High-starch-content waterproof totally-decomposed composite material and preparation method thereof

A composite material, fully degradable technology, applied in the field of high starch content water-resistant fully degradable composite materials and its preparation, can solve the problems of less environmental pollution, difficult plasticization, insufficient toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

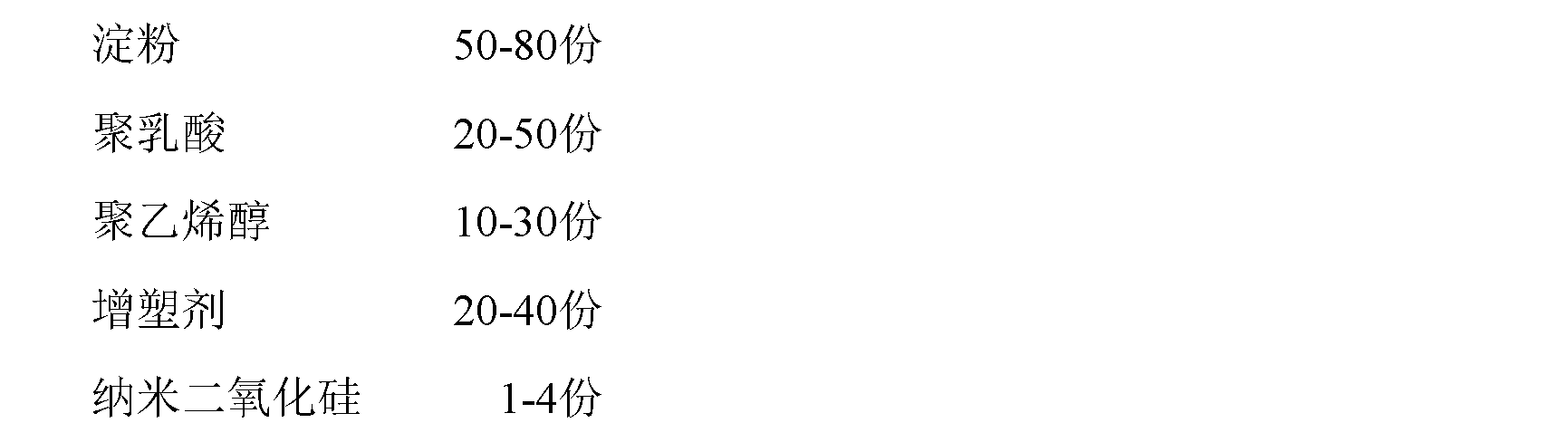

[0021] Material provided by the invention is formulated by weight ratio by following raw materials:

[0022]

