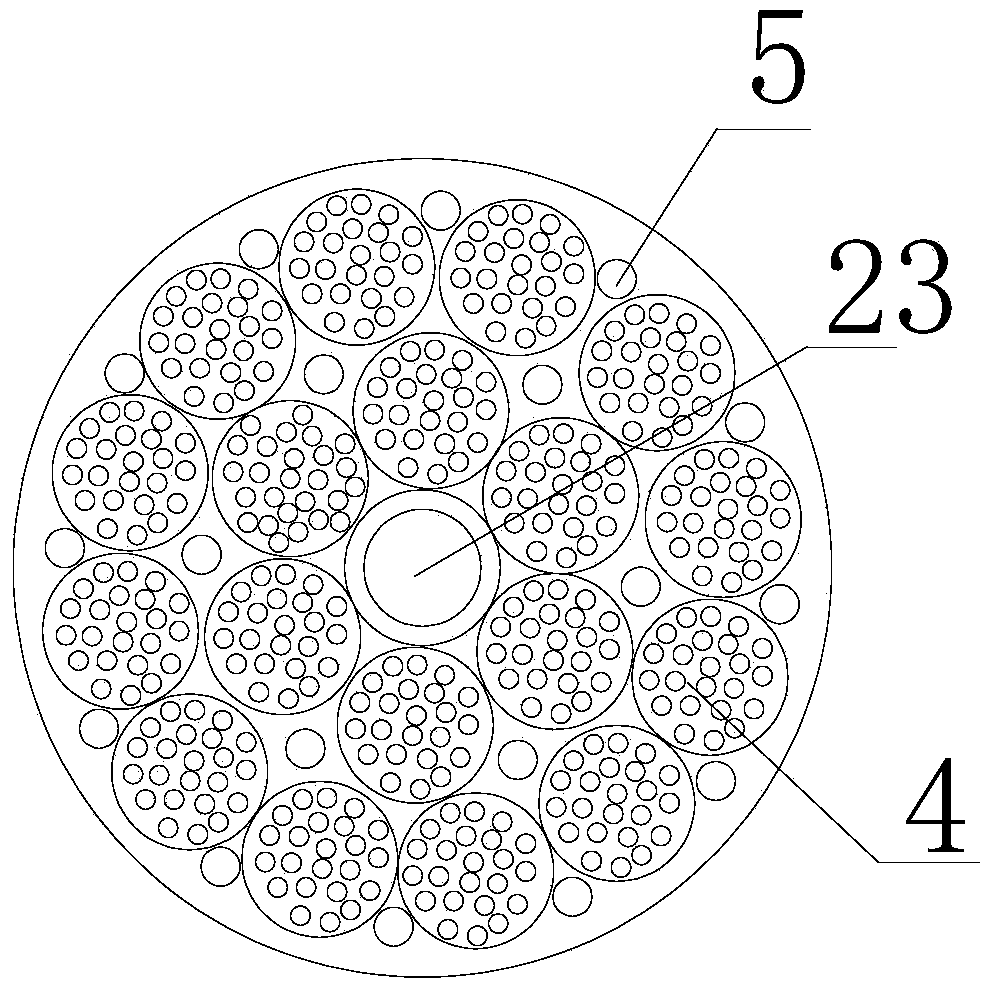

Novel cylindrical external compression ultrafilter membrane assembly

ActiveCN104028106ACompact structureSmall footprintUltrafiltrationWater/sewage treatment bu osmosis/dialysisEngineeringSmall footprint

The invention provides a novel cylindrical external compression ultrafilter membrane assembly. The novel cylindrical external compression ultrafilter membrane assembly comprises an external coarse filtering unit, an upper end closure unit, a lower end closure unit, and an ultrafilter membrane cluster combination filtering unit and an aeration hole arranged in the external coarse filtering unit; two ends of the external coarse filtering unit are connected with the upper end closure unit and the lower end closure unit respectively; the upper end closure unit is provided with an upper water outlet tube, a gas discharging tube and an ultrasonic device interface, and the lower end closure unit is provided with a water outlet tube and a gas inlet tube; water outlets at two ends of the ultrafilter membrane cluster combination filtering unit are connected with the upper water outlet tube and the lower water outlet tube respectively; and gas holes are arranged at the bottom of the gas discharging tube of the upper end closure unit and the bottom of the gas inlet tube of the lower end closure unit respectively. The ultrafilter membrane assembly has the advantages of compact structure, small occupied area, use convenience, flexible operation, wide application range and good popularization application prospect.

