Patents

Literature

277results about How to "High in starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

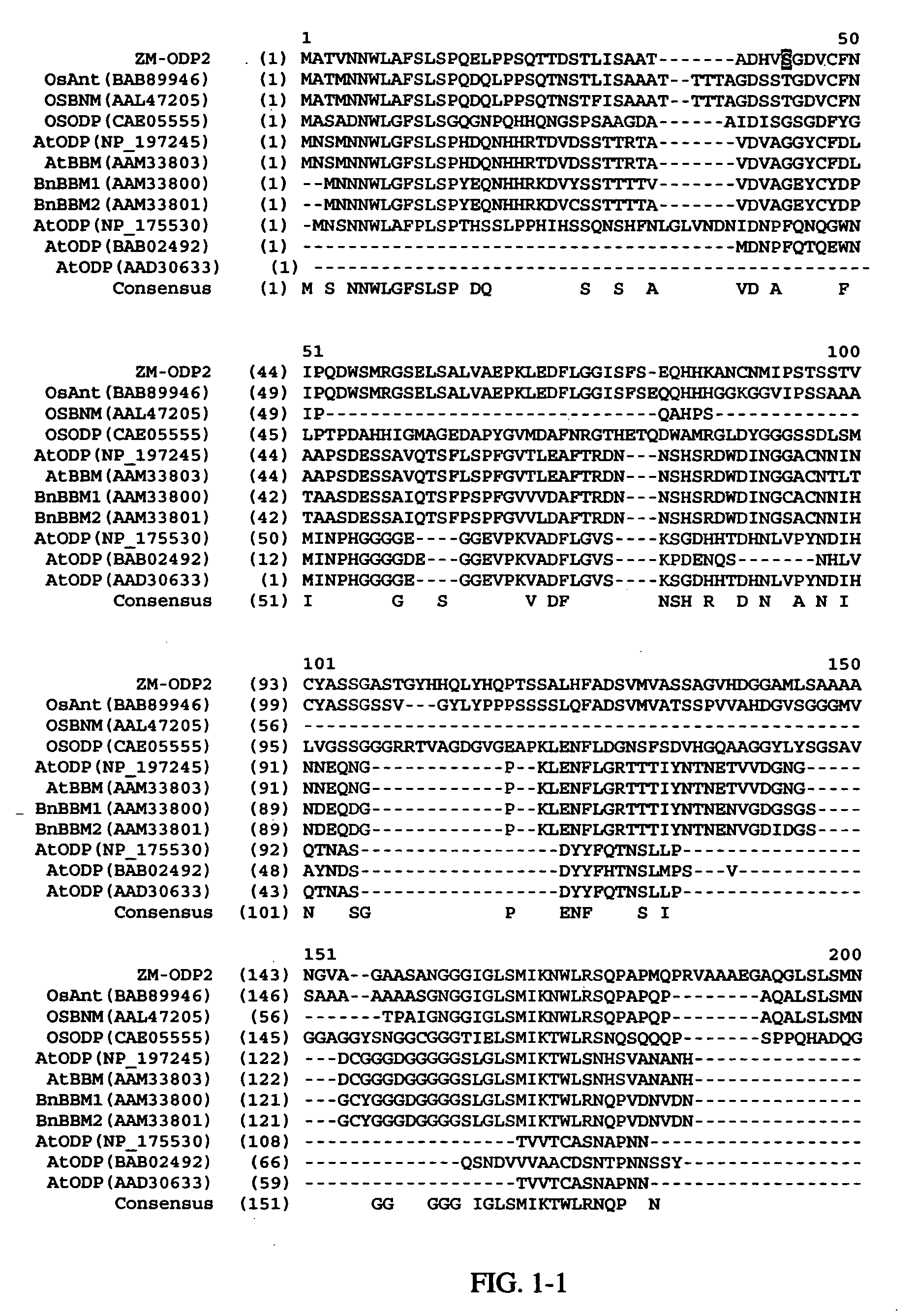

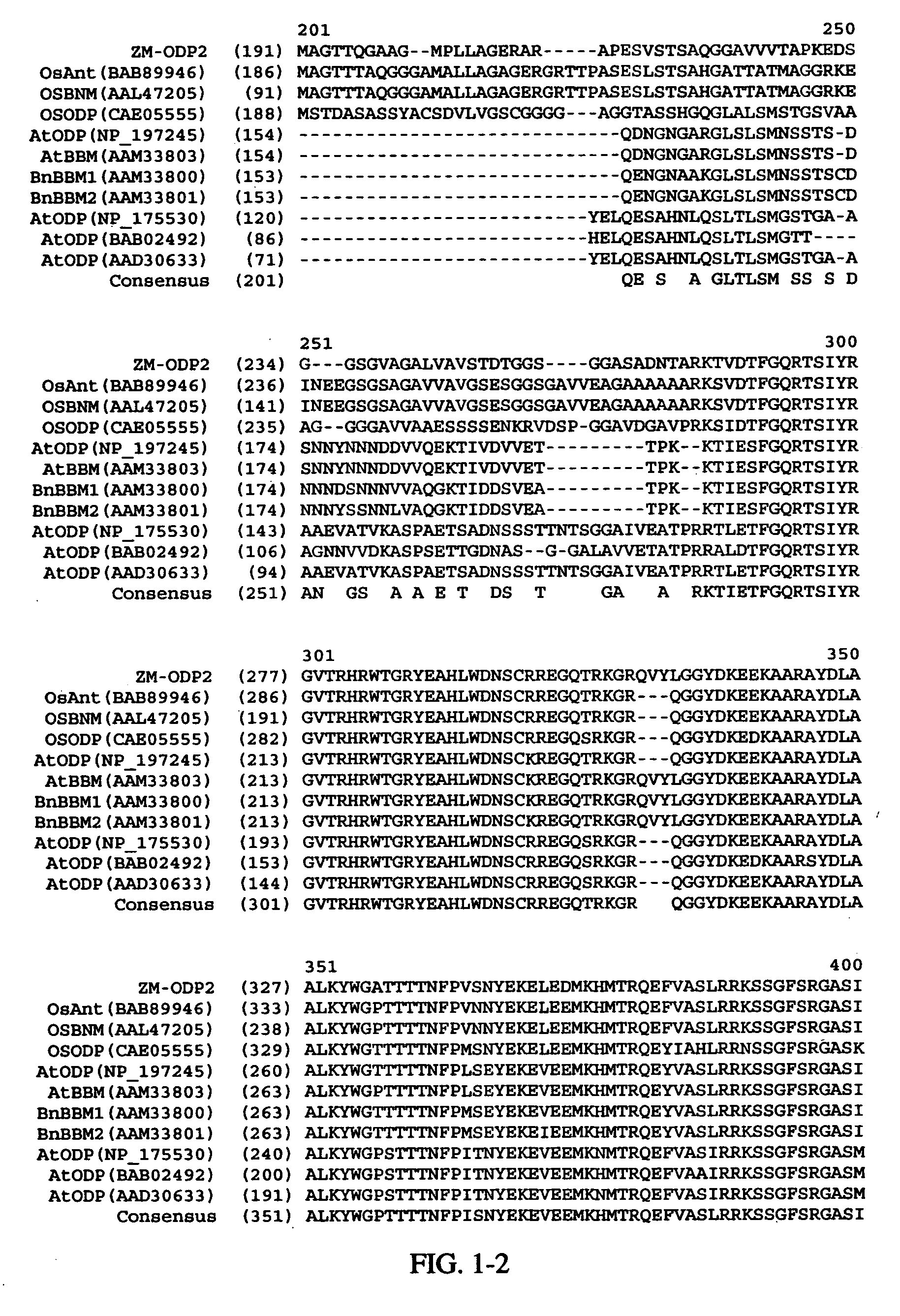

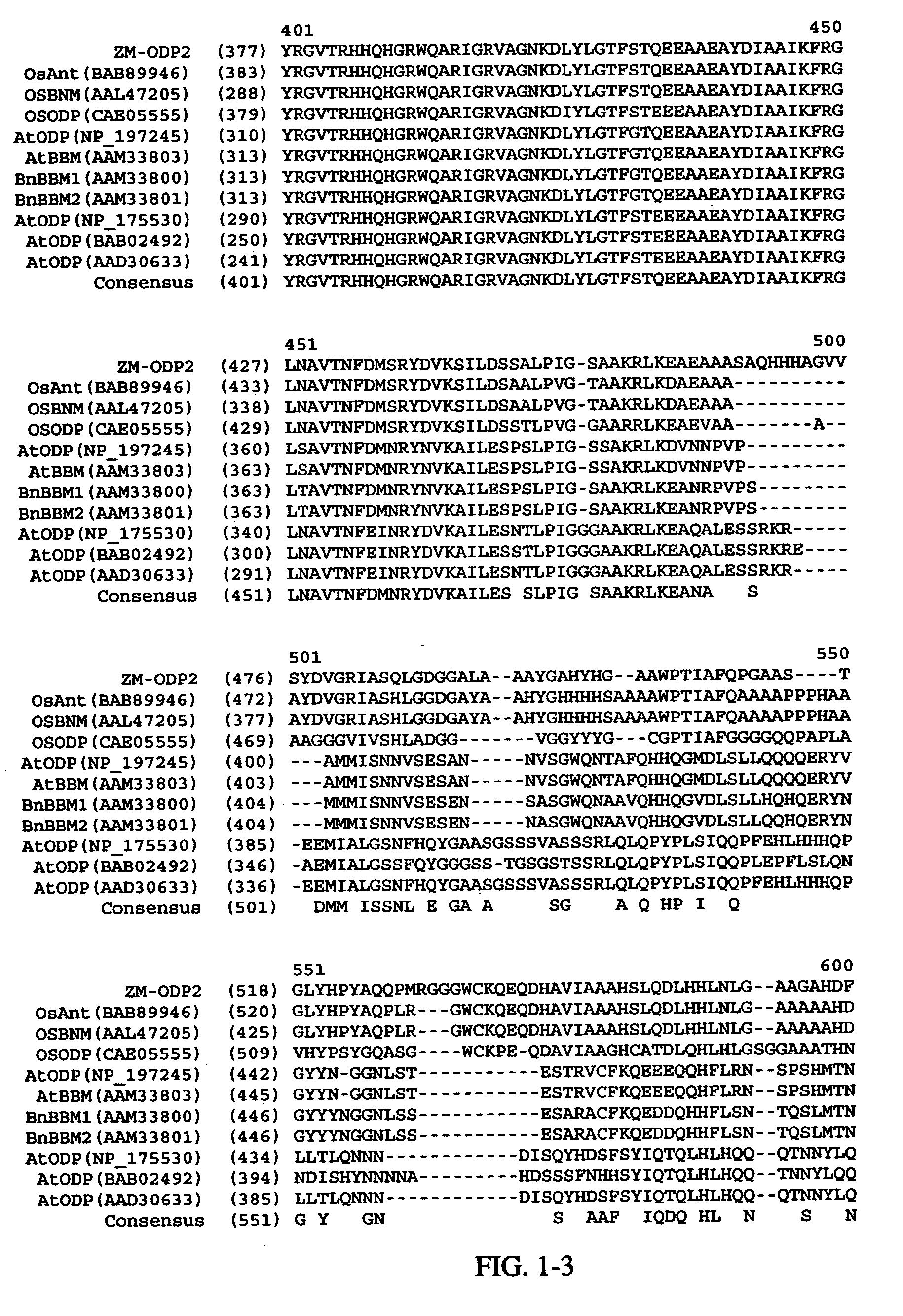

AP2 domain transcription factor ODP2 (ovule development protein 2) and methods of use

ActiveUS7579529B2Altered oil phenotypeReduce oil contentSugar derivativesClimate change adaptationPlant cellTransformation efficiency

Owner:PIONEER HI BRED INT INC

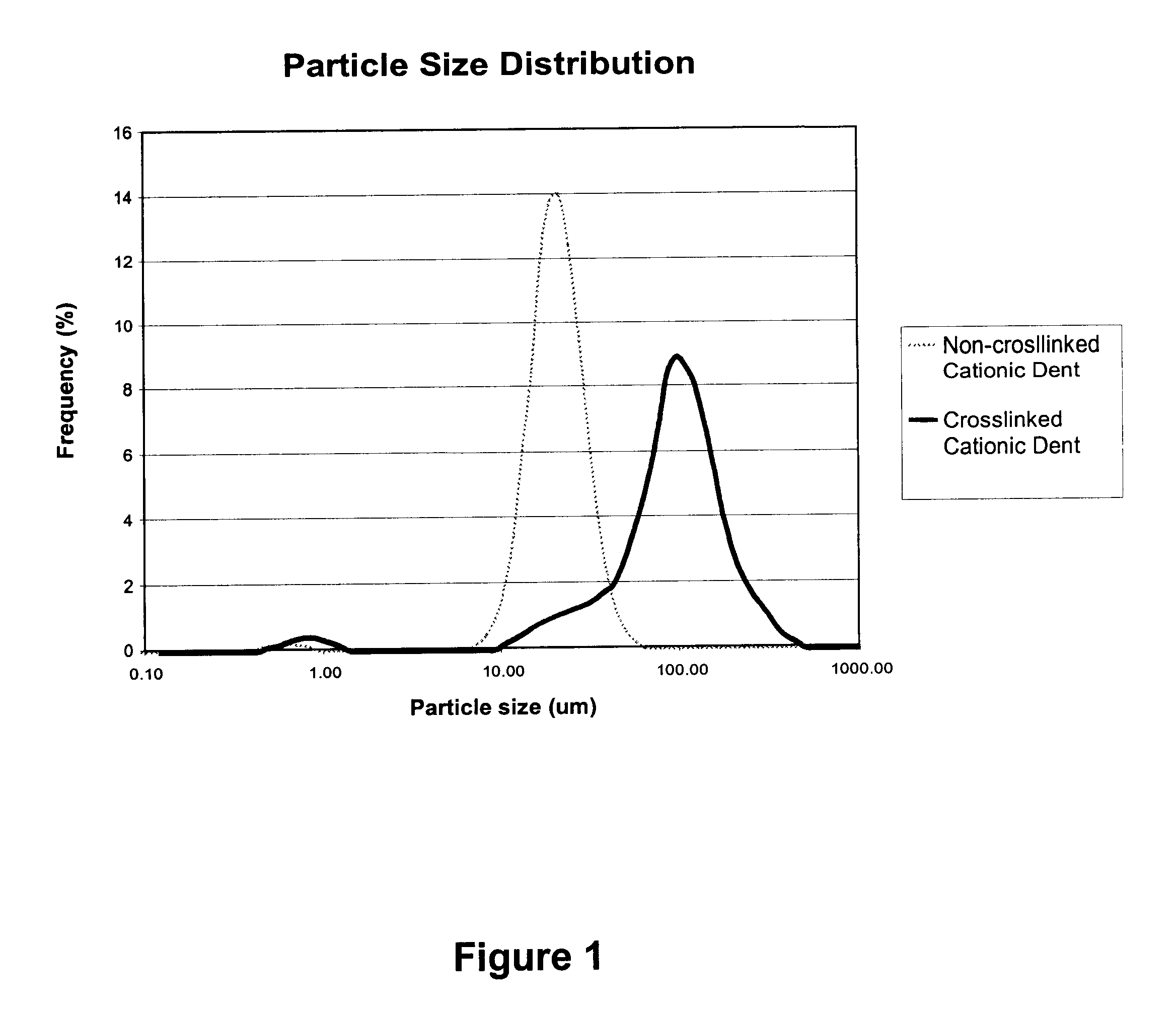

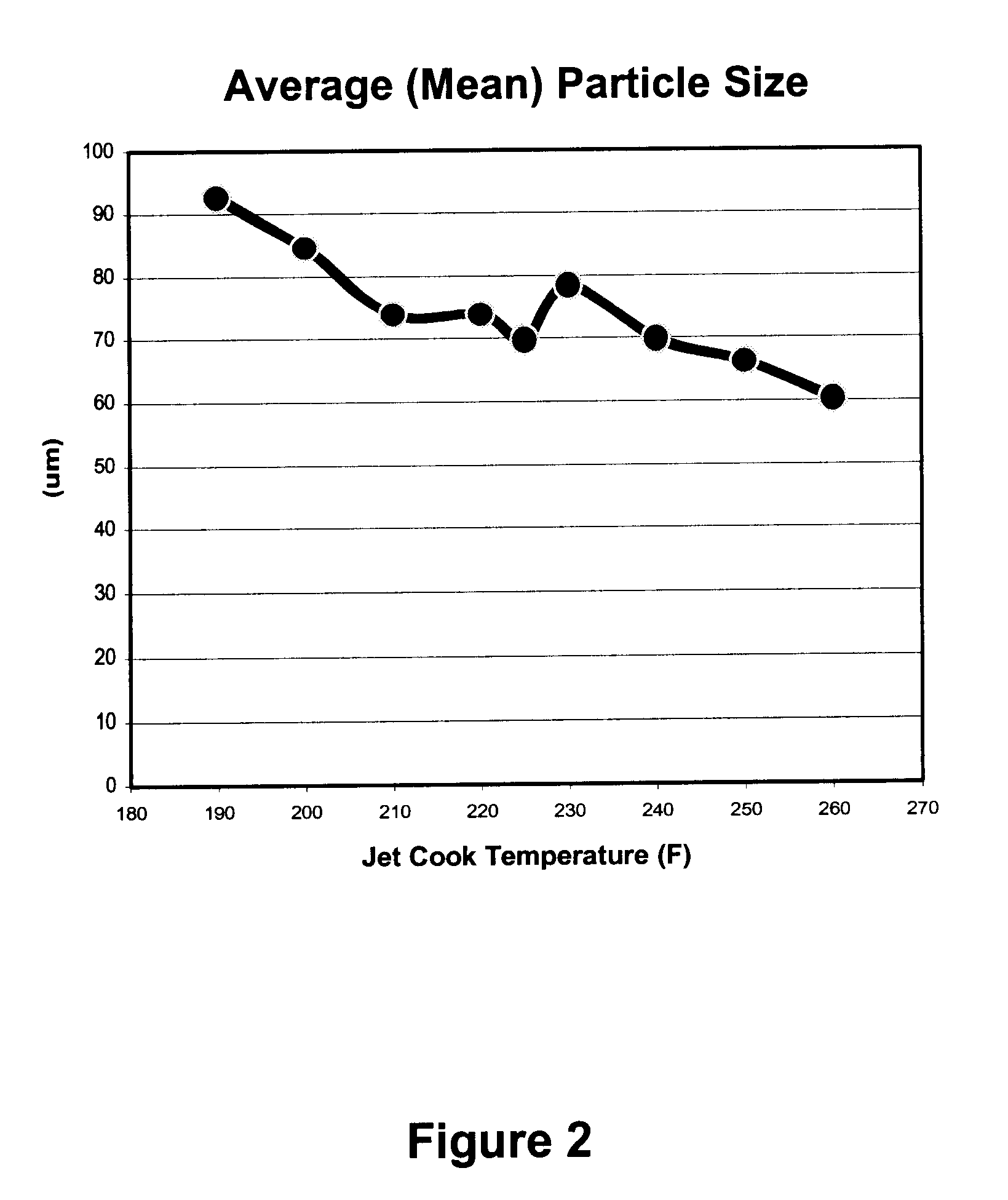

Starch compositions and methods for use in papermaking

InactiveUS6451170B1Drainage and retention property is alteredImprove performanceNatural cellulose pulp/paperSpecial paperPapermakingChemistry

