Patents

Literature

324results about How to "Improve degassing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

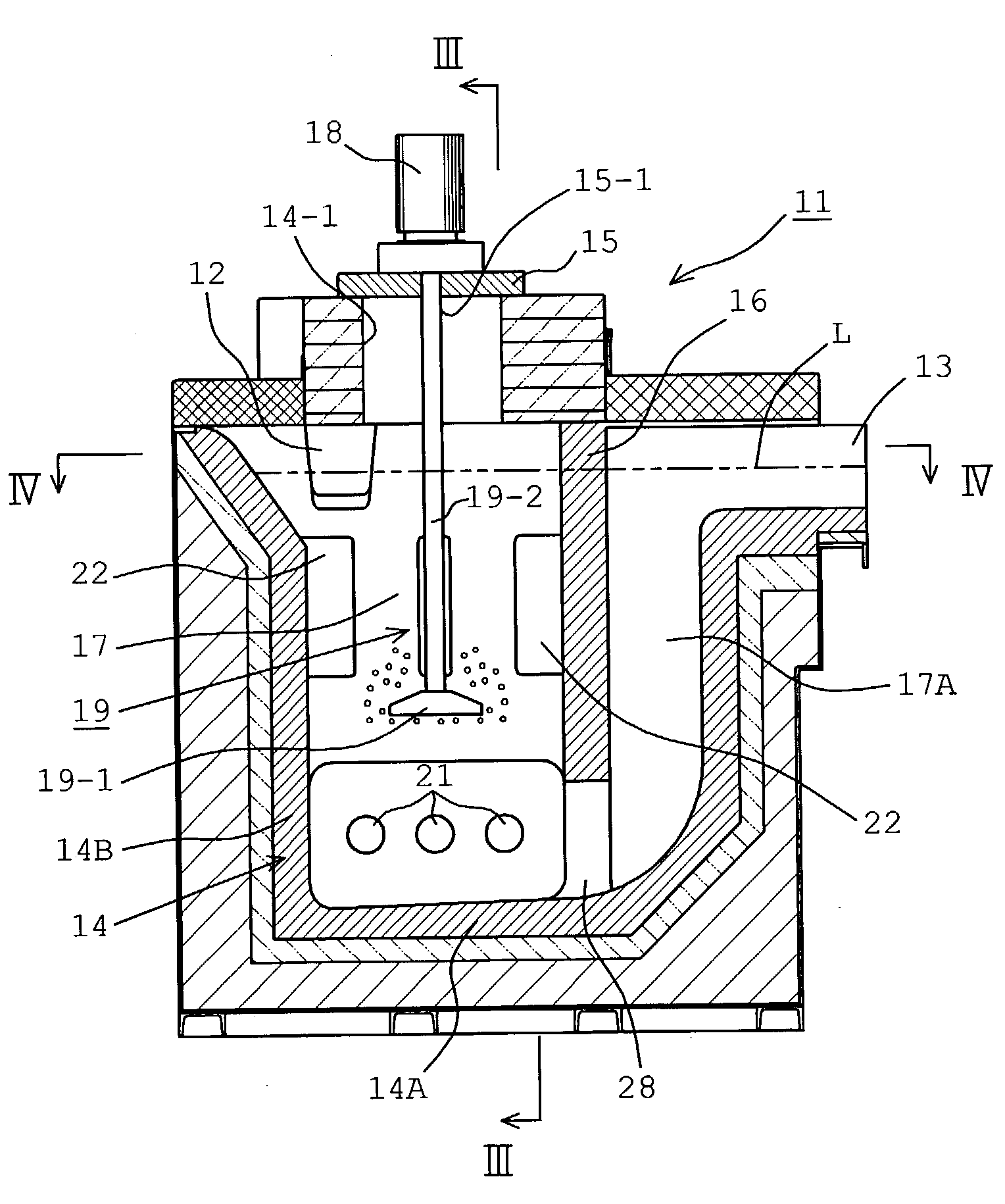

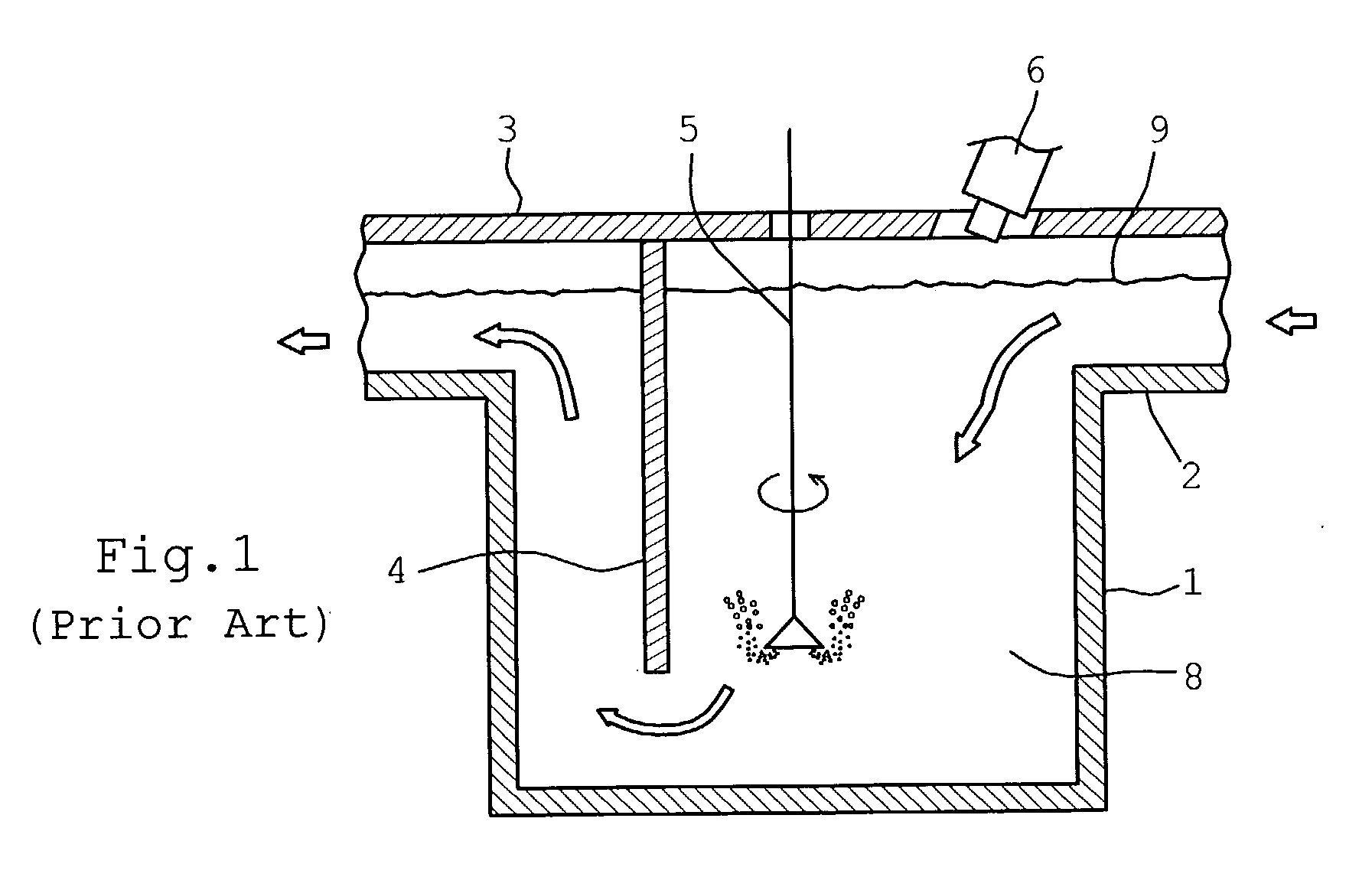

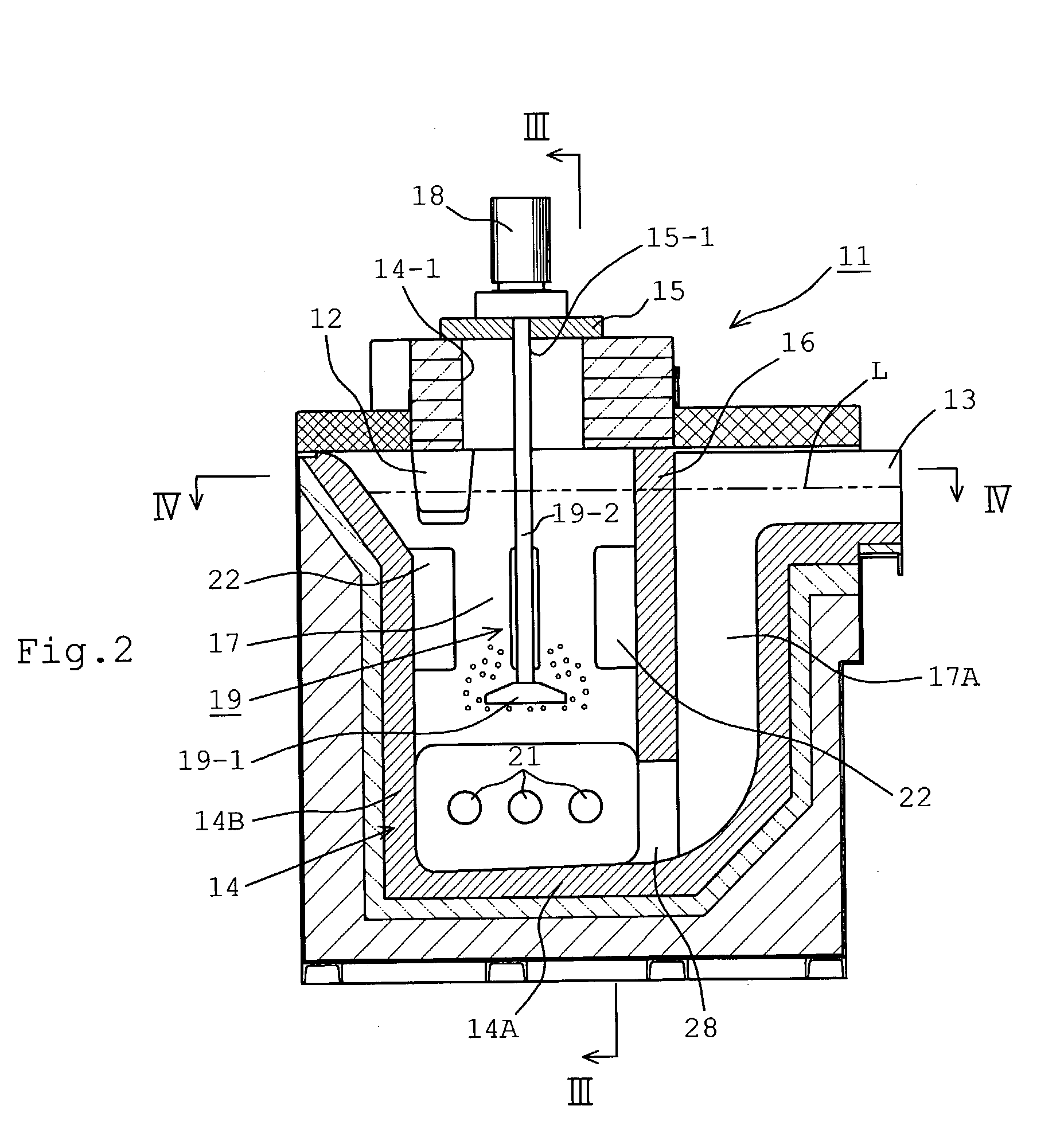

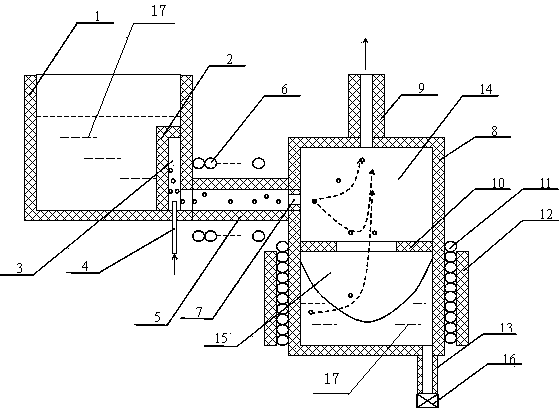

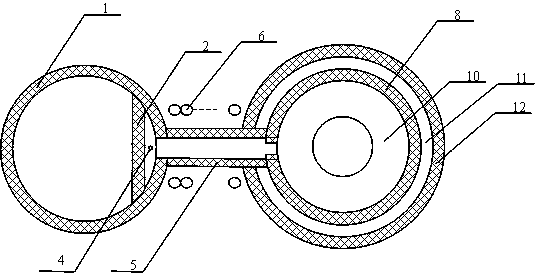

Inline degassing apparatus

InactiveUS20030151176A1Chance of damageExtended service periodMelt-holding vesselsStirring devicesNon-metallic inclusionsProduct gas

An inline degassing apparatus for removing solid solution gases as well as nonmetallic inclusions from molten metal in a degassing container, to which the molten metal is continuously introduced for degassing operation and from which the degassed molten metal is continuously removed. A rotary diffusing device is arranged in the degassing container for generating bubbles of inert gas diffused into the molten metal, thereby entrapping solid solution gases as well as nonmetallic inclusions into the bubbles, which are then floated and separated. Heaters are provided, which extend, in a cantilever fashion, from a side wall of container at a position adjacent the bottom wall of the container substantially parallel to the bottom wall.

Owner:PYROTEK JAPAN +1

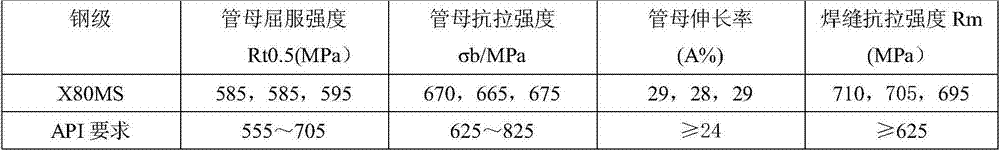

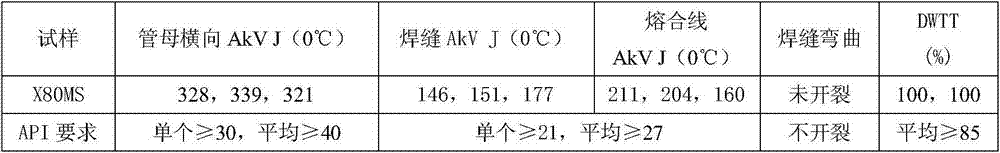

X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as manufacturing method thereof

The invention discloses an X80-level straight seam submerged-arc welded pipe with hydrogen sulfide stress corrosion resistance as well as a manufacturing method thereof. The straight seam submerged-arc welded pipe comprises a welding seam and a welded pipe body, and is characterized in that the welded pipe body consists of the following elements in percent by mass: not greater than 0.04% of C, 0.20%-0.40% of Si, 1.20%-1.80% of Mn, not greater than 0.008% of P, not greater than 0.002% of S, 0.10%-0.30% of Ni, not greater than 0.15% of Cr, not greater than 0.15% of Cu, 0.01%-0.10% of Nb, 0.01%-0.10% of Ti, 0.10%-0.30% of Mo, 0.04%-0.10% of Al, not greater than 0.0005% of B, not greater than 0.002% of Ca, and the balance of Fe and inevitable impurities. According to the X80-level straight seam submerged-arc welded pipe and the manufacturing method thereof disclosed by the invention, the X80 straight seam submerged-arc welded pipe disclosed by the invention has good strength, toughness, welding performance, ductility and corrosion resistance through reasonably deploying and controlling material components, a manufacturing process, a manufacturing technology and subsequent processing. Besides, high-pressure large-flow conveying requirements of oil gas under an acidic environment are satisfied.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Aluminum alloy for high power radiator and purification method of melt of aluminum alloy

ActiveCN104233020AMeet quality requirementsImprove degassing effectPurification methodsHydrogen content

The invention relates to an aluminum alloy for a high power radiator. The aluminum alloy is characterized by being prepared from the following chemical components in percentage by weight: 0.50-0.55% of Mg, 0.40-0.45% of Si, less than 0.19% of Fe, less than or equal to 0.05% of Ti, less than or equal to 0.02% of Cr, less than or equal to 0.02% of Mn, less than or equal to 0.02% of Zn, less than or equal to 0.02% of Cu, less than or equal to 0.02% of a single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. According to a purification method of the melt of the aluminum alloy for the high power radiator, the hydrogen content in the aluminum alloy melt is reduced to below 0.07ml / 100g and the dregginess of the melt is reduced to below 0.01% by virtue of process control of aluminum alloy smelting, refining, degassing, deslagging and the like, so that the processing quality requirement on the aluminum alloy for the high power radiator is satisfied.

