Patents

Literature

1107results about How to "Reduce oil content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

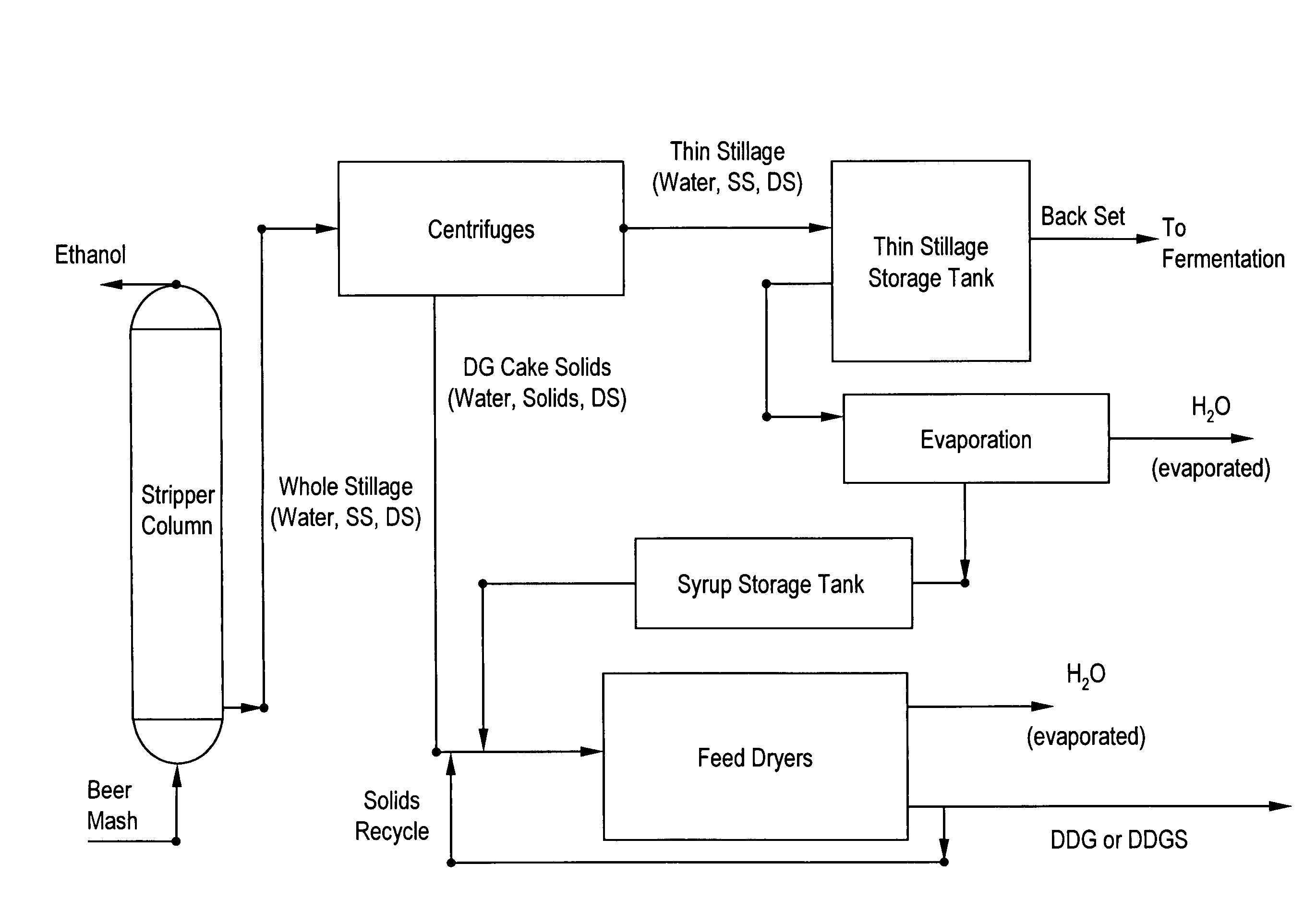

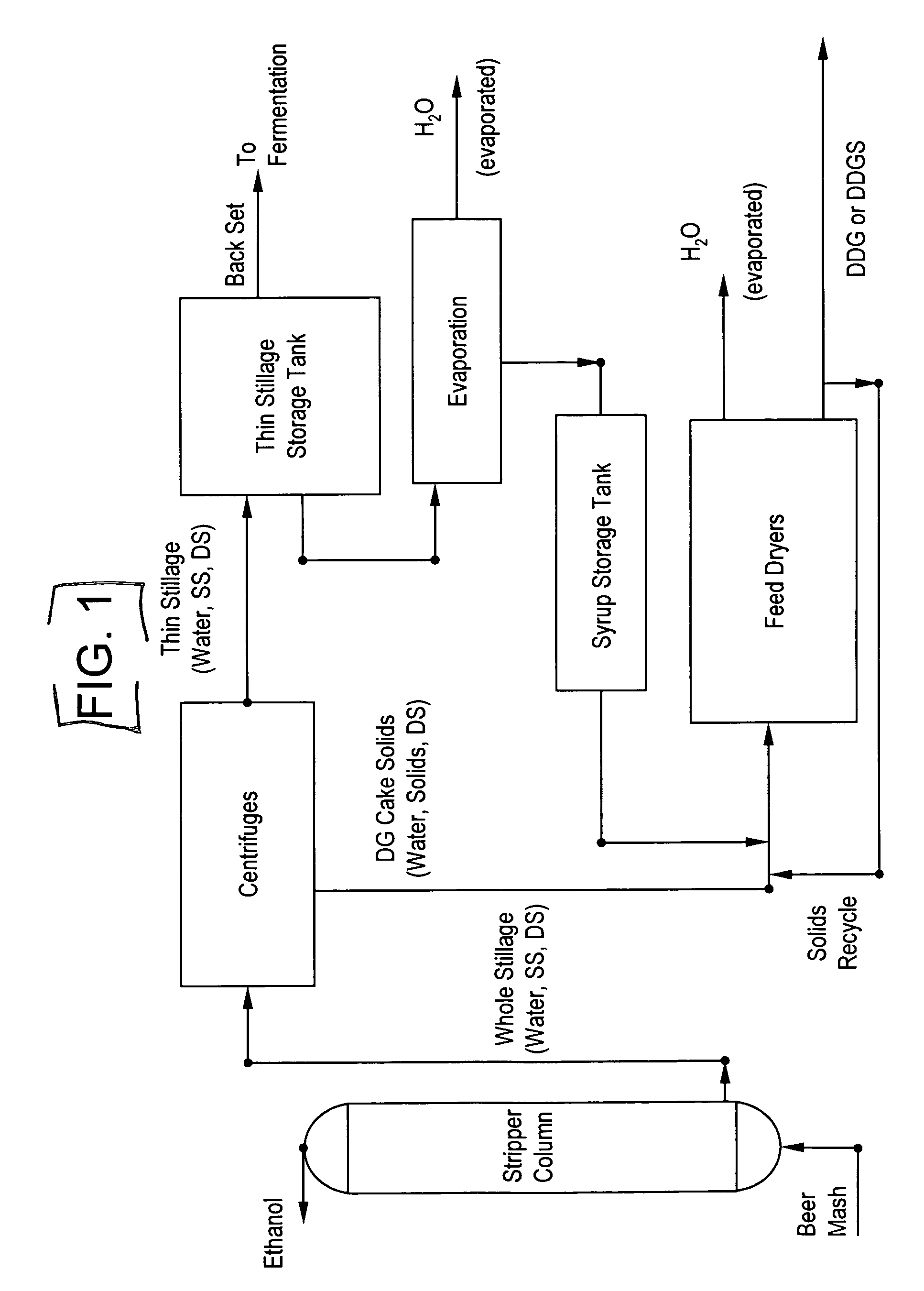

Method of dewatering thin stillage processing streams

InactiveUS20060006116A1Improve agglomerationAbility to withstandBy-product recoveryWater treatment parameter controlAcryditeSodium methacrylate