Owner:CARGILL INC

Biodegradable polymer

InactiveUS20040122135A1Significant comprehensive benefitsImproved melt processabilityFireproof paintsPigmenting treatmentUrea derivativesPolyester

A biodegradable polymer includes a) 20 to 60% of a mixture of starch and / or a modified starch, b) 8 to 22% of starch plasticisers and processing agents c) 30 to 70% of one or more biodegradable aliphatic polyesters d) 1 to 10% of a layered silicate clay mineral. The silicate mineral is an organoclay which has been formed by reacting clay with an intercalating chemical to compatibilise it with the polymers so that the clay is exfoliated and makes the blend amorphous. The polymers may also include the usual additives including e) from 0 to 20% by weight of a polyol plasticiser f) from 0.1 to 1.5% by weight of a C12-22 fatty acid or salt or a destructing agent preferably urea and / or urea derivatives, and g) from 0 to 12% by weight of added water. The polyester may be modified by reaction with maleic anhydride.

Owner:PLANTIC TECH

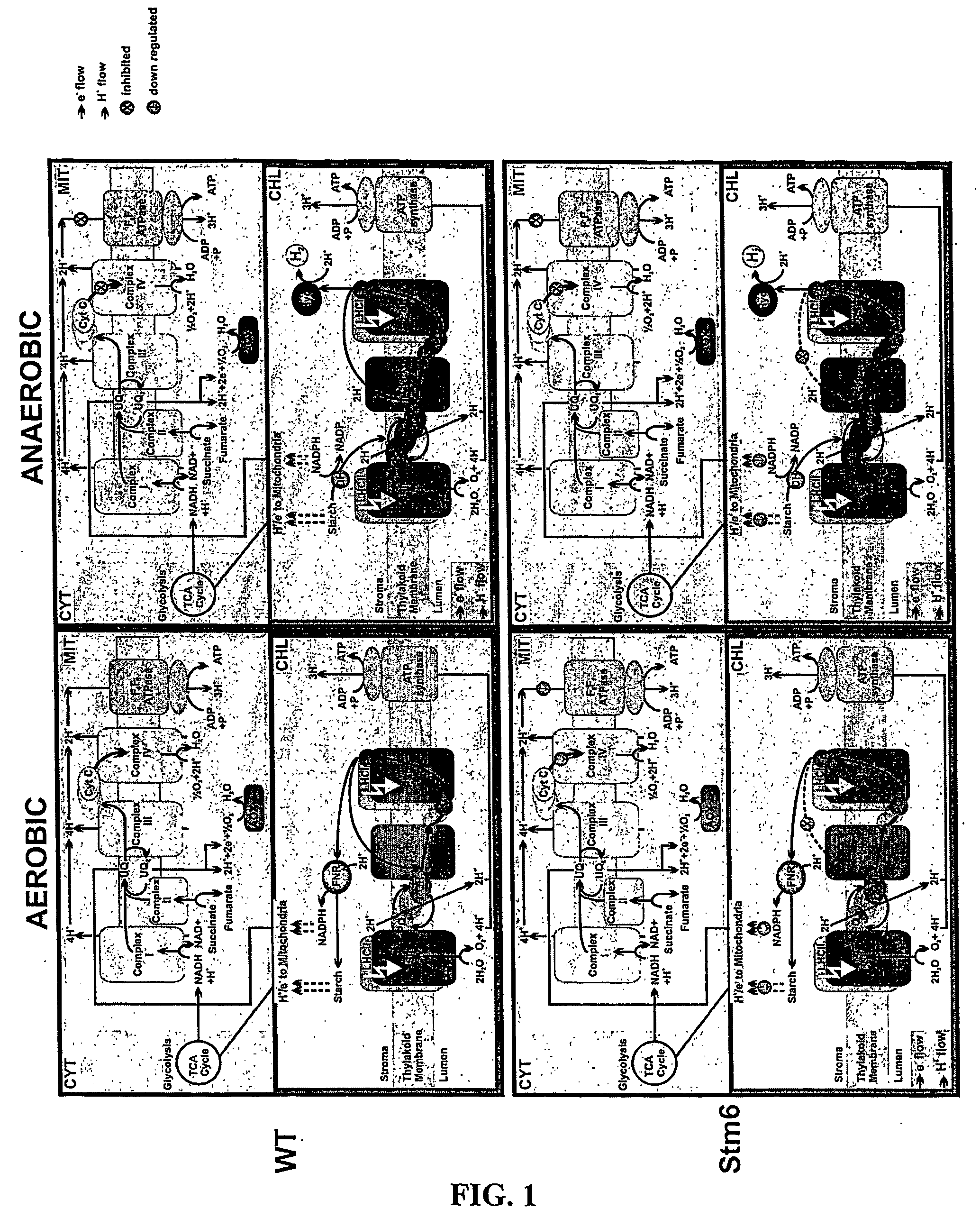

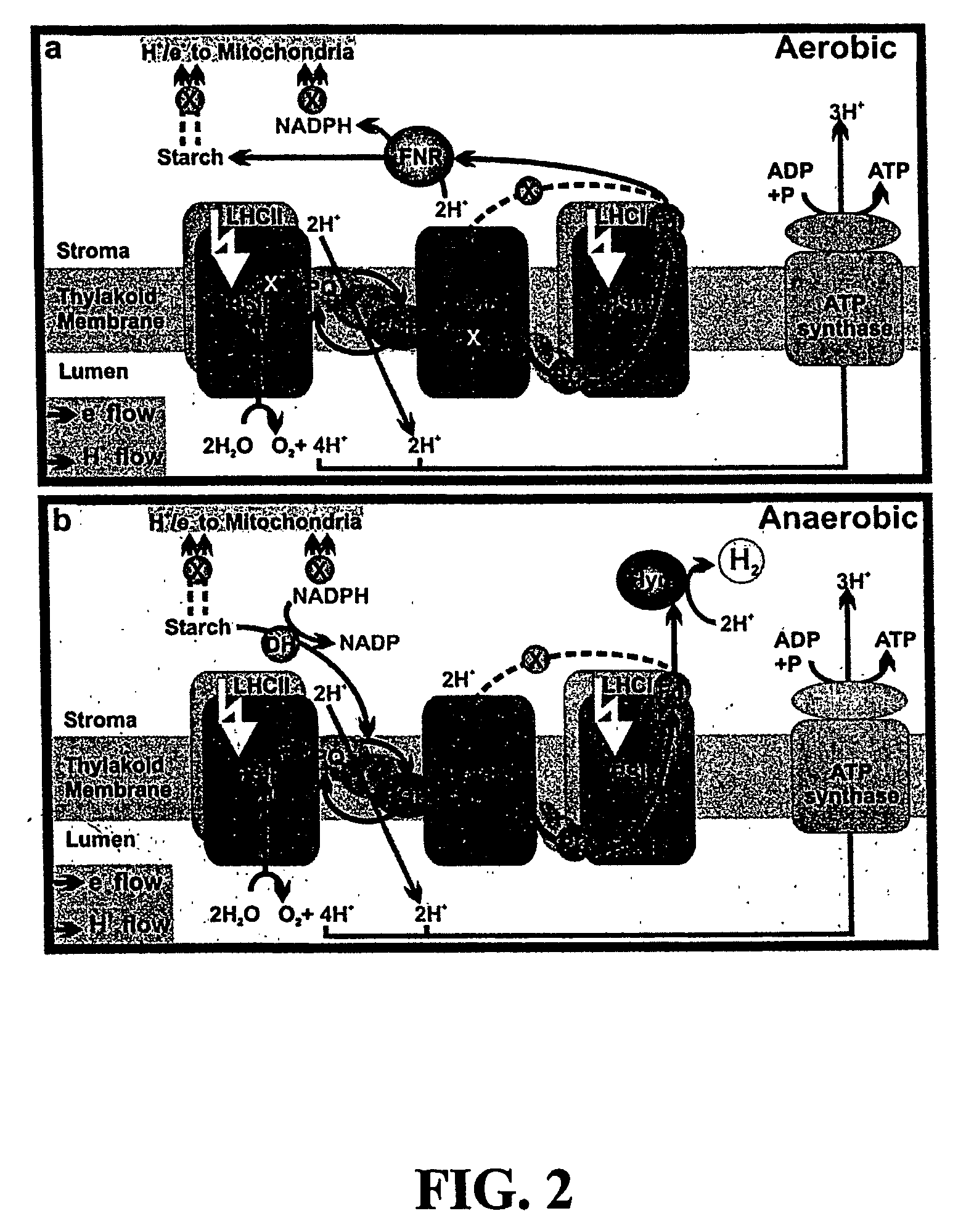

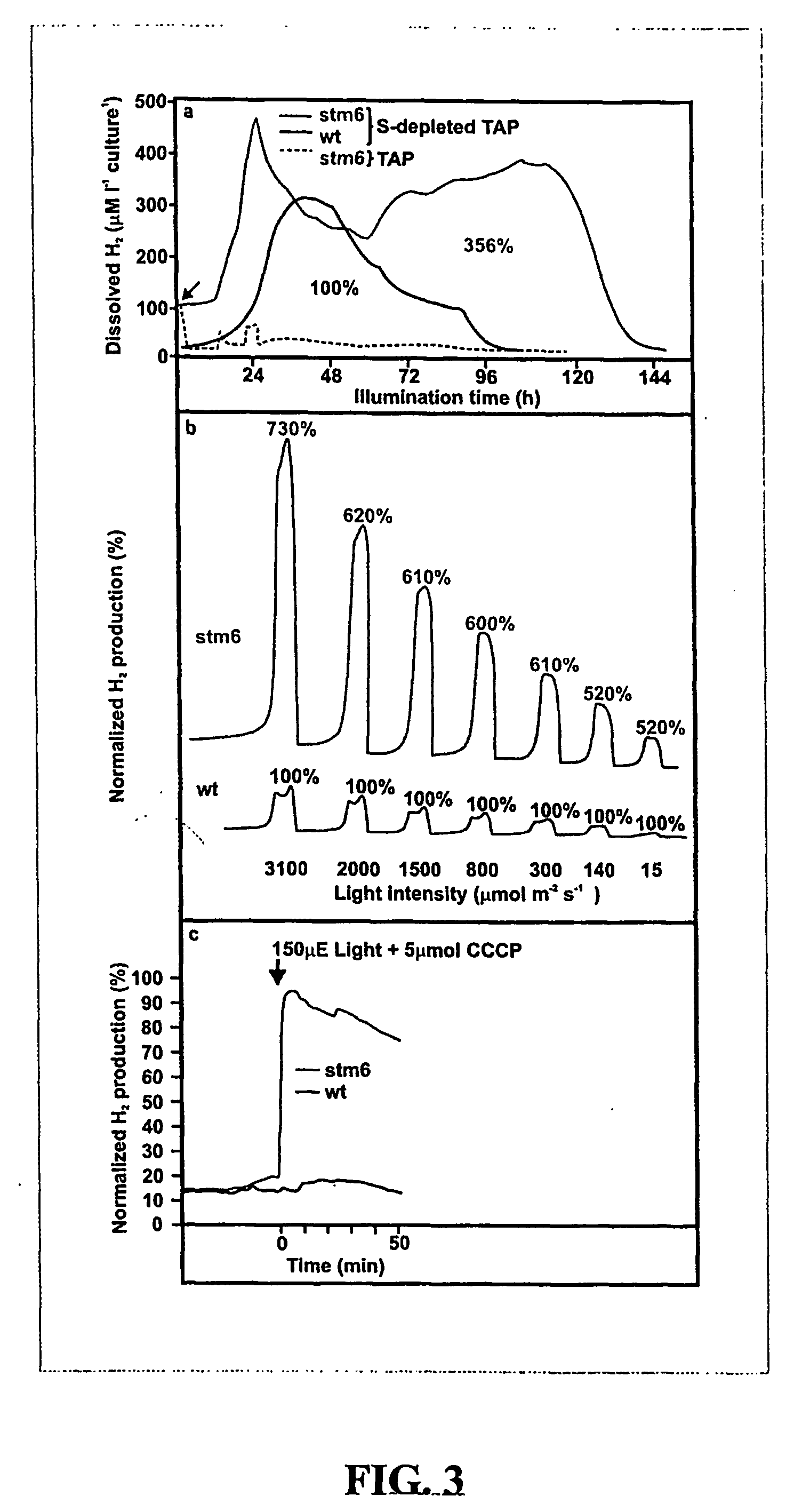

Photosynthetic hydrogen production

A process for the production of hydrogen, comprising the steps of: (i) providing a photosynthetic microorganism having electron transfer capability through a photosynthetic “light” reaction pathway and through a respiratory electron transfer chain involving an oxidative phosphorylation pathway, and which expresses a hydrogenase, wherein regulation of the oxidative phosphorylation pathway is disrupted with the result that electron flow along the respiratory electron transfer chain toward cytochrome oxidase (complex IV) is reduced; ii) culturing the microorganism under microoxic and illuminated conditions; and (iii) collecting evolved hydrogen.