Owner:HOHAI UNIV

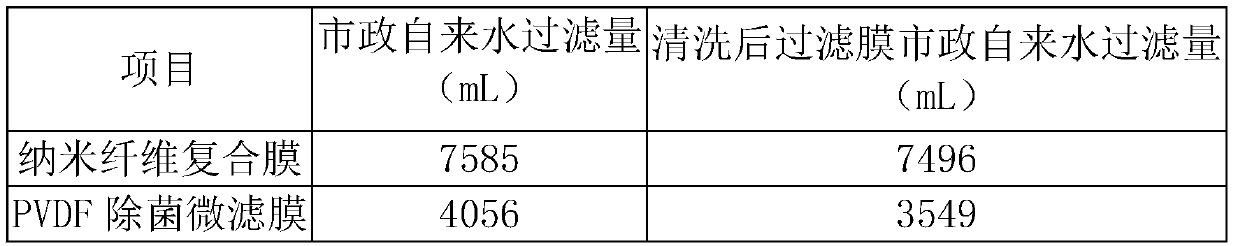

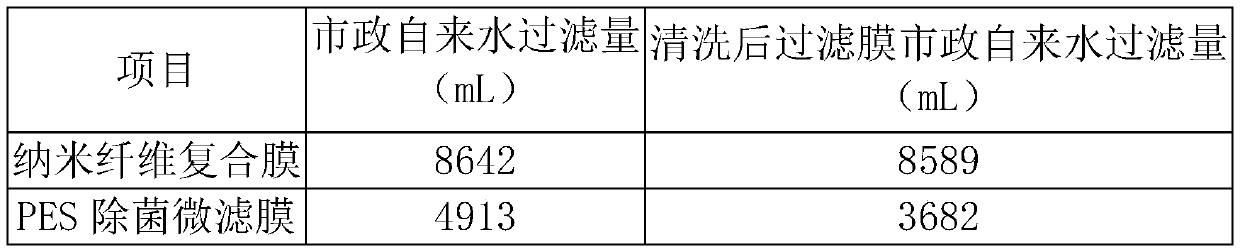

Nanofiber composite membrane with base material and preparation method thereof

PendingCN111068528AAdd attachment pointsImprove adhesionSemi-permeable membranesMonocomponent halogenated hydrocarbon artificial filamentSpinningMicrofiltration membrane

The invention discloses a nanofiber composite membrane with a base material and a preparation method thereof, and relates to the technical field of nanofiber membranes. According to the method, micro-etching liquid is sprayed on a base material micro-filtration membrane to obtain a pretreated base material micro-filtration membrane, then at least one nanofiber layer is compounded on the surface ofthe pretreated base material micro-filtration membrane through electrostatic spinning, finally, the nanofiber composite membrane is obtained through two times of water bath cleaning and drying, and the nanofiber composite membrane is rolled up. According to the nanofiber composite membrane and the preparation method, electrostatic spun nanofibers can be tightly combined with the base material microfiltration membrane by pretreating the base material microfiltration membrane, and the prepared nanofiber composite membrane is good in filtering efficiency and greatly prolonged in service lifetime.

Owner:HANGZHOU DEEFINE FILTRATION TECH

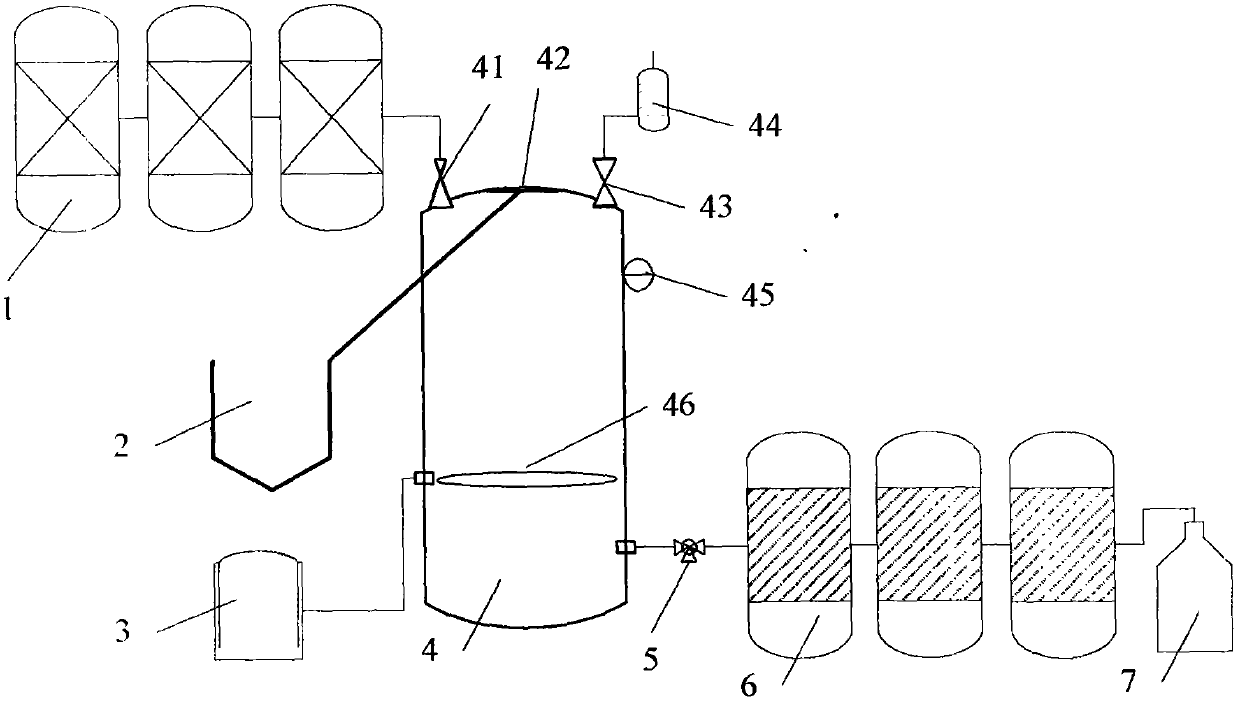

Automotive urea production equipment and process

InactiveCN107774183AGood purification effectLow impurity contentGas treatmentTransportation and packagingThree stageWater filter

The invention discloses automotive urea production equipment and process. The automotive urea production equipment comprises a water filtering system, a charging system, a gas storage system, a dissolving tank, a urea purifying system and a finished product storage tank. Industrial water is added in the dissolving tank through the three-stage water filtering system; agricultural urea is added in the dissolving tank through the charging system; a gas spraying system is arranged in the dissolving tank and is connected with the gas storage system, when urea solid is dissolved, the gas storage system is opened, and compressed gas is sprayed into the dissolving tank so as to facilitate dissolving; ammonia is generated in a dissolving process, enters a filter through an exhaust pipe on the top of the dissolving tank, and is absorbed and then is discharged into the atmosphere; and a urea solution enters a three-stage solution filter via a solution discharge pipe and then is filtered, and a finished product is placed in the storage tank. By the scheme, the shortcoming that lots of biuret is generated by traditional heating and dissolving is overcome, and meanwhile, the ammonia generated bydissolving is purified and then discharged.