Owner:ALNAN ALUMINIUM CO LTD

Ionic conductive membrane for chlorine-alkali industry and preparation method thereof

The invention relates to the technical field of ionic membranes, and particularly relates to an ionic conductive membrane for a chlorine-alkali industry and a preparation method thereof. The ionic conductive membrane comprises a perfluorinated ion exchange resin base membrane, a micro-porous reinforcing material and a surface layer of a perfluorinated ion exchange resin microparticle. The perfluorinated ion exchange resin microparticle is a mixture of one or two of a perfluorinated carboxylic acid resin microparticle or perfluorinated sulfonic acid-carboxylic acid copolymer resin microparticle and a perfluorinated sulfonic acid resin microparticle, wherein the perfluorinated sulfonic acid resin microparticle accounts for 95%-50% of the percentage by mass of the mixture. The surface layer of the ionic conductive membrane has good compatibility and adhesion and maintains a good degassing effect in the whole service life of the ionic conductive membrane. An alkali metal chloride solution of which the range of concentration is wide can be efficiently and stably treated by the ionic conductive membrane in the chlorine-alkali industry, and the ionic conductive membrane is applicable for running in a zero-pole electrolytic cell under a novel high current density condition and a very excellent product purity index is achieved. The invention also provides a preparation method of the ionic conductive membrane, the process is simple and reasonable and industrial production is easily achieved.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Novel ionic conduction membrane for chlor-alkali industry and preparation method thereof

The invention belongs to the technical field of ionic membranes and particularly relates to a novel ionic conduction membrane for chlor-alkali industry. The membrane consists of a perfluorosulfonate ion-exchange resin based membrane, a porous reinforcing material and a surface layer formed by mixing microparticles of fluorine-containing resin and particles of an inorganic compound. The particles of the inorganic compound are selected from one or more of oxides, hydroxides and nitrides of group IV-A, group IV-B, group V-B, iron, cobalt, nickel, chromium, manganese or boron. The microparticles of fluorine-containing resin comprise one or more of microparticles of polytetrafluoroethylene, microparticles of PFA (Polyfluoroalkoxy), microparticles of polyfluorinated ethylene propylene, microparticles of polyfluorinated propyl vinyl ether or microparticles of polyvinylidene fluoride. The ionic conduction membrane for chlor-alkali industry can stably and efficiently treat alkali chloride solutions with wide concentration range and is suitable for operation in a zero polar distance electrolytic bath under a novel electric current density condition, so that the product purity is high. The invention further provides a preparation method of the ionic conduction membrane and the preparation method is simple and reasonable in process and easy for industrialized production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

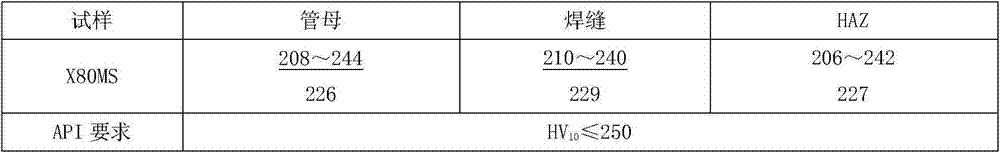

Tantalum-silicon alloy sputtering target material and preparation method thereof

InactiveCN110952064AUniform structureAvoid direct contactTransportation and packagingMetal-working apparatusSilicon alloyTantalum

The invention relates to a tantalum-silicon alloy sputtering target material and a preparation method thereof. The preparation method comprises the steps: (1) tantalum powder and silicon powder are mixed; (2) a mixture is loaded into a mold, and the mold is sealed; (3) the sealed mold is subjected to cold isostatic pressing treatment, and a tantalum-silicon blank is obtained; (4) the obtained tantalum-silicon blank is subjected to degassing treatment; (5) a degassed casing is subjected to hot isostatic pressing treatment at 1050-1350 DEG C, and a tantalum-silicon alloy sputtering target material crude product is obtained; and (6) the tantalum-silicon alloy sputtering target material is obtained by machining. According to the preparation method, oxidation of the silicon powder is effectively prevented, the product purity is guaranteed, the prepared tantalum-silicon alloy sputtering target material can further reach the density of 99% or above, the requirements of uniform density and internal organization structure of the tantalum-silicon alloy sputtering target material are met, a more excellent performance guarantee is provided for subsequent sputtering use, and the characteristicsof simple process, convenient operation and short production cycle are achieved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Ion-conducting membrane and preparation method thereof

ActiveCN103993329AGood degassing effectGood compatibilityOrganic diaphragmsHigh current densitySurface layer

The invention belongs to the technical field of ion membranes and specifically relates to an ion-conducting membrane and a preparation method thereof. The ion-conducting membrane comprises a perfluorinated ion-exchange resin-based membrane, a porous reinforced material and a perfluorinated sulfonic acid resin micro-particle surface layer. The perfluorinated ion-exchange resin-based membrane comprises a resin layer which is mainly composed of perfluorinated sulfonic acid resin and another resin layer which is mainly composed of perfluorinated carboxylic acid resin. The surface layer of the ion-conducting membrane provided by the invention has good compatibility and adhesion, so that the good degassing effect throughout the whole life of the ion-conducting membrane can be ensured. When used in the chlor-alkali industry, the ion-conducting membrane is capable of treating an alkali metal chloride solution in a wide concentration range stably and efficiently; and the ion-conducting membrane is suitable for operation in a zero-polar distance electrolyzer under high current density condition and has very excellent product purity index. The invention further provides the preparation method thereof, the process is simple and reasonable and the industrial production is easy to realize.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

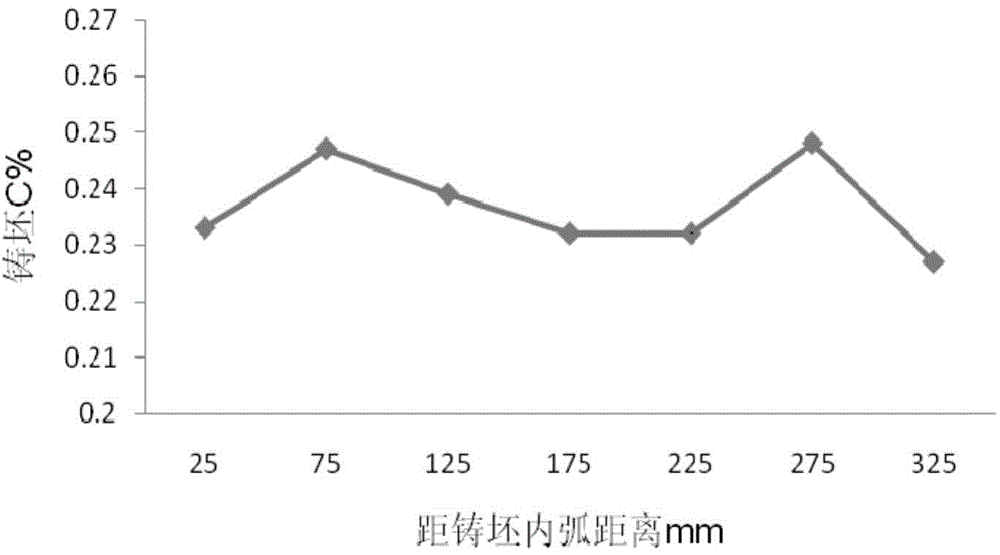

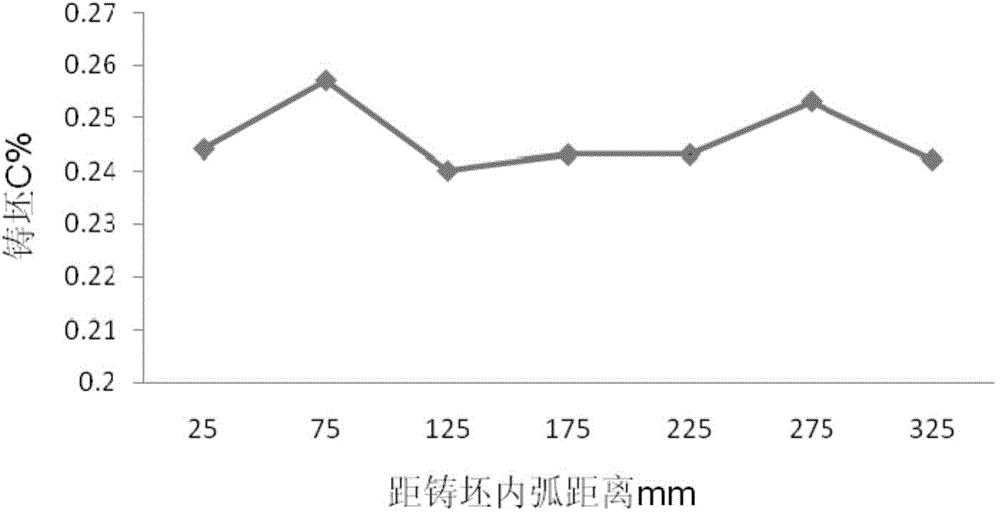

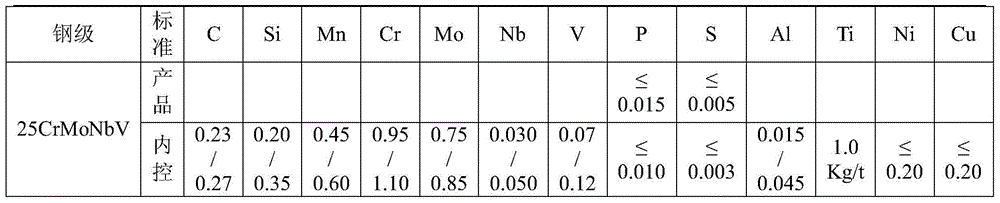

Preparation method of V150-steel-grade high-strength high-toughness casing steel

The invention relates to a smelting process of seamless petroleum casing steel in iron and steel industries and particularly relates to a preparation method of V150-steel-grade high-strength high-toughness casing steel. The preparation method comprises the following steps: smelting; carrying out LF refining; carrying out VD vacuum processing; and finally casting to prepare a continuous casting round blank. Round tube blank steel prepared by virtue of the preparation method is high in steel purity degree and small in segregation; a seamless steel tube is high in matching degree of strength and toughness, excellent in comprehensive mechanical property and long in service life.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Novel ionic conduction membrane and preparation method thereof

ActiveCN104018179AGood compatibilityGood adhesionOrganic diaphragmsHigh current densityInorganic compound

The invention belongs to the technical field of ionic membranes, and particularly relates to a novel ionic conduction membrane. The novel ionic conduction membrane comprises a perfluoro ion exchange resin basal membrane, a porous reinforcing material and a surface layer made of a mixture of perfluoro ion exchange resin microparticle and inorganic compound particle, wherein the inorganic compound particle is one of or a mixture of oxides, hydroxides and nitrides of IV-A groups, IV-B groups, V-B groups, iron, cobalt, nickel, chromium, manganese or boron elements; and the perfluoro ion exchange resin microparticle is a mixture of one or two of perfluoro carboxylic acid resin microparticle or perfluoro sulfonic acid carboxylic acid copolymerization resin microparticle and perfluoro sulfonic acid resin microparticle. The novel ionic conduction membrane is used for the chlorine-alkali industry and is capable of stably and efficiently treating an alkali chloride solution wide in concentration range and suitable for operation in a novel zero-polar-distance electrolytic bath under the condition of high electric current density, and the product is high in purity. The invention also provides a preparation method of the novel ionic conduction membrane, which is simple and reasonable in process and facilitates industrial production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

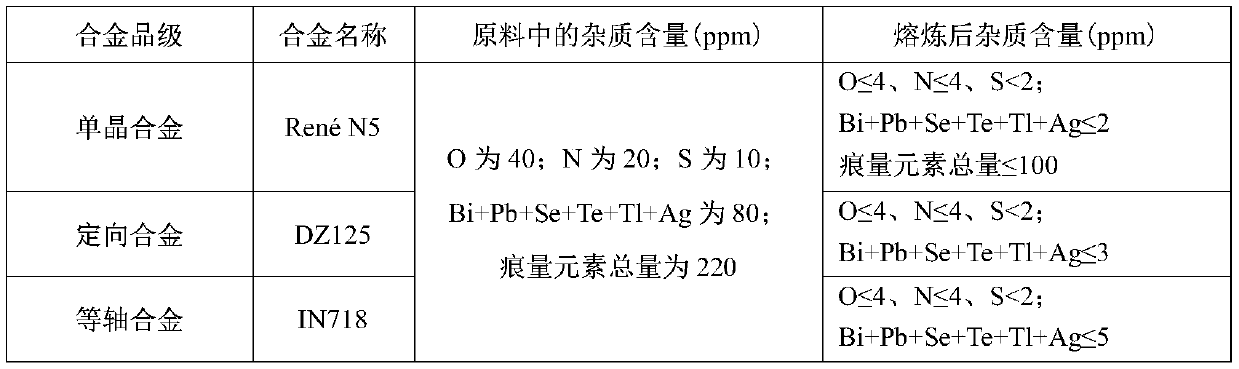

Pure purification smelting method used for nickel-based high-temperature alloy master alloy

The invention relates to a pure purification smelting method of an alloy, in particular to a pure purification smelting method for a nickel-based high-temperature alloy master alloy, and belongs to the technical field of metal smelting. According to the method, pure purification smelting of a master alloy is completed through material distributing and alloy melting, primary refining, alloying andsecondary refining, microalloying controlling and casting. The method has the advantages that the purity of vacuum melting can be effectively improved, the element segregation can be improved, and a nickel-based high-temperature alloy prepared by the method has the advantages that the purity is high, the segregation is low, the quality is remarkably higher than that of an alloy prepared through the existing technology and method, the quality of the nickel-based high-temperature alloy is improved, and the application field is expanded; nickel-based high-temperature alloys with different gradesand marks smelted by adopting the method has good effects; vacuum induction furnaces with the furnace types of 250 kg-grade and 1.5 ton-grade are adopted; and compared with an alloy before smelting and prepared through other technologies and methods, the alloy is remarkably improved in purity and uniformity.

Owner:METALINK SPECIAL ALLOYS CORP

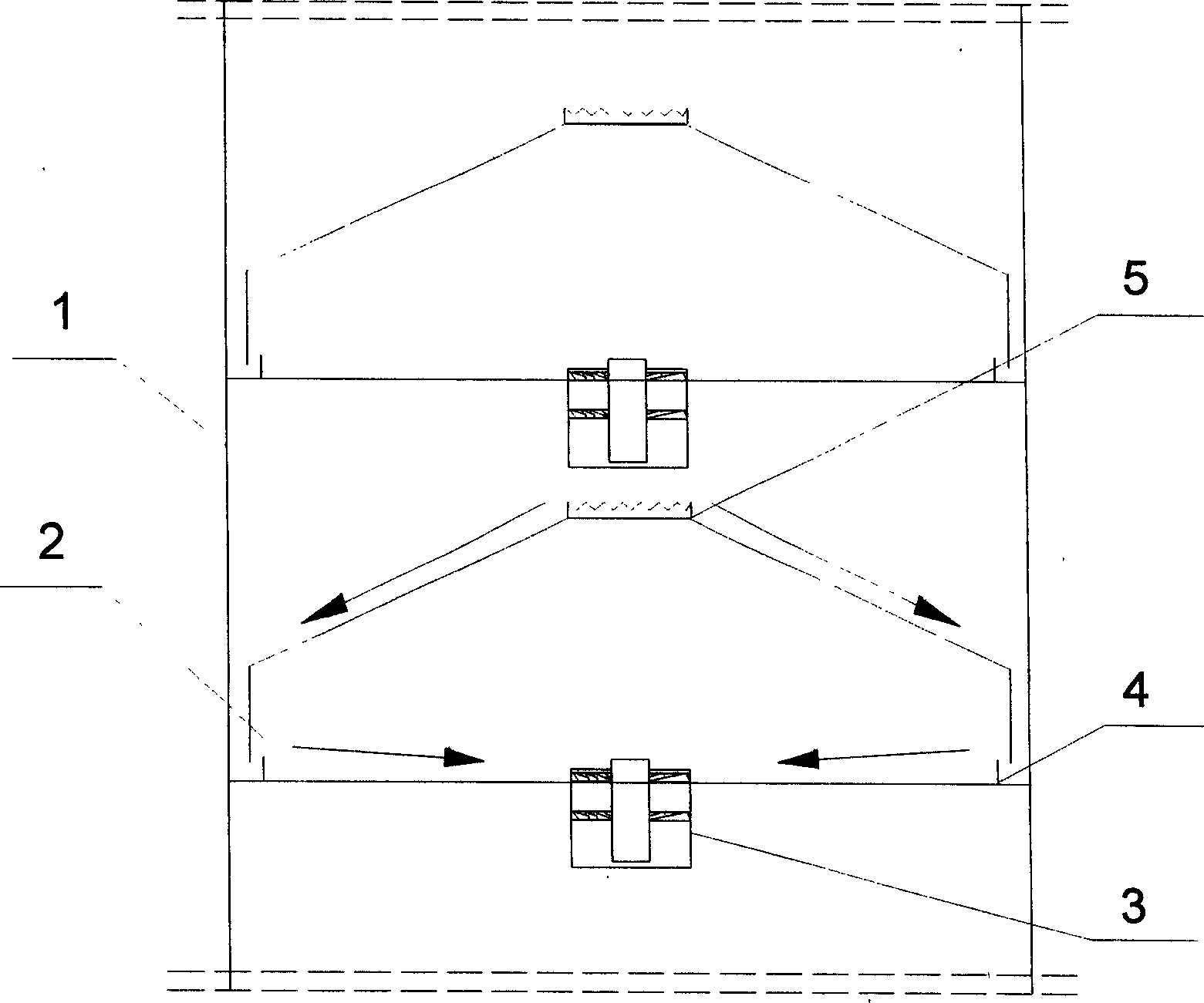

Pyramidal laying liquid typed high performance mass transfer tray with central downcast pipe

InactiveCN1695768AIncrease the effective areaImprove tray efficiencyFractional distillationRetaining ringProduct gas