Owner:THE UNIV OF QUEENSLAND

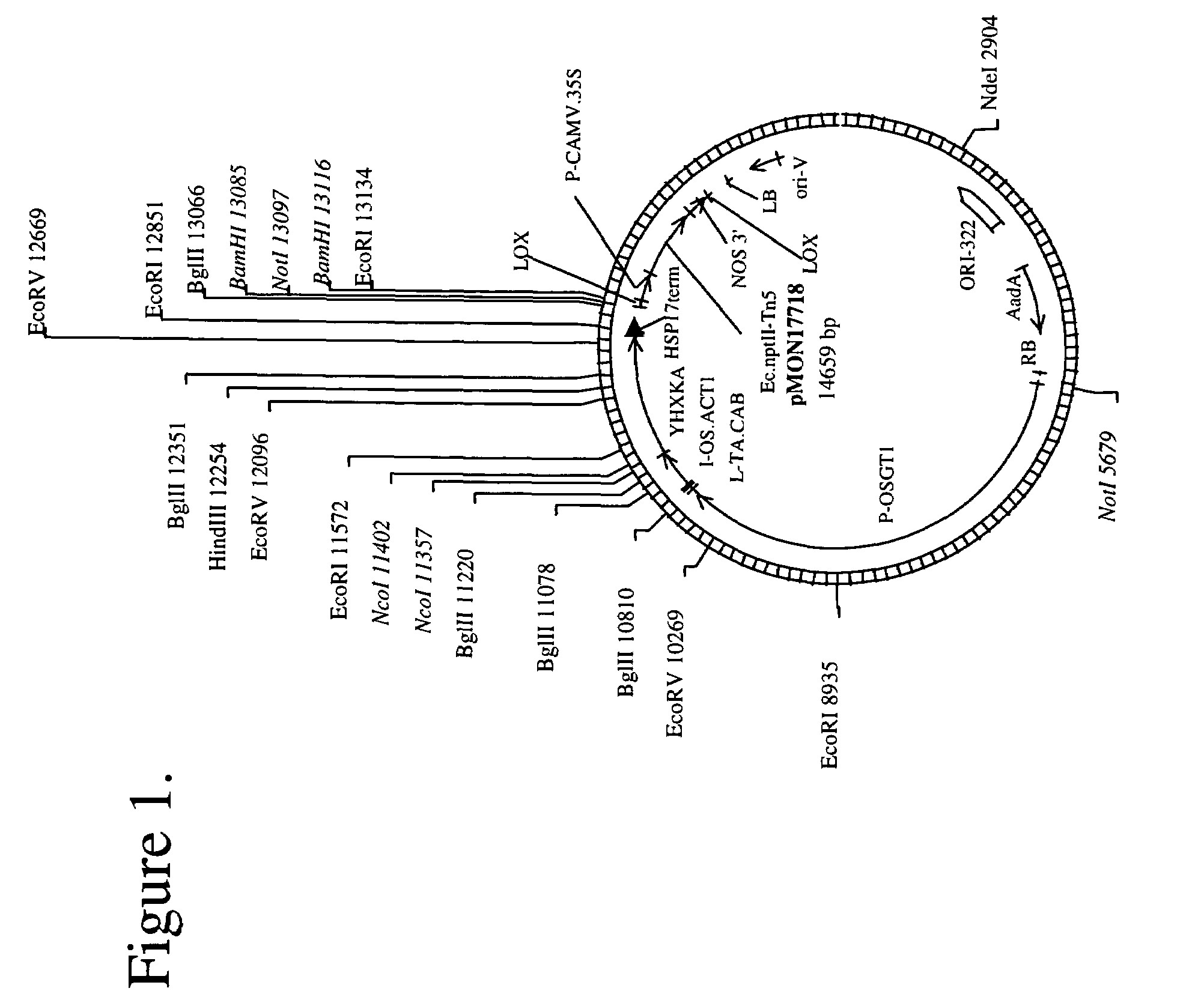

AP2 domain transcription factor ODP2 (ovule development protein 2) and methods of use

ActiveUS20050257289A1Improve conversion efficiencyImprove planting efficiencySugar derivativesClimate change adaptationNucleotideTransformation efficiency

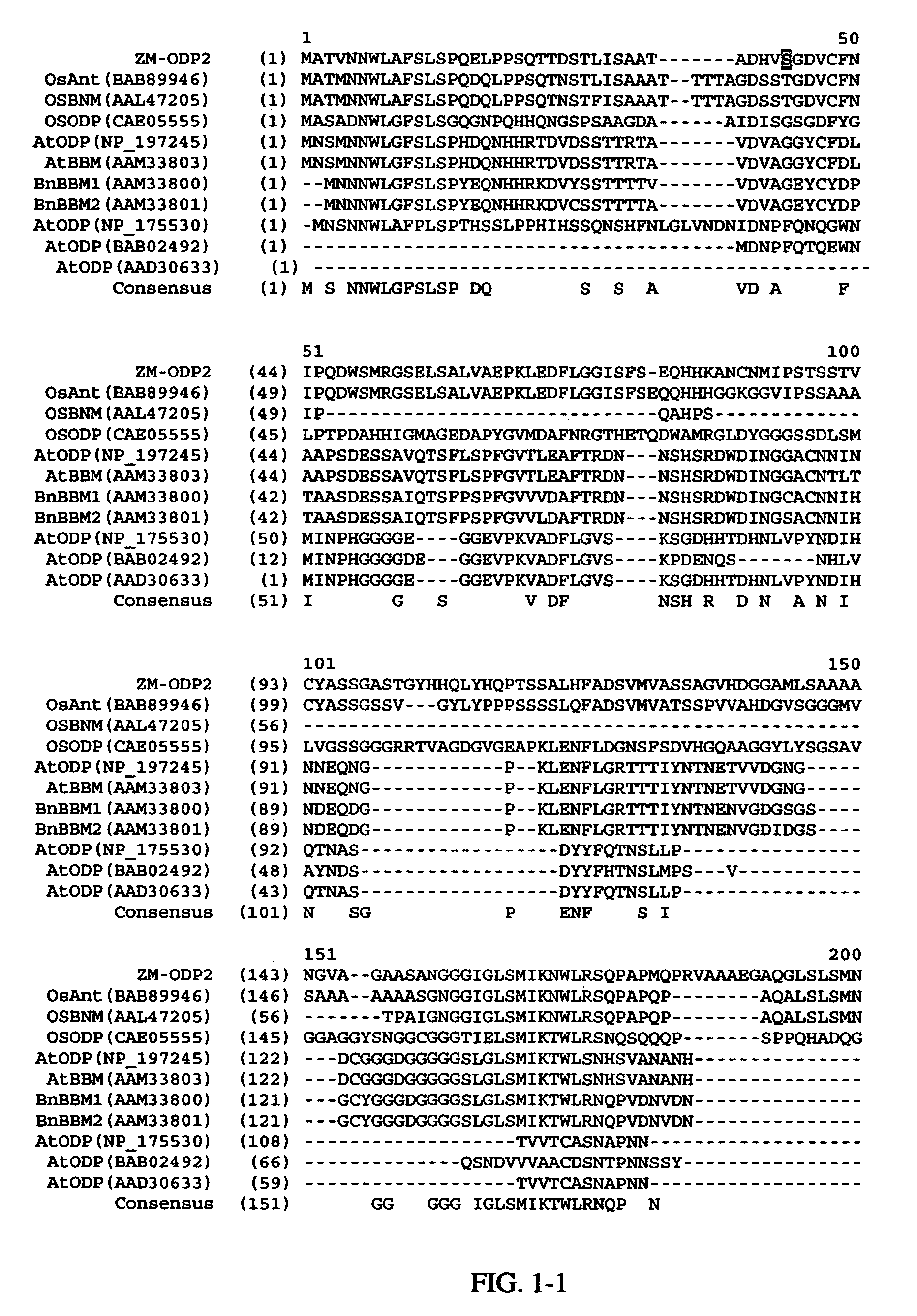

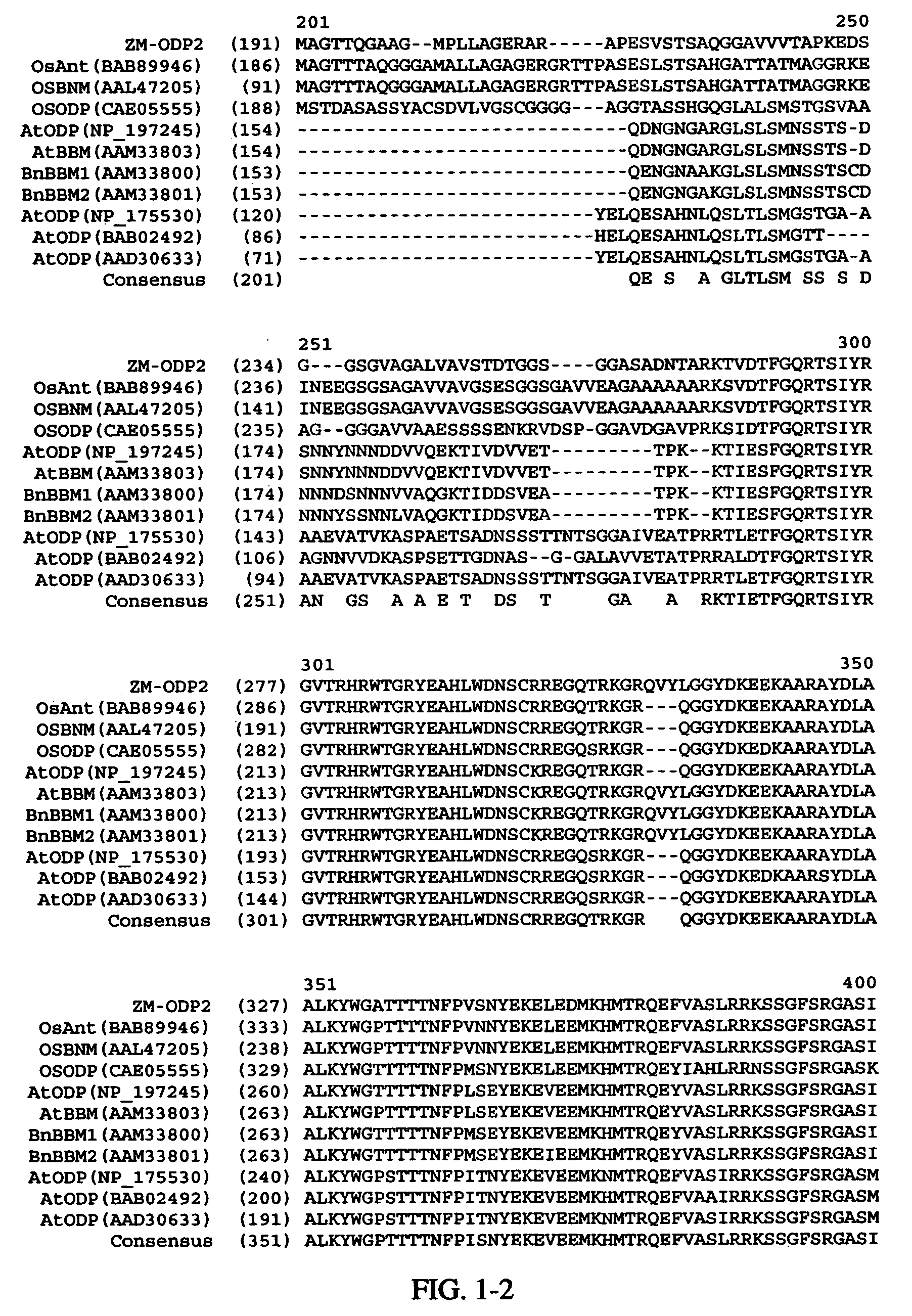

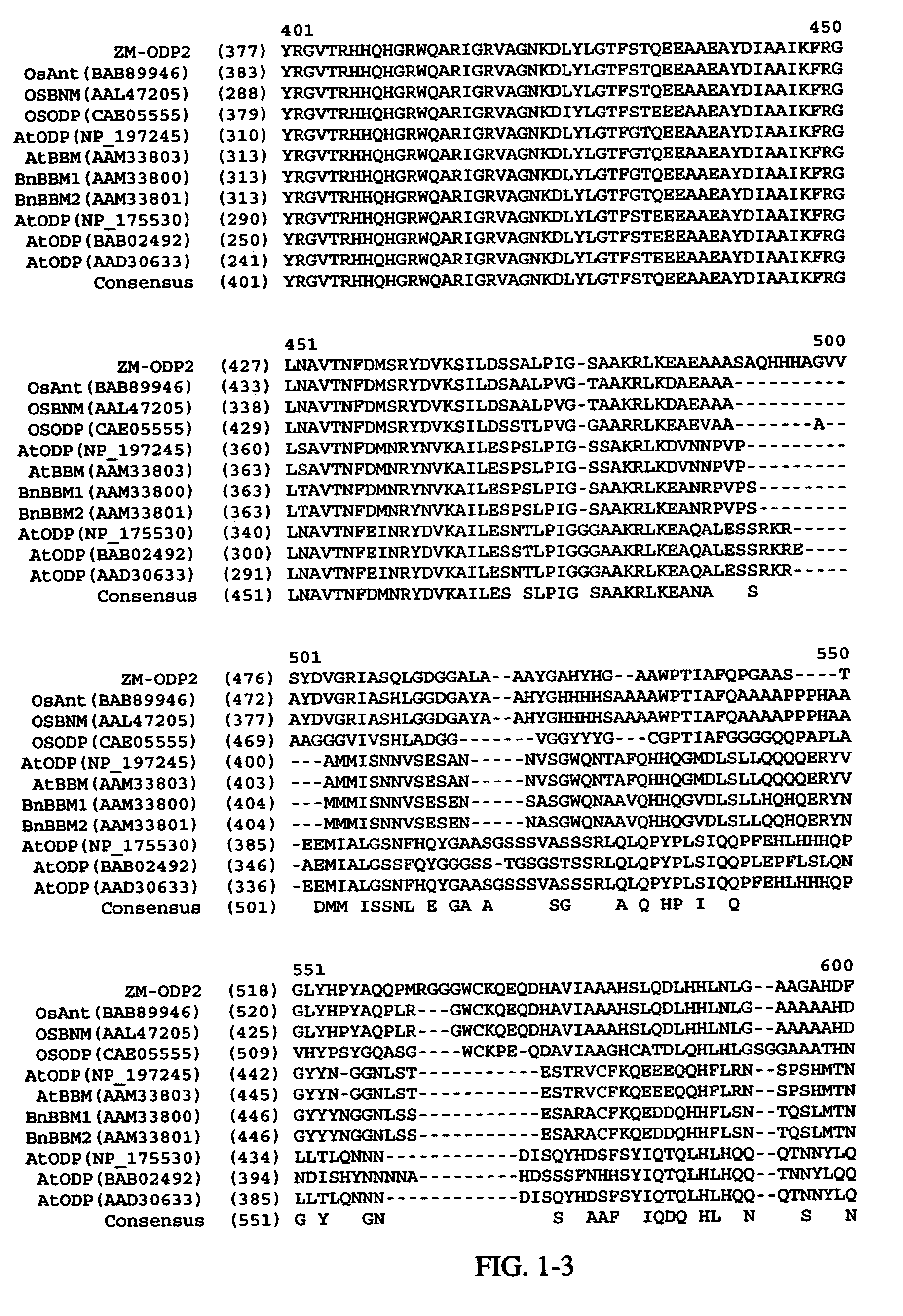

Methods and compositions for modulating plant development are provided. Nucleotide sequences and amino acid sequences encoding Ovule Development Protein 2 (ODP2) proteins are provided. The sequences can be used in a variety of methods including modulating development, developmental pathways, altering oil content in a plant, increasing transformation efficiencies, modulating stress tolerance, and modulating the regenerative capacity of a plant. Transformed plants, plant cells, tissues, and seed are also provided.

