Oil-base drilling cuttings thermal analytical treatment method

A technology of oil-based drilling cuttings and treatment methods, which is applied in the field of offshore or onshore oil-based drilling cuttings treatment and thermal analysis of waste oil-based drilling cuttings. It can solve the problems of pollution, reduce the oil content of drilling cuttings, and achieve oil content The effect of low cost, convenient transportation and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

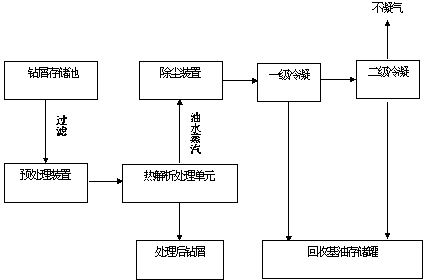

[0033] see figure 1 Shown, the present invention comprises the following steps:

[0034] (1) Filter the oil-based drilling cuttings to remove impurities and large particle cuttings; for large particle cuttings, crush them and filter again;

[0035] (2) Transport the filtered oil-based cuttings to the pretreatment device, carry out stirring and preheating treatment on the cuttings, improve the fluidity of the oil-based cuttings to facilitate the pumping of the feed pump (gear pump and plunger pump) Enter the thermal analysis processing host for thermal analysis processing;

[0036] (3) Keep the feeding process and the entire pipeline in a sealed state. Before the oil-based drilling cuttings enter the thermal analysis processing main engine, the main engine and gas phase pipeline must be replaced with inert gas to ensure the safety of the treatment process;

[0037] (4) Use the feed pump to transport the oil-based drilling cuttings in the pretreatment device to the thermal ana...

Embodiment 2

[0045] On the basis of Example 1, the specific implementation of this example is: the specific method of filtering oil-based cuttings in step (1) is: using a storage box to stir the oil-based cuttings to be processed by forward and reverse spirals After that, it is sent to the vibrating screen to remove solid phase particles and sundries above Φ10mm, and the oil-based cuttings passing through the vibrating screen enter the pretreatment device; these oily cuttings particles above Φ10mm are crushed together and then pass through the vibrating screen again and enter the pretreatment device again. The processing device is to enter the next step of processing flow.

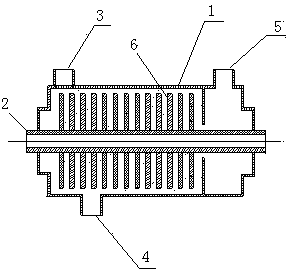

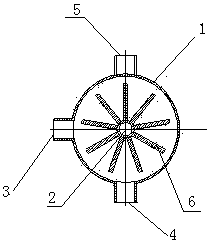

[0046] In step (2), the filtered oil-based drilling cuttings are pumped to the pretreatment device (the pretreatment device is a prior art equipment, which is a storage tank with an interlayer, the storage tank has a stirring impeller, and has A device with a stirring function, circulating water in the interlay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com