Oil tanker ballast water management system installing and design method

A management system and design method technology, applied in water treatment equipment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing system manufacturing costs and potential safety hazards, increasing ballast pump load, troublesome construction process, etc. To achieve the effect of solving the need for explosion protection, reducing pressure loss and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

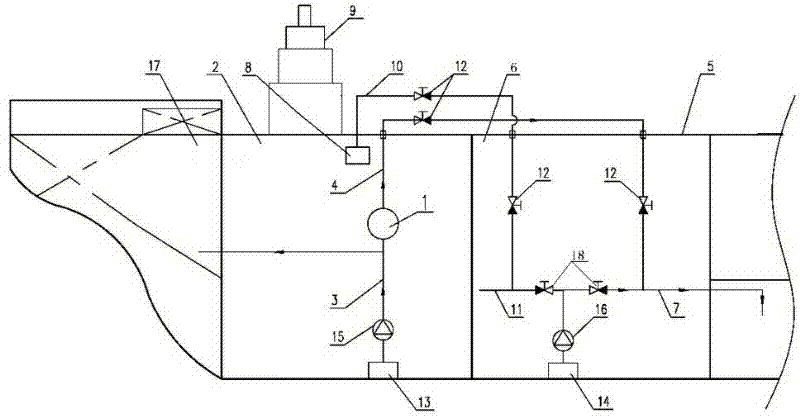

[0014] see figure 1 , for a 76,000-ton oil tanker, the method of the present invention is adopted to install the electrolysis unit 1 of the ballast water management system in the engine room 2, and the electrolysis unit 1 takes water from the main seawater pipeline 3 of the engine room, and the sodium hypochlorite solution produced after electrolysis is used for dosing The pipeline 4 passes upwards through the main deck 5, runs horizontally above the main deck to the top of the pump room 6, and then passes down through the main deck 5 and injects into the ballast water main pipeline 7 of the pump room 6 to realize active substance dosing.

[0015] The neutralization unit 8 of the ballast water management system is also installed in the engine room 2, and the dosing pipeline 10 of the neutralization unit 8 is the same as the dosing pipeline of the electrolysis unit 1, passes through the main deck 5 upwards, and is horizontal on the main deck 5 Take the pipe to the top of the p...

Embodiment 2

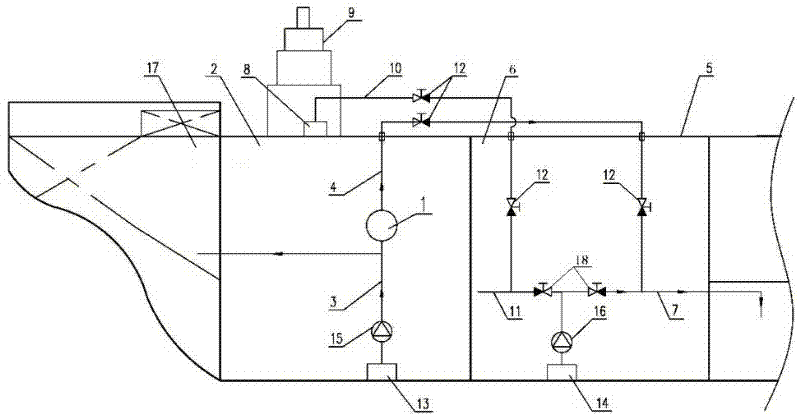

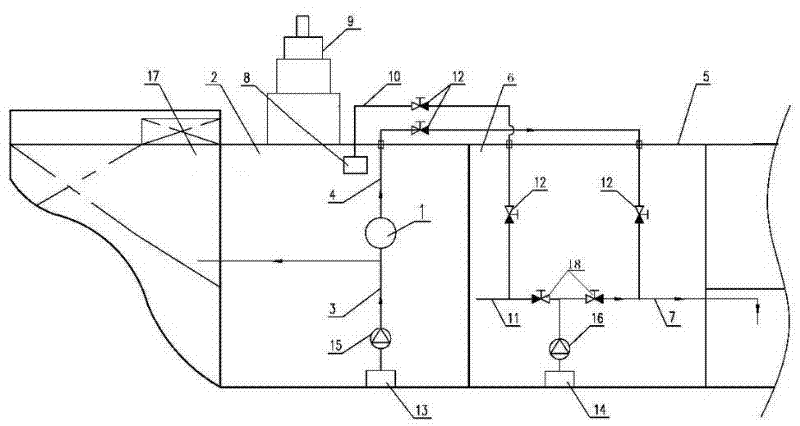

[0019] see figure 2 , for a 300,000-ton oil tanker, the method of the present invention is adopted to install the electrolysis unit 1 of the ballast water management system in the engine room 2, and the electrolysis unit 1 takes water from the main seawater pipeline 3 of the engine room, and the sodium hypochlorite solution produced after electrolysis is added. The drug pipeline 4 passes through the main deck 5 upwards, and runs horizontally on the main deck to the top of the pump room 6, and then passes down through the main deck 5 and injects into the ballast water main pipeline 7 of the pump room 6 to realize activity. Dosing of substances.

[0020] The neutralization unit 8 of the ballast water management system is installed on the superstructure 9, and the dosing pipeline 10 of the neutralization unit 8 is routed horizontally above the main deck 5 to the top of the pump room 6, and then injected downward through the main deck 5 The ballast water drainage main pipeline 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com