Owner:BAYER TECH & ENG SHANGHAI

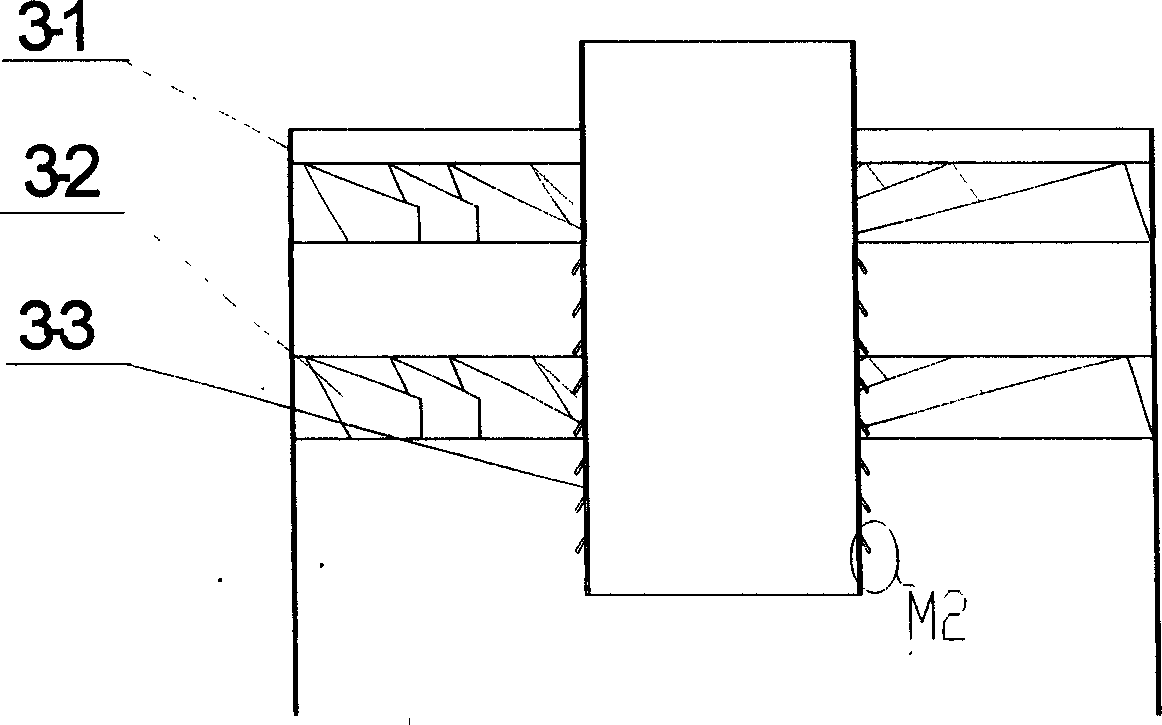

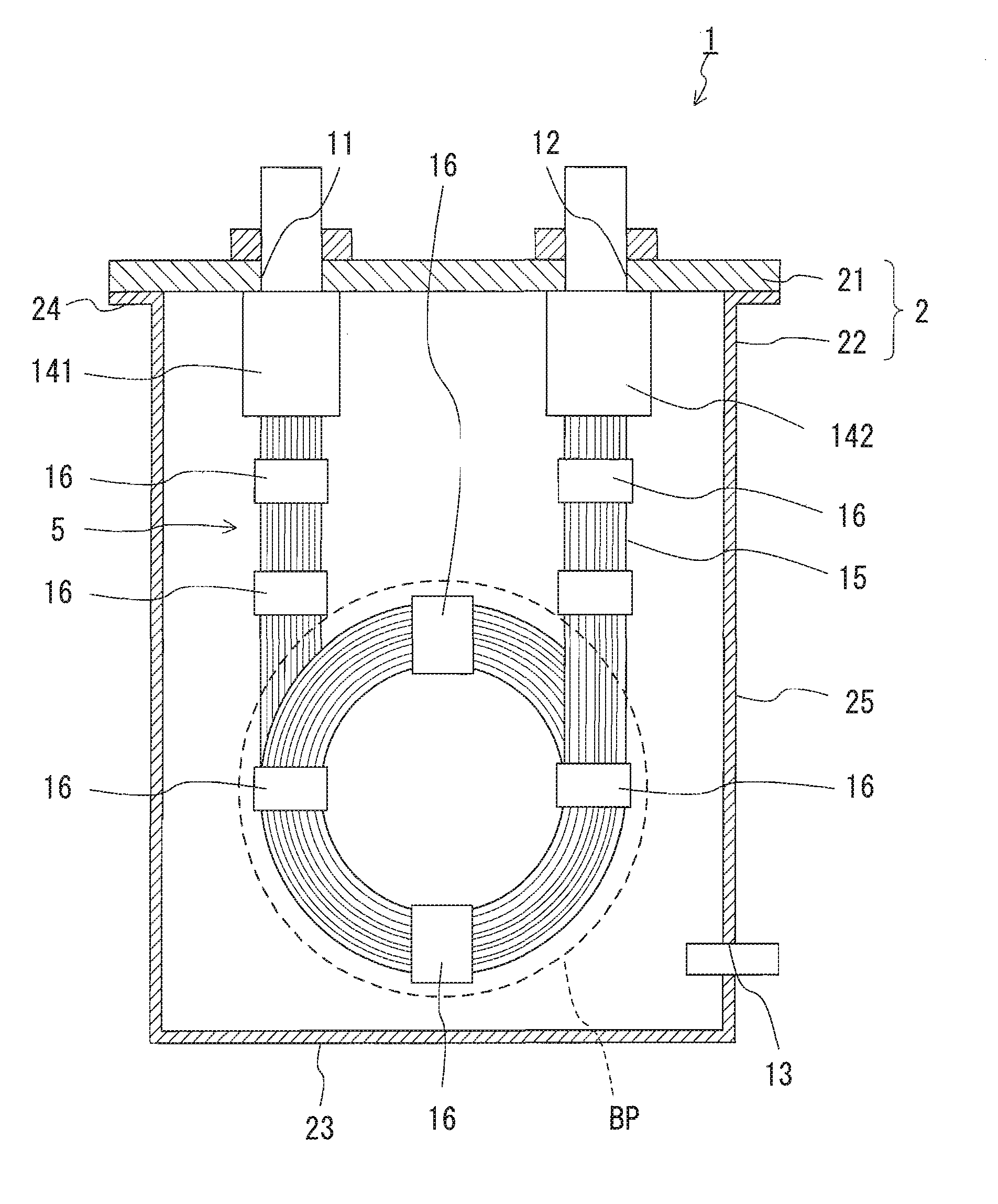

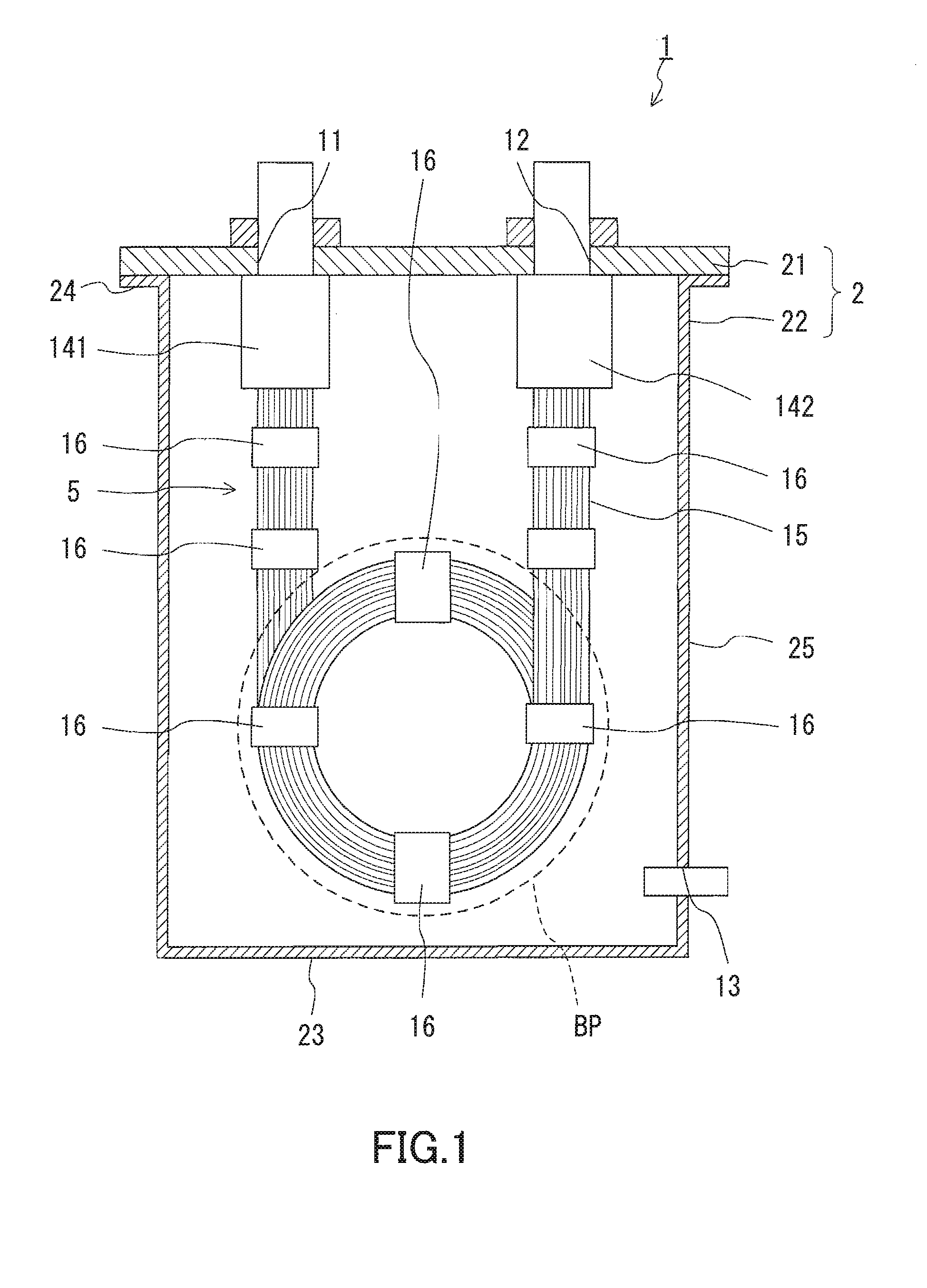

Gas removal device

InactiveUS20090301306A1Improve degassing effectRelieve pressureSemi-permeable membranesMembranesDecompression chamberEngineering

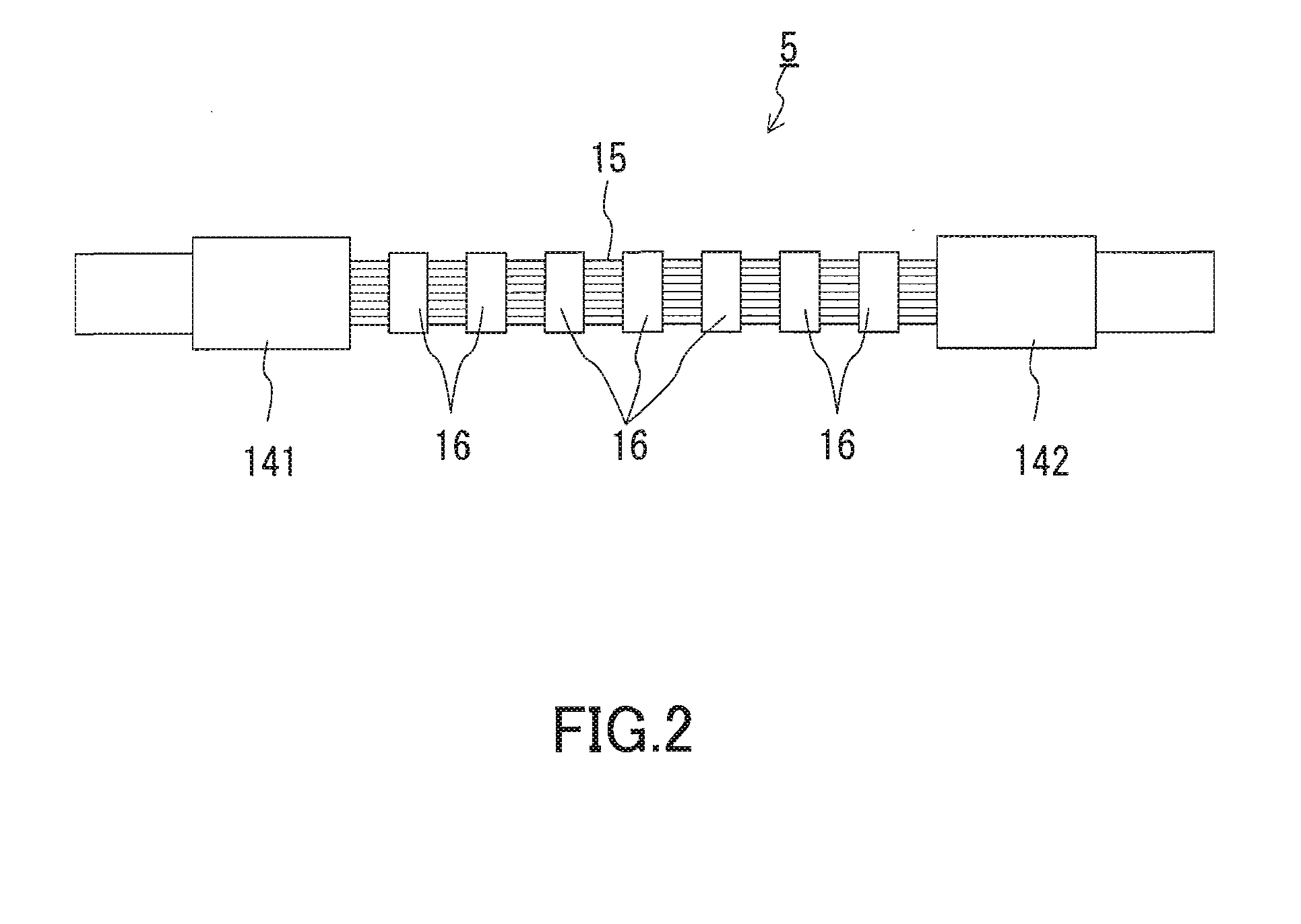

A gas removal device 1 includes a decompression chamber 2 with an inlet 11 and an outlet 12 through which a liquid to be degassed flows therein and thereout, and a degassing element 5 that is accommodated in the decompression chamber 2 while having one end connected to the inlet 11 and another end connected to the outlet 12, and that allows the liquid to be degassed entering into the inlet 11 to pass through the degassing element 5. The degassing element 5 includes a tube bundle 15 composed of a plurality of flexible gas-permeable tubes 151, and a tying member 16 tying the plurality of gas-permeable tubes 151 to form the tube bundle 15. The tube bundle 15 is bent in a shape of coil with multiple turns in such a manner that a portion tied by the tying member 16 is included in a bent portion BP.

Owner:NITTO DENKO CORP

Efficient refining agent for smelting aluminum alloy and preparation method thereof

The invention discloses an efficient refining agent for smelting an aluminum alloy. The efficient refining agent is prepared from the following raw materials in parts by weight: 6-8 parts of plant ash, 8-10 parts of bentonite, 3-5 parts of wollastonite in powder, 3.5-5.5 parts of celestite powder, 0.5-2 parts of graphite powder, 3-5 parts of jade powder, 2-4 parts of quartz sand, 8-10 parts of magnesium hydroxide, 8-10 parts of lithium chloride, 6-8 parts of zinc chloride, 3-4 parts of calcium chloride, 2-4 parts of barium chloride, 4-5 parts of potassium fluosilicate, 1-2 parts of potassium tripolyphosphate, 2-3 parts of sodium sulfate, 1-2 parts of sodium metasilicate, 7-8 parts of rare earth carbonate, 0.1-1.0 part of boron oxide, 0.8-1.2 parts of yttrium fluoride and 3-5 parts of cerium oxide. The efficient refining agent can be used for effectively removing nonmetallic inclusions from an aluminum alloy melt and reducing the loss of rare earth elements in the alloy, and has a good degassing effect; and when the efficient refining agent is used for refining, aluminum dross is separated thoroughly, so that the porosity and oxide inclusions in an alloy casting are obviously reduced, and the comprehensive performance of an aluminum alloy profile is improved.

Owner:XUZHOU NAILI MACROMOLECULE TECH CO LTD

Heat filler type deaerator with stable deaerating function and atomizing function

InactiveCN103292311AConstant and reliable water levelEnsure water qualityLiquid degasificationBlowoff valveDifferential pressure

The invention discloses a heat filler type deaerator with a stable deaerating function and an atomizing function. The heat filler type deaerator is characterized in that a heat-side inlet of an exhaust heat exchanger is communicated with a blowoff valve through a pipeline, a cold-side inlet of the exhaust heat exchanger is communicated with a deaerator water supply pipe, a cold-side water outlet of the exhaust heat exchanger is communicated with a deaerator water supply inlet through a pipeline, a heat-side inlet of a water outlet heat exchanger is communicated with a deaerator water outlet, a boiler water supply pump is connected to a heat-side outlet pipeline, a cold-side water inlet of the water outlet heat exchanger is communicated with the deaerator water supply pipe, a water supply pump is arranged on the deaerator water supply pipe, a differential pressure transmitter is arranged in a deaerator water tank, detected water level signals in the deaerator water tank are transmitted to a controller through the differential pressure transmitter, the controller transmits signals to a frequency converter, the frequency converter controls rotation speed of the water pump to adjust water supply, a pressure control gauge transmits pressure signals to the controller which controls opening of preheating pipeline electromagnetic valves, a temperature sensor transmits temperature signals to the controller, and then the controller controls opening of reheating steam electromagnetic valves.

Owner:JIHUA 3539 SHOE MAKING

Preparation method and application method of electrocatalysis electrode

ActiveCN105776431ALarge specific surface areaExtended service lifeWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsHeat depositionTitanium

The invention provides a preparation method and an application method of an electrocatalysis electrode. The preparation method includes: taking titanium as a substrate, depositing Bi-SnO2-Sb2O3-CNT on the titanium substrate by means of heat deposition, and then depositing a PbO2 active surface layer on a Bi-SnO2-Sb2O3-CNT interlayer by the aid of electrodeposition to prepare a Ti / Bi-SnO2-Sb2O3-CNT / PbO2 electrocatalysis electrode. The electrocatalysis electrode is used for ultrasound electrocatalysis algae killing and microcystin degradation. The electrocatalysis electrode is taken as an anode, a stainless steel or copper sheet is taken as a cathode, microcystis aeruginosa solution added with electrolyte is subjected to electrolysis, and ultrasonic treatment is applied in the electrolytic process. The preparation method and the application method of the electrocatalysis electrode have the advantages that the electrode has more catalytic activity sites, and catalytic activity of the electrode is improved; electrical conductivity of the electrode can be improved, and energy consumption can be lowered; electrocatalytic activity is high, and service life is long; ultrasonic oxidation and electrocatalytic oxidation are combined, synergistic effect is generated, and efficiency of algae killing and microcystin degradation is highly increased.