Owner:衡水卡力洁环保科技有限公司

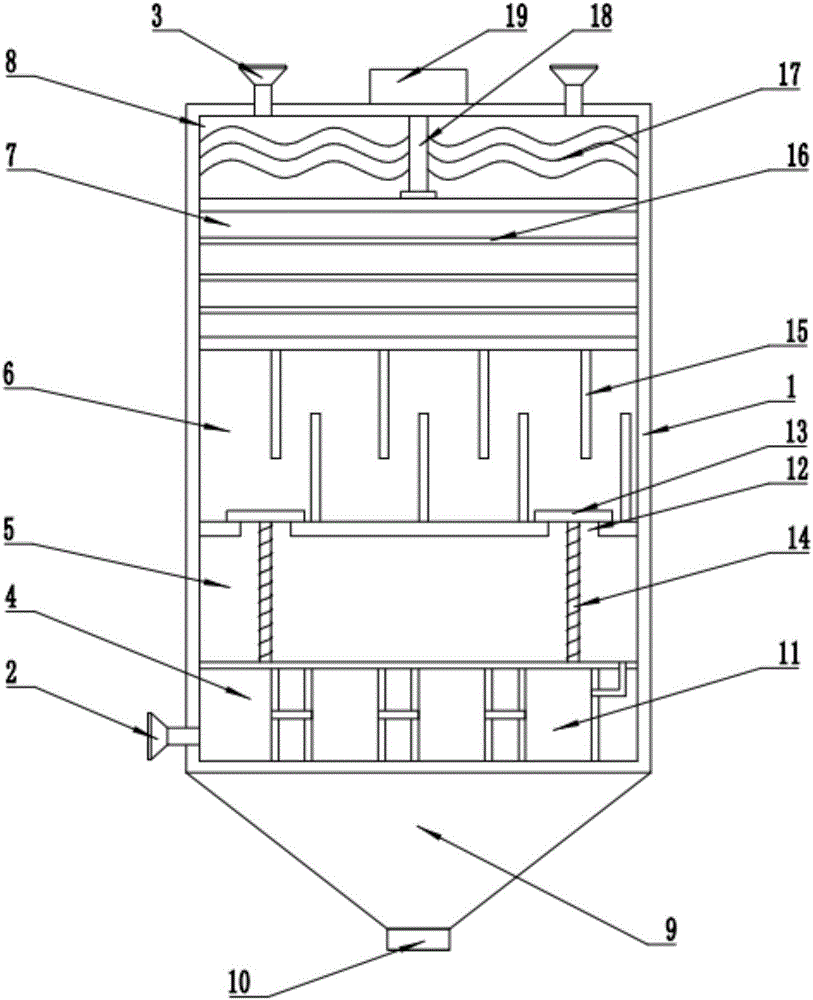

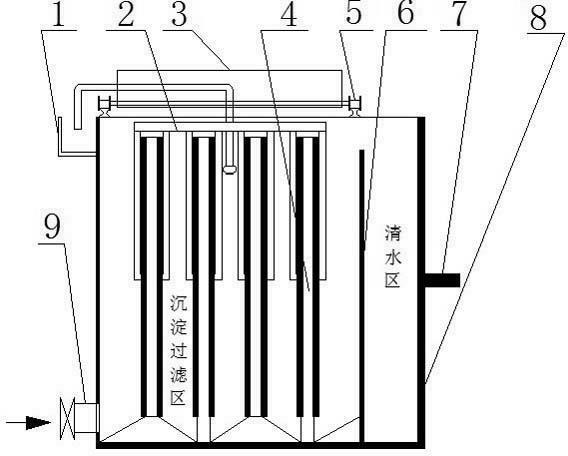

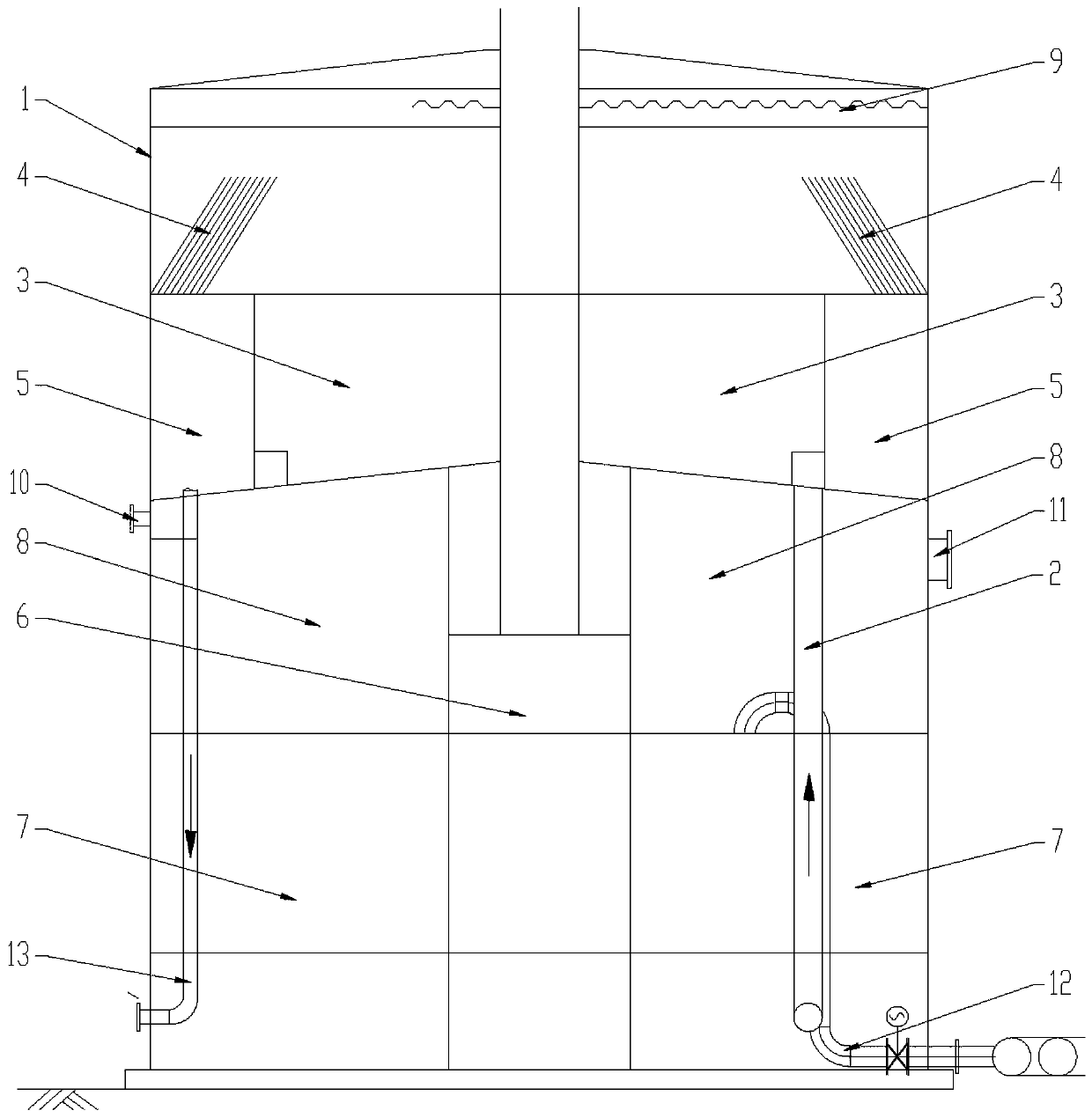

High-efficiency rotational flow sewage purifier

The invention discloses a high-efficiency rotational flow sewage purifier. The purifier comprises a tank body (1), the upper part of an inner cavity of the tank body (1) is provided with rotational flow centrifugalization zones (3) which communicate with a sewage pipe (2), dynamic sedimentation zones (4) are arranged on the rotational flow centrifugalization zones (3), and the outer side of the rotational flow centrifugalization zones (3) is provided with sludge concentration zones (5) which are located directly under the dynamic sedimentation zones (4), sewage subjected to rotational flow separation is divided into different flows through the dynamic sedimentation zones (4), an obtained sewage enters a gravity center separation zone (6) in an overflow manner and then falls at the bottom of the tank body (1), the bottom of the gravity center separation zone (6) communicates with the lower parts of dynamic filter zones (7), thus sewage subjected to gravity center separation passes through upward the dynamic filter zones (7) and achieves clear-water zones (8), and therefore a whole sewage purifying process is finished. According to the invention, processes such as straight-flow coagulation, micro-flocculation granulation, centrifugalization, gravity separation, dynamic filter and sludge concentration are integrated organically, multiple-stage purification is performed, and therefore online quick continuous and high-efficiency treatment is realized.