Owner:PIONEER HI BRED INT INC

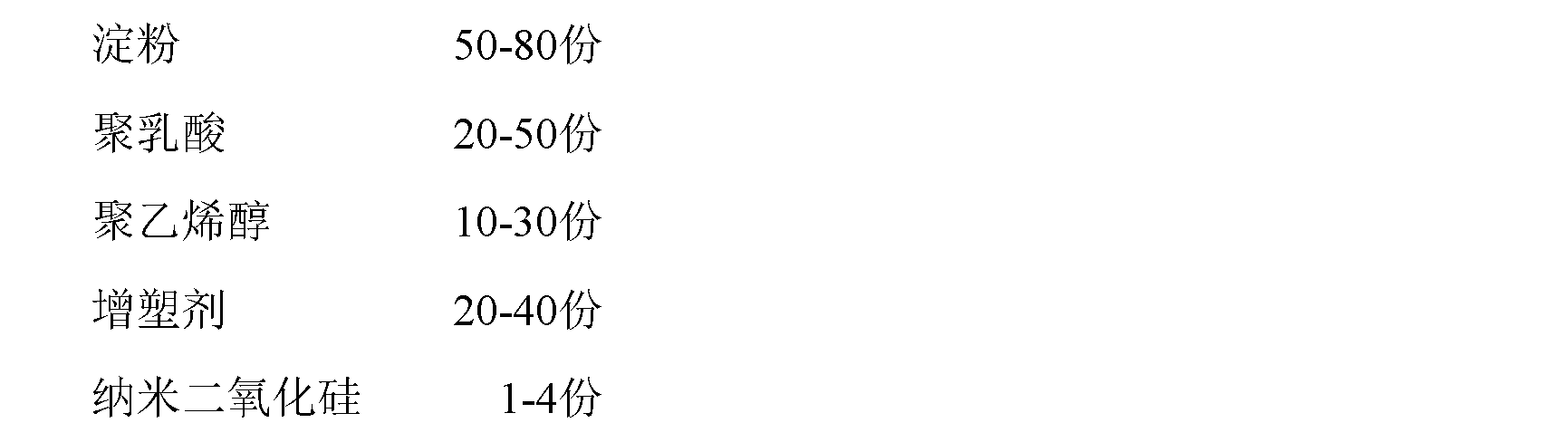

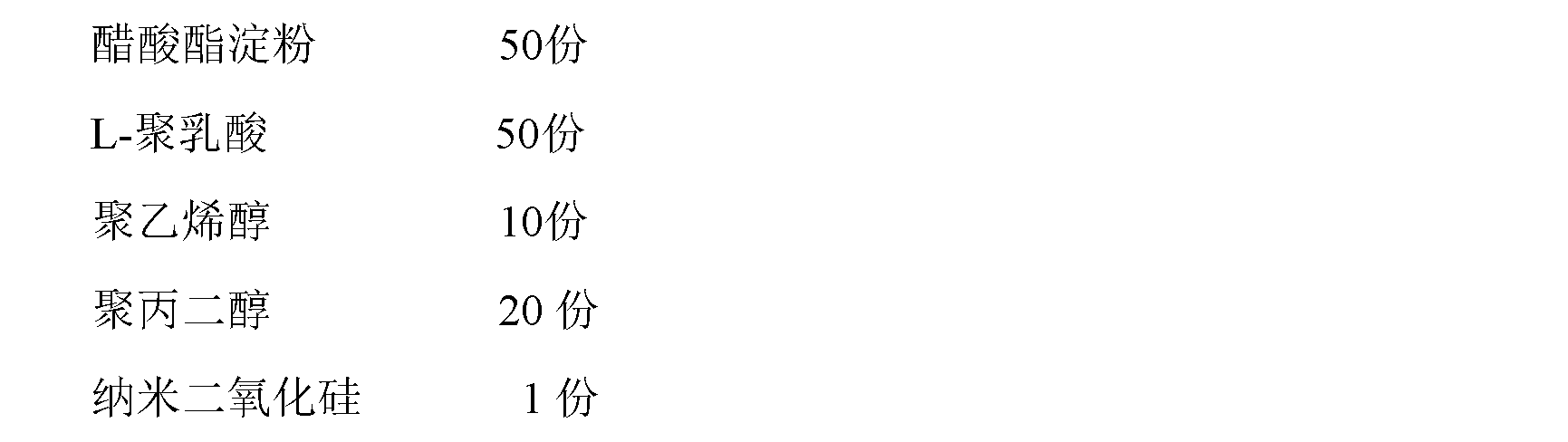

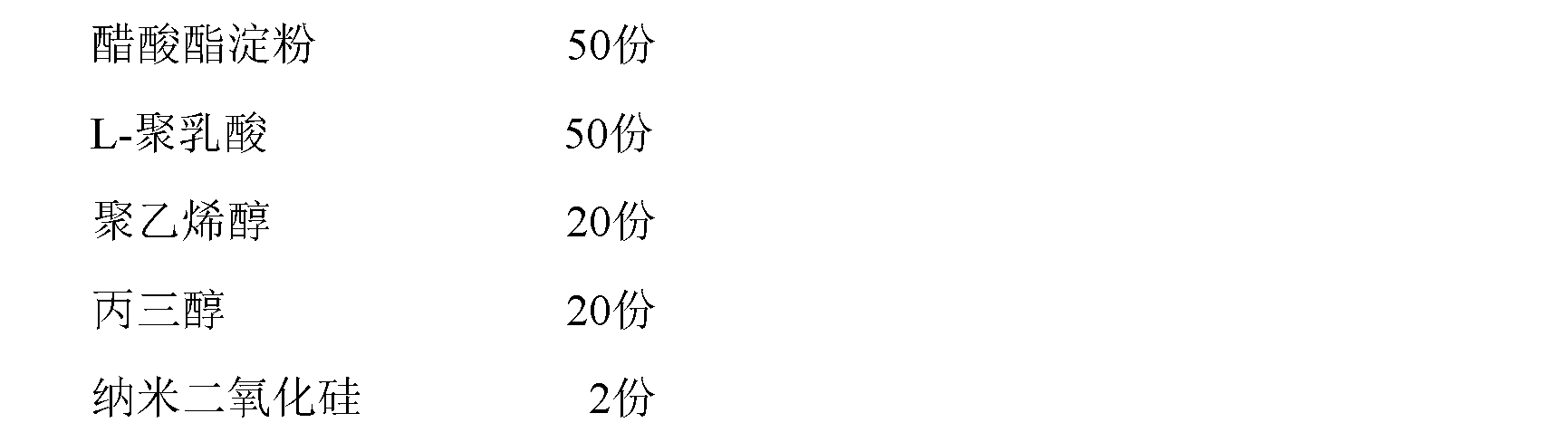

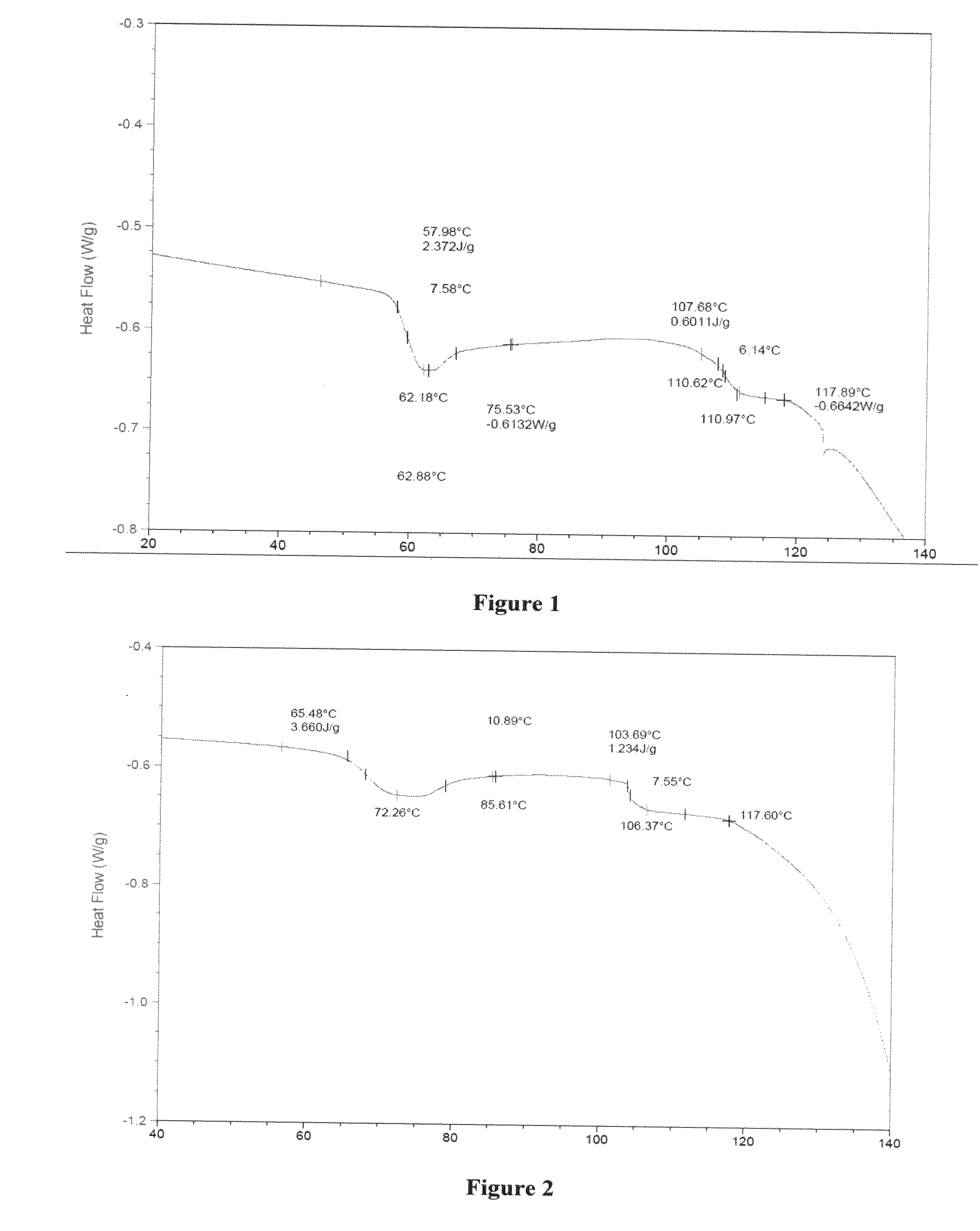

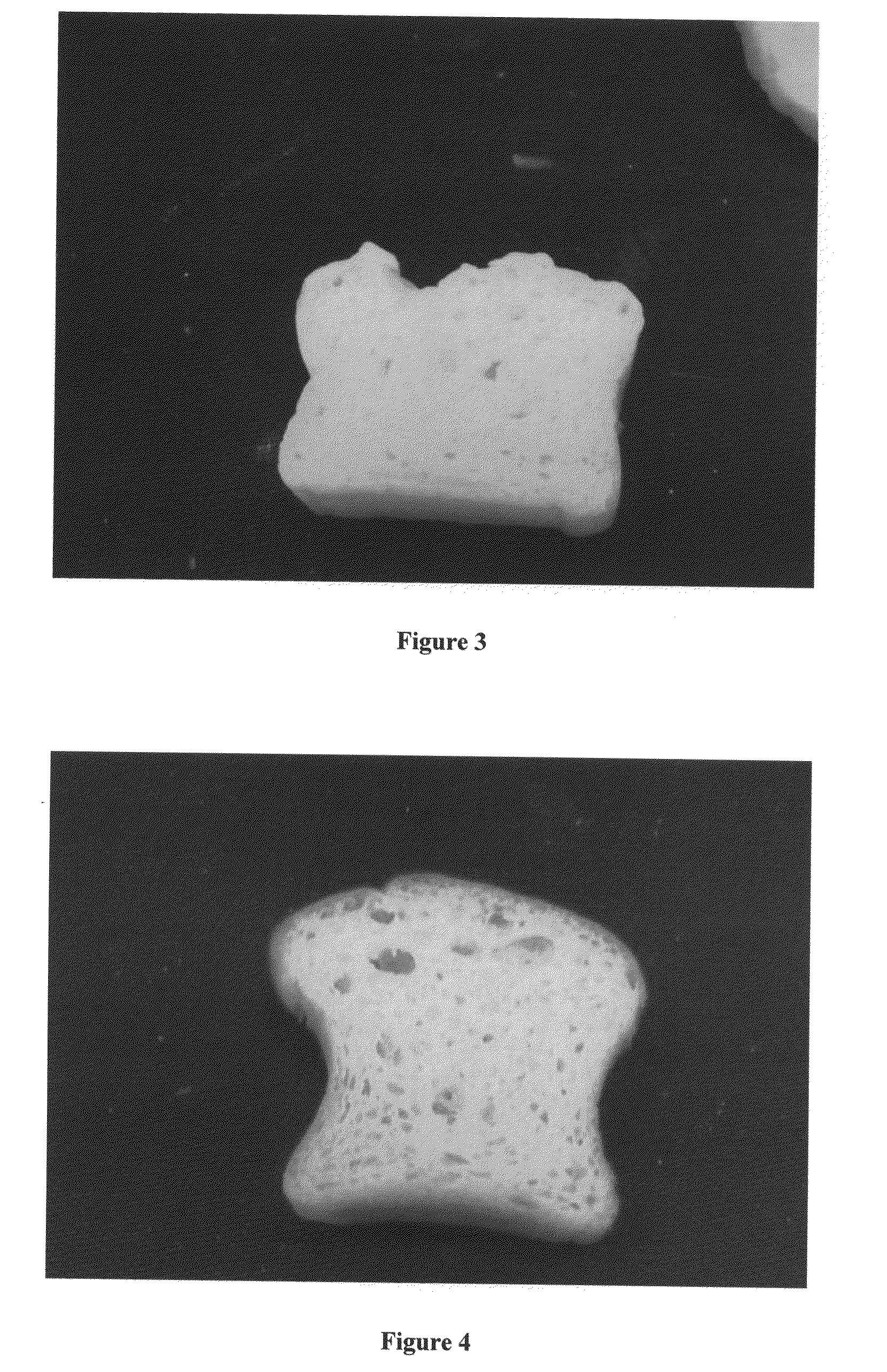

High-starch-content waterproof totally-decomposed composite material and preparation method thereof

InactiveCN103304851AGood component compatibilityImprove mechanical propertiesAdditive ingredientPlasticizer

The invention relates to a high-starch-content waterproof totally-decomposed composite material and a preparation method thereof. The method comprises the steps of: firstly dispersing nanosilicon dioxide particles in a plasticizer in advance to obtain nano sol; secondly, evenly blending the sol and starch in a high-speed mixer, and then kneading the mixture together with polyvinyl alcohol in a kneading machine to obtain starch-based master batch; and finally carrying out melt blending on the starch-based master batch and polylactic acid through one of or a combination of more of an open mill, an internal mixer and an extruder to obtain the high-starch-content waterproof totally-decomposed composite material. Compared with the ordinary biology-based composite material, the high-starch-content waterproof totally-decomposed composite material is high in starch content, low in cost, and good in ingredient compatibility, the mechanical property and waterproof property of the material can be both obviously improved, and all ingredients can be totally decomposed, so that the excellent sustainable development characteristic can be achieved; and meanwhile, the high-starch-content waterproof totally-decomposed composite material can be machined by adopting die pressing, extrusion, injection molding and other technologies on general plastic machining equipment.

Owner:EAST CHINA UNIV OF SCI & TECH

High-starch full biodegradable composition and preparation method thereof

ActiveCN104119647AHigh in starchGood compatibilityMechanical properties of carbon nanotubesHigh polymer

The invention belongs to the technical field of high molecular materials, and relates to a high-starch full biodegradable composition and a preparation method thereof. The high-starch full biodegradable composition comprises the following components in parts by weight: 10-80 parts of full biodegradable thermoplastic starch masterbatches, 20-90 parts of biodegradable polyester and 0.3-5 parts of compatilizers. The full biodegradable composition provided by the invention has the advantages of high starch content and good compatibility of starch and a substrate and ensures the mechanical property the material in a long-time storage process; a film product prepared by using the composition can be greatly reduced in cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

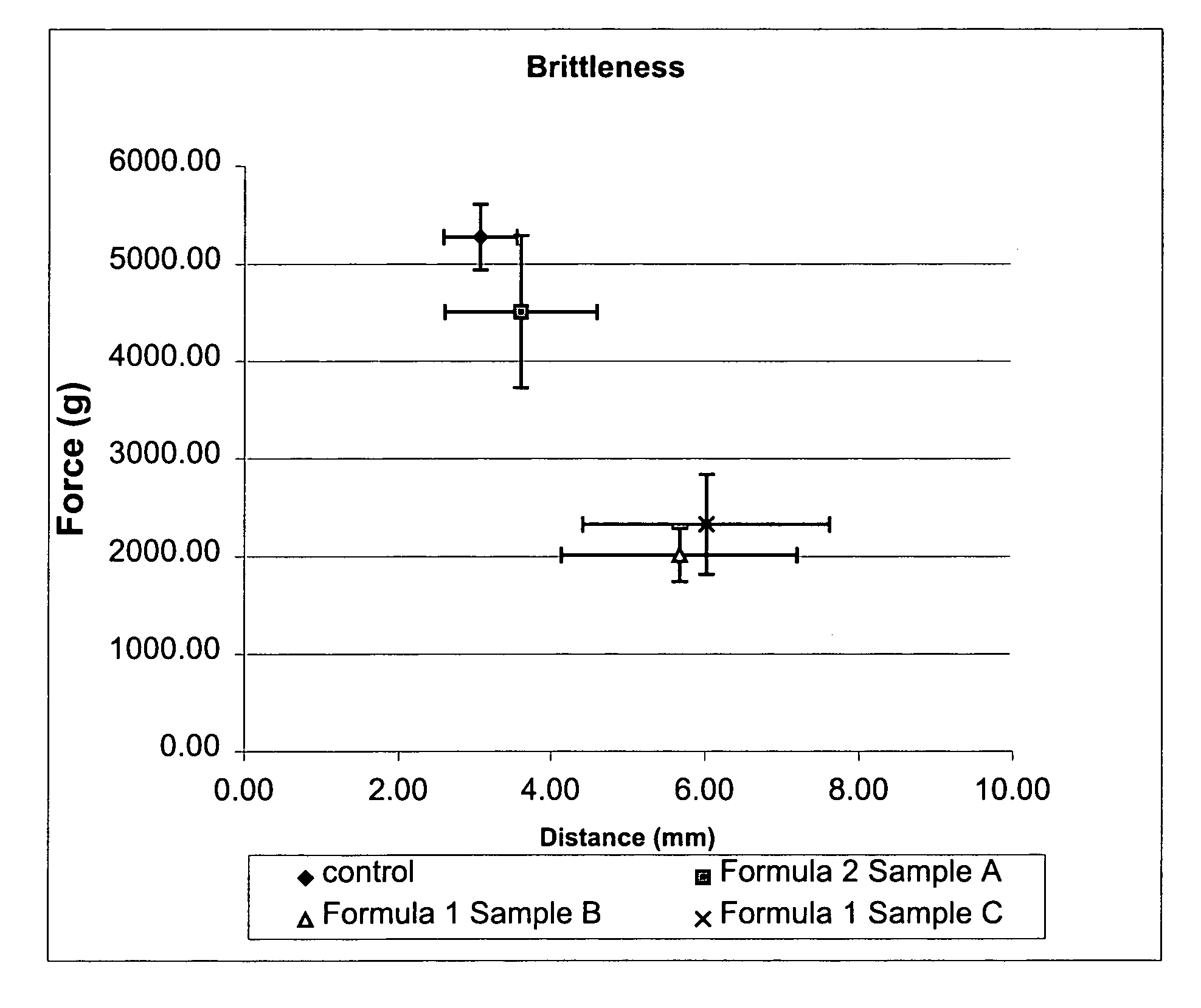

Formula and process for producing gluten-free bakery products

InactiveUS20100119652A1High in starchLow in sugarReady-for-oven doughsMilk preparationGluten freeStarch

Owner:RICH PRODUCTS

Preparation method of starch-base biodegradation material

The invention provides a preparation method of a starch-base biodegradation material. The starch-base biodegradation material is characterized by comprising the following raw materials in parts by weight: 70-85 parts of starch, 0.05-0.5 part of amylase, 1-11 parts of acetylating agent, 4-11 parts of plasticiser, 3-6 parts of hydrophobic modifier and 5-20 parts of biomass polymer. The preparation method comprises the following step of: (1) adding water into the starch, and adding amylase, and stirring for gelatinization; (2) adding the acetylating agent into the product in step (1), and stirring for reaction; (3) adding the plasticiser into the product in step (2), and to continuously stirring; (4) adding the hydrophobic modifier into the product in step (3), and continuously stirring to obtain starch gel; (5) adding the biomass polymer into the starch gel in the step (4), uniformly mixing, and delivering the uniform mixture into a twin-screw extruder to extrude and granulate. The invention has the advantages of simple operation, stable technology, low cost and high efficiency, and the obtained product has the advantage of good film forming property, mechanical property, water resistance property and degradation property.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Efficient slow-release urea and preparation method thereof

ActiveCN102584496AIncrease profitEasy to separateAgriculture gas emission reductionFertilizer mixturesCoated ureaAdhesive

The invention discloses an efficient slow-release urea. The efficient slow-release urea is prepared by coating urea by utilizing a coating slow-release solution and drying and solidifying the coated urea, wherein the coating slow-release solution consists of the following components in percentage by mass: 1 to 5 percent of gamma-polyglutamic acid, 1 to 5 percent of nitration inhibitor, 0.5 to 5 percent of adhesive, 0.05 to 2 percent of surfactant and the balance of water; and the pH of the efficient slow-release urea is 5.5 to 6.5. The invention also discloses the preparation method of the efficient slow-release urea. The gamma-polyglutamic acid in the efficient slow-release urea has the effects of coating and chelating the urea and the nitration inhibitor, so that separation of the nitration inhibitor and a nitrogen fertilizer is reduced, leaching and runoff losses of nitrate nitrogen are reduced, one-time fertilization can be realized, top dressing is not required, the utilization rate of the fertilizer can be improved by over 15 percent, and the yield of the crops is increased by 10 to 30 percent.

