Explosion-proof scale cleaning tool for wave guide tube of radar liquid level gauge of floating-roof oil tank

A technology of radar liquid level gauge and floating roof oil tank, which is applied in the direction of cleaning methods and appliances, cleaning hollow objects, chemical instruments and methods, etc., and can solve the problems of inability to implement dynamic monitoring of oil storage tanks, low accuracy of scale cleaning in operation, and cleaning Insufficient scaling effect and other problems, to achieve the effect of ensuring accuracy, short cleaning time and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment the present invention is further described.

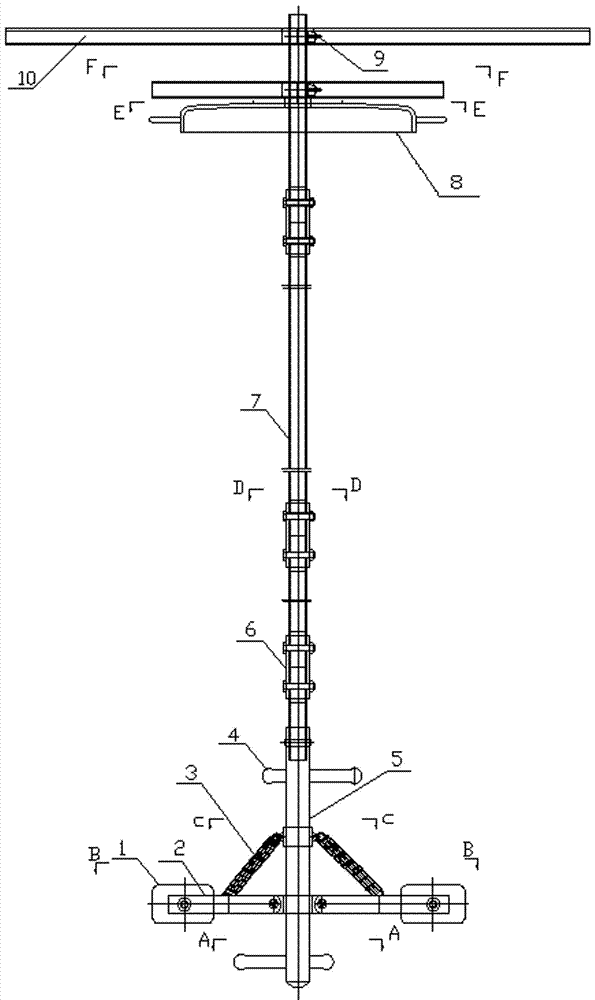

[0031] Such as Figure 1-Figure 9 As shown, a floating roof oil tank radar level gauge waveguide anti-explosion descaling tool, which includes a rotating descaling part, an extension rod part, an operating platform part and an operating handle part;

[0032] The extension rod part includes an extension rod 7, one end of the extension rod 7 is connected to the rotating descaling part, and the other end of the extension rod 7 passes through the operation platform part and extends out of the waveguide to connect with the operation handle part. connected;

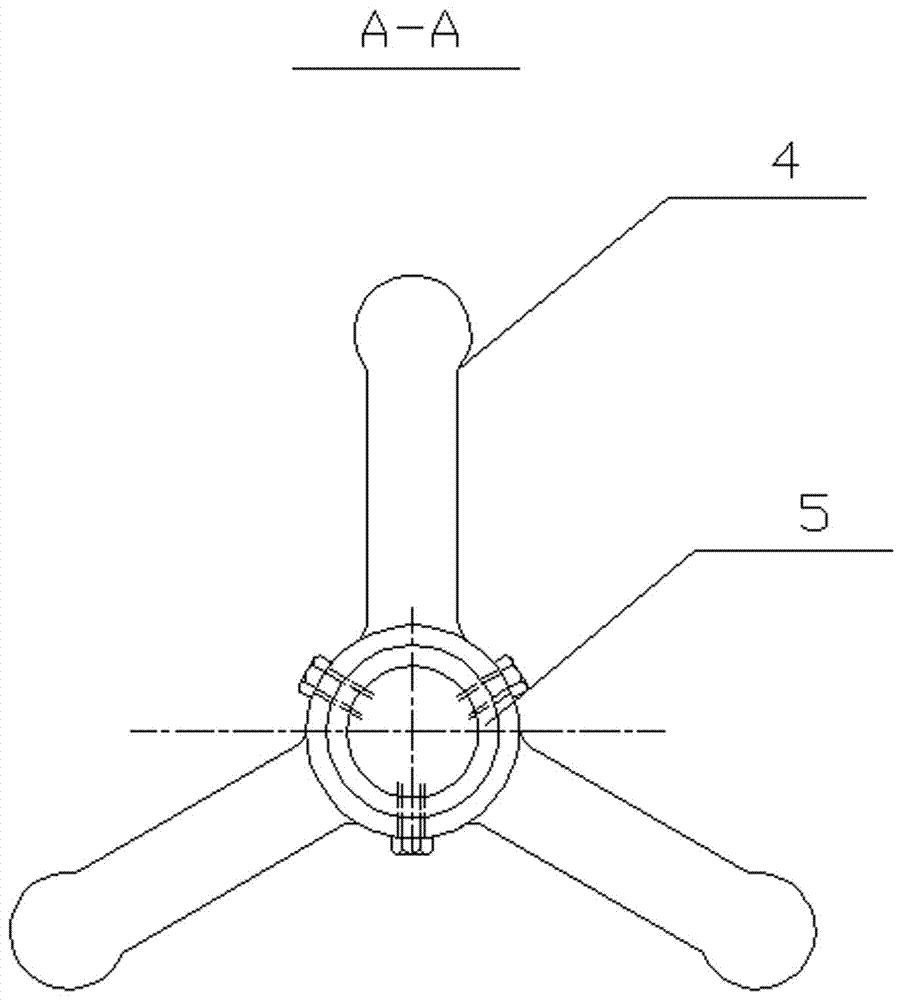

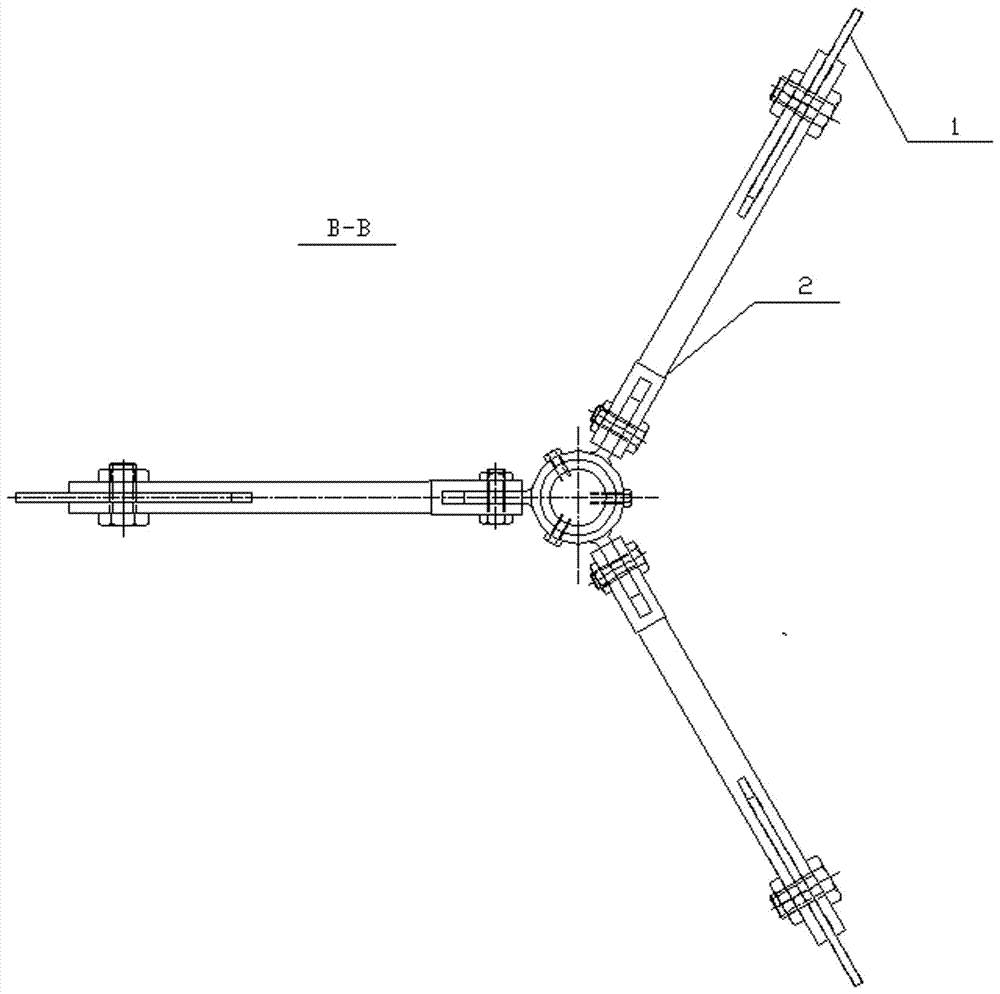

[0033] refer to figure 1 , image 3 ,, Figure 4 , the rotating cleaning part includes a rotating center rod 5, which is plugged with the extension rod 7 and fixed in a detachable manner. Several rotating center rods are hinged on the peripheral surface of the rotating center rod 5. 5. Axis center symmetrical connection support 2, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com