Owner:HARBIN ENG UNIV

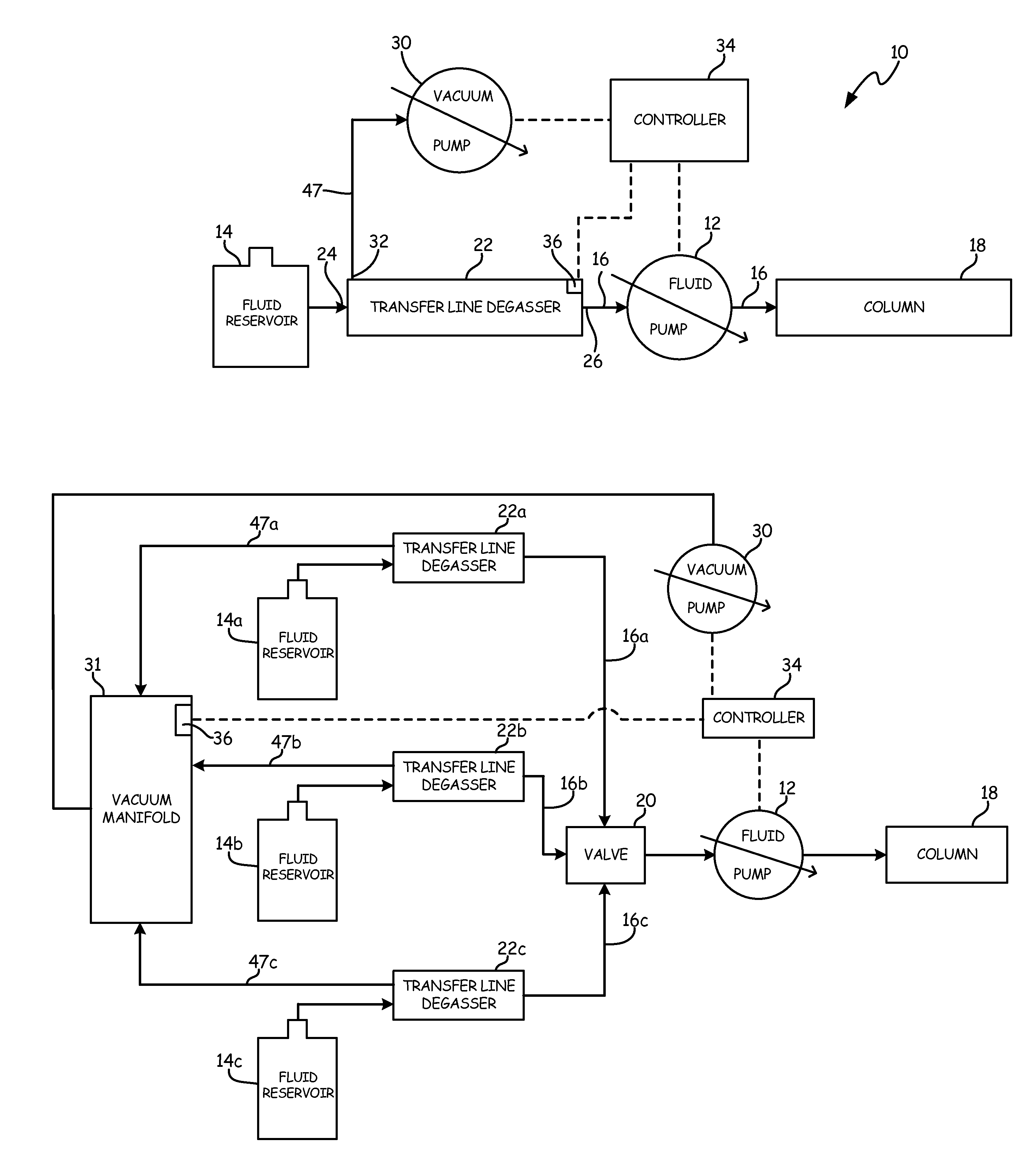

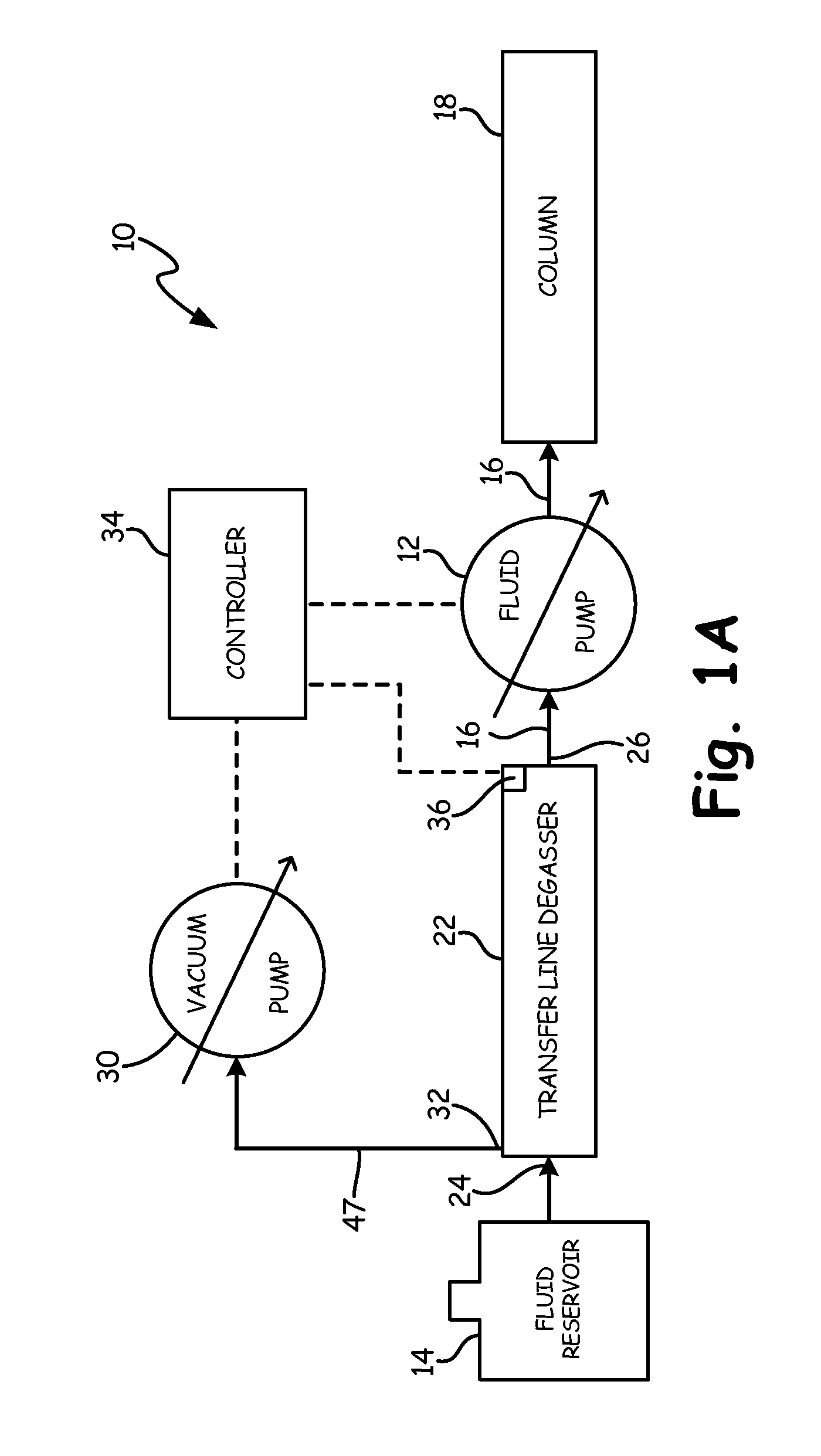

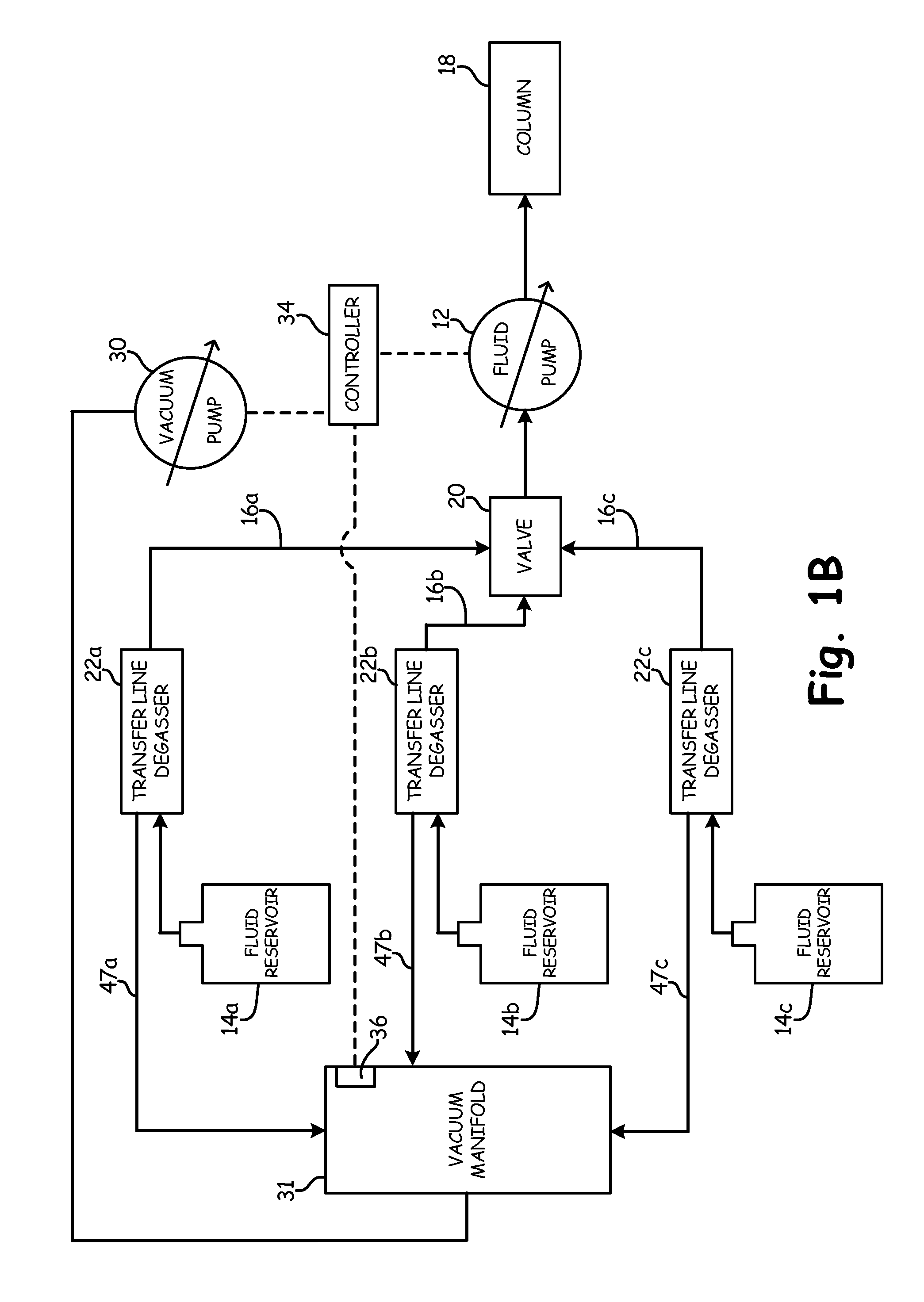

Axial Transfer Line Shell Side Degassing

ActiveUS20160114264A1Efficient and replicative degassingEfficient and replicative shell-side degassing is facilitatedSemi-permeable membranesIsotope separationDegasserEngineering

An elongated fluid degassing apparatus may be employed as a fluid transfer line for fluidly connecting components in a liquid system, while at the same time degassing, or preventing re-gassing of, the fluid. The fluid transfer line degassing apparatus forms a shell and tube degassing arrangement, wherein shell-side fluid flow is facilitated by one or more spacer elements that centrally position a semi-permeable separation membrane in the shell chamber. The degasser may include one or more tubular separation membranes that provide a gas-permeable, liquid-impermeable contact surface to effect the gas-liquid separation of the process fluid.