Owner:江苏巨昌环保集团有限公司

Front-end filtering device of filter

ActiveCN107740738AReduce filter loadExtended service lifeMachines/enginesAir cleaners for fuelInlet manifoldWire brush

The invention discloses a front-end filtering device of a filter. The front-end filtering device of the filter comprises a filter air inlet and a filtering cover, wherein a plurality of first filtering holes which are distributed uniformly are formed in a side surface of the filtering cover; the bottom of the filtering cover is connected with the filter air inlet through a connecting ring; a filtering plate is arranged at the bottom of the filtering cover; a plurality of second filtering holes distributed uniformly are formed in the filtering plate; a rotating shaft is arranged in the middle of the filtering cover; a cleaning rod is arranged at the bottom of the rotating shaft; a cleaning wire brush is arranged on the cleaning rod; the upper end of the rotating shaft penetrates through thefiltering cover and is connected with a motor; dust suction tubes are arranged on two sides of the motor, and are connected with a small fan through an air inlet manifold; and an exhaust tube is arranged on the other side of the fan. The preliminary filtering device is arranged at the air inlet front end of the filter, filtering load of the filter is relieved, and therefore, the service life of the filter is greatly prolonged. The front-end filtering device of the filter is simple to design and operate, high in comprehensive practicability and easy to popularize and use.