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:NALCO CO

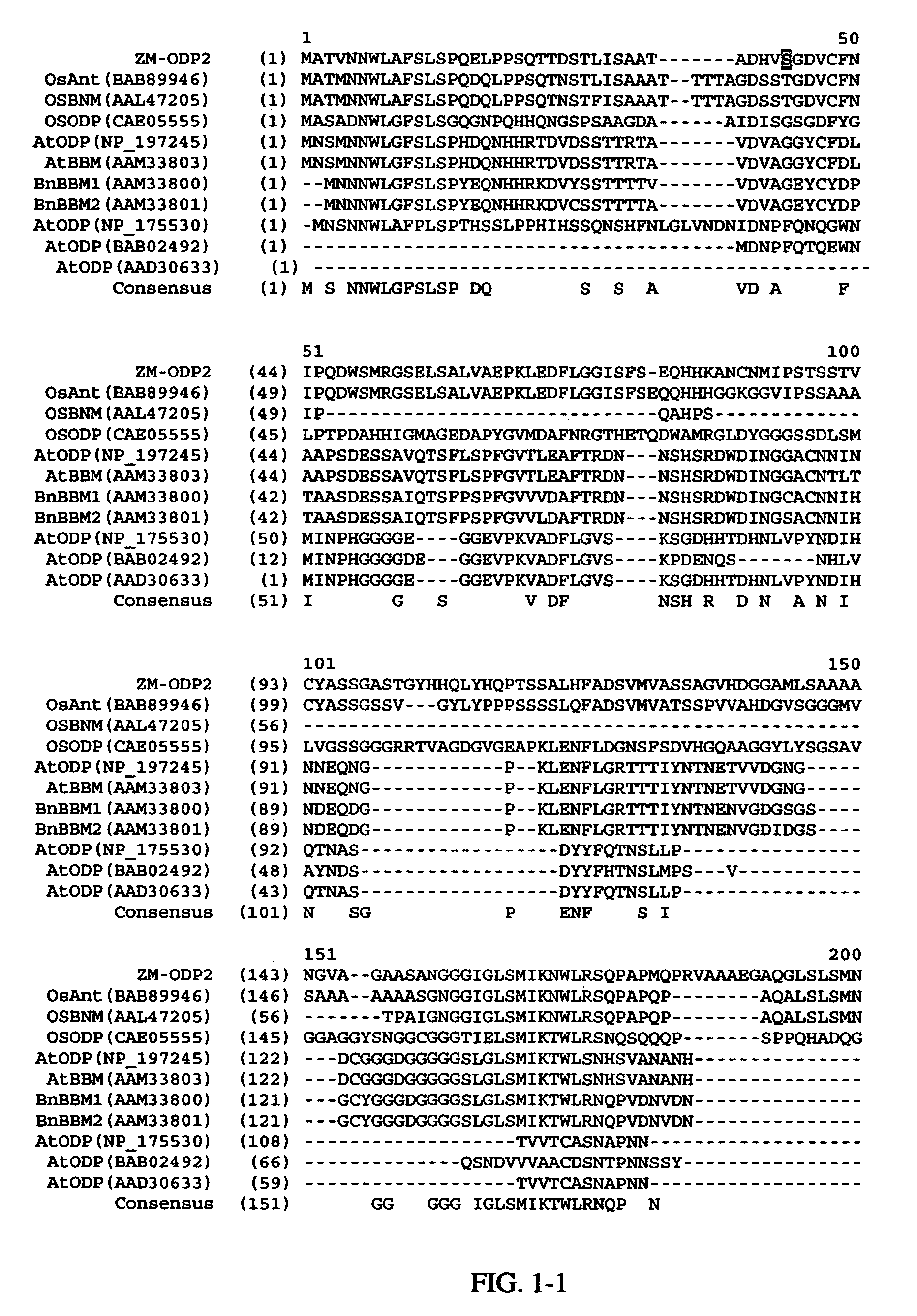

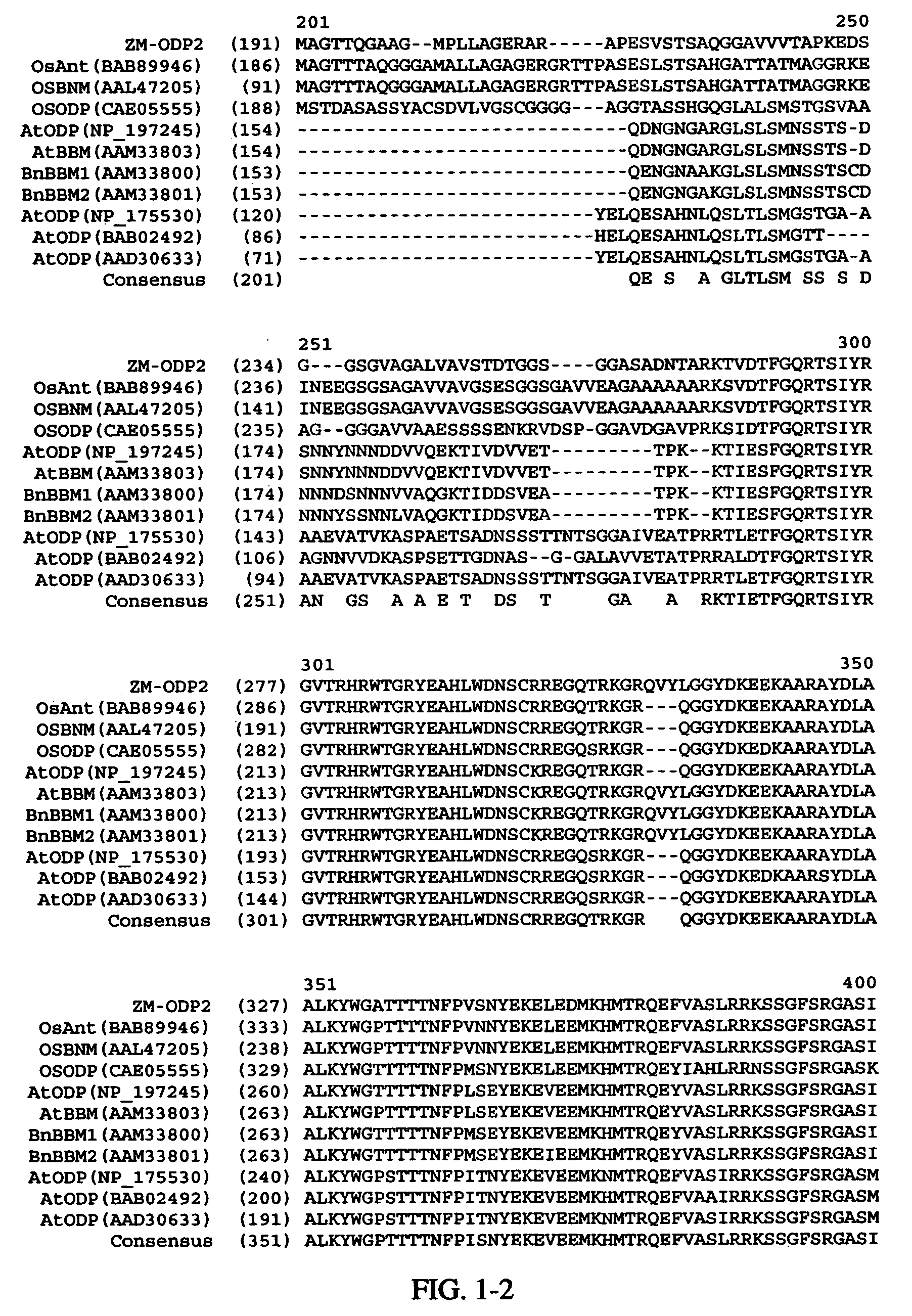

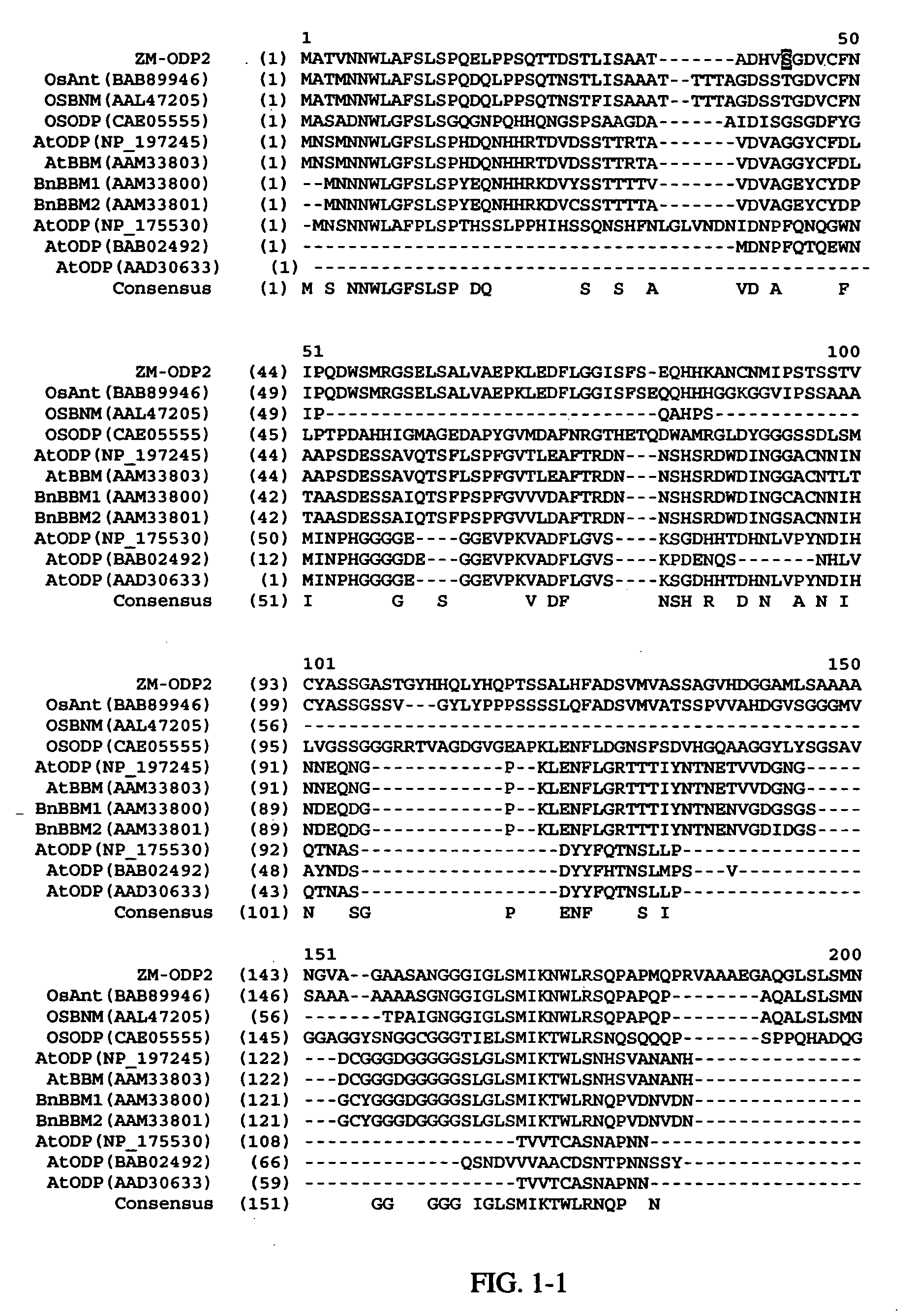

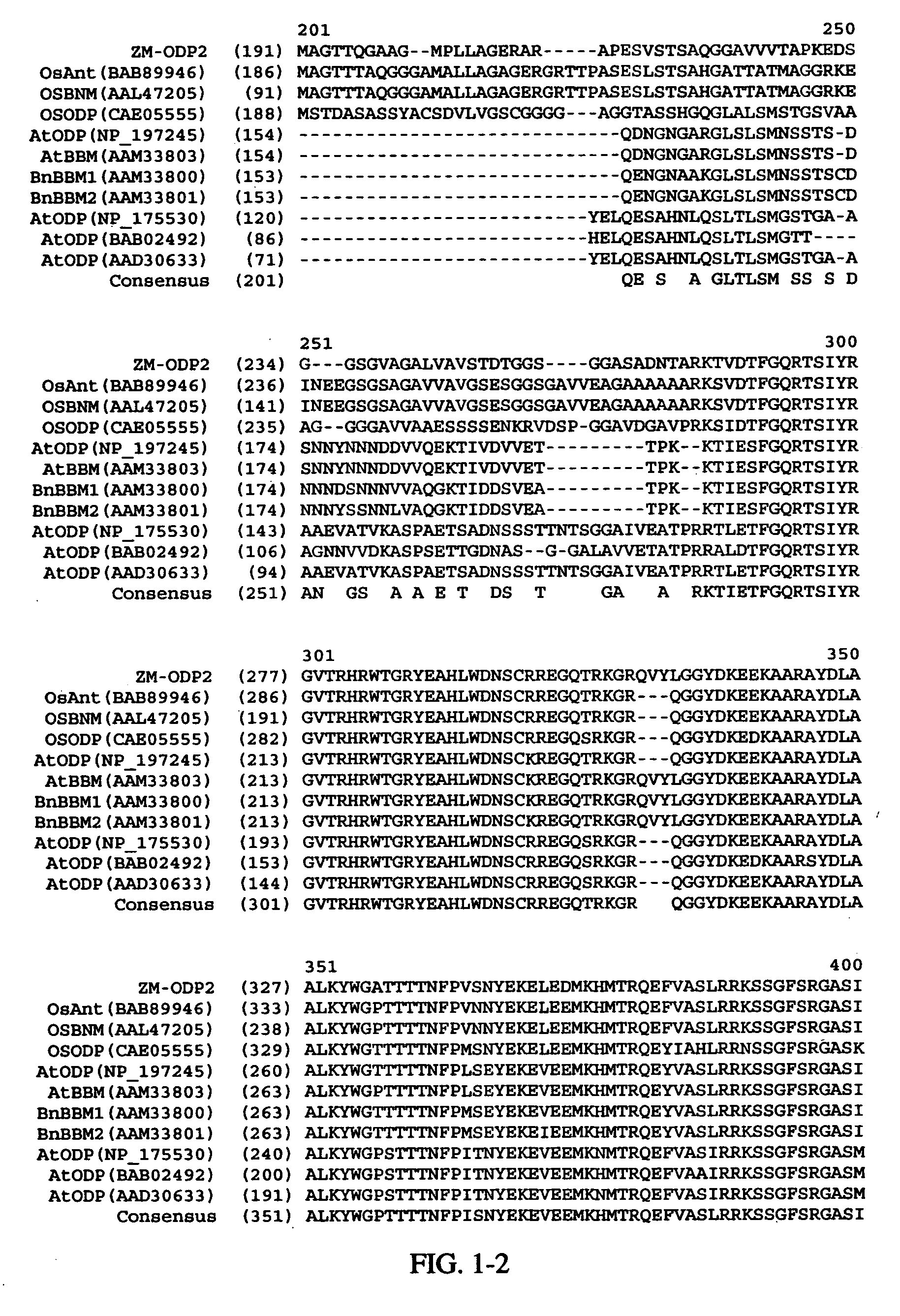

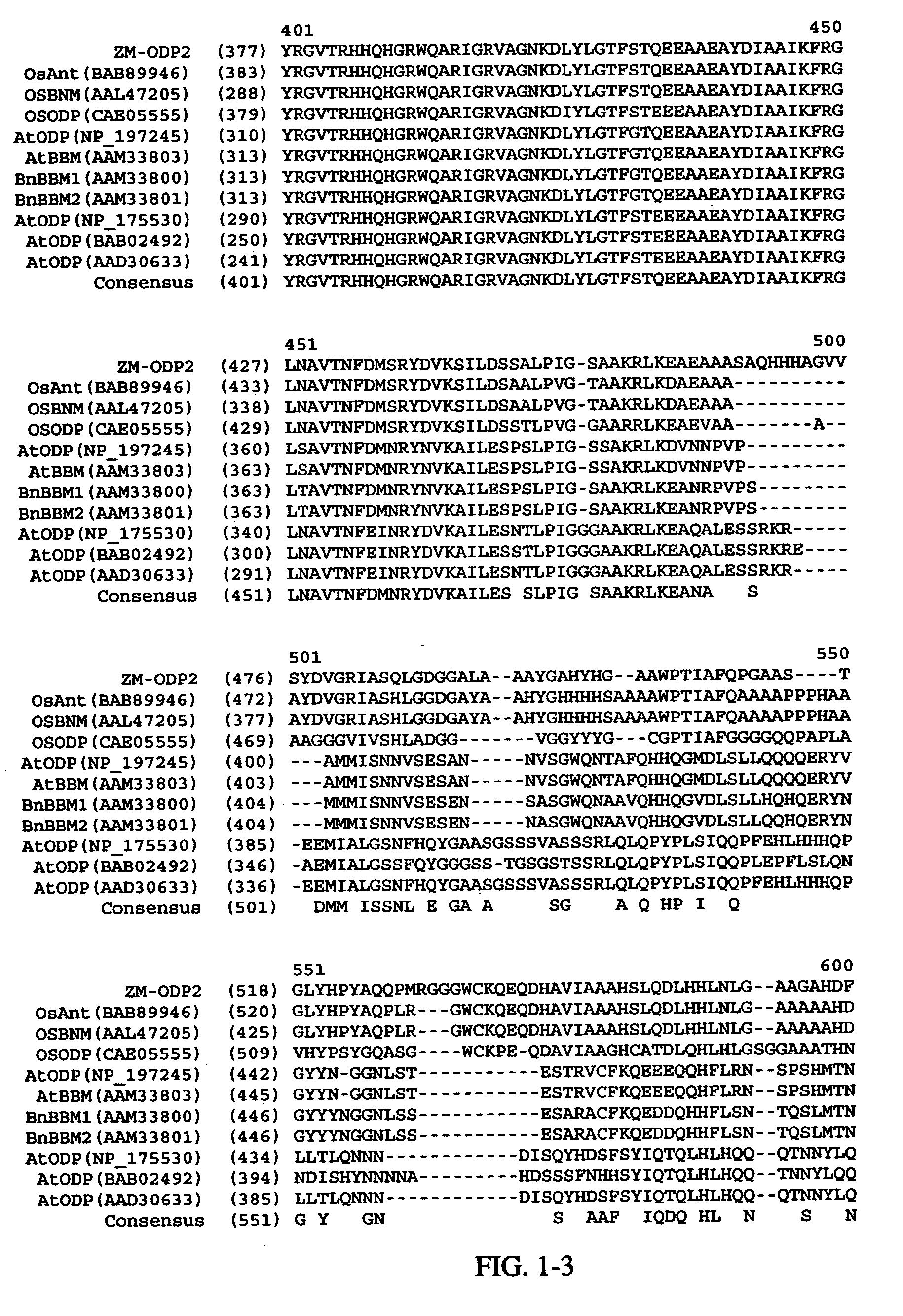

AP2 domain transcription factor ODP2 (ovule development protein 2) and methods of use

ActiveUS7579529B2Altered oil phenotypeReduce oil contentSugar derivativesClimate change adaptationPlant cellTransformation efficiency

Owner:PIONEER HI BRED INT INC

Composite fruit and vegetable crisp chip and manufacturing method thereof

The invention relates to a composite fruit and vegetable crisp chip and a manufacturing method thereof, especially to a composite fruit and vegetable crisp chip manufactured by using combined microwave vacuum freeze drying technology and vacuum low temperature frying technology, belonging to the field of food processing technology. The manufacturing method for the composite fruit and vegetable crisp chip comprises the following steps: preparation of condensed fruit and vegetable pulp; batching; batch mixing; die molding; microwave vacuum freeze drying; vacuum low temperature frying; etc. With the manufacturing method, generation of harmful substances like acrylamide and trans-fatty acids is reduced in the process of manufacturing, and the manufactured composite fruit and vegetable crisp chip has the advantages of crisp taste, a bright color, small nutrient loss, etc.

Owner:宁夏虹桥有机食品有限公司

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Method of dewatering thin stillage processing streams

ActiveUS7497955B2Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsSodium methacrylateSodium salt