Owner:NANJING UNIV OF TECH

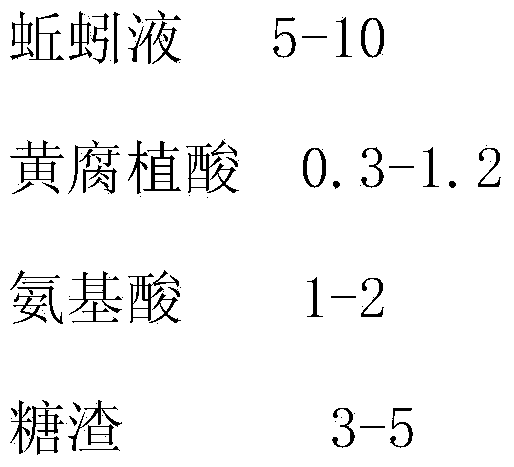

Preparation method of earthworm liquid organic fertilizer

InactiveCN103848654AIncrease profitAvoid churnBio-organic fraction processingOrganic fertiliser preparationPhytic acidSlurry

The invention provides a preparation method of an earthworm liquid organic fertilizer, which utilizes living earthworms to prepare organic liquid fertilizer; the preparation method comprises the following steps: (1) uniformly pulping the living earthworms in an electric stirrer to obtain earthworm serous fluid; (2) placing the earthworm serous fluid into a fermentation kettle, and then fermenting; (3) filtering the fermented earthworm serous fluid to obtain solid residues and earthworm liquid, wherein the solid residues are used as a solid earthworm fertilizer; (4) placing the earthworm liquid obtained in the step (3), fulvic acid, amino acid, sugar residues, fermentation group, urea and bran material into a fertilizer preparation kettle, and fermenting; and (5) filtering products after fermentation, and packaging filtrate. Compared with the prior art, the earthworm liquid organic fertilizer prepared by the preparation method disclosed by the invention improves ability of mud for retaining nutrients and moisture, so that applied fertilizer is reduced, nutrients are prevented from running off on the ground, utilization efficiency of fertilizer is improved, plant yield is improved, and guarantee period is prolonged.

Owner:安徽利海新城镇开发有限公司

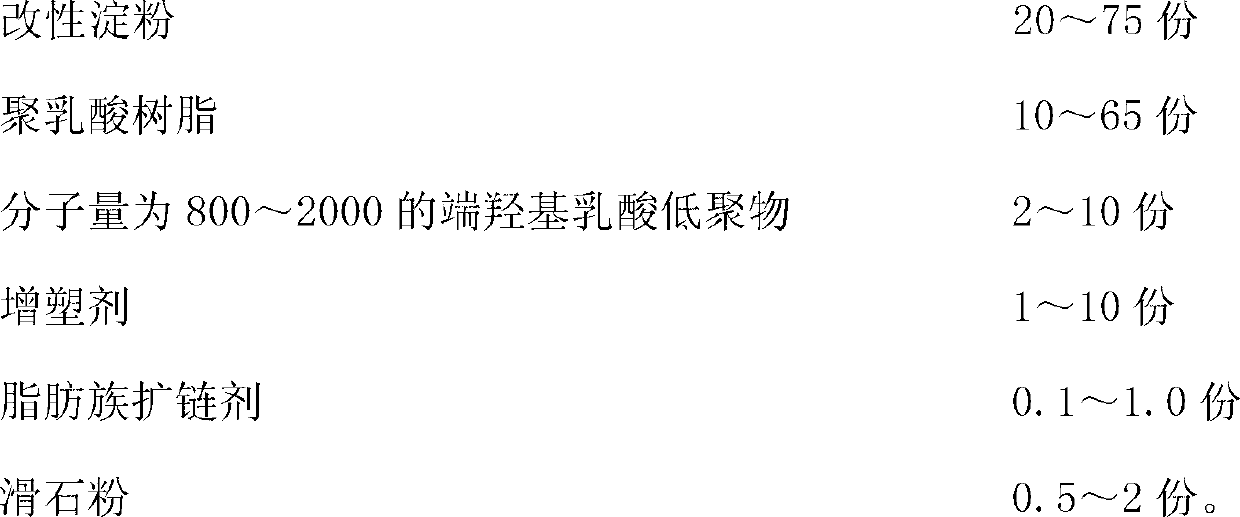

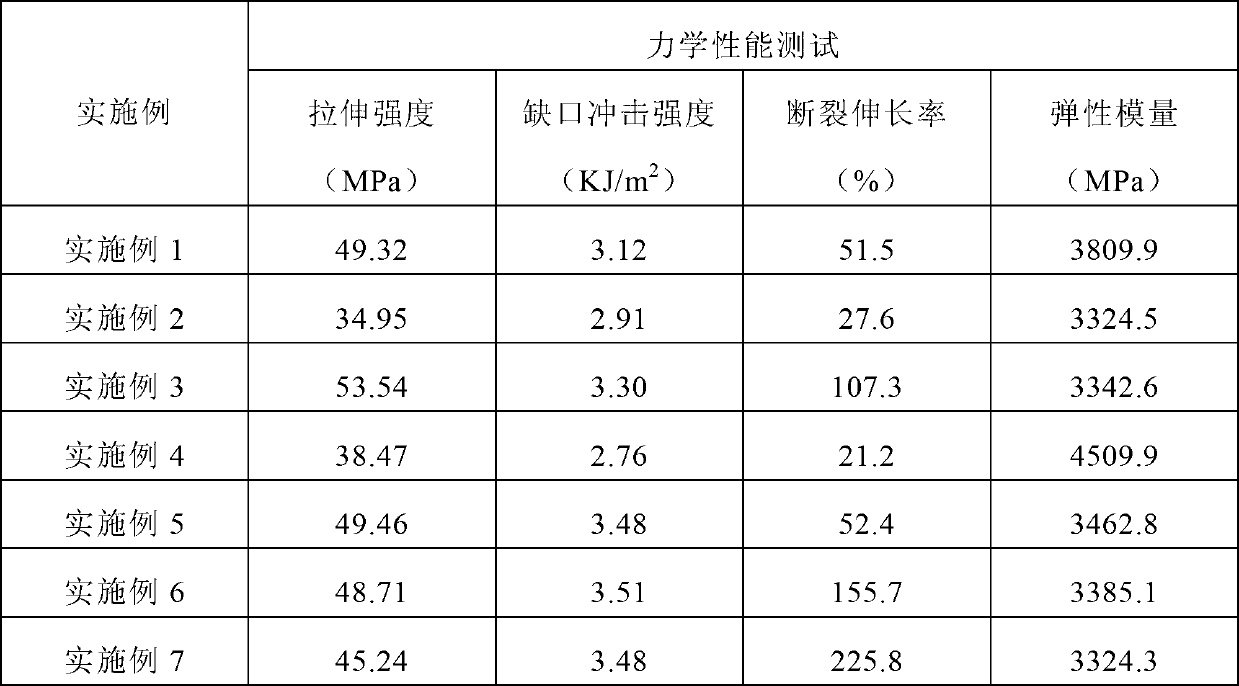

Starch and polylactic acid composite material and preparation method thereof

The invention relates to a starch and polylactic acid composite material and a preparation method thereof. The composite material comprises, by weight, 20 to 75 parts of modified starch, 10 to 65 parts of polylactic resins, 2 to 10 parts of hydroxy-terminated lactic acid oligomer with molecular weight of 800 to 2000, 1 to 10 parts of plasticizers, 0.1 to 1.0 part of aliphatic chain extenders, 0.5 to 2 parts of talcum powders and 0.1 to 3 parts of auxiliaries. The preparation method includes that firstly the modified starch, the polylactic acids, the hydroxy-terminated lactic acid oligomer, the plasticizers, the talcum powders, lubricating agents and coupling agents are blended together in a homogenizer to obtain a blend, and then a mixed material of the blend and the chain extenders is added in a twin-screw extruder to be subjected to melt extrusion, cooling and granulation to obtain the starch and polylactic acid composite material. The starch and polylactic acid composite material has the advantages that the compatibility, toughness and heat resistance are good, the cost is low, the biodegradation can be completely achieved, the preparation technique process is simple, the 'three wastes' emission is absent, and the mass production can be achieved.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

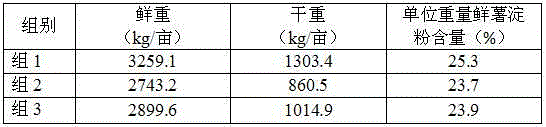

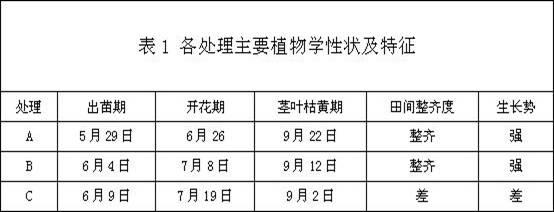

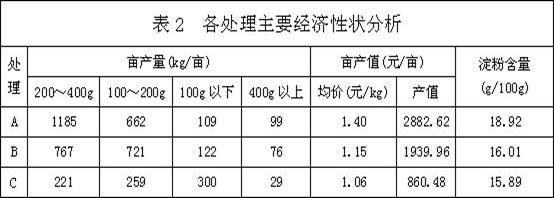

Cultivation method for promoting stable yield of dried sweet potatoes in northern sweet potato area plains to exceed one ton per mu

InactiveCN104855115AExtended growth timeHigh in starchPlant cultivationCultivating equipmentsDiseaseDrip irrigation

The invention provides a cultivation method for promoting stable yield of dried sweet potatoes in northern sweet potato area plains to exceed one ton per mu. The cultivation method comprises the steps of carefully selecting the variety, selecting land to form a ridge, performing formulated fertilization, selecting strong seedlings, performing film mulching and early planting, appropriately increasing the density, performing drip irrigation under a mulch, strictly preventing diseases and pests, chemically controlling the excessive vegetative growth and performing mechanical harvesting. According to the cultivation method, through early planting and close planting and by the matching of other advanced planting technologies, the growth time of the sweet potatoes is prolonged, the content of starch in the sweet potatoes and the sweet potato dry matter accumulation amount in unit area land are remarkably improved, and the per mu yield of the dried sweet potatoes can exceed one ton. The comprehensive degree of the technology is improved, the fusion of the improved variety and the good method and the combination of an agricultural machine and the agricultural technology are performed, the matching of engineering measures and cultivation measures is achieved, the level of the cultivation technology is fully improved, the working efficiency is improved, and the production cost is reduced. The standard degree of the technology is improved, the technology details and parameters are further clearer through the quantitative data indexes, and the basis is laid for the standard forming and popularization of the planting technology.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

Bioldegradation plastic masterbatch and its preparation method

A mother particle for bioderadation plastic is prepared from starch, resin, polymer, plasticizer with high boiling point, lubricant and oxidizing degradation promoter, through preparing modified superfine starch, mixing with others, and granulating.

Owner:叶新建

Compositions comprising thermoplastic starch

ActiveUS20120022188A1Improve compatibilityMaintain good propertiesPaper coatingCoatingsLow-density polyethyleneThermoplastic

The invention relates to a composition comprising very low density polyethylene having a density of less than 0.905 g / cm3, ethylene acrylic acid copolymer and thermoplastic starch and / or the constituent components thereof.

Owner:SETEC

Roll printing paper suitable for cold set printing and process for its production

InactiveUS6413370B1Offset printing processSufficient dimensional stabilityNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryPaper sheet

A coated roll printing paper for printing with the cold-set offset-printing process is described, which gives a printing result comparable with that of low-weight coated matte grades. The paper is characterized by a high proportion of a fine calcium carbonate in the coating pigment, and a relatively low proportion of highly active binders.

Owner:HAINDL PAPIER

Planting method of Pueraria root

The invention discloses a planting method of Pueraria root. The planting method includes the steps of (1) growing seedlings; (2) selecting lands; (3) performing transplanting; (4) checking the seedlings and filling the gaps with the seedlings; (5) performing weeding and fertilizing; (6) setting supports with height of 2.5-3m spaced with 0.8m; (7) reserving 4-5 main vines of each Pueraria root with lateral branches and buds cut; (8) cutting vines and digging roots in autumns and winters. According to the planting method, the lands are scientifically selected, and base fertilizer application, top dressing are reasonable, and absorption of the Pueraria root is facilitated to achieve rapid thriving of the Pueraria root with excellent root size, and potassium sulfate and calcium superphosphate are applied to facilitate germination; the Pueraria root is rapid to grow and high in quality and yield. Starch content of the Pueraria root reaches 26-27% and is greatly higher than that of wild pueriara root with 12-15%. Puerarin content of the Pueraria root reaches 2.0-2.3% and is higher than that of the wild Pueraria root with 1.4-2.0%. The Pueraria root yields 2200-2400kg / mu.