Owner:BENGBU HUATAI FILTER

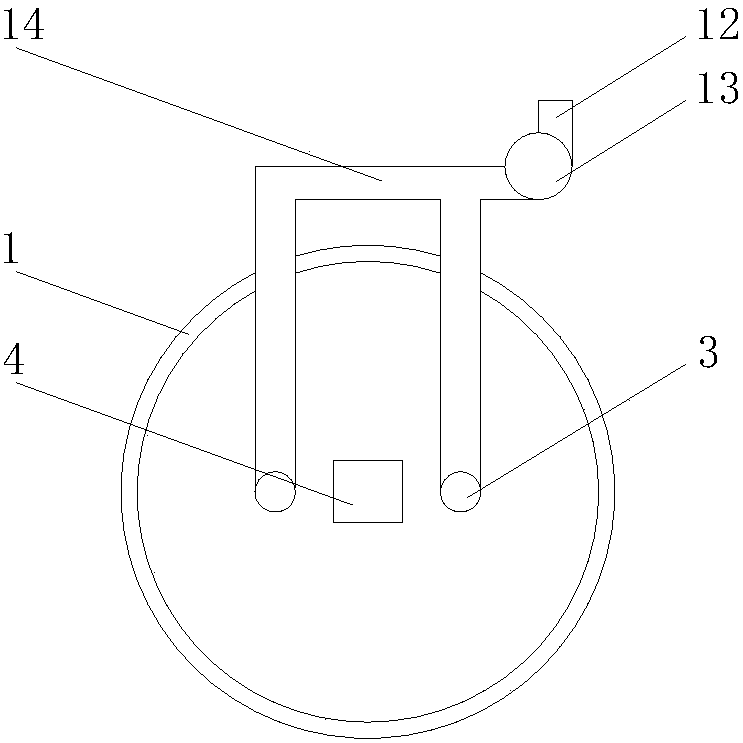

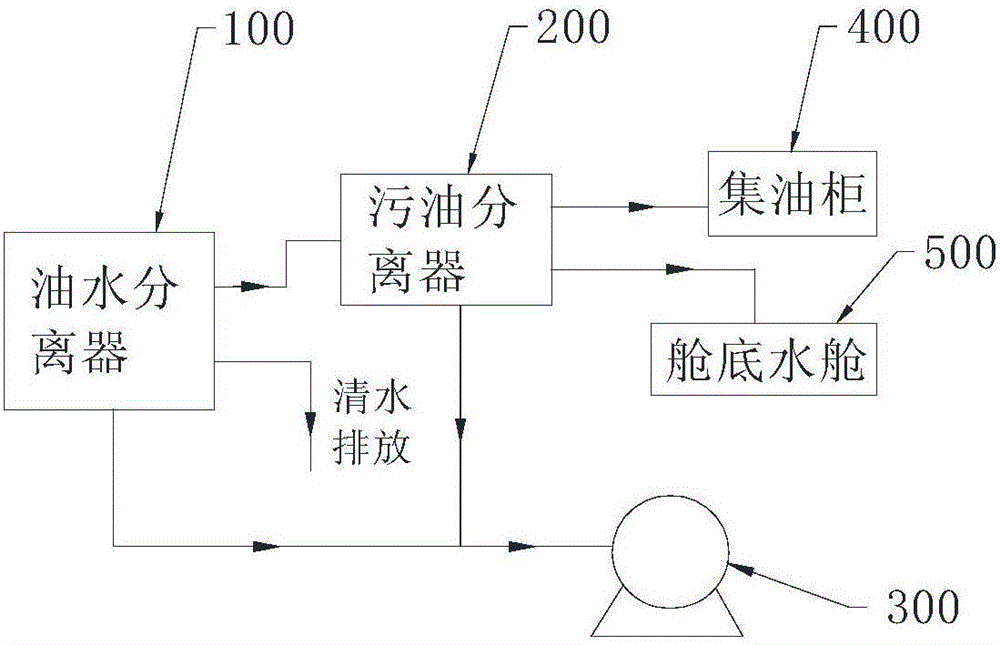

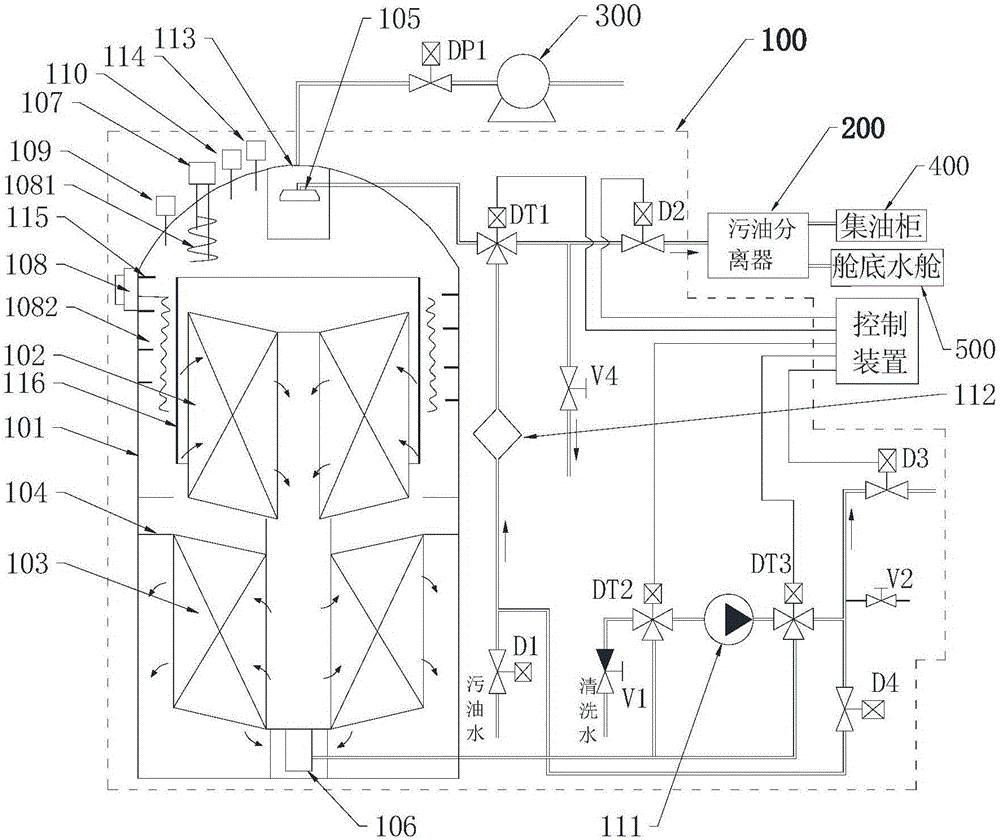

Oily water vacuum separation device

InactiveCN106673125AReduce oil contentReduced Disturbance EmulsificationFatty/oily/floating substances removal devicesNature of treatment waterPulp and paper industrySewage

The invention discloses an oily water vacuum separation device. The oily water vacuum separation device comprises an oil-water separator, a dirty oil separator, a vacuum pump and a control device, wherein a water outlet for outputting sewage is positioned in the lower part of the oil-water separator and is communicated with an input port of a water pump, and an oil outlet for discharging dirty oil is positioned in the upper part of the oil-water separator and is communicated with a dirty oil input port of the dirty oil separator; a filtering element and a heater for heating to-be-separated oily water are arranged in the oil-water separator; a first extraction opening is formed in the top of the oil-water separator; a second extraction opening is formed in the top of the dirty oil separator; and the first extraction opening and the second extraction opening are communicated with an input port of the vacuum pump respectively. The oily water vacuum separation device provided by the invention separates the to-be-separated oily water and dirty oil under the vacuum condition and has a good separation effect, the oil content of the separated sewage is reduced, the water content of the separated dirty oil is reduced, disturbance and emulsification of the water pump on the oily water are reduced, and the service life of the water pump can be prolonged.