Owner:IDEX HEALTH & SCI

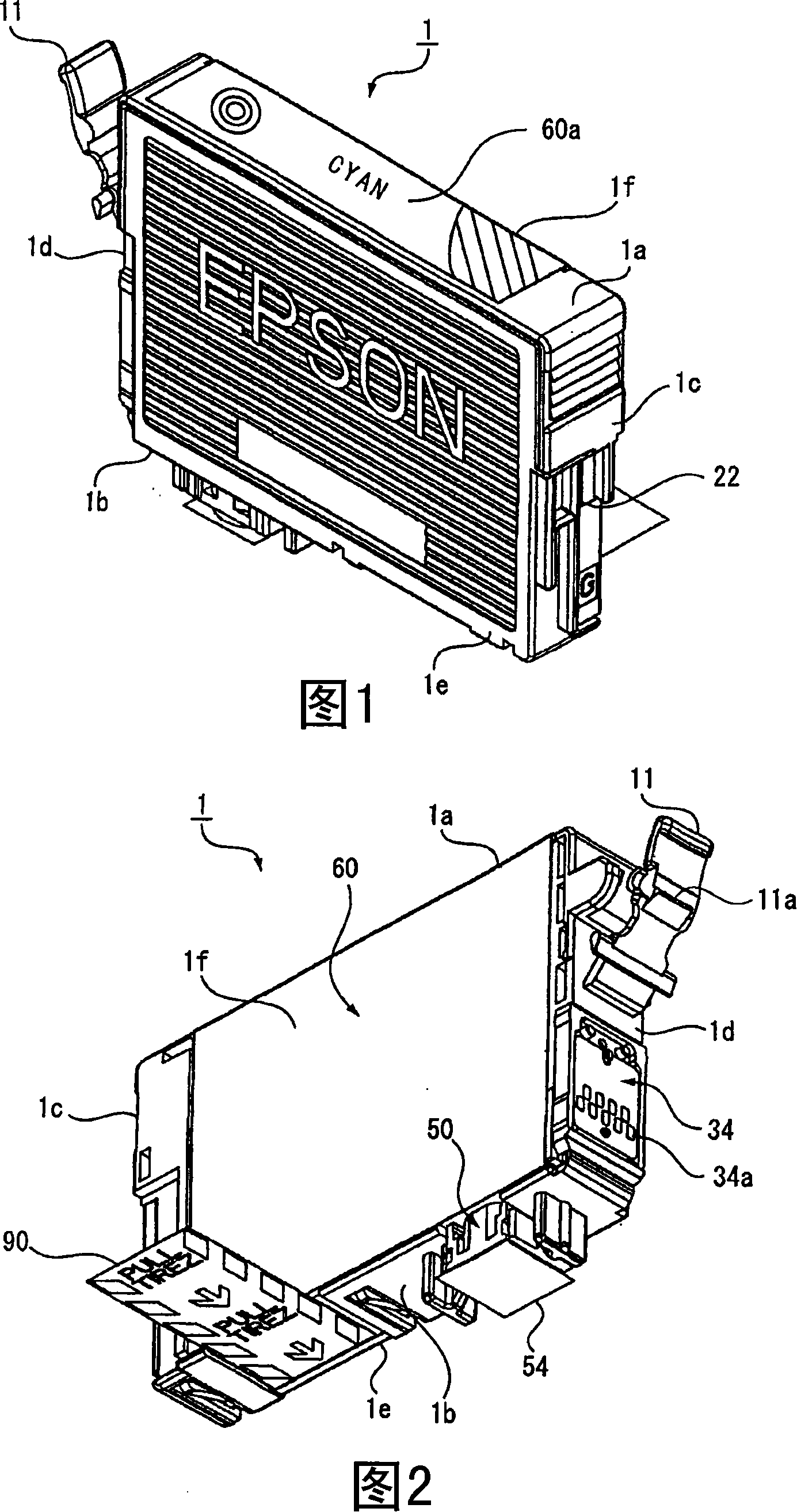

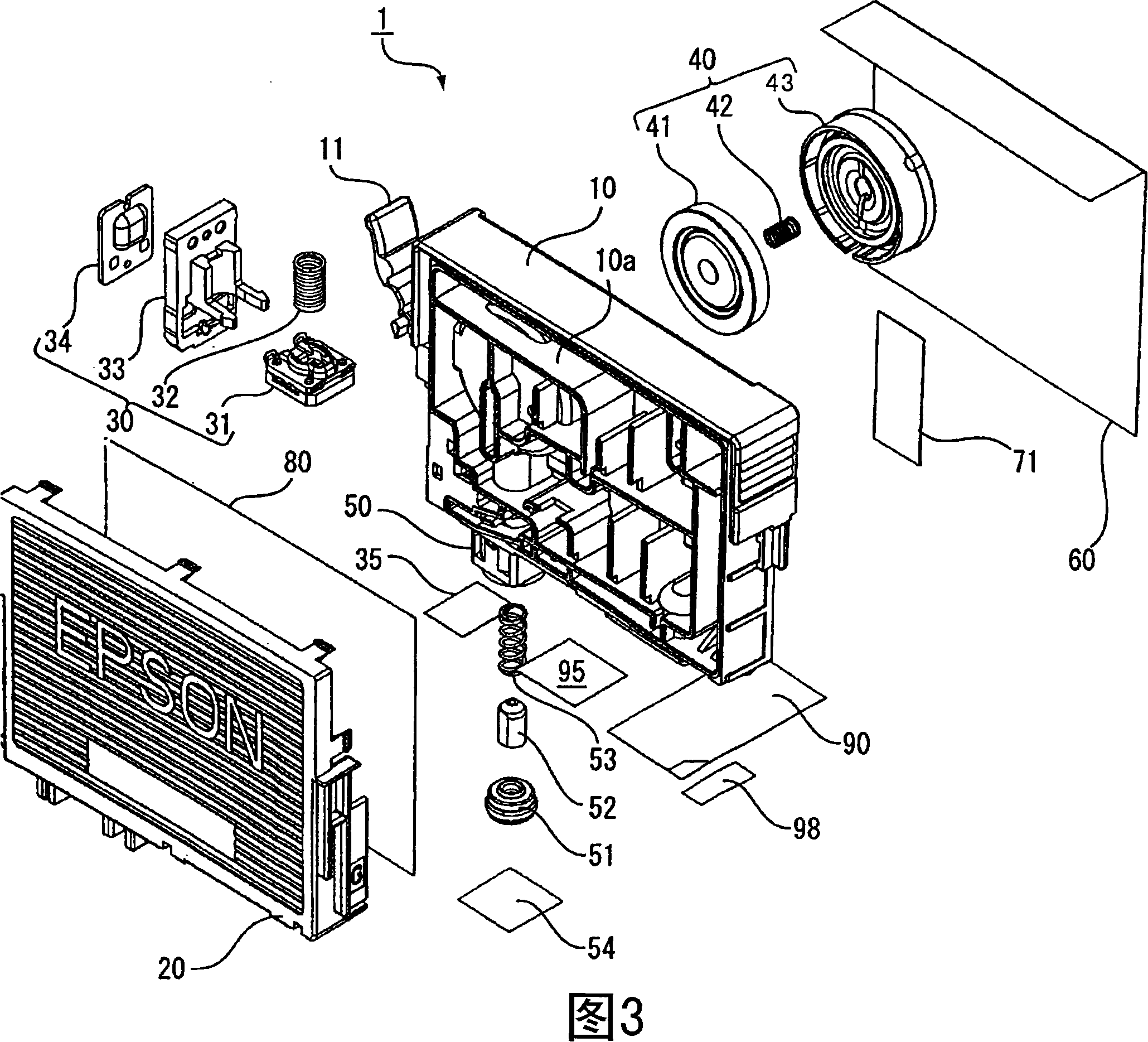

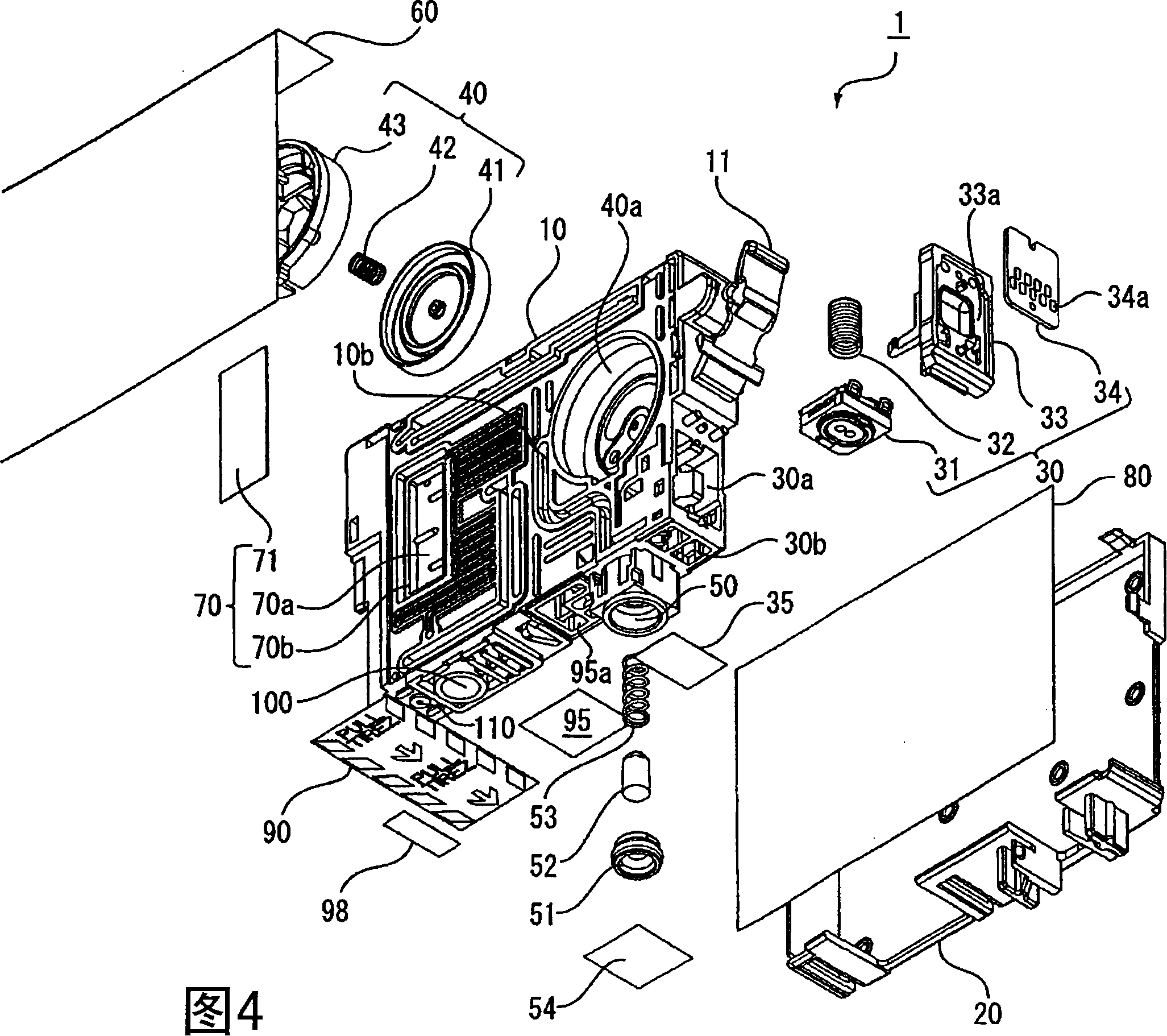

Liquid container

InactiveCN101121337AImprove degassing effectPrevent false detectionPrintingElectricityResidual vibration

The present invention provides a liquid container, which can eliminate air bladder even though the air bladder generating in the cavity of the liquid residual capacity sensor, so as to prevent the liquid residual capacity sensor from measuring by accident due to the air bladder. The container body (10) comprises: liquid containing chambers (370, 390, 430), for holding liquid; and liquid residual capacity sensor (31), for detecting the presence or absence of liquid based on residual vibration by piezoelectricity elements. A no-liquid-filled chamber (501) which is in communication with the outside of the container body (10), when casing the liquid container (1) through decompression and encapsulation, the no-liquid-filled chamber (501) becomes a deaeration chamber which contains negative pressure for deaeration, to eliminate the air bladder in the sensor by means of the decompression of the deaeration chamber.

Owner:SEIKO EPSON CORP

Emulsified high-alcohol degasifying agent for papermaking

The invention discloses an emulsified high-alcohol degasifying agent for papermaking. Based on the totally 100-percent weight of the components, the agent comprises the following components in percentage by weight: (1) 30 to 59 percent of degasifying active substance, (2) 0.01 to 5 percent of non-cationic surfactant and (3) 40 to 69 percent of water, wherein the degasifying active substance comprises the following components in percentage by weight: (A) 20 to 40 percent of high alcohols, (B) 40 to 20 percent of fatty acid ester, (C) 40 to 20 percent of low melting grease, (D) 0.05 to 0.25 percent of polysaccharide compound and (E) 0.01 to 0.1 percent of water-soluble styrene-maleamic acid copolymer which are added into 100 percent in percentage by weight. The emulsified high-alcohol degasifying agent for the papermaking has the advantages of good storage stability, good high-temperature degasifying property, moderate preparation condition and the like, and can be widely applied to a papermaking process in the papermaking industry and other industries to achieve highly-efficient degasifying and deforming effect.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

