Glass anti-fog and anti-frost agent and preparation method thereof

An anti-frost and anti-fog technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high corrosiveness and toxicity of anti-fog and anti-frost, short duration of effect, and difficult to clean, and achieve anti-fog. Long-lasting anti-frost effect, good overall performance, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0044] The present invention will be described in detail below in conjunction with examples.

[0045] This embodiment relates to a glass anti-fog and anti-frost agent, which has better anti-fog and anti-frost functions, has a long-lasting anti-fog and anti-frost effect, and has better comprehensive performance.

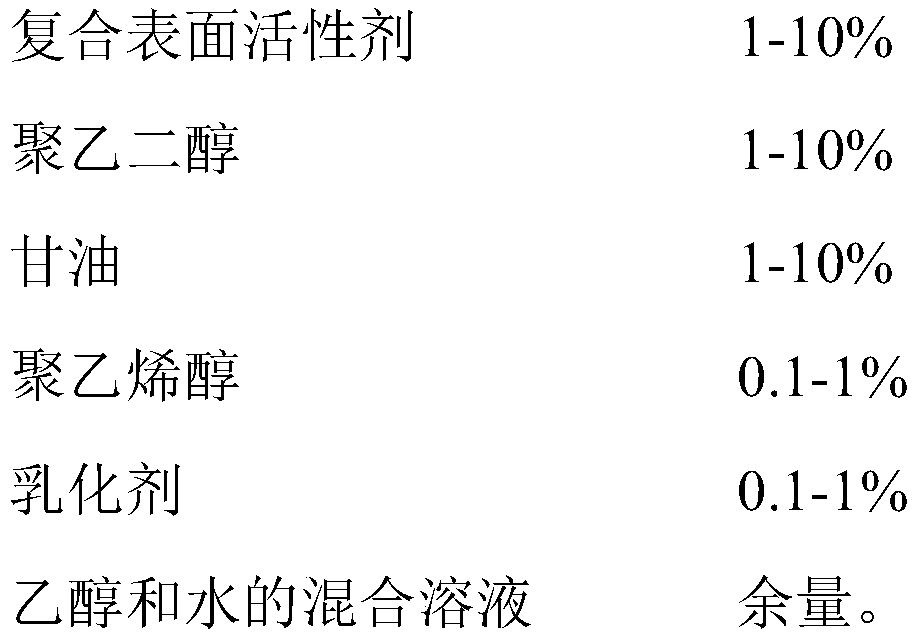

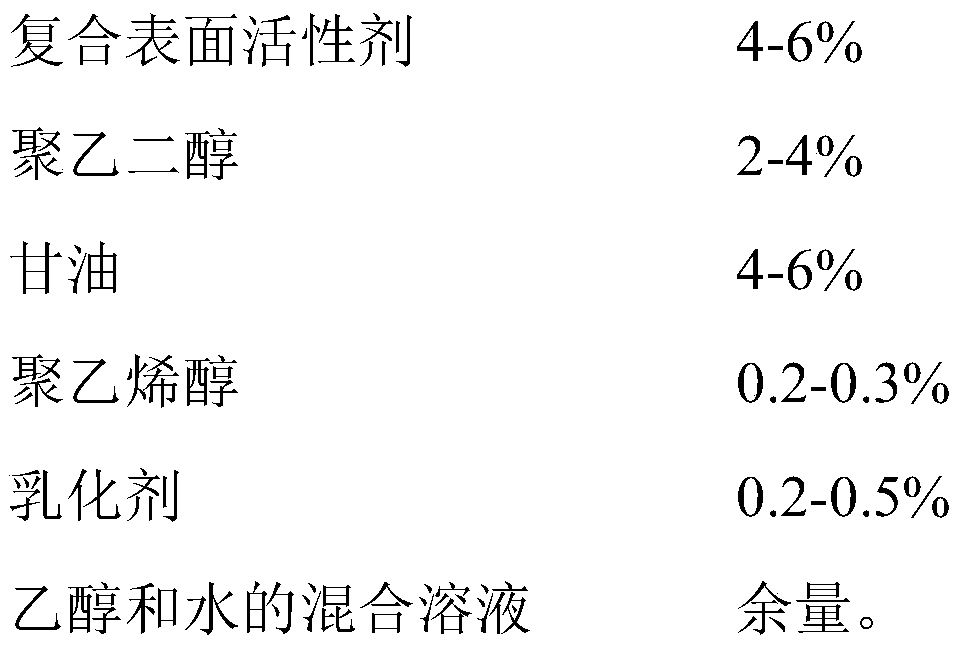

[0046] Based on the design idea above, the chemical components of the glass anti-fog and anti-frost agent of this embodiment mainly include complex surfactants, polyethylene glycol, glycerin, polyvinyl alcohol, emulsifiers, ethanol and water. Among the above chemical components, ethanol and water are solvents. After the glass anti-fog and anti-frost agent is sprayed on the glass surface, the ethanol and water will volatilize, and the remaining chemical components on the glass will form a thin film o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com