Owner:NINGGUO THOUSAND SQUARE TCM DEV

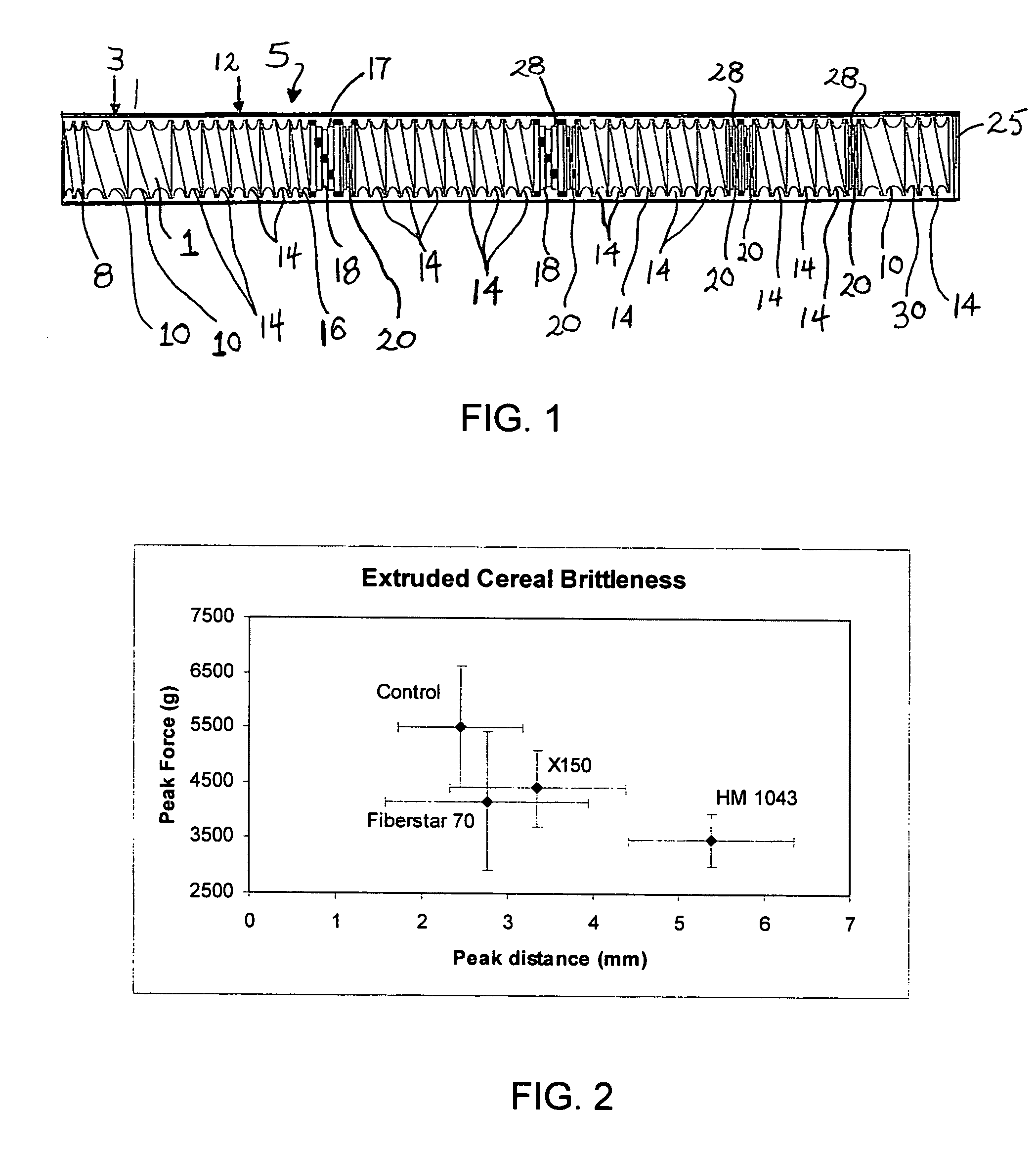

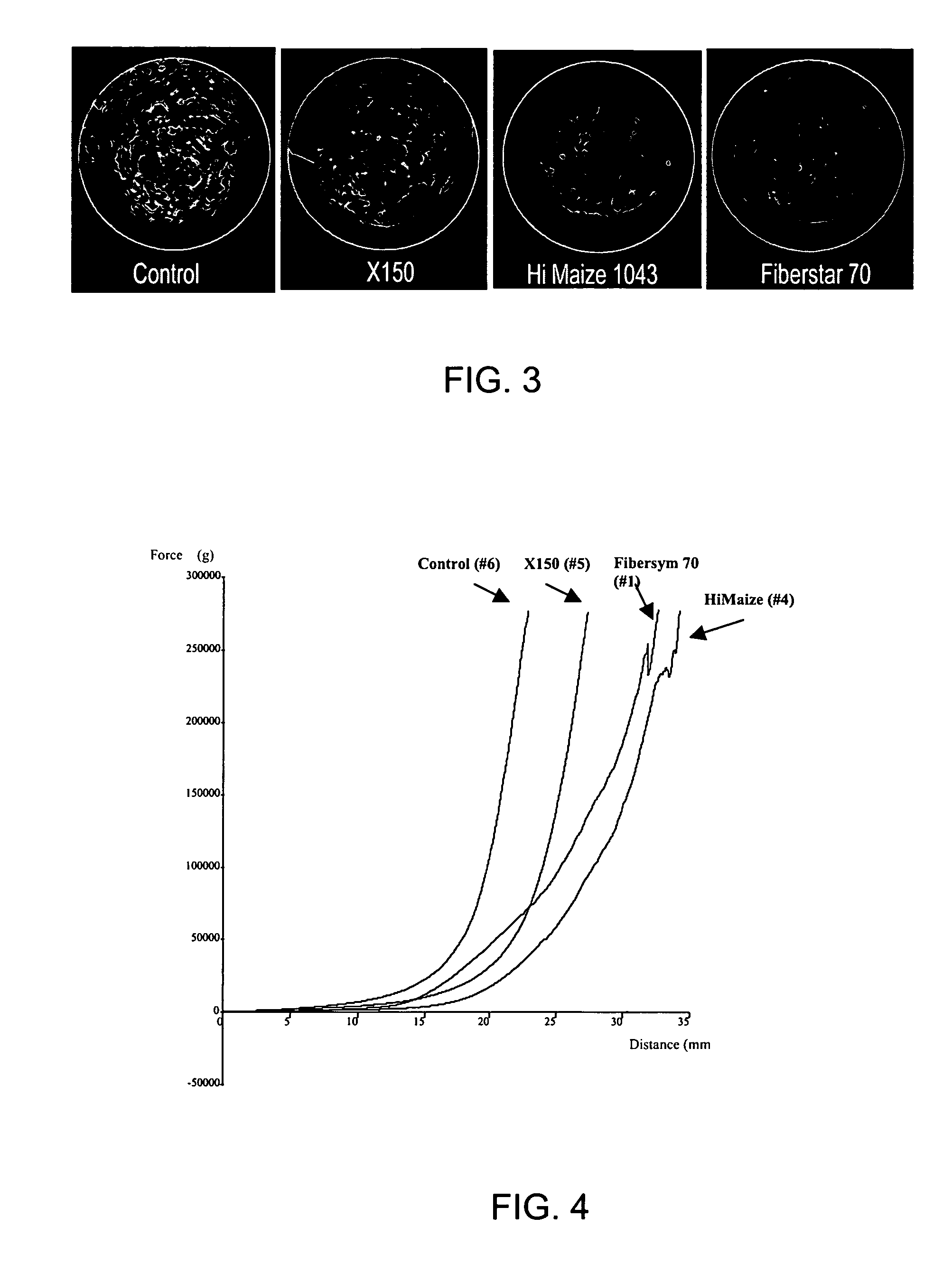

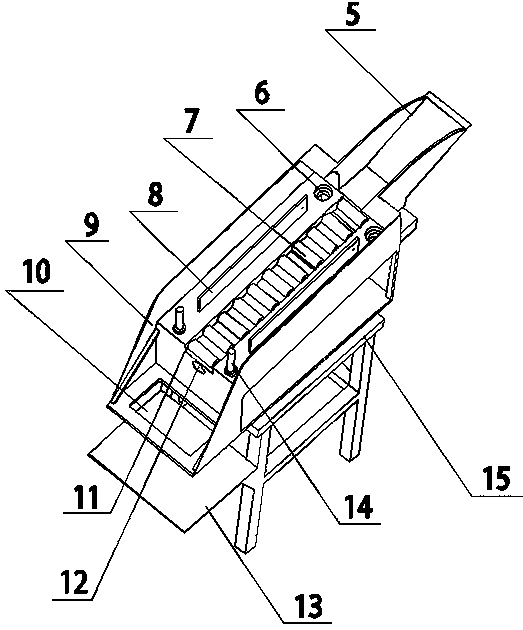

Production of low calorie, extruded, expanded foods having a high fiber content

InactiveUS7648723B2Reduce capacityHigh melting pointDough treatmentMilk preservationReady to eatAdditive ingredient

An extruded, directly expanded, high fiber reduced calorie food product, such as a ready-to-eat (RTE) cereal or sweet or savory snack, is produced at high production rates without substantial loss of extrusion functionality and extrudability by replacing a substantial portion of at least one flour with a gelatinized, enzyme-resistant starch type III ingredient or bulking agent as a reduced-calorie, high fiber flour replacer. The resistant starch type III ingredient or bulking agent contains an enzyme-resistant starch type III having a melting point with an endothermic peak temperature of at least about 140° C., and may have a water-holding capacity of less than 3 grams water per gram of the starch-based bulking agent. The total dietary fiber retention of the gelatinized, starch-based bulking agent may be at least about 90% by weight after the extrusion using a die temperature of least about 100° C., and a die pressure of at least about 150 psig.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

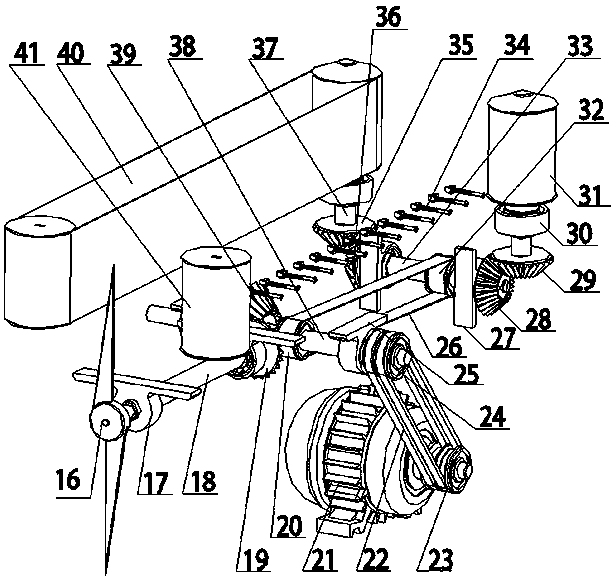

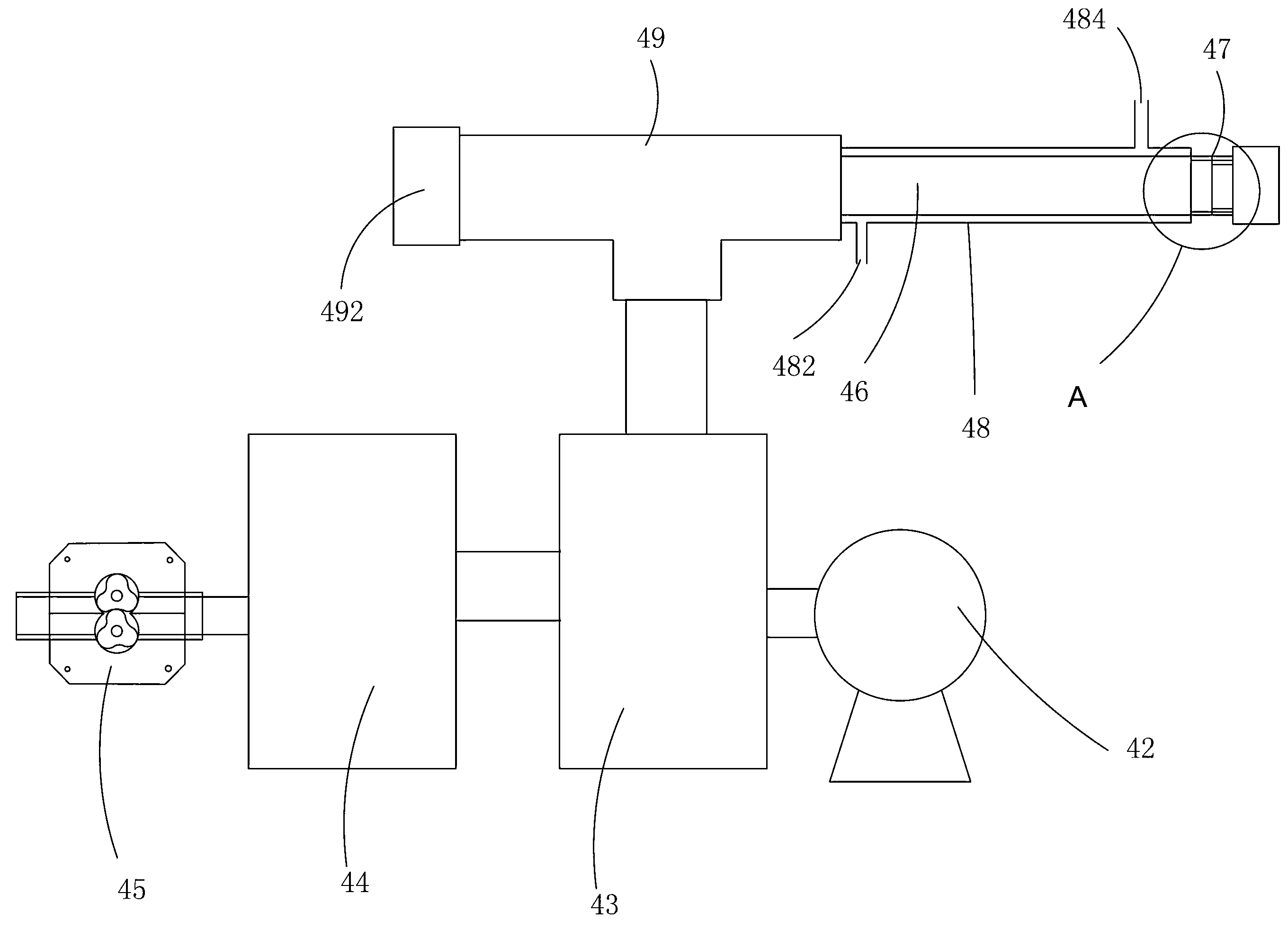

Feeding type automatic lotus root slicing machine

InactiveCN104385338ASlicing is stable and efficientClamp firmlyMetal working apparatusMechanical engineeringLotus root

The invention relates to a feeding type automatic lotus root slicing machine, in particular to novel lotus root processing equipment. The feeding type automatic lotus root slicing machine consists of a frame, a lotus root conveying unit, a lotus root clamping unit, a lotus root slicing unit and a lotus root slice collecting unit, wherein the lotus root conveying unit and the lotus root clamping unit are embedded together; and the lotus root clamping unit is contacted with a conveying belt on the lotus root conveying unit through a roller on a pressurizing chuck, so that processed lotus roots can be smoothly fed in the lotus root slicing unit through the lotus root conveying unit. The lotus root slicing unit is positioned at the tail end of the lotus root conveying unit; and the lotus root slice collecting unit is positioned rightly below the lotus root slicing unit. The feeding type automatic lotus root slicing machine adopts the pressurizing chuck to perform the point clamping for the lotus roots through flexible transition of the conveying belt, the lotus root conveying unit and the lotus root clamping unit are embedded together, and the lotus root conveying unit and the lotus root slicing unit are linked, so that the structure is compact, and the stability is enhanced; and all the component units of the whole machine are higher in working coordination degree, facilitate automatic production control, are excellent in use effect, and are strong in practicability.

Owner:WUHAN TEXTILE UNIV

High-efficiency microbial organic fertilizer prepared from methane slag and application

InactiveCN102320893AImprove fertilizer efficiencyIncrease productionClimate change adaptationBioloigcal waste fertilisersBiotechnologySlag

The invention relates to high-efficiency microbial organic fertilizer prepared from methane slag. The high-efficiency microbial organic fertilizer mainly comprises methane slag, plant growth regulator, microbial functional bacteria, binder and disintegrating agent which are used as active ingredients. The high-efficiency microbial organic fertilizer comprises the following components in percentage by weight: 30.0 to 85.0 percent of methane slag, 0.001 to 3.0 percent of plant growth regulator, 0.1 to 1.0 percent of microbial functional bacteria, 0.5 to 1.0 percent of binder and 3.0 to 10.0 percent of disintegrating agent and the balance of other aids and fillers which are allowable and acceptable in chemical fertilizer and pesticide. The high-efficiency microbial organic fertilizer is abundant in organic matters, amino acid, nitrogen, phosphorus, potassium, trace elements and the proper plant growth regulator, and can obviously improve fertilizer efficiency of the methane slag, reduce the using amount of the methane slag, regulate growth of potatoes, obviously increase the yield of the potatoes and improve the quality of the potatoes. The high-efficiency microbial organic fertilizer is mainly applied to planting of the potatoes, Chinese medicinal materials and vegetables.