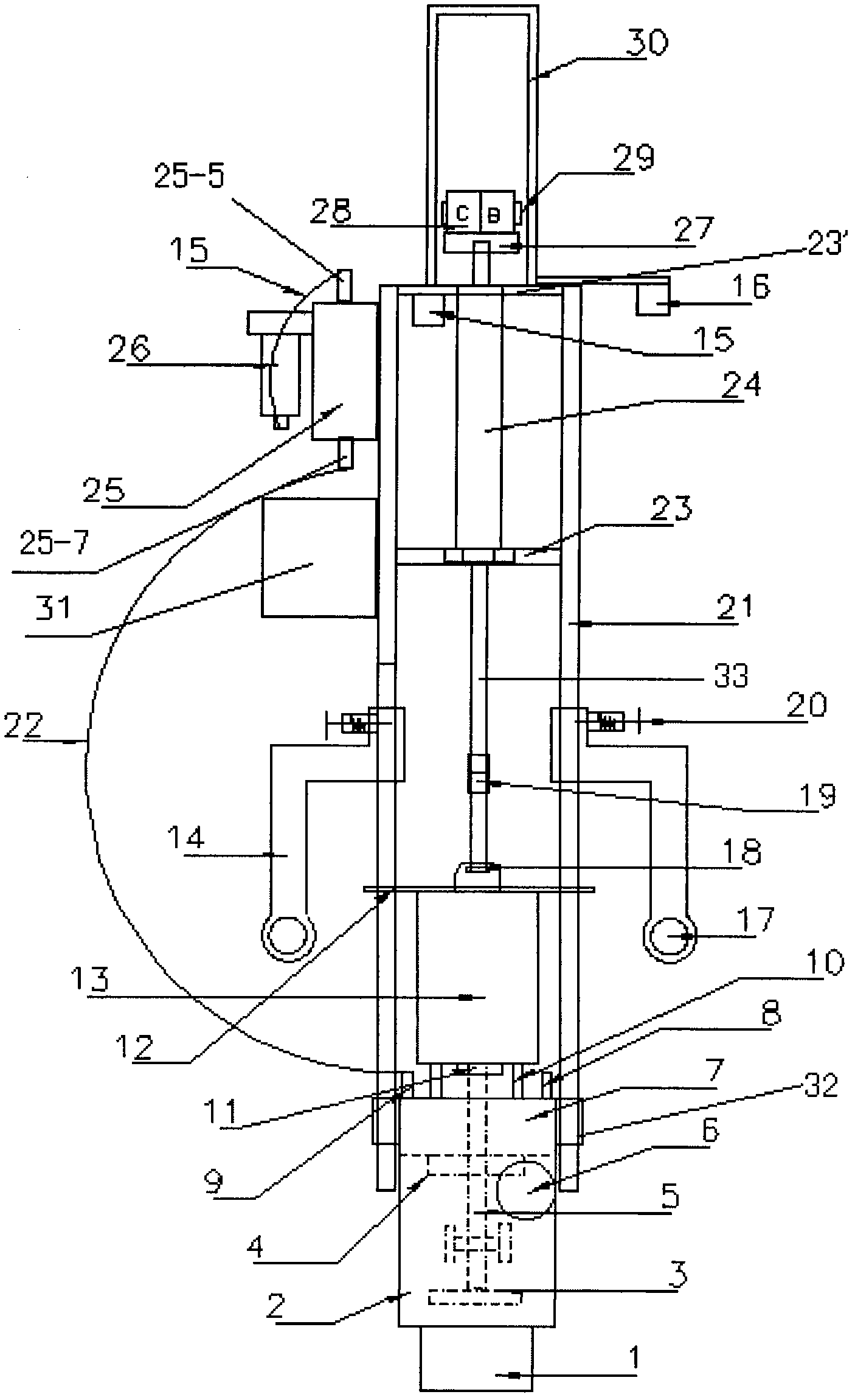

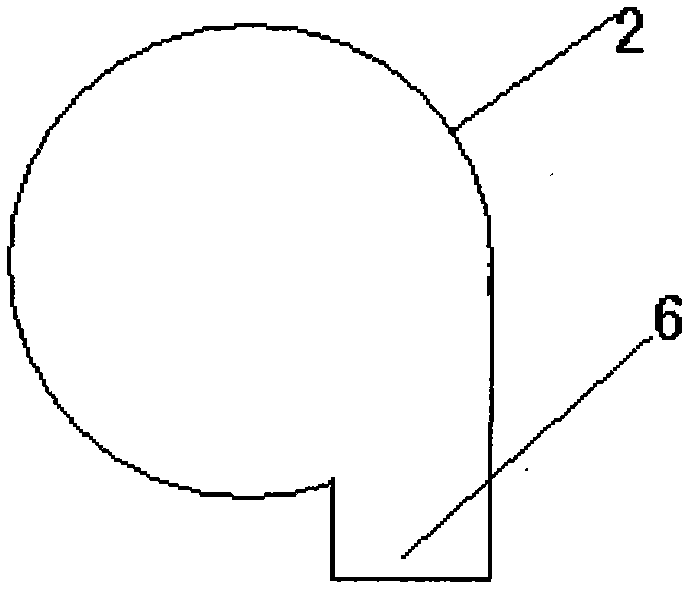

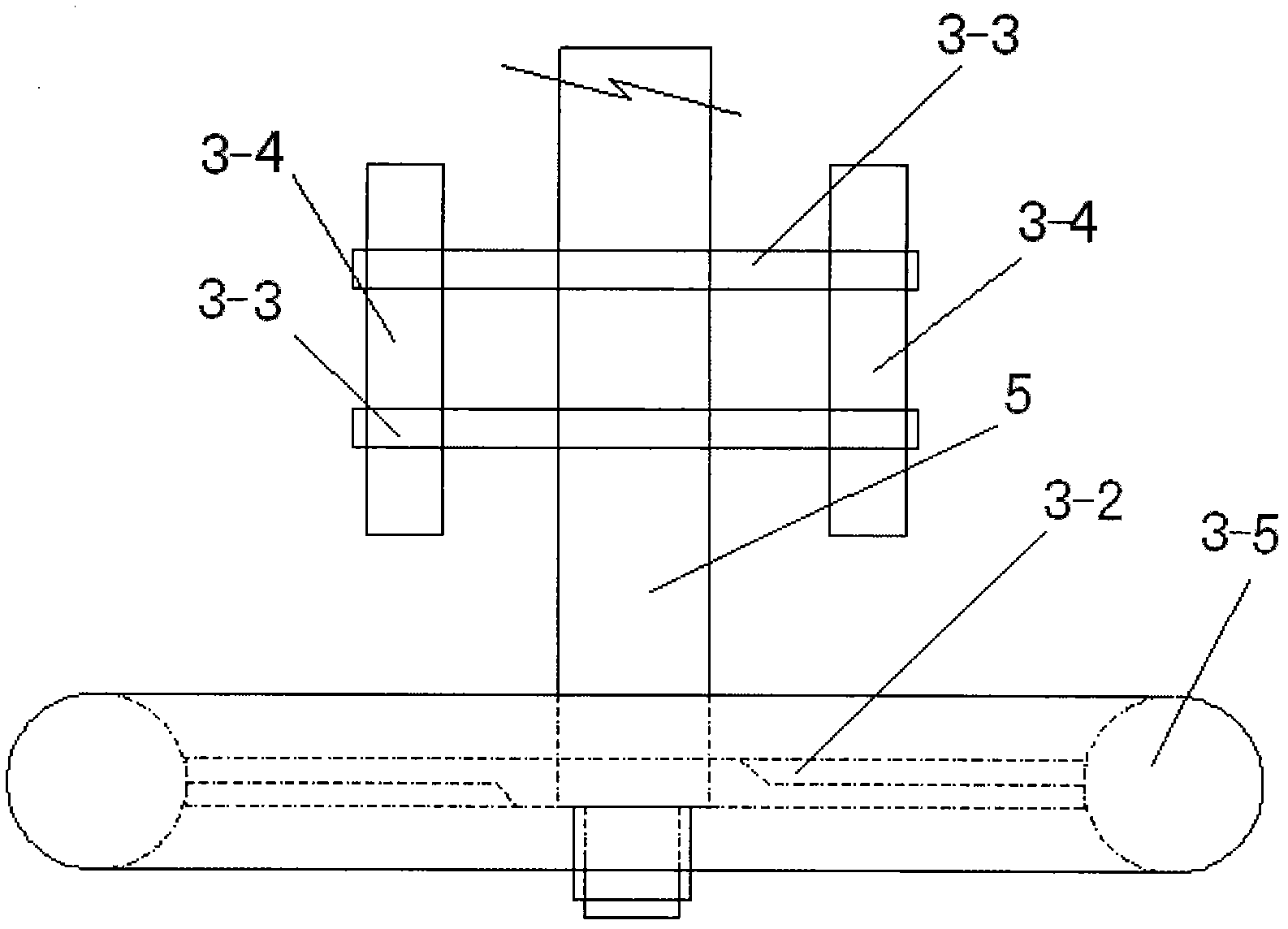

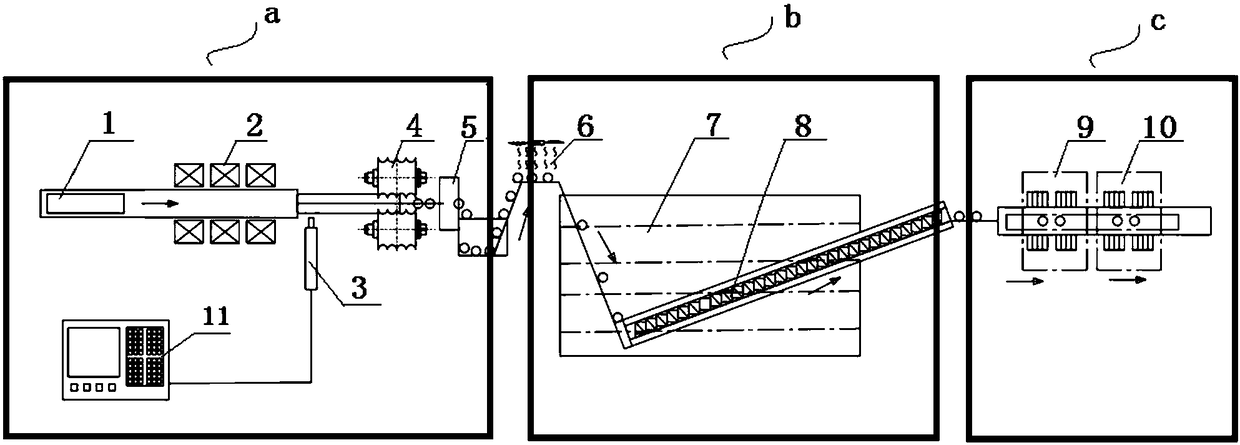

A fully automatic degasser

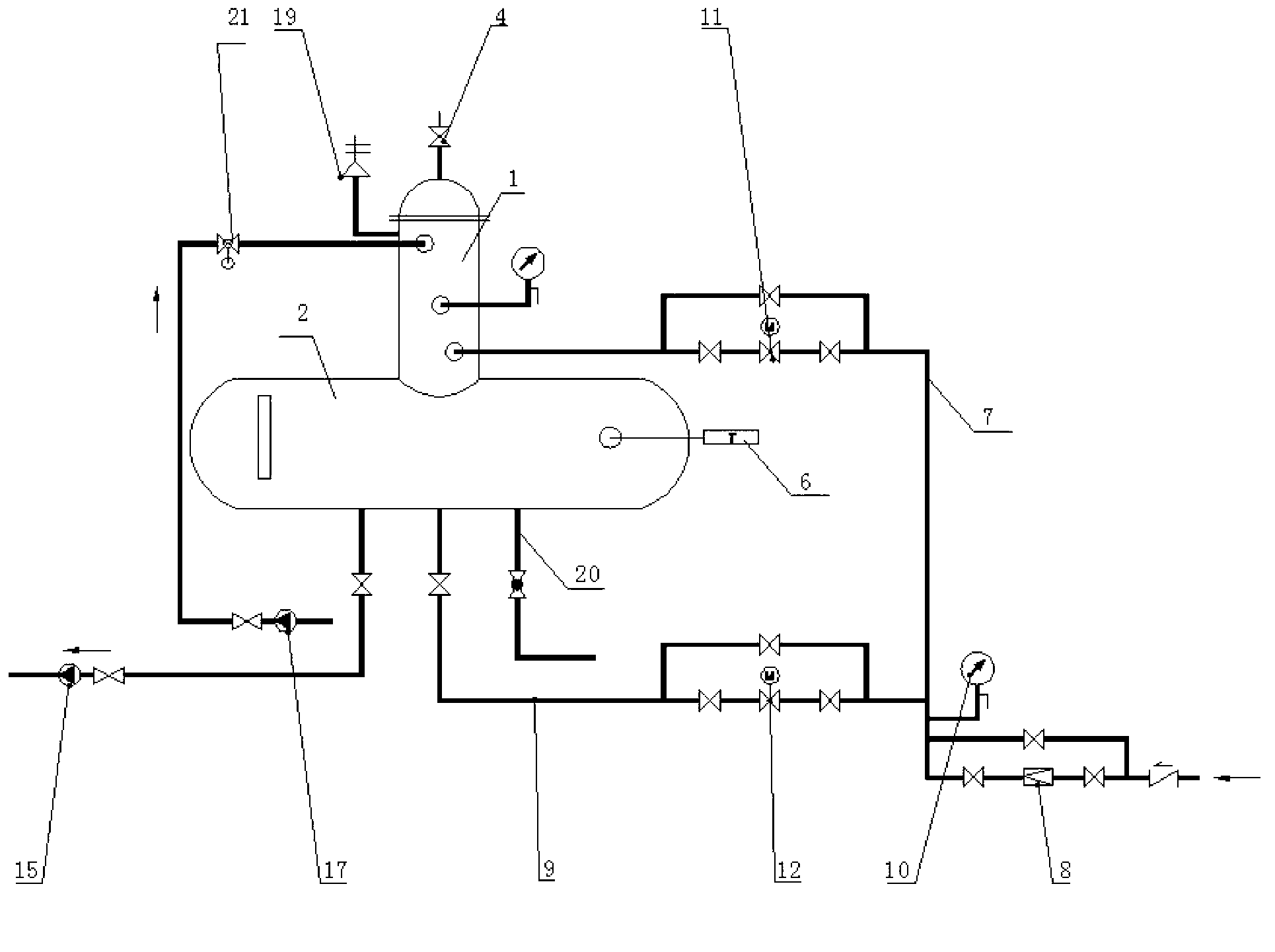

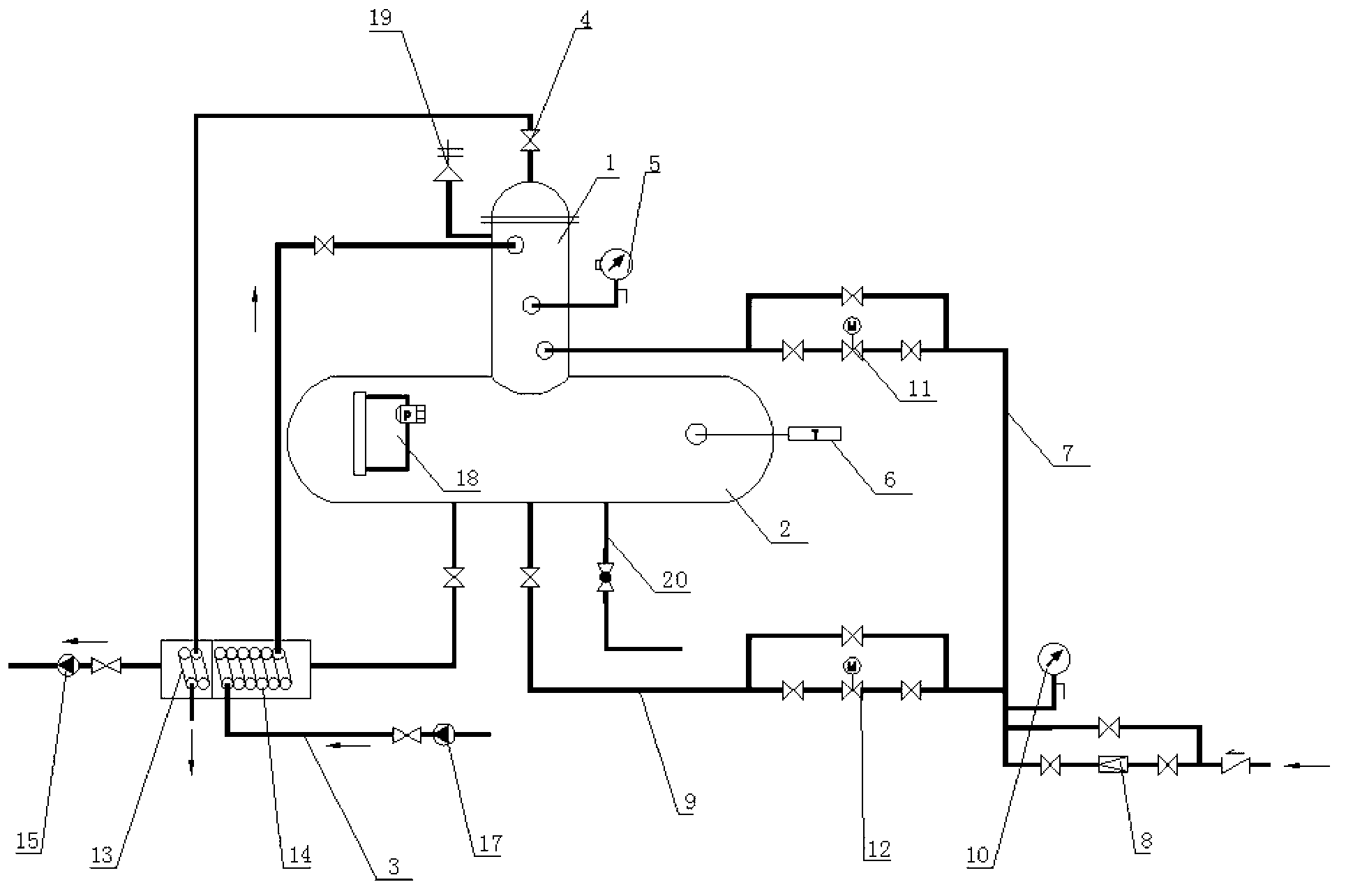

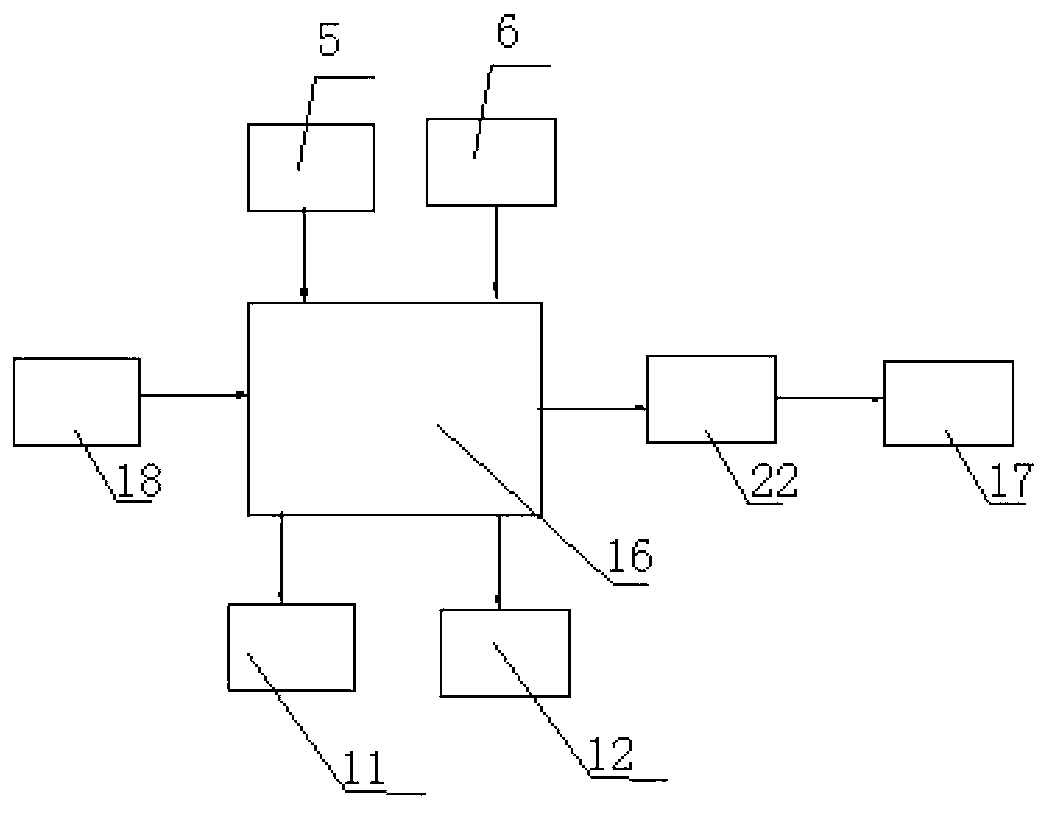

InactiveCN102278105AMeet explosion-proof requirementsReduce weightLiquid degasificationRotary stirring mixersDegasserSlurry

The invention discloses a full-automatic degassing machine, comprising a degassing barrel (2), a slurry inlet (1), a slurry outlet (6), a stirring and crushing device (3) and a motor. The invention is characterized in that the full-automatic degassing machine also comprises an air cavity (7), an air inlet (8), an oil gas suction inlet (9), a lifting support sliding rod (21), a guide rail locatingplate (12), a double spindle lifting cylinder (24) and a brake friction plate (30), and a first ultrasonic wave probe (15), a second ultrasonic wave probe (16), a slurry blocking detection device (25) and an automatic drainer (26), and the double spindle lifting cylinder (24), a braking cylinder (28), the slurry blocking detection device (25), the motor (13), the first ultrasonic wave probe (15) and the second ultrasonic wave probe (16) are all connected with an electric control device (31). The full-automatic degassing machine disclosed by the invention has a reasonable design, a simple structure, economy and practicability, convenience in operation, good degassing efficiency, high efficiency, long service life and simplicity in mounting and dismounting.

Owner:胜利油田胜油测录工程技术有限公司

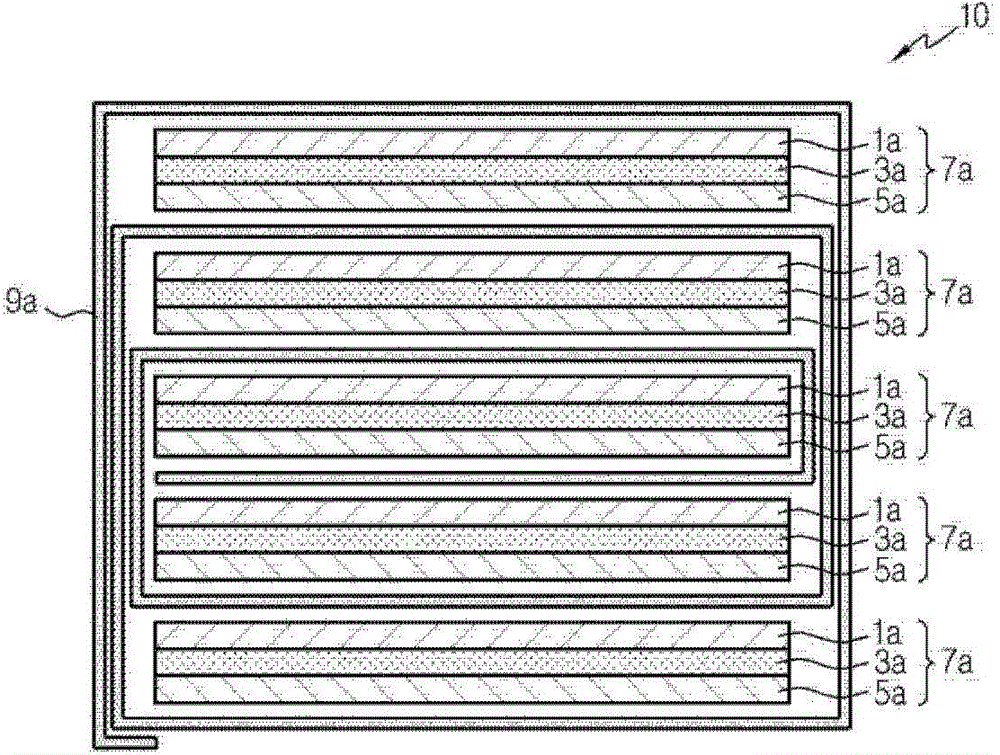

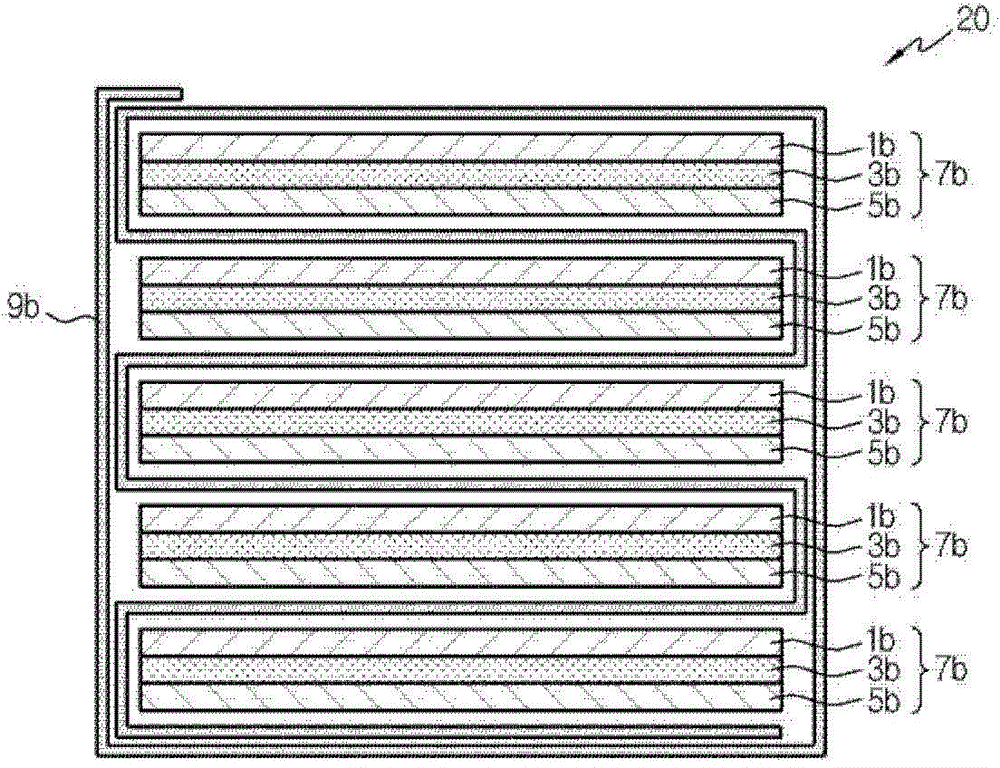

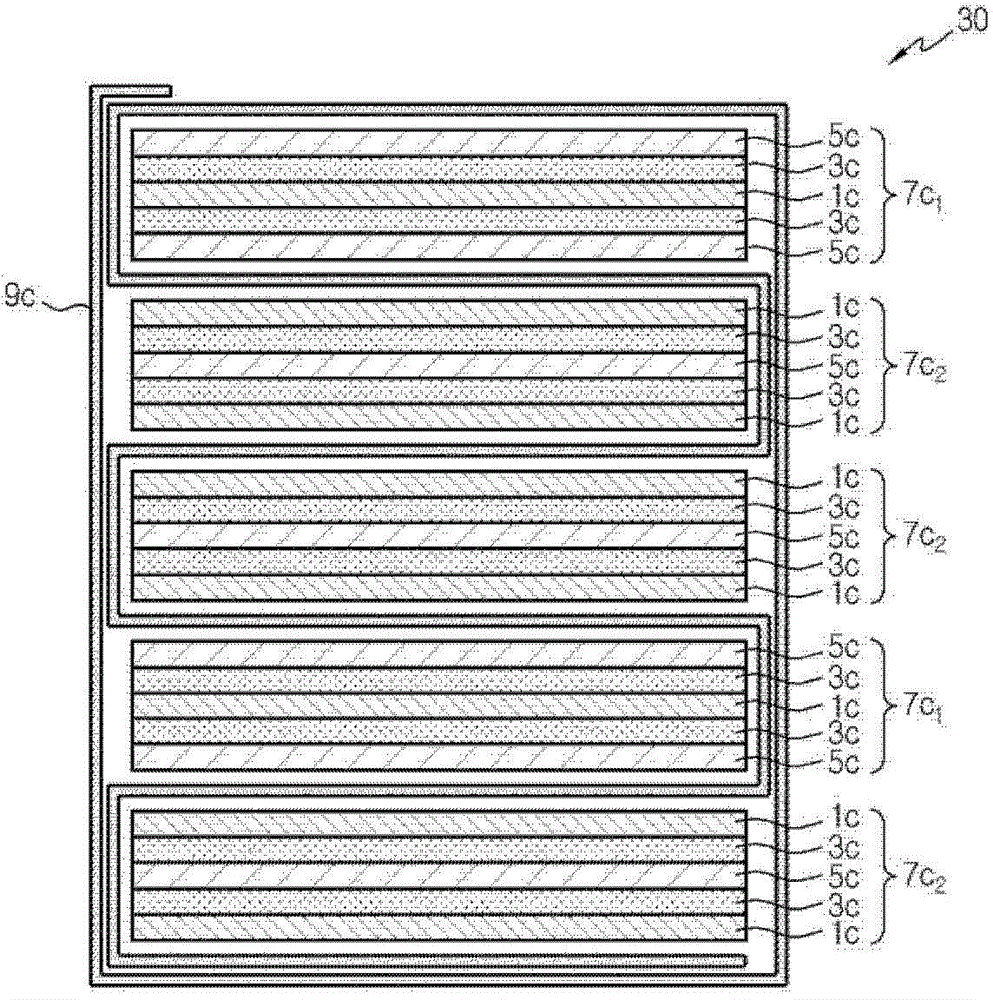

Electrode assembly and electrochemistry device comprising the electrode assembly

ActiveCN104600228AReduce bloatImprove performanceFinal product manufactureLi-accumulatorsElectrochemistrySide reaction

The invention provides an electrode assembly and an electrochemistry device comprising the electrode assembly. The electrode assembly includes a plurality of unit batteries. Each unit battery includes an anode, a cathode, and a first separator between the anode and the cathode, and which overlaps a plurality of cells by enclosing full cell or bi-cell unit cells using a second separator, an electrode assembly is disclosed in which the average gas bubble diameter (d2) of the second separator is greater than the average gas bubble diameter (d1) of the first separator amidst the unit cells. The electrode assembly of the invention has raised wettability and raised performance of removing gasses generated by side reaction of the batteries, so that electrolytes will not leak and the expansion of the batteries is smaller. Thus good battery performance can be maintained when the batteries are in long-term usage, and deformation of the batteries due to outside bumping is smaller.

Owner:LG ENERGY SOLUTION LTD

Rapid degassing method of vacuum induction furnace

InactiveCN102212652AImprove degassing effectFully degassedProcess efficiency improvementOxygenVacuum pump

The invention discloses a rapid degassing method of a vacuum induction furnace. The method comprises the following steps: (1) according to the requirements of steel components, calculating weight of the needed scrap steel raw material and pre-deoxidizer as well as various alloys, weighing the materials, and pre-drying the pre-deoxidizer and the alloys; (2) placing the scrap steel raw material in a crucible, and placing the pre-deoxidizer and the alloys in a storage bin; (3) closing a vacuum chamber of the vacuum induction furnace and vacuumizing for 3-8 minutes; (4) transferring electrochemical steel into an inductor, then keeping vacuum degree at 0.05-0.1Pa, and continuously vacuumizing for 10-20 minutes; (5) stopping vacuumizing, charging argon into the vacuum chamber until pressure reaches 500-700Pa, starting a vacuum pump for vacuumizing to 0.05-0.1Pa, and then maintaining the vacuum degree for 10-20 minutes; (6) stopping vacuumizing, and then filling argon into the vacuum chamber until pressure reaches 500-700Pa; (7) adding the pre-deoxidizer and the alloys in the storage bin to molten steel for full circulation; and (8) naturally cooling the molten steel for 5-10 minutes in a vacuum state and then performing vacuum breaking and demoulding. Practices prove that, in the molten steel treated by the degassing method, the contents of the carbon element, the nitrogen element and the oxygen element are extremely low and are respectively not more than 15ppm, not more than 15ppm and not more than 20ppm.

