Method for producing edible vinegar

A production method and product technology are applied in the production field of vinegar products to achieve the effects of sufficient saccharification, ensuring safety and improving starch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

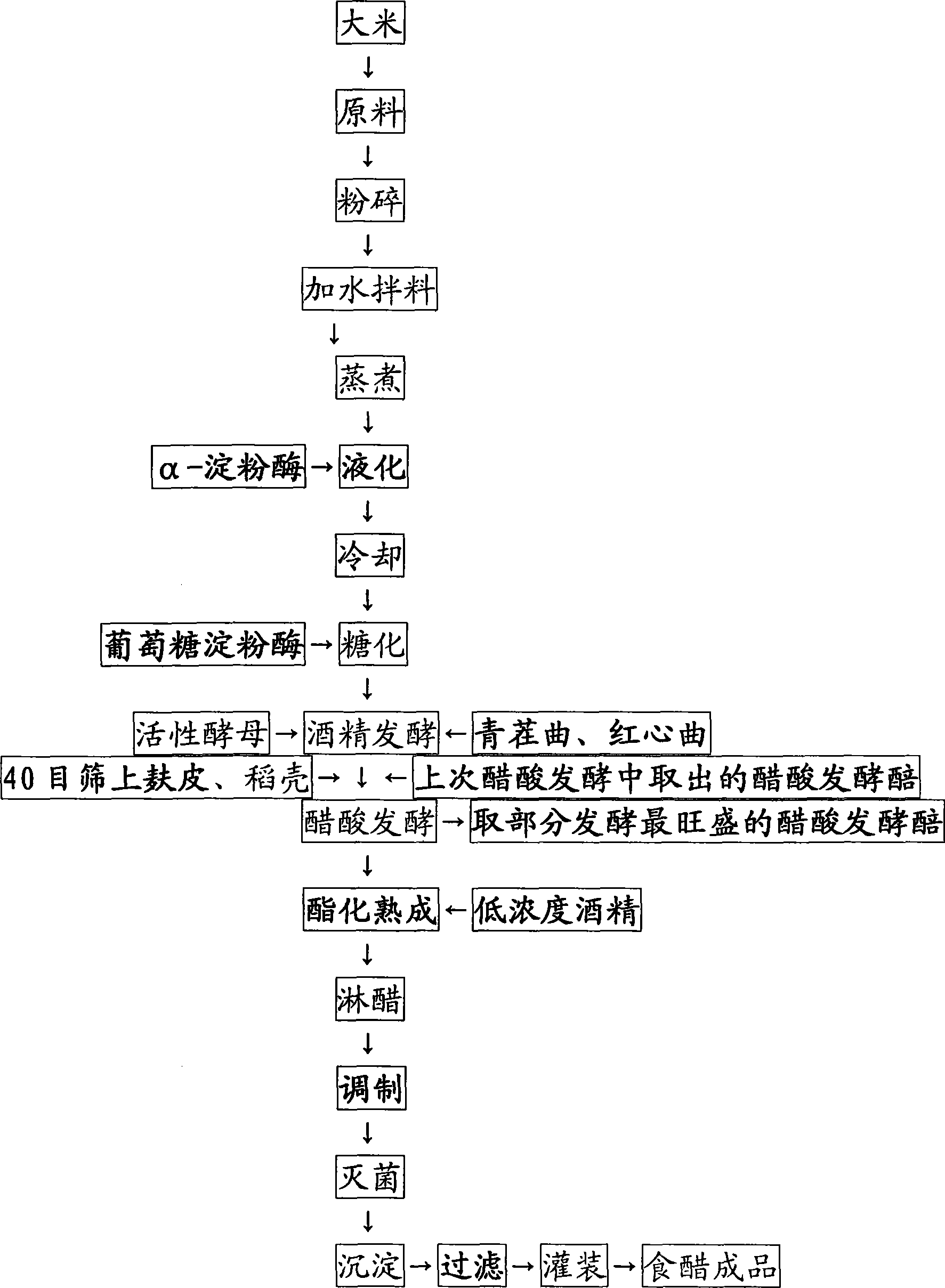

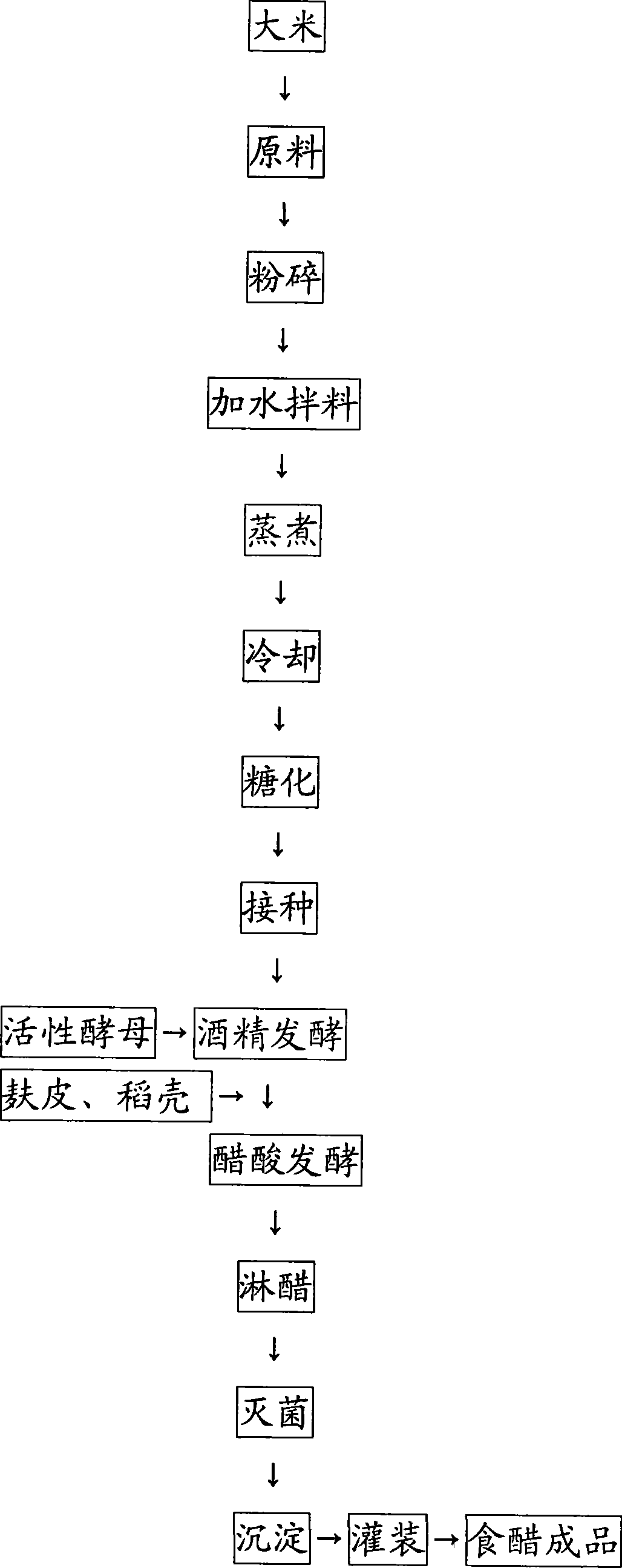

[0052] Below in conjunction with the accompanying drawings of the description, the production method of the vinegar product of the present invention is described in detail, just as the attached description figure 1 Shown:

[0053] A production method of a vinegar product, comprising rice raw materials in units of weight, and the raw materials are crushed, mixed with water, steamed, cooled, saccharified, inoculated, alcoholic fermentation, acetic acid fermentation, vinegar drenched, sterilized, precipitated, The production process of obtaining vinegar products through filling; its outstanding technical characteristics are mainly manifested in:

[0054] (1), the raw material: the raw material is a non-transgenic raw material that can guarantee the safety of vinegar products and a standard raw material that meets the requirements of pesticide residues and harmful heavy metal residues stipulated by green food, and the raw material of rice Rice polishing rate increased from 90% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com