Owner:JIANGSU MARITIME INST

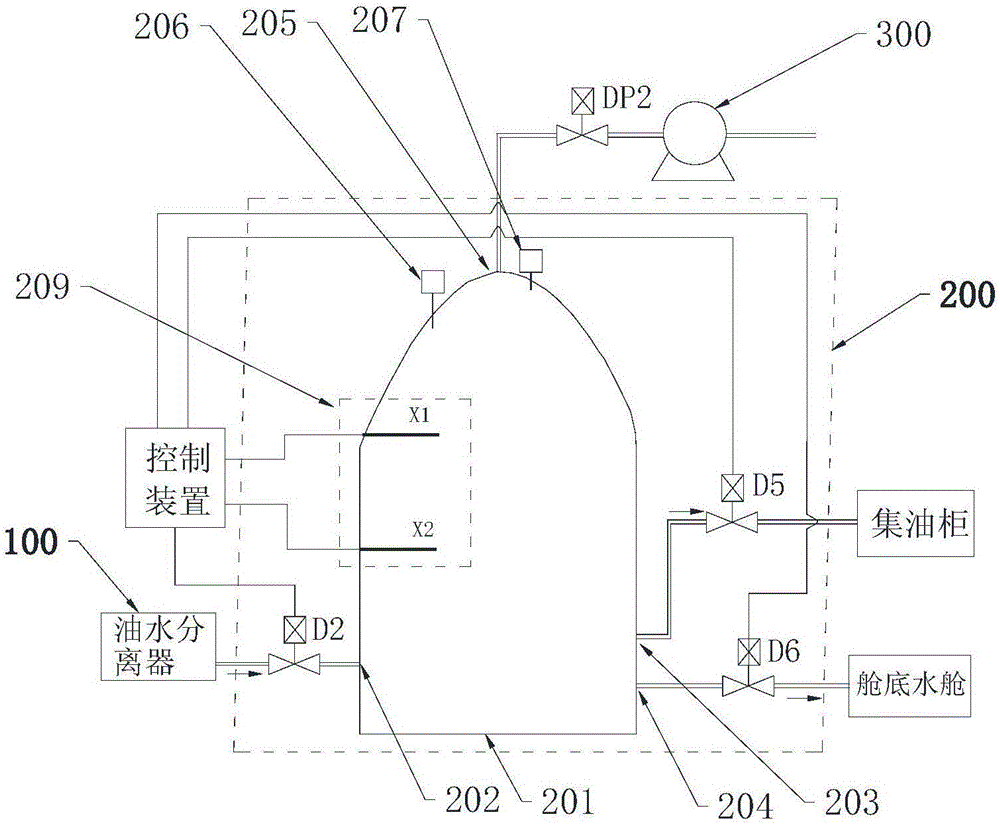

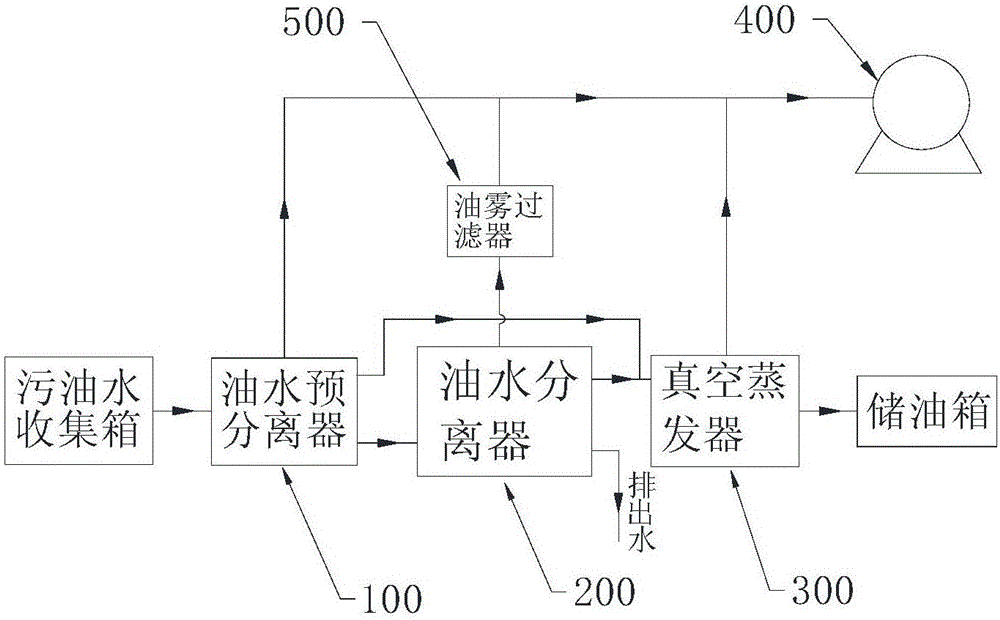

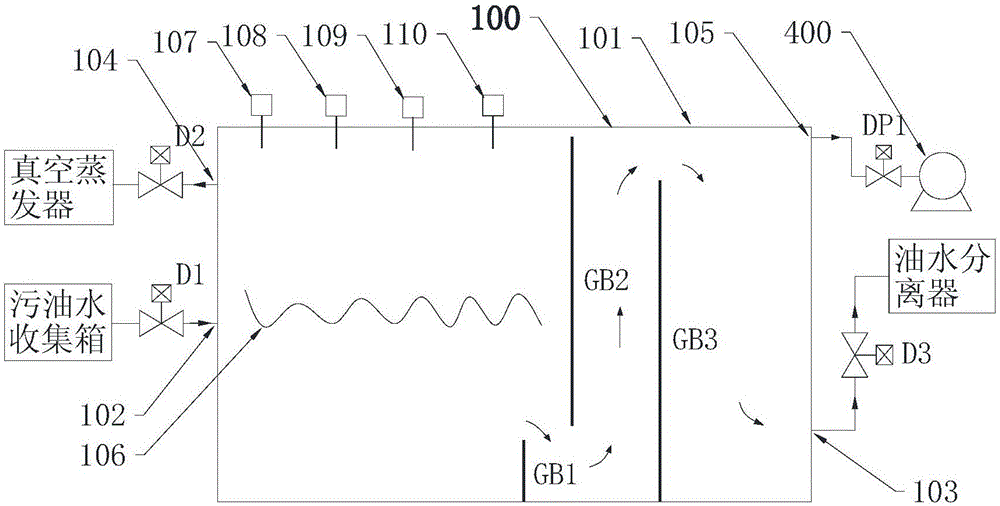

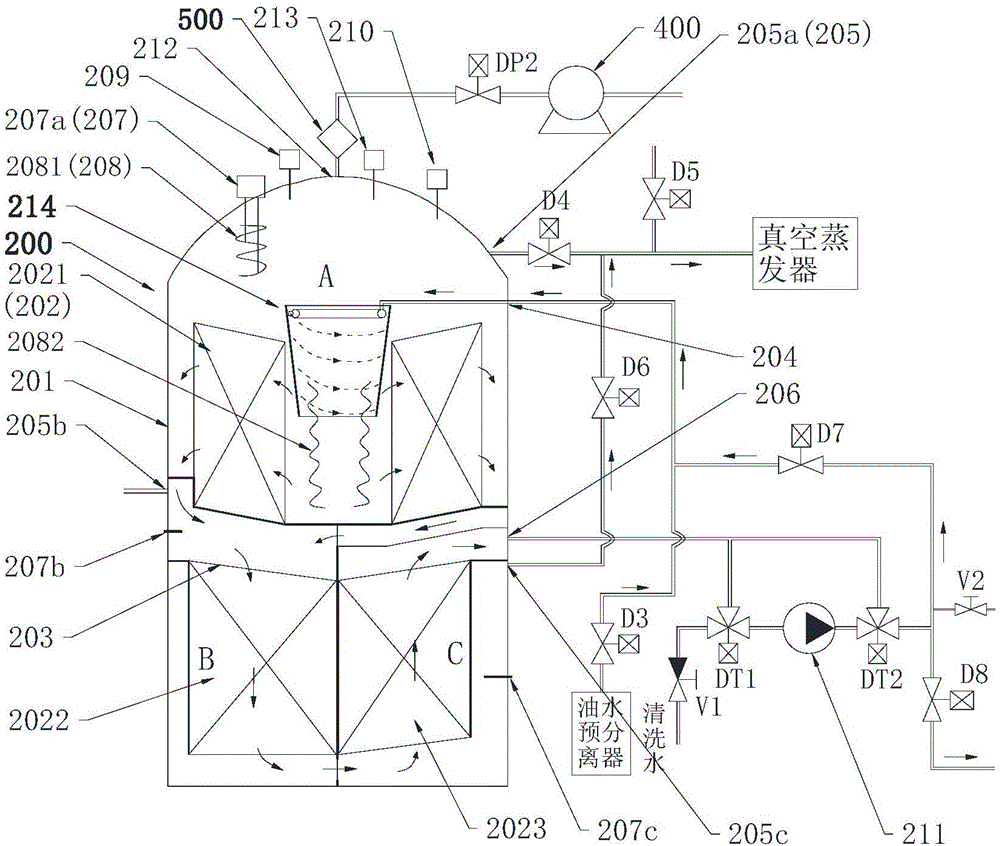

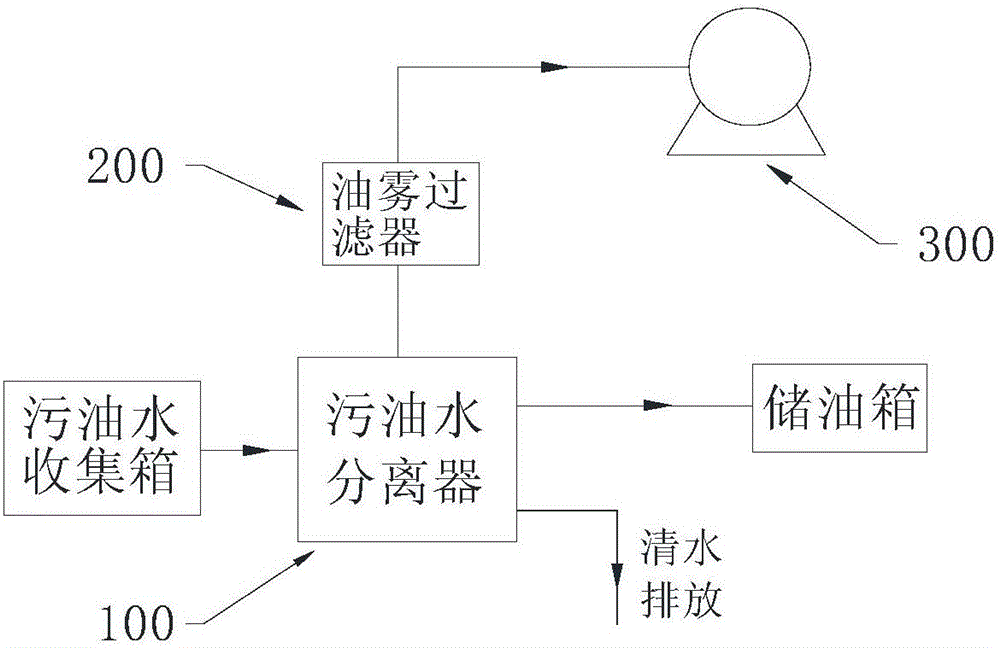

Oily water vacuum separating device

ActiveCN106430791AEasy to separateImprove separation efficiencyFatty/oily/floating substances removal devicesSpecific water treatment objectivesWater flowOil water