Owner:常华

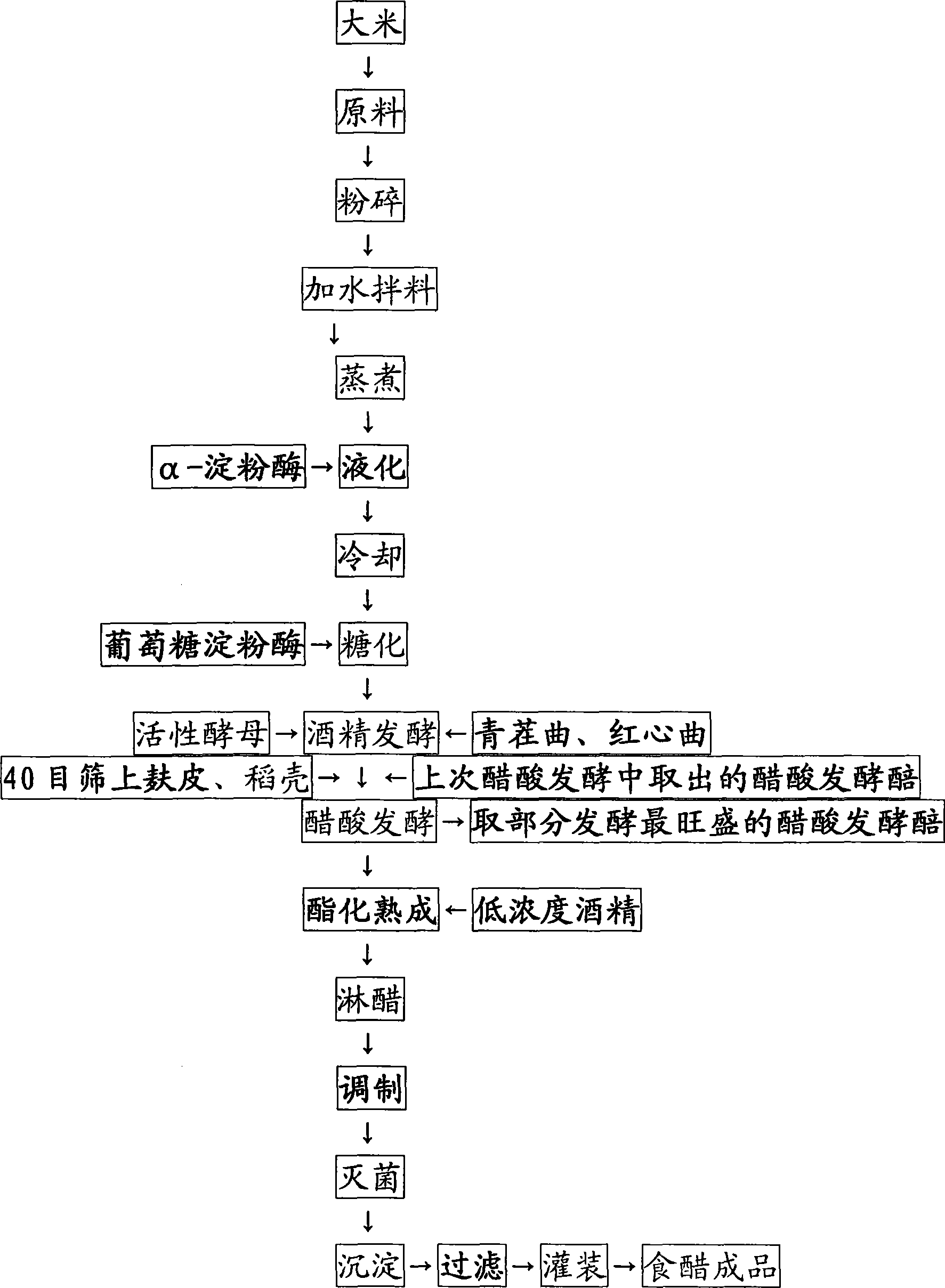

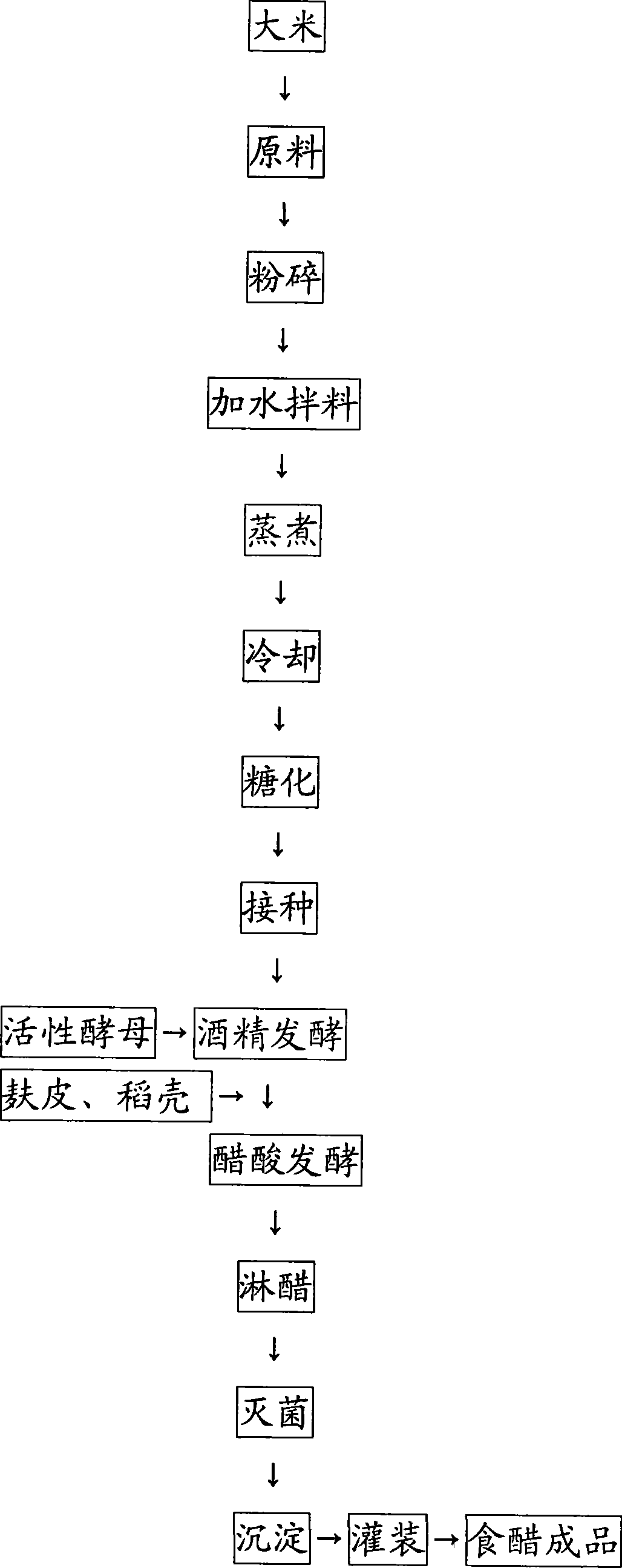

Method for producing edible vinegar

InactiveCN101381670AMeet quality requirementsEnsure safetyVinegar preparationBiotechnologyCritical control point

The invention discloses a method for producing an edible vinegar product, which relates to the technical field of edible vinegar production. The top-class optimization of key control points is used to determine a new method and a new edible vinegar product, including the prior technology of the production process of edible vinegar; raw materials are non-transgenic and meet the requirement of green food, the polished rice rate of rice is 80 percent, and the ratio of the materials to water is 1 to 3; eight ten-thousandths liquefying enzyme is added, and the temperature is increased by 120 DEG C for liquefaction; 100U of saccharifying enzyme is added for each gram of starch for saccharification; during the alcohol fermentation, qingchaqu which accounts for 10 to 12 percent of the raw materials and hongxin daqu which accounts for 18 to 20 percent of the raw materials are added, and the alcohol content of mash is 9 degree; during the fermentation of acetic acid, bran which can pass through a 40-mesh sieve and five thousandths of acetic acid fermenting grains are added; 1 to 3 percent of white spirit with the content of between 16 and 18 degrees is added for esterification ripening for 30 days; the blending and filtration are performed; the standard for edible vinegar products for Olympic Games is executed; and no additives are added expect potassium sorbate during the whole production process. The method is used for the production of the edible vinegar. The method is scientific and the product has high quality.

Owner:北京六必居食品有限公司

Starch-based biodegradable combination as well as preparation method and application thereof

The invention provides a completely biodegradable combination which comprises the following components: a natural biopolymer occupying 5-70 percent of the total weight of the combination, a biodegradable polymer occupying 5-90 percent of the total weight of the combination, an interface reinforcing agent occupying 3-20 percent of the total weight of the combination, a plasticizer occupying 5-50 percent of the weight of starch and the balance of other processing additives acceptable to a plastic processing technology, wherein the natural biopolymer is the starch or modified starch, the biodegradable polymer is synthesized polyester, the interface reinforcing agent is thermoplastic hydroxylation polyester, and the compound plasticizer is compounded by glyceride of hydroxyl diacid and glycerol. The biodegradable combination has the advantages of higher starch content and good mechanical properties. The invention also provides a preparation method and application of the combination in preparing a plastic product.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

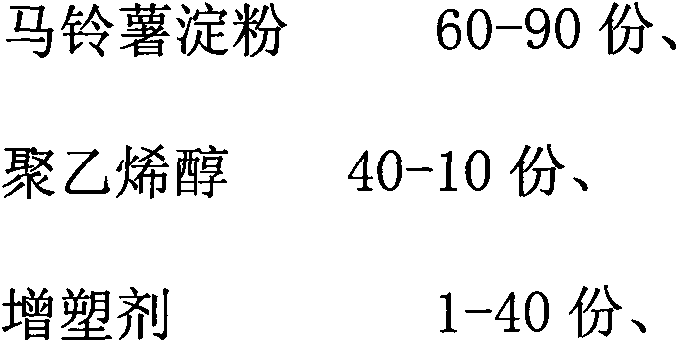

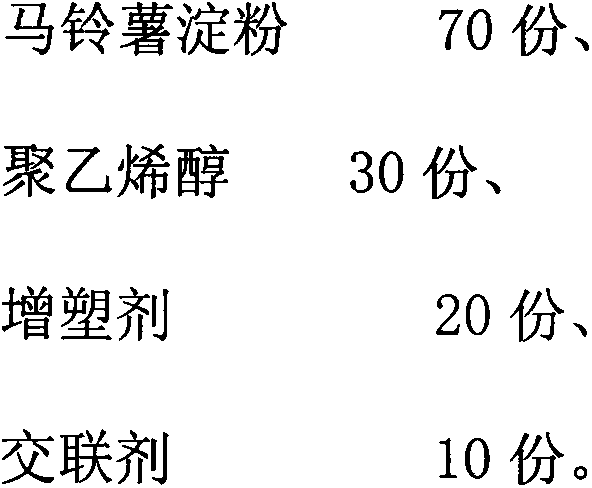

Method for preparing degradable mulching film by taking potato starch as raw material

InactiveCN103242561AReach the function of fully degradable mulch filmHigh in starchPlant protective coveringsCross-linkPolymer science

The invention provides a method for preparing a degradable mulching film by taking potato starch as a raw material, relating to the field of degradable plastics. The method is provided for solving the problem of environmental pollution caused by the existing plastic mulching film. A completely-degradable film material is obtained from potato starch, polyvinyl alcohol, a plasticizer, a cross-linking agent and the like by blending, cross-linking reaction and then casting film formation or extrusion film formation; and the method is characterized in that specific conditions are used in the preparation process, such as the raw material composition, the weight parts of each component and the reaction conditions. By taking potato starch as a major raw material or directly using potato as a raw material, the method provided by the invention realizes uniform film formation, realizes the mechanical properties of a common polyethylene film, and can be used for degrading the mulching film material; and moreover, the preparation technology is simple, and the method has great popularization values.

Owner:XINJIANG NORMAL UNIVERSITY

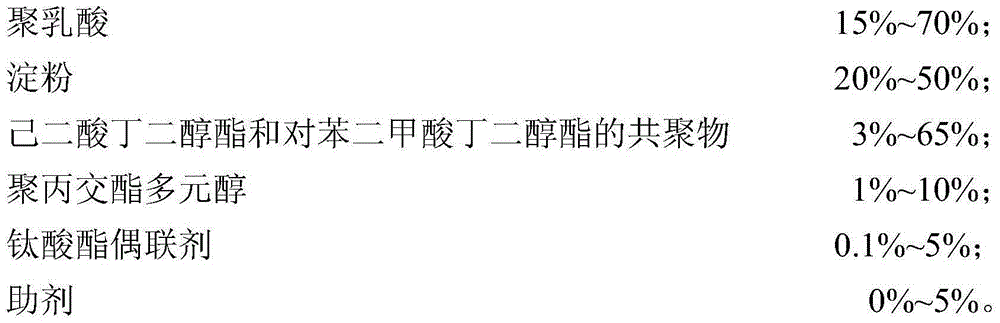

Fully-biodegradable material as well as preparation method and application thereof

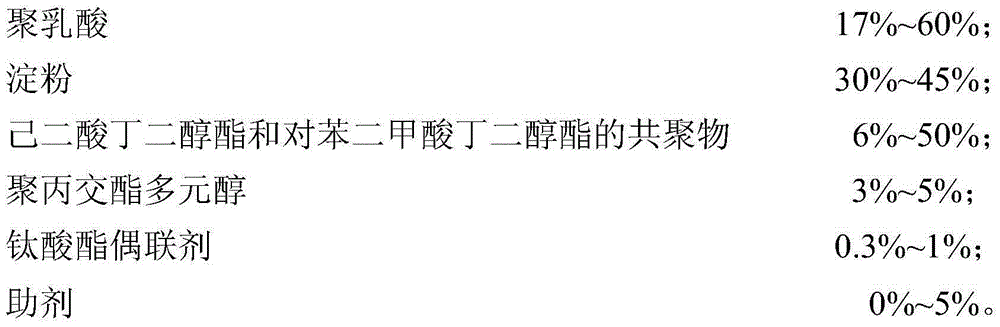

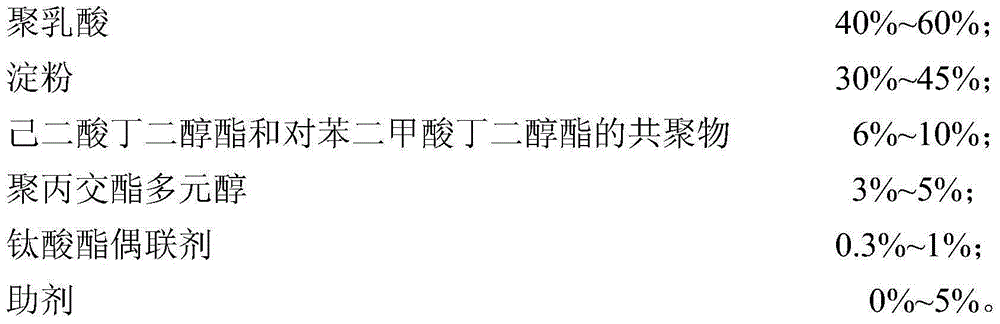

The invention discloses a fully-biodegradable material as well as a preparation method and application thereof. The fully-biodegradable material is prepared from the following raw materials in percentage by weight: 15%-70% of polylactic acid, 20%-50% of starch, 3%-65% of a copolymer of butanediol adipate and butanediol terephthalate, 1%-10% of polylactide polyol, 0.1%-5% of a titanate coupling agent and 0-5% of an aid. The fully-biodegradable material has excellent mechanical property, can be biologically degraded and is relatively low in cost. The preparation method can be easily implemented by virtue of existing high-speed mixing equipment and double-screw extruders. The fully-biodegradable material has excellent and stable performance, can be biologically degraded, is relatively low in cost and is applicable to the fields of plastic packaging materials, agricultural plastic mulching films, disposable tableware and the like.

Owner:ECOTA ENVIRONMENTAL TECH

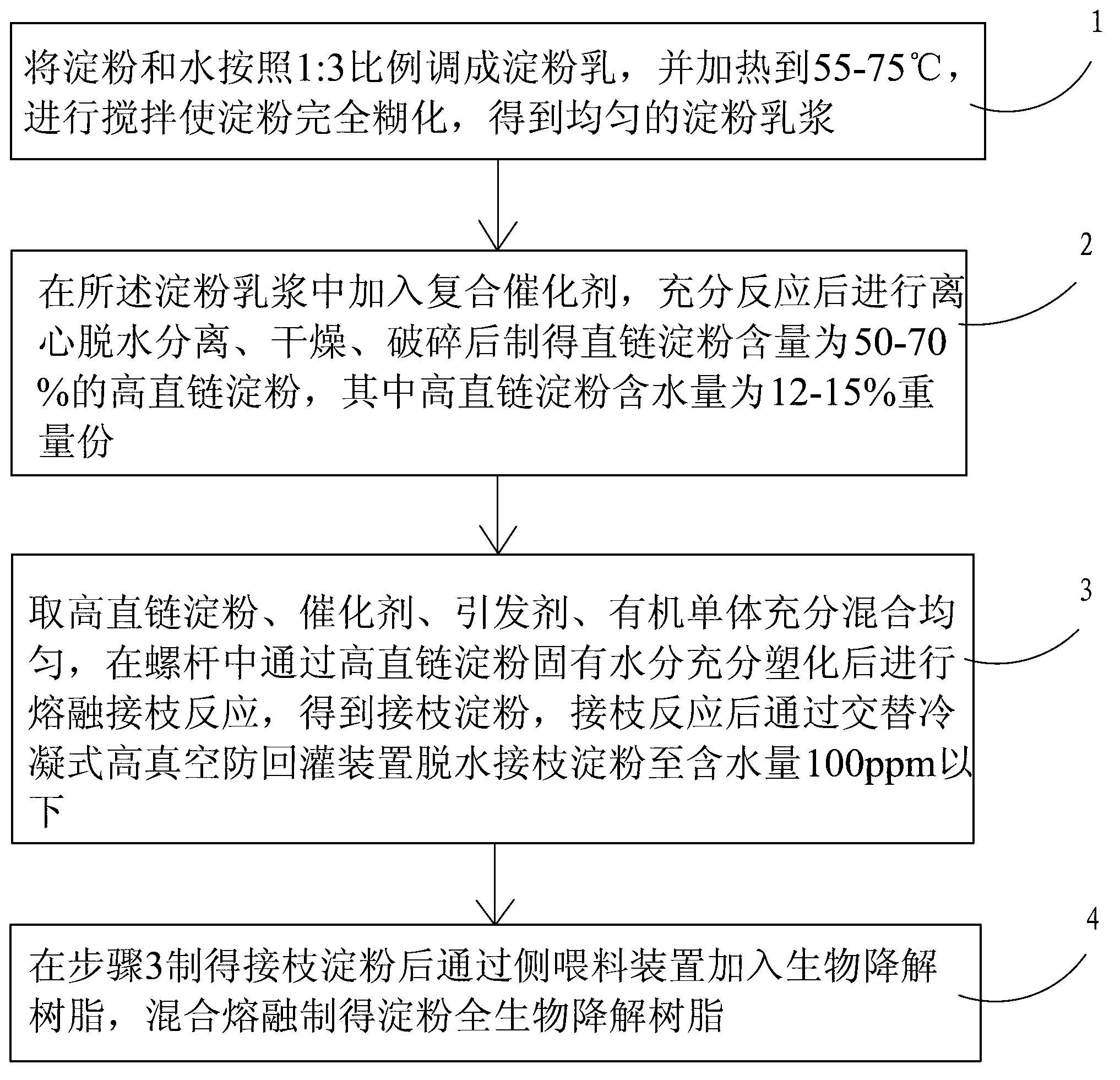

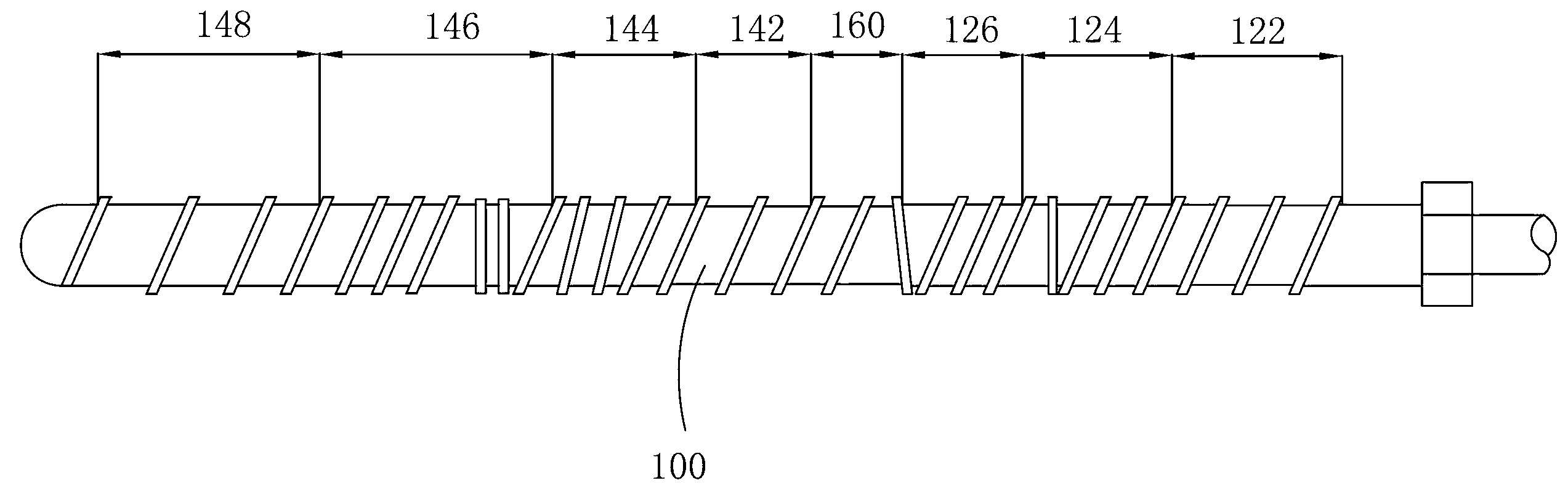

Starch full-biodegradable resin and continuous preparation method thereof

The invention provides a starch full-biodegradable resin and a continuous preparation method thereof. The starch full-biodegradable resin comprises the following components in parts by weight: 100 parts of high amylose, 0.05-0.10 part of catalyst, 0.1-0.15 part of initiator, 3-5 parts of organic monomer and 65-170 parts of biodegradable resin. The starch full-biodegradable resin is high in starch filling content and excellent in mechanical property and secondary processability, and can meet a stricter sanitary standard. According to the continuous preparation method of the starch full-biodegradable resin, the starch grafting and blending is carried out through continuous operation, the phenomena that the mechanical property and secondary processability of the products are lowered caused by migration of plasticizers and ordered reconfiguration of structures carried out spontaneously among chains are avoided, and a stricter sanitary standard can be met. The prepared starch full-biodegradable resin is high in starch content and excellent in mechanical property, and the cost is greatly reduced.