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

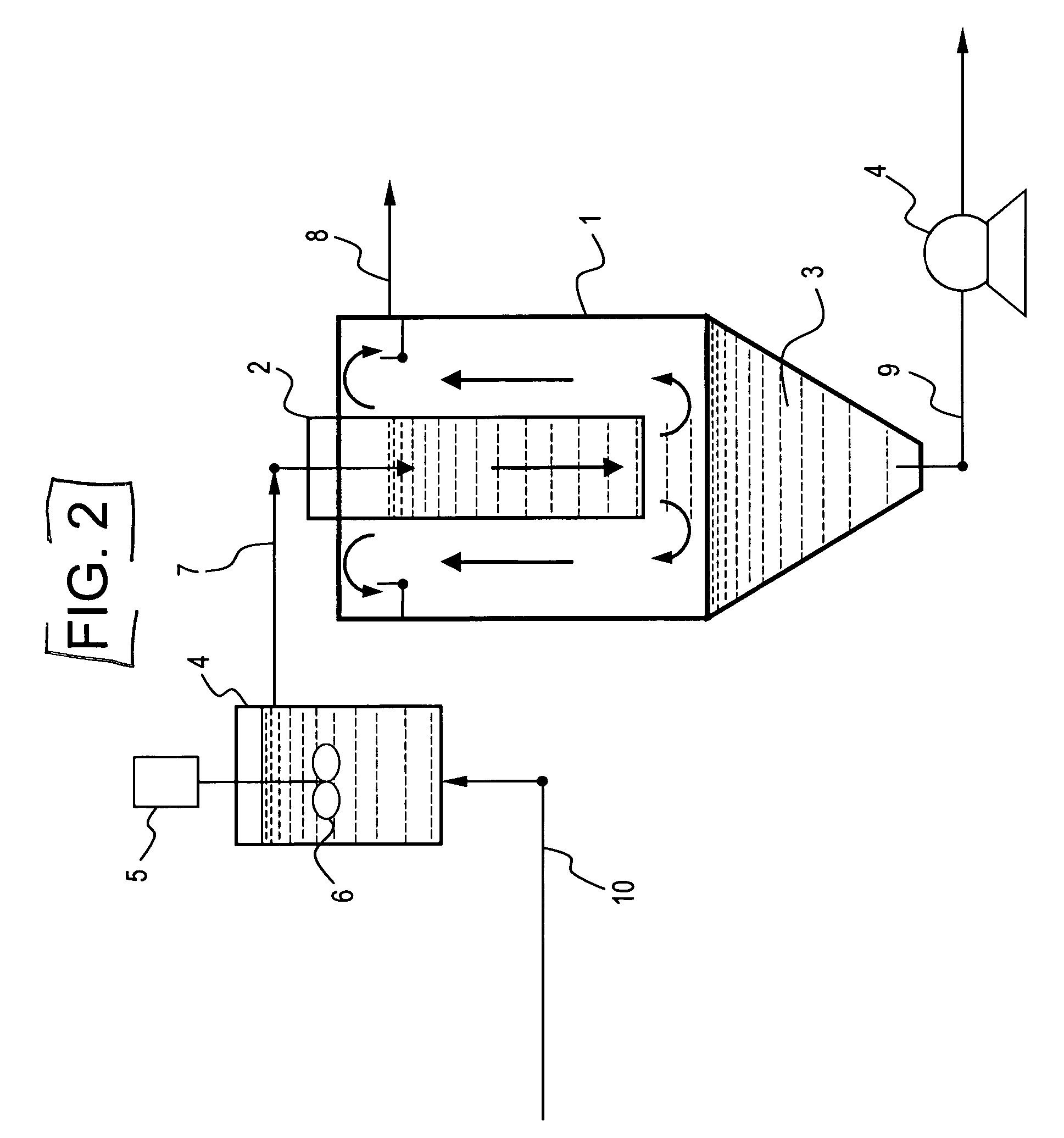

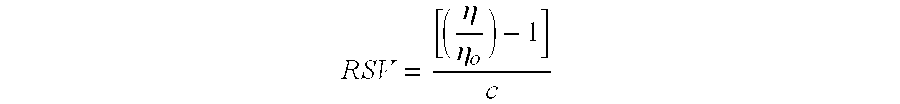

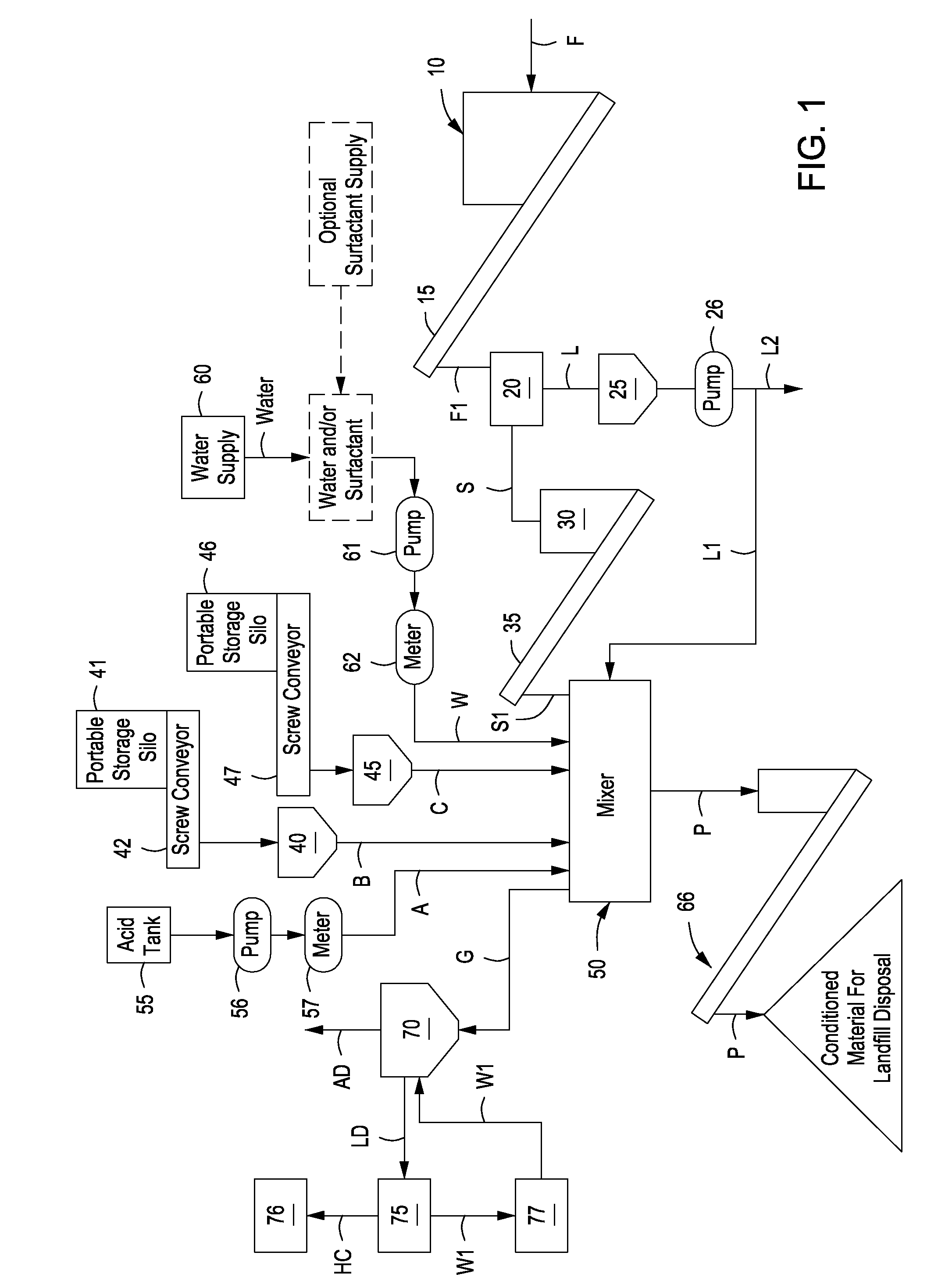

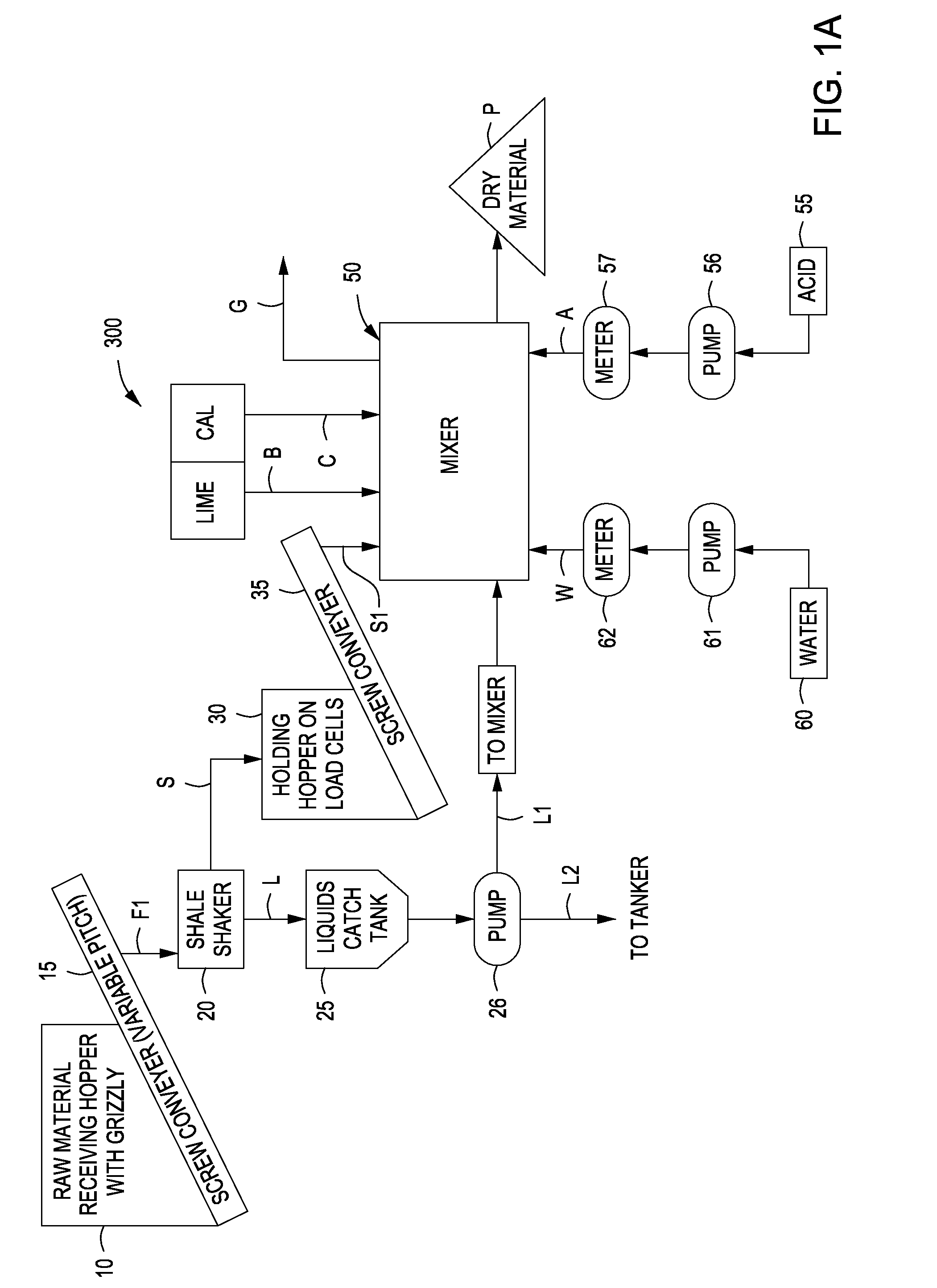

System and method for treating a contaminated substrate

InactiveUS20130269735A1Reduce oil contentElectrostatic cleaningFlushingAlkaline earth metalCollection system

A method and apparatus is disclosed for treating and processing an oil, water or oil and water-contaminated substrate such as oil field waste. The substrate may be pretreated with water and / or surfactant and may be mixed under low shear conditions with a base such as a compound containing alkaline earth or lime and an optional catalyst. Mixing the substrate with the base creates a heat. Next, the substrate may be mixed with an acid such as sulfuric acid. As the substrate is mixed, it causes an exothermic reaction with a heat that vaporizes the oil, reaction products and water. Recoverable constituents in the vapor can be condensed in a vapor collection system. The treated substrate may be essentially free of oil and has a controlled water content and pH that can be adjusted according to the use of the end dry product.

Owner:GREEN OILFIELD ENVIRONMENTAL SERVICES

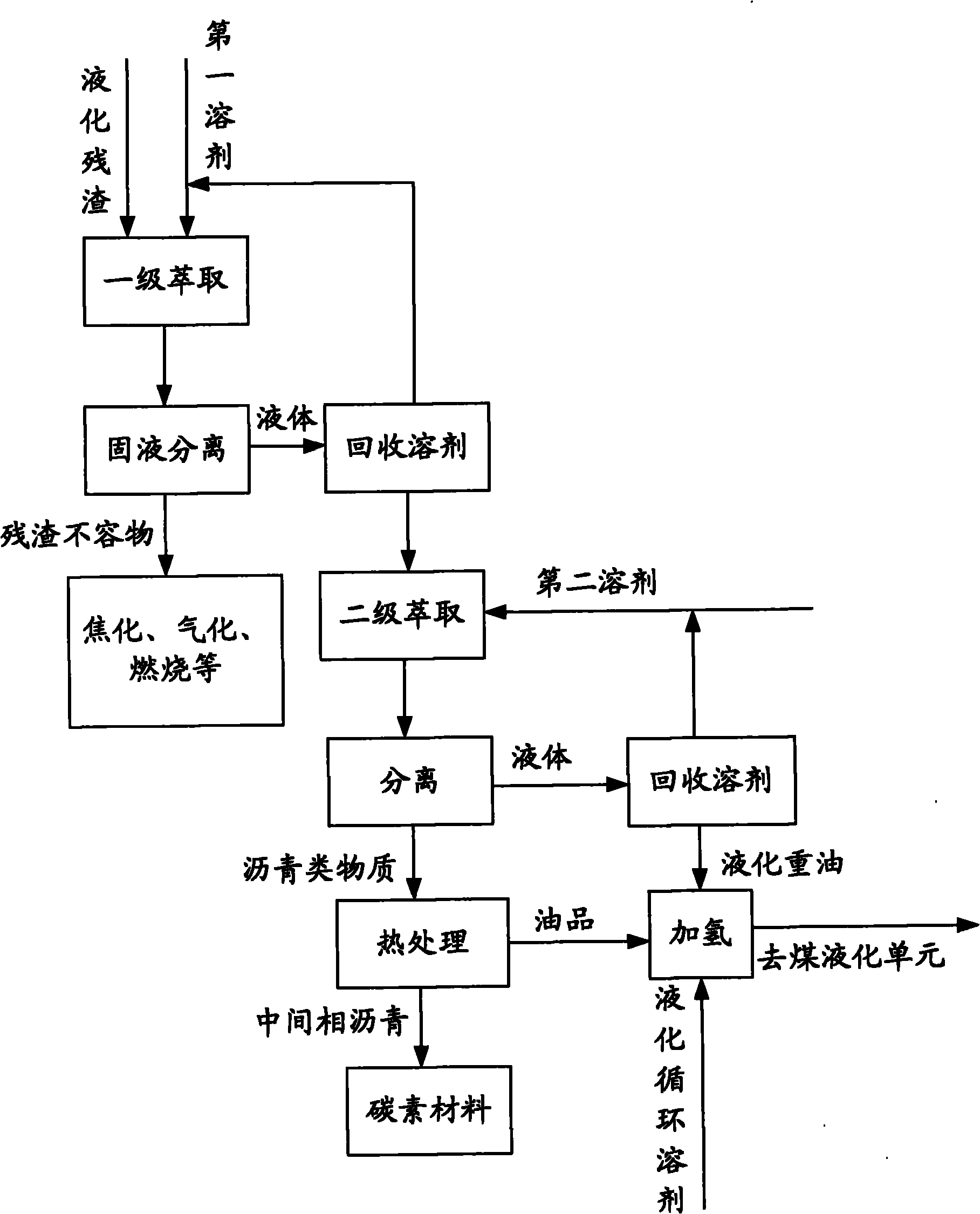

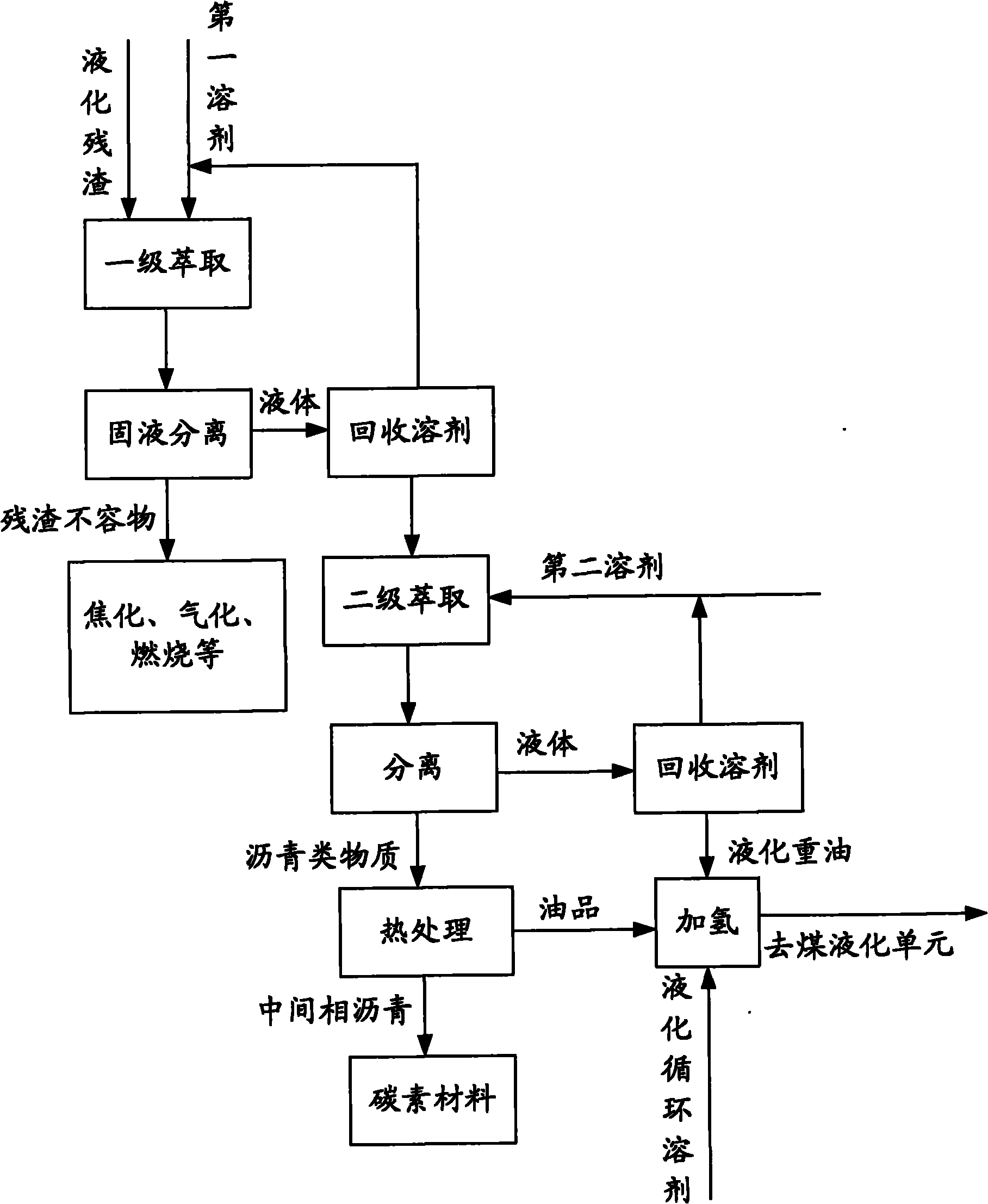

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

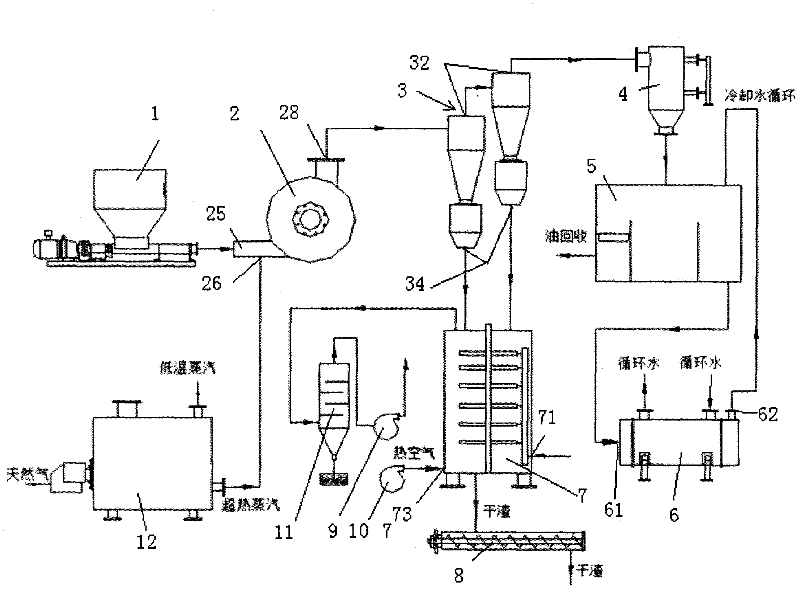

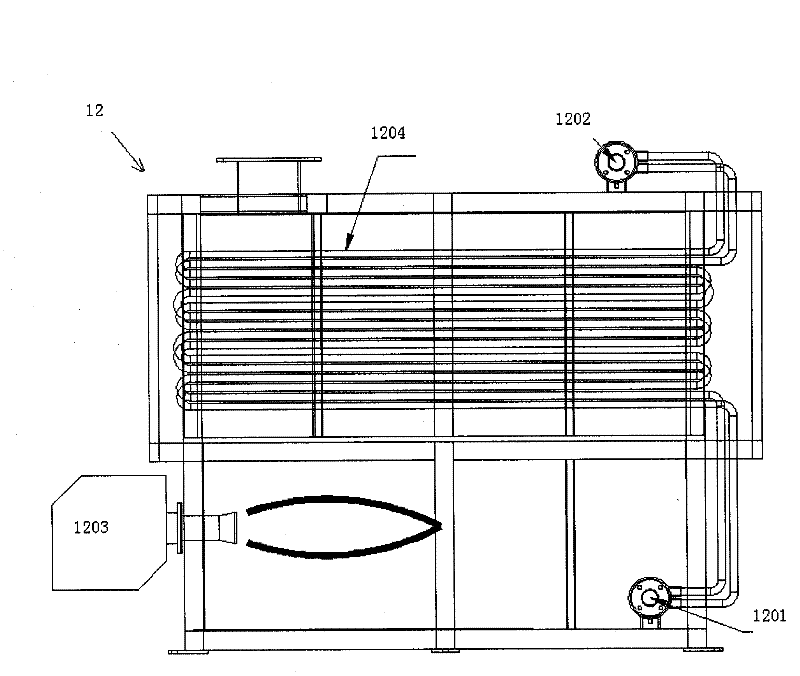

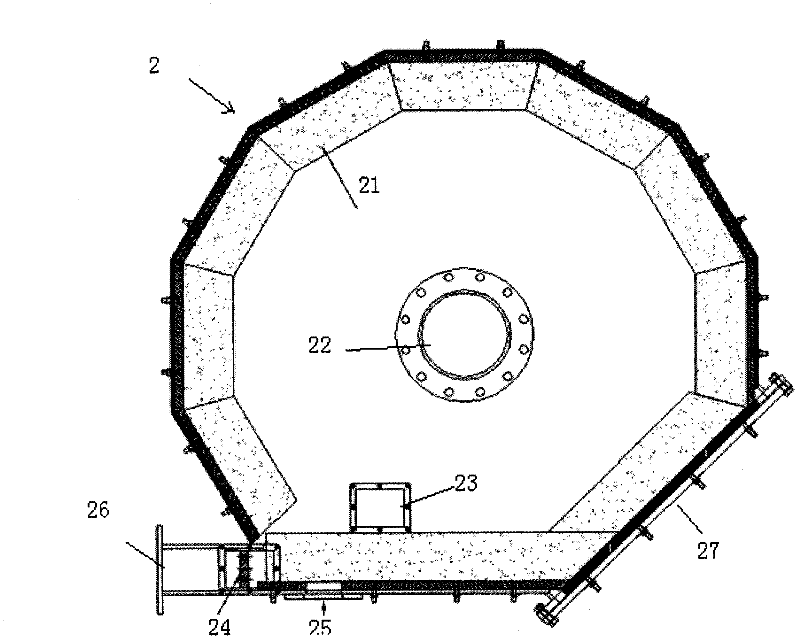

Treatment method and treatment apparatus of oily sludge

InactiveCN102503055AHigh recovery rateReduce moisture contentSludge treatment by thermal conditioningSludgeLiquid state

The invention provides a treatment method of oily sludge, which comprises the steps of: introducing overheated vapor into a high temperature treatment groove to roast the oily sludge so as to evaporate the liquid containing oil and water in the oily sludge to gas; separating the solid granules from the oily sludge and contained in the gas in a gas-solid separator, and conveying the solid granules to a drying machine to be dried and burnt so as to be discharged; condensing the gas separated from the gas-solid separator to liquid state oil and water, separating the liquid state oil and water in an oil-water separator to be respectively recycled, wherein the oily sludge is introduced into the high temperature treatment groove in a pumping manner, the overheated vapor is introduced into the high temperature treatment groove by supersonic jet flow and is vertically collided with the oily sludge. The invention further provides a treatment apparatus of oily sludge for executing the method; the treatment method and treatment apparatus provided by the invention have the advantages of guaranteeing high crude oil recovery, and small water content and oil content of finally generated dry residues.