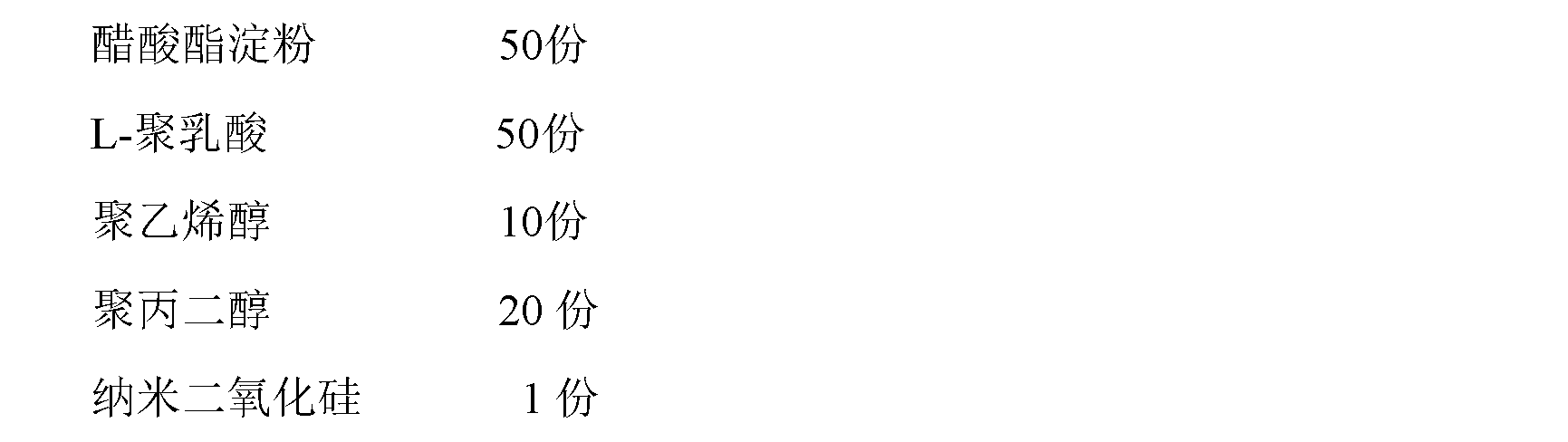

[0023] First, mix the nano-silica and polypropylene glycol in the above raw materials with an ultra-speed mixer, the time is 1h, and the rotation speed is 700-3000rpm, and then use an ultrasonic generator to drive out the bubbles, and the time is 1h to make a nano-sol; Nano-sol and acetate starch were mixed in a high-speed mixer for 30 minutes, and then kneaded with polyvinyl alcohol with a degree of polymerization of 1700 and an alcoholysis degree of 88% in a kneader to make a starch-based masterbatch for 10 minutes ;Finally, the starch-based masterbatch and L-polylactic acid were melt-blended through a banbury mixer, the banbury temperature was 180°C, the time was 6min, and the rotation speed was 60rpm to obtain a high-starch content water-resistant fully degradable composite material.

Embodiment 2

[0025] Material provided by the invention is formulated by weight ratio by following raw materials:

[0026]

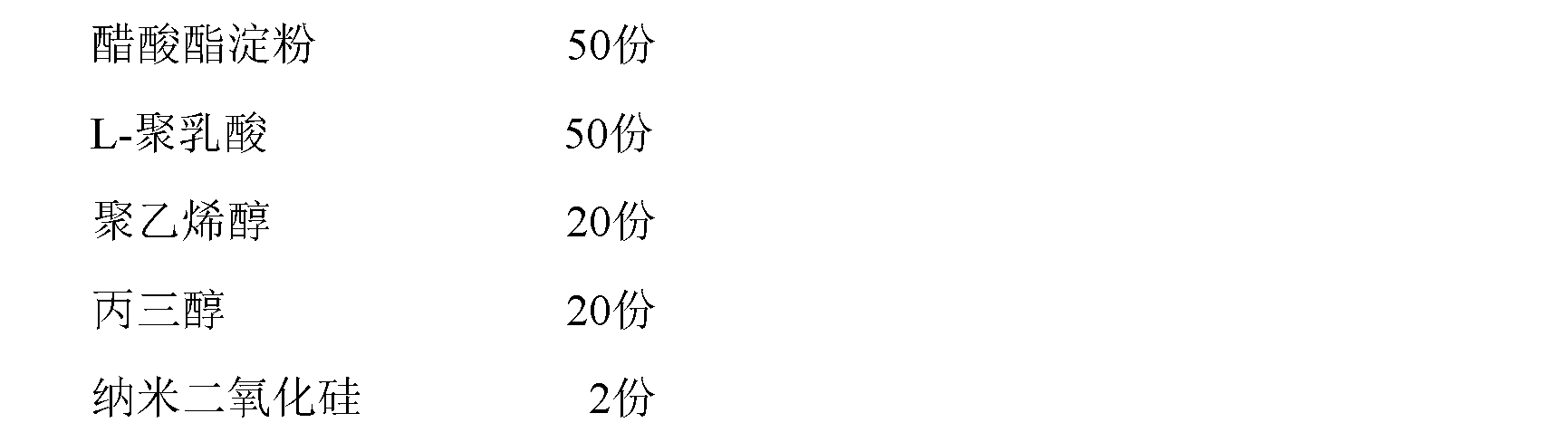

[0027] Firstly, the nano-silica and glycerin in the above raw materials are mixed with a high-shear emulsifier for 1.5 hours at a speed of 700-3000 rpm, and then an ultrasonic generator is used to drive out the air bubbles for 1.5 hours. into a nano-sol; secondly, mix the nano-sol and acetate starch in a high-speed mixer for 30 minutes, and knead with polyvinyl alcohol with a polymerization degree of 500 and an alcoholysis degree of 88% in a kneader to make a starch-based Masterbatch, the time is 10min; finally, the starch-based masterbatch and L-polylactic acid are melt-blended through an internal mixer, the mixing temperature is 180°C, the time is 8min, and the rotation speed is 60rpm, and the high starch content is water-resistant and fully degradable. composite material.

Embodiment 3

[0029] Material provided by the invention is formulated by weight ratio by following raw materials:

[0030]

[0031] First, mix the nano-silica and tri-n-butyl citrate in the above raw materials with an emulsification pump for 1.5 hours at a speed of 700-3000rpm, and then use an ultrasonic generator to drive out the bubbles in it for 2 hours to produce Nano sol; secondly, mix nano sol and phosphate starch in a high-speed mixer for 30 minutes, and then knead with polyvinyl alcohol with a polymerization degree of 500 and an alcoholysis degree of 88% in a kneader to make a starch-based matrix The time is 10 minutes; finally, the starch-based masterbatch and D-polylactic acid are melt-blended through an open mill at a temperature of 190 °C for 10 minutes to obtain a high-starch content water-resistant fully degradable composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com