Oily water vacuum separation device

A technology of vacuum separation and oil-water separator, applied in liquid separation, separation method, grease/oily substance/float removal device, etc., can solve the problem of substandard discharge water, reduced reuse value of sewage oil, poor separation effect, etc. problems, to achieve the effect of reducing maintenance costs, reducing water content, and reducing disturbance emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

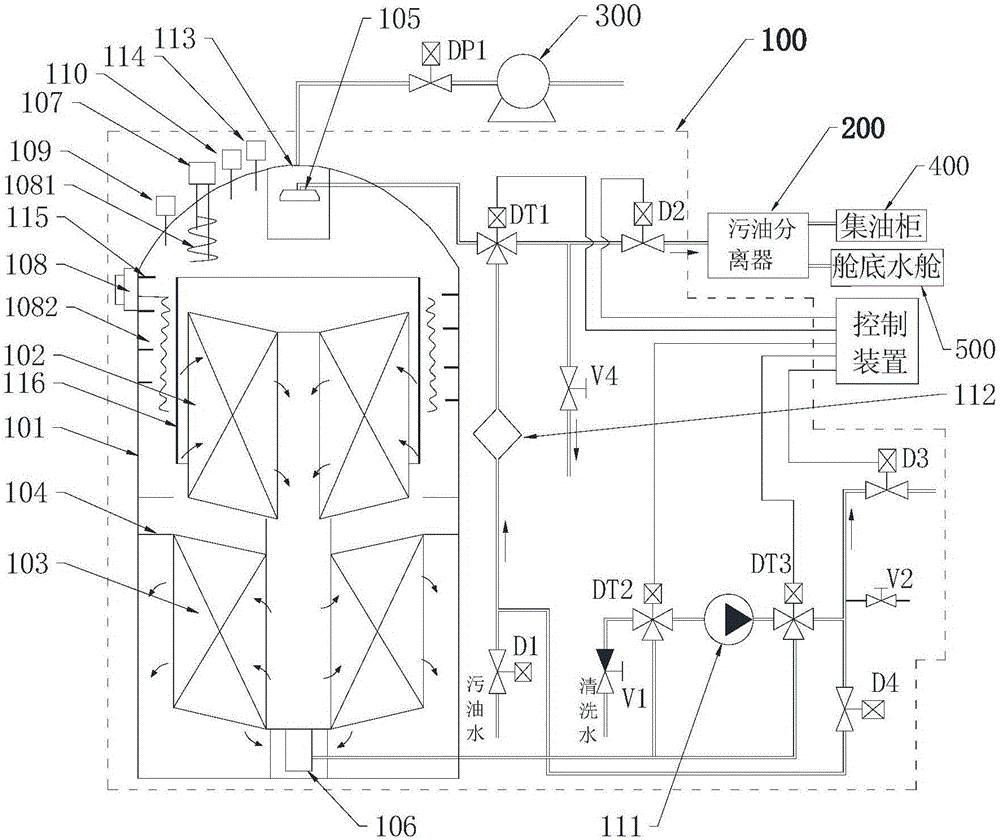

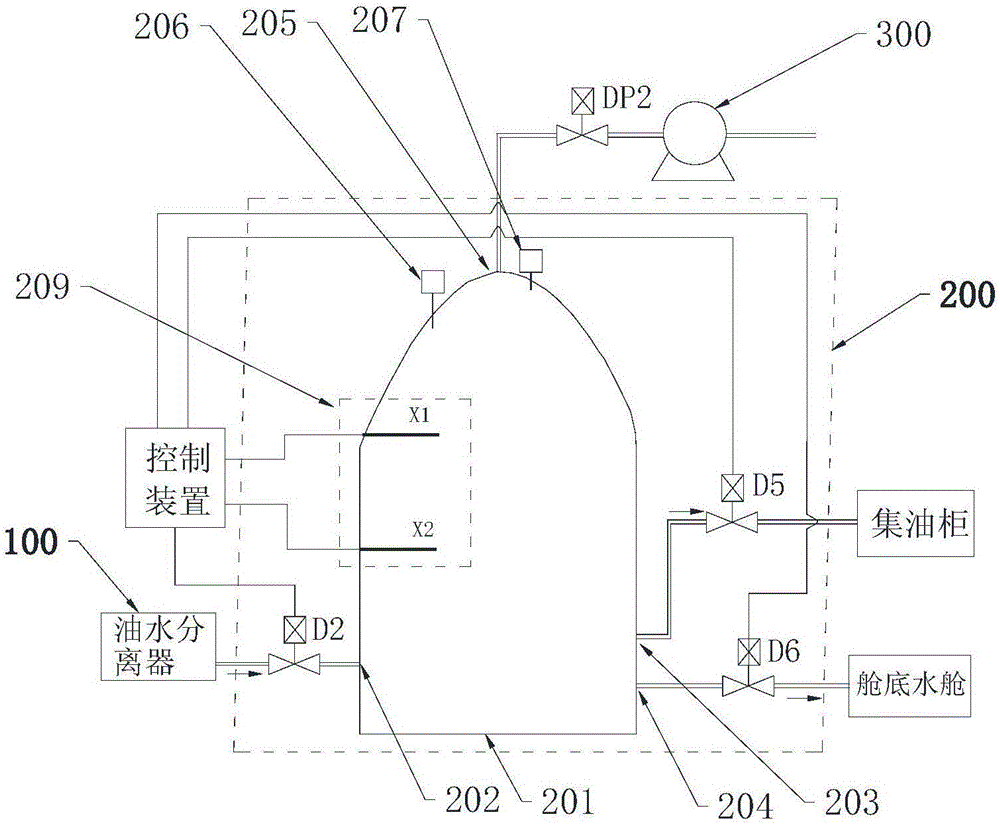

[0024] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

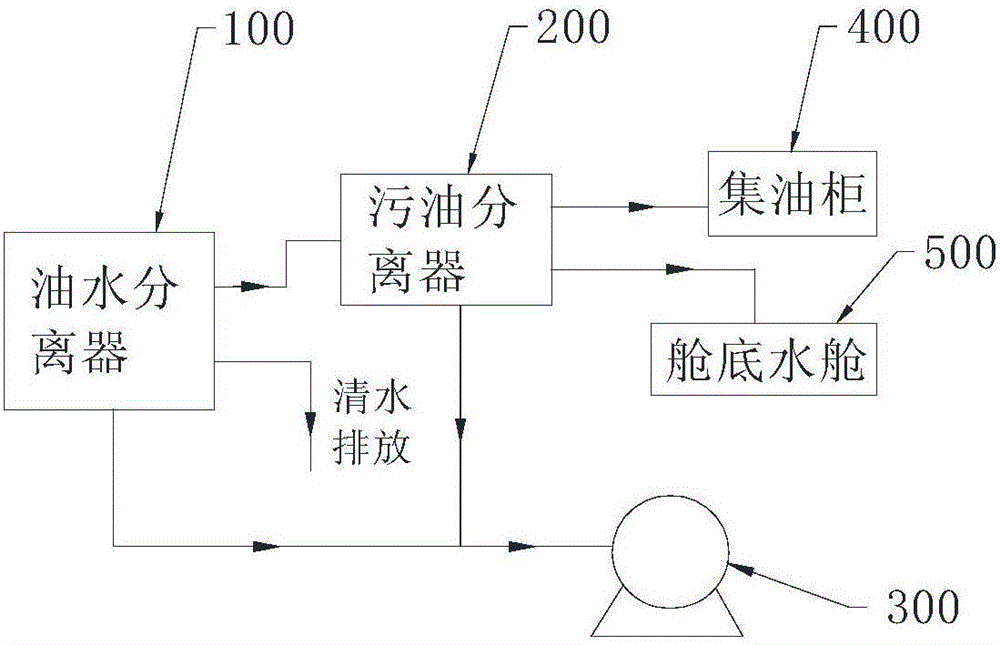

[0025] A kind of waste oil water vacuum separation device of the present invention, as Figure 1-Figure 3 As shown, the separation device includes an oil-water separator 100, a waste oil separator 200, a real sudden pump 300, an oil collection tank 400, a bilge tank 500 (which can be replaced by a water collection tank) and a control device. The top of the oil-water separator 100 is provided with a first suction port 113, and the top of the dirty oil separator 200 is provided with a second suction port 205, and the first suction port 113 and the second suction port 205 are connected with the vacuum pump 300 respectively. The input port is connected. The bottom of the oil-water separator 100 is provided with a water outlet 106 for discharging th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com