Owner:河北海清大地环保科技有限公司

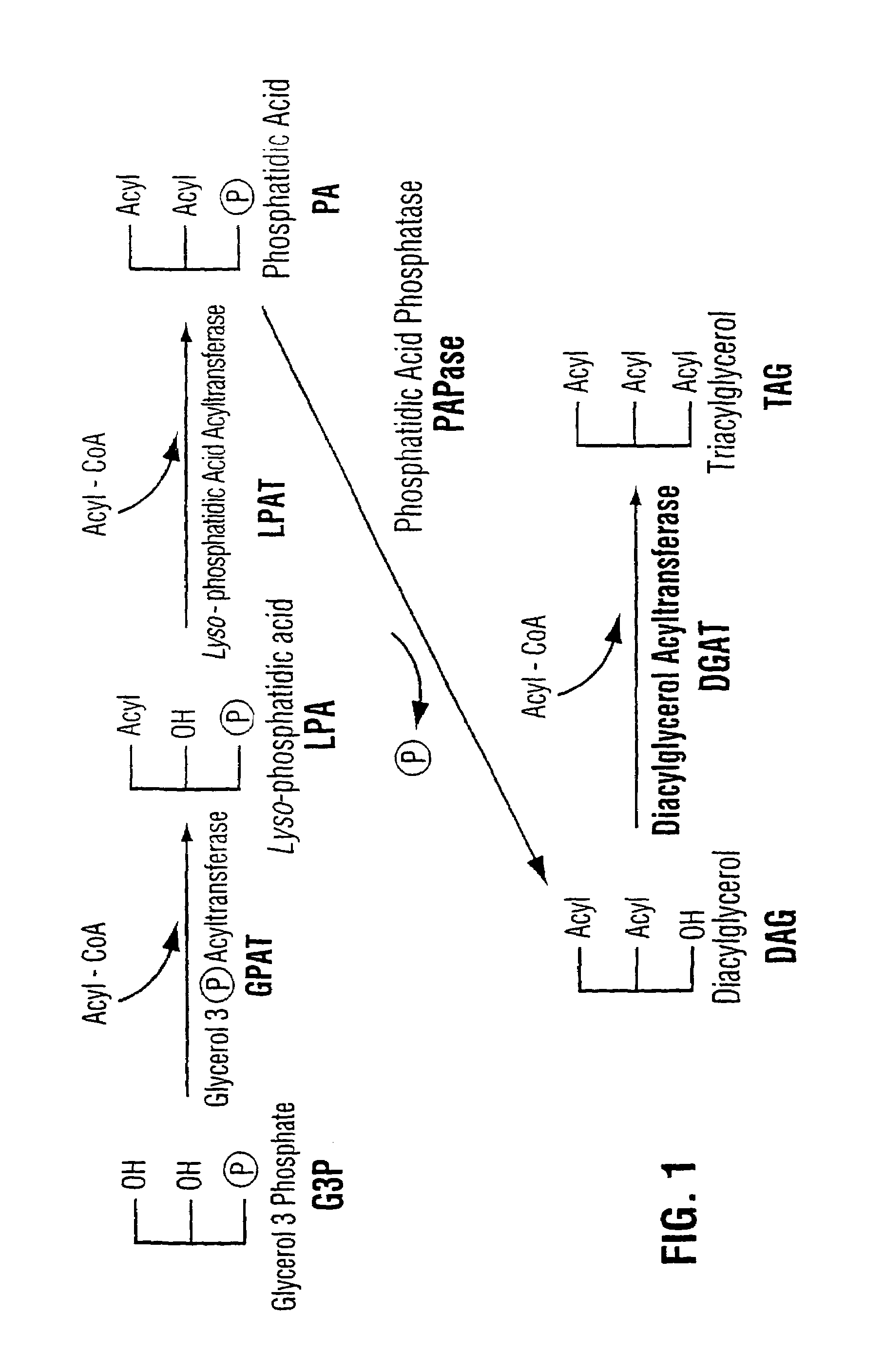

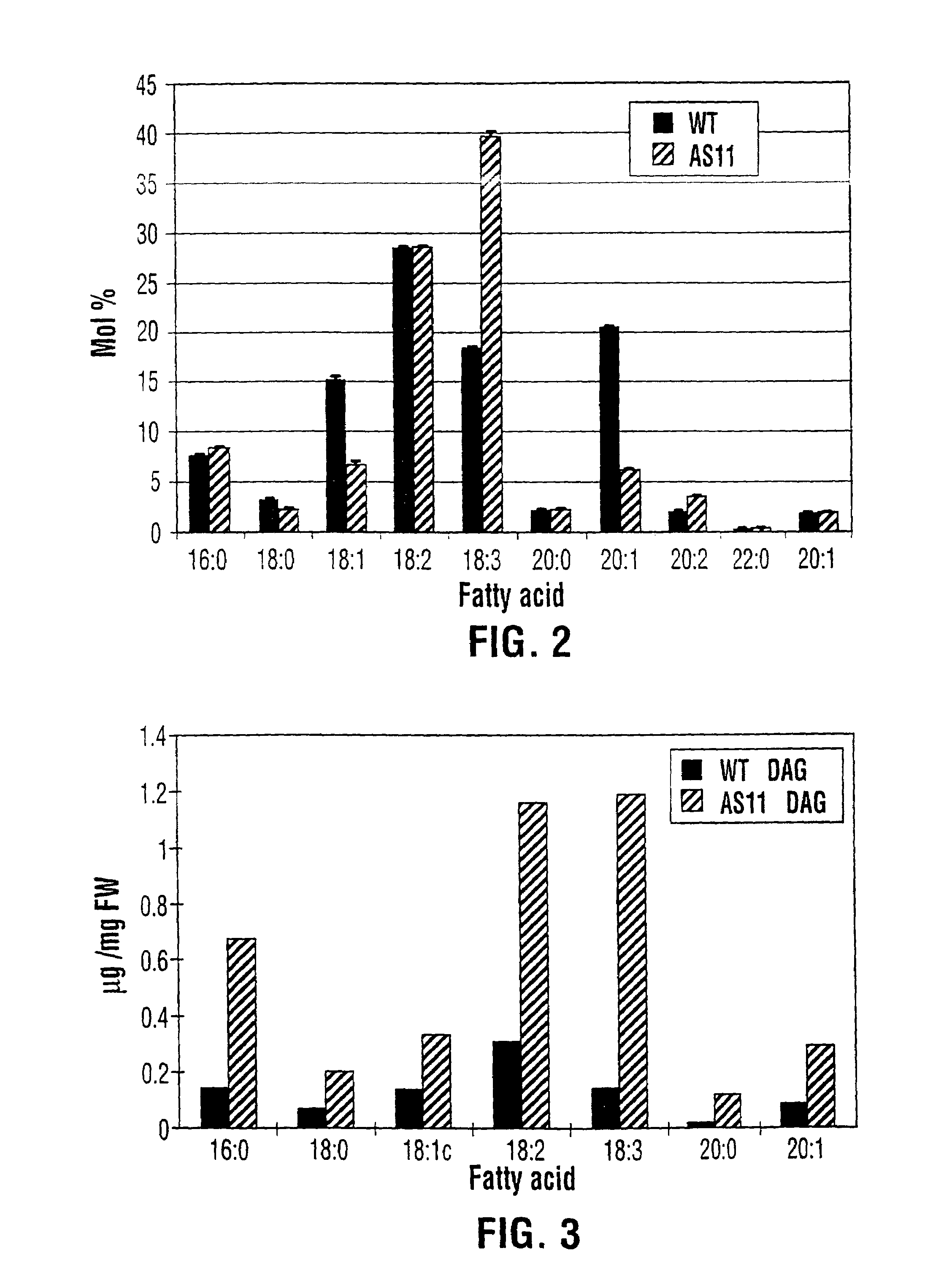

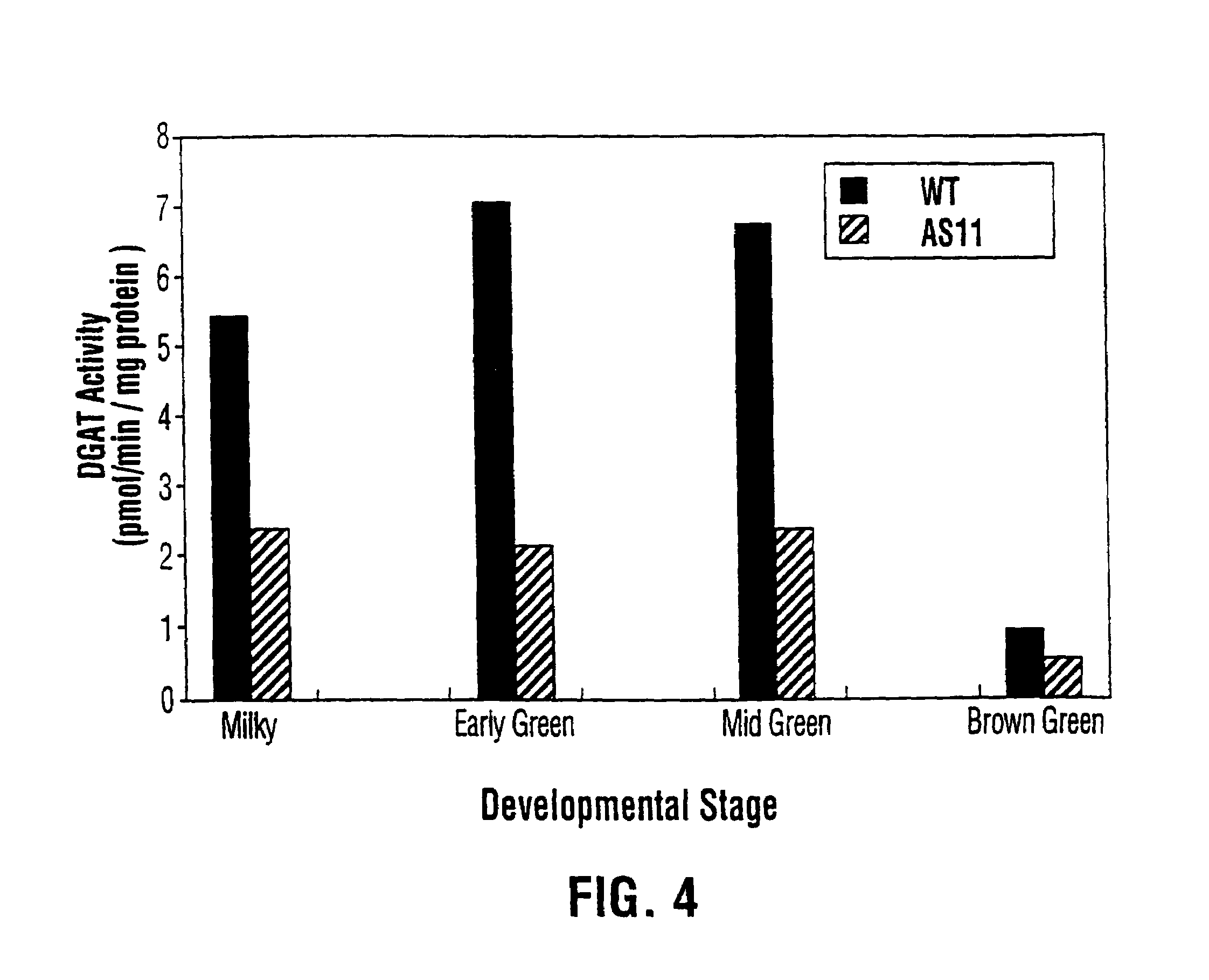

Diacylglycerol acyltransferase gene from plants

InactiveUS7015373B1Reduced DGAT activityReduce rateSugar derivativesTransferasesBrassicaceaePlanting seed