Owner:安徽华哲虹彩科技有限公司

Jujube-flavored white spirit and brewing process thereof

InactiveCN104651182AReduce Methanol ContentFully fermentedAlcoholic beverage preparationYeastLiver and kidney

The invention discloses jujube-flavored white spirit and a brewing process thereof. A preparation method of the liquor comprises the following steps: grinding, steaming and spread-cooling jujube, wheat, sorghum, glutinous rice, corn, rice, pea and rice hull according to certain proportions, uniformly mixing with the addition of yeast powder, sealing and fermenting in pit mud for more than 4 months; beginning to distill after 4 months in a mode of distilling twice every month; ultrasonically processing liquor obtained from distillation firstly, and then storing the liquor together with tourmaline, limonite and medicinal stone in a porcelain jar for more than 6 months, thus completing aging. The liquor overcomes shortcomings in the prior art, and is simple and convenient in operation, short in production cycle, high in liquor yield and good in quality. The jujube-flavored white spirit disclosed by the invention is stable in quality, free from restoring and long in aftertaste, people drinking the white spirit are not easy to become drunk and quick to be sobered up, and the white spirit, after drunk, is free from a problem of headache, free from such harmful material components as methanol, and is capable of relieving pressure on liver and kidney after drinking and effectively relieving damage to body.

Owner:栗臣川

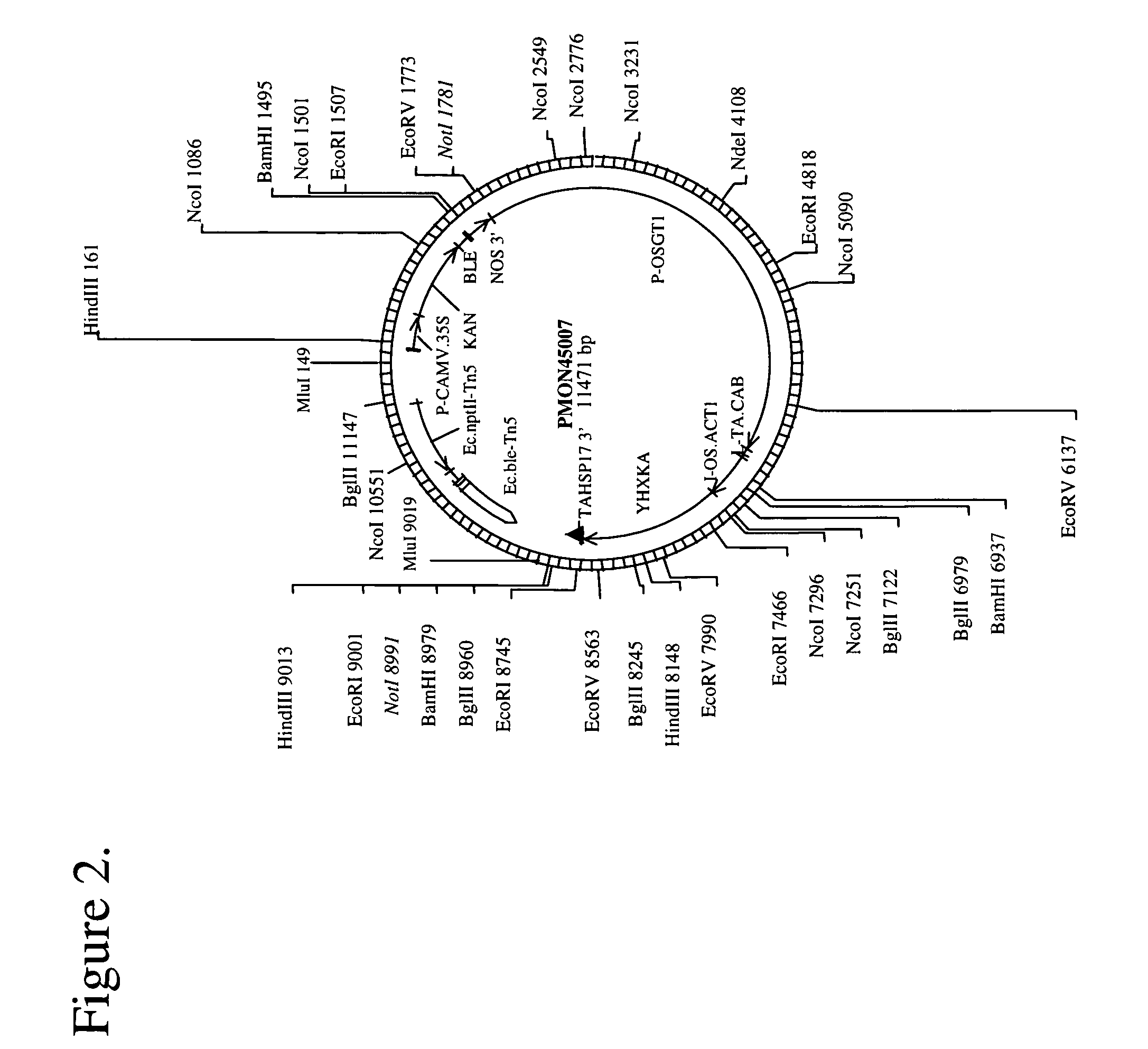

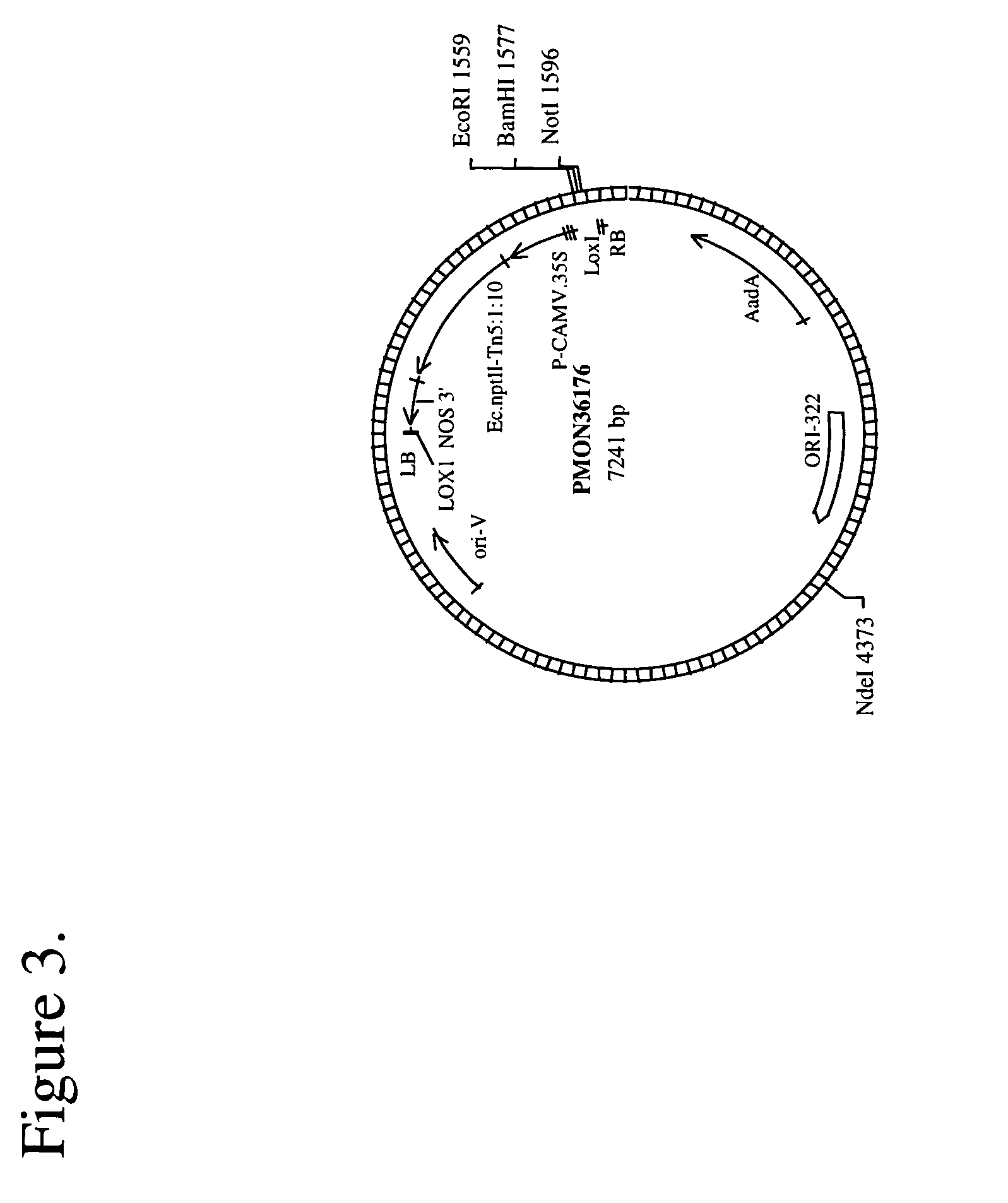

Method of increasing yield in a plant and genes useful therefor

ActiveUS7423203B2High in starchReduced reducing sugar contentSugar derivativesClimate change adaptationPlanting seedHexokinase activity

A method of changing the activity of hexokinases in a plant sink comprising introducing into the plant a gene encoding a fungal hexokinase. In the method, the gene is expressed in the plant seed tissue to produce the protein, thereby changing characteristics of hexokinase activity in the seed of the plant.

Owner:MONSANTO TECH LLC

Full biological degradation plastic and production method thereof

The invention discloses a full biological degradation plastic and production method thereof. The full biological degradation plastic contains the following components(weight percentage): amylum 30~60%, resin 10~15%, grease 12~20%, PE 10~30%, accessory ingredient 3~5%, plant perfume materials 0.5~1%. The production method includes the following steps: (A)calendering and polymerizing the amylum materials filtrated by 120 meshes and PE according to said percentage composition for 6~10 minutes; (B)blending the materials obtained in step A by high-speed muller at the temperature between 90~160 degrees and pelleting by extruding machine; (C)blending, polymerizing and extruding the materials obtained in step B by injection machine at the temperature between 110~130 degrees and blow molding according to requirements. The invention has a relatively higher content of amylum, good biological degradability, low cost and does not pollute environment.

Owner:胡燕针

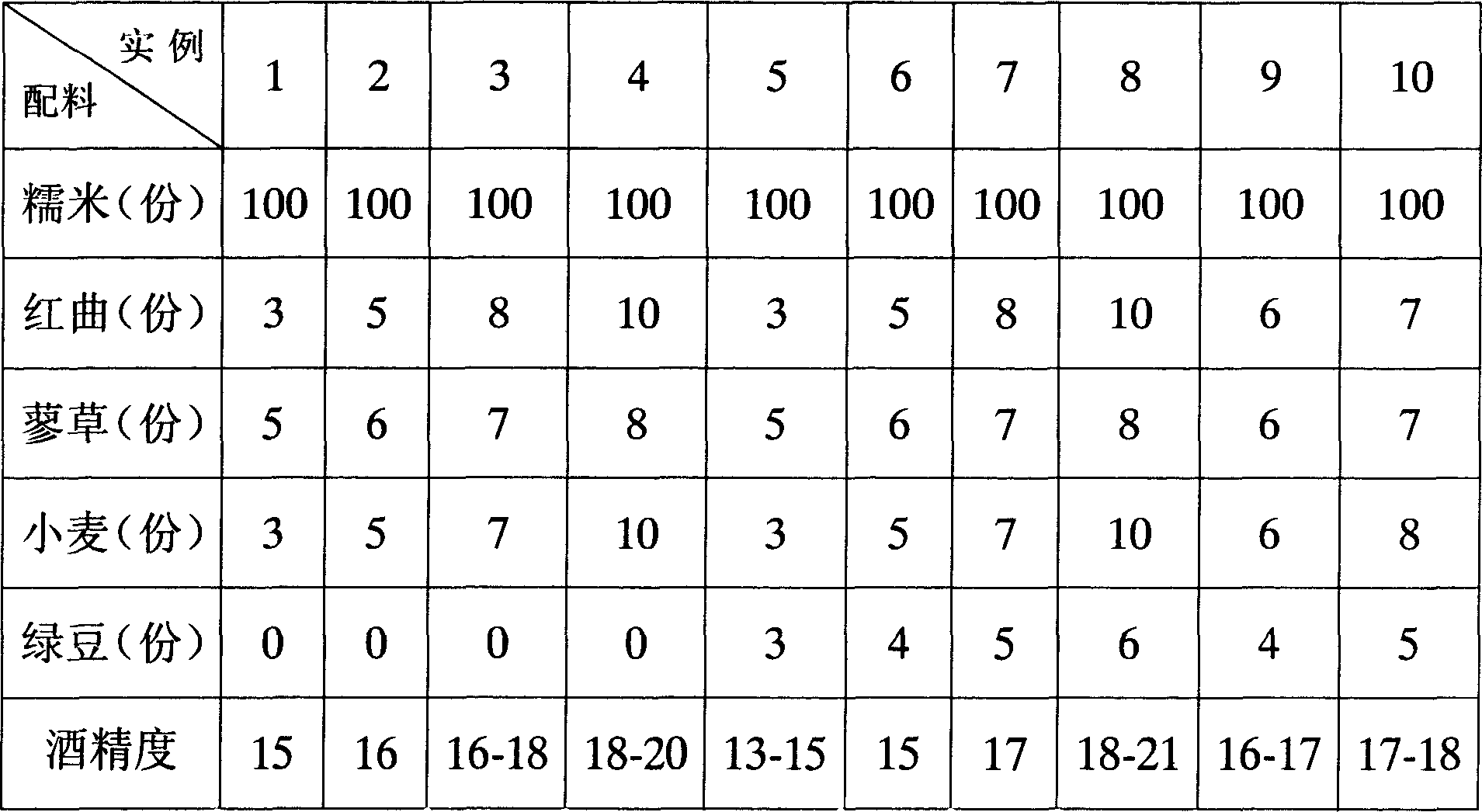

Formulation for health-care red rice wine

InactiveCN1566313AGuarantee clarificationFull of rice grainsAlcoholic beverage preparationDry weightMung bean

The invention discloses a formulation for health-care red rice wine which comprises (by weight portion, based on 100 parts of glutinous rice dry weight), Monascus color 3-10, buckwheat 5-8 parts, the preparing process comprises the steps of, fermenting 2 months, extracting juice 5-20 parts.

Owner:陈豪锋

Greenhouse plantation method or highly yielding potatoes

InactiveCN106912217AIncrease resistanceYield effectSeed and root treatmentGrowth substratesFertilizerBud

The invention relates to the field of potato plantation, and discloses a greenhouse plantation method for highly yielding potatoes. The method comprises the following steps: (1) processing seeds to make the processed seeds have the advantages of accelerated seedling come-up speed, strong breeding ability, rapid growth of vines, supply of a large amount of nutrient components to the root tuber and increase of the yield and the differentiation speed of skins; (2) preparing soil and building a greenhouse to make suitable soil environment accelerate the growth of potatoes and improve the resistance of the potatoes to pests and diseases and to make the temperature in the greenhouse help the potatoes to resist low temperatures and prevent rainwater striking caused bacteria; and (3) sowing and managing: carrying out whole bud coverage sowing to improve the prosperity of the root and avoid burnt seedlings caused by after manuring in the rapid growth of the seedlings, and covering the applied fertilizer with loose nutrient soil to effectively retain the fertilizer and increase the upward growth of the potatoes. The method increases the yield by 28-35%, and the starch content of the obtained potatoes is extremely high.

Owner:蚌埠市乔峰农业蔬菜专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com