Owner:武钢集团有限公司

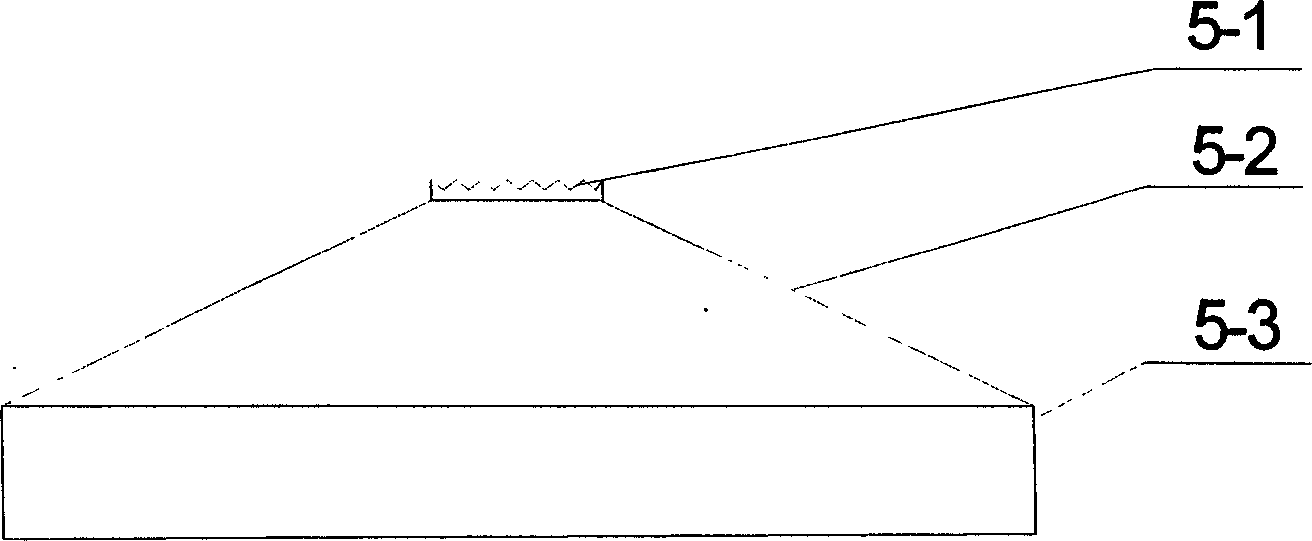

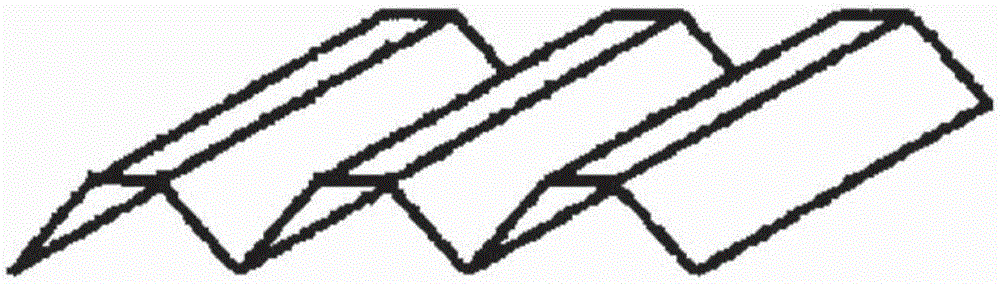

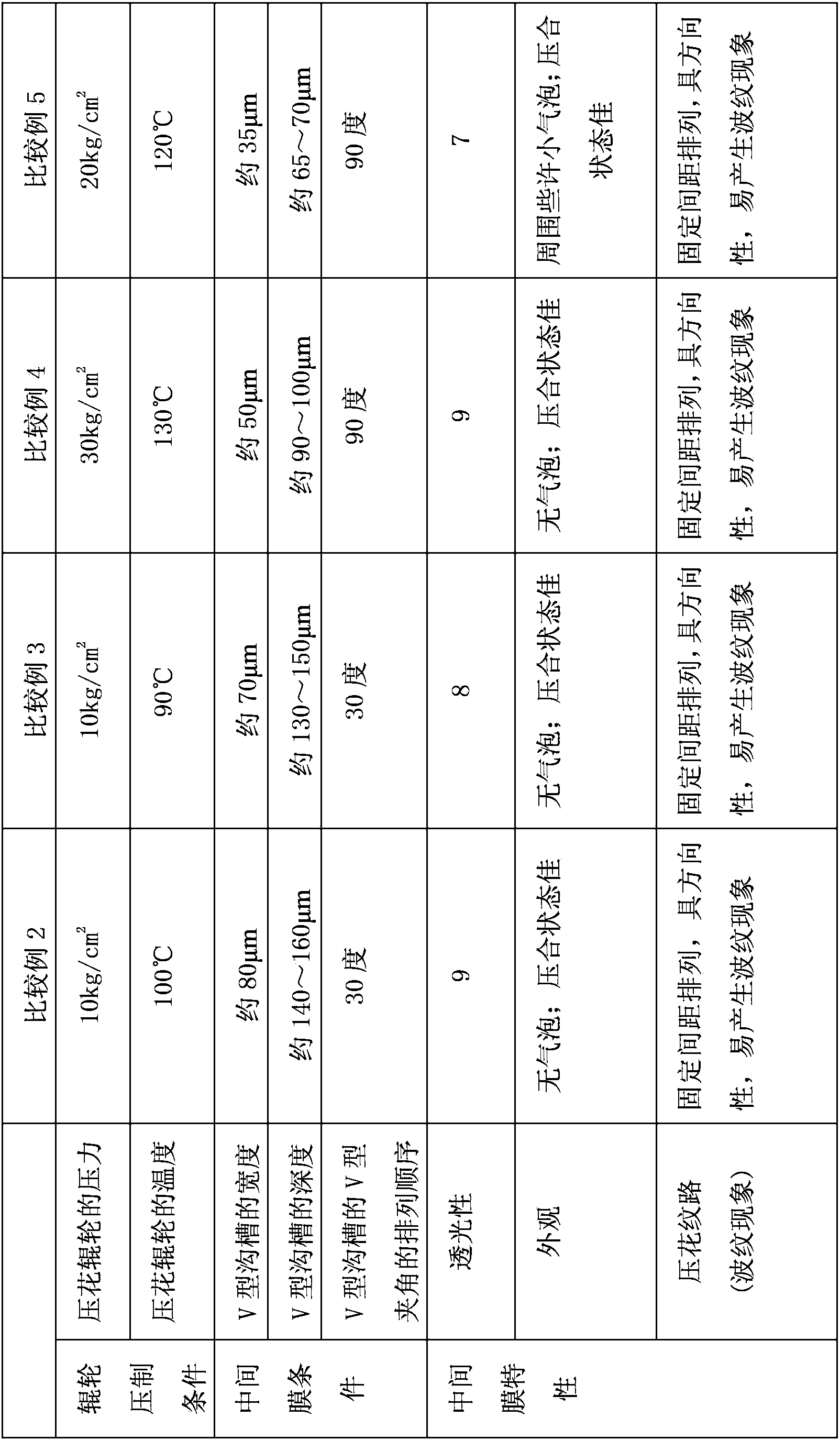

Laminated glass interlayer and laminated glass

InactiveCN105358503AImprove degassing effectAvoid ghostingSynthetic resin layered productsConstructions elementsMetallurgyPolyresin

The purpose of the present invention is to provide a laminated glass interlayer and a laminated glass that includes the laminated glass interlayer, the laminated glass interlayer comprising two or more layered resin layers, having excellent degassing properties during a laminated glass production process, and being capable of preventing the occurrence of ghost images. The present invention is a laminated glass interlayer comprising two or more layered resin layers, at least one surface of the laminated glass interlayer having a plurality of concave portions and a plurality of convex portions. Bottom portions of the concave portions have continuous groove shapes, and adjacent concave portions are parallel and arranged regularly in lines. On the surface that has the plurality of concave portions and the plurality of convex portions, the groove depths (Rzg) of the concave portions are 10-40 [mu]m as measured in accordance with JIS-B0601 (1994), and the intervals between adjacent concave portions are 1000-1500 [mu]m.

Owner:SEKISUI CHEM CO LTD

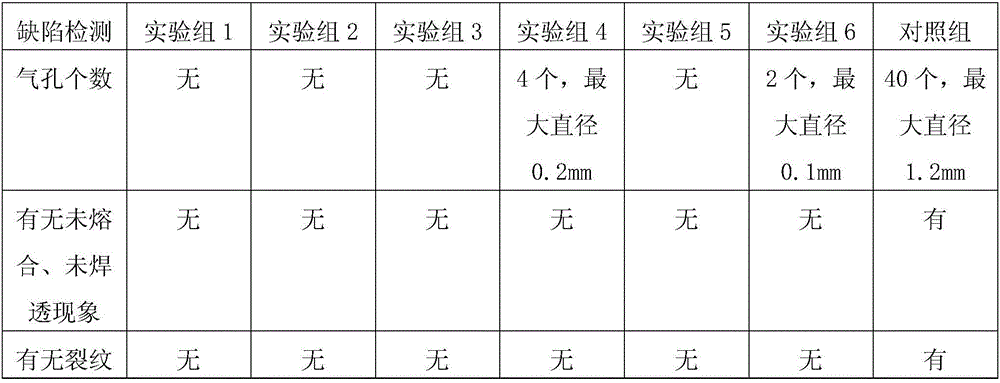

Aluminum alloy welding process

InactiveCN106825871AHigh tensile strengthDoes not affect aestheticsArc welding apparatusWelding/cutting media/materialsSlagMegasonic cleaning

The invention discloses an aluminum alloy welding process and belongs to the technical field of metal welding. The aluminum alloy welding process comprises the following steps: (1) a welding area of the surface of an aluminum alloy plate is put into a cleaning fluid for ultrasonic cleaning and then dried; (2) the welding area of the to-be-welded aluminum alloy plate is heated to 150-200 DEG C; (3) the welding area of the to-be-welded aluminum alloy plate is heated to 750-830 DEG C, a degasifier is sprayed to the welding area of the aluminum alloy plate, and the aluminum alloy plate is welded with a special aluminum alloy welding wire; (4) the welded part of the aluminum alloy plate is subjected to solid solution at the temperature of 300-450 DEG C, and the aluminum alloy plate is subjected to degasification treatment through ultrasonic waves; (5) the welded part of the aluminum alloy plate after solid solution treatment is transferred to cold water and cooled to the room temperature; (6) clearing and removal of welding powder or slag are performed. With the adoption of the aluminum alloy welding process, the pore problem can be effectively solved, and incomplete fusion, incomplete penetration and cracking phenomena are unlikely to occur.

Owner:玉林博飞商贸有限公司

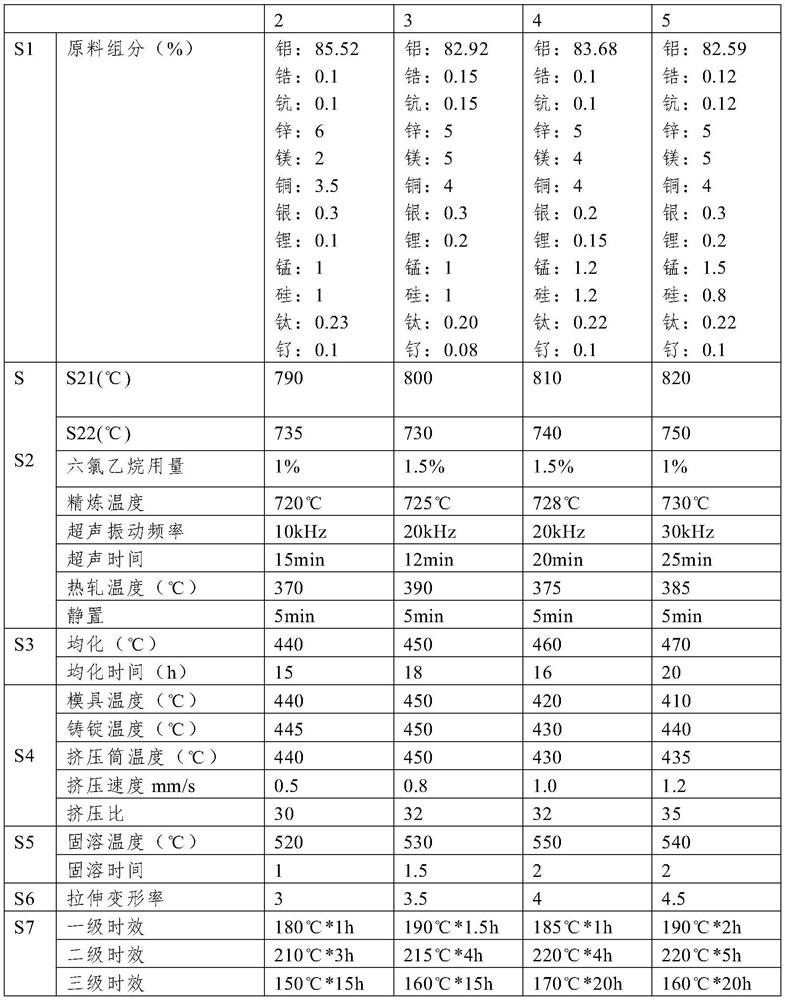

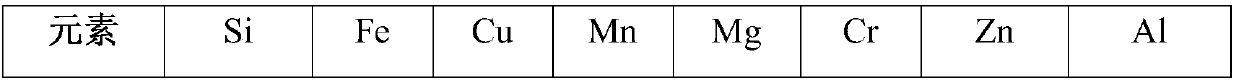

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

Nickel-chromium-molybdenum alloy welding wire for surfacing welding of ball valves

ActiveCN110977245AReduce generationImprove high temperature strengthWelding/cutting media/materialsSoldering mediaSmelting processIngot

The invention provides a nickel-chromium-molybdenum alloy welding wire for surfacing welding of ball valves. The nickel-chromium-molybdenum alloy welding wire includes the following chemical components including, by mass percentage, 0.01% of C, not larger than 0.3% of Si, not larger than 0.5% of Mn, not larger than 0.015% of P, not larger than 0.01% of S, not larger than 0.2% of Al, not larger than 0.3% of Ti, 21.5%-22.2% of Cr, not larger than 0.3% of Fe, 8.5%-9% of Mo, 3.5%-3.8% of the sum of Nb and Ta and the balance Ni. According to the nickel-chromium-molybdenum alloy welding wire, the type and content of elements in the alloy composition are strictly controlled, an alloy is conveniently processed into thinner welding wires, and element ratio control helps to reduce the occurrence ofhot cracks during welding; and a vacuum smelting and electroslag double smelting process is adopted, and a refining method combining high-temperature instantaneous refining and low-temperature long-term refining is adopted in the vacuum smelting process, the purity and the degassing effect are further improved, the quality and performance of alloy ingots are improved, and plasticity and impact toughness are improved.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

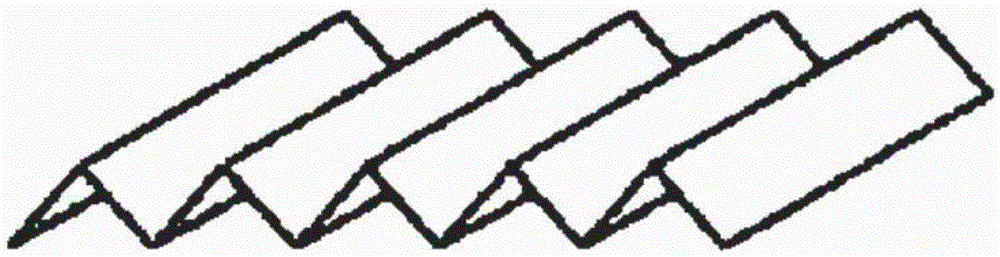

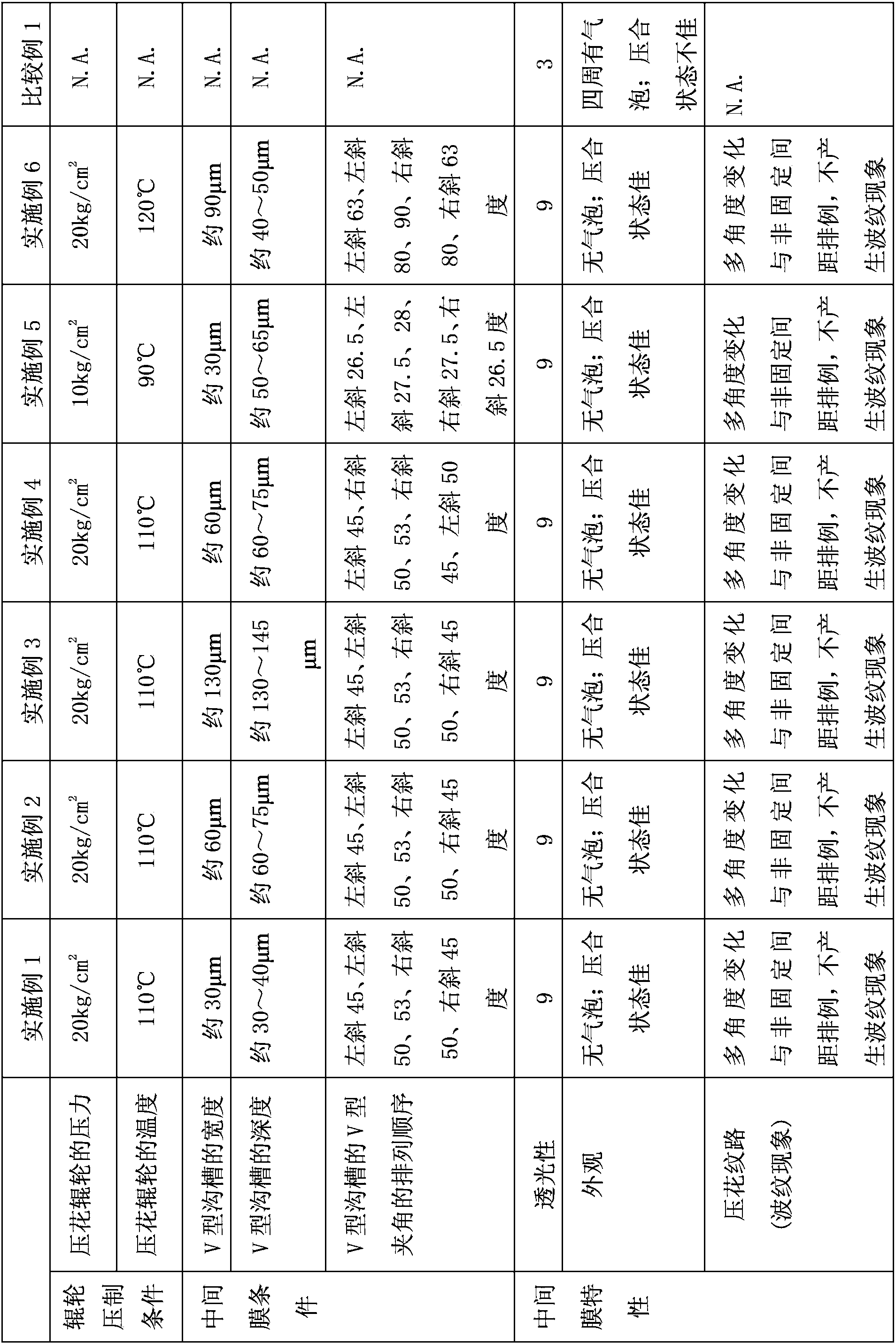

Interlayer film for laminated glass and laminated glass containing same

ActiveCN103788553AImprove degassing effectEasy to processLamination ancillary operationsSynthetic resin layered productsEngineeringLaminated glass