Owner:NAT RES COUNCIL OF CANADA

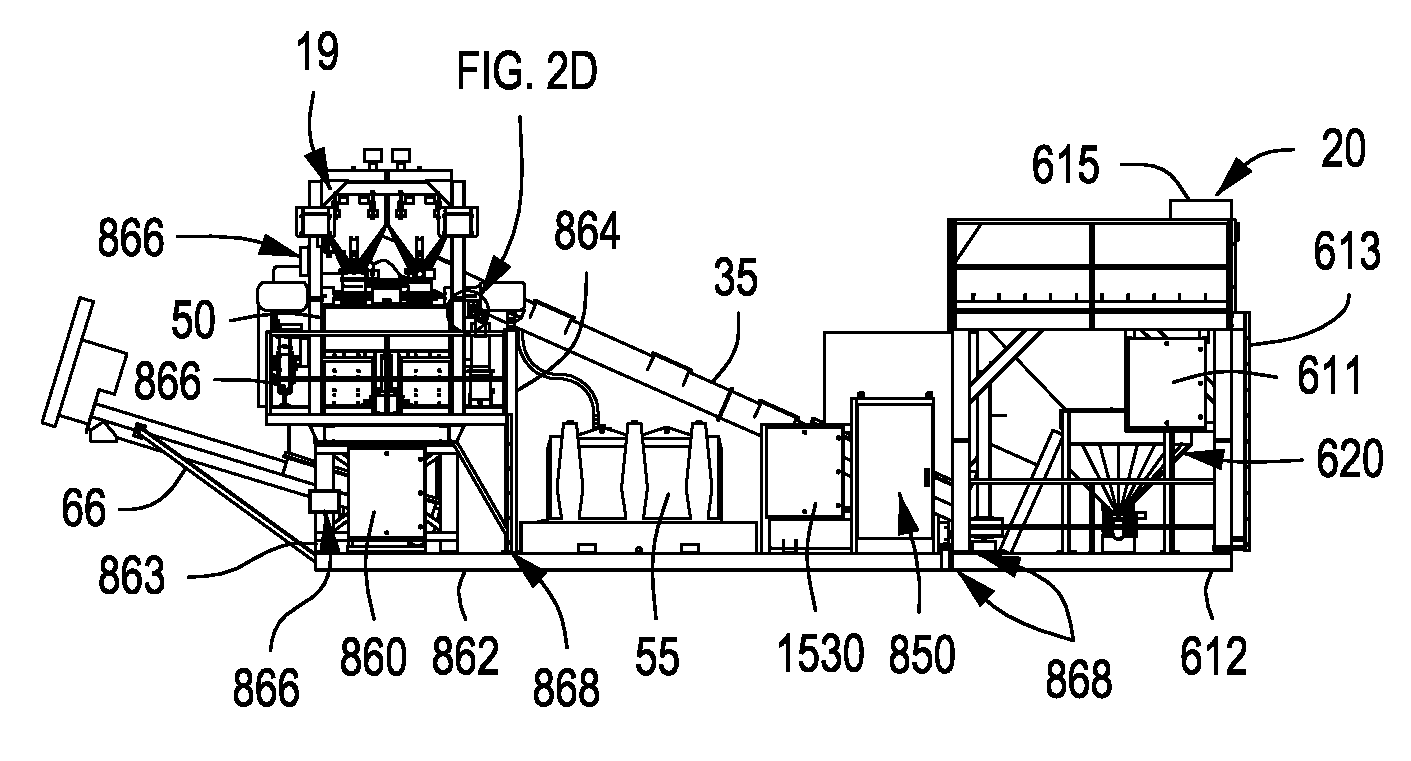

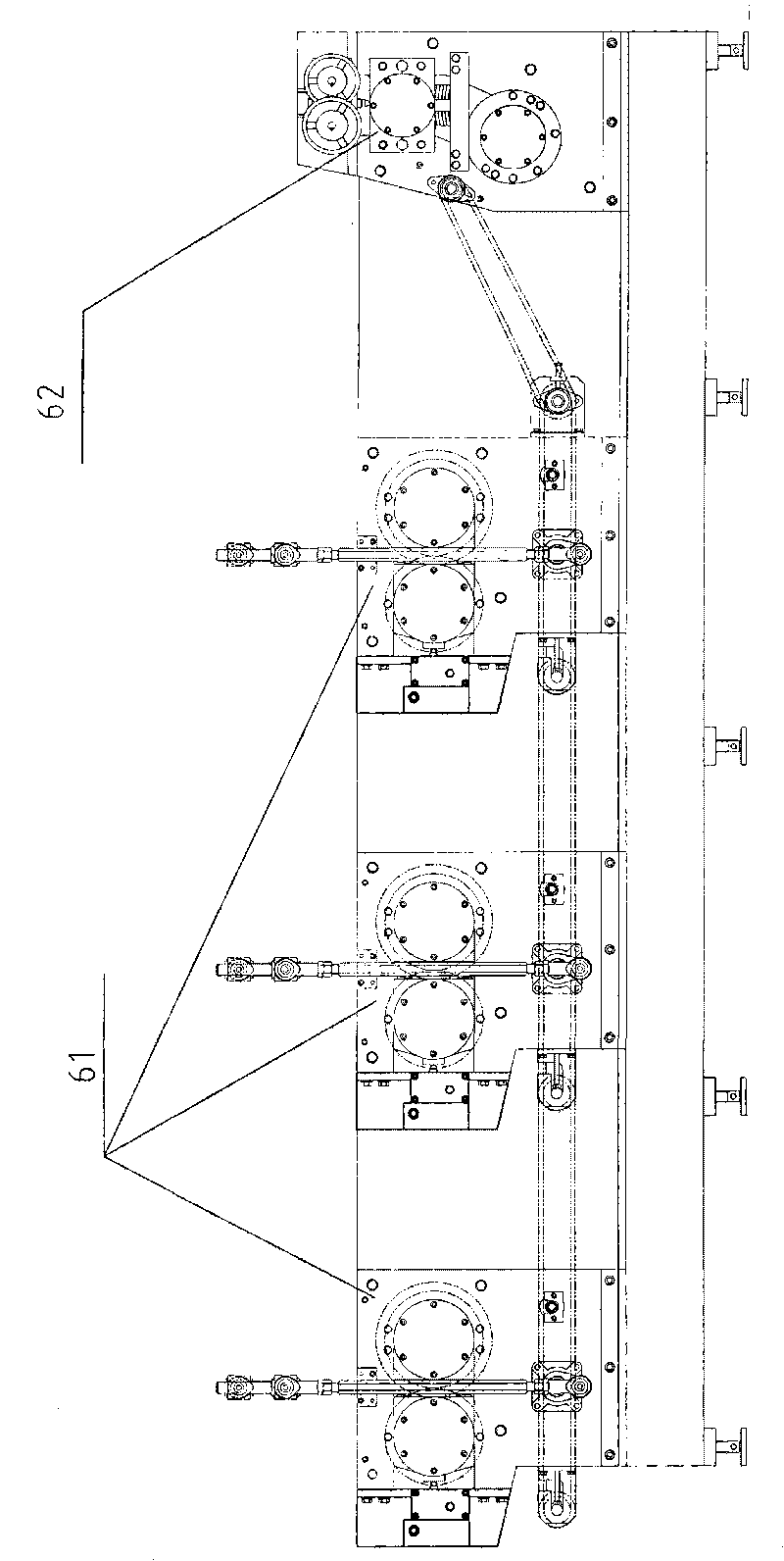

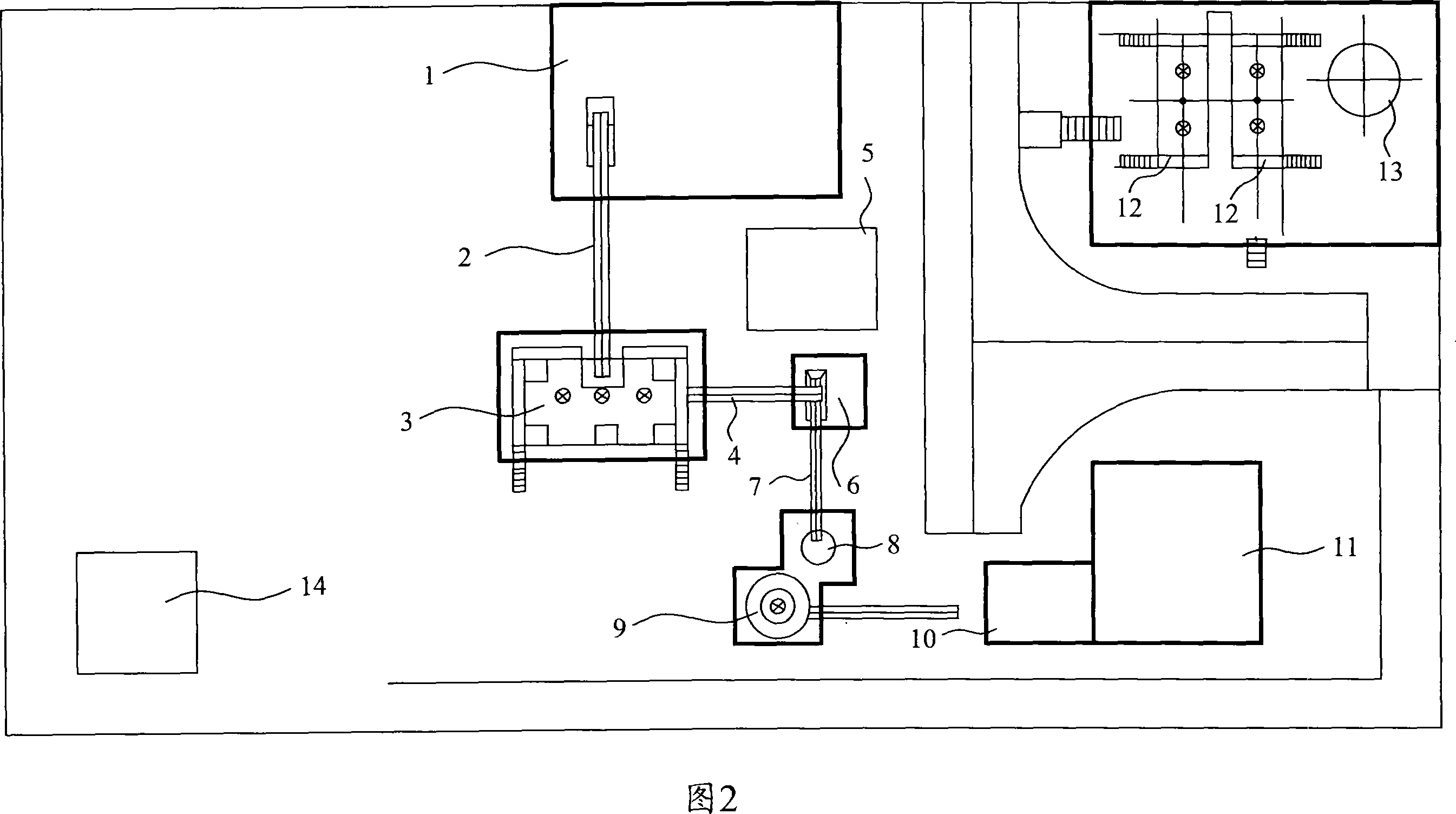

Oil spraying instant noodle production line and production technology thereof

InactiveCN101720890AFragrant and delicious tasteReduce oil contentFood preparationDough processingAlkaline waterHigh volume manufacturing

The invention relates to oil spraying instant noodle production line and production technology thereof. The production line is sequentially provided with an alkaline water bucket, a quantitative water adding bucket, a vibrating screen, a double shaft flour-mixing machine, a curing feeder, a composite tablet machine, a continuous tablet machine, a three-layer vaporizer, a cutting folder, a spraying flavouring machine, an oil spraying noodle frying machine, a microwave drying machine, an air cooling machine and an output packaging device. The equipment is full automatic, production efficiency is high, thus being applicable to mass production; in the production equipment, oil spraying device is adopted to carry out oil spraying treatment on noodle block, the noodle block has the flavour of common instant noodles while the oil content thereof is only about 5%, thus the noodle block is a good low oil content healthy food.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

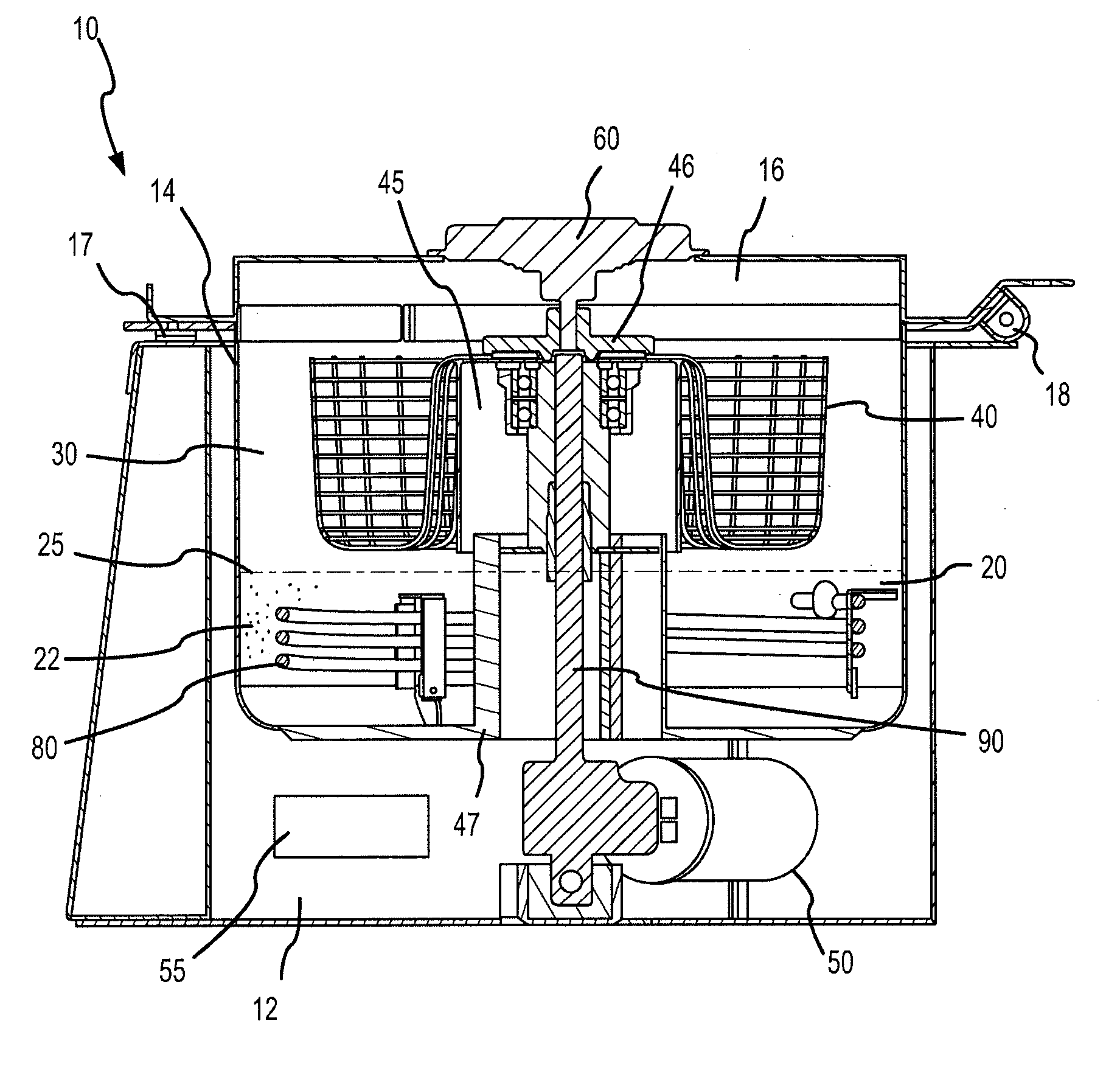

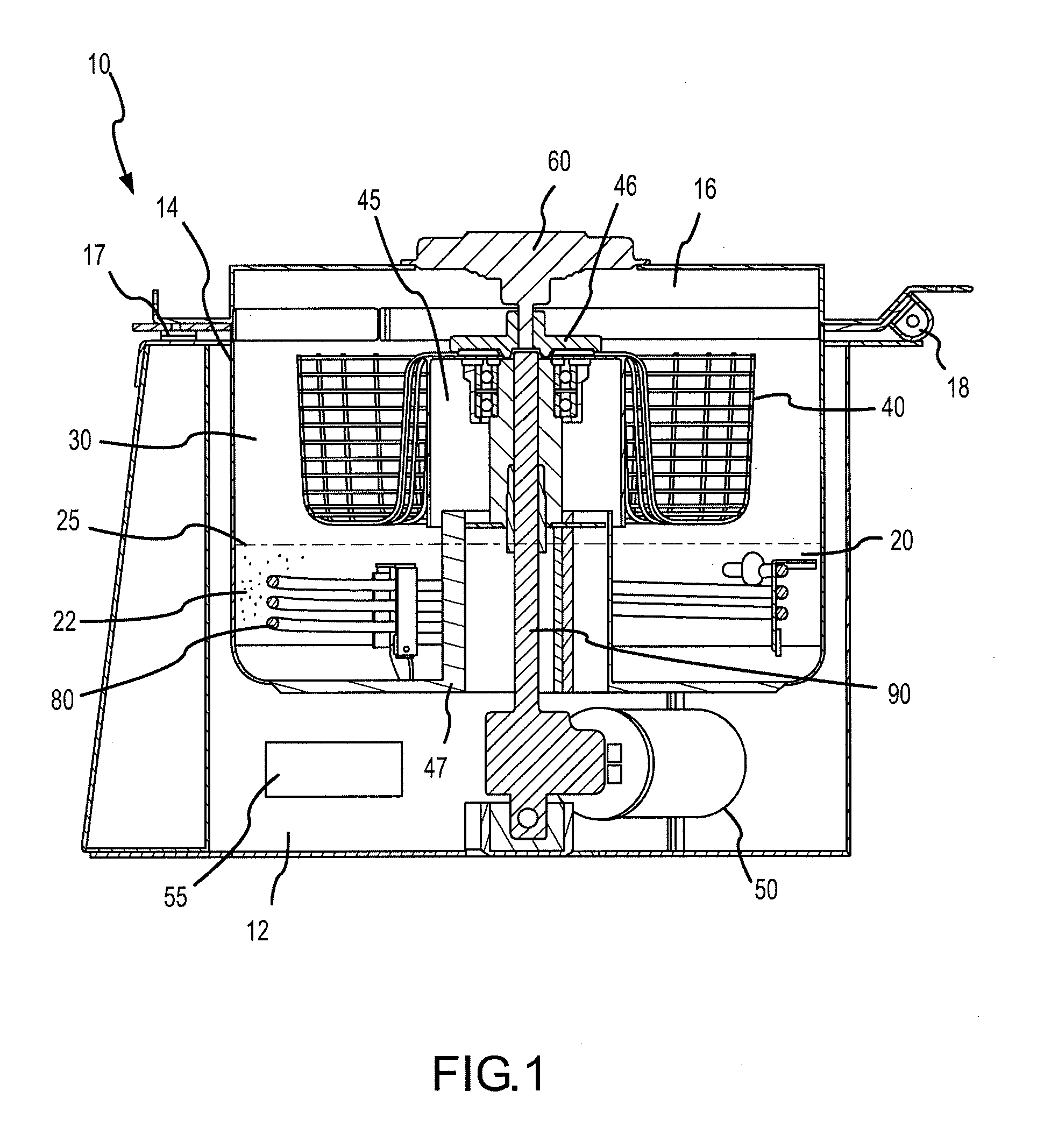

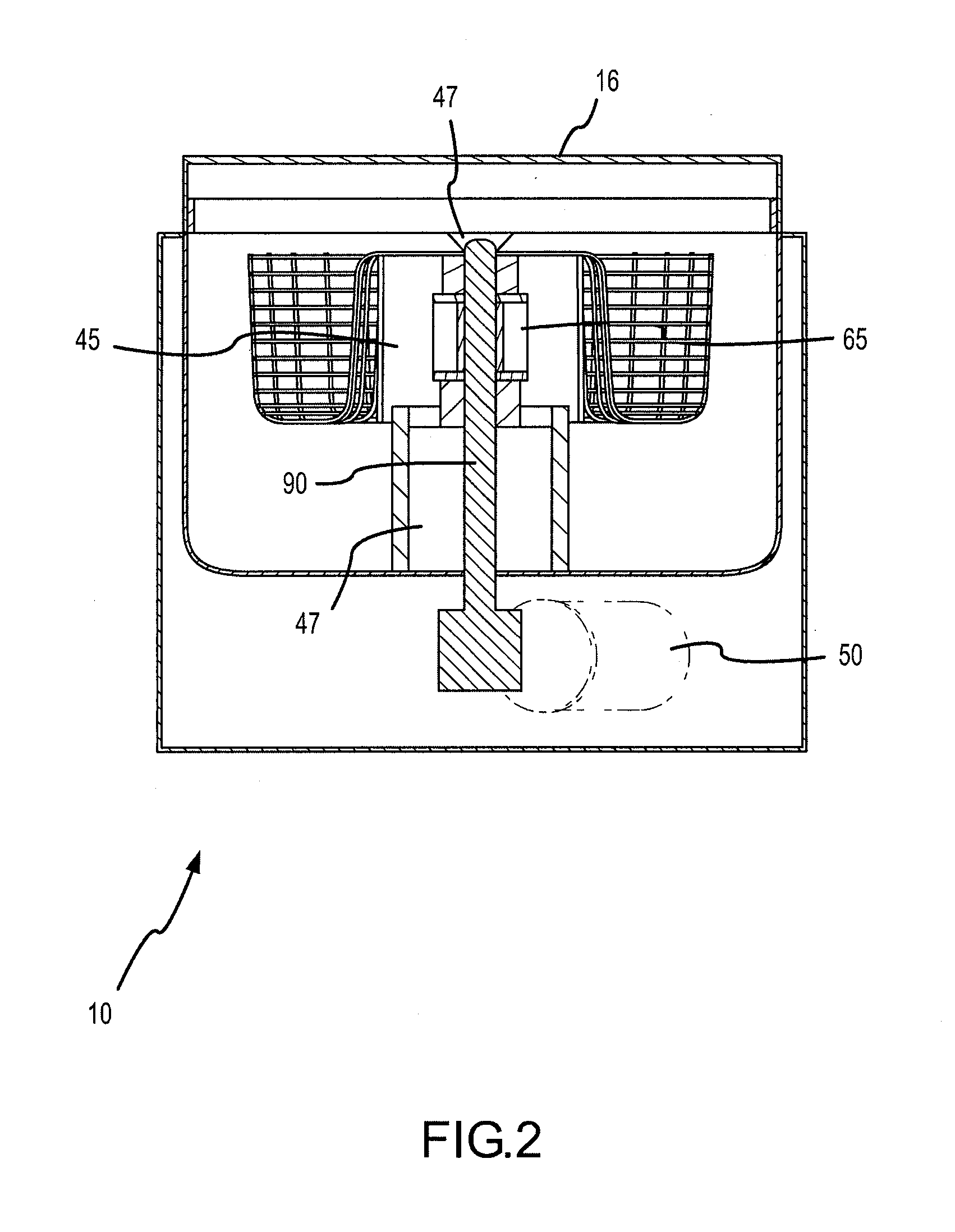

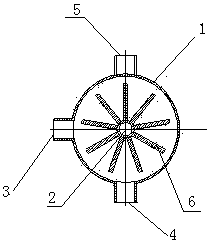

Fryer device

The present invention relates to a food fryer. The food frying apparatus generally comprises two sections: a frying section and an oil removal section. The frying section houses and / or heats oil for frying the food, and the oil removal section is operable to reduce the oil content of the food. Exemplary embodiments of the invention comprise a basket well that is configured to be movable between a cooking section and a spinning section. The basket well may be configured to comprise a bearing surface and a basket well gear. The fryer device may further comprise a frame that comprise a bearing configured to interface with the bearing surface. Further, the fryer device may comprise a rotational motor that comprises a spinning gear configured to interface with the basket well gear. The fryer device may also comprise a drawer configured to be slidably removable from the fryer device. The fryer device may also comprise a retrofit fryer device configured to be adaptable to pre-existing fryer devices. In other embodiments, the fryer device may be configured to be operated at least in part by a processor, and the processor may receive instructions from a storage medium. Various aspects of the fryer device are configured to be automatically controlled.