The invention discloses an oily water vacuum separating device which comprises an oil-water preseparator, an oil-water separator, a vacuum evaporator, a vacuum pump and a guiding device. A water draining port of the oil-water preseparator is communicated with an input port of the oil-water separator, an oil discharging port of the oil-water preseparator and an oil draining port of the oil-water separator are communicated with an input port of the vacuum evaporator, and an air exhausting port of the oil-water preseparator, an air exhausting port of the oil-water separator and an air exhausting port of the vacuum pump are communicated with the vacuum pump. A cylindrical filter element is built in the oil-water separator, and the guiding device comprises a guiding portion arranged in the same angle direction and is assembled inside the top of the filter element. The oily water vacuum separating device performs oil-water separation under vacuum conditions, the guiding device conducts flow guiding on oily water flowing towards the filter element and meanwhile conducts oil-water preseparation on oily water again, oily water drops gathered on the filter element are removed in time, the filtering load of the filter element is reduced, and improvement of the separation effect and the separation efficiency of the separating device is promoted.

Owner:SHANGHAI HONESS ENVIRONMENTAL TECH CORP

Effluent oil water separation device

ActiveCN106745502AReduce filter loadTo promote floatingLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesFiltrationOil water

The invention discloses an effluent oil water separation device. The device comprises an effluent oil water separator, a flow guiding device and a vacuum pump. An exhaust port and an inlet port for flowing into the effluent oil water are arranged on the effluent oil water separator, a cylindrical first filter element for course filtration is built in the effluent oil water separator, and the first filter element is vertically arranged. The flow-guiding device comprises an inlet port and a flow-guiding part for guiding the flow direction of the effluent oil water; an output port of the flow-guiding device is distributed along an anticlockwise direction or a clockwise direction; the flow-guiding device is assembled at the top side of the first filter element, and the outlet port of the flow-guiding part is located arranged in the first filter element; the inlet port of the vacuum pump is communicated with the exhaust port of the effluent oil water separator. The flow-guiding device of the device guides the flow direction of the effluent oil water flowing to the first filter element, and pre-separates the oil from the water in the effluent oil water, and immediately removes the effluent oil drops gathered on the first filter element, thereby reducing the filtration load of the filter element; and the oil-water separation is performed under a vacuum condition, so that the separation effect and the separation efficiency of the separation device are improved.

Owner:江苏天淳环保科技有限公司

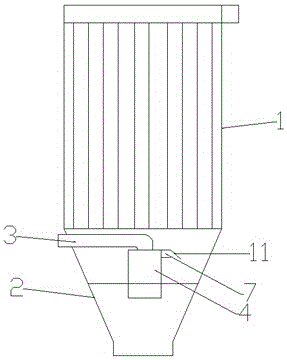

A filter cartridge dust collector with uniform air supply

ActiveCN106422614BConsistent dust removal loadImprove dust removal efficiencyCombination devicesEngineering

The invention discloses a filter cartridge dust collector with uniform air supply, which comprises a dust removal box body and an ash hopper, wherein the ash hopper is arranged below the dust removal box body and communicated; And the filter cartridge, the outer side wall of the upper end of the ash hopper is provided with an air duct and a static pressure box. Through the different settings of the vent area, the consistency of the air volume of each air outlet is ensured. After further equalization by the static pressure box, the air flow into the filter cartridge is uniform in size, ensuring the same dust removal load of each filter cartridge, and improving the filter cartridge. The dust removal efficiency also prolongs the service life of the filter cartridge. The airflow enters the annular pipe and the static pressure box through the air inlet, the contact area suddenly increases, the gas pressure becomes smaller, and the large particles in the air sink to the ash hopper under the action of gravity to prevent the filter cartridge from being blocked by large particles. Improve the dust removal effect.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Switching water production method of double outlet pure water machine with concentrated drain water recovery device

ActiveCN106186391BHigh utilization rate of concentrated waterExtend your lifeMultistage water/sewage treatmentWater productionElectric control

The invention relates to a water treatment industry, and concretely relates to filtering of drinking water. The invention discloses relates to a double-outlet purified water machine switching water-production method having a discharged thick water recovery device. According to the invention, the booster pumps connected in series are arranged between a preposition filter bladder and a fine filter bladder; a thick water receiver with a backwater port is communicated with a discharged thick water outlet of the fine filter bladder, the backwater port is communicated with a booster pump inlet pipeline; the water outlet of the fine filter bladder is communicated with a pure water interface of a double-outlet faucet, and a water sensor is arranged on the water outlet of the fine filter bladder, the booster pump outlet pipeline is communicated with a purified water interface of the double-outlet faucet through a first purified water pipeline of the water sensor; a purified water valve or a pure water valve are opened for triggering the corresponding water sensor, an electric signal corresponding to purified water outlet or pure water outlet are output to an electric control apparatus for driving the booster pump for extracting the discharged thick water in the thick water receiver, or conveying is carried out with purified water in the preposition filter bladder, or successive conveying is respectively carried out with the purified water in the preposition filter bladder, and the discharged thick can be individually flowed out from the purified water interface or the pure water interface.

Owner:杜也兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com