The invention provides an interlayer film for laminated glass and the laminated glass containing the same. Both sides of the interlayer film are embossed to form a plurality of V-shaped grooves on each side, and angles of the V-shaped included angles between adjacent V-shaped grooves are different. Because of arrangement of the grooves, a ripple phenomenon cannot be generated when the interlayer film is used in the laminated glass, the interlayer film is allowed to have excellent processability during a cutting or laminating process, and a good exhaust property is provided during a pre-compression connection process.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

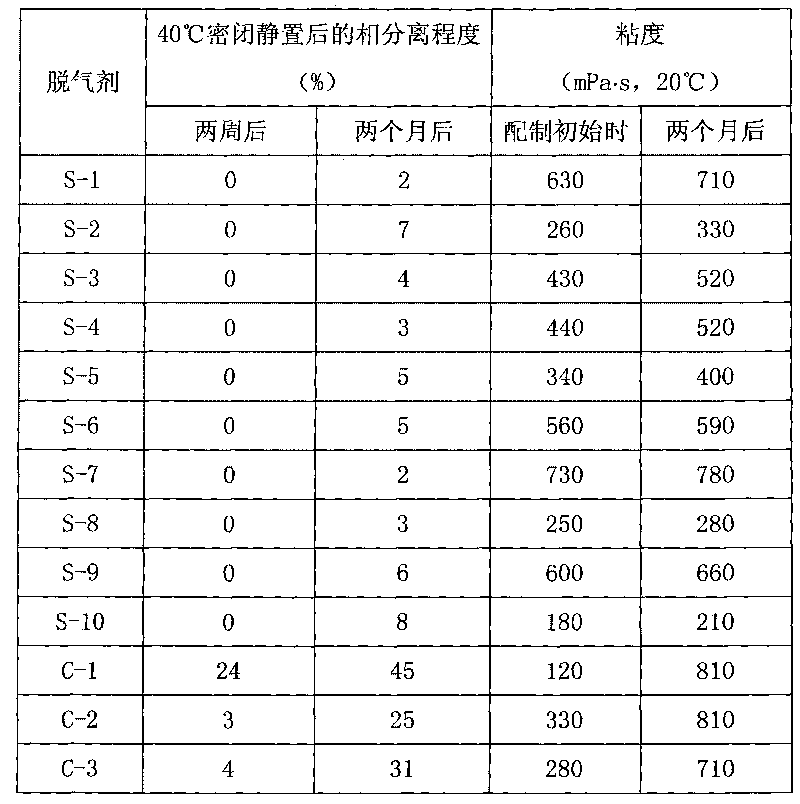

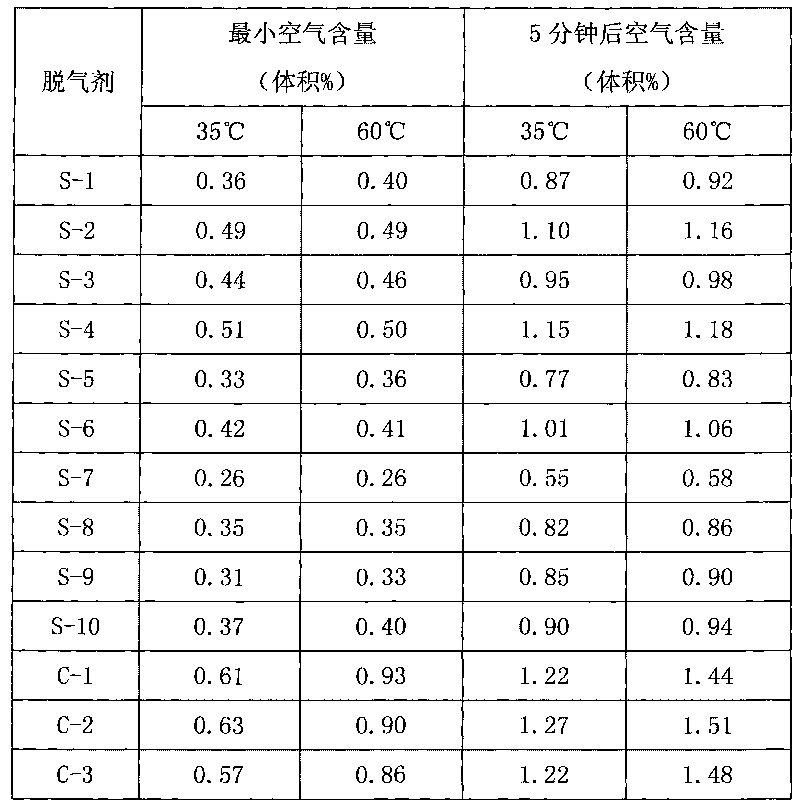

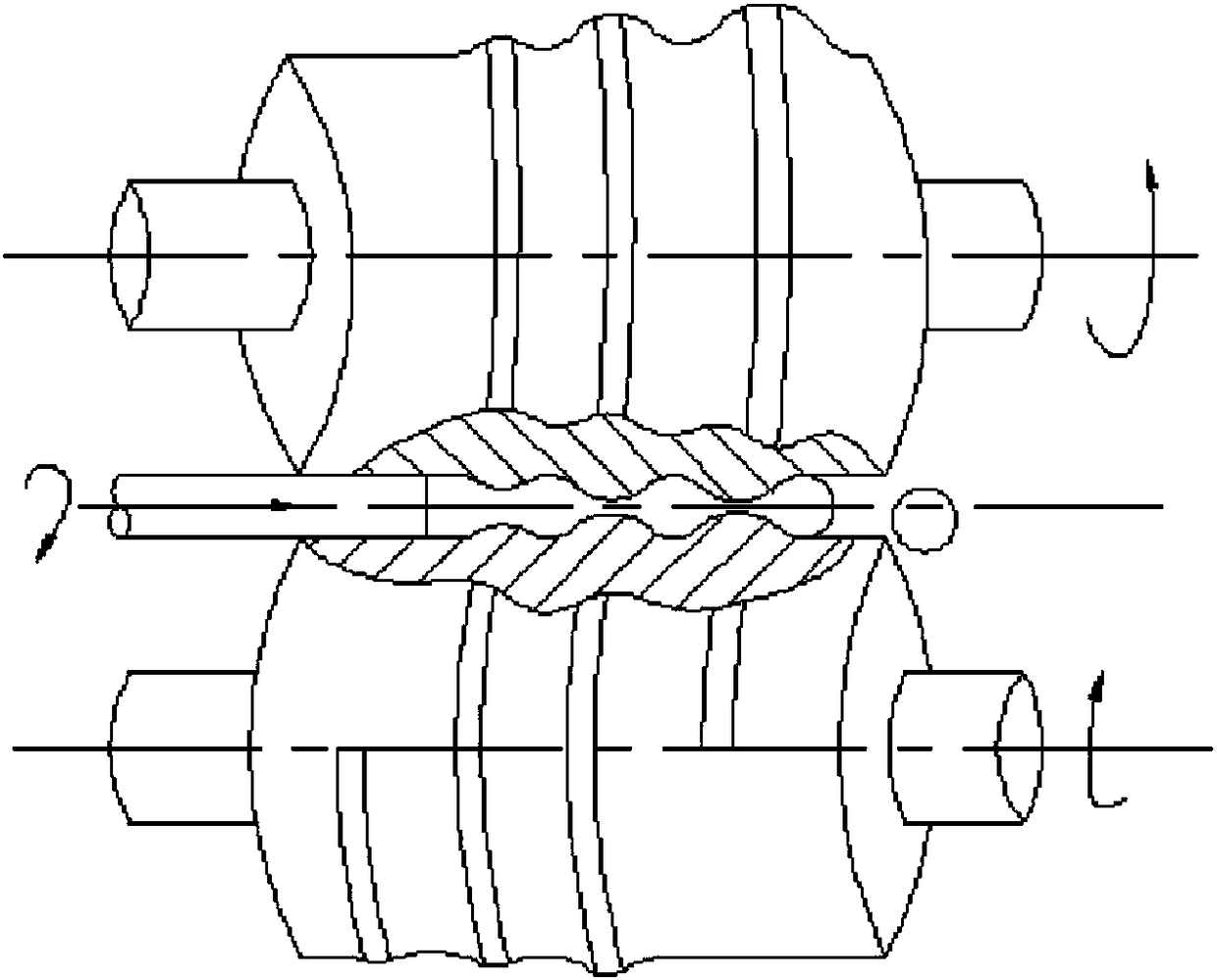

Degassing method for regenerated aluminum alloy melt

The invention belongs to the technical field of secondary metals, and in particular relates to a degassing method of a regenerated aluminum alloy melt. Gas diffusion and tension adsorption between bubble surfaces and oxide inclusions are realized through a hydrogen partial pressure difference between a degassing agent and a melt to realize degassing. The degassing method comprises one or two of in-furnace degassing and on-line degassing, wherein the in-furnace degassing adopts a conduit to inject the degassing agent into the aluminum alloy melt for degassing, and the on-line degassing is box-type rotary degassing or runner-type rotary degassing. The degassing agent is a gas or fusing agent (containing KCl, NaCl, Na3AlF6, Na2CO3, KNO3 and rare earth), the gas or gas+fusing agent is sprayedinto the aluminum alloy melt for refining, and impurities in the aluminum alloy melt are removed by a filtration method to finally obtain an aluminum alloy product with low gas content. The degassingmethod provided by the invention can effectively control the gas content of the aluminum alloy melt, and the hydrogen content of the degassed aluminum alloy melt is 0.02-0.26ml / 100gAl.

Owner:DELTA ALUMINUM IND

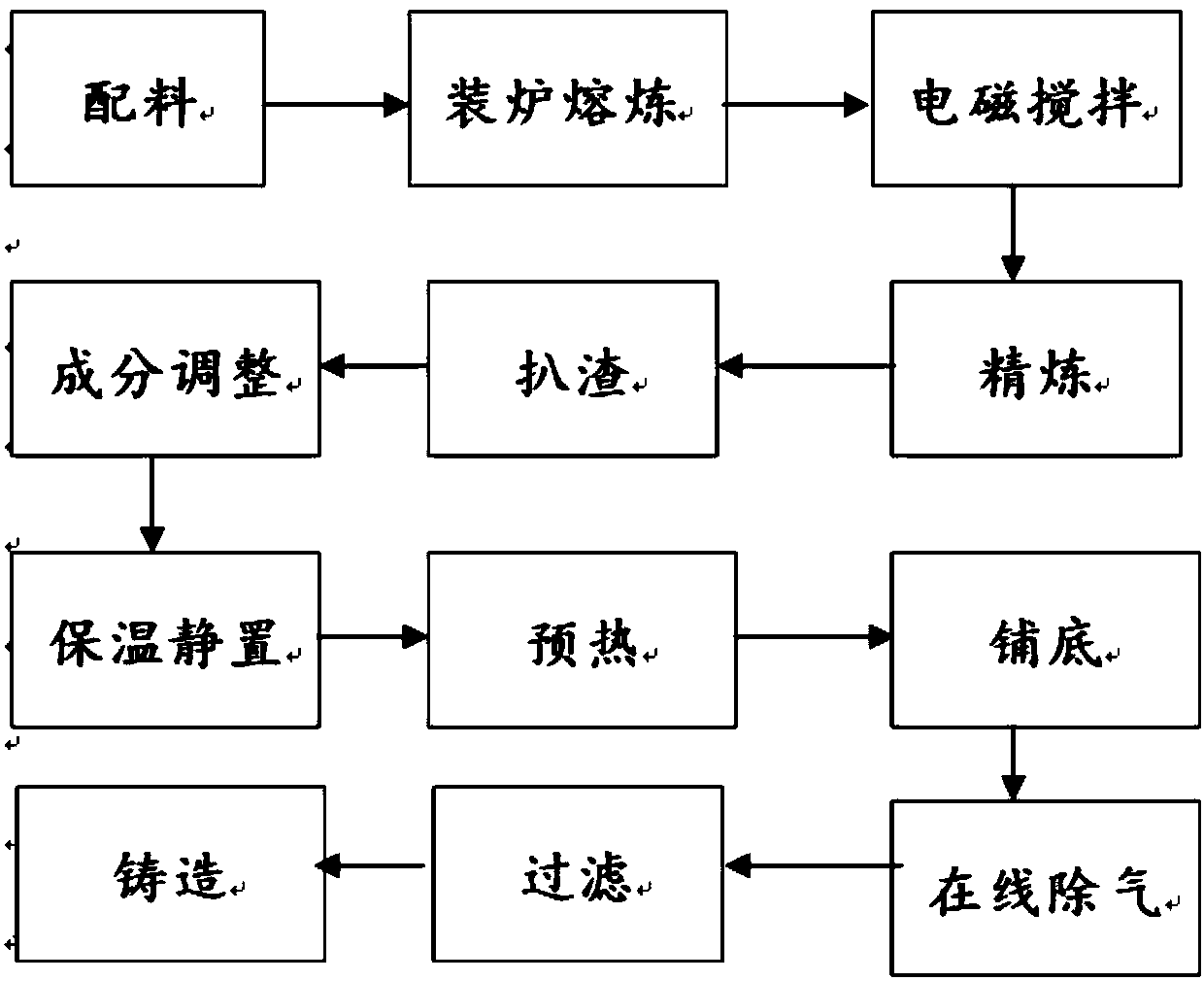

2-system aluminum alloy and smelting and casting method thereof

The invention belongs to the field of metal smelting, and relates to a 2-system aluminum alloy with high Fe and Ni content and a smelting and casting method thereof. The 2-system aluminum alloy comprises, in weight percent, 0.15-0.2% of Si, 1.4-1.6% of Fe, 1.4-1.6% of Ni, 2.6-2.8% of Cu, 1.7-1.9% of Mg, less than or equal to 0.1% of Zn, 0.06-0.09% of Ti, less than or equal to 0.1% of Mn, less thanor equal to 0.1% of Cr and the balance Al. The smelting and casting method includes the steps: performing smelting, refining, degassing, slag removal and casting on raw materials; performing castingby the aid of a semi-continuous casting process; adding 1.0-2.0% of yttrium aluminum intermediate alloys in the refining process; controlling casting temperature to be 690-700 DEG C, controlling casting speed to be 20-30mm / min, and connecting single water flow to be 15-16m<3> / h to obtain 2-system aluminum alloy cast ingots. The 2-system aluminum alloy cast ingots with high content of Fe and Ni produced by the smelting and casting method are less in shortcoming and good in heat resistance and has good economic benefits, finished product rate is increased, and energy consumption and production cost are reduced.

Owner:CHINA ZHONGWANG

System for removing hydrogen in molten aluminum

The invention discloses a system for removing hydrogen in molten aluminum. The system comprises a molten aluminum tank, a communication tube and a double-cavity type degassing tank, wherein the molten aluminum tank is communicated with the double-cavity type degassing tank by the communication tube; the double-cavity type degassing tank comprises a vacuum cavity and a molten aluminum cavity, wherein a partition plate is arranged between the vacuum cavity and the molten aluminum cavity; a through hole is formed in the middle part of the partition plate; the vacuum cavity is arranged above the molten aluminum cavity; an electromagnetic oscillating coil is arranged outside the molten aluminum cavity; a rotary drive coil is arranged outside the electromagnetic oscillating coil; a liquor taking tube is arranged on the lower part of the molten aluminum cavity; a valve is arranged on the lower part of the liquid taking tube; a gas pumping tube is arranged on the upper part of the vacuum cavity; a gas filling cavity enclosed by a ceramic filter plate and the inner wall of the molten aluminum tank is arranged inside the molten aluminum tank; a gas filling tube is arranged below the gas filling cavity; one end of the gas filling tube extends into the gas filling cavity; the other end of the gas filling tube is arranged outside the gas filling cavity. The system disclosed by the invention adopts the double-cavity type degassing tank, and integrates the technologies, such as electromagnetic driving, ultrasonic-vibration degassing, inert gas removing, spraying and degassing, degassing by centrifugal force, and vacuum degassing, so that the optimal degassing effect is achieved.

Owner:STATE GRID CORP OF CHINA +2

Microalloying wear resisting ball and preparation method and preparation system thereof

ActiveCN108588551APurifyStrong deoxygenation abilityBearing componentsFurnace typesToughnessQuenching

The invention provides a microalloying wear resisting ball and a preparation method and a preparation system thereof. The microalloying wear resisting ball comprises the following components in percentage by weight: 0.75-0.85% of C, 0.15-0.35% of Si, 0.65-0.75% of Mn, 0.4-0.5% of Cr, 0.05-0.1% of B, 0.01-0.05% of N, 0.01-0.015% of Mg, 0.05-0.15% of Ca, S not more than 0.010%, P not more than 0.015%, and the balance of Fe. The invention further discloses the preparation method of the microalloying wear resisting ball; and the preparation method comprises the steps of induction smelting-continuous casting and rolling of rods-medium-frequency induction heating-inclined rolling and rotary cutting of balls-heat treatment process (quenching+tempering). The microalloying wear resisting ball has the advantages of high strength, high toughness, simple production process and low cost.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com