Owner:SPINFRY

AP2 domain transcription factor ODP2 (ovule development protein 2) and methods of use

ActiveUS20050257289A1Improve conversion efficiencyImprove planting efficiencySugar derivativesClimate change adaptationNucleotideTransformation efficiency

Methods and compositions for modulating plant development are provided. Nucleotide sequences and amino acid sequences encoding Ovule Development Protein 2 (ODP2) proteins are provided. The sequences can be used in a variety of methods including modulating development, developmental pathways, altering oil content in a plant, increasing transformation efficiencies, modulating stress tolerance, and modulating the regenerative capacity of a plant. Transformed plants, plant cells, tissues, and seed are also provided.

Owner:PIONEER HI BRED INT INC

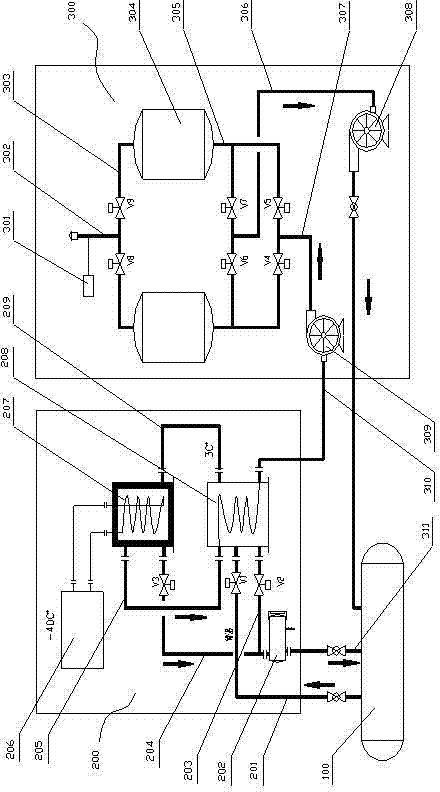

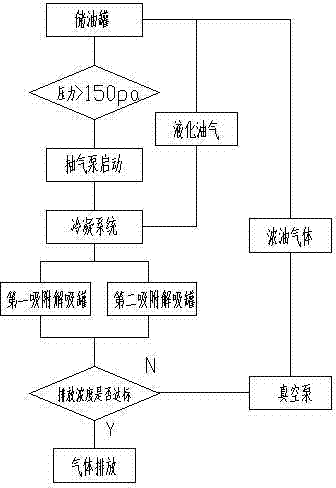

Oil gas recovery system

InactiveCN102899064AReduce oil contentReduce the use effectDispersed particle separationLiquid hydrocarbon mixture recoveryPlate heat exchangerDesorption

The invention relates to an oil gas recovery system. The oil gas recovery system comprises an adsorption unit and a condensing unit, wherein a gas inlet pipe for oil gas to be adsorbed, an exhaust pipe for adsorbed oil gas and a return pipe for desorbed oil gas are arranged on the adsorption unit; a gas inlet pipe for oil gas to be condensed, an exhaust pipe for condensed oil gas and a return pipe for condensate are arranged on the condensing unit; the exhaust pipe for the condensed oil gas of the condensing unit is connected with the gas inlet pipe of the oil gas to be adsorbed of the adsorption unit; a first adsorption / desorption tank and a second adsorption / desorption tank are arranged on the adsorption unit to alternately adsorb and desorb the oil gas; and two condensing plants namely an oil gas heat exchanger and a cold box are arranged on the condensing unit to sequentially condense the oil gas. The oil gas recovery system is high in treatment capacity and recovery efficiency, can continuously work, and is mainly suitable for recovering the oil gas generated during oil injection of a buried oil tank of a gas station and refueling of a fuel tank of an automobile.

Owner:陈玲海

Healthcare potato chip and processing method thereof

The invention discloses a healthcare potato chip and a processing method of the healthcare potato chip. The healthcare potato chip is composed of the following raw materials in percentage by weight: 72-85% of potato, 5-10% of glutinous rice flour, 2-5% of palm oil, 1-3% of Chinese herbal medicine, 0.5-2% of a condiment and the balance of water, wherein the Chinese herbal medicine is composed of 8-15 parts of liquorice, 5-11 parts of peppermint, 1-3 parts of corktree and 3-8 parts of chrysanthemum, and the Chinese herbal medicine is processed by steps of treating the raw materials, hot ironing and freezing, preparing additives, dipping, coating lining, microwave roasting and cooling, packaging, and the like. The healthcare potato chip has the characteristics of good taste, low heat and green health, the microwave roasting procedure is used for saving oil consumption and reducing the production cost, and the oil content of the chip is low, thereby capable of being stored for a long time.

Owner:王惠莹

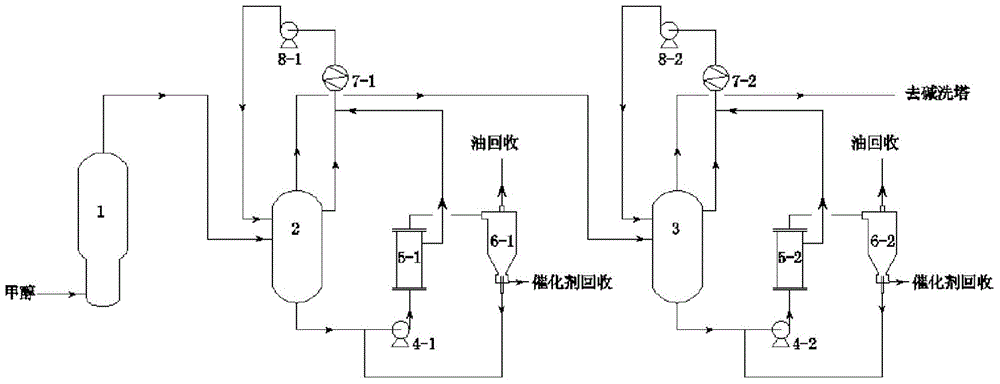

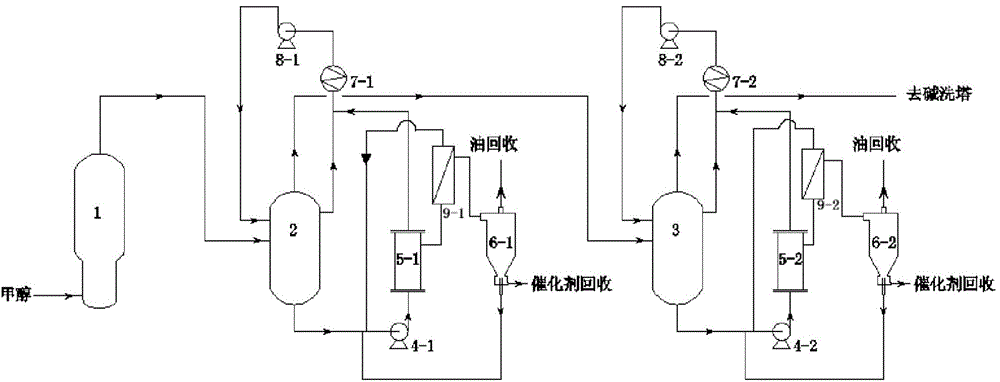

Solid and oil removal method and device for chilled water and washed water in MTO (methanol to olefin) process

ActiveCN103951098AEliminate enrichmentReduce the probability of forming large particlesHydrocarbon from oxygen organic compoundsMultistage water/sewage treatmentUF - UltrafiltrationChemistry

The invention relates to a solid and oil removal method and device for MTO (methanol to olefin) / MTP (methanol to propylene) chilled water and washed water. The method disclosed by the invention mainly comprises the following steps of carrying out ultrafiltration membrane separation on MTO / MTP chilled water, feeding an ultrafiltration membrane concentrated solution into a three-phase cyclone-separator separation system, and recovering a catalyst and oil; cooling ultrafiltration membrane permeated liquid, and feeding the obtained liquid back to a chilled water system to cyclically reuse; carrying out ultrafiltration membrane separation on MTO / MTP washed water, feeding an ultrafiltration membrane concentrated solution into the three-phase cyclone-separator separation system, and recovering a catalyst and oil; and cooling ultrafiltration membrane permeated liquid and feeding the obtained liquid back to a washed water system to cyclically reuse. The invention also provides a solid and oil removal device for MTO / MTP chilled water and washed water.

Owner:JIANGSU JIUWU HITECH

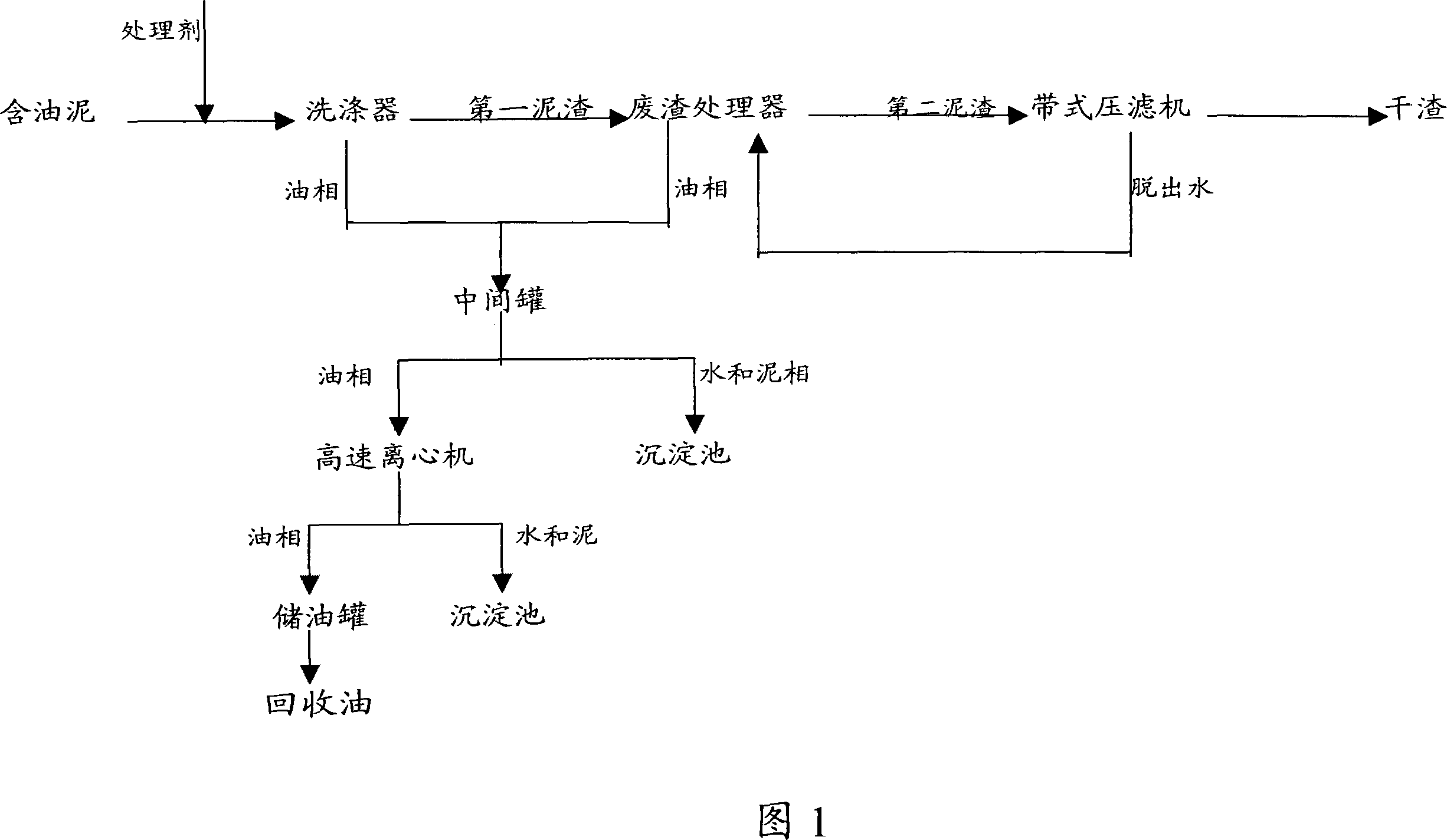

Method and system for processing oil-containing sludge

ActiveCN101250420AReduce pollution intensityEliminate sources of pollutionSludge treatmentSolid separationScrubberResidual oil

The invention relates to a method for processing oil-bearing mud, which comprises the following steps: firstly, mixing and stirring oil-bearing mud and right amount of water in a washer under the condition of heating, stewing, separating out oil phase and a first sludge layer, secondly, stirring in a middle tank, heating oil phase from the washer, stewing, and then discharging water and sludge on the lower portion, keeping oil phase on the upper portion, thirdly, finely separating oil phase which is kept in the middle tank in a centrifugal machine through a centrifugal effect, discharging oil phase which is separated into an oil storage tank, fourthly, stewing oil products which is from the centrifugal machine after dewatering and desliming in the oil storage tank, and getting recovery oil, fifthly, cavitating first mud residue from the washer in a mud residue processor, stripping residual oil in the first mud residue, and discharging oil phase on the upper portion of the mud residue processor into the middle tank. The invention also relates to a system which utilizes the method to process oil-bearing mud. Oil-bearing rate of oil-bearing mud which is processed by the method and the system of the invention is below 4%.

Owner:里群 +1

Solvent dewaxing method

ActiveCN1648216AImprove crystal structureEasy to separateMineral wax recovery/refiningParaffin waxMicrocrystalline wax

During solvent dewaxing, the mixture of wax containing material oil, dewaxing solvent and dewaxing assistant is made to pass through two stages of dewaxing material oil and deoiling cerate; the filtrate from the deoiling stage is returned to the dewaxing stage completely; and dewaxed oil and deoiled wax are obtained after recovering the solvent. The dewaxing assistant is ashless polymer mixture of high branched chain degree polymer and low branched chain degree polymer. The method improves the crystal structure of wax, raises oil-wax separating effect, raises dewaxed oil yield and filtering speed obviously, lowers the solvent ratio and lowers the oil content in cerate. The cerate may be used in producing paraffin or microcrystal wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

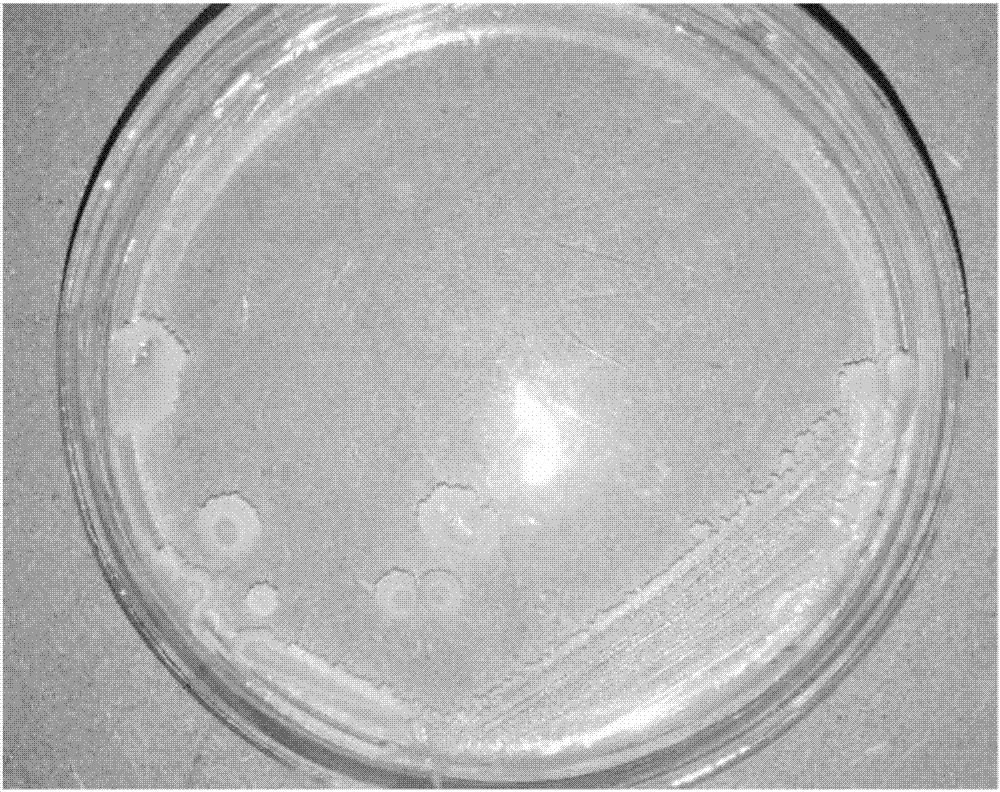

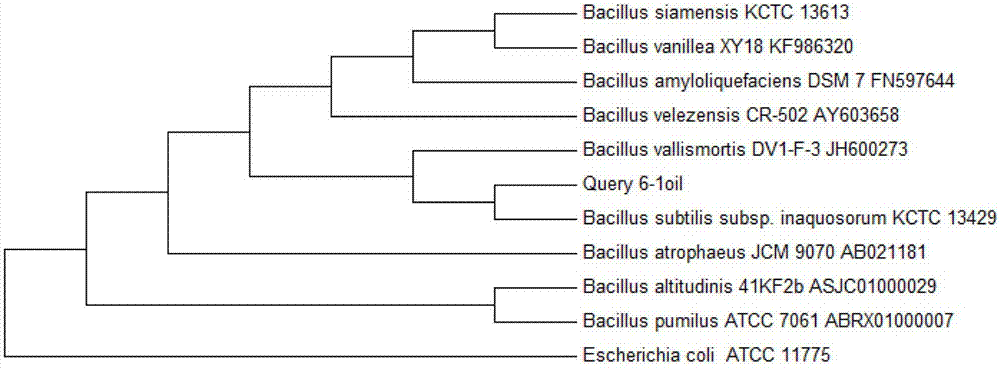

Bacillus subtilis for effectively degrading grease and application thereof

ActiveCN106929449AEfficient degradationMeet the needs of aerobic compostingNon-ionic surface-active compoundsOrganic detergent compounding agentsAdditive ingredientBacteroides dorei

The invention provides a bacillus subtilis for effectively degrading grease. The bacillus subtilis 6-loil is preserved at Guangdong Province Microbiological Culture Collection Center on December 22, 2016. The preservation number is GDMCC No. 60134. The bacillus subtilis 6-loil provided by the invention can utilize the grease as a growth carbon source, can normally grow under an environment of higher grease content and has a capacity of efficiently degrading grease. The bacillus subtilis 6-loil provided by the invention can be compounded with bacillus coagulans, brewer yeast and carrier ingredients so as to be prepared into a kitchen garbage disposal fungicide. The prepared kitchen garbage disposal fungicide can adapt to the condition of high grease content of the domestic kitchen garbage, so that the condition of failure in aerobic composting caused by the reduction of microbial activity resulted from the microorganism wrapped by the grease in aerobic composting can be effectively avoided and the bacillus subtilis can meet the requirement of the domestic kitchen garbage aerobic composting. The bacillus subtilis 6-loil also can be applied to the fields of soil oil stain treatment, biosurfactant production, biological detergent preparation, and the like.

