A fully automatic degasser

A degasser, fully automatic technology, used in liquid degassing, mixers, electrical components, etc., can solve the problems of heavy disassembly, transfer, installation, asynchronous drilling fluid flow rate, harsh operating environment, etc. Accuracy and scientificity, the effect of expanding the oil and gas separation surface and improving the degassing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

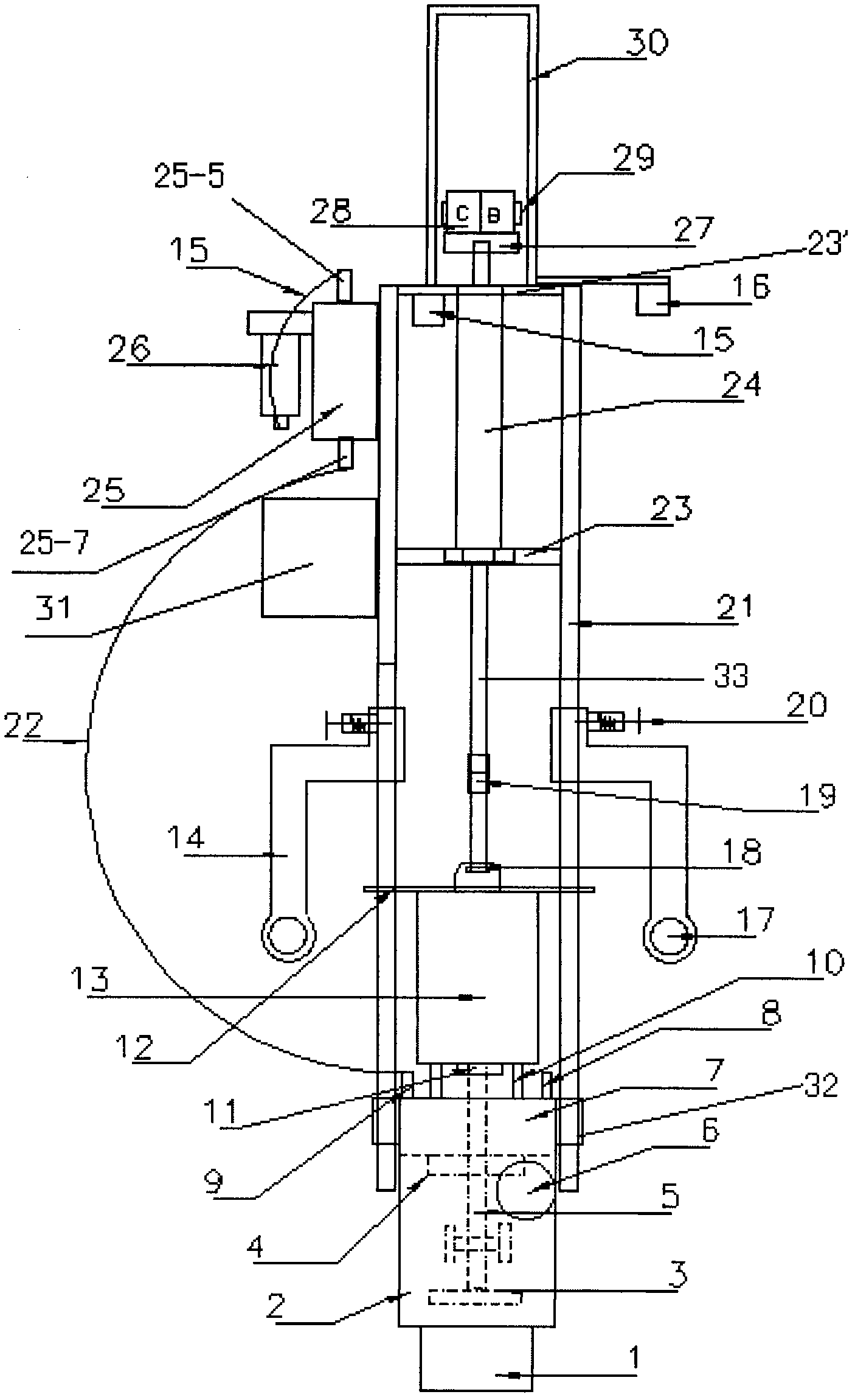

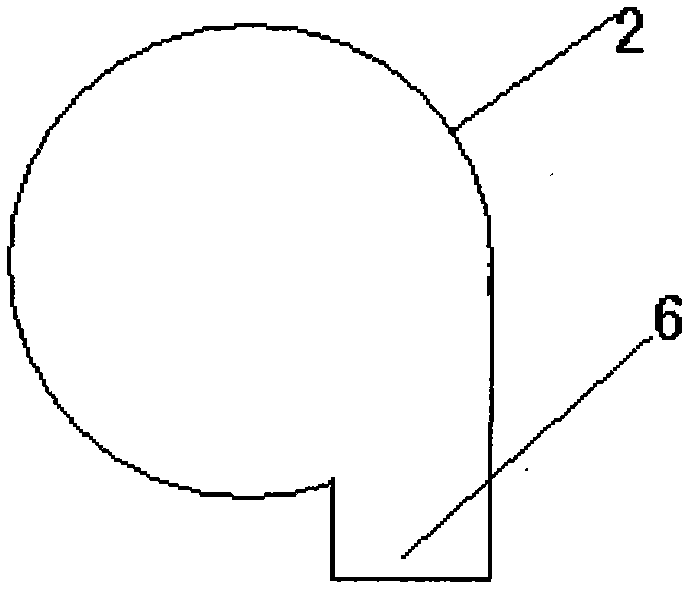

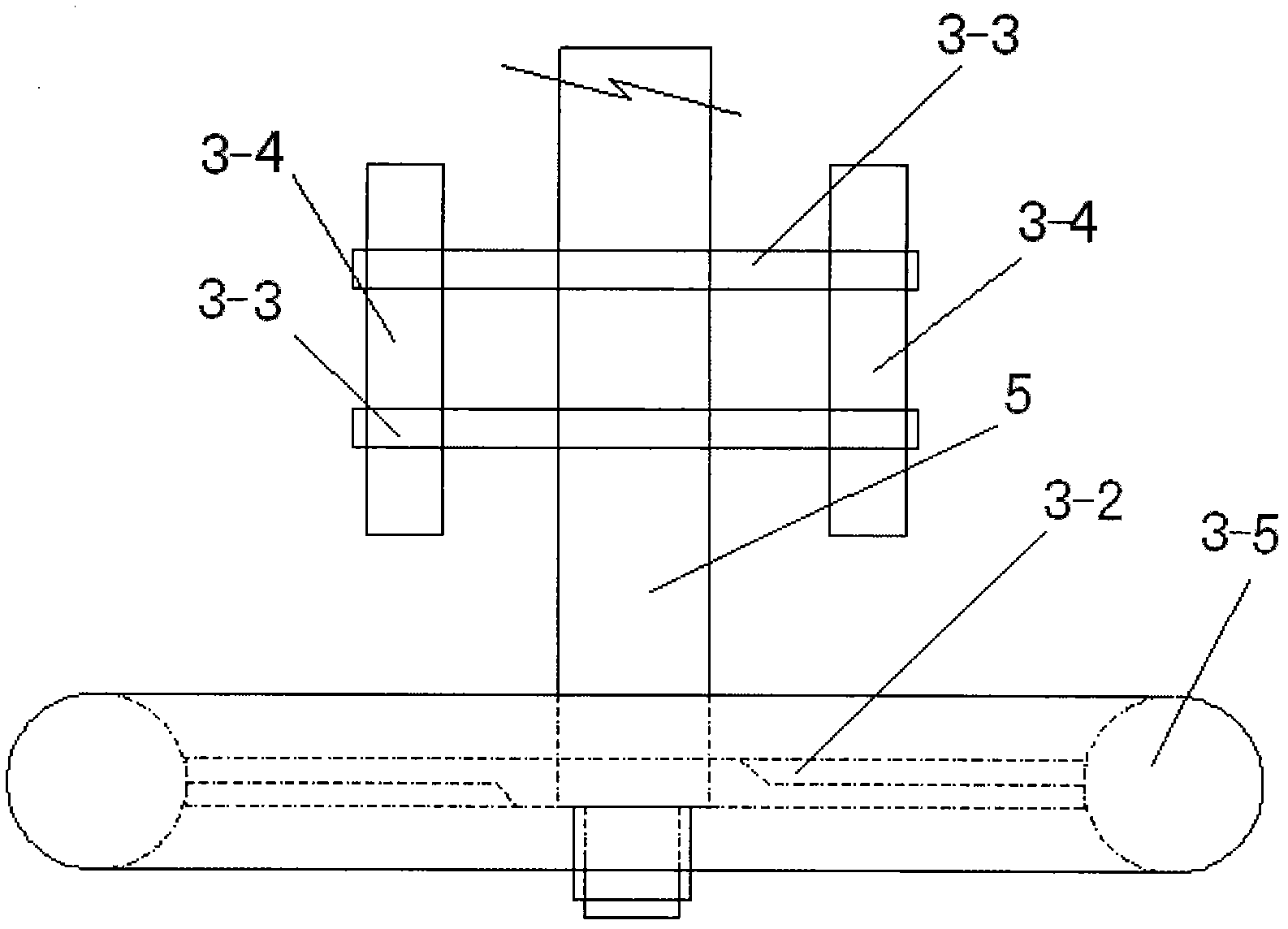

[0031] Embodiment: a kind of fully automatic degasser (see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5), it comprises degassing barrel 2, and the lower end of degassing barrel 2 is provided with mud inlet 1, and the barrel wall of degassing barrel 2 is vertically provided with mud outlet 6, and the barrel wall of mud outlet 1 and degassing barrel 2 is tangent. The degassing barrel 2 is provided with a stirring and crushing device 3, the stirring and crushing device 3 includes a stirring shaft 5, the middle part of the stirring shaft 5 is connected with a fixed plate 3-3, and the two ends of the fixed plate 3-3 are provided with a crushing rod 3-4, and the stirring The lower end of the shaft 5 is connected with the drainage impeller 3-2, and the drainage impeller 3-2 is connected with the circular stabilization ring 3-5. The upper part of the degassing barrel 2 is provided with an air chamber 7, the lower end of the air chamber 7 is provided with a mud baffle 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com