Patents

Literature

847 results about "Micromachinings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

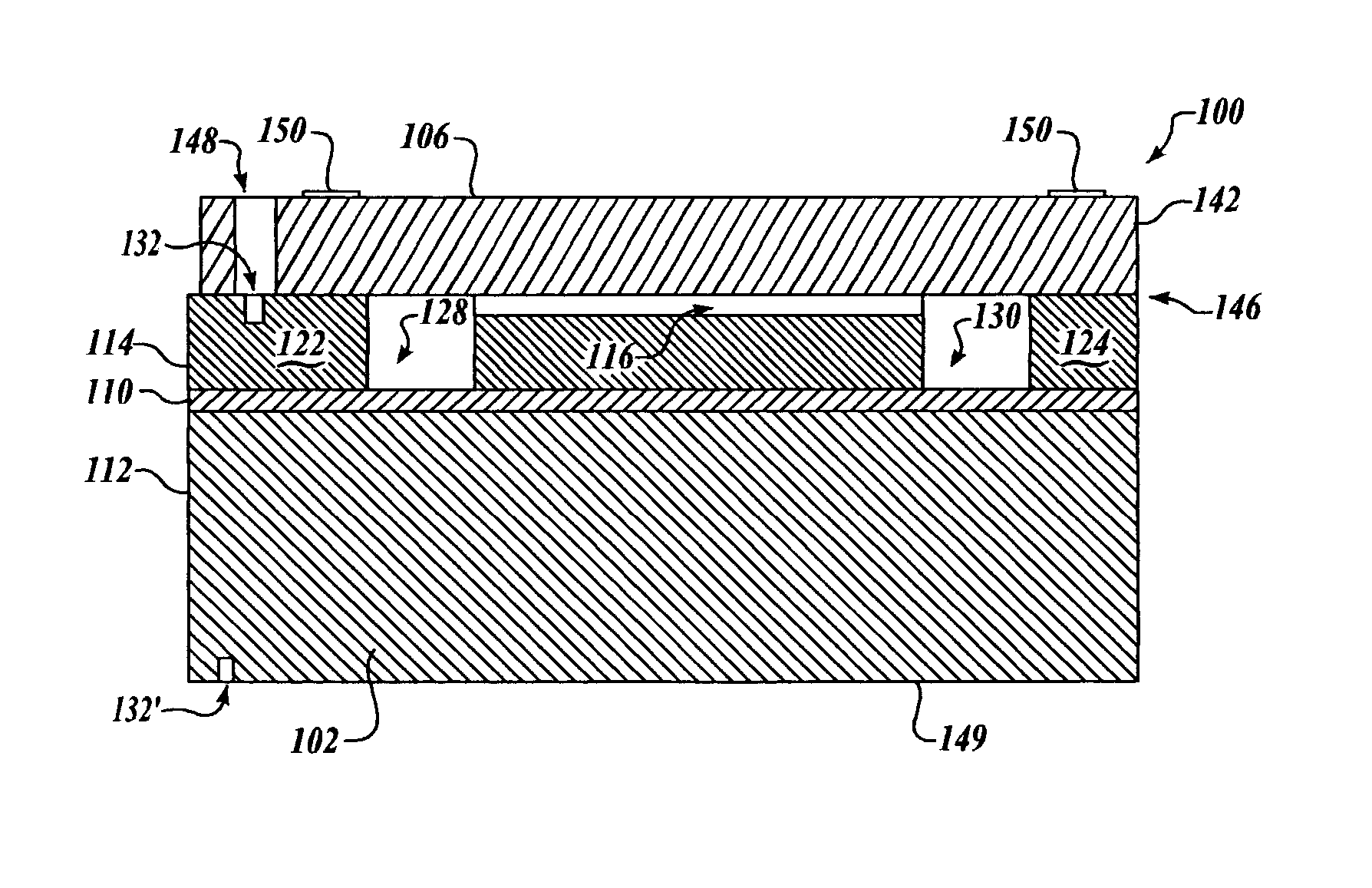

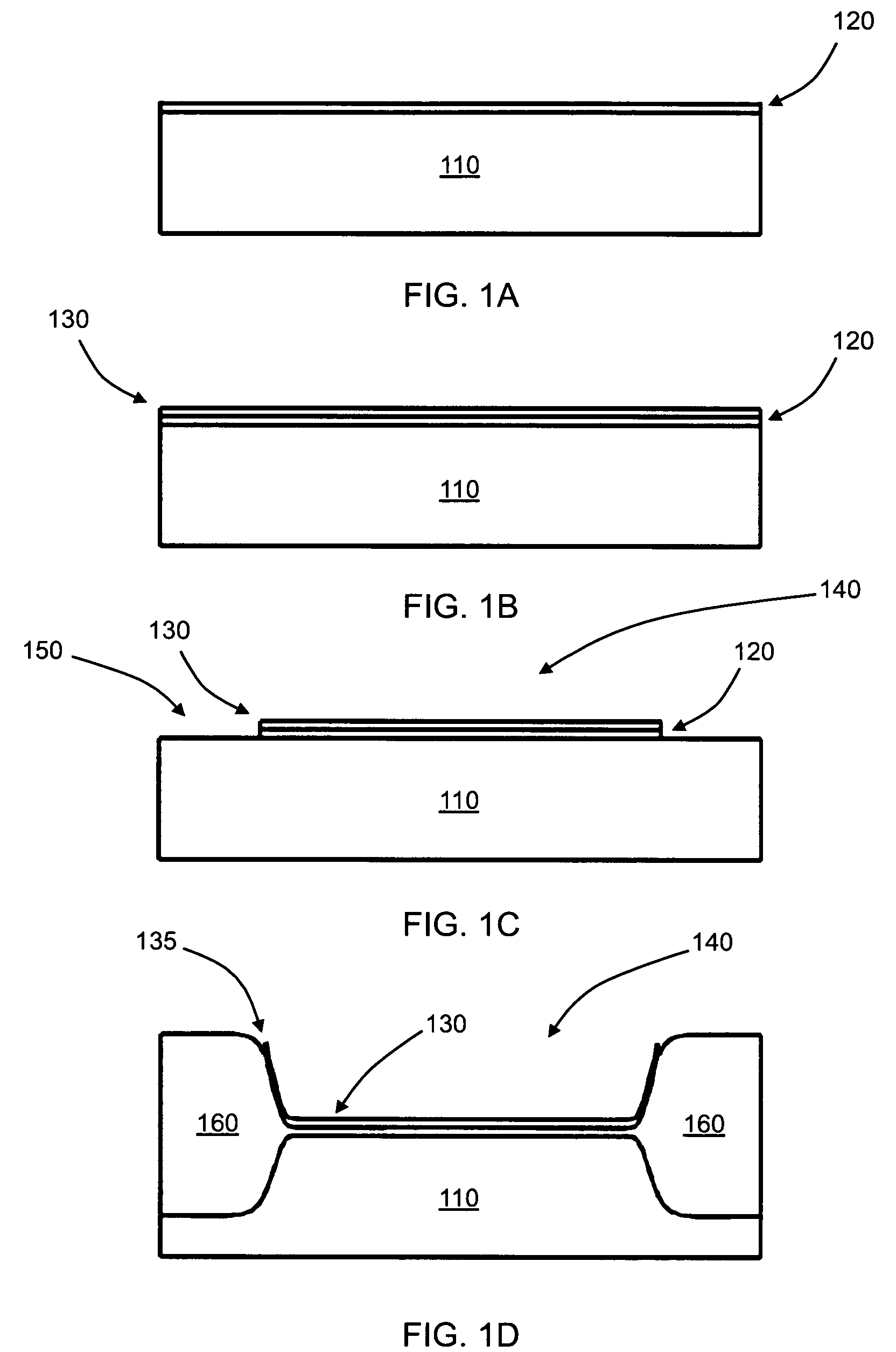

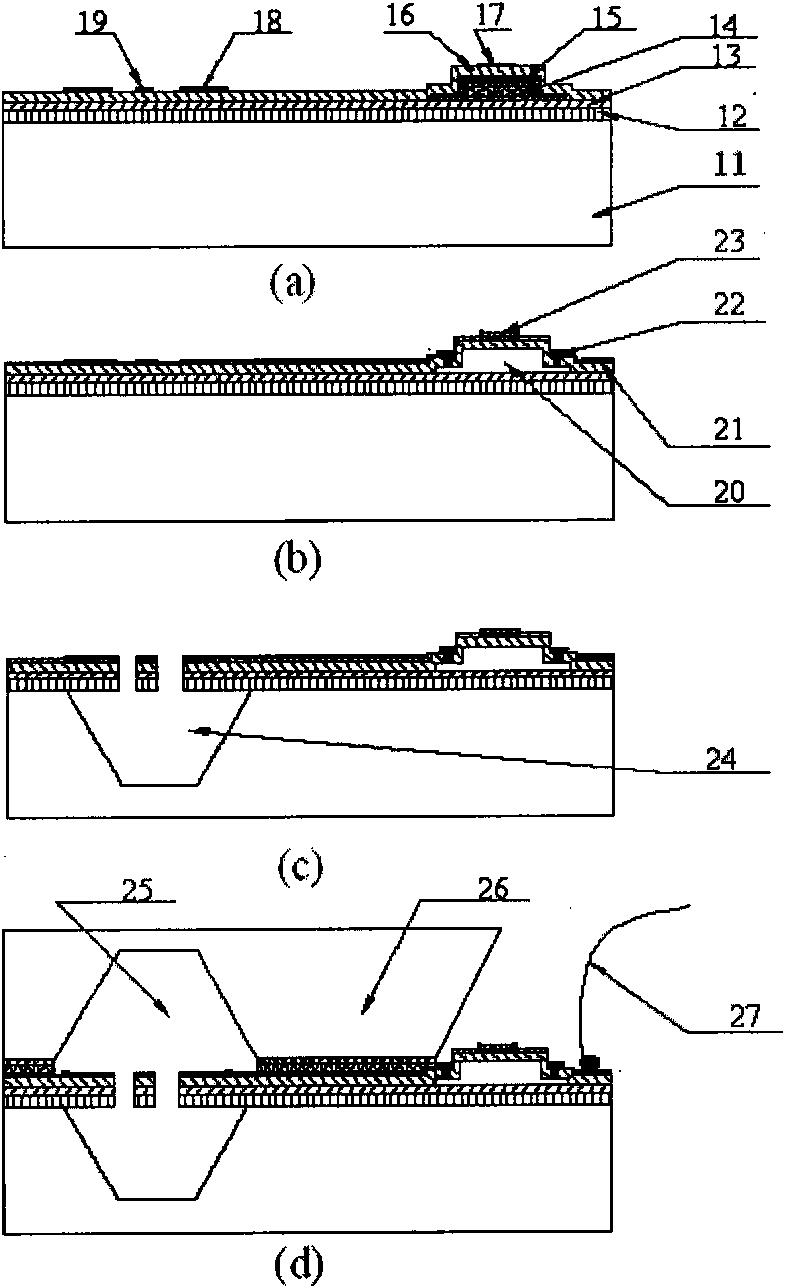

Method of manufacturing vibrating micromechanical structures

A method for fabrication of single crystal silicon micromechanical resonators using a two-wafer process, including either a Silicon-on-insulator (SOI) or insulating base and resonator wafers, wherein resonator anchors, a capacitive air gap, isolation trenches, and alignment marks are micromachined in an active layer of the base wafer; the active layer of the resonator wafer is bonded directly to the active layer of the base wafer; the handle and dielectric layers of the resonator wafer are removed; viewing windows are opened in the active layer of the resonator wafer; masking the single crystal silicon semiconductor material active layer of the resonator wafer with photoresist material; a single crystal silicon resonator is machined in the active layer of the resonator wafer using silicon dry etch micromachining technology; and the photoresist material is subsequently dry stripped.

Owner:HONEYWELL INT INC

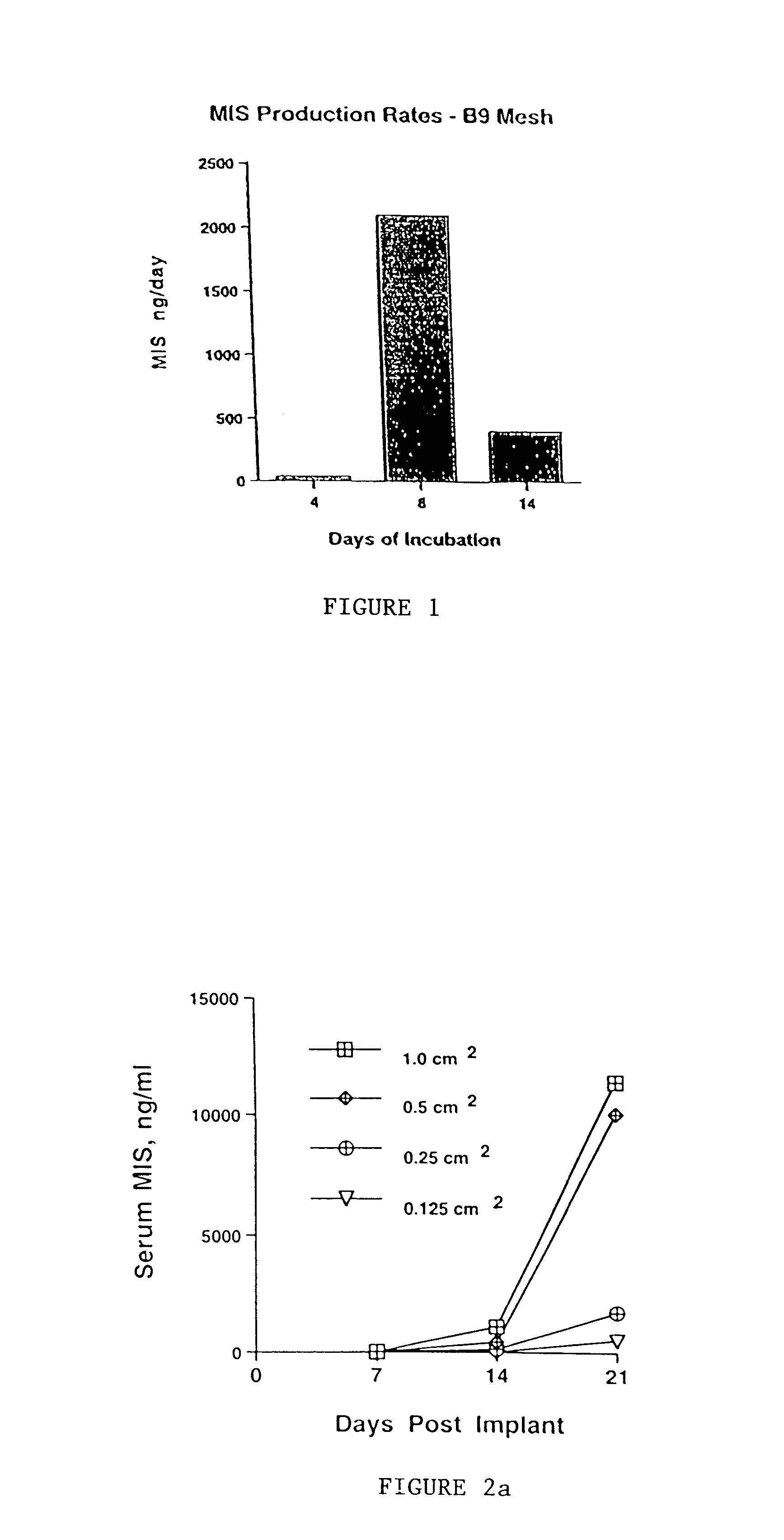

Delivery of therapeutic biologicals from implantable tissue matrices

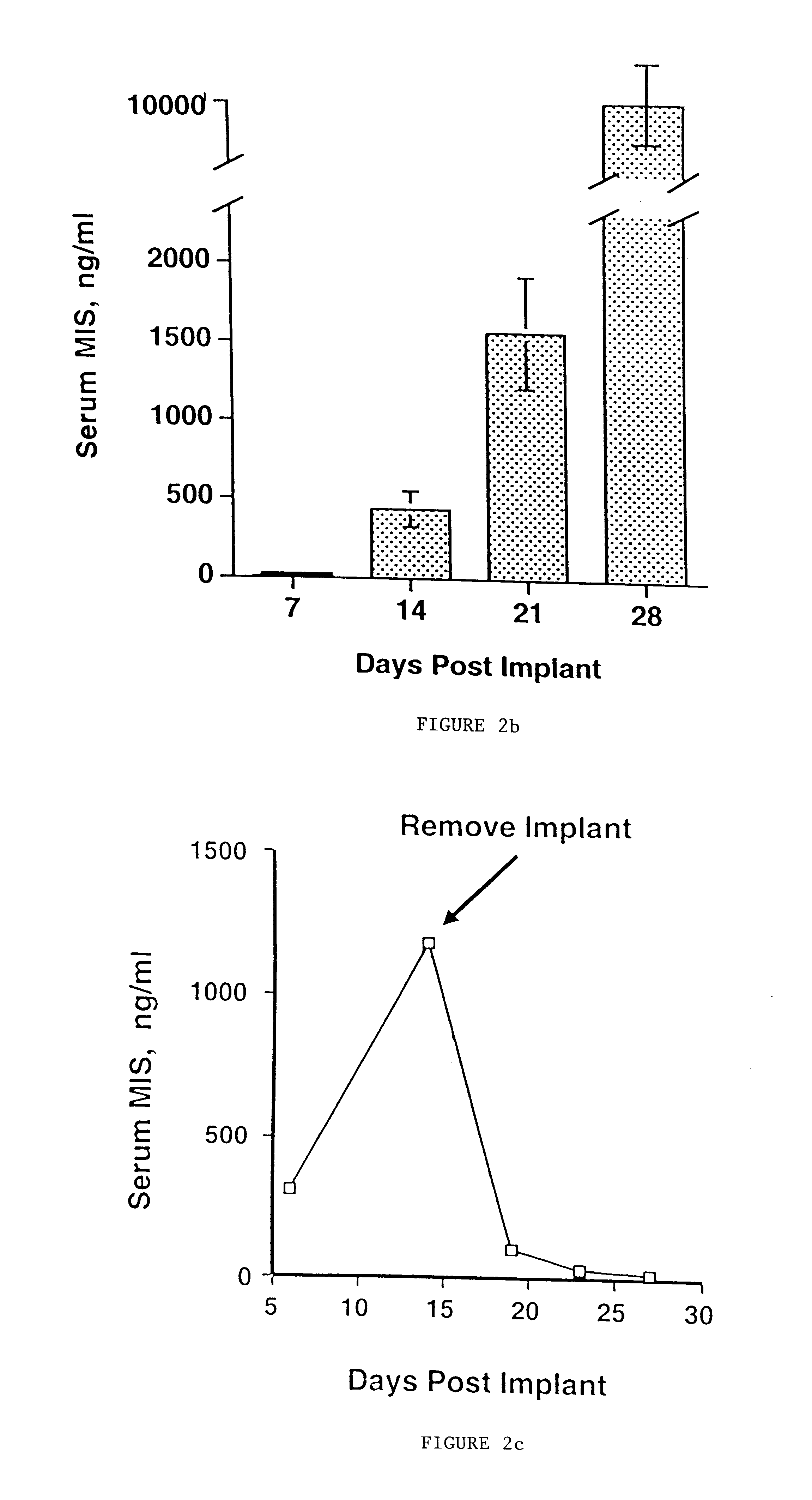

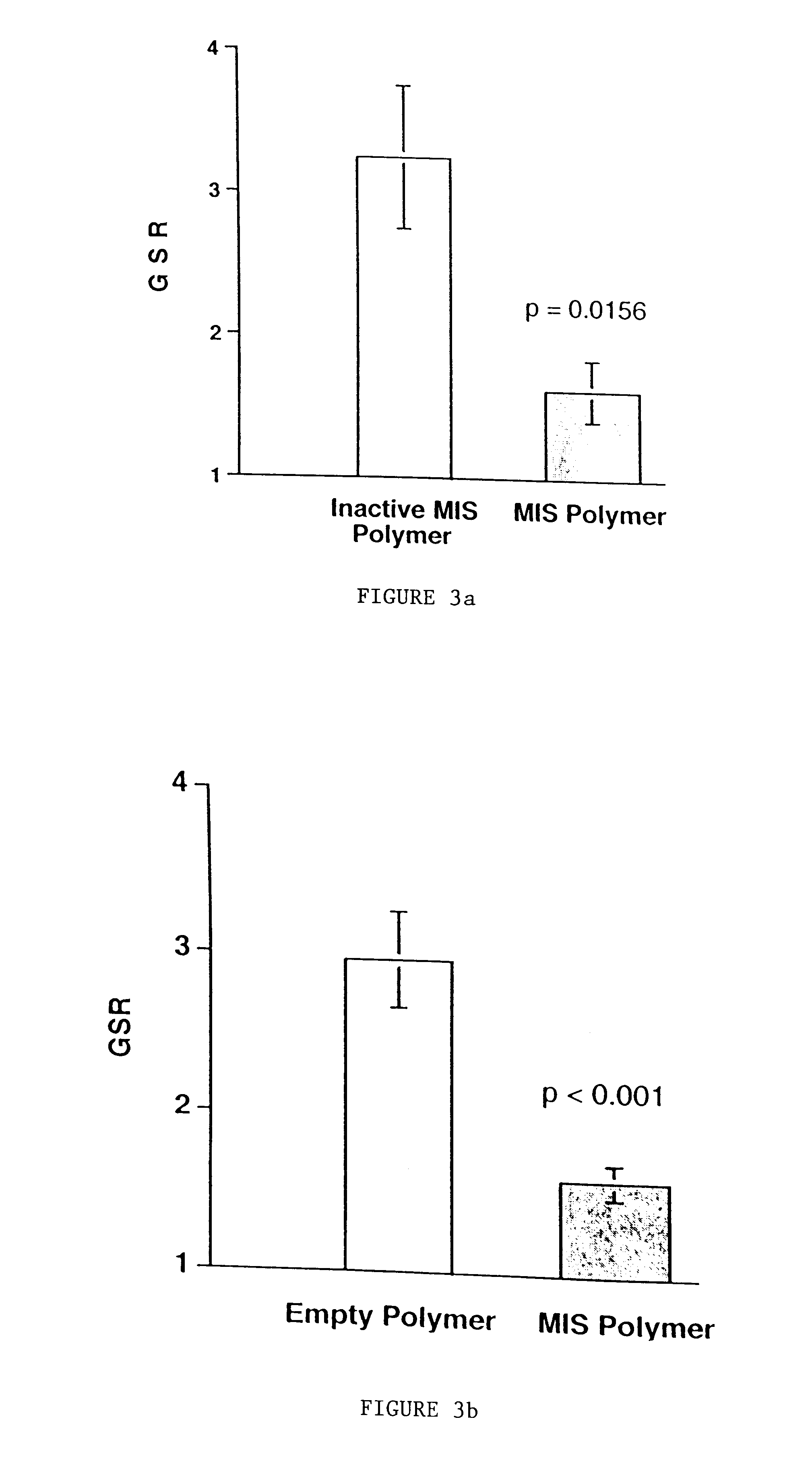

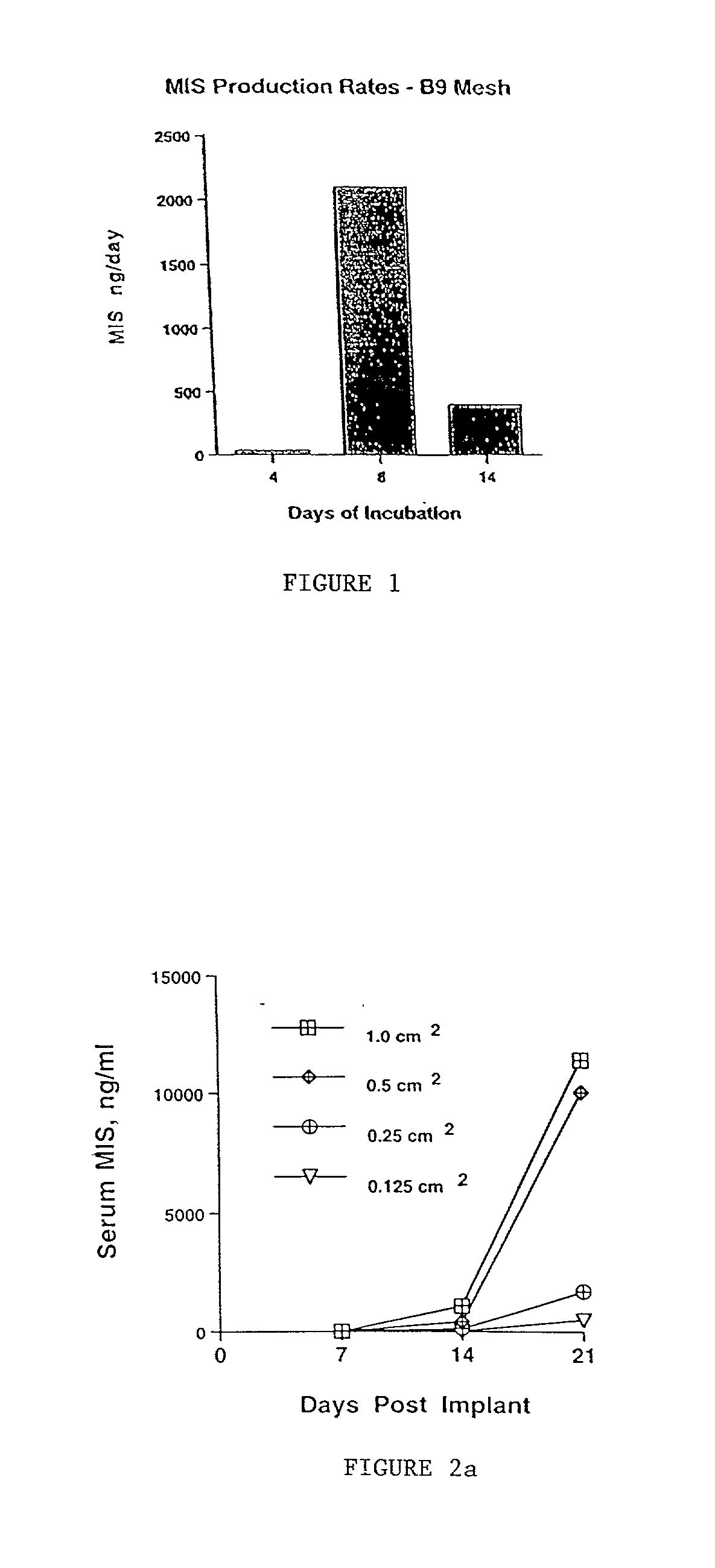

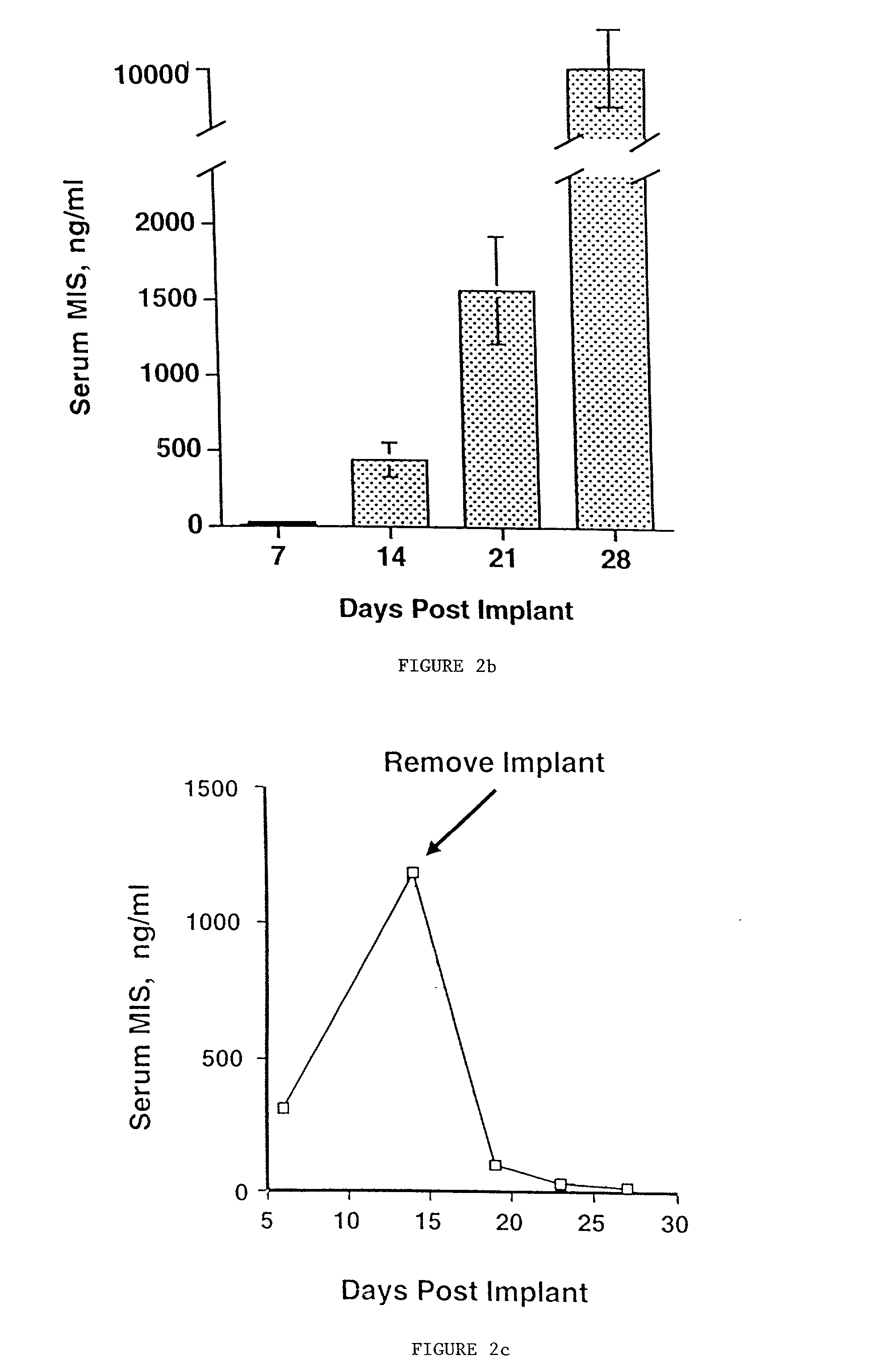

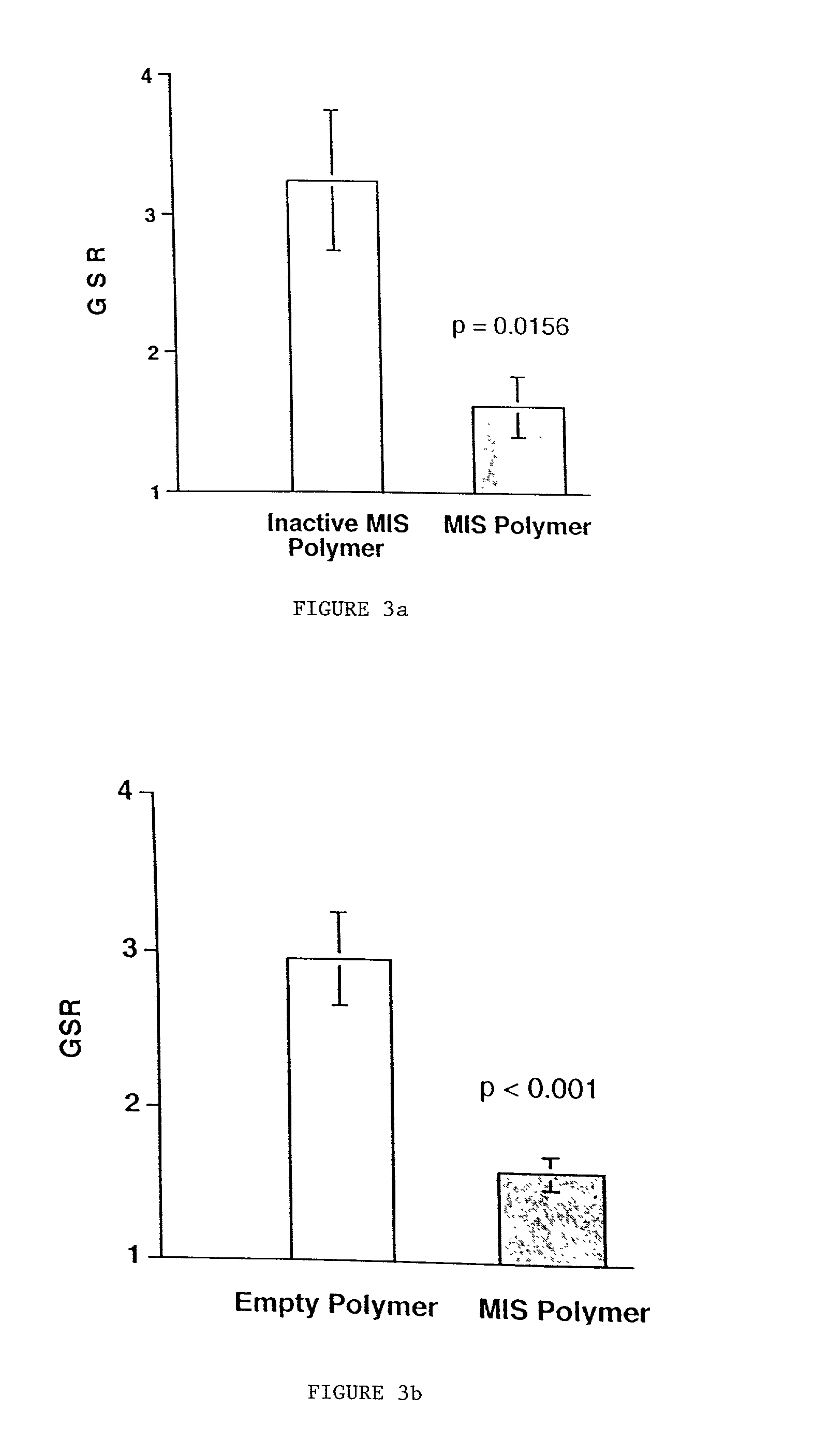

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

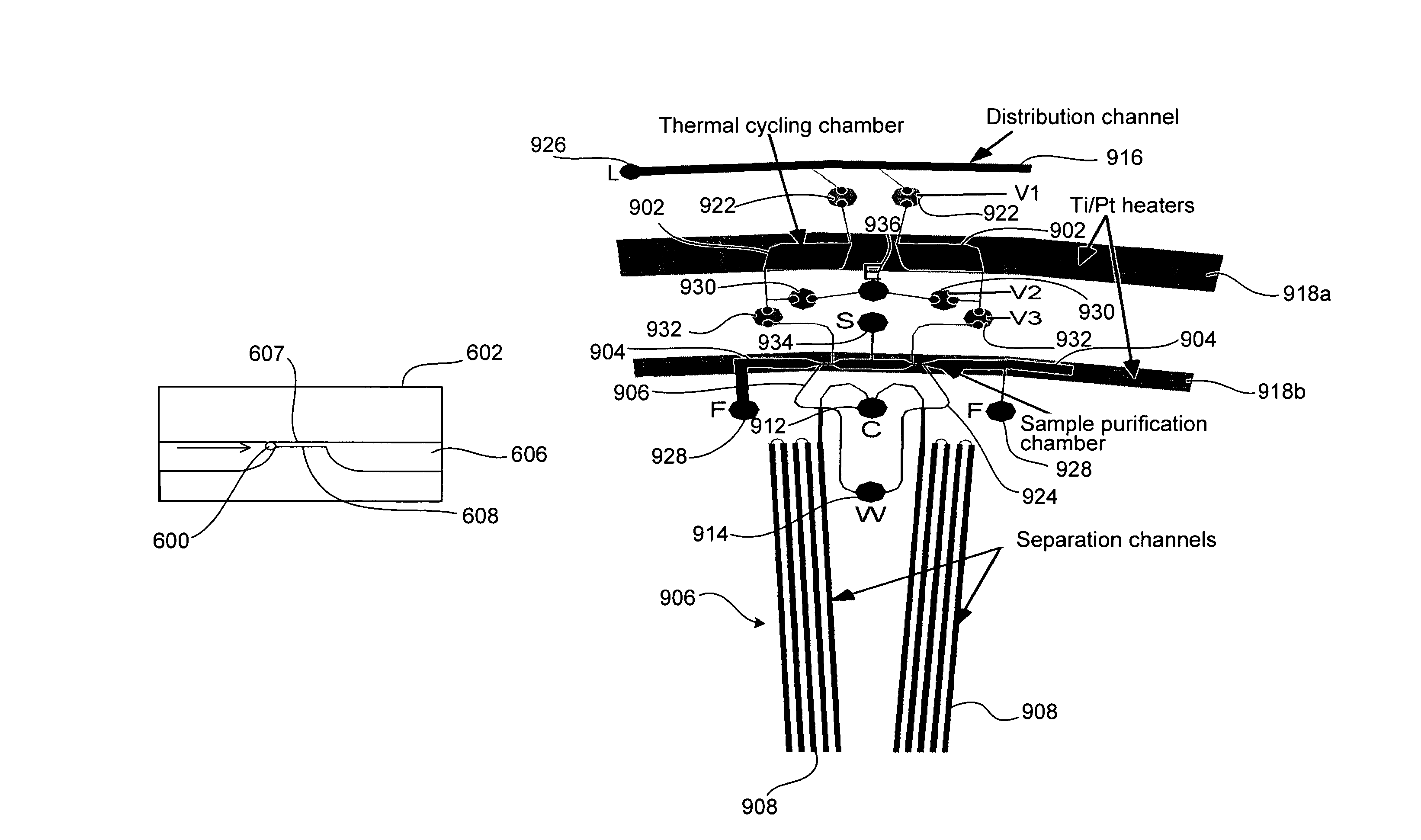

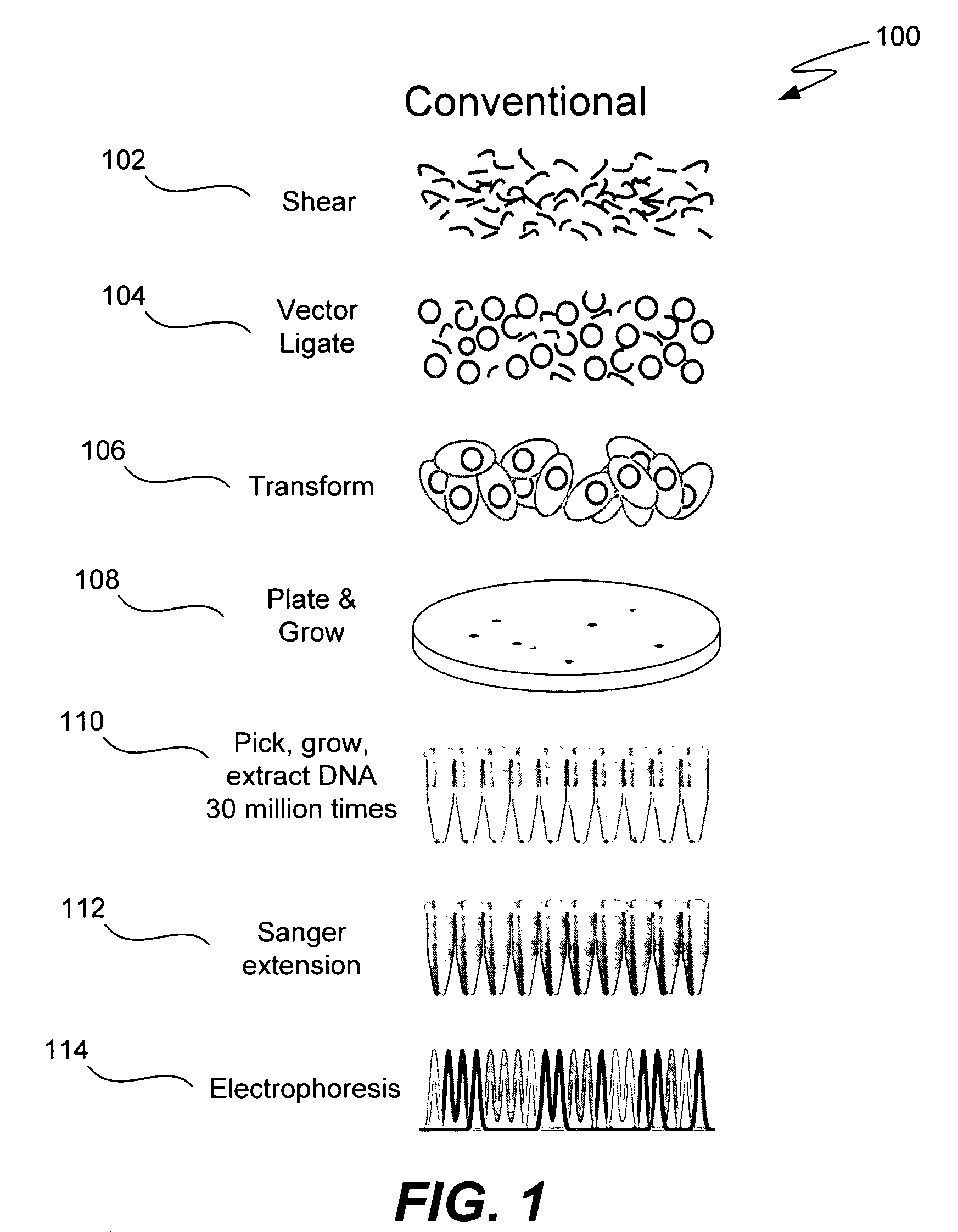

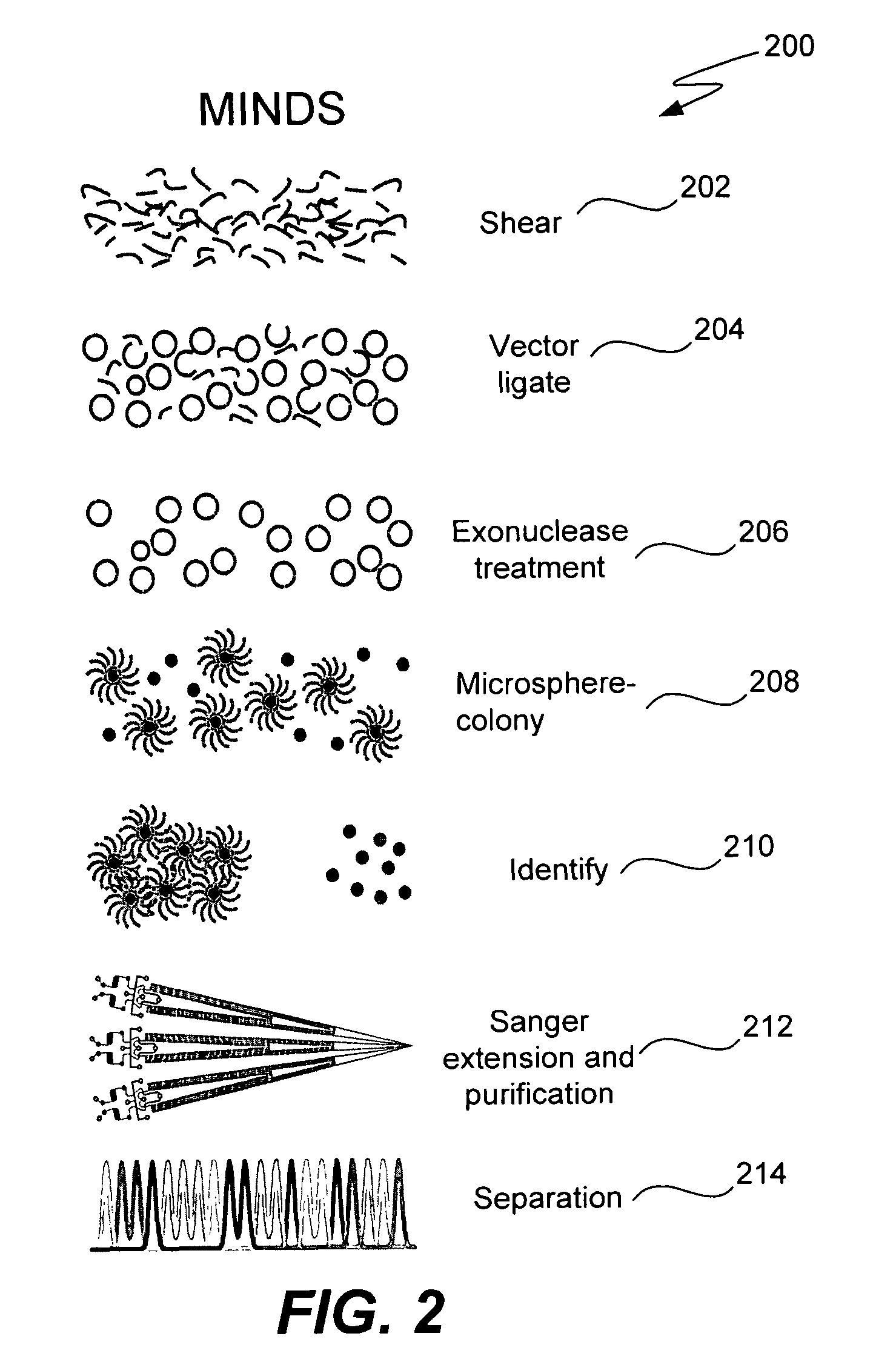

Microfabricated integrated DNA analysis system

ActiveUS7799553B2Improve automationBig spaceBioreactor/fermenter combinationsElectrolysis componentsMicroreactorMicrosphere

Methods and apparatus for genome analysis are provided. A microfabricated structure including a microfluidic distribution channel is configured to distribute microreactor elements having copies of a sequencing template into a plurality of microfabricated thermal cycling chambers. A microreactor element may include a microcarrier element carrying the multiple copies of the sequencing template. The microcarrier element may comprise a microsphere. An autovalve at an exit port of a thermal cycling chamber, an optical scanner, or a timing arrangement may be used to ensure that only one microsphere will flow into one thermal cycling chamber wherein thermal cycling extension fragments are produced. The extension products are captured, purified, and concentrated in an integrated oligonucleotide gel capture chamber. A microfabricated component separation apparatus is used to analyze the purified extension fragments. The microfabricated structure may be used in a process for performing sequencing and other genetic analysis of DNA or RNA.

Owner:RGT UNIV OF CALIFORNIA

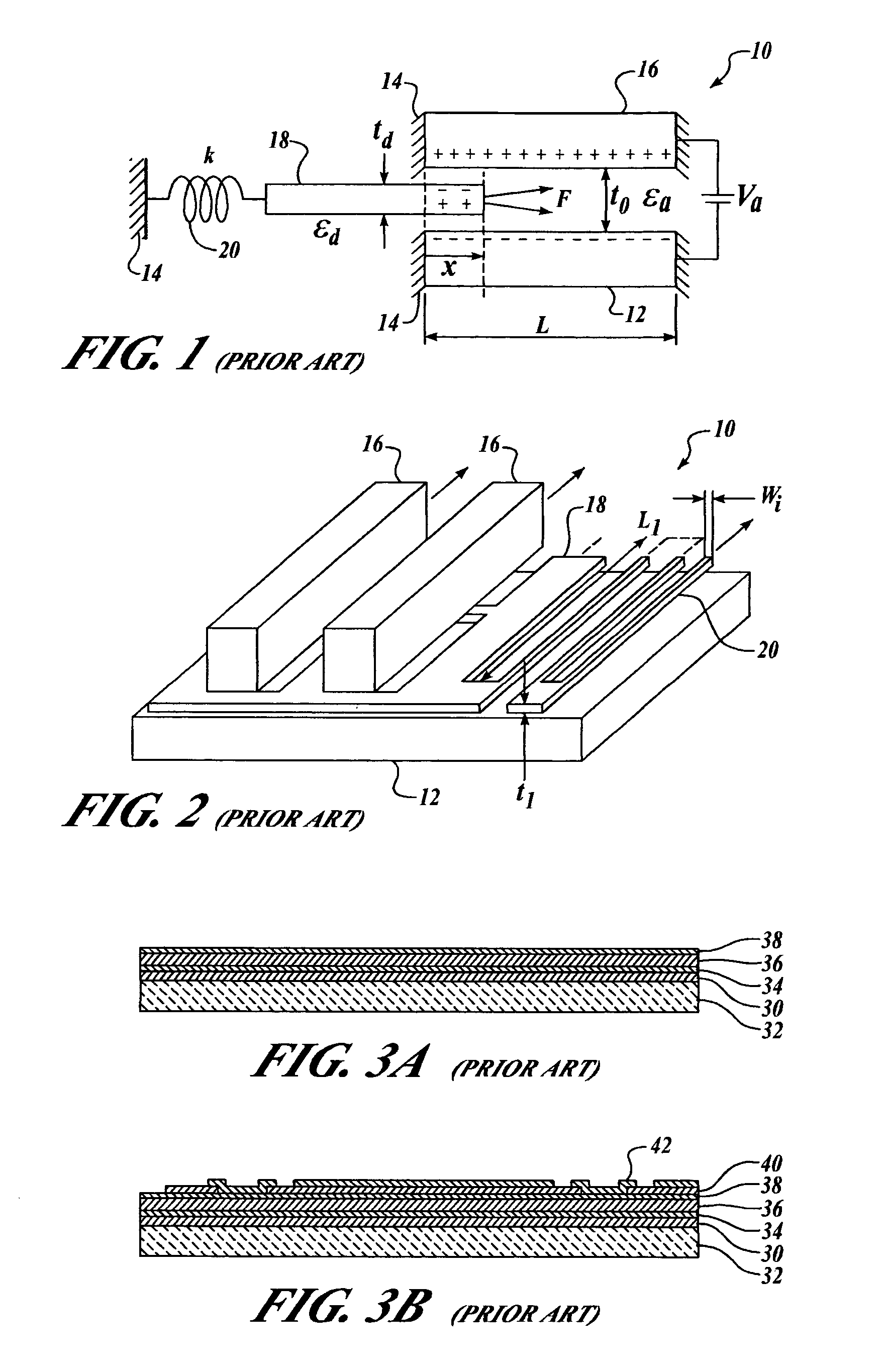

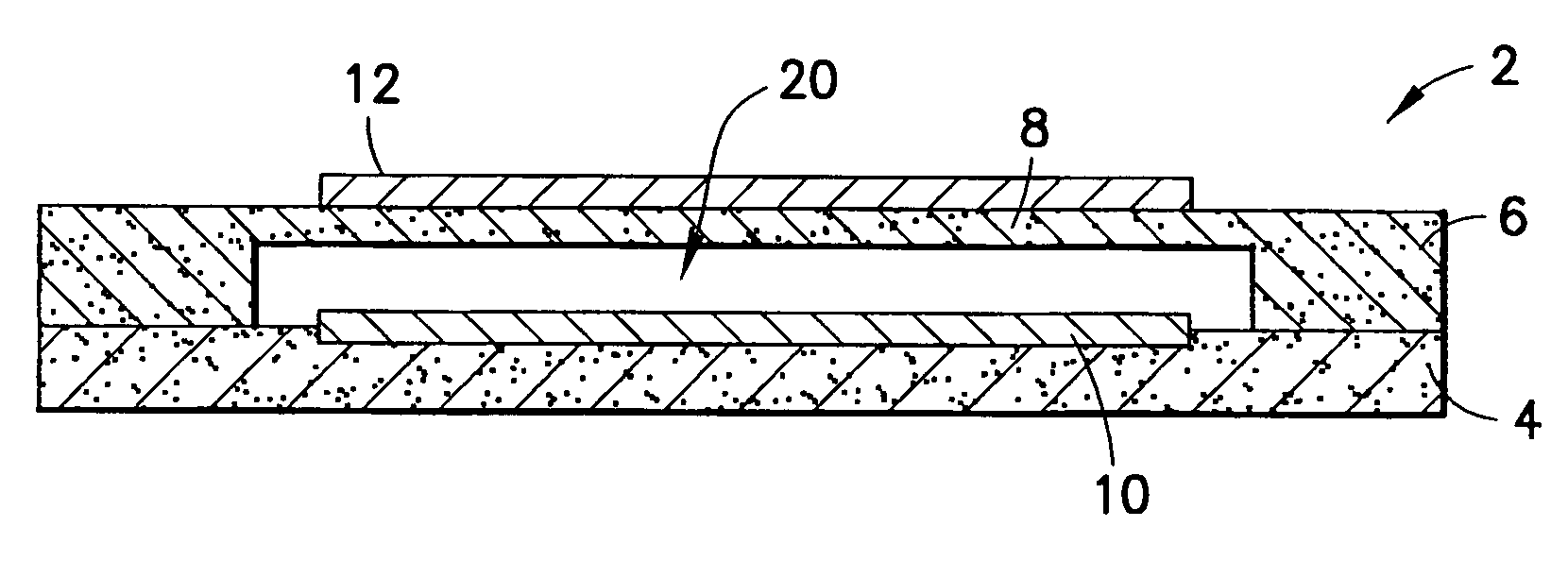

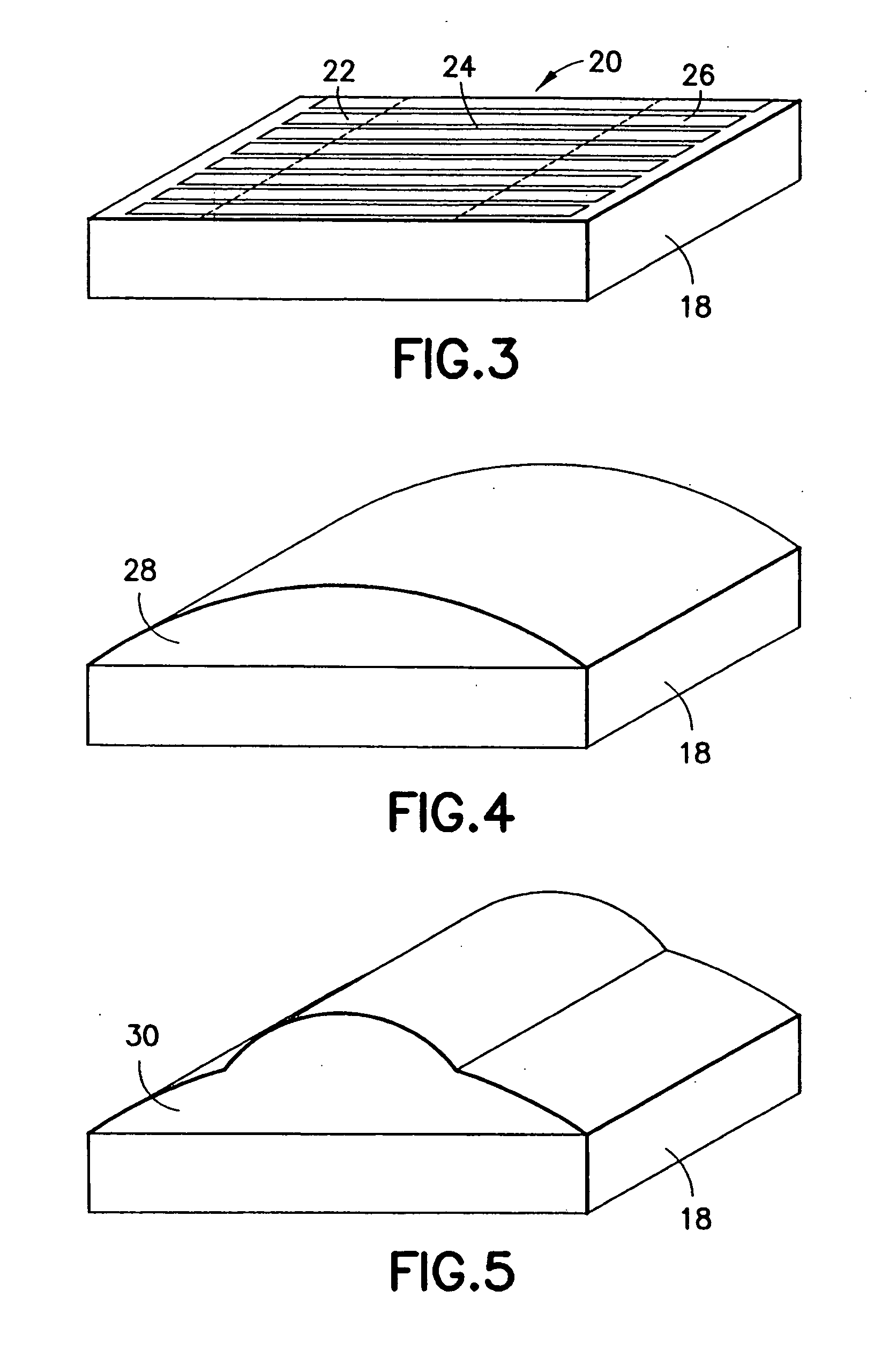

Focusing micromachined ultrasonic transducer arrays and related methods of manufacture

InactiveUS20050075572A1Improvement of contrast resolutionUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive transducersContrast resolutionLight beam

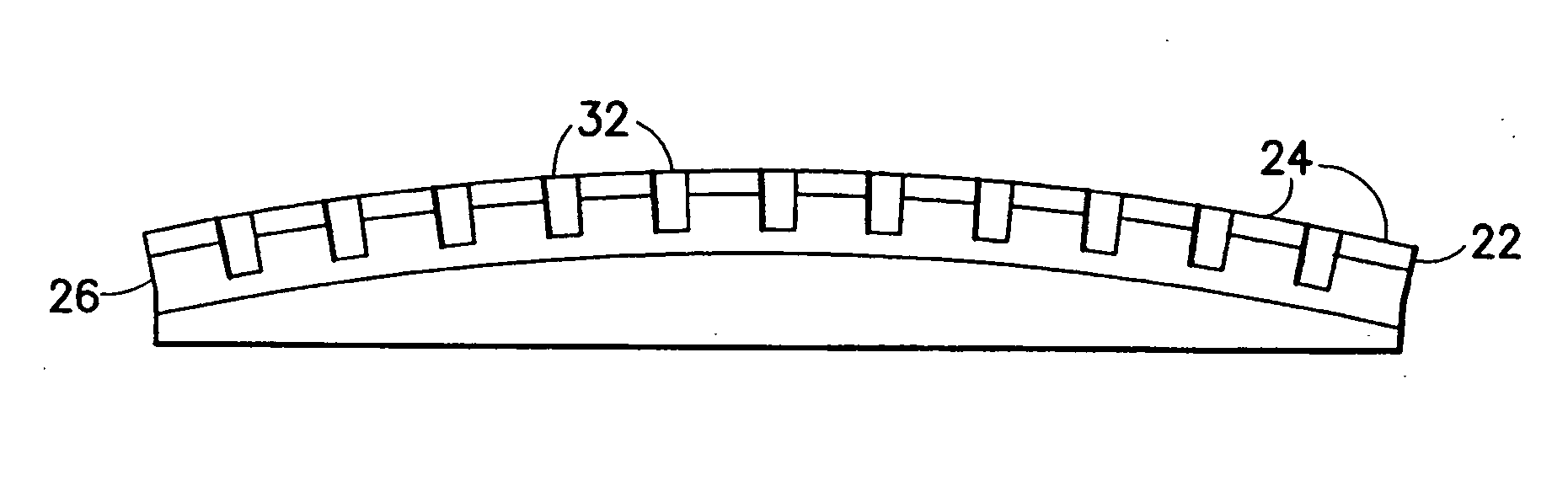

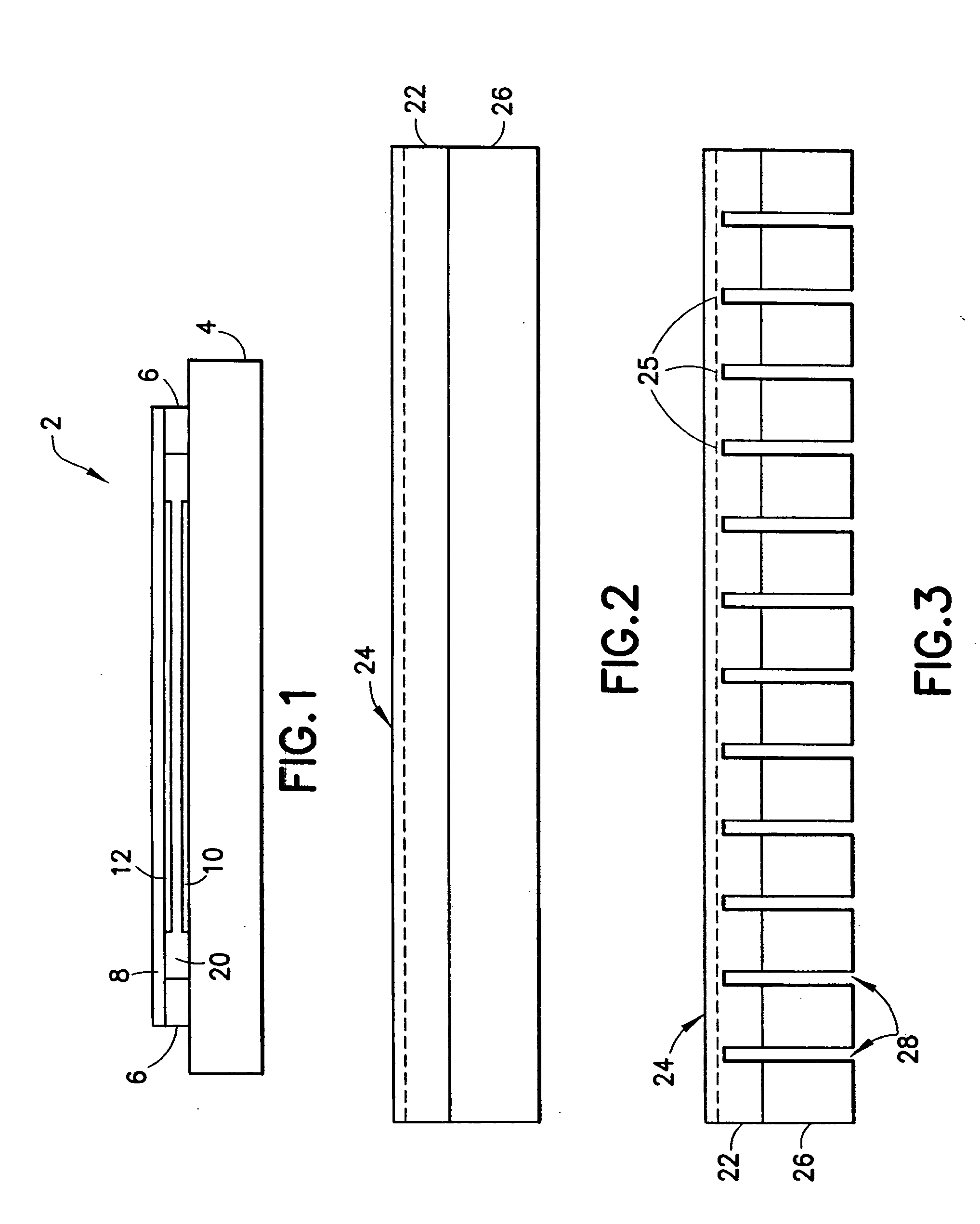

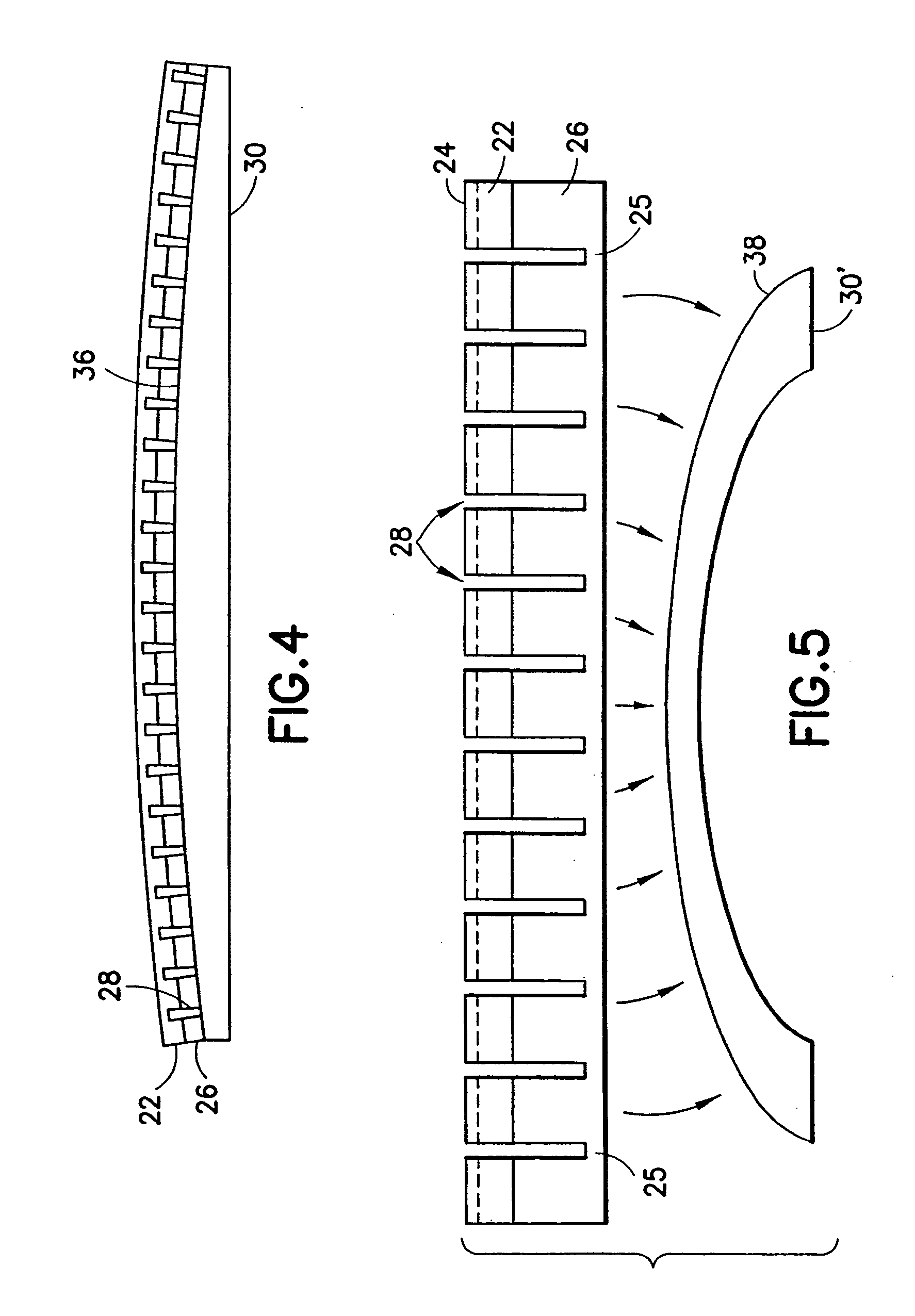

A micromachined ultrasonic transducer array that focuses in the elevation direction. A curved lens is used to narrow the beam width in the elevation direction so that contrast resolution is improved and clinically relevant. Alternatively, a curved probe is formed by bending a micromachined substrate to have a predetermined curvature. The invention is further directed to methods of manufacturing such transducers.

Owner:GENERAL ELECTRIC CO

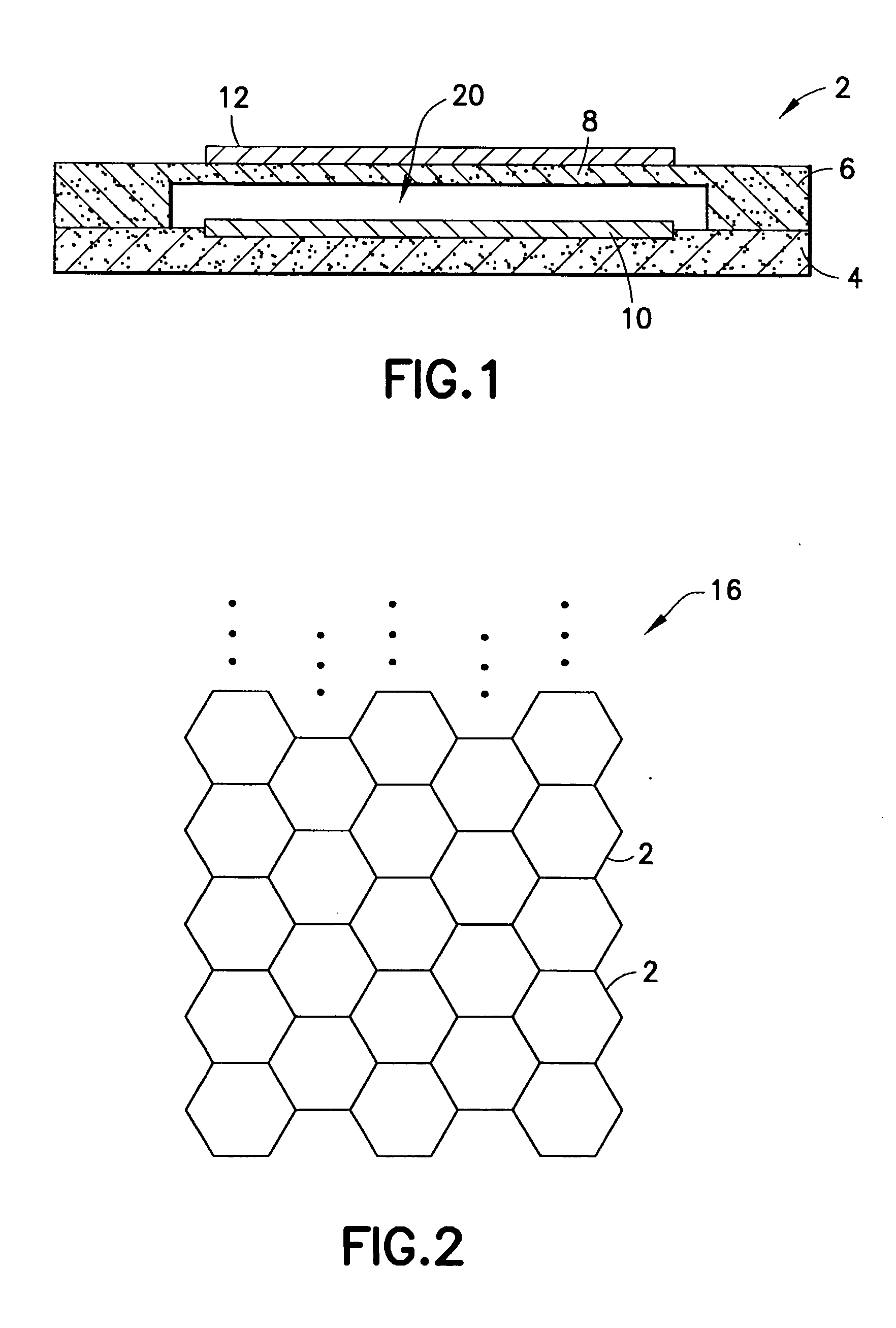

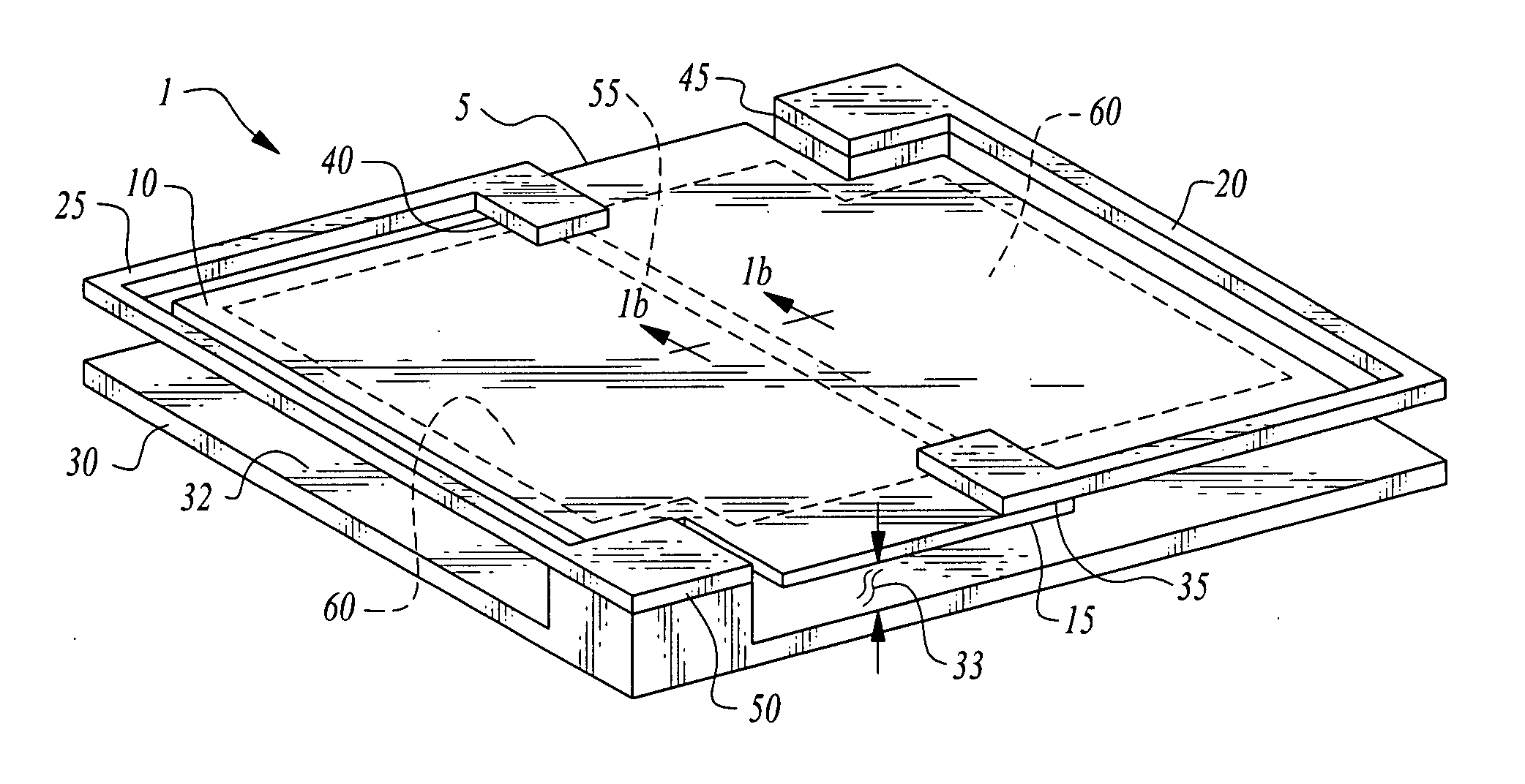

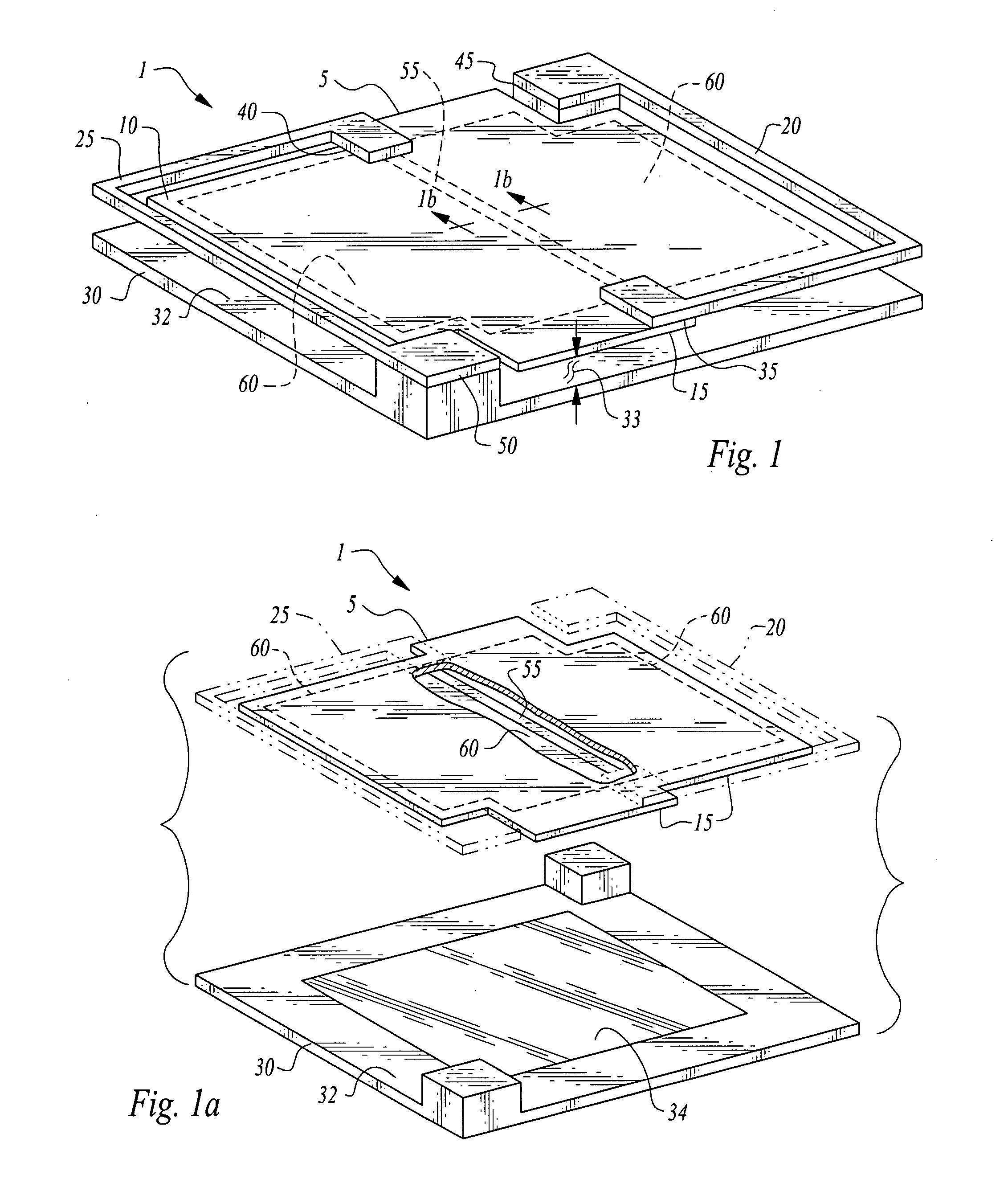

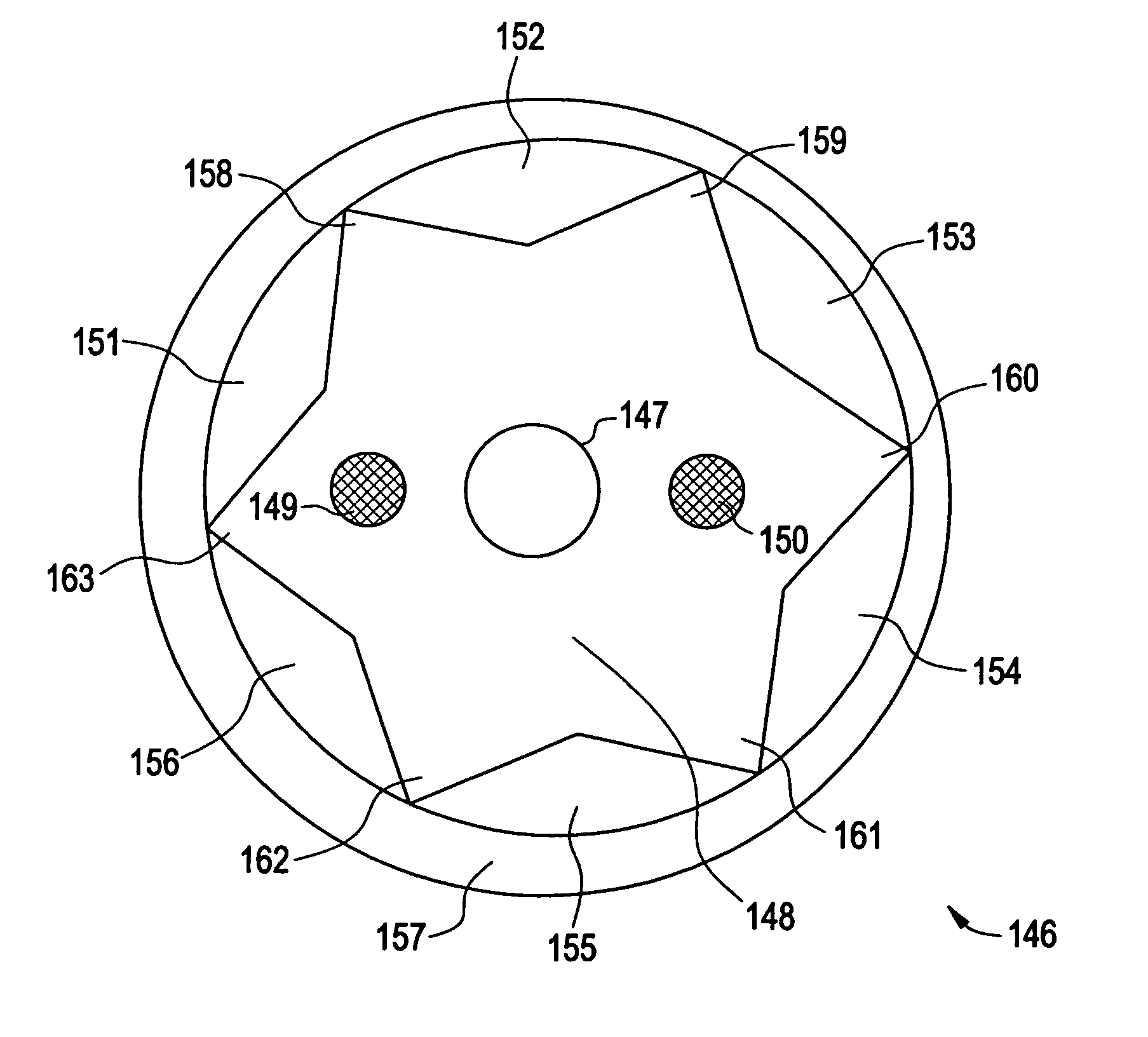

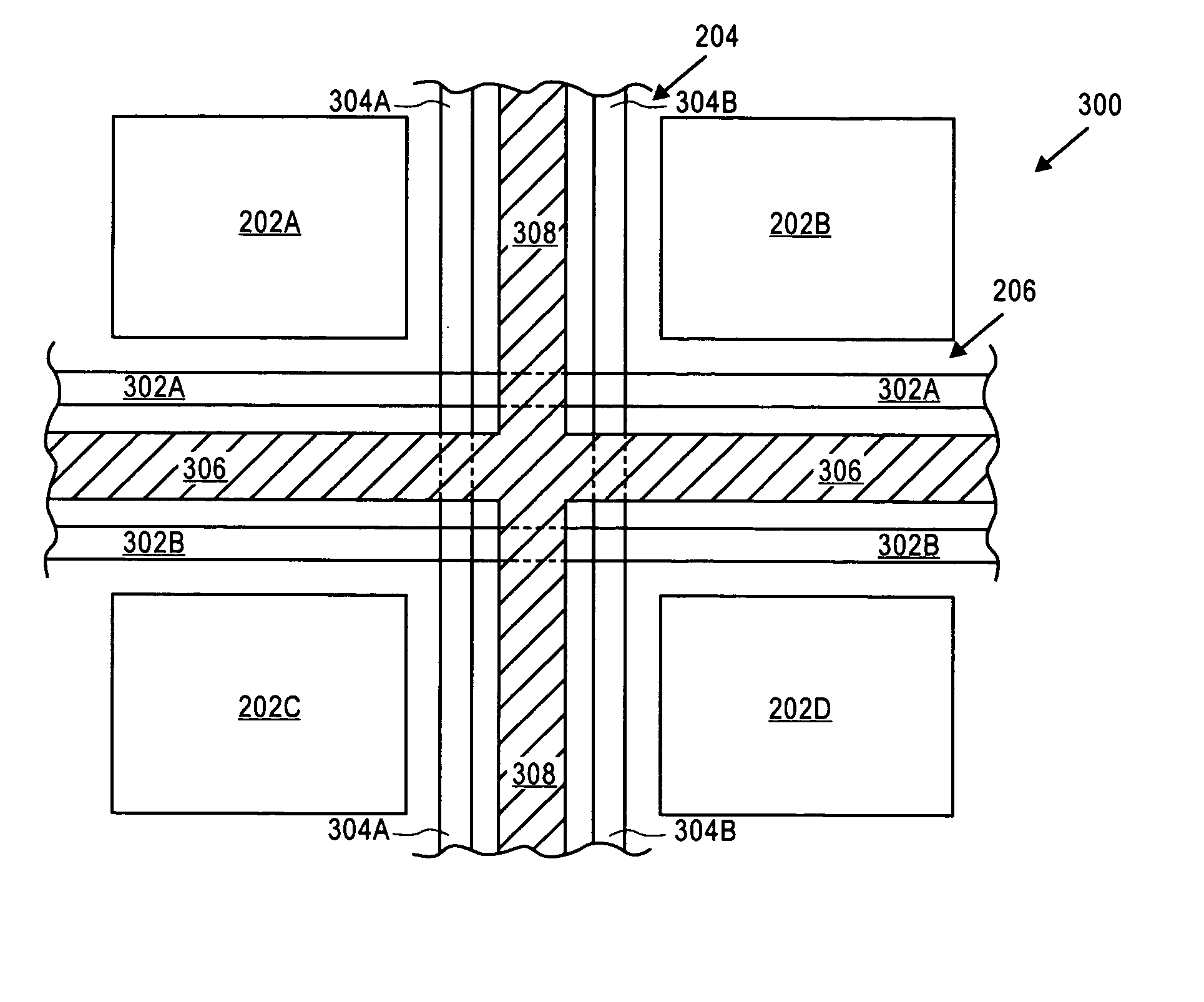

Curved micromachined ultrasonic transducer arrays and related methods of manufacture

ActiveUS20050146247A1Ultrasonic/sonic/infrasonic diagnosticsFixed microstructural devicesPMUTEngineering

A curved sensor device, such as an ultrasonic transducer array, is fabricated from a flat micromachined sensor (such as cMUT or pMUT) array constructed using micromachined electromechanical systems (MEMS) techniques. The device comprises: a support structure comprising a spine having a profile that is generally curved and a multiplicity of teeth extending from one side of the curved spine; and a multiplicity of sensors built on the support structure. The spine can be bent forward or backward and attached to a curved front face of a support member, thereby causing the sensors to adopt a curved array.

Owner:GENERAL ELECTRIC CO

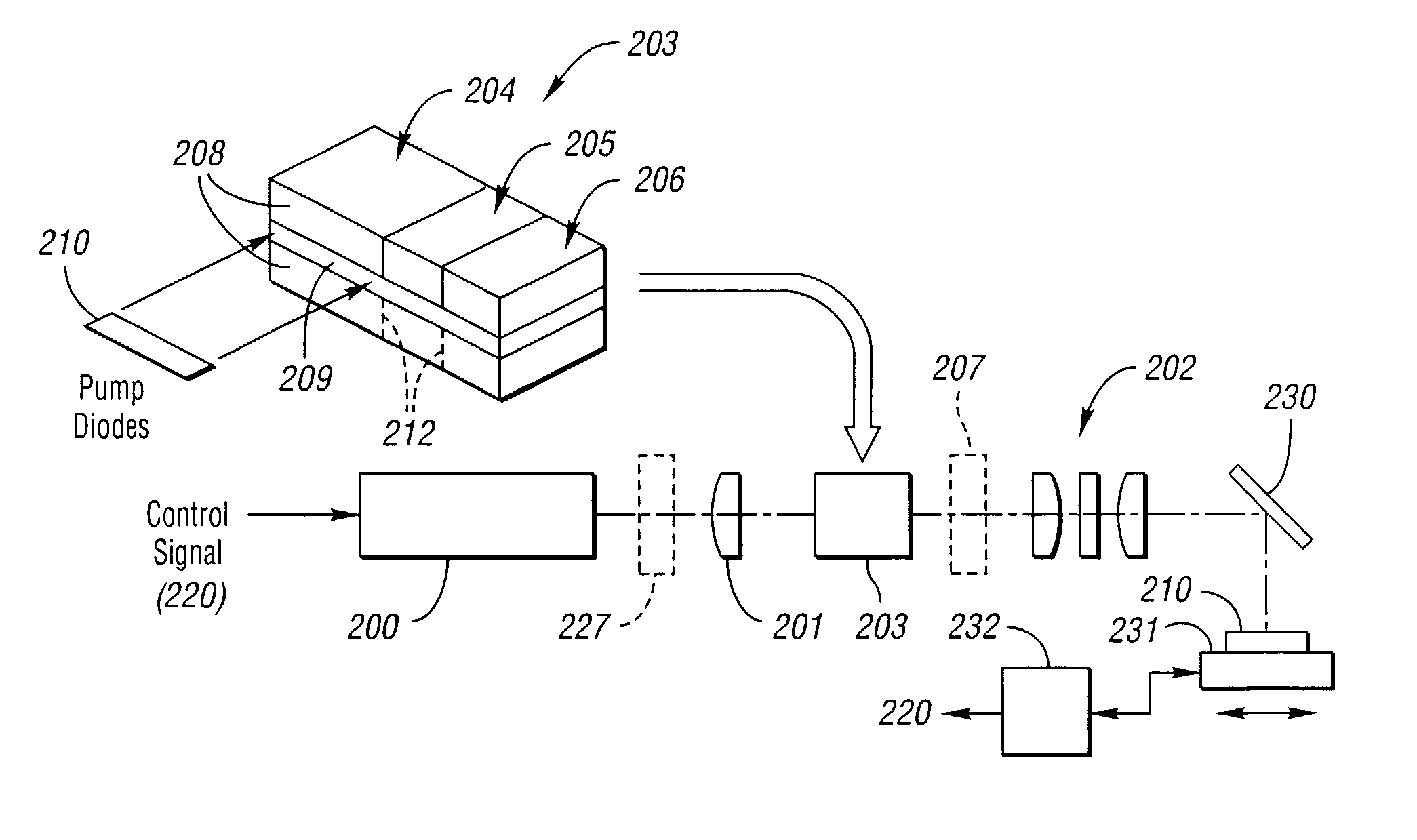

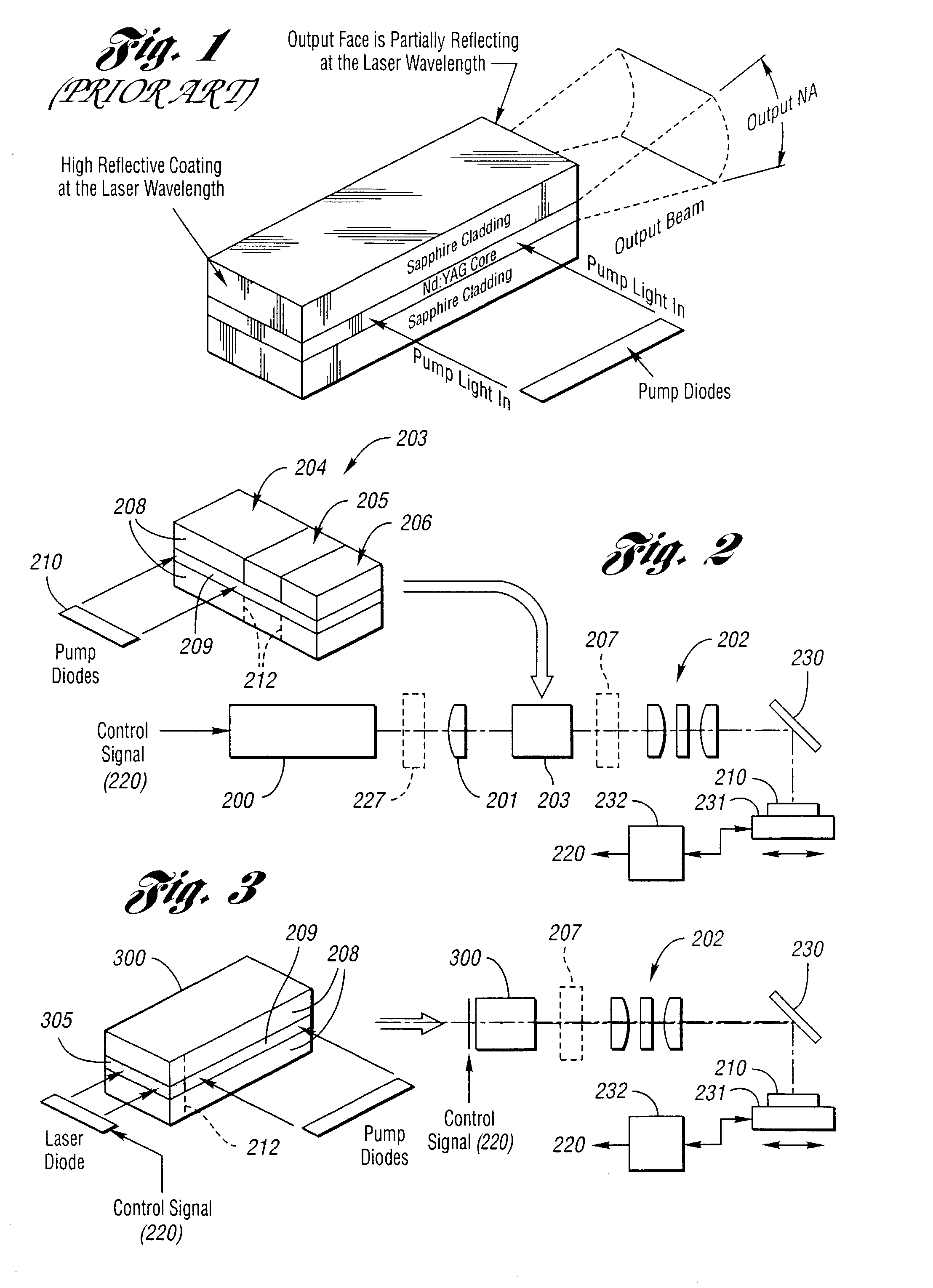

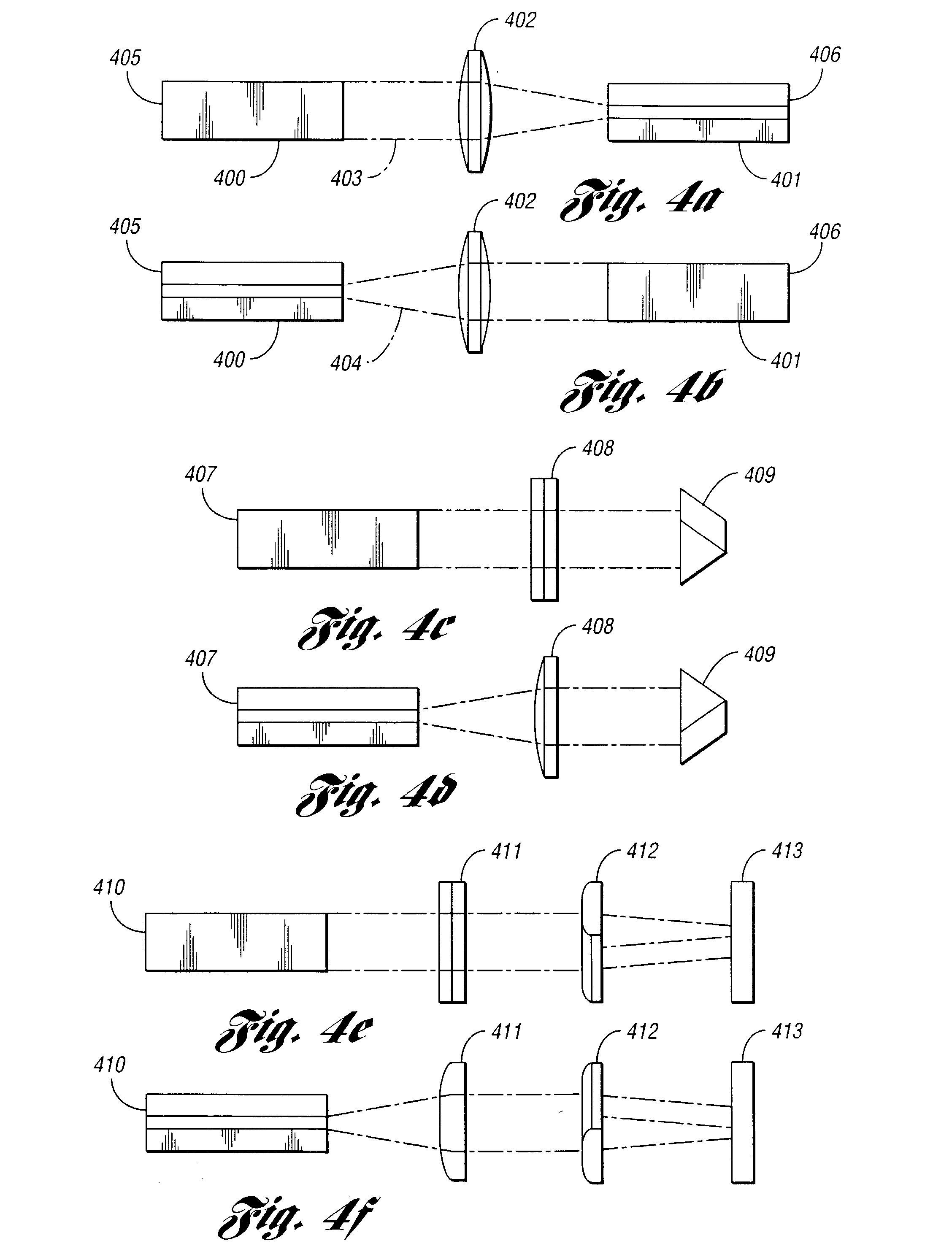

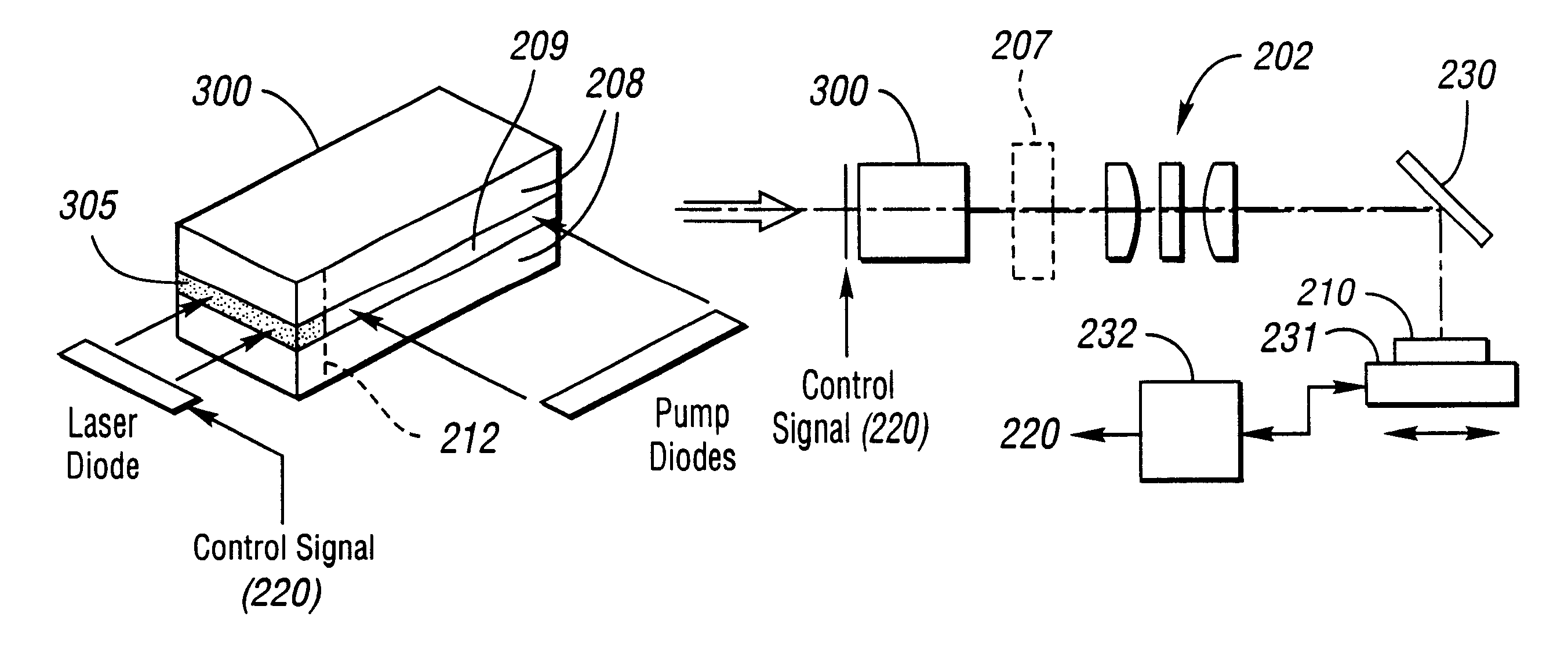

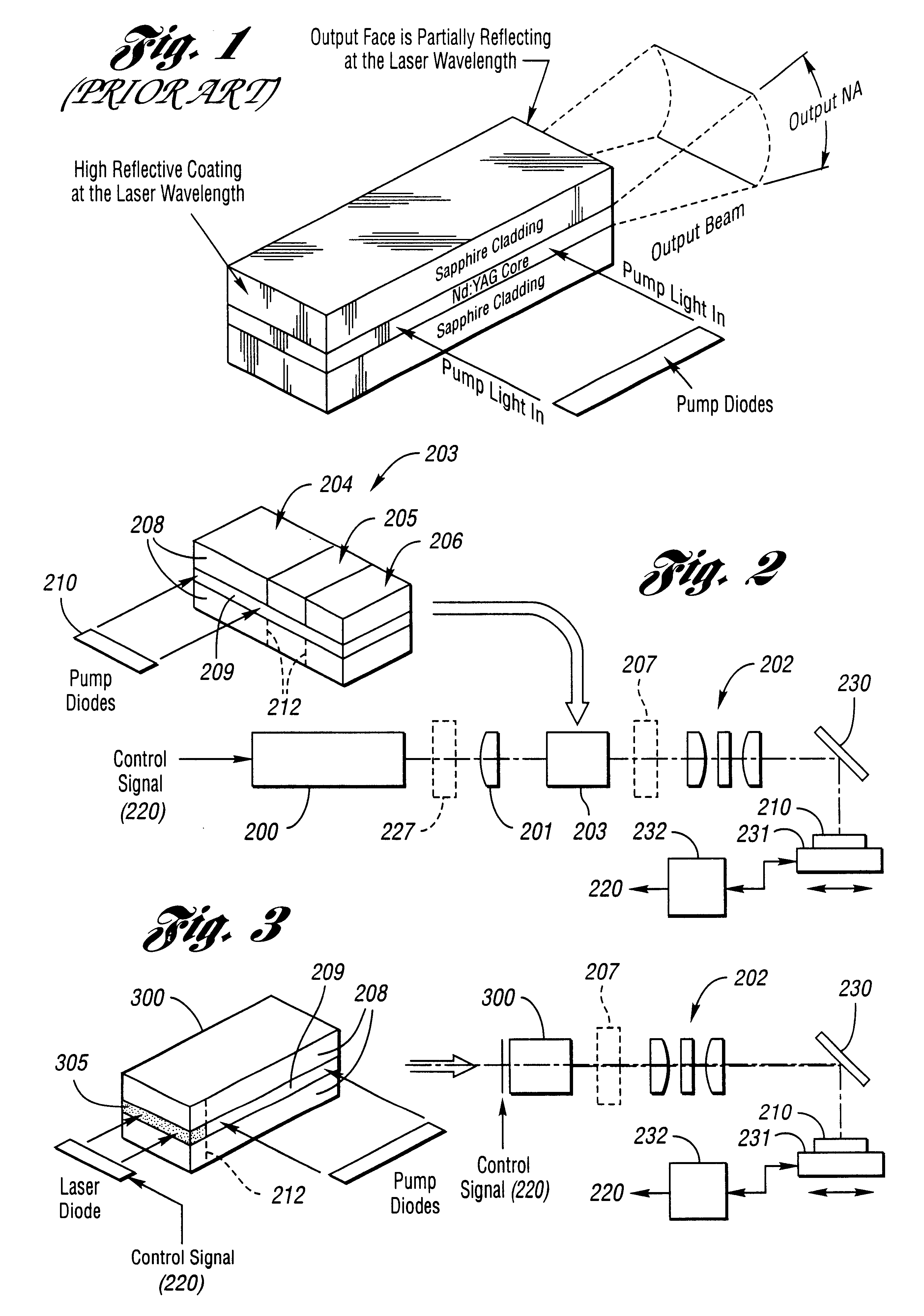

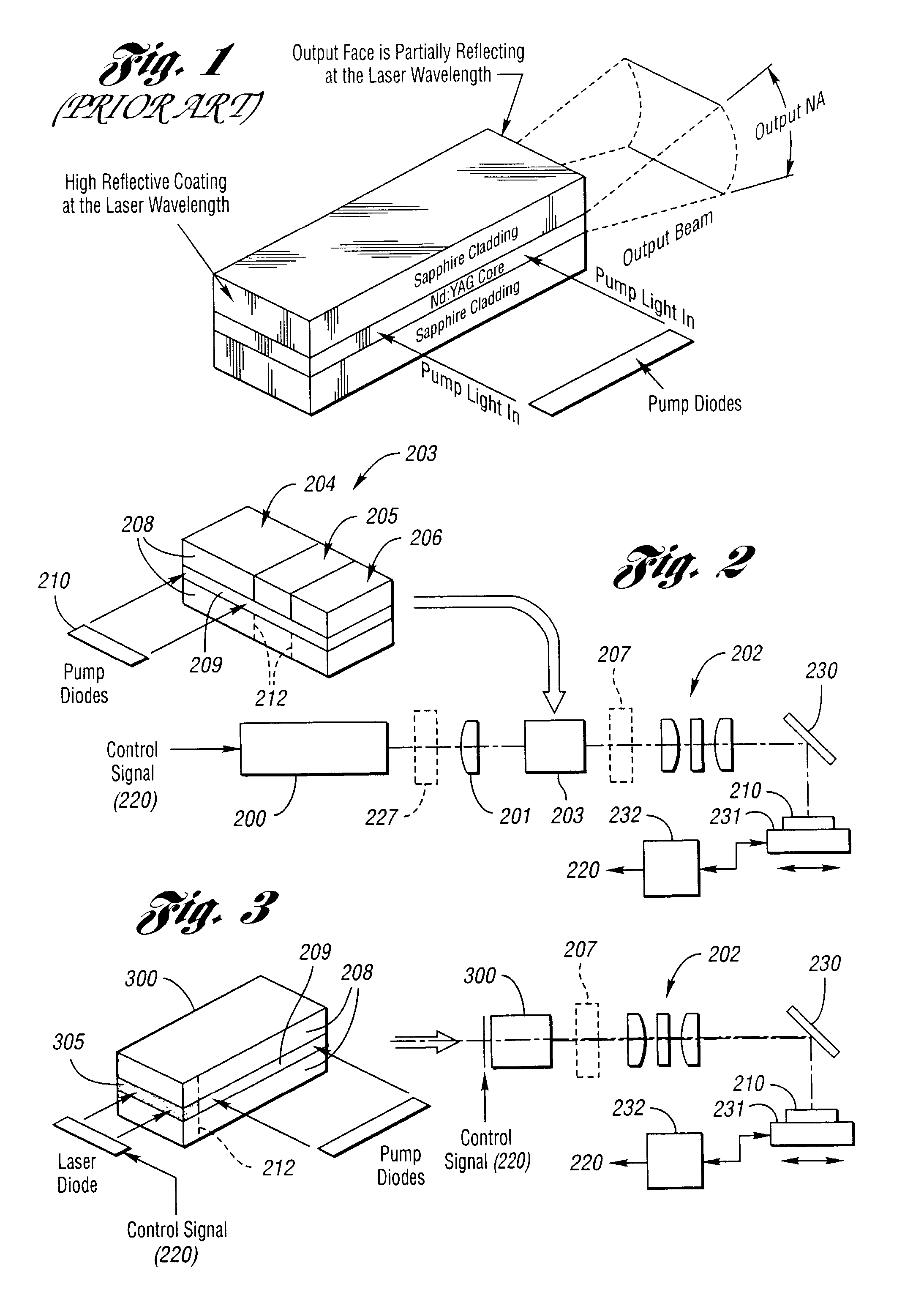

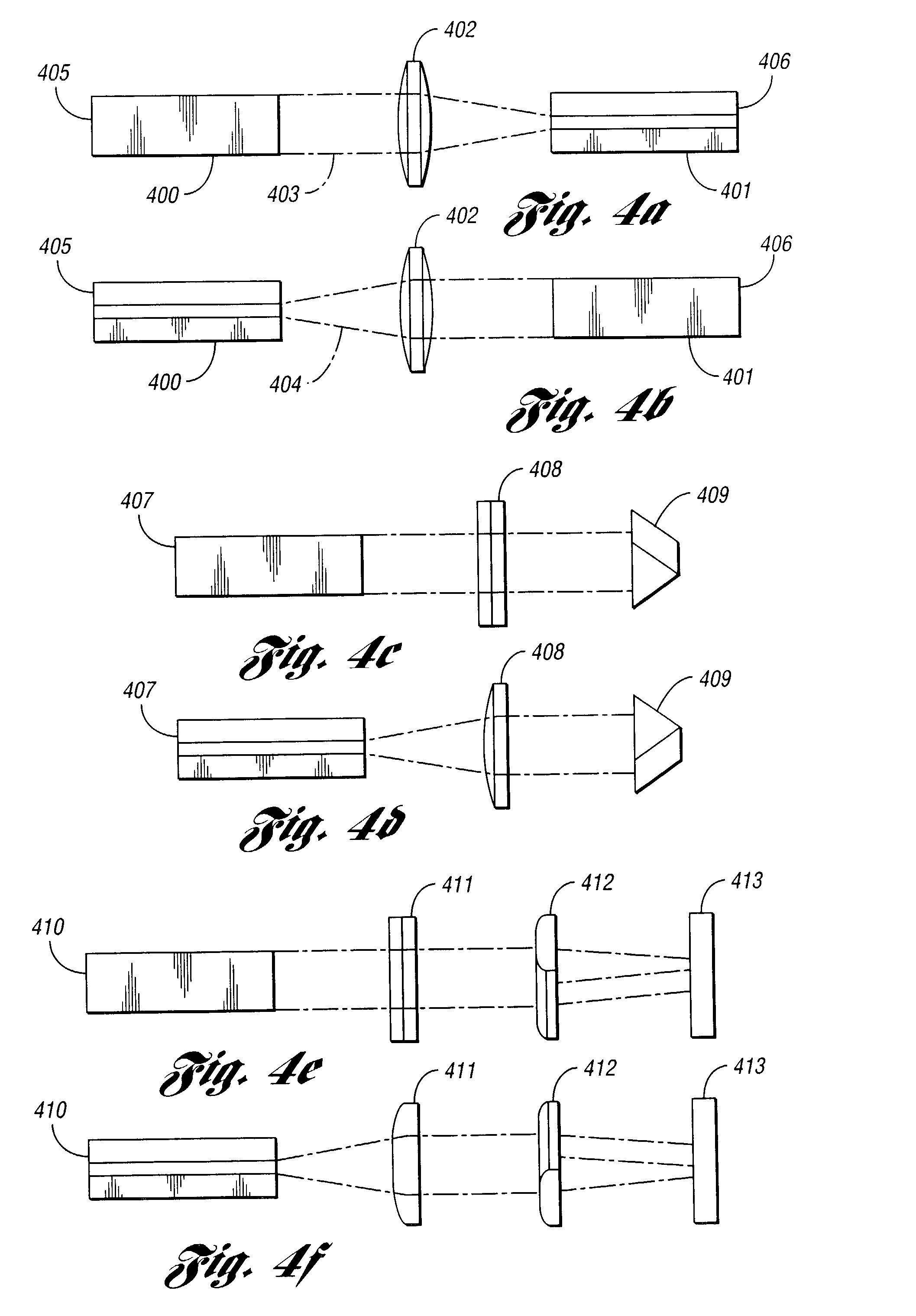

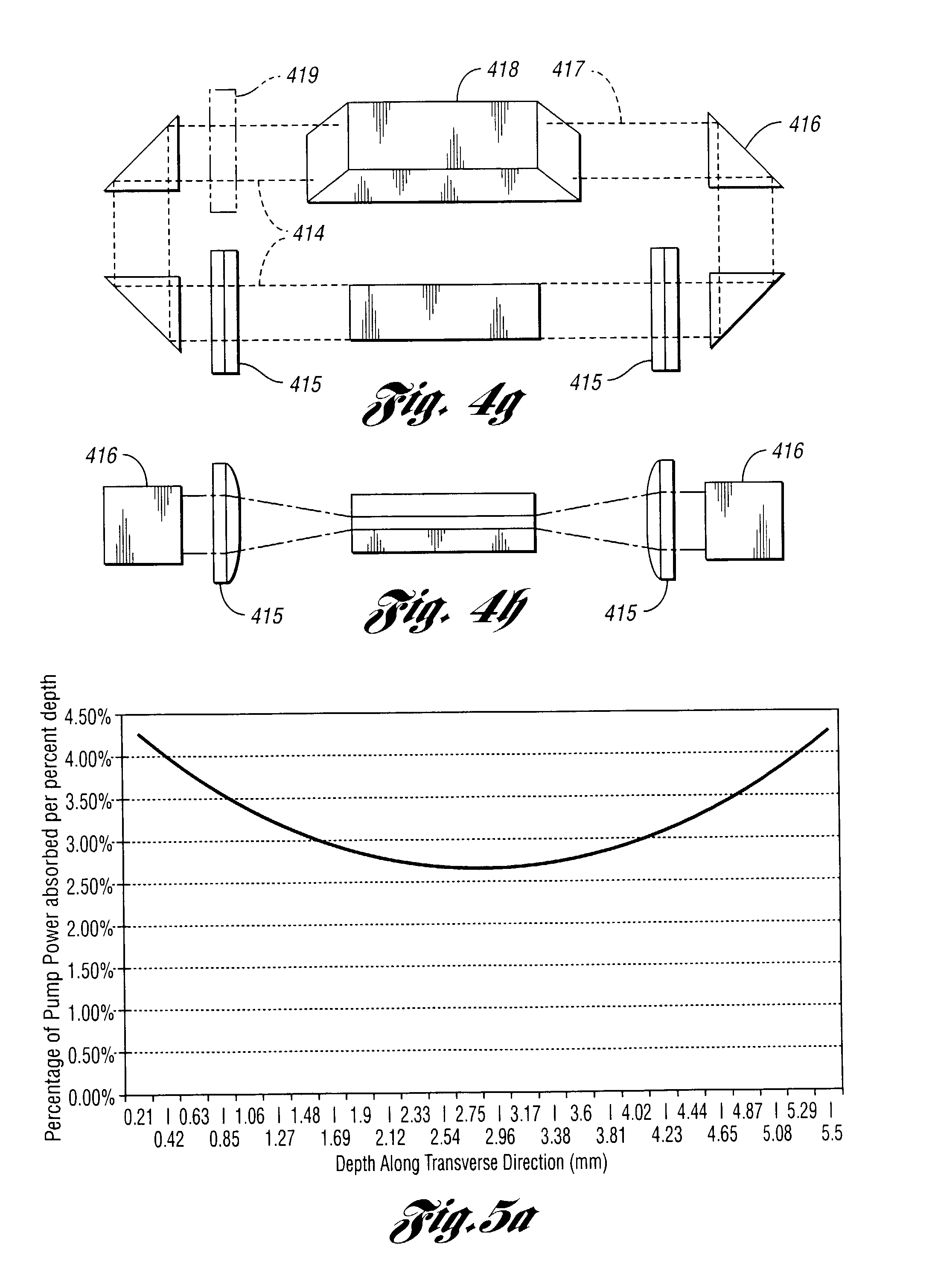

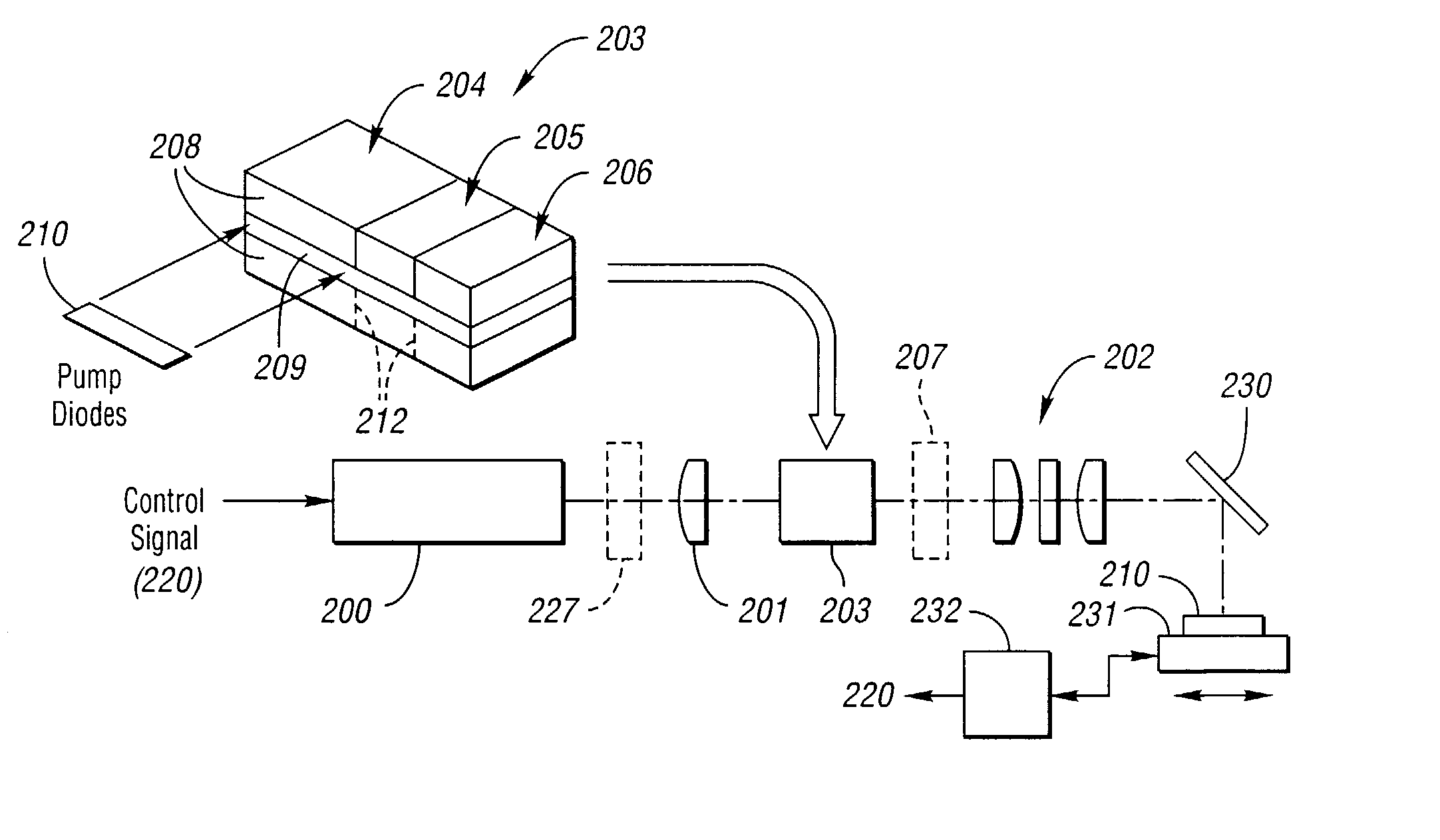

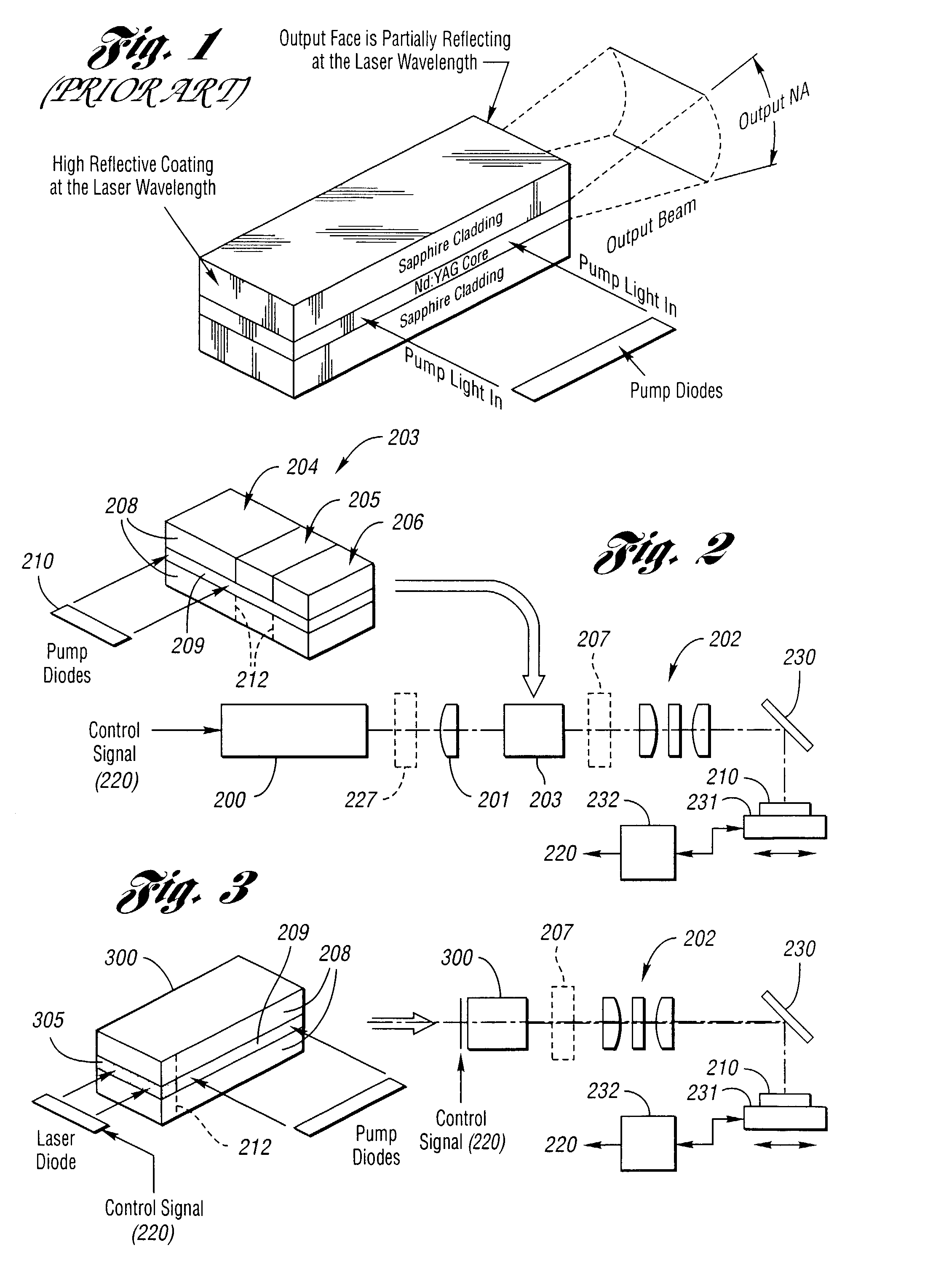

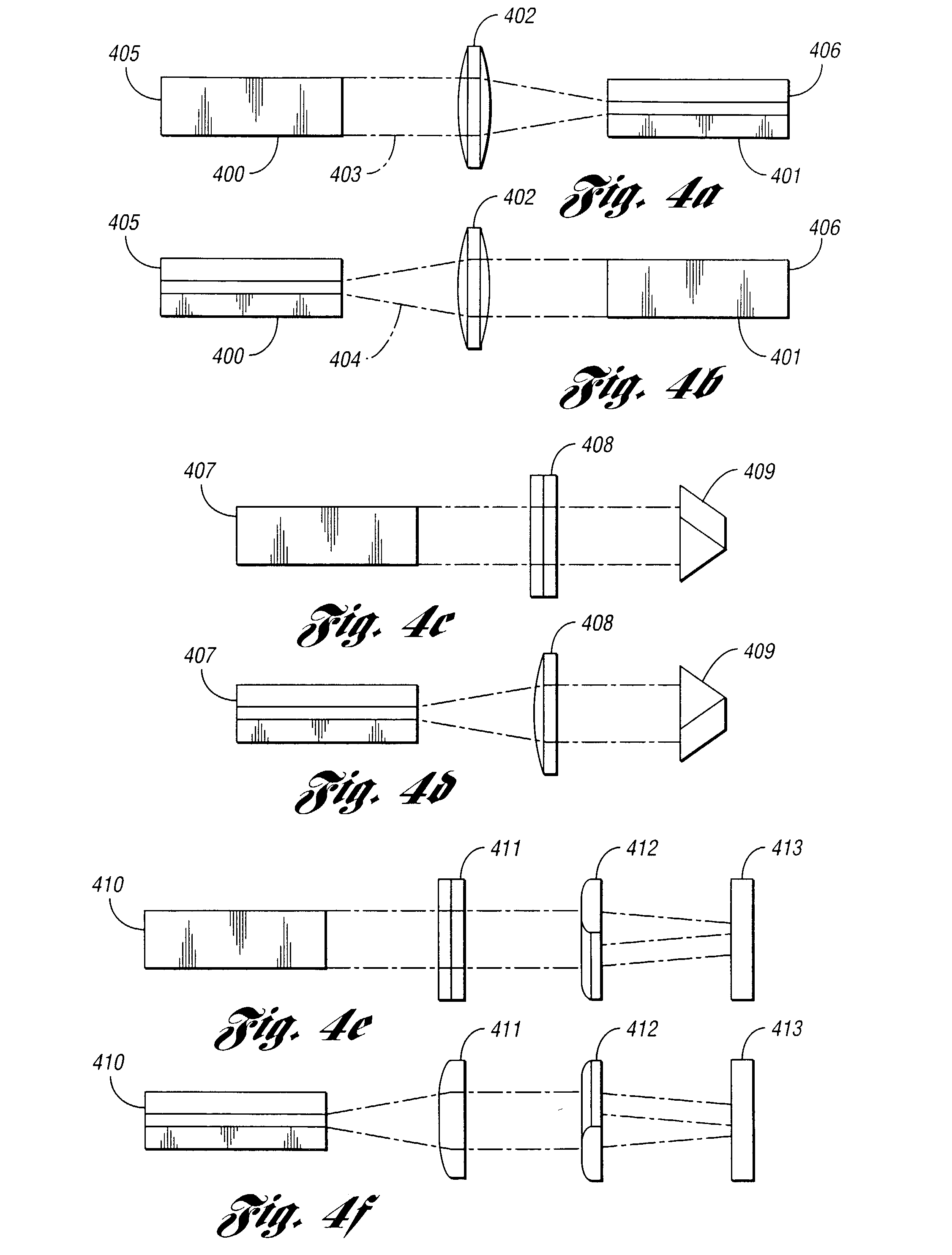

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS20030161375A1Optical resonator shape and constructionActive medium shape and constructionEngineeringWaveguide

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

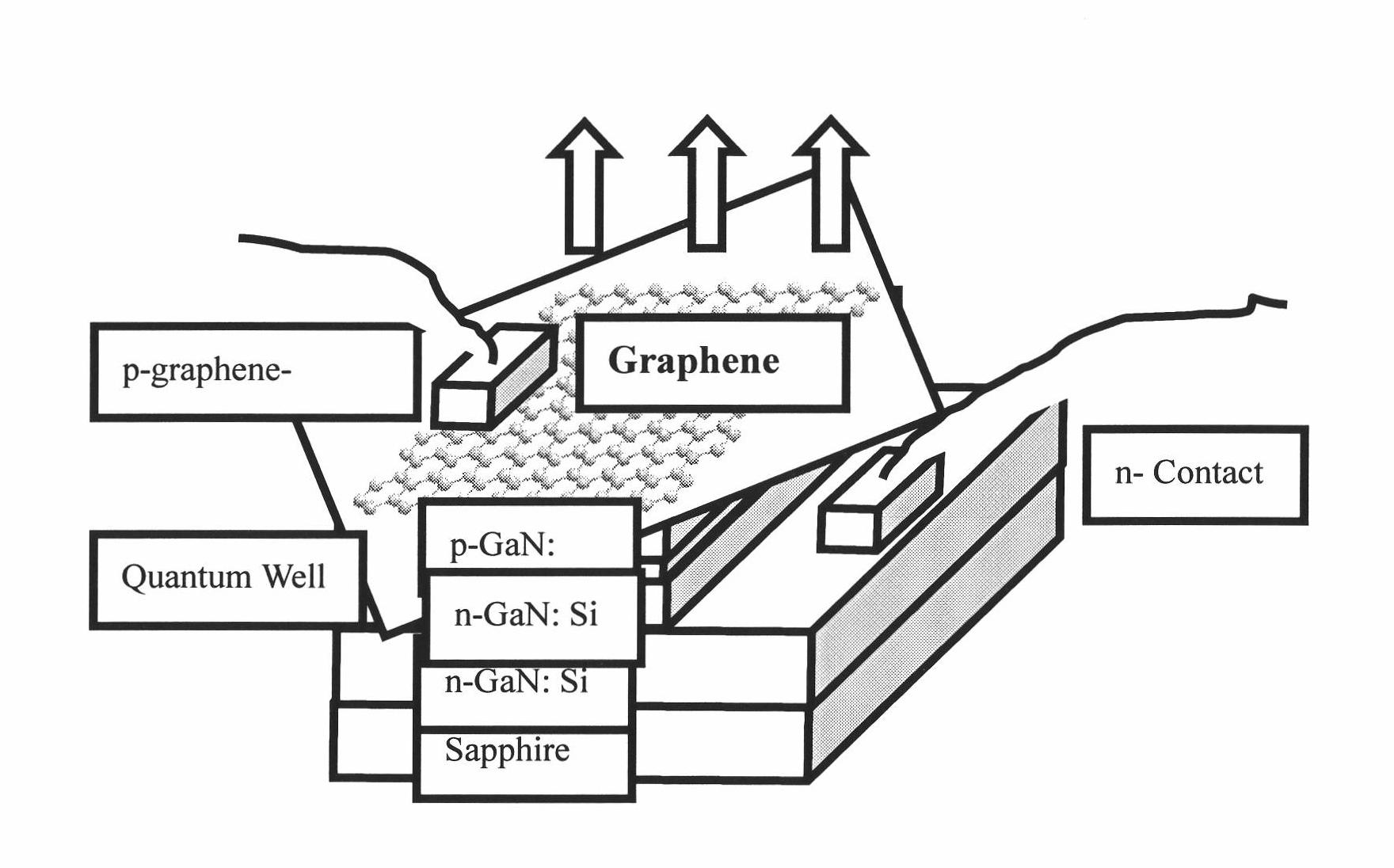

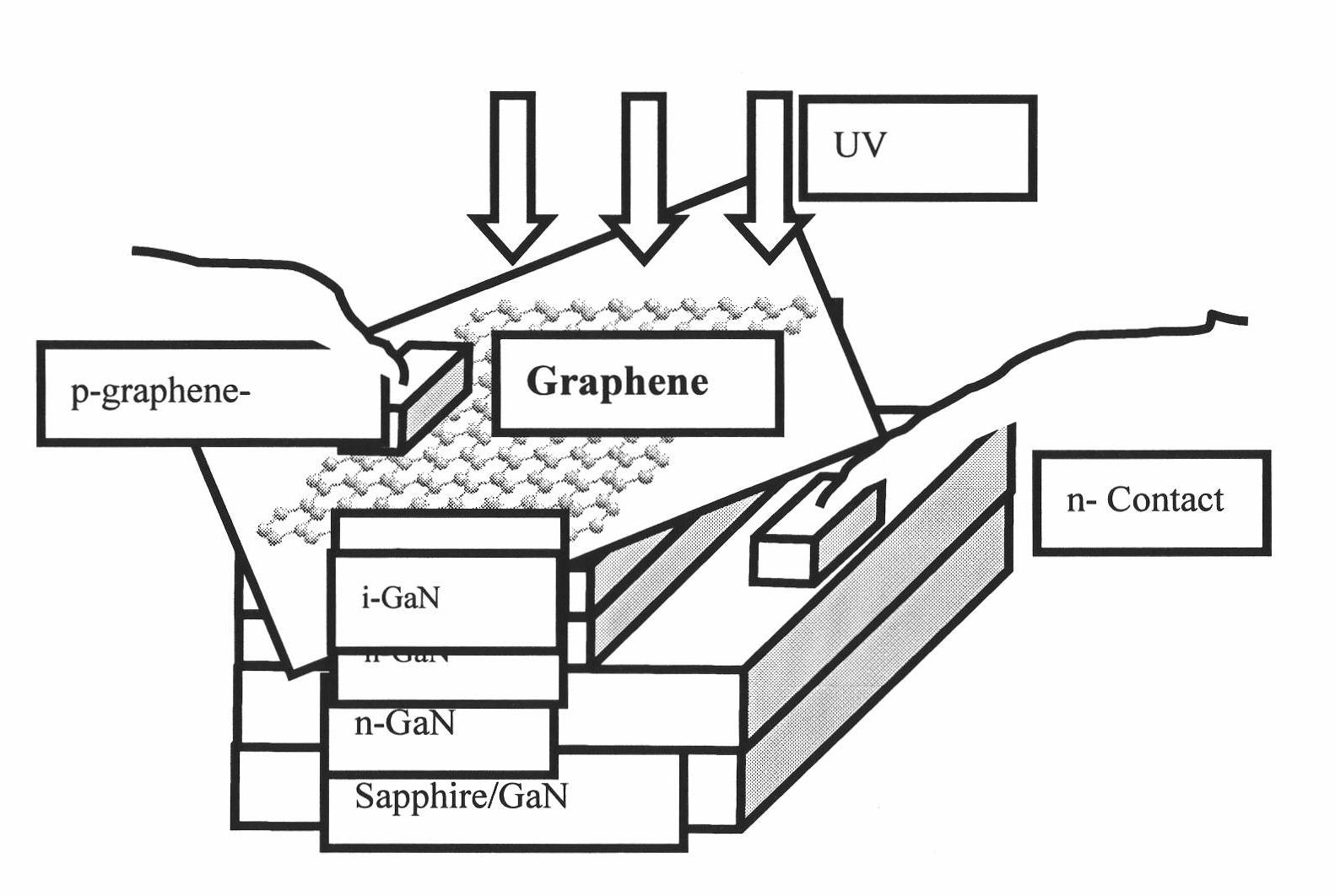

Transparent conducting electrode based on graphene and manufacture method and applications thereof

InactiveCN101859858ALow costIncrease brightnessFinal product manufactureSemiconductor devicesEtchingGas phase

The invention discloses a transparent conducting electrode using a graphene film as a GaN-based LED (light-emitting diode) or ultraviolet light detector and a manufacture method and applications thereof. The graphene film is solidified and bonded on the surface of the GaN substrate of the LED or ultraviolet light detector. The transparent graphene conducting film is prepared by adopting a chemical vapor deposition or reduction-oxidation method, and the GaN-based LED or ultraviolet light detector is manufactured by utilizing a micromachining photoetching, etching and metal deposition method; the graphene film is moved to the p-type GaN-based substrate of the LED or ultraviolet light detector to serve as the transparent conducting electrode instead of ITO or Ni / Au. In the invention, the graphene film is used as the transparent conducting electrode, which can realize low-cost and high-brightness luminescent devices and expands the applications of carbon nanometer materials in the field of GaN-based photoelectric devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Laser based material processing methods and scalable architecture for material processing

InactiveUS6738396B2Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

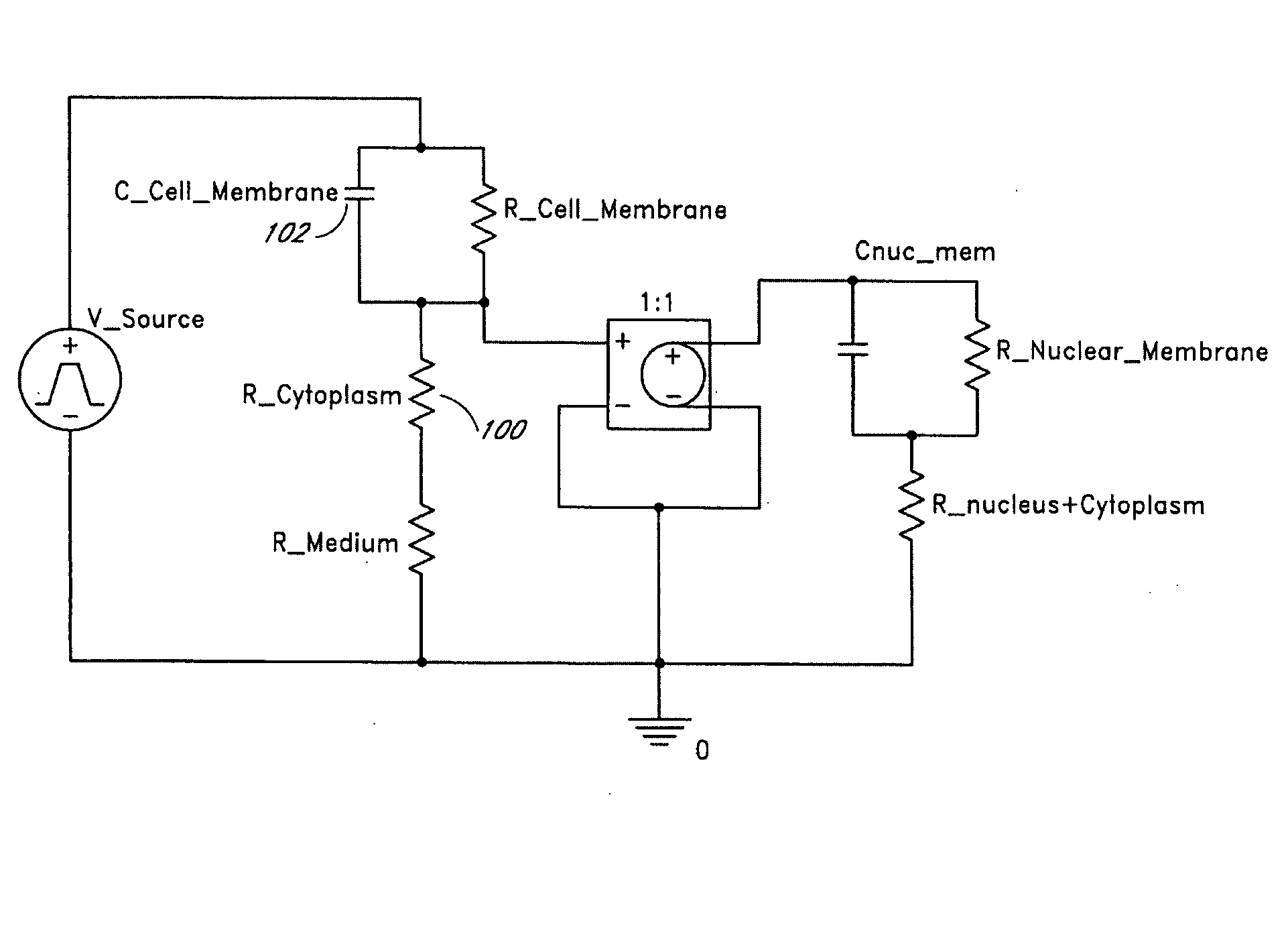

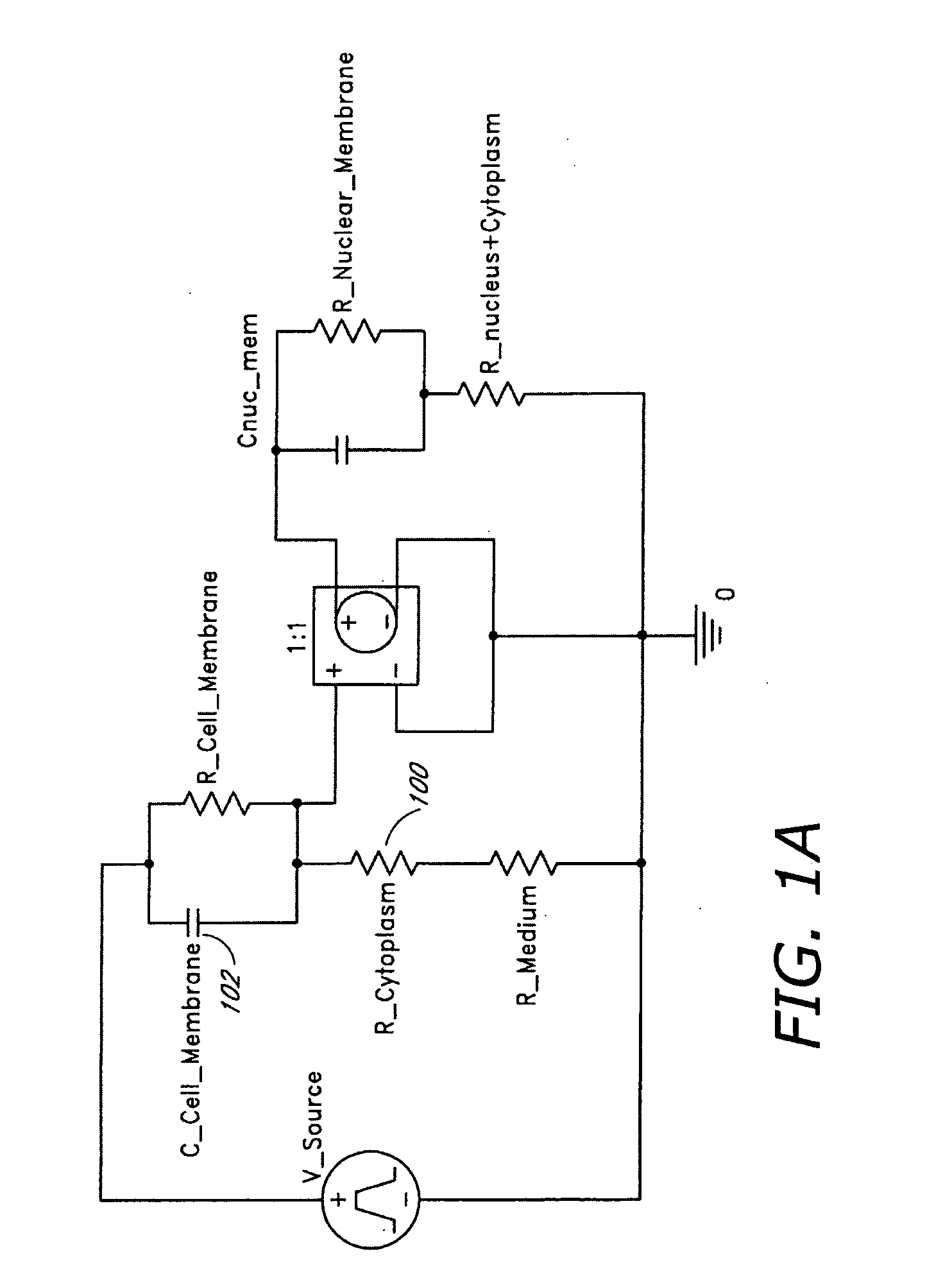

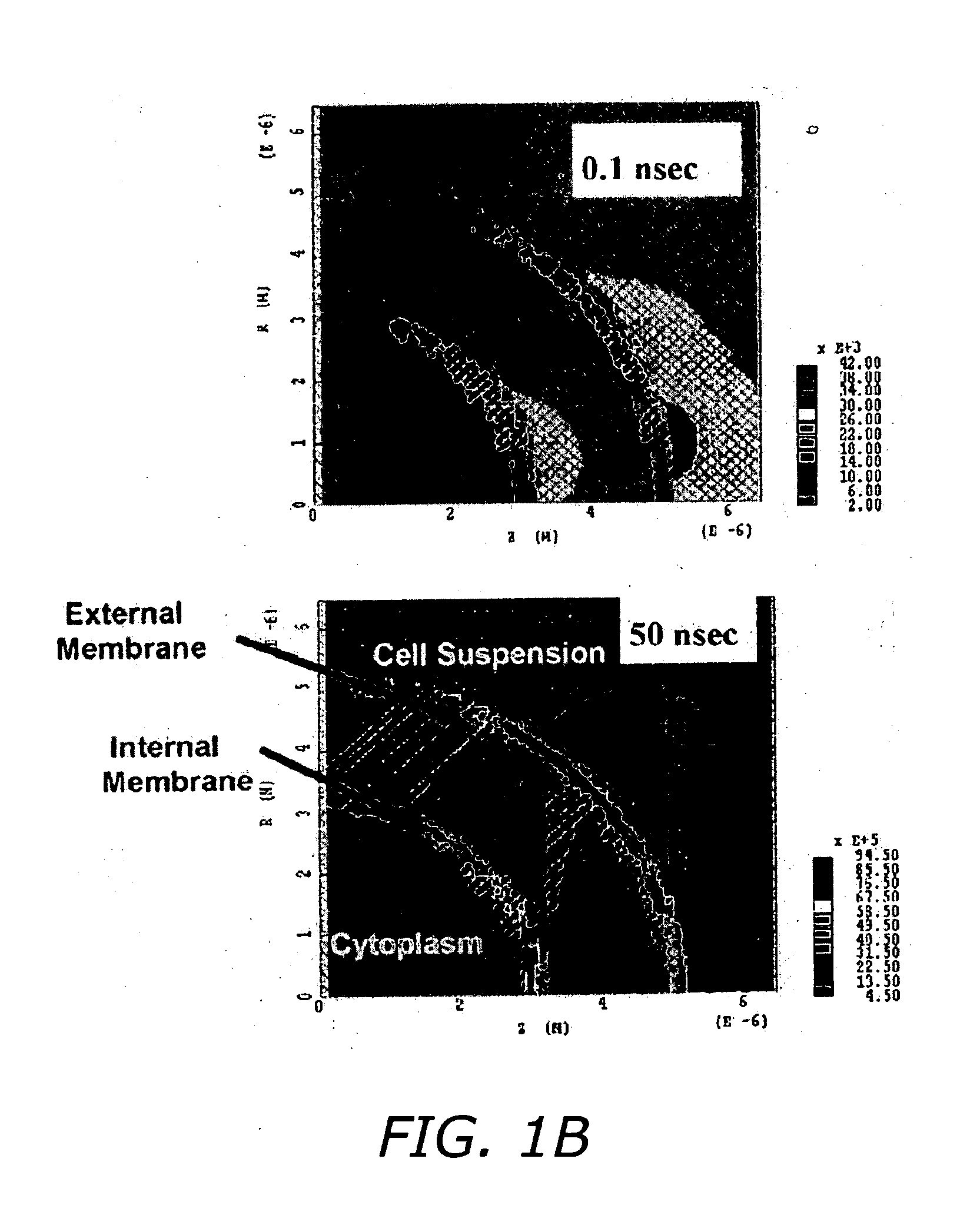

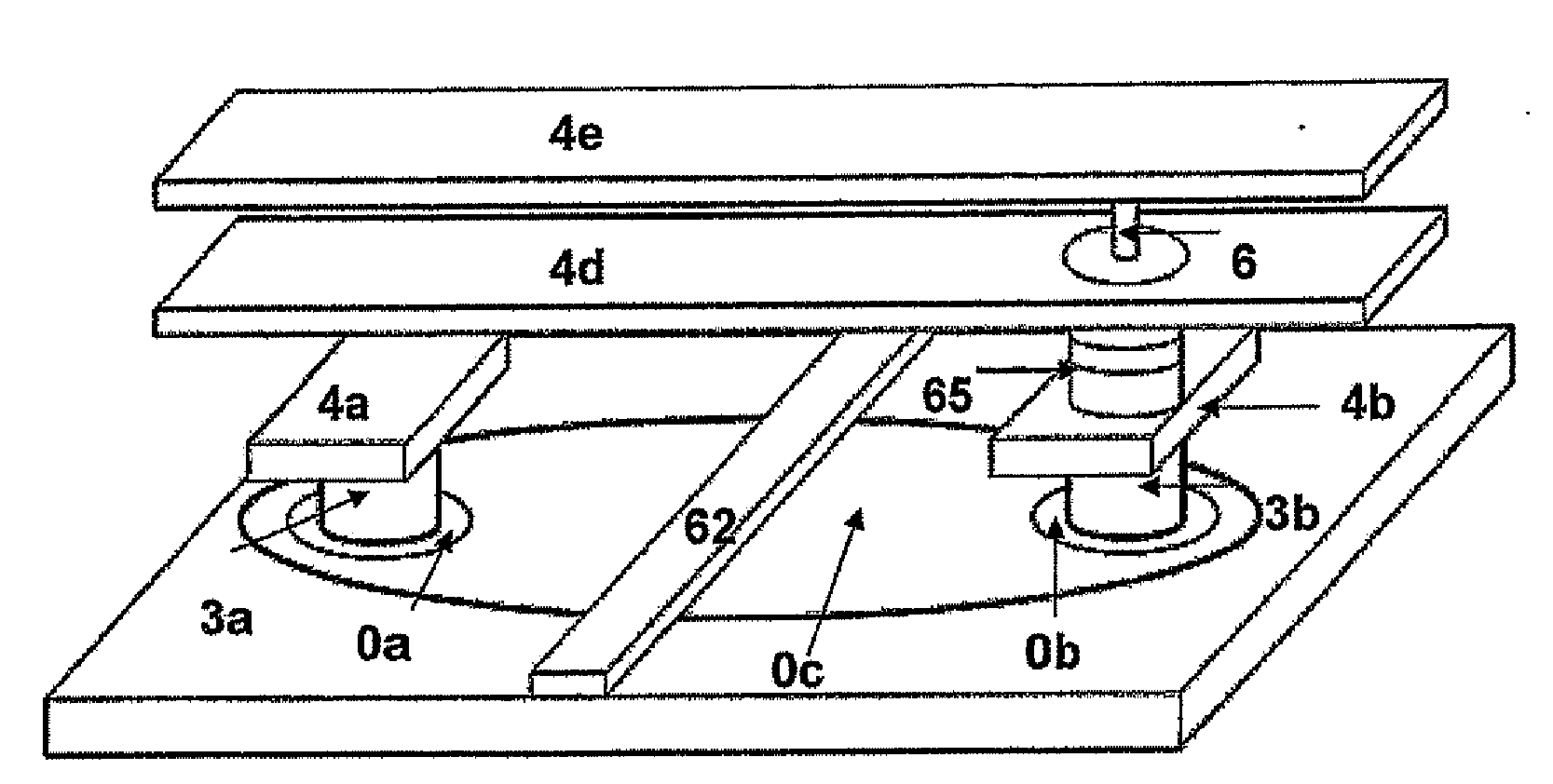

Compact subnanosecond high voltage pulse generation system for cell electro-manipulation

ActiveUS20080231337A1Good treatment effectGood effectElectrotherapyDelay line applicationsDistortionHigh bandwidth

Disclosed are methods and systems for subnanosecond rise time high voltage (HV) electric pulse delivery to biological loads. The system includes an imaging device and monitoring apparatus used for bio-photonic studies of pulse induced intracellular effects. The system further features custom fabricated microscope slide having micro-machined electrodes. A printed circuit board to interface the pulse generator to the micro-machined glass slide having the cell solution. An low-parasitic electronic setup to interface with avalanche transistor-switched pulse generation system. The pc-board and the slide are configured to match the output impedance of the pulse generator which minimizes reflection back into the pulse generator, and minimizes distortion of the pulse shape and pulse parameters. The pc-board further includes a high bandwidth voltage divider for real-time monitoring of pulses delivered to the cell solutions.

Owner:UNIV OF SOUTHERN CALIFORNIA

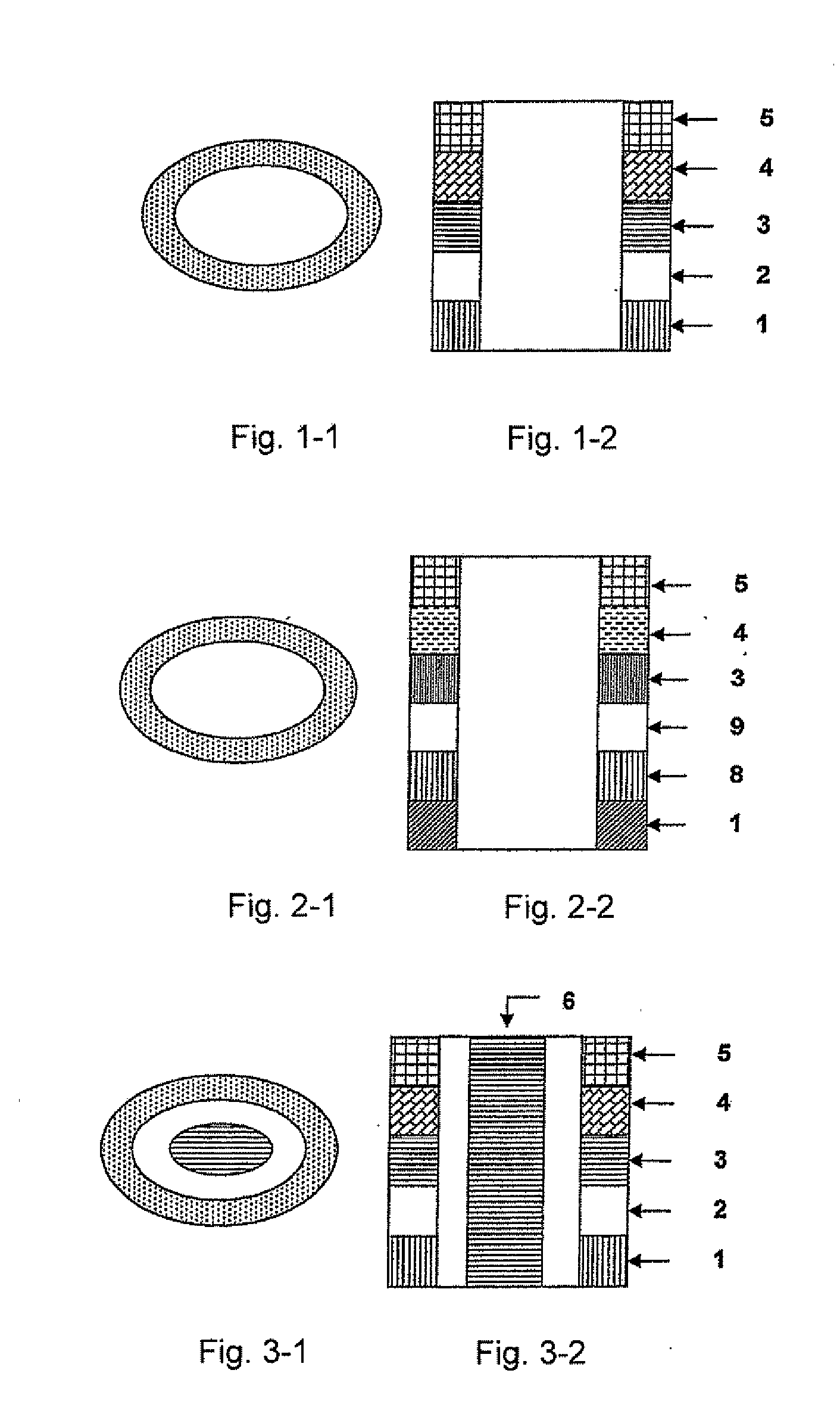

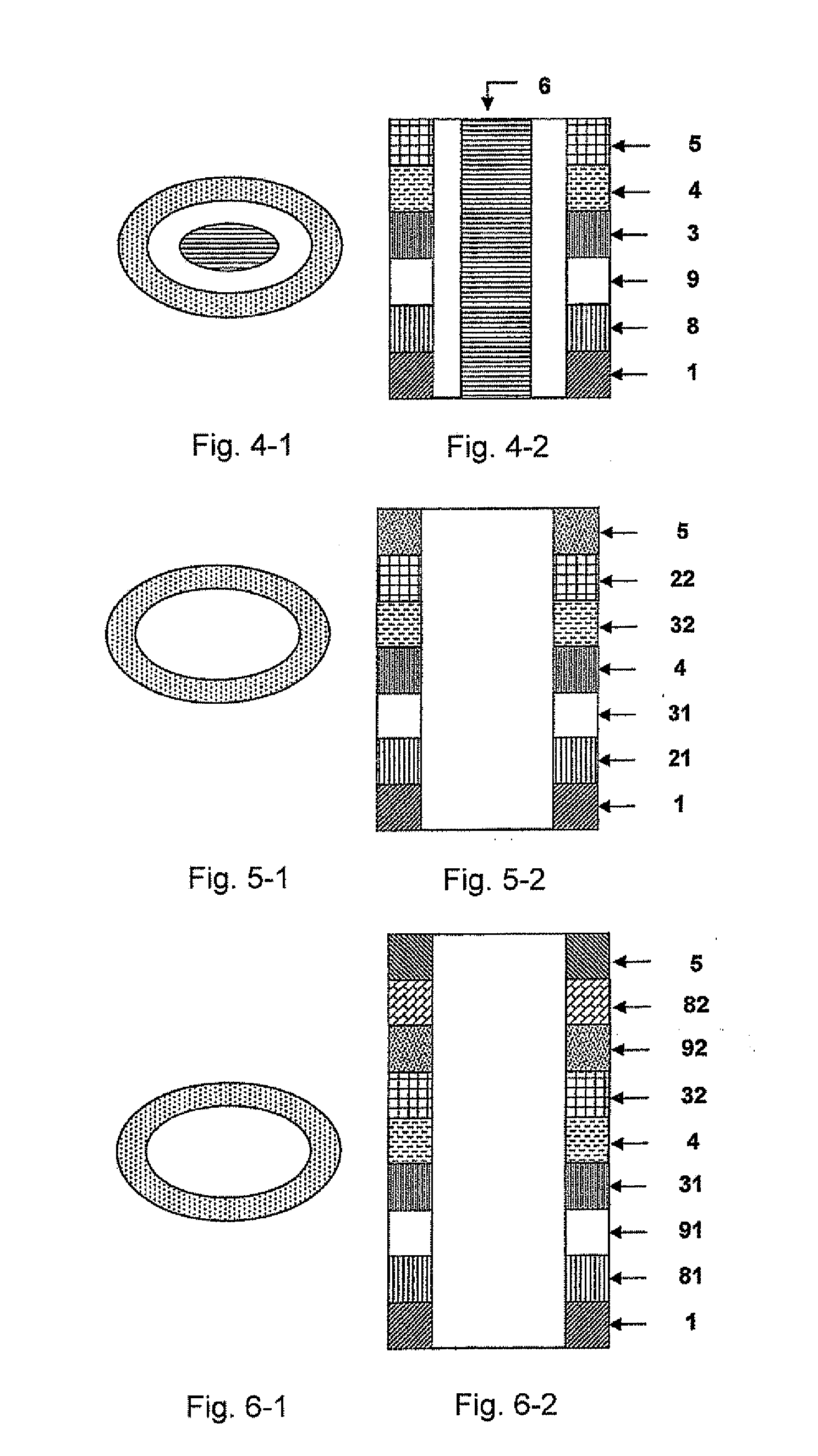

Close shaped magnetic multi-layer film comprising or not comprising a metal core and the manufacture method and the application of the same

InactiveUS20090168506A1High densitySmall scaleNanomagnetismMagnetic measurementsMagnetic beadMagnetic logic

Each layer in the magnetic multilayer film is a closed ring or oval ring and the magnetic moment or flux of the ferromagnetic film in the magnetic unit is in close state either clockwise or counterclockwise. A metal core is put in the geometry center position in the close-shaped magnetic multilayer film. The cross section of the metal core is a corresponding circular or oval. A MRAM is made of the closed magnetic multilayer film with or without a metal core. The close-shaped magnetic multilayer film is formed by micro process method. The close-shaped magnetic multilayer film can be used broadly in a great variety of device that uses a magnetic multilayer film as the core, such as MRAM, magnetic bead in computer, magnetic sensitive sensor, magnetic logic device and spin transistor.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

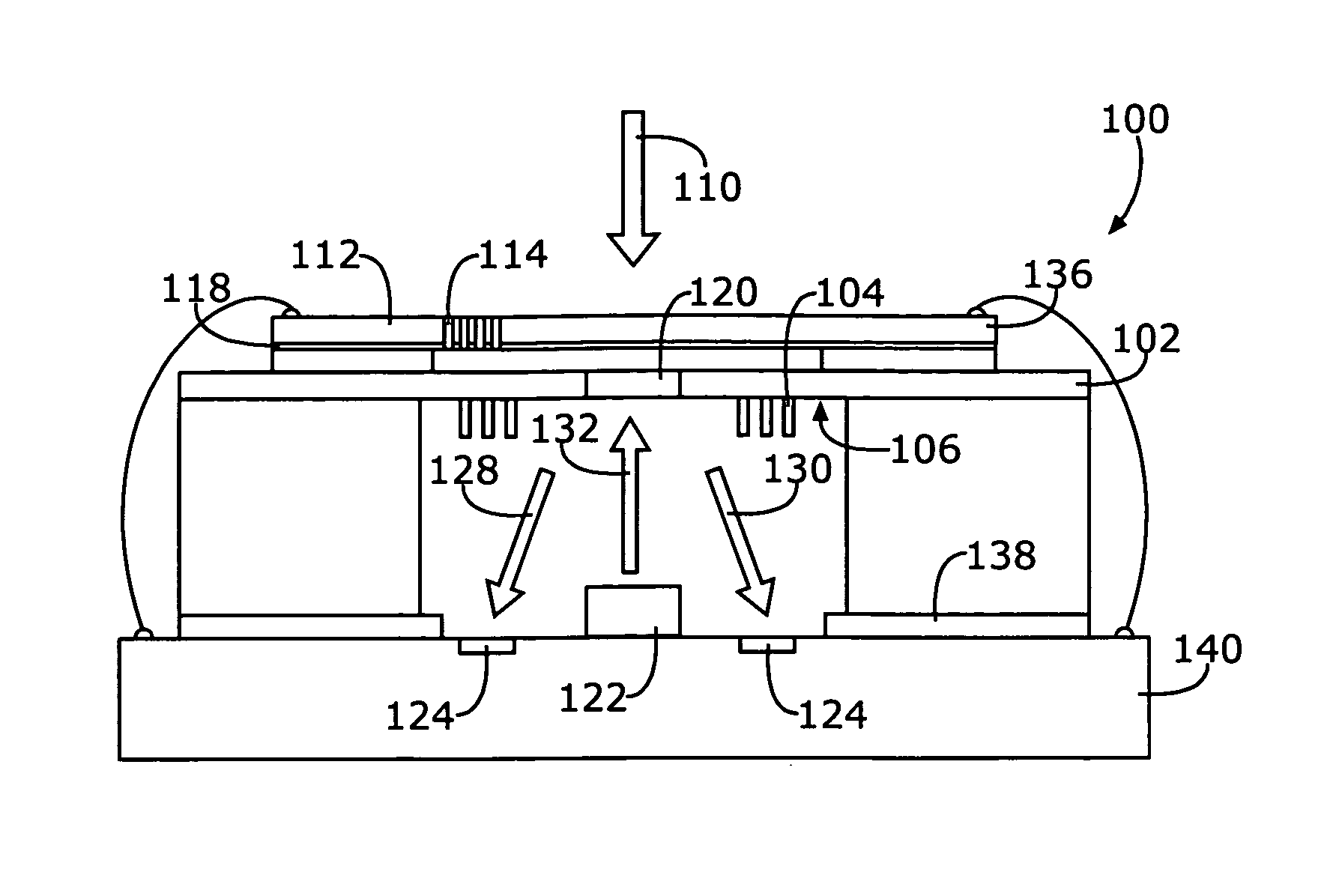

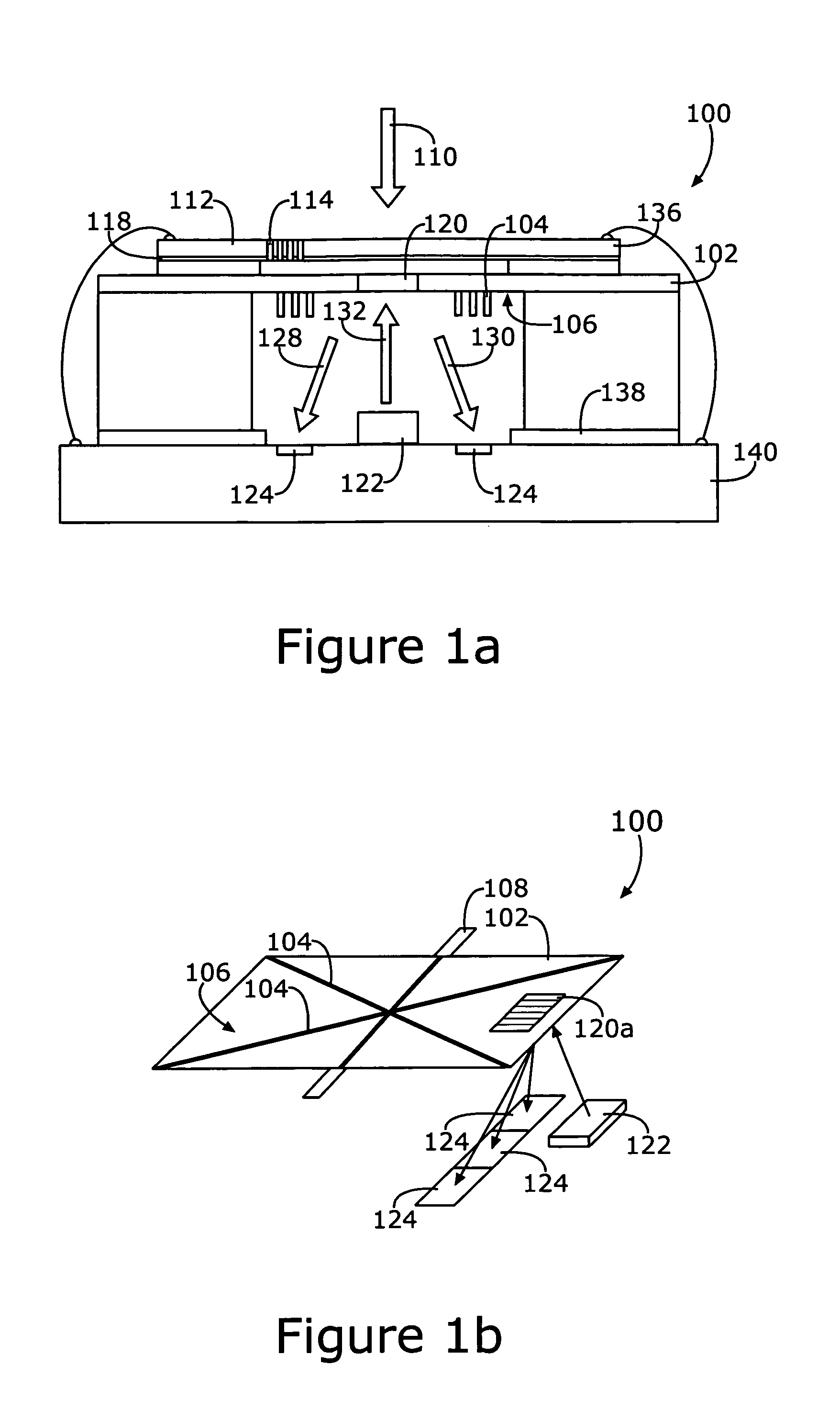

Optical sensing in a directional MEMS microphone

InactiveUS20070165896A1Bulky and heavyReduce external noiseVibration measurement in solidsSolid state device transducersEngineeringMems microphone

A microphone having an optical component for converting the sound-induced motion of the diaphragm into an electronic signal using a diffraction grating. The microphone with inter-digitated fingers is fabricated on a silicon substrate using a combination of surface and bulk micromachining techniques. A 1 mm×2 mm microphone diaphragm, made of polysilicon, has stiffeners and hinge supports to ensure that it responds like a rigid body on flexible hinges. The diaphragm is designed to respond to pressure gradients, giving it a first order directional response to incident sound. This mechanical structure is integrated with a compact optoelectronic readout system that displays results based on optical interferometry.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

Laser based material processing methods and scalable architecture for material processing

InactiveUS20030160034A1Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

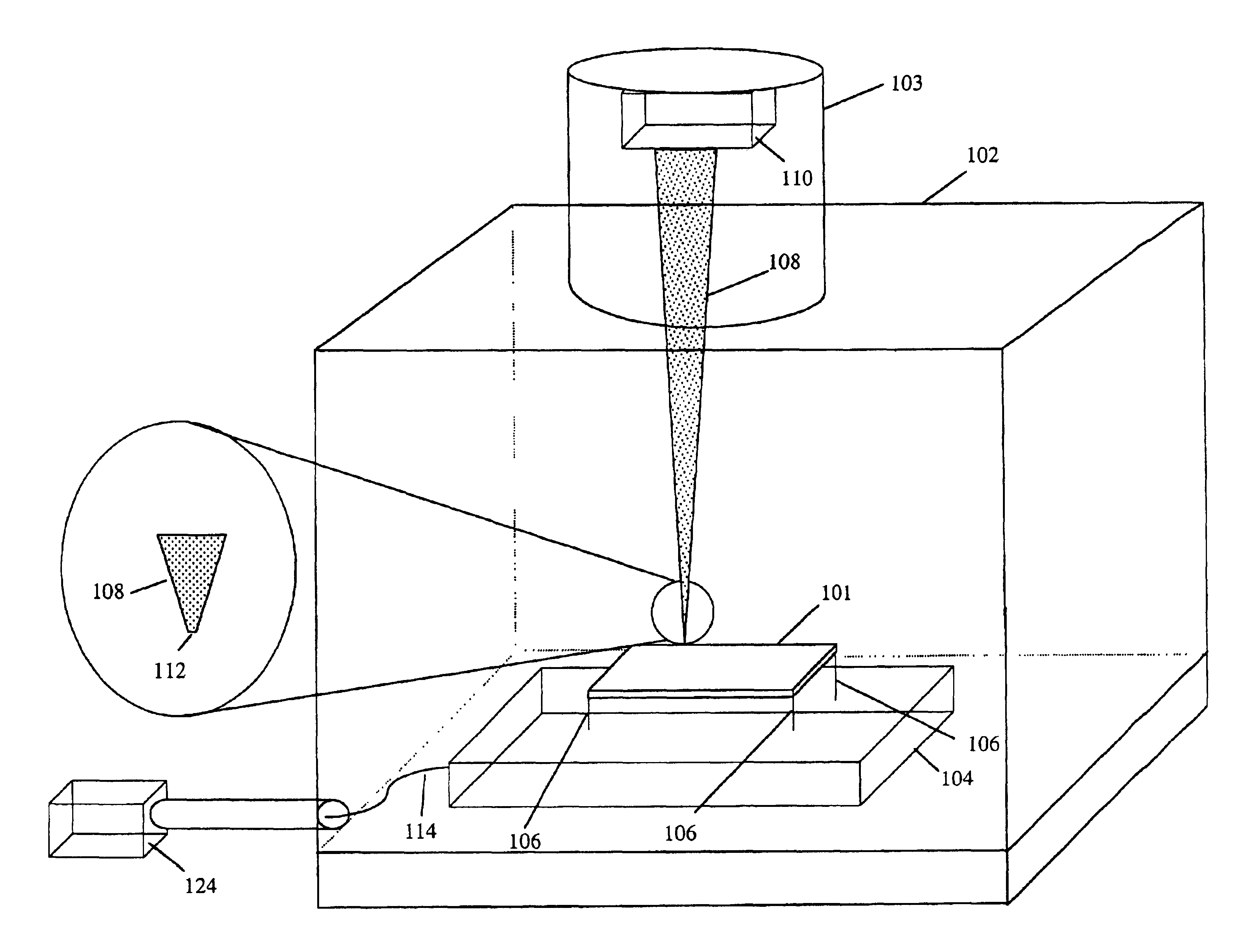

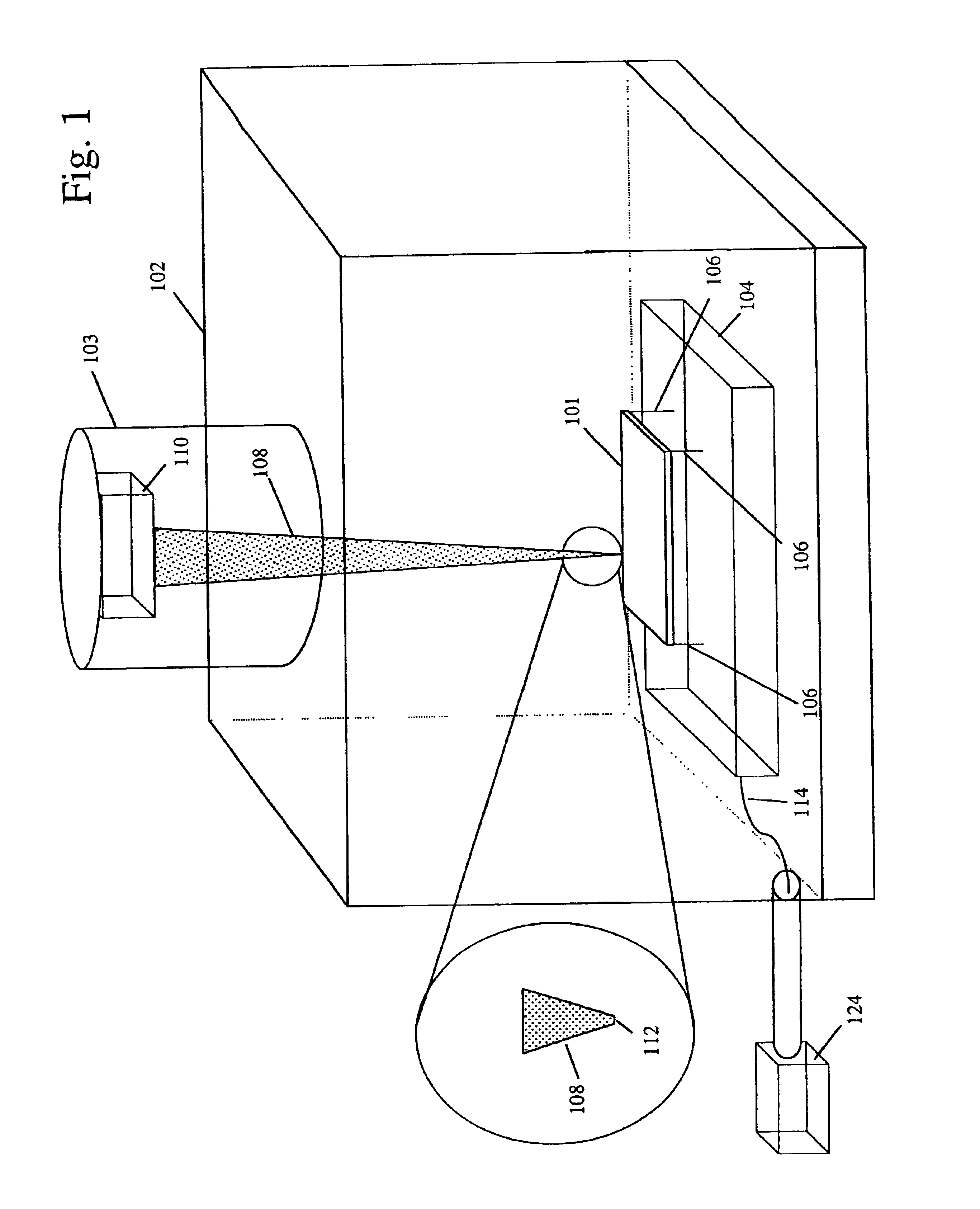

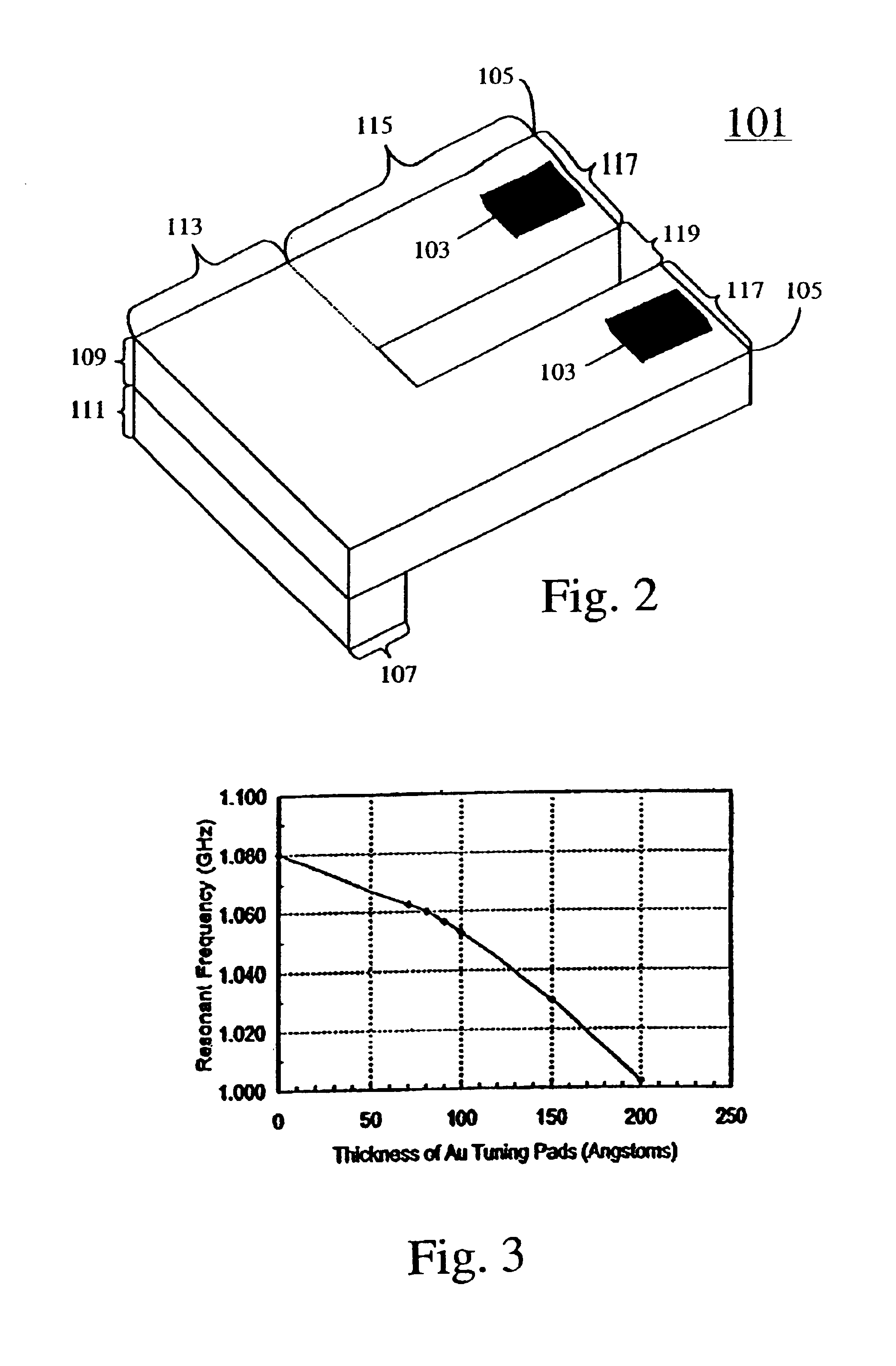

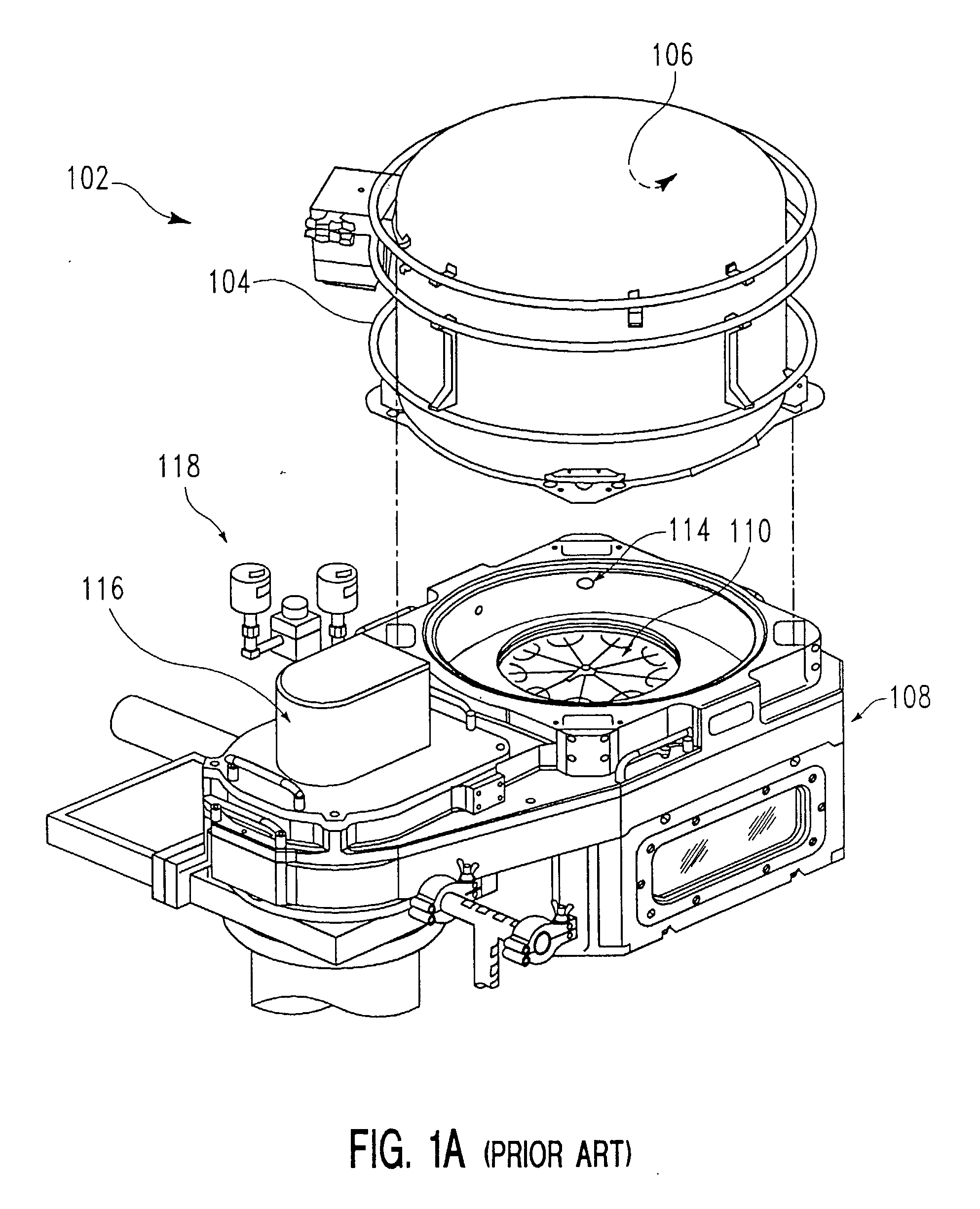

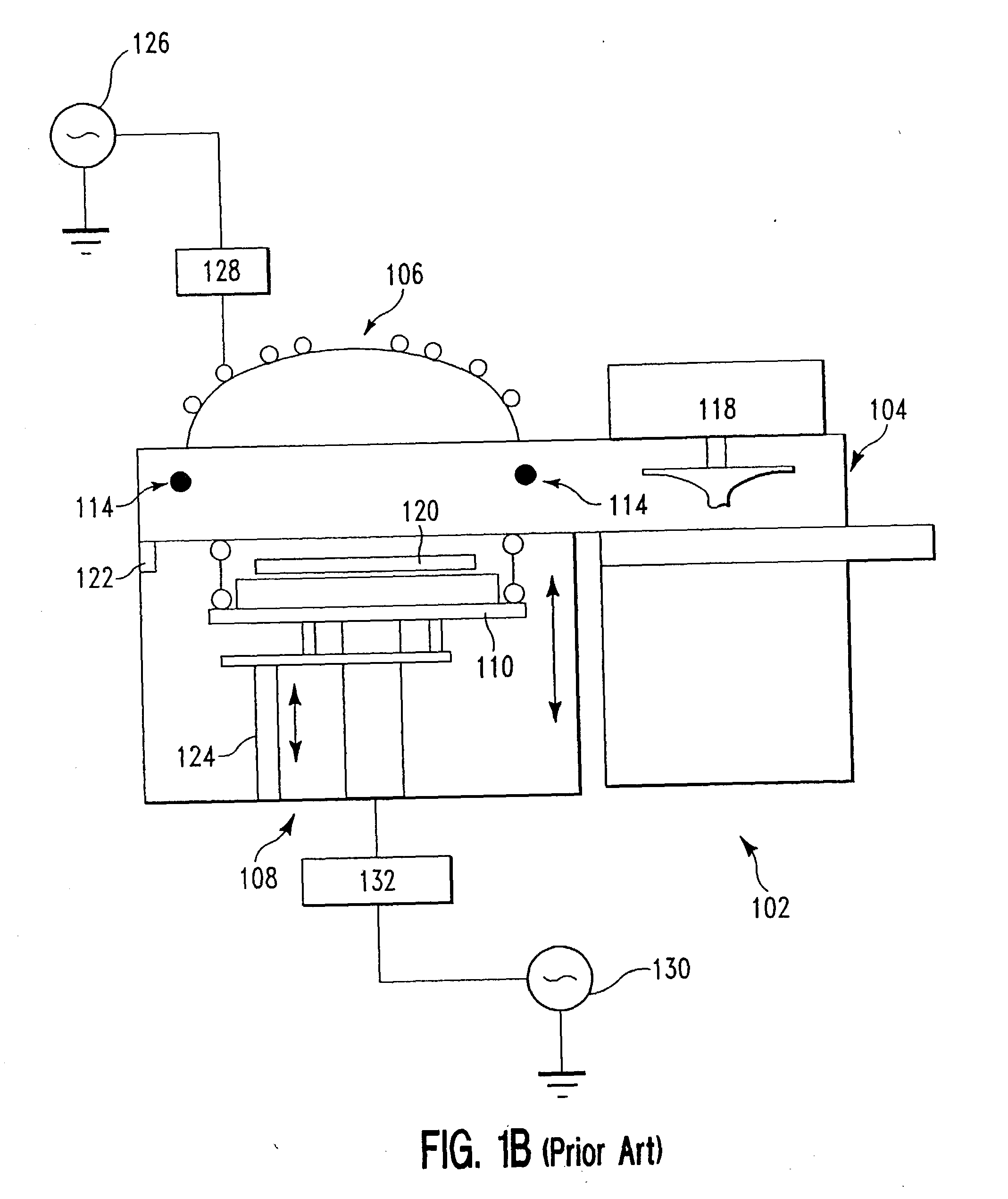

Micro electrical mechanical system (MEMS) tuning using focused ion beams

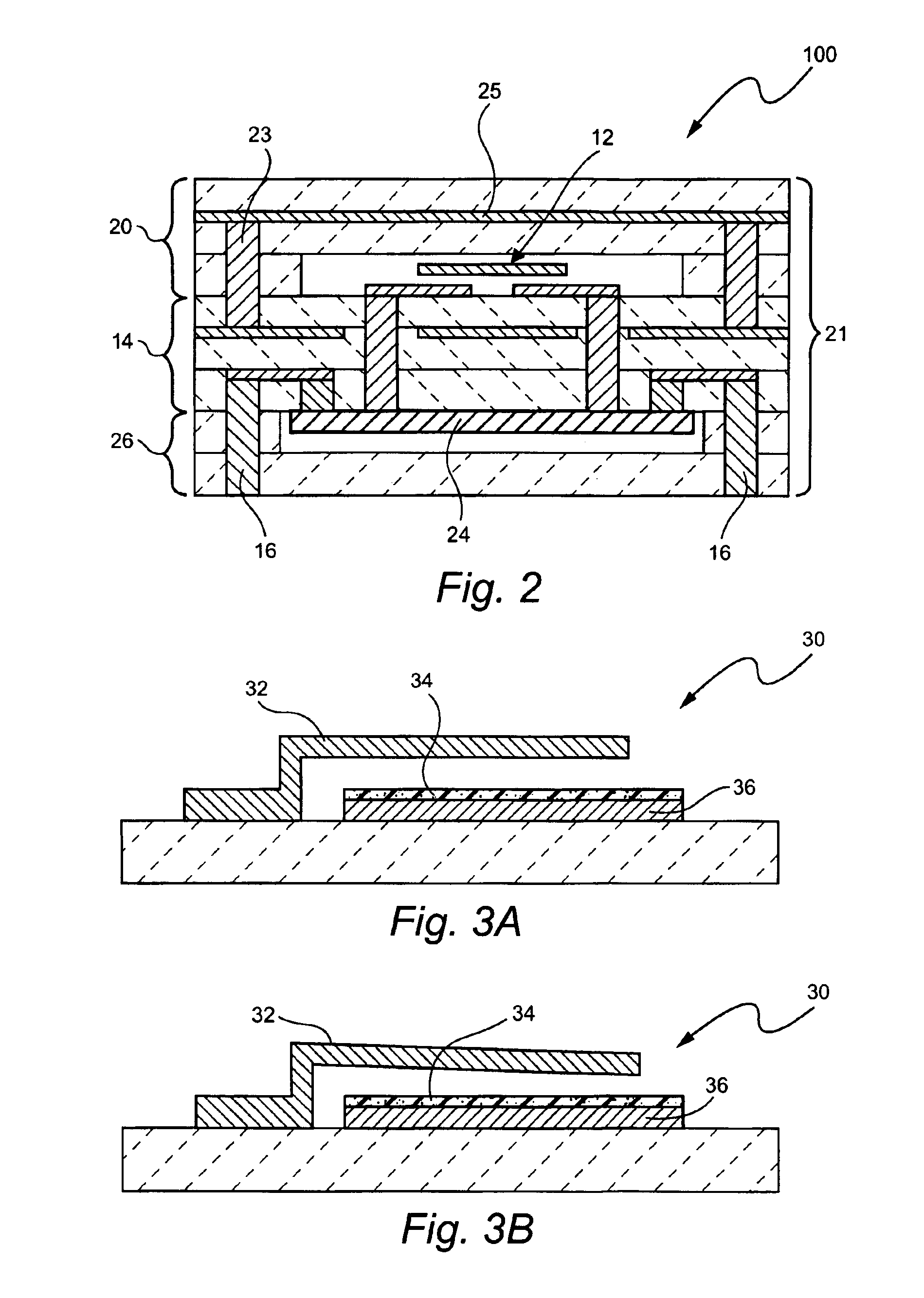

InactiveUS6922118B2Quality improvementChange the resonant frequencyCellsPiezoelectric/electrostriction/magnetostriction machinesIon beamActive layer

A method for tuning an electro-mechanical device such as a MEMS device is disclosed. The method comprises operating a MEMS device in a depressurized system and using FIB micromachining to remove a portion of the MEMS device. Additionally, a method for tuning a plurality of MEMS devices by depositing an active layer and then removing a portion of the active layer using FIB micromachining. Also, a method for tuning a MEMS device and vacuum packaging the MEMS device in situ are provided.

Owner:HRL LAB

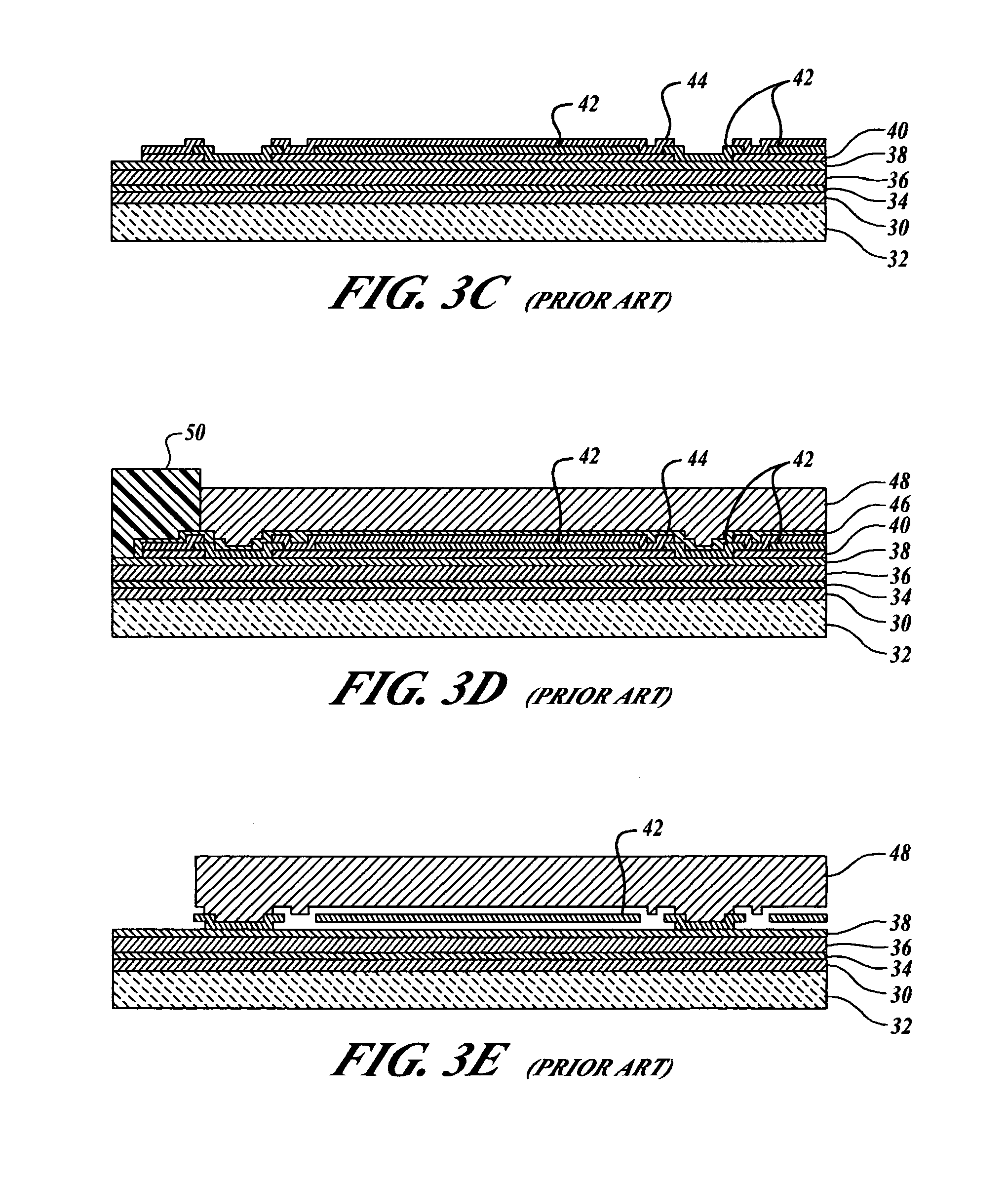

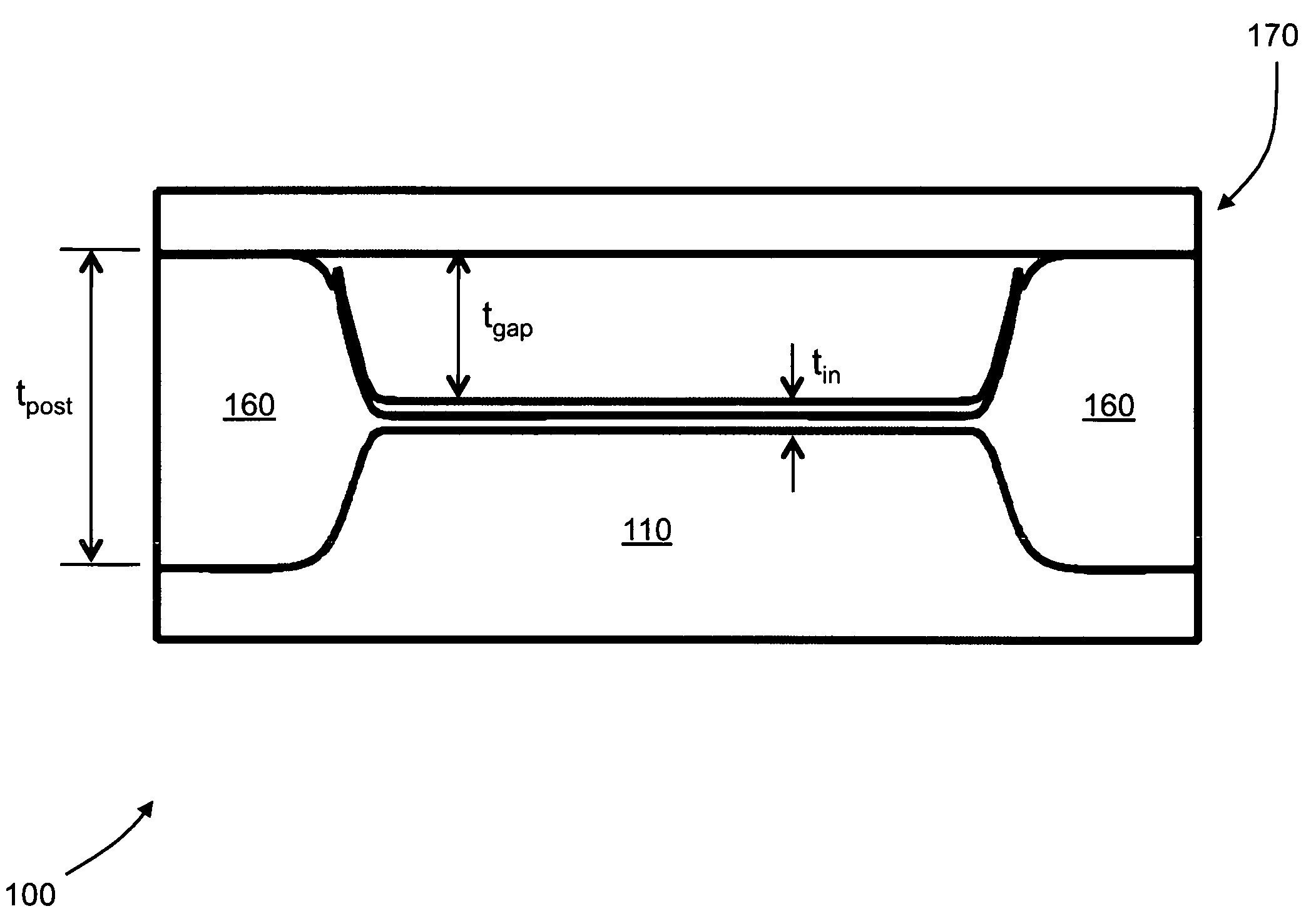

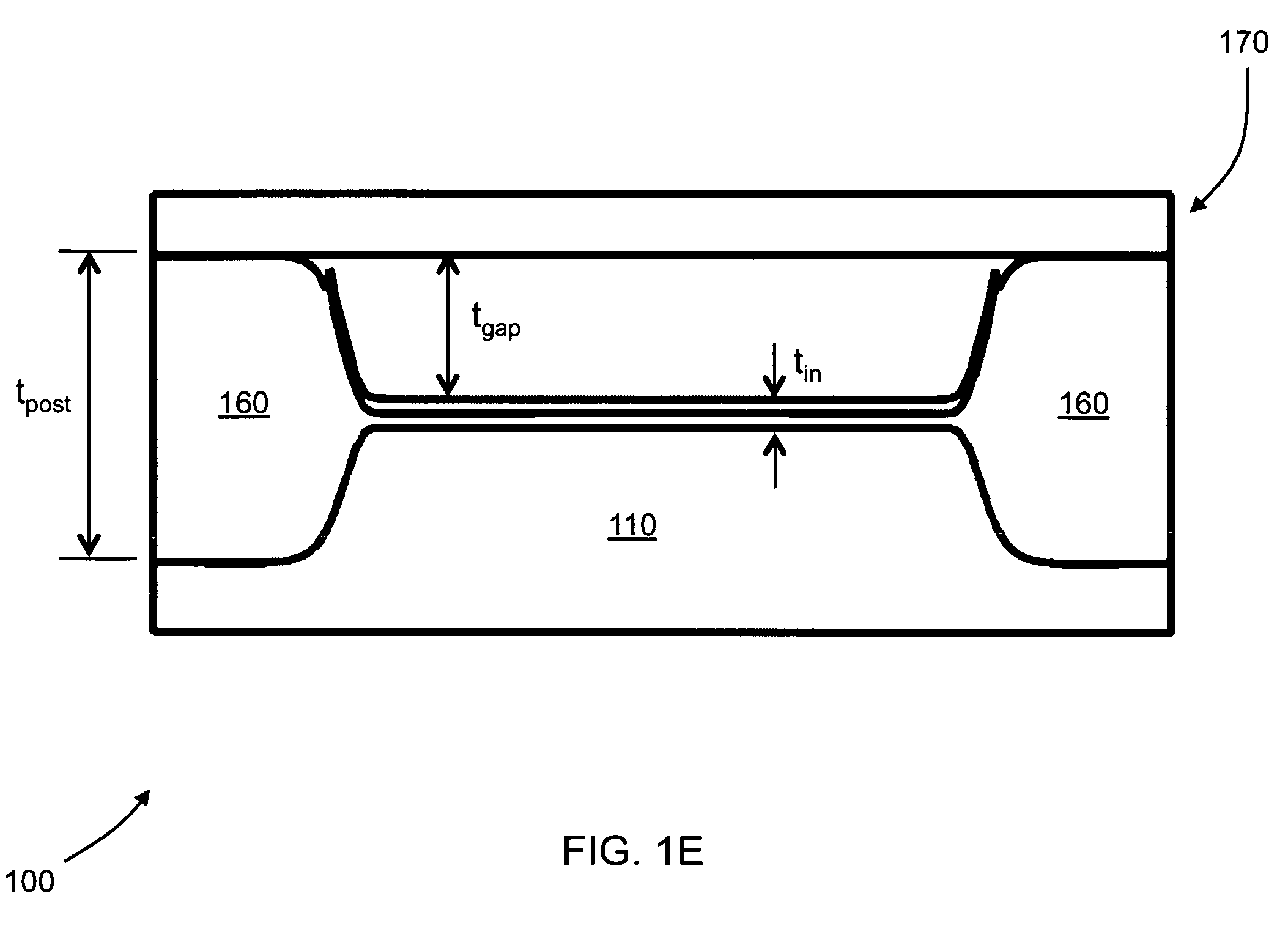

Fabrication of capacitive micromachined ultrasonic transducers by local oxidation

ActiveUS7745248B2Reduce parasitic capacitanceImprove breakdown voltageSemiconductor/solid-state device manufacturingMechanical vibrations separationCapacitanceCapacitive micromachined ultrasonic transducers

The current invention provides methods of fabricating a capacitive micromachined ultrasonic transducer (CMUT) that includes oxidizing a substrate to form an oxide layer on a surface of the substrate having an oxidation-enabling material, depositing and patterning an oxidation-blocking layer to form a post region and a cavity region on the substrate surface and remove the oxidation-blocking layer and oxide layer at the post region. The invention further includes thermally oxidizing the substrate to grow one or more oxide posts from the post region, where the post defines the vertical critical dimension of the device, and bonding a membrane layer onto the post to form a membrane of the device. A maximum allowed second oxidation thickness t2 can be determined, that is partially based on a desired step height and a device size, and a first oxidation thickness t1 can be determined that is partially based on the determined thickness t2.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

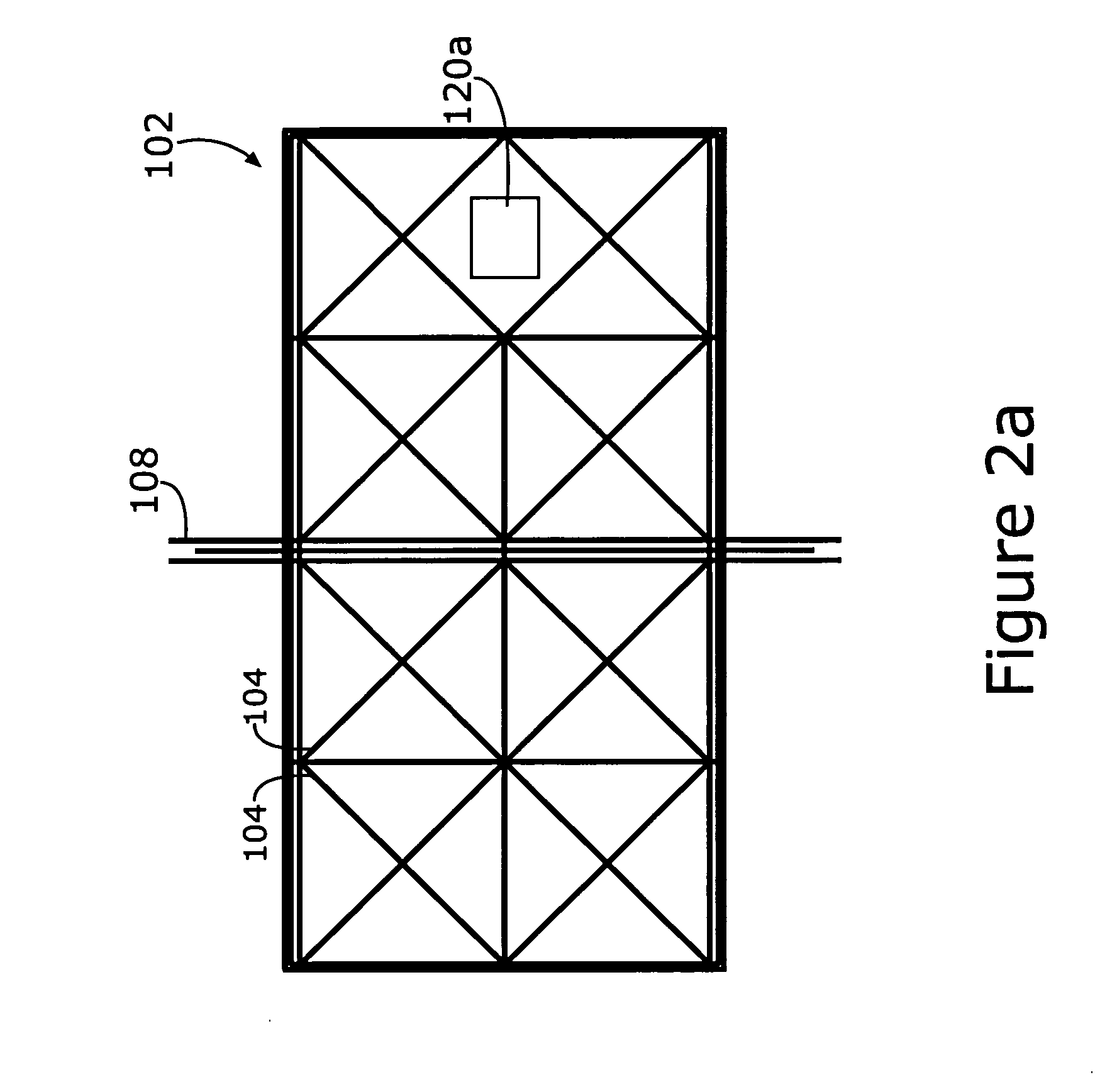

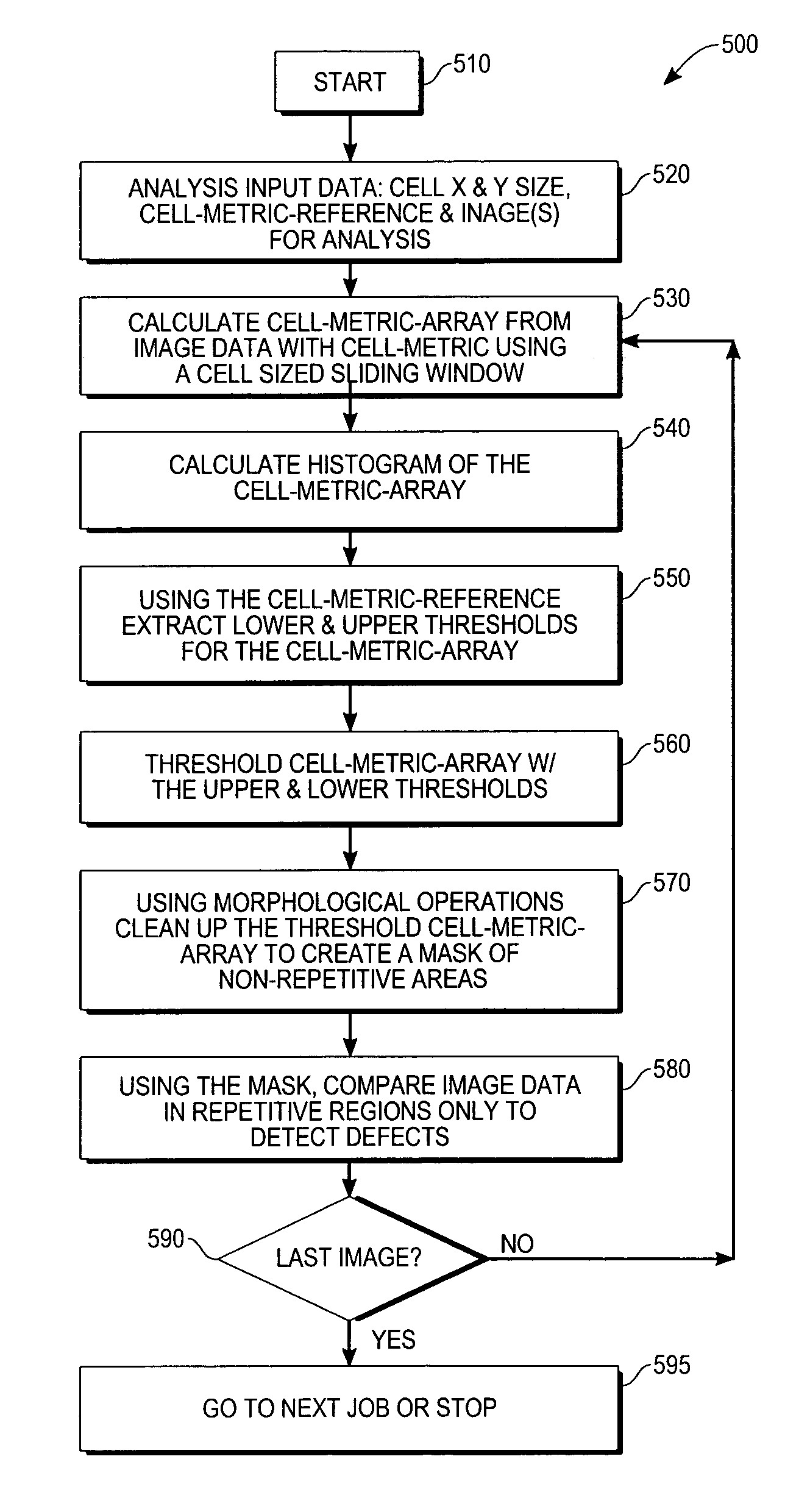

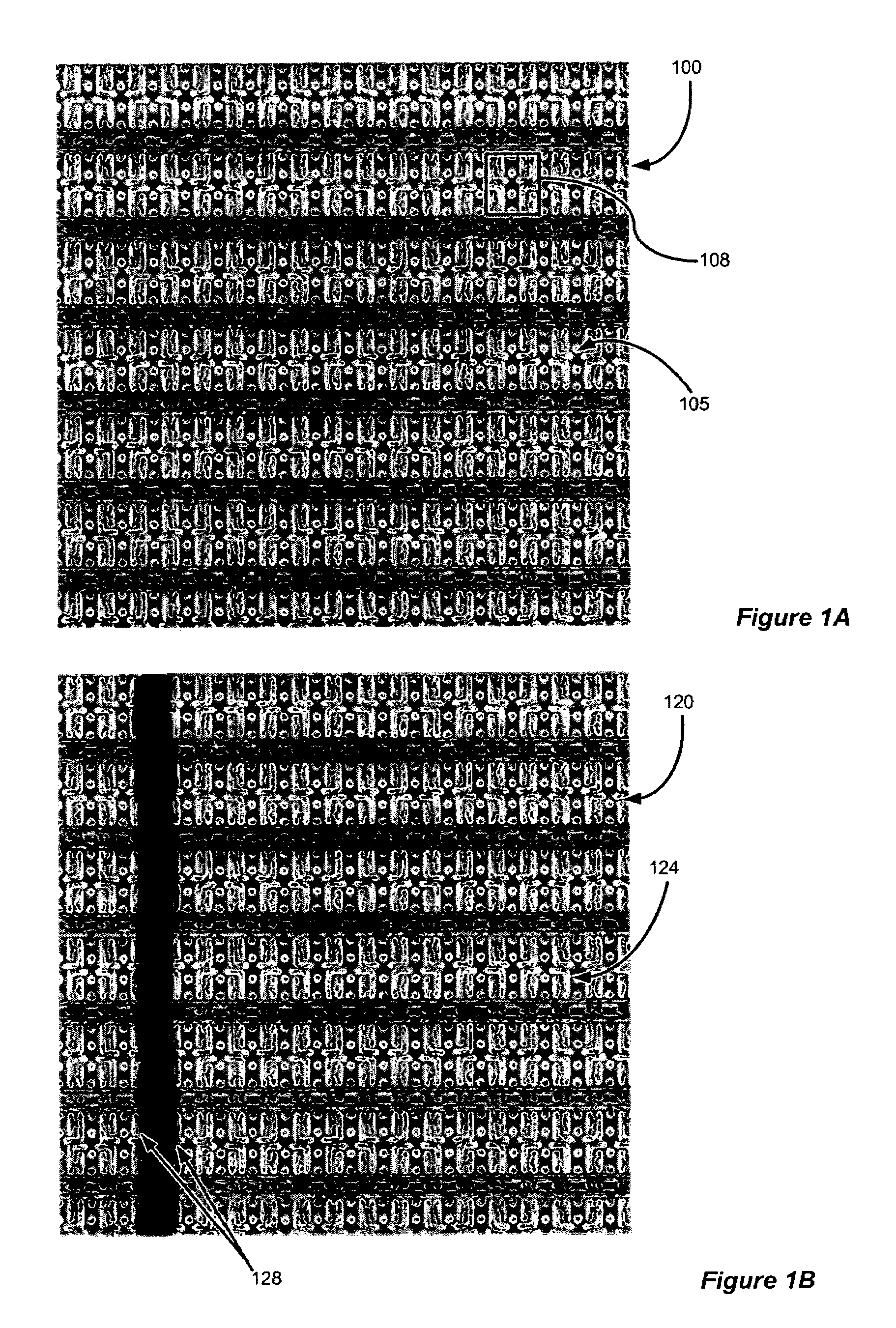

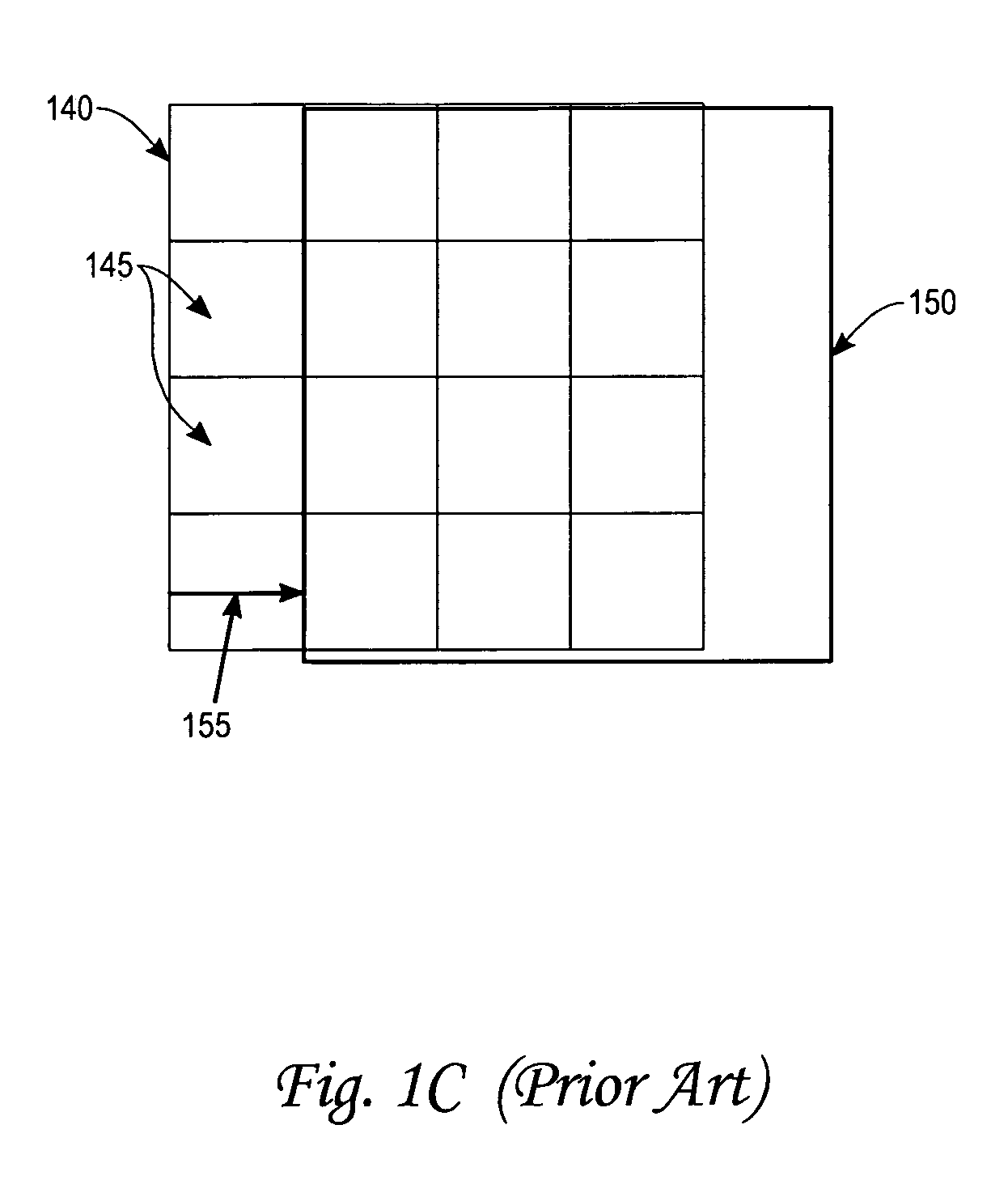

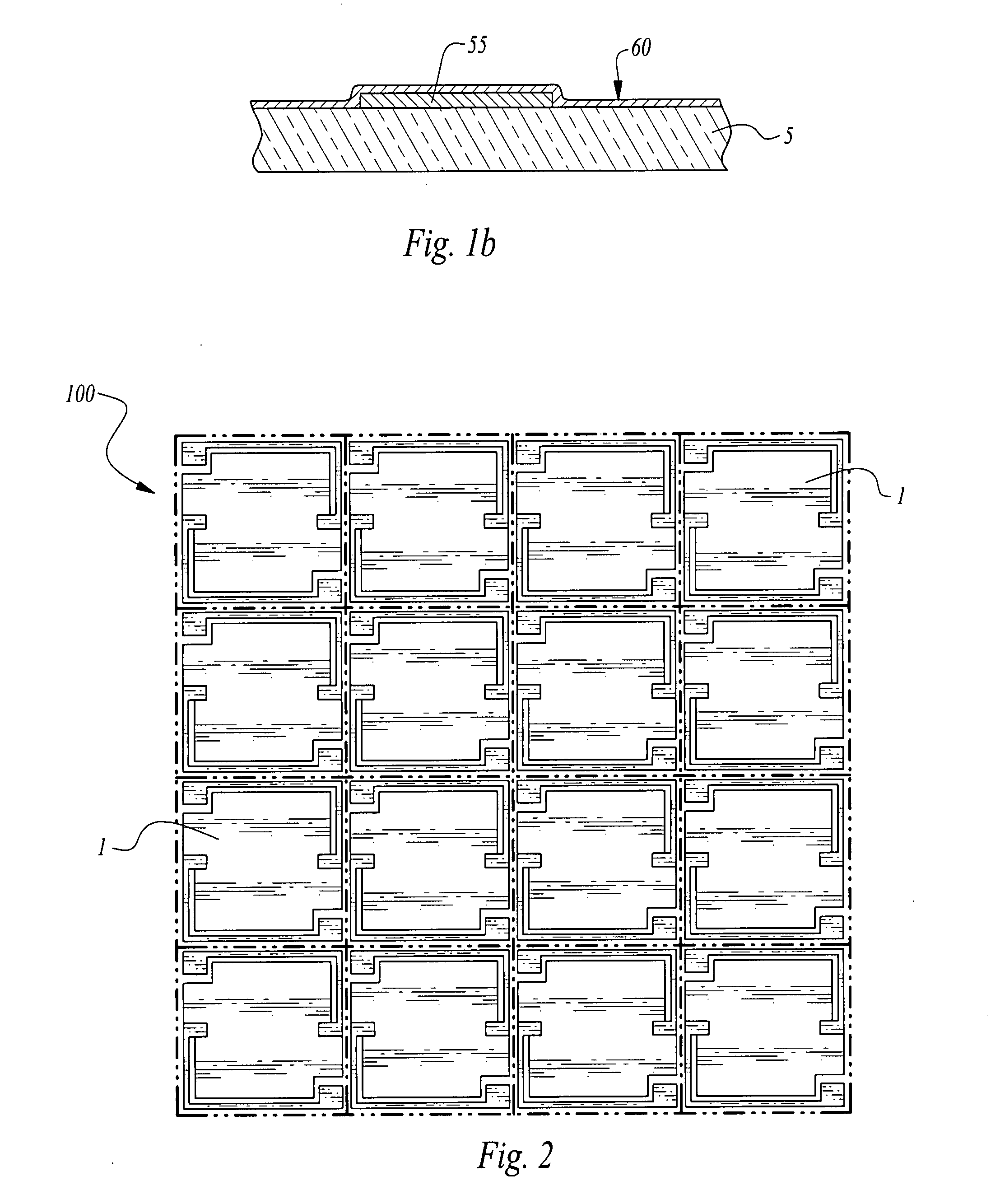

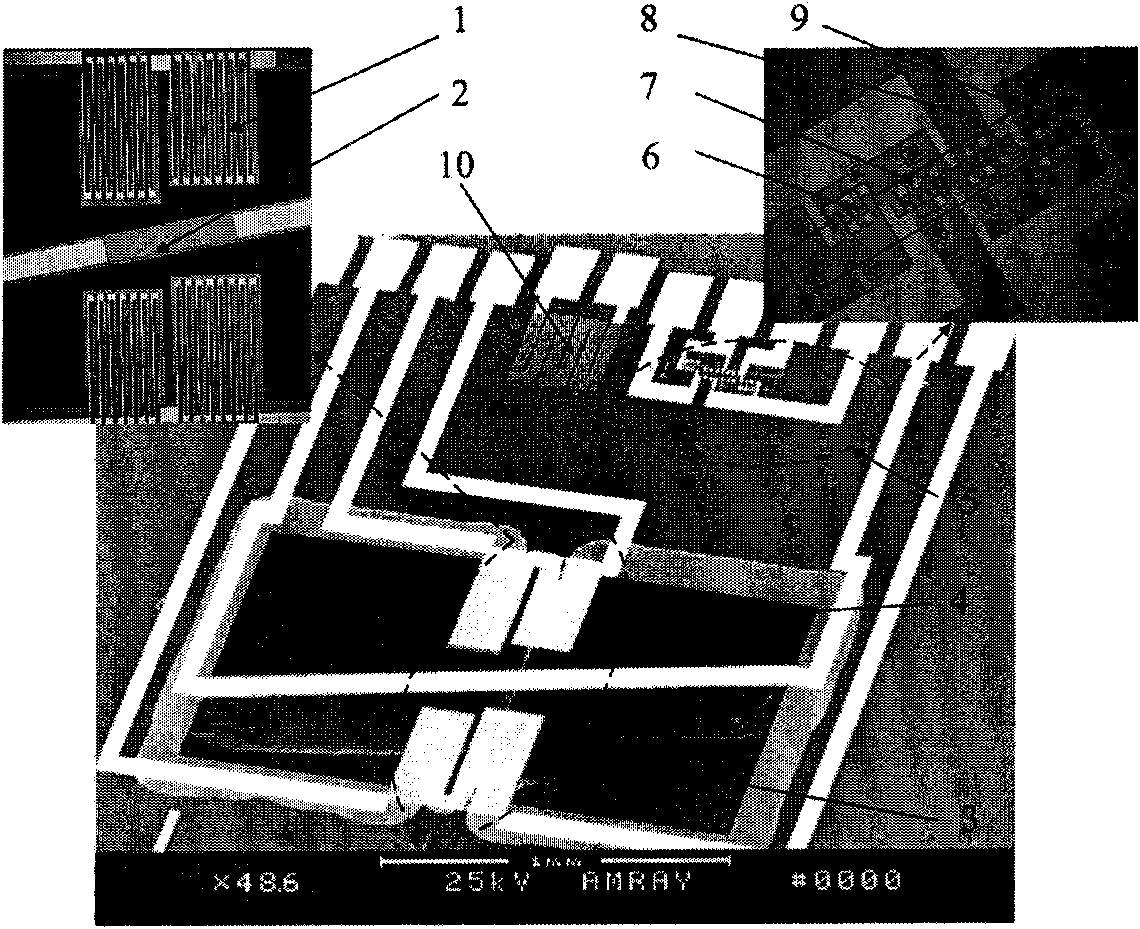

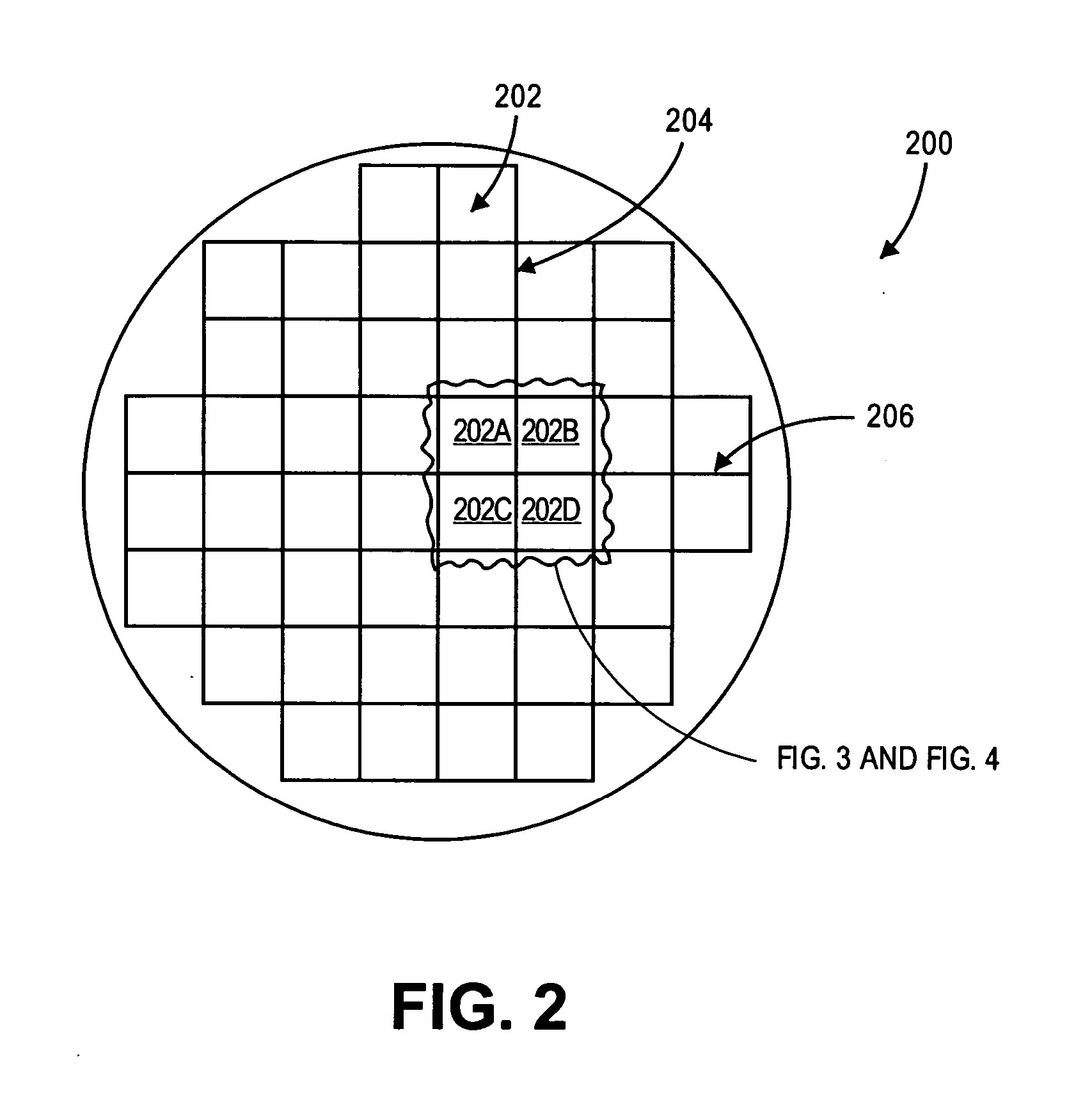

Automated repetitive array microstructure defect inspection

InactiveUS7065239B2Eliminating and minimizing impactImage enhancementImage analysisMicro fabricationDisplay device

A method and system for defect inspection of microfabricated structures such as semiconductor wafers, masks or reticles for micro-fabrication, flat panel displays, micro-electro-mechanical (MEMs) having repetitive array regions such as memories or pixels. In one embodiment a method of inspection of microfabricated structures includes the steps of acquiring contrast data or images from the microfabricated structures, analyzing automatically the contrast data or images to find repetitive regions of the contrast data and comparing the repetitive regions of the contrast data with reference data to detect defects in the microfabricated structures. In the analyzing step, a cell-metric such as the range, or mean or other statistical or mathematical measure of the contrast data is used to find the repetitive regions. Image or contrast data acquisition can be performed with an optical, e-beam or other microscope suited for microfabricated structures.

Owner:APPLIED MATERIALS INC

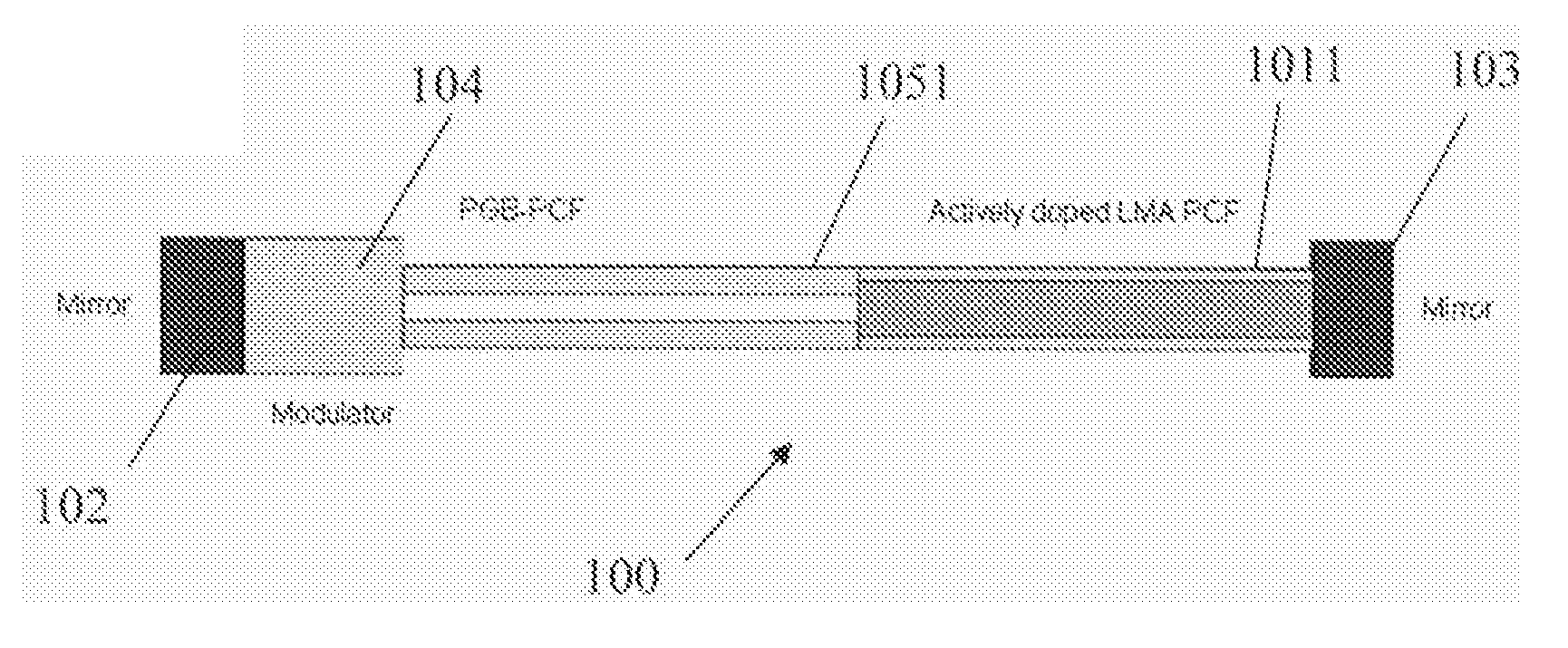

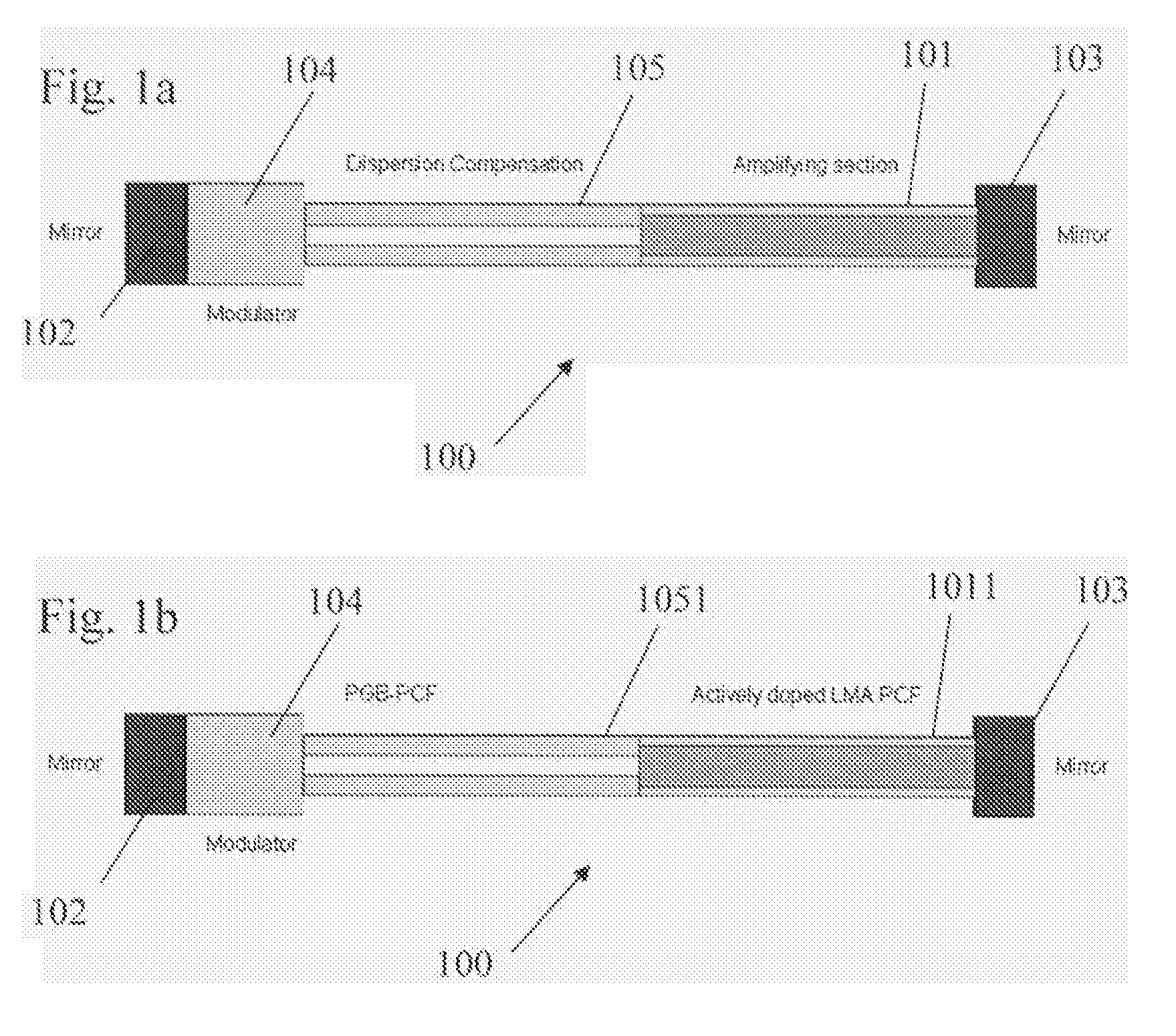

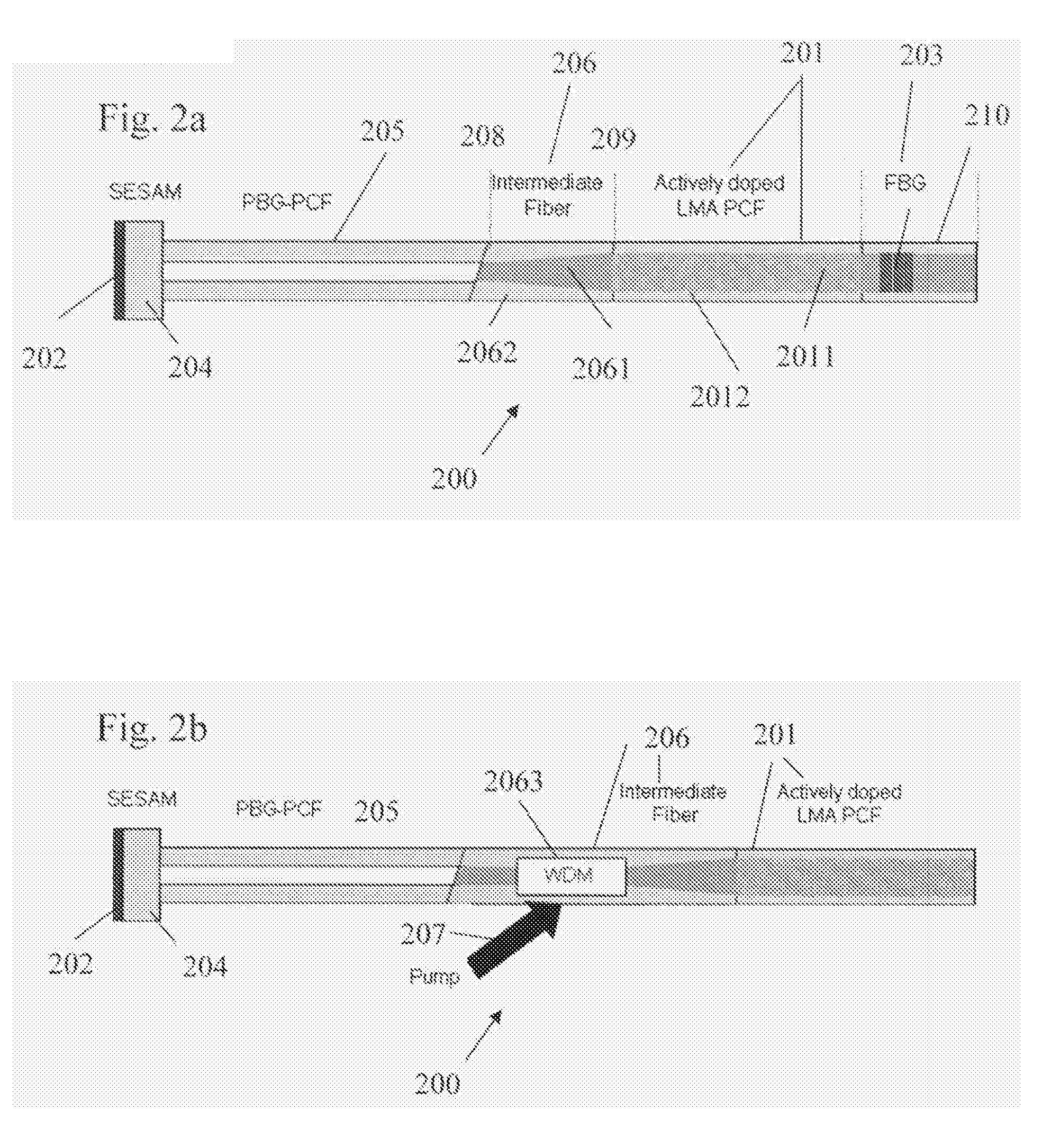

An Optical System For Providing Short Laser-Pulses

InactiveUS20060209908A1High core diameterIncrease valueCladded optical fibreLaser using scattering effectsCost effectivenessPhotonic bandgap

The present invention deals with optical systems for providing short laser pulses. An object of the invention is to provide an optical system providing compact and cost-effective short laser-pulses using fibers with anomalous dispersion and high non-linear thresholds. The object is achieved by a short pulse optical system for generating or processing short laser-pulses, said optical system comprises an optical fiber in the form of a photonic crystal fiber arranged to provide guidance of light in the core region due to the photonic bandgap effect (PBG), where light propagates in a hollow or solid core surrounded by a Silica cladding comprising a substantially periodic distribution of micro-structural elements, and where the refractive index of the core is lower than the effective refractive index of the cladding. The invention may be useful in applications such as laser-based micromachining, thin-film formation, laser cleaning, in medicine and biology.

Owner:NKT PHOTONICS

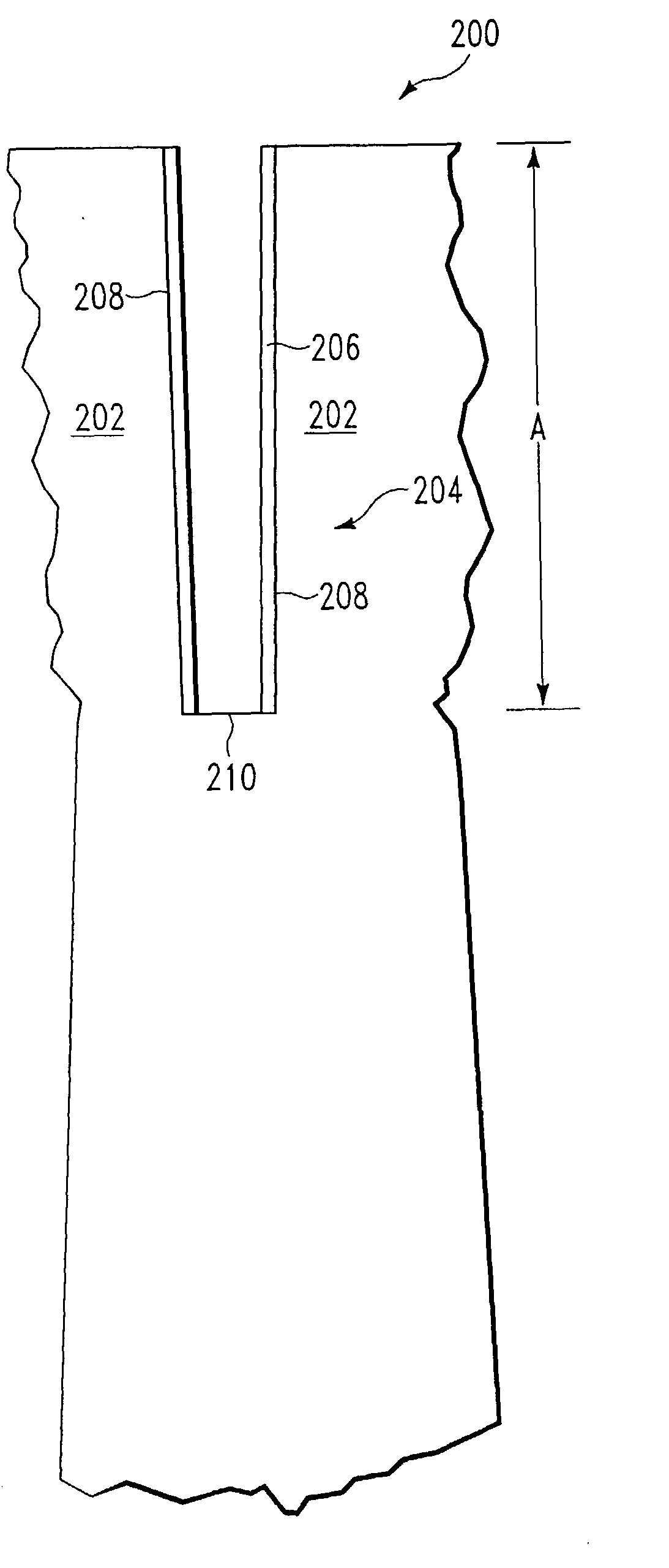

Method of micromachining a multi-part cavity

InactiveUS20020185469A1Decorative surface effectsSolid-state devicesProtection layerMaterials science

The present disclosure pertains to our discovery of a particularly efficient method for etching a multi-part cavity in a substrate. The method provides for first etching a shaped opening, depositing a protective layer over at least a portion of the inner surface of the shaped opening, and then etching a shaped cavity directly beneath and in continuous communication with the shaped opening. The protective layer protects the etch profile of the shaped opening during etching of the shaped cavity, so that the shaped opening and the shaped cavity can be etched to have different shapes, if desired. In particular embodiments of the method of the invention, lateral etch barrier layers and / or implanted etch stops are also used to direct the etching process. The method of the invention can be applied to any application where it is necessary or desirable to provide a shaped opening and an underlying shaped cavity having varying shapes. The method is also useful whenever it is necessary to maintain tight control over the dimensions of the shaped opening.

Owner:APPLIED MATERIALS INC

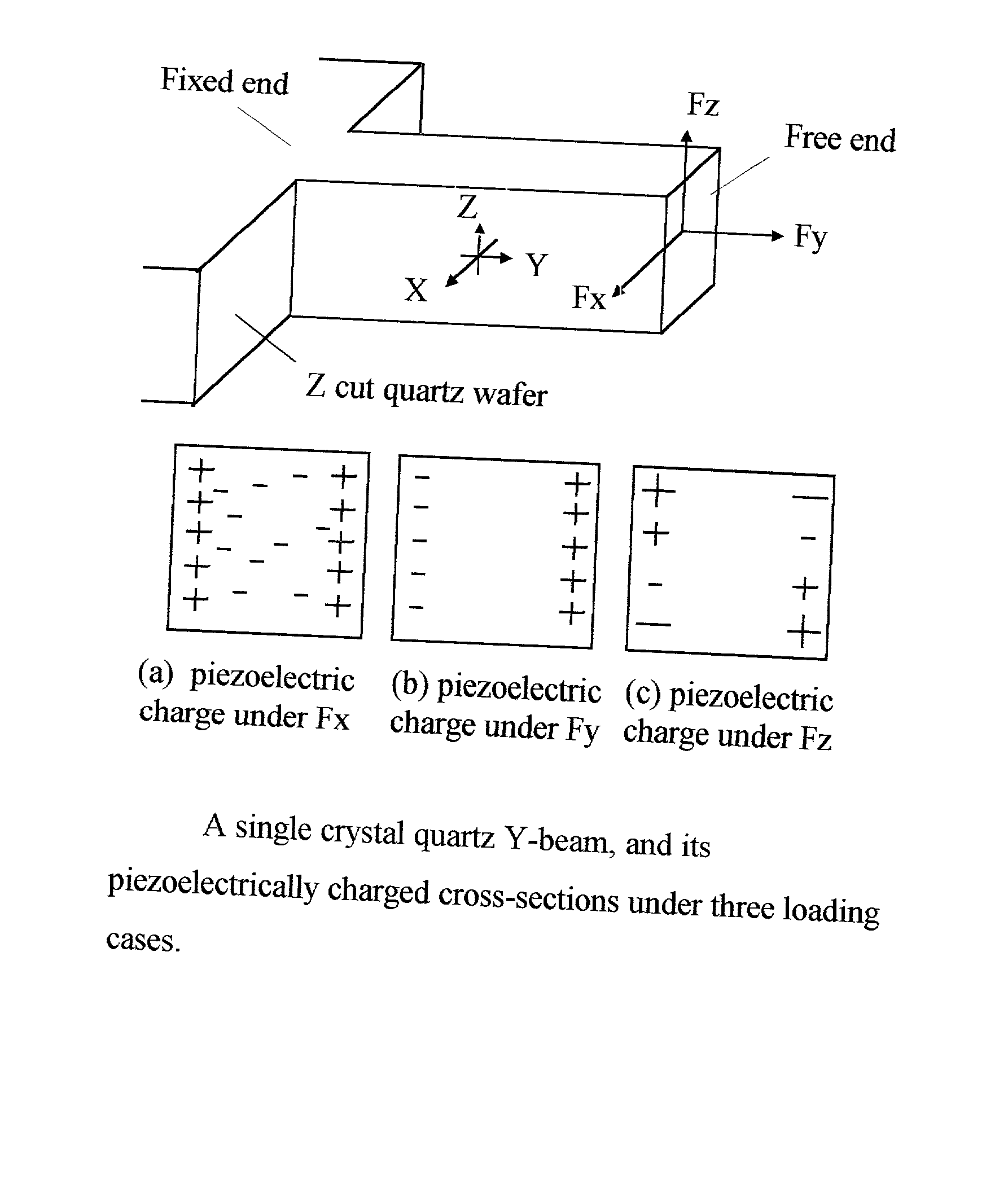

Micro yaw rate sensors

InactiveUS20020066317A1Electric signal transmission systemsAcceleration measurement using interia forcesEngineeringMicromachinings

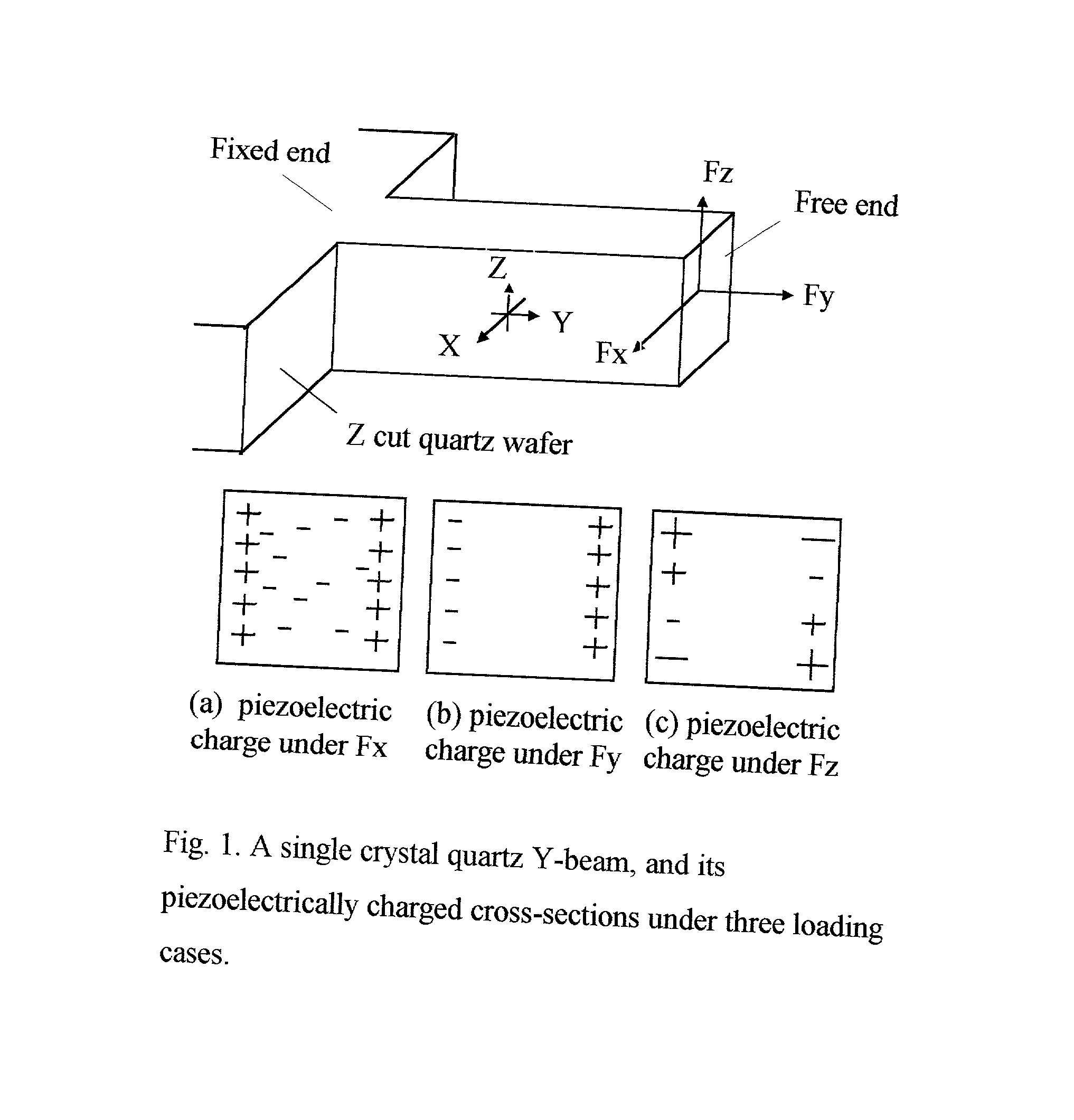

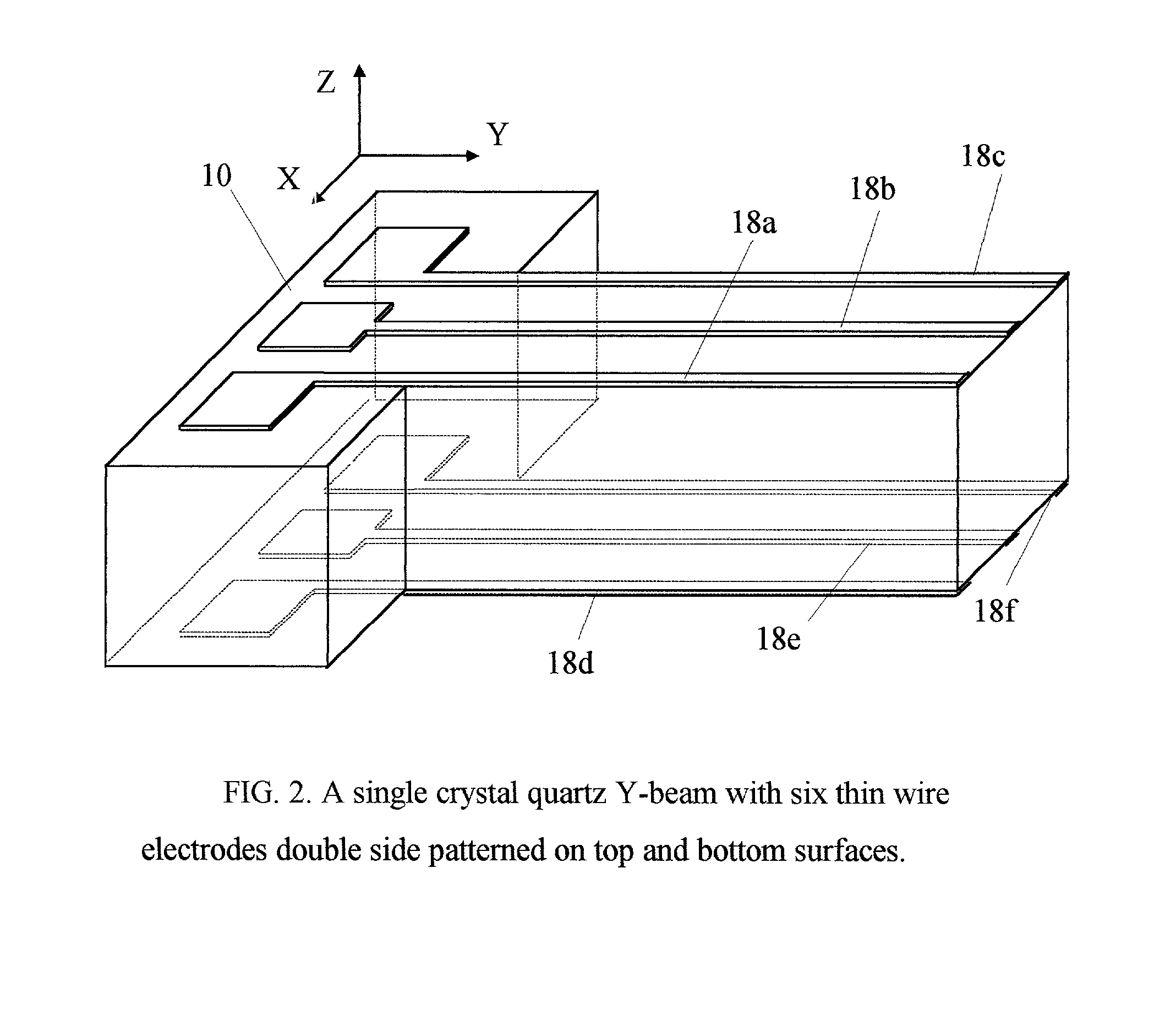

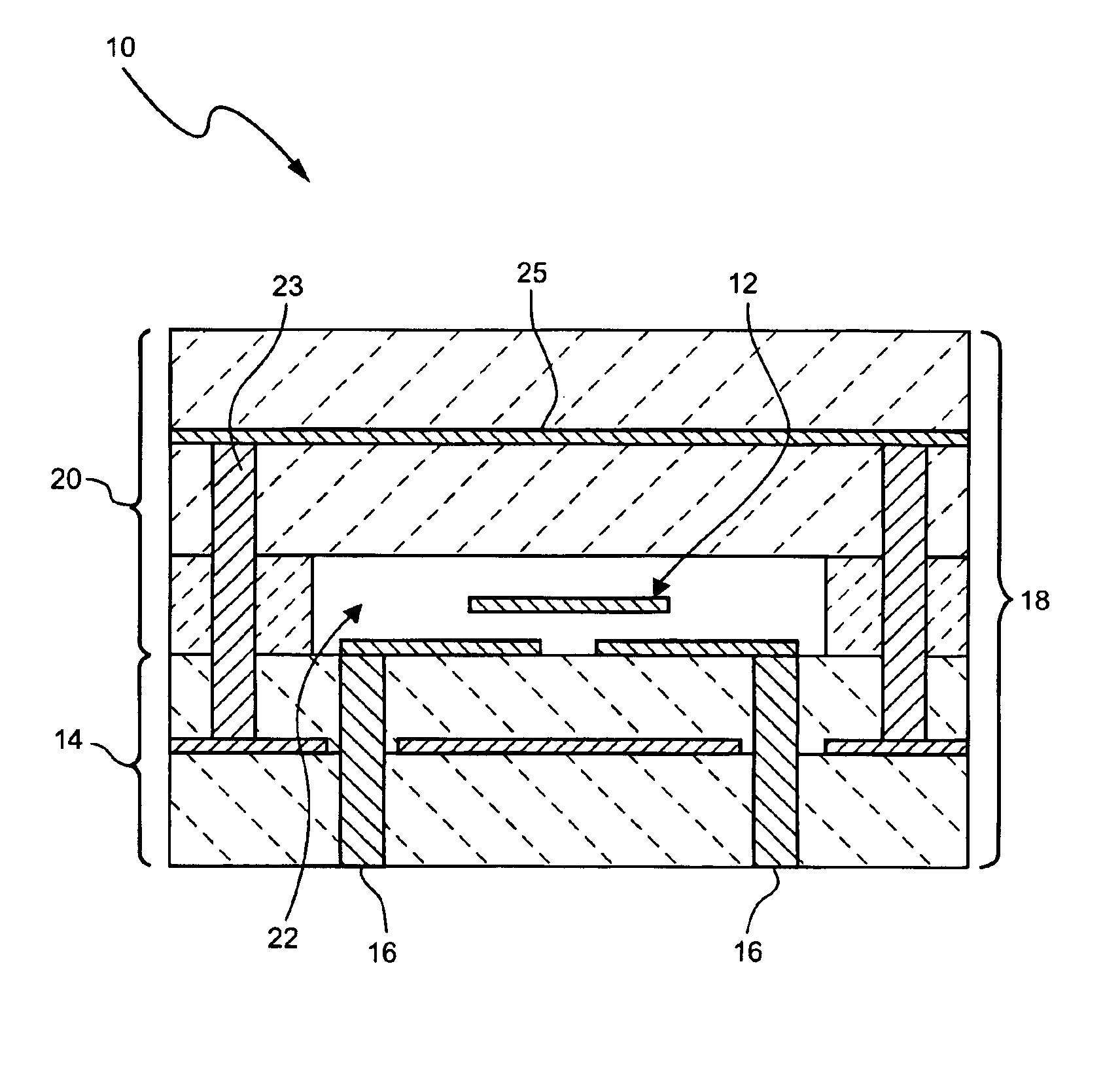

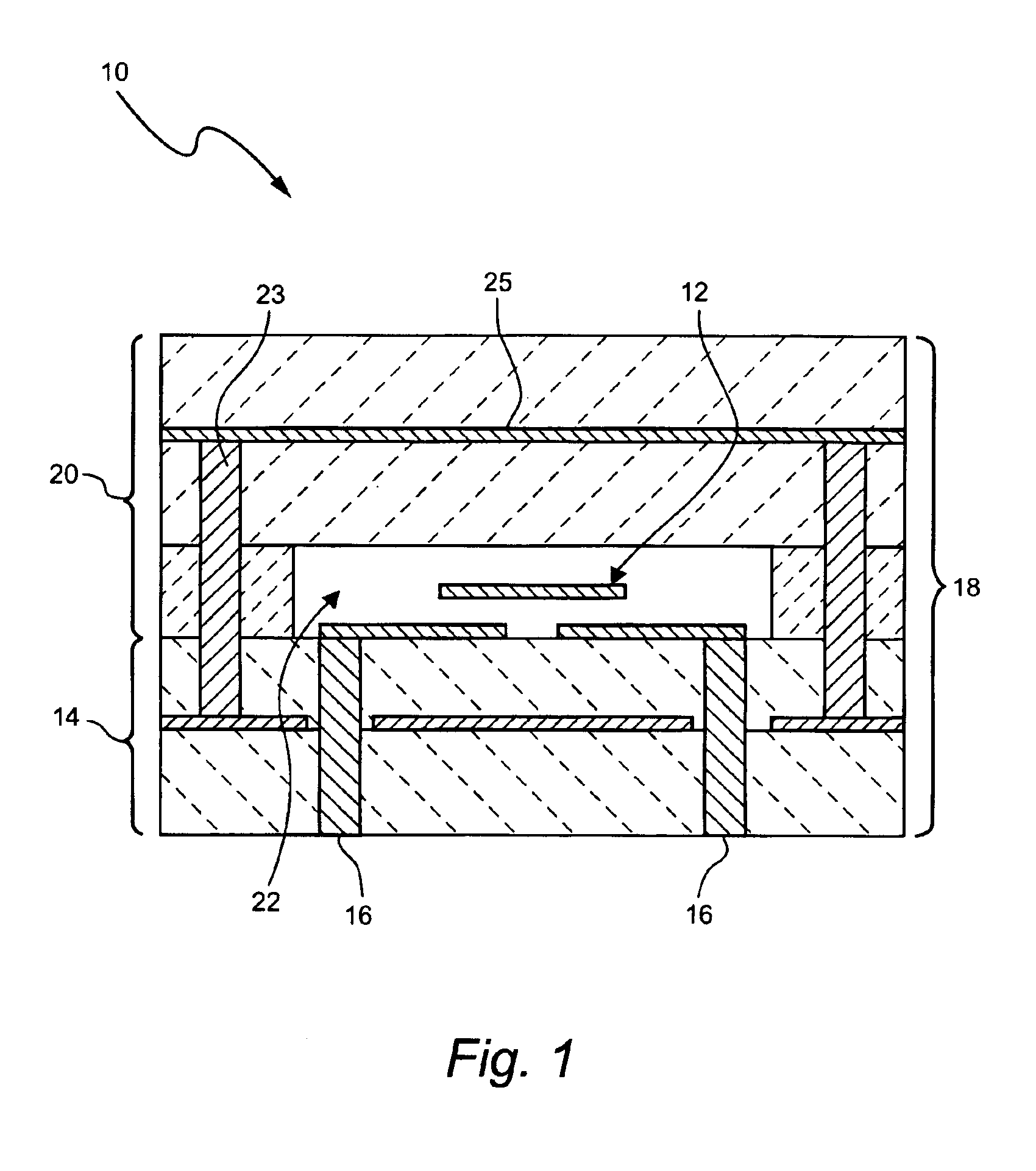

Yaw rate sensors are provided, the use of which permits quantitative measurement of yaw rate. The yaw rate sensor comprises at least a base, a first suspension and a second suspension with a proof mass supported between the two suspensions, which together form a resonator. The first suspension has a pair of thin-wire driving electrodes double side patterned on the surfaces. When a driving voltage is applied to the driving electrodes, it imposes an electric field to piezoelectrically induce a driving resonance. When the sensor is rotated around its sensing axis, the resonator will be forced to generate a sensing resonance out of the driving resonance plane to compensate the change in the linear momentum which must be conserved. The piezoelectric charge signal generated by the sensing resonance on the sensing electrodes which are double side patterned on the surfaces of the second suspension is used to detect the yaw rate. Specifically, the amplitude of the sensing resonance is in proportion to the yaw rate. The structure of the yaw rate sensors of this invention is suitable for mass production by lithographic micromachining techniques at low cost.

Owner:LIN GANG

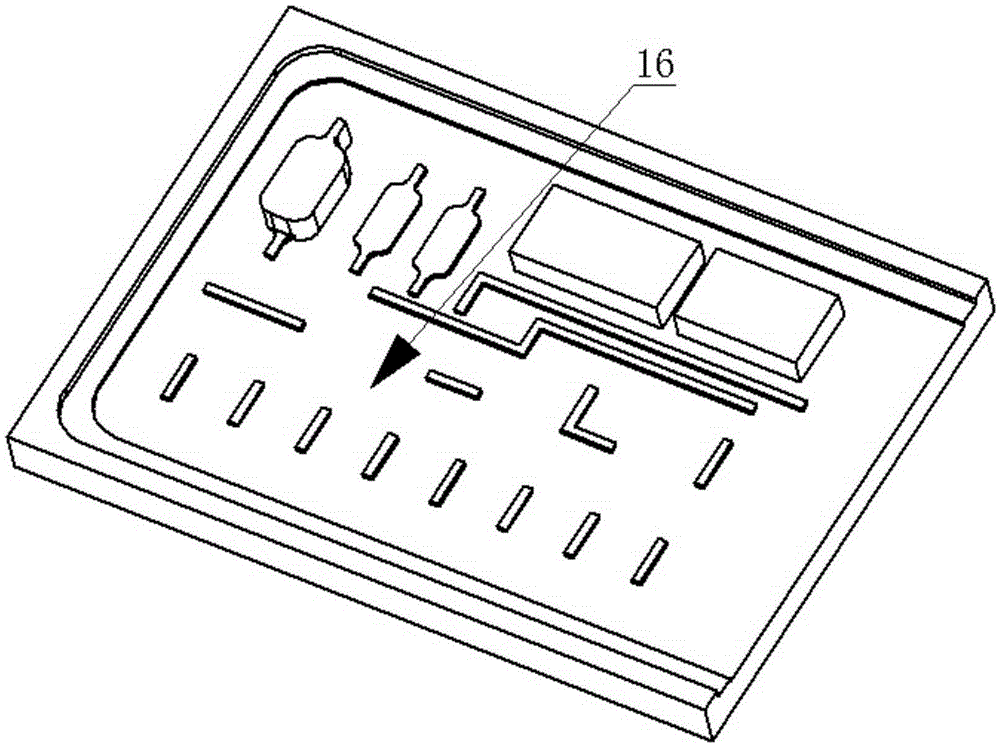

MEMS-based variable capacitor

ActiveUS6909589B2Low loss tangentSimple processMechanically variable capacitor detailsSemiconductor/solid-state device detailsCapacitanceClosed loop

A variable capacitor device using MEMS or micromachining techniques wherein thin-films of materials are deposited, patterned and etched to form movable micromechanical elements on the surface of a substrate composed of either semiconductor, glass, metal, or ceramic material. In one embodiment of the present invention to achieve higher frequency performance as well as other benefits, the substrate is comprised of Low-Temperature Co-Fired Ceramics (LTCC). The variable capacitor is an electrostatically actuated micromechanical device and if fabricated on a LTCC multi-layered substrate material has continuous electrical connections through the layers. The same LTCC substrate material can also be used to enclose the device by selectively removing a portion of the upper substrate so as to form a cavity. The two substrates are then bonded together to enclose and protect the variable capacitor. An integrated circuit can be incorporation onto the multi-level substrate structure to enable a electronic closed-loop controlled variable capacitor module. The integrated circuit is flip-chip bonded at the bottom of the substrate structure with appropriate electrical connections between the integrated circuit and the MEMS variable capacitor device. A variation of the present invention utilizes a zipper actuation method wherein the tuning ratio of the variable capacitor is increased to very high levels. Yet another variation of the present invention utilizes a differential gap between the top and bottom electrodes such that the actuation electrodes do not physically contact one another. Yet another implementation of the present invention uses an extra set of electrodes or mechanical mechanism so as to lock the value of the capacitor indefinitely. Yet another implementation uses shaped actuation electrodes so as to linearize the relationship between the applied actuation voltage and the resultant capacitance of the device.

Owner:FOR NAT RES INITIATIVES

Large format thermoelectric infrared detector and method of fabrication

ActiveUS20100031992A1Promote absorptionSimple structureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device manufacturingNano compositesBismuth telluride

The thermoelectric detector consists of an absorber structure supported by two electrically connected beams made of thermoelectric materials such as polysilicon, polysilicon / germanium, bismuth-telluride, skutterrides, superlattice structures, nano-composites and other materials. One end of the thermoelectric beam connects to the absorber structure; the other end connects to the substrate. Infrared radiation incident on the absorber heats up the absorber, resulting in a temperature gradient along the length of the thermoelectric legs, and generating an electrical voltage. The detector arrays are fabricated using micromachining process. The absorber structure is formed over a sacrificial material that is removed at the end of the processing, leaving the detector suspended and thermally isolated. The sacrificial processing method enables the production of small pixel thermoelectric detectors in large two-dimensional arrays with high sensitivity.

Owner:NYTELL SOFTWARE LLC

Integrated silicon chip for testing acceleration, pressure and temperature, and manufacturing method thereof

ActiveCN101551403AHigh sensitivityImprove stabilityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsAccelerometerThermopile

The invention relates to an integrated silicon chip for testing acceleration, pressure and temperature, and the manufacturing method thereof. The invention is characterized in manufacturing the pressure sensor, temperature sensor and accelerometers of thermoelectric pile on to one chip by the same micro processing technology. The acceleration is detected by adopting thermal convection type accelerometers, using polysilicon resistor as heater, using a thermoelectric pile composed of two pairs of metals (such as aluminium and tungsten-titanium) and P type or N type polysilicon to detect the temperature difference in the sealed cavity caused by acceleration. The high accurate absolute pressure sensor is manufactured by using silicon nitride film with low stress as the core structure layer of the pressure sensor chip, and forming force sensitive resistor track by polysilicon film, forming vacuum reference cavity by TEOS bolt in LPCVD furnace. At the same time, the temperature sensor is composed by using polysilicon thermistor to detect temperature change. The integrated chip achieves the advantages of microminiaturization, low cost, high precision, high reliability and high stability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

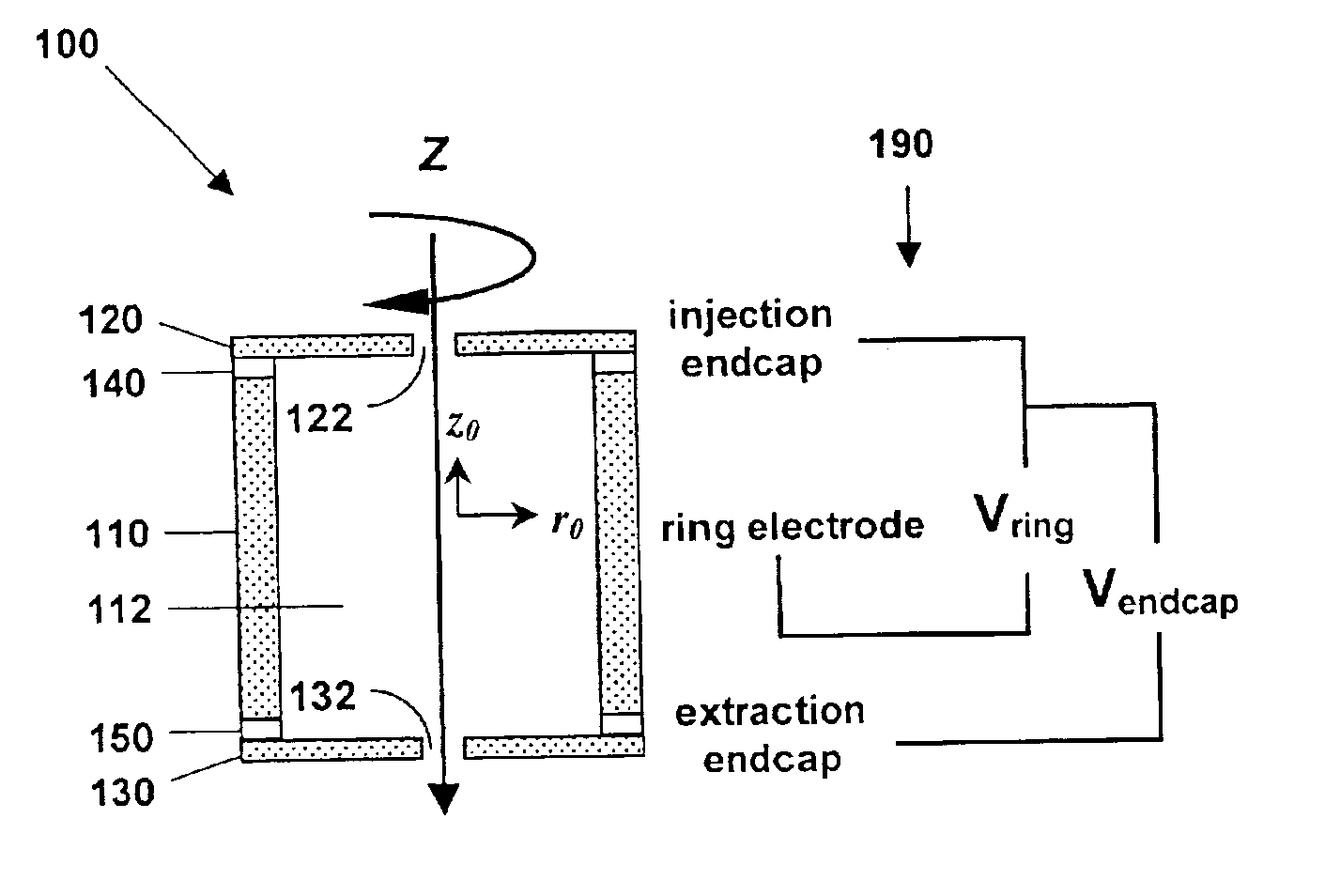

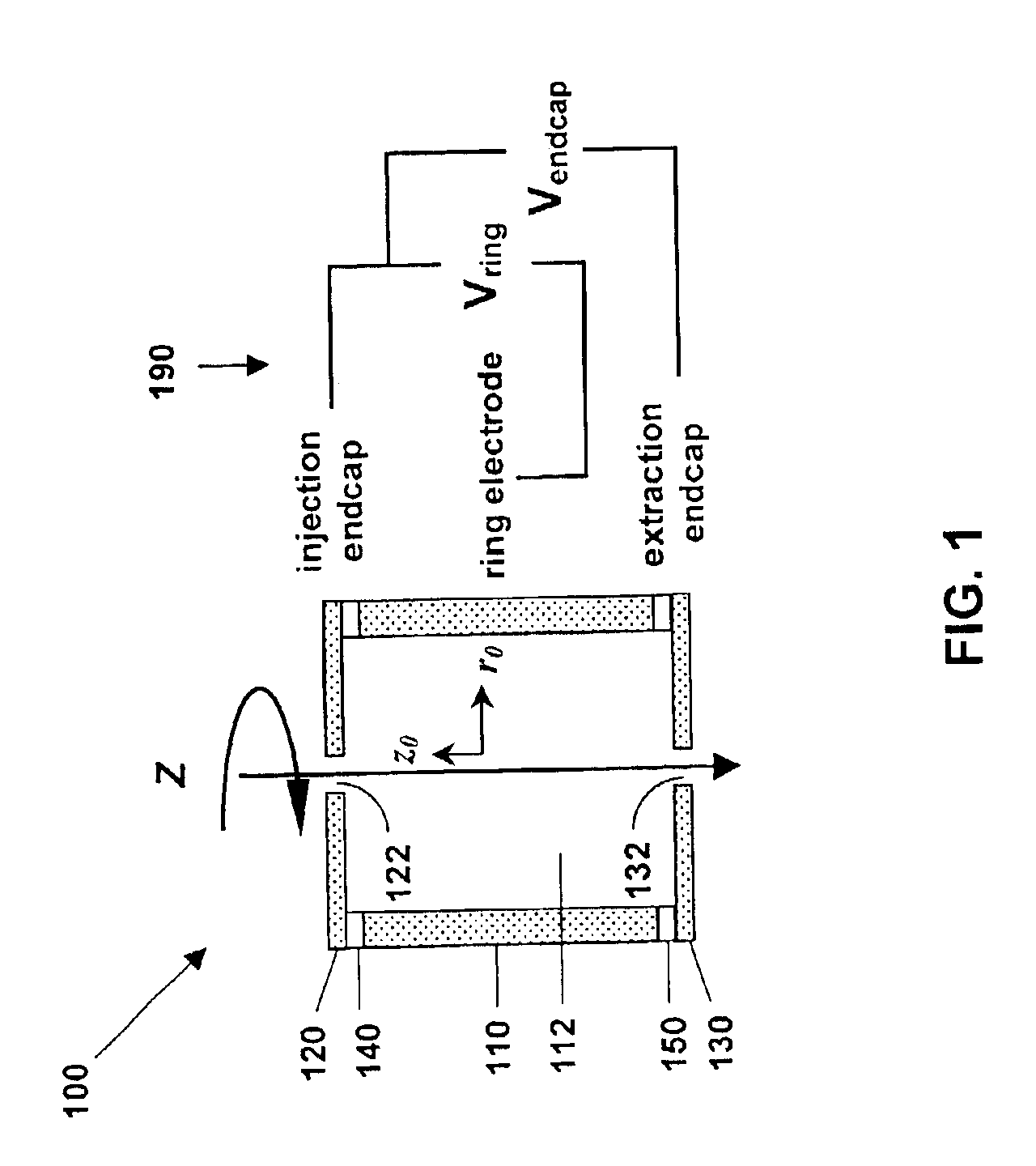

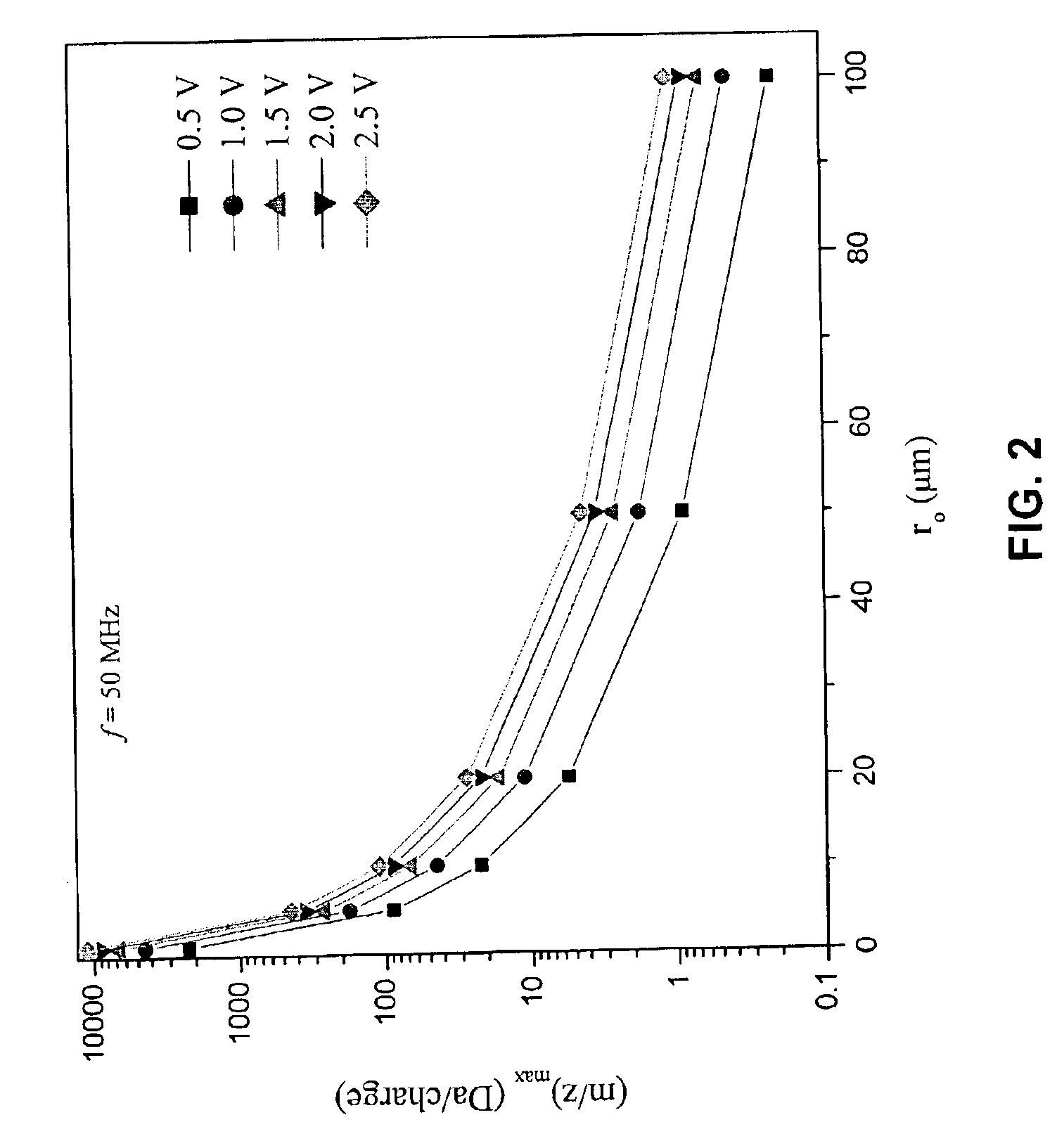

Microfabricated cylindrical ion trap

InactiveUS6870158B1Stability-of-path spectrometersIsotope separationManufacturing cost reductionHigh pressure

A microscale cylindrical ion trap, having an inner radius of order one micron, can be fabricated using surface micromachining techniques and materials known to the integrated circuits manufacturing and microelectromechanical systems industries. Micromachining methods enable batch fabrication, reduced manufacturing costs, dimensional and positional precision, and monolithic integration of massive arrays of ion traps with microscale ion generation and detection devices. Massive arraying enables the microscale cylindrical ion trap to retain the resolution, sensitivity, and mass range advantages necessary for high chemical selectivity. The microscale CIT has a reduced ion mean free path, allowing operation at higher pressures with less expensive and less bulky vacuum pumping system, and with lower battery power than conventional- and miniature-sized ion traps. The reduced electrode voltage enables integration of the microscale cylindrical ion trap with on-chip integrated circuit-based rf operation and detection electronics (i.e., cell phone electronics). Therefore, the full performance advantages of microscale cylindrical ion traps can be realized in truly field portable, handheld microanalysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

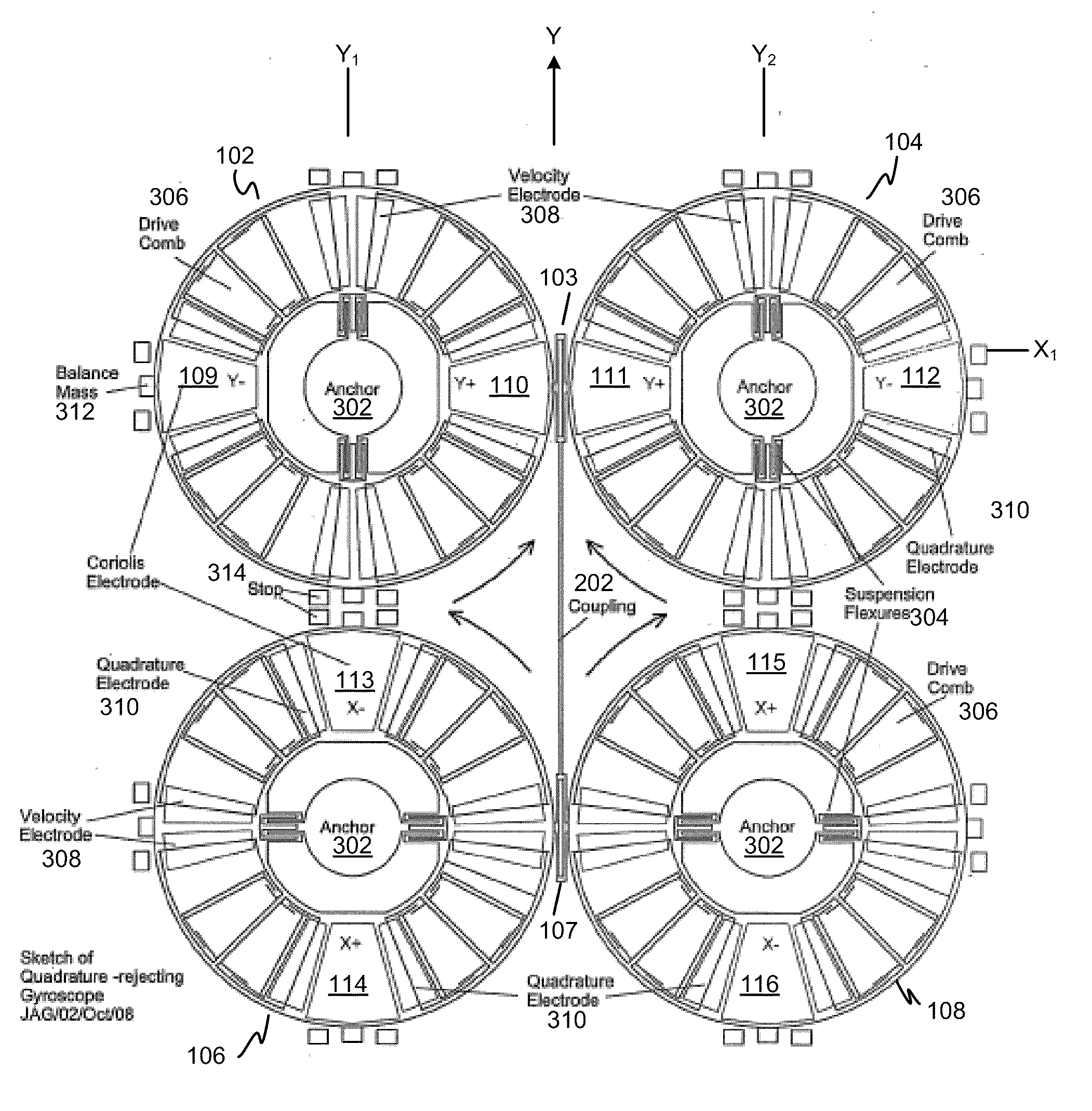

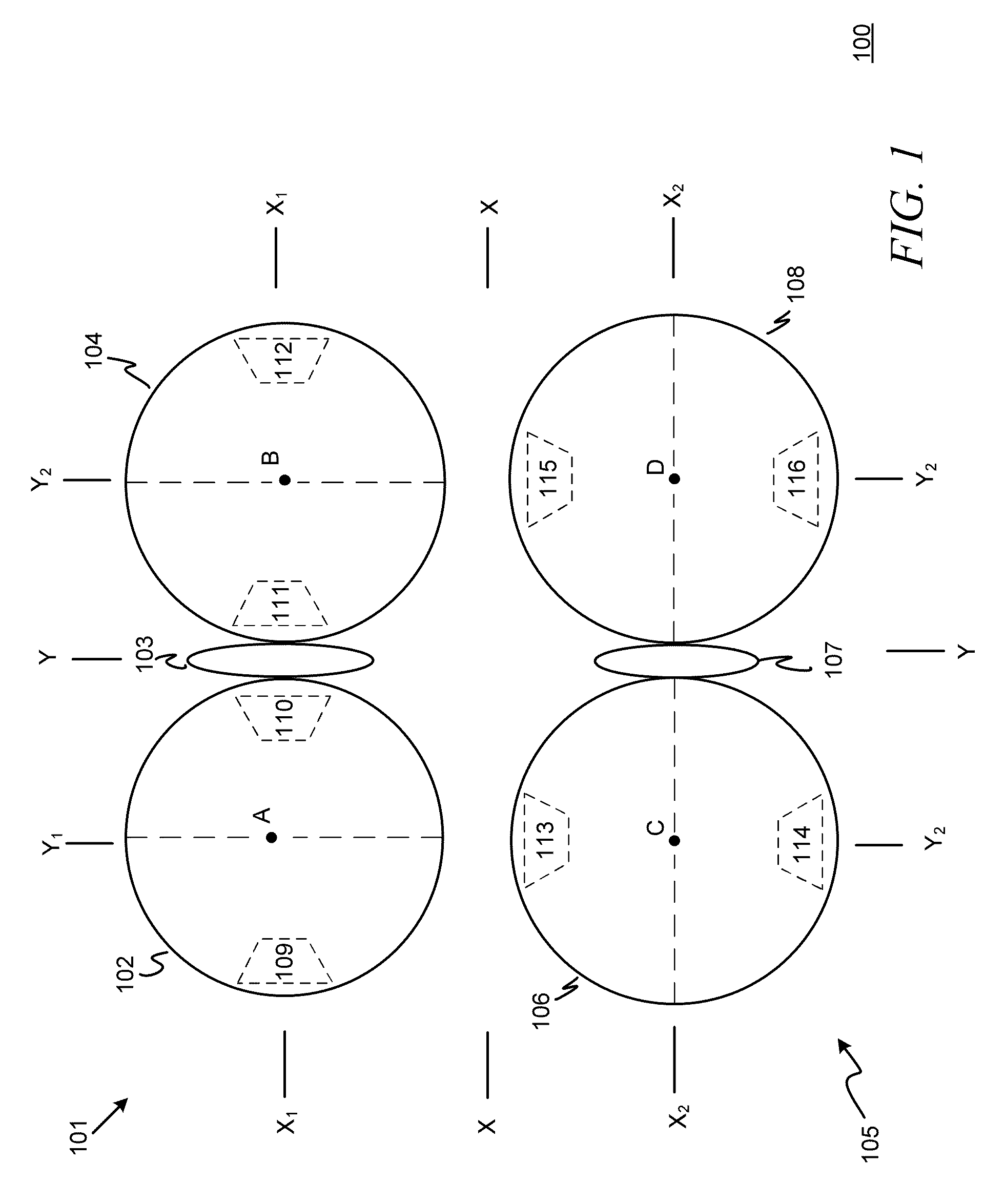

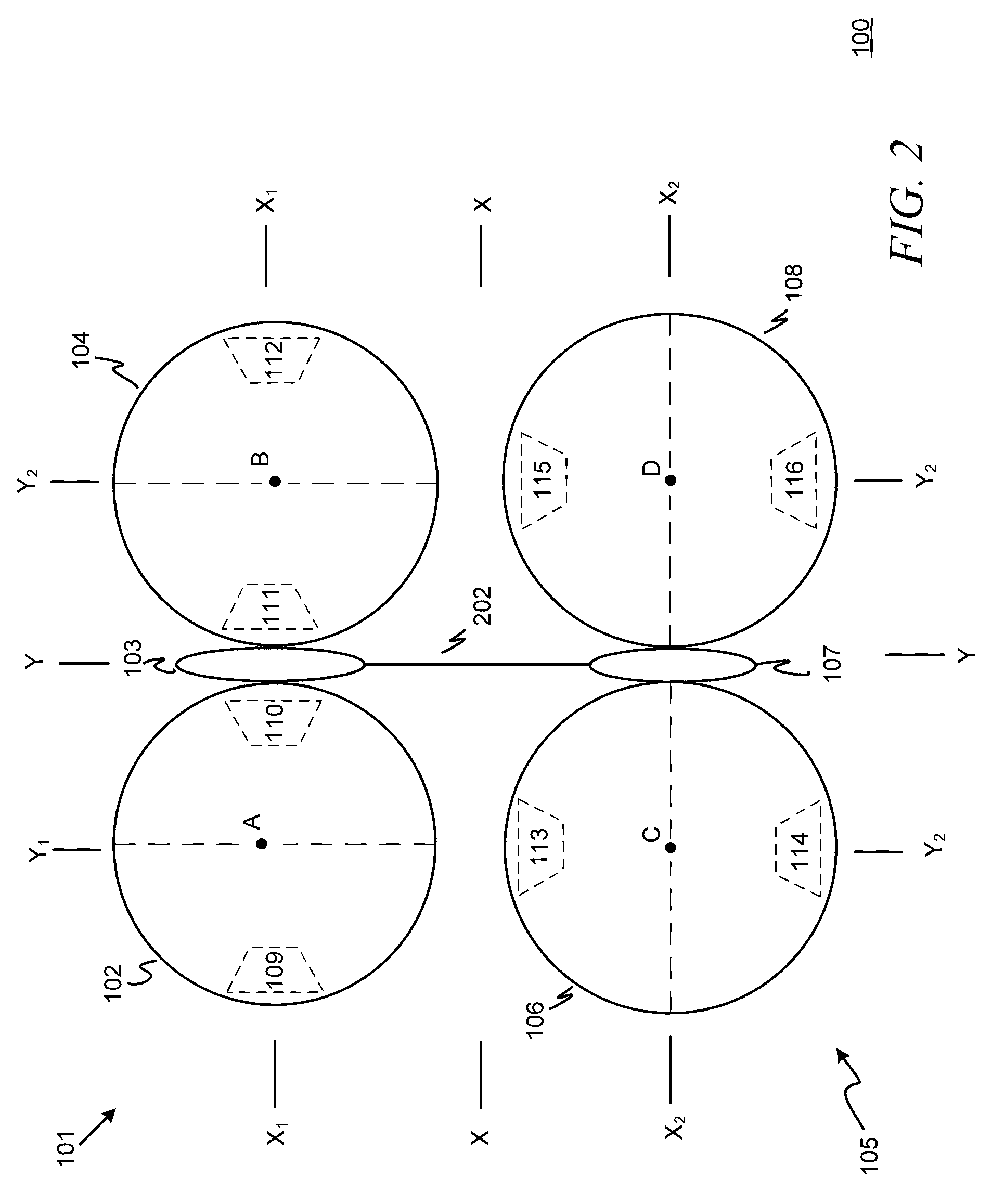

Inertial Sensors with Reduced Sensitivity to Quadrature Errors and Micromachining Inaccuracies

ActiveUS20110030474A1Inhibit transferAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsPhase couplingMicromachinings

Inertial sensors with reduced sensitivity to quadrature errors and micromachining inaccuracies include a gyroscope incorporating two specially-configured single-axis gyroscopes for sensing rotations about two orthogonal axes (the axes of sensitivity) in the device plane, where each single-axis gyroscope includes a resonator having two rotationally-dithered shuttles interconnected by a fork and each shuttle is configured to tilt out-of-plane along a tilt axis perpendicular to the axis of sensitivity and includes corresponding Coriolis sensing electrodes positioned along an axis perpendicular to the tilt axis (i.e., parallel to the axis of sensitivity). The two single-axis gyroscopes may be interconnected, e.g., by one or more in-phase or anti-phase couplings interconnecting the forks and / or the shuttles.

Owner:ANALOG DEVICES INC

Waveguide architecture, waveguide devices for laser processing and beam control, and laser processing applications

InactiveUS7065121B2Optical resonator shape and constructionActive medium shape and constructionWaveguideBeam control

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100 W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:GSI LUMONICS LTD

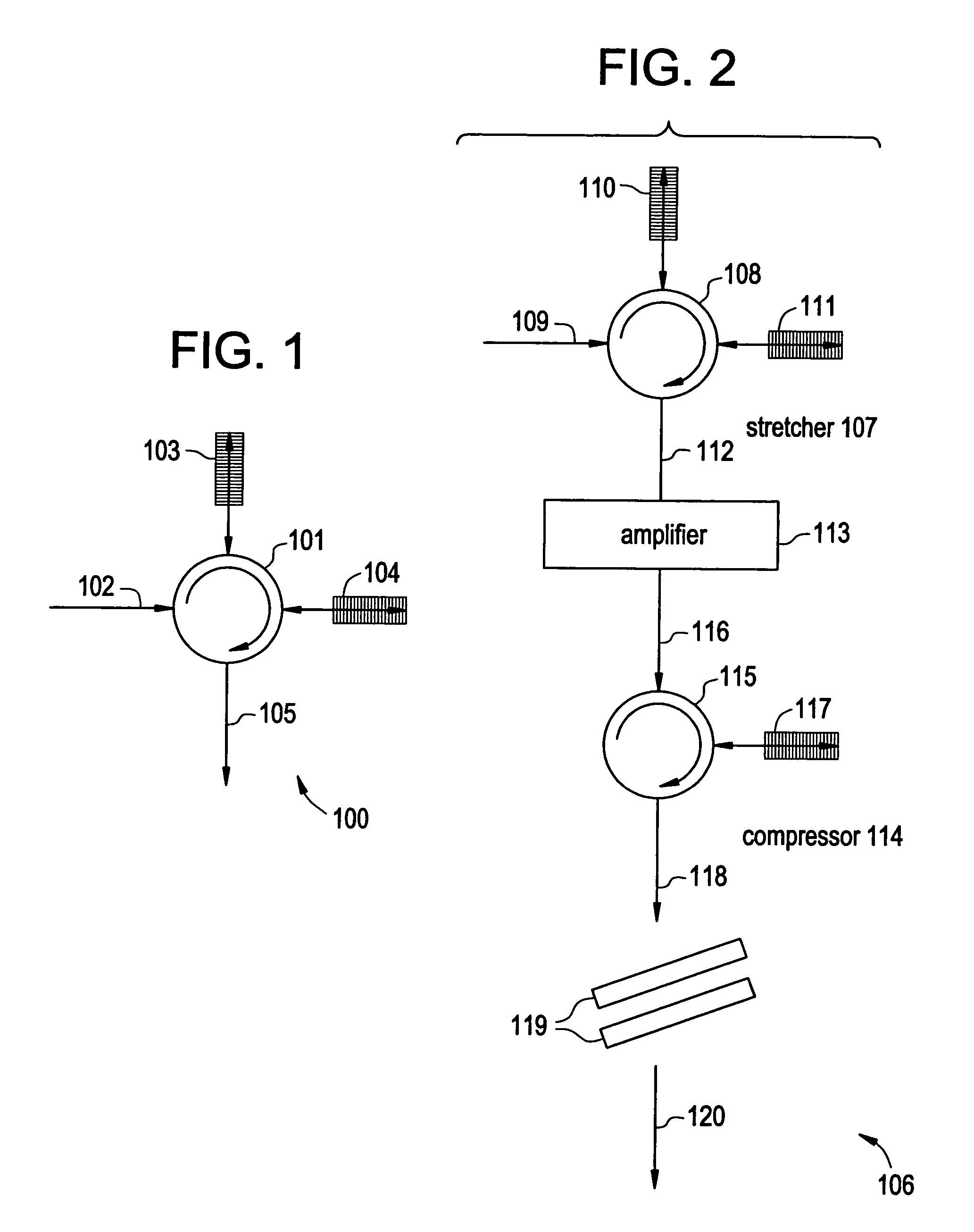

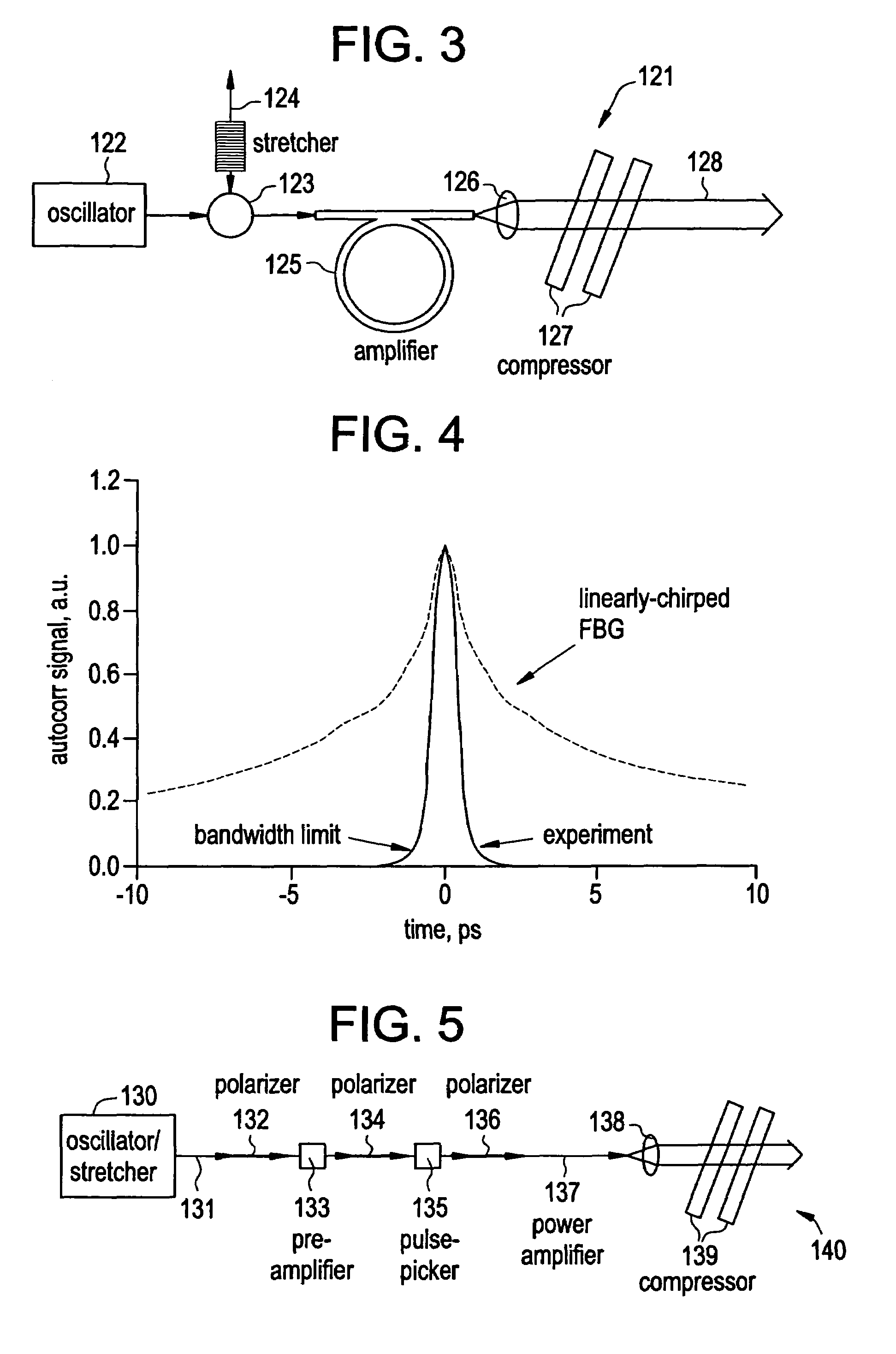

In-line, high energy fiber chirped pulse amplification system

InactiveUS7257302B2Accurately dispersion matchedBig ratioOptical fibre with multilayer core/claddingLaser arrangementsGratingHigh energy

By writing non-linear chirp into fiber Bragg gratings, greater control over dispersion compensation in CPA systems is obtained, such that, for example, the dispersion profile of the fiber Bragg grating and a bulk compressor may be matched. An iterative method of writing the fiber grating can reduce the group delay ripple to very low levels; and adaptive control of the fiber grating dispersion profile can further reduce these levels, while in addition offering greater acceptable yield in the manufacture of such gratings. Fiber Bragg gratings may be designed so as to provide customized pulse shapes optimized for various end uses, such as micromachining, for example, and may also be used to counteract gain-narrowing in a downstream amplifier.

Owner:IMRA AMERICA

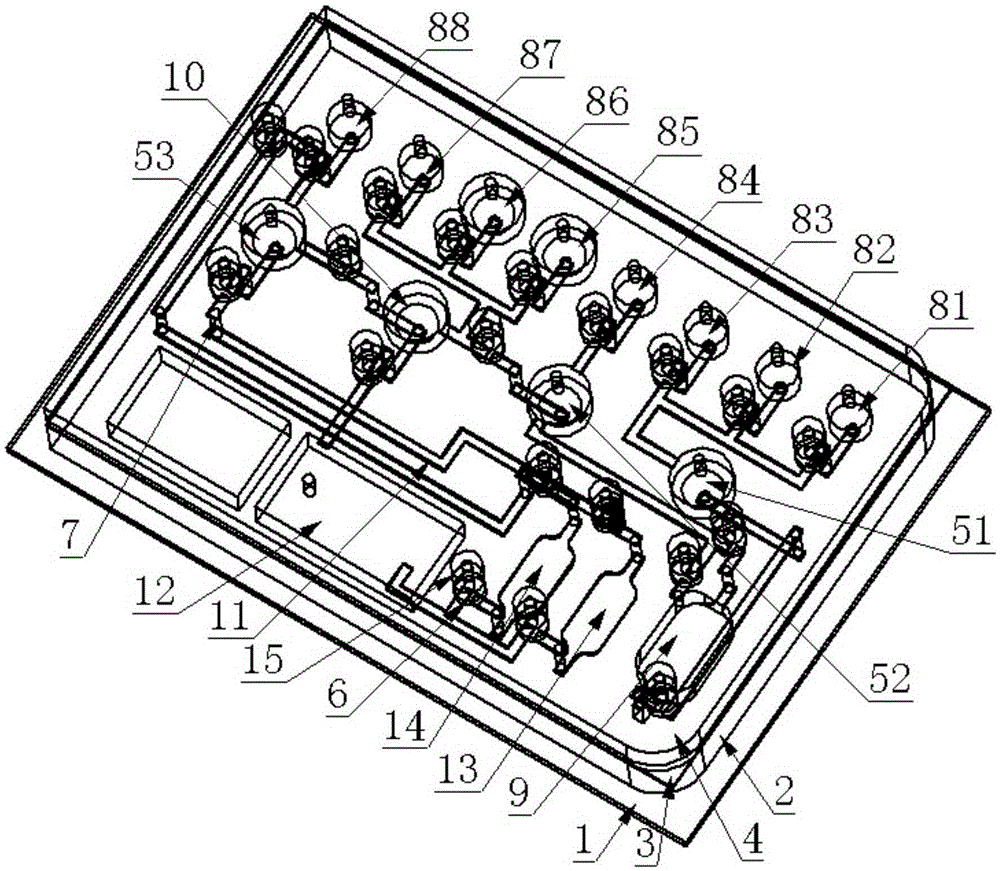