Owner:HANYU GRP CO LTD

Instant bagged edible fungus and its making method

InactiveCN1582745AGuaranteed NutrientsNutritional diversityFood preparationBiotechnologyDietary fiber

An instant edible fungus is prepared from raw edible fungus through washing, shaping, scalding, immersing, freezing, vacuum frying in oil, removing oil and flavouring. Its advantages are good color, smell and taste, and rich nutrients.

Owner:KUNMING FUNGUS GARDEN FOOD

Preparation method of instant crisp okra slices

ActiveCN103844217AGuaranteed uniformityElimination of deterioration in sensory qualityFood coatingFood shapingNutritionProcess engineering

The invention relates to a preparation method of instant crisp okra slices. The preparation method mainly comprises the following steps: selecting; blanching; slicing; quick-freezing; vacuum frying and pre-puffing; vacuum deoiling; separating fruits from seeds; spraying; puffing again; and packaging. The instant crisp okra slices prepared by the method provided by the invention are low in oil ratio, crisp rather than greasy and stable in quality, and the original shape, flavor and nutritional quality of okra are maintained.

Owner:HUNAN AMAZING GRACE BIOTECH

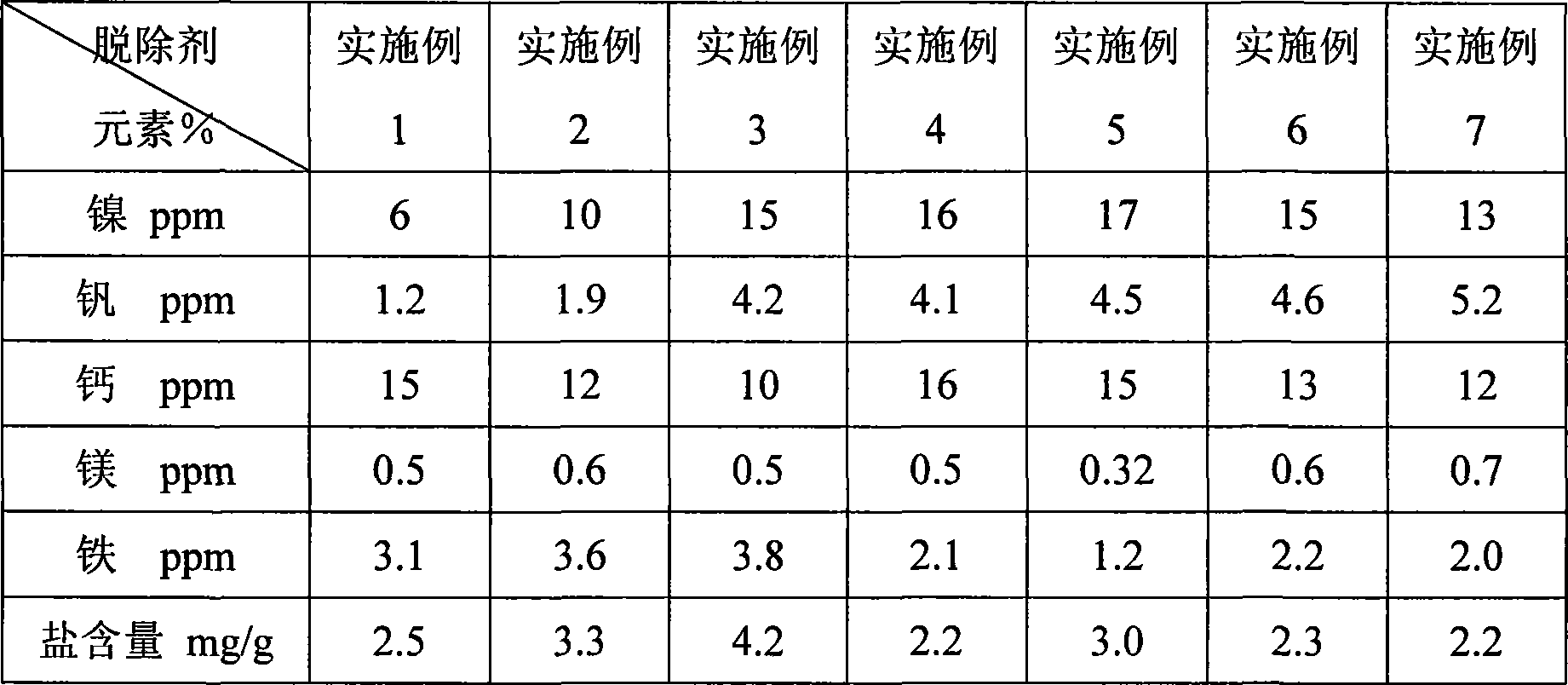

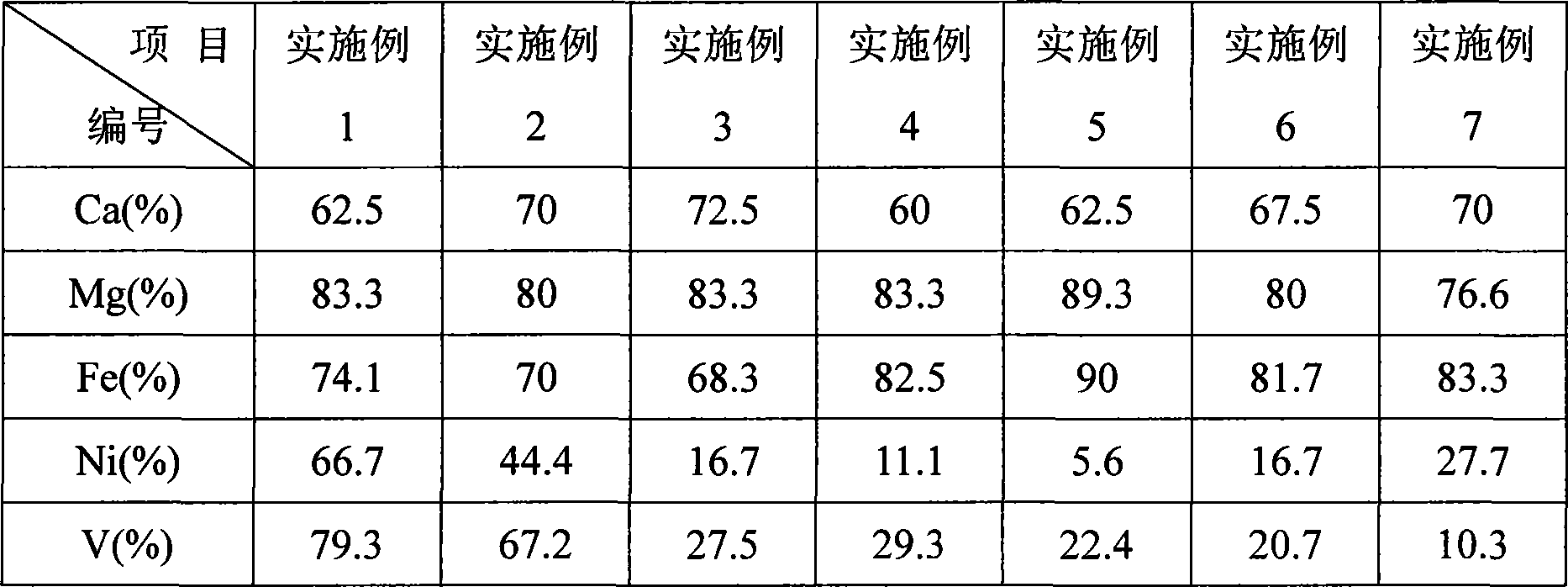

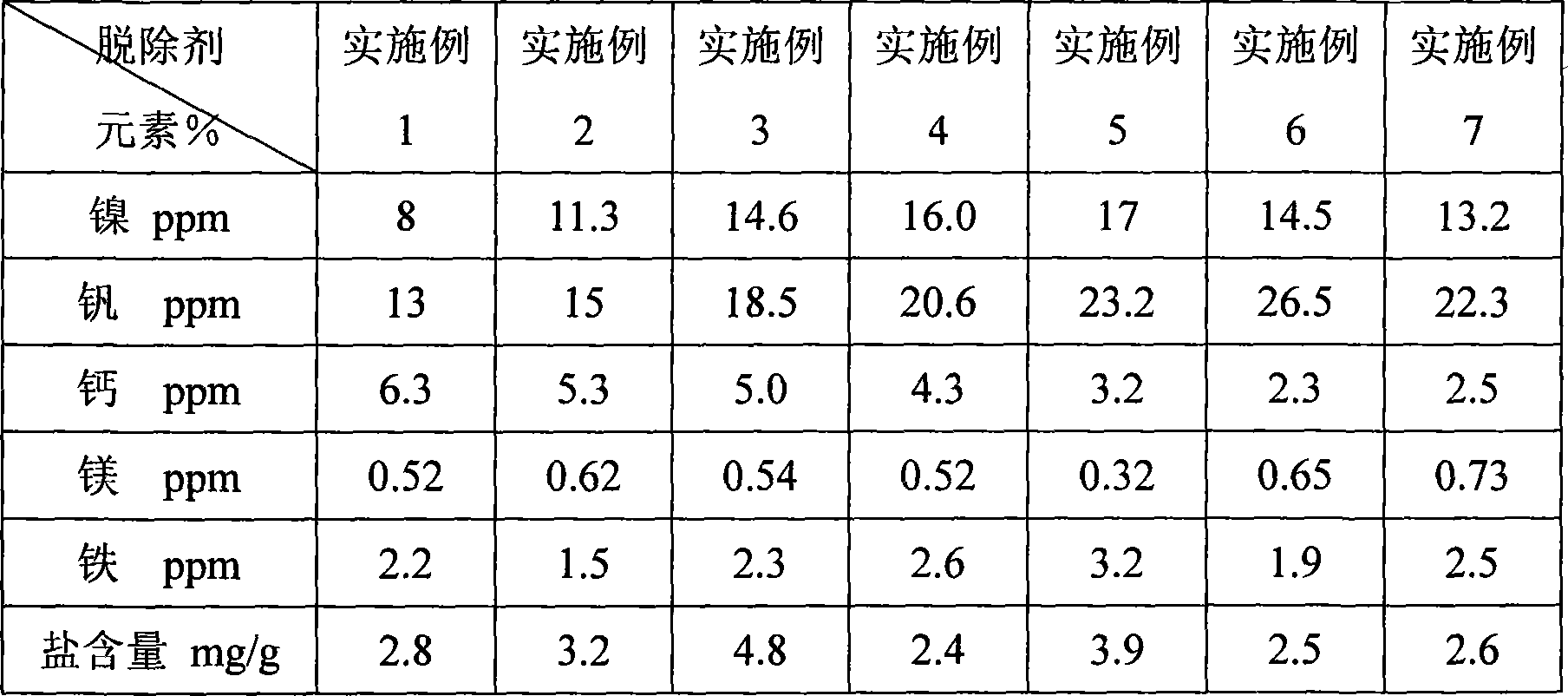

Heavy metal removing agent for crude oil

The invention relates to base oil heavy metal removing agent which removes metallic elements such as nickel, vanadium and the like from base oil and is mainly applied in oil refining electric desalting devices. The invention is characterized in that the removing agent components and the weight percentage of each component are that: carbonic ester 10-40%, organic acids 0-30%, non-ionic surfactant 5-20%, chelator 10-45%, urea compounds 0.5-1% and alcohol water 2-10%. The invention is not soluble in oil, the specific density is bigger than that of the base oil, the removing agent is easy to be separated, porphyrin compounds of the nickel and the vanadium and other metallic ions in the base oil can be removed without changing operational parameters of the electric desalination, wherein the removal rate of the nickel and the vanadium can reach about 60%, which effectively protects catalyst in the following working procedure.

Owner:金浦新材料股份有限公司

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

Deep-fry cereal instant noodles and preparation method thereof

The invention discloses deep-fry cereal instant noodles and a preparation method thereof. The deep-fry cereal instant noodles are prepared from wheat flour, solanum tuberdsm, tapioca starch, guar gum, sodium polyacrylate, composite phosphate and sodium carbonate in parts by weight. The preparation method comprises the following steps of: putting the materials into a dough mixer, adding water to prepare paste, and curing the paste; compositing the cured paste to be strips through a laminating machine, and cutting the strips and shaping; and cooking the shaped noodles, spraying condiments, frying, finally carrying out regular air cooling and then packaging. The deep-fry cereal instant noodles prepared according to the technical scheme are good in mouth feeling, rich in nutrition and few in oil content, and are beneficial to the health of people.

Owner:河南面之缘食品有限公司

Process for freezing and frying fruit slices in vacuum

InactiveCN101669605APrevents oxidative browningFlat as everFood preparationRefrigerated temperatureImpurity

The invention discloses a process for freezing and frying fruit slices in vacuum, which is characterized in that the process flow comprises the following steps: selecting raw material, cleaning and removing impurities, slicing precisely, protecting color, dipping, draining, placing into a basket, quick-freezing in a tunnel or a refrigerator, freezing and frying in vacuum, deoiling in vacuum, relishing, packaging, inspecting and putting in storage. The process effectively prevents fruit slices from being easily oxidized and browned; the shape of the fried fruit slice is smooth as original; thecolor is close to the natural color of the raw material; the mouth feel is fragrant and crisp; the thickness is even, the oil content is extra-low ranging from 17% to 20%; and the oil content is lowerby at least 25% than that of the same type of fruit crisp chips. Meanwhile, the vacuum freezing and frying technology effectively prevents generation of harmful substances, such as acrylamide and trans fatty acid and the like, and the traditional constant pressure high temperature frying method and the routine vacuum low temperature frying method can not match with the technology.

Owner:张利彬

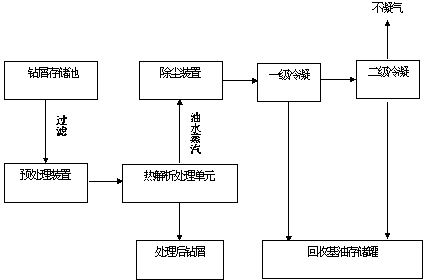

Oil-base drilling cuttings thermal analytical treatment method

ActiveCN104178200AReduce oil contentMeet emission requirementsLiquid hydrocarbon mixture productionAfter treatmentReaction temperature

The invention belongs to the technical field of environment protection of oil and gas fields and particularly provides an oil-base drilling cuttings thermal analytical treatment method. The method comprises the following main steps: conveying the oil-base drilling cuttings after pre-treatment to a processing unit; heating to raise the reaction temperature to the volatilization temperature of hydrocarbon in the components in the drilling cuttings; then, maintaining for a certain standing time till oil gas is completely volatilized; after treatment, storing the drilling cuttings by virtue of a discharge device for discharging; feeding the oil gas into a recovering and separating unit by virtue of an exhaust device; recovering components with different condensation points in different condensation recovery units; and maintaining the recovered oil unchanged for further preparing an oil-base drilling fluid. The method solves the defects and shortcomings of other methods well. By adopting the oil-base drilling cuttings thermal analytical treatment technology, the oil content of the drilling cuttings is low (less than 1%), so that the discharge requirement is satisfied. The method provided by the invention further achieves the purposes of treating the oil-base drilling cuttings and recycling resources while the problem of environmental pollution is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

