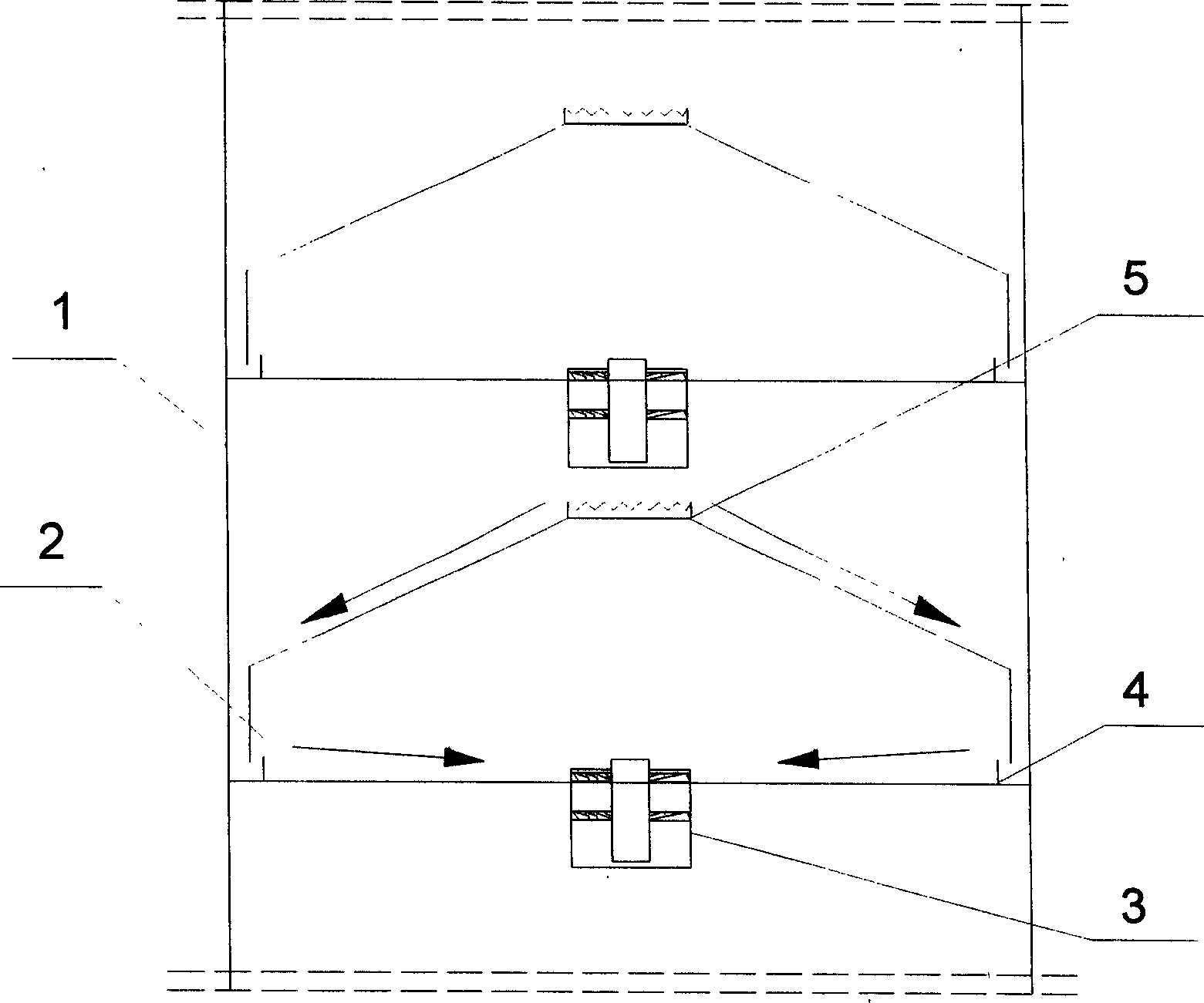

Pyramidal laying liquid typed high performance mass transfer tray with central downcast pipe

A downcomer and mass transfer tower technology, which is applied in the field of central downcomer cone liquid distribution type high-efficiency mass transfer trays, can solve the problem of uneven distribution of gas-liquid flow, low mass transfer efficiency of trays, and occupied tray area Large and other problems, to achieve the effect of increasing the effective area of the tray, improving the uniformity of gas-liquid flow, and improving the flux of the tray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] The present invention will be further explained in conjunction with the drawings:

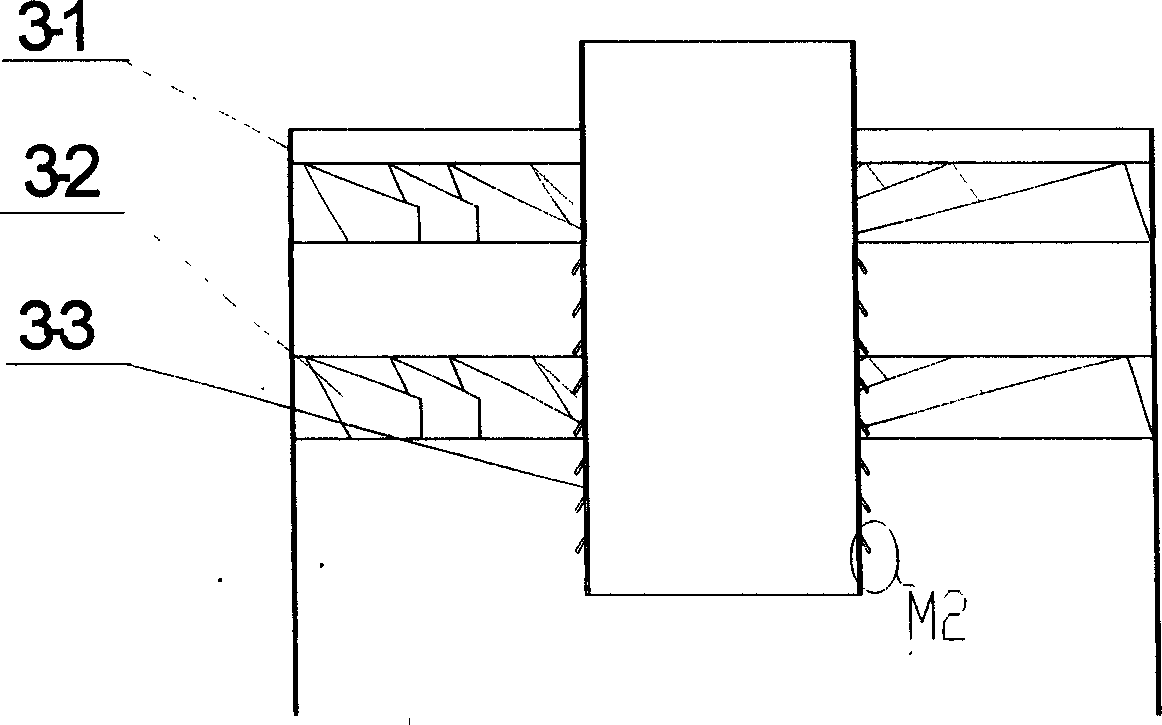

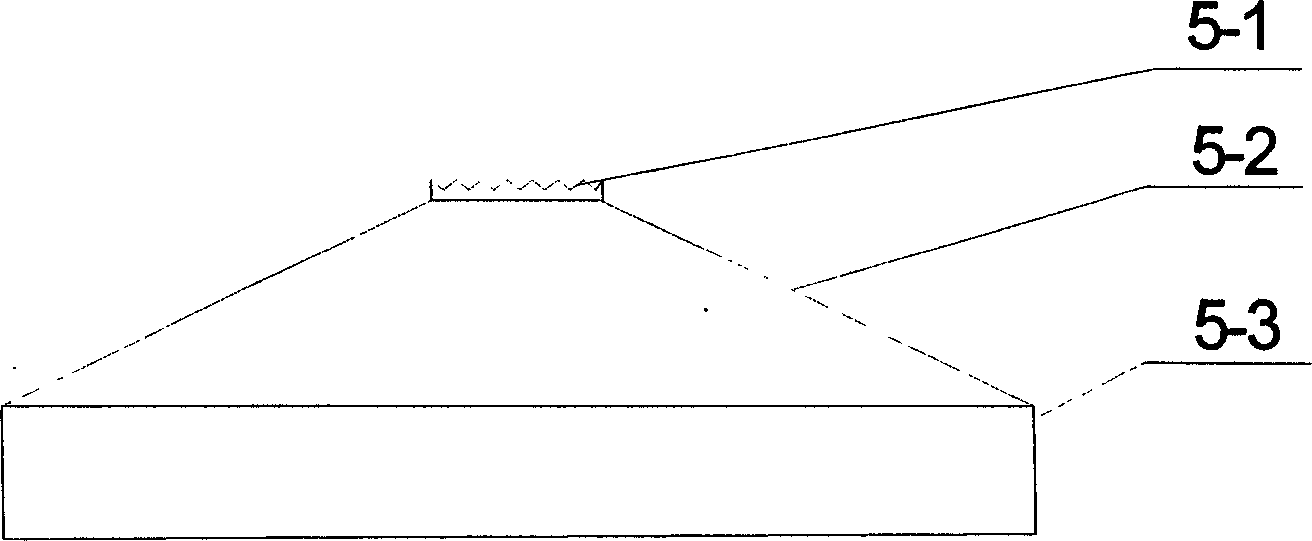

[0014] Now take the float valve tray with a tower diameter of 2000mm and a plate spacing of 550mm, and the use of the tray of the present invention to transform old float valve trays as an example to illustrate the present invention in detail: a cone dispenser with a flat-top blind plate in the center The diameter of the central blind plate is 400mm, and the distance between it and the lower end of the downcomer on the upper tray is 50mm; the height of the zigzag overflow weir is 30mm, the tooth depth is 10mm, and the tooth shape is equilateral triangle; The angle between the cone and the horizontal is 20 degrees. The horizontal projection diameter of the cone liquid distributor of the central flat-top blind plate is 1840mm. The cone liquid distributor is provided with a circular hole with a diameter of 20mm, arranged in a regular triangle, and the opening rate is 40%; the cylinder diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com