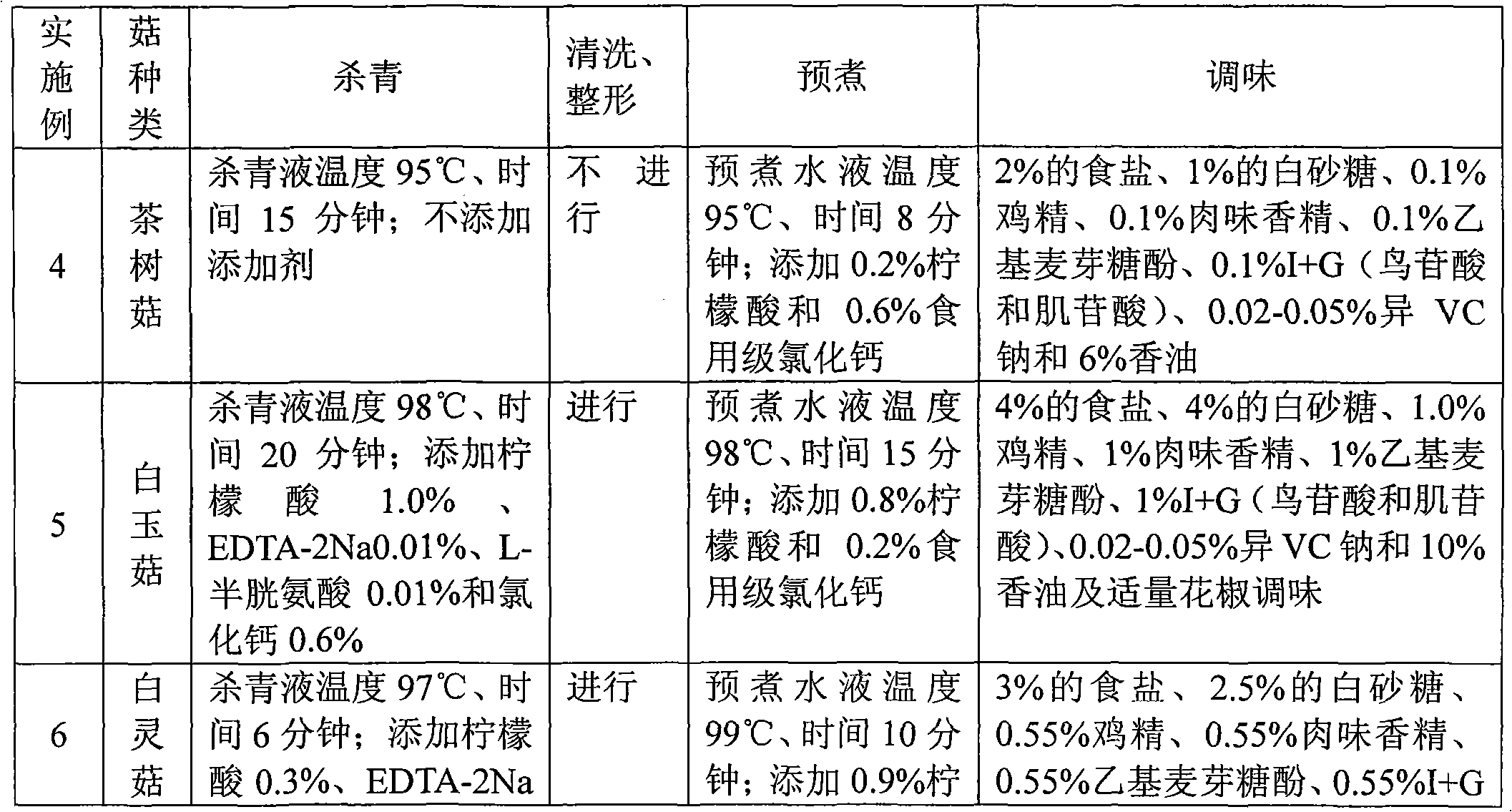

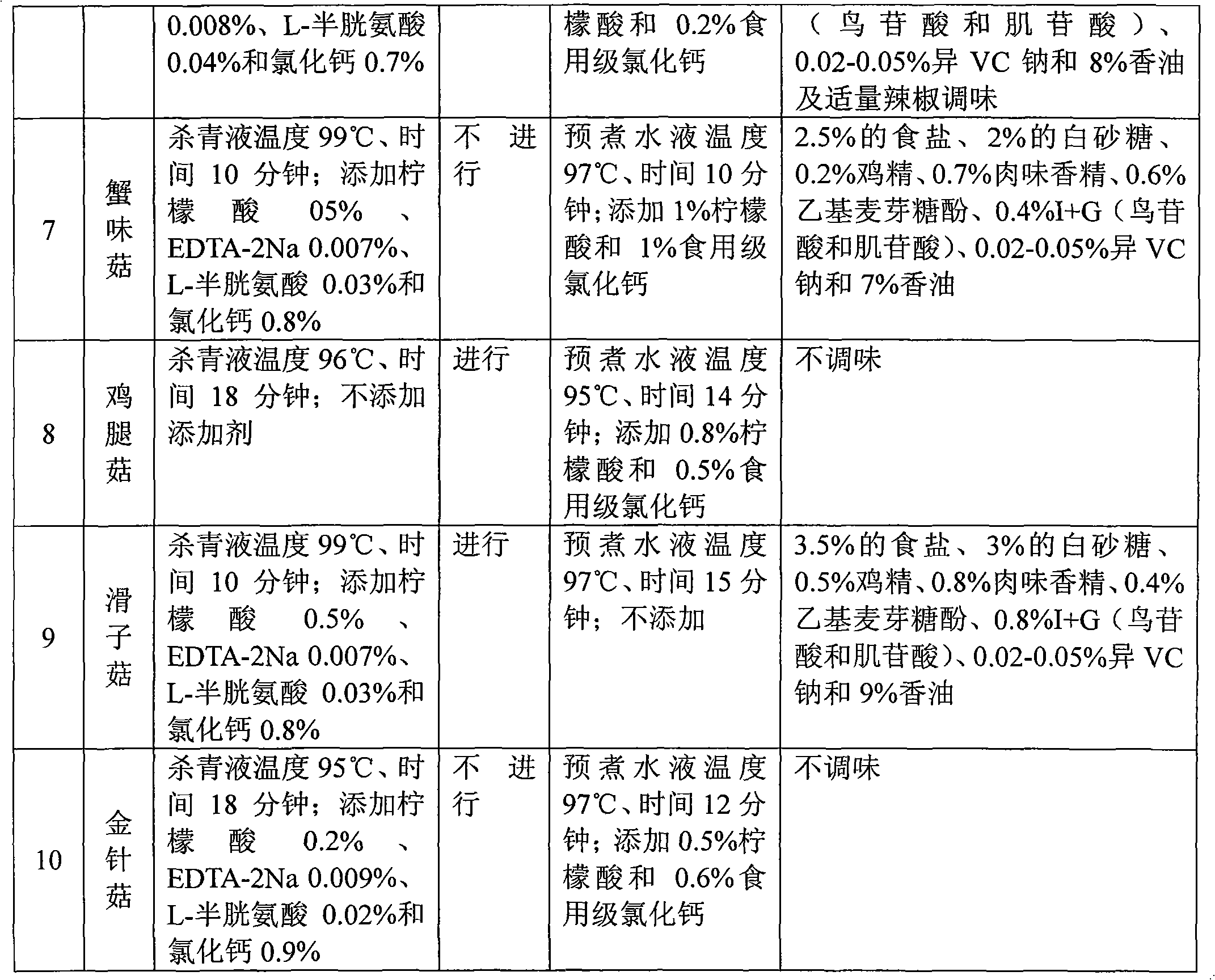

Method for processing ready-to-use edible fungi

The invention provides a method for processing ready-to-use edible fungi. The method comprises the steps of enzyme deactivating, precooking, dewatering, packaging and sterilizing, wherein the enzyme deactivating means processing fresh edible fungi for 5 to 20 minutes by using enzyme deactivating aqueous solution at the temperature of between 95 and 100 DEG C; and the precooking means processing the edible fungi for 8 to 15 minutes by using precooking aqueous solution at the temperature of between 95 and 100 DEG C. An edible fungus product processed by the method of the invention not only maintains the original nutritive materials of the edible fungi and the edible function and the appearance characteristics of plant dietary fibers but also endows the product with good color, smell and taste, and has the characteristics of low oil content, no oily mouthfeel, ready-to-use performance and the like; and the edible fungi which have strong seasonal characteristics, difficult fresh preservation, unique flavor, comprehensive nutrient and strong heath care functions can be processed into new modern and convenient edible fungus products with the unique flavor.

Owner:CHONGQING ACAD OF AGRI SCI

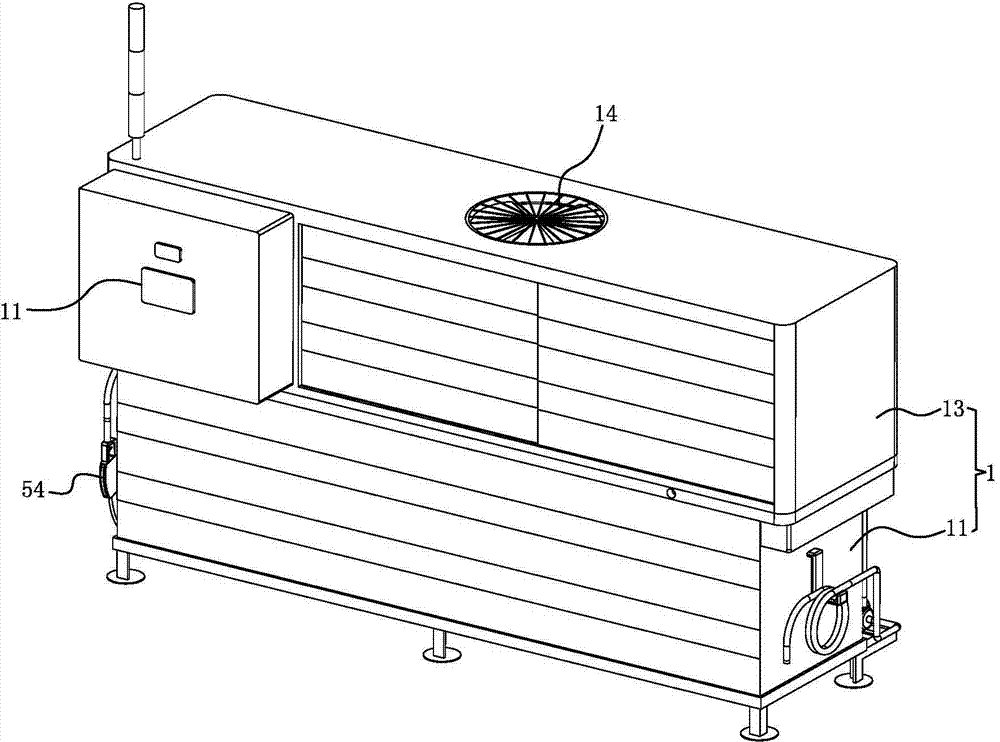

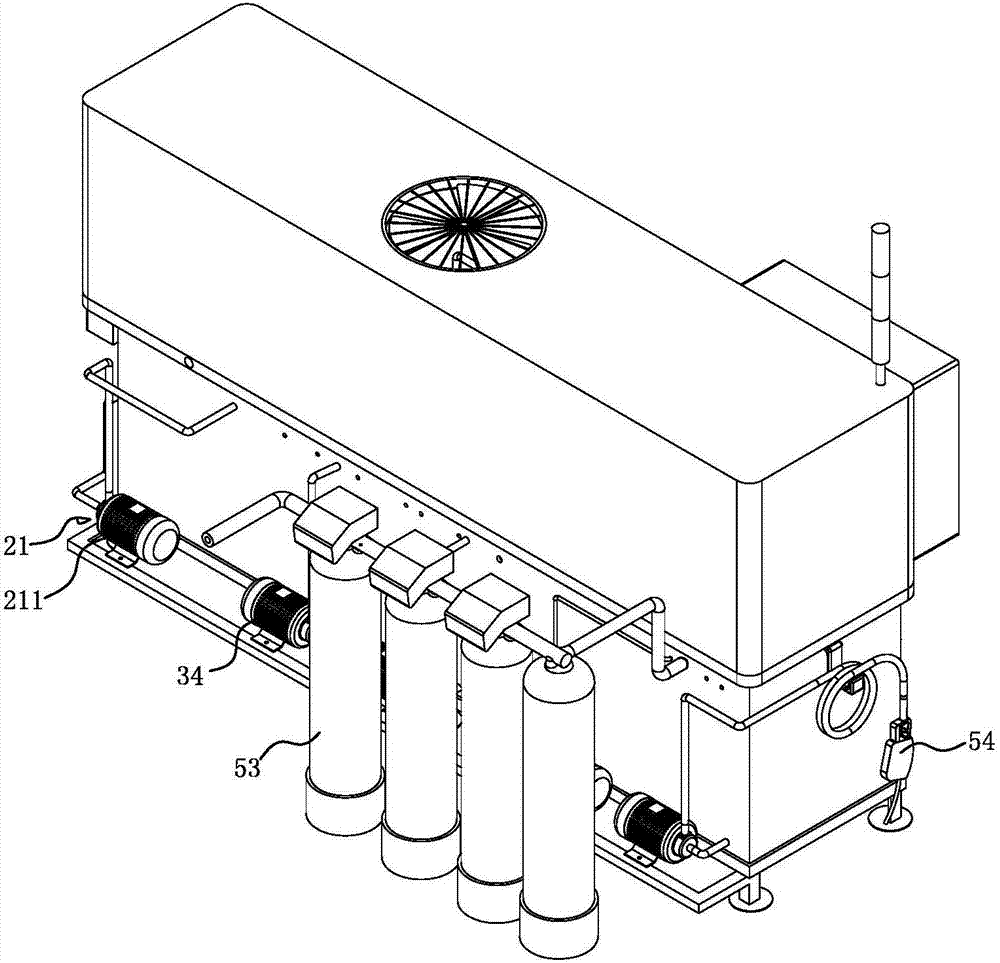

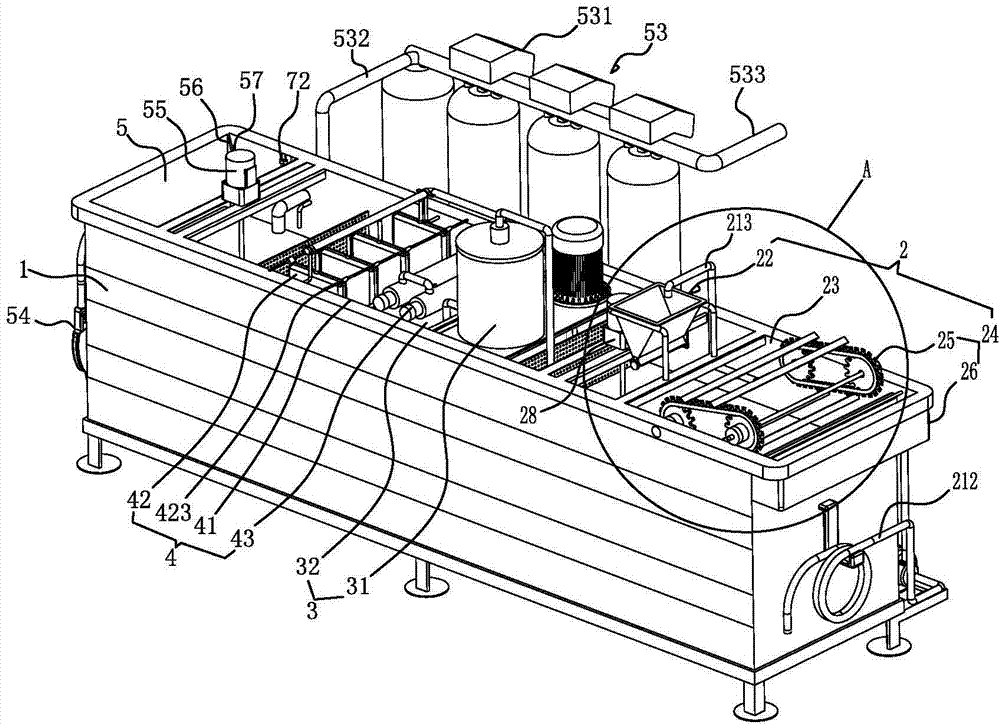

Intelligent cyclic regeneration equipment for cutting fluid

ActiveCN103865624ATo achieve the effect of coarse filtrationGood effectLubricant compositionParticulatesIron powder

The invention discloses intelligent cyclic regeneration equipment for cutting fluid. The intelligent cyclic regeneration equipment comprises a rack, a first stage of filter device, a second stage of filter device, a third stage of filter device, and a liquid purifying box, wherein a control system touch screen is arranged on the rack; the first stage of filter device comprises a first suction device, a particulate matter filter, a soiling solution tank, a first agitator, a white alum water injection device and an efficient oil removing device; the second stage of filter device comprises a high-speed centrifugal filter device, a first filter tank and a second suction device; the third stage of filter device comprises a second filter tank, an ultraviolet sterilization device and a bag-type zipper filter device; a concentration monitoring device, a concentrate supplement device and a deionized water supplement device are arranged inside the liquid purifying box; the first stage of filter device, the second stage of filter device, the third stage of filter device and the liquid purifying box are internally provided with deodorization devices. By adopting the intelligent cyclic regeneration equipment, cuttings, iron powder, oil slick pollution, cenobium, floccules and impurities in a soiling solution of the cutting liquid can be effectively removed, new cutting liquid with proper concentration is formed, and the intelligent cyclic regeneration equipment also has sterilization and deodorization functions.

Owner:中科循美(广东)智能科技有限公司

Preparation method for puffed sandwich crispy date

InactiveCN103621933AReduce oil contentAvoid greasy tasteFood shapingFood ingredient functionsDietary fiberDeep frying

The invention discloses a preparation method for a puffed sandwich crispy date. A differential-pressure puffing technique is adopted, the method is simple and safe, any additive is not required to be added, the product effect is good, the appearance of the red date is better kept, the Vc, polysaccharide and dietary fiber of the red date and rich protein and unsaturated fatty acid of almond are combined to enable the snack food to have more comprehensive nutrients, most importantly, the problems of high oil and fat content, oily taste, serious destroy of nutritional ingredients and short expiration date in the deep-frying and puffing are avoided, and as a result, the snack food is green, safe and nutritious.

Owner:GUANGXI UNIV

Processing method of vacuum low-temperature fried okra

The invention discloses a processing method of vacuum low-temperature fried okra. The processing method comprises the following steps of: blanching okra after being cleaned in hot water; after cooling, quickly freezing in an instant freezer; placing the frozen okra in maltose solution for vacuum impregnation; after leaching, putting the mixture in the instant freezer for quick freezing; placing the frozen okra in a vacuum fryer for frying; and rotating a centrifugal deoiling machine for deoiling. The processing method has the characteristics that vacuum low-temperature frying technique is adopted for processing, the original color, flavor, taste and nutritional ingredients of okra are kept, the okra is crispy in mouthfeel, and secondary cooking is not required.

Owner:LAIYANG HENGRUN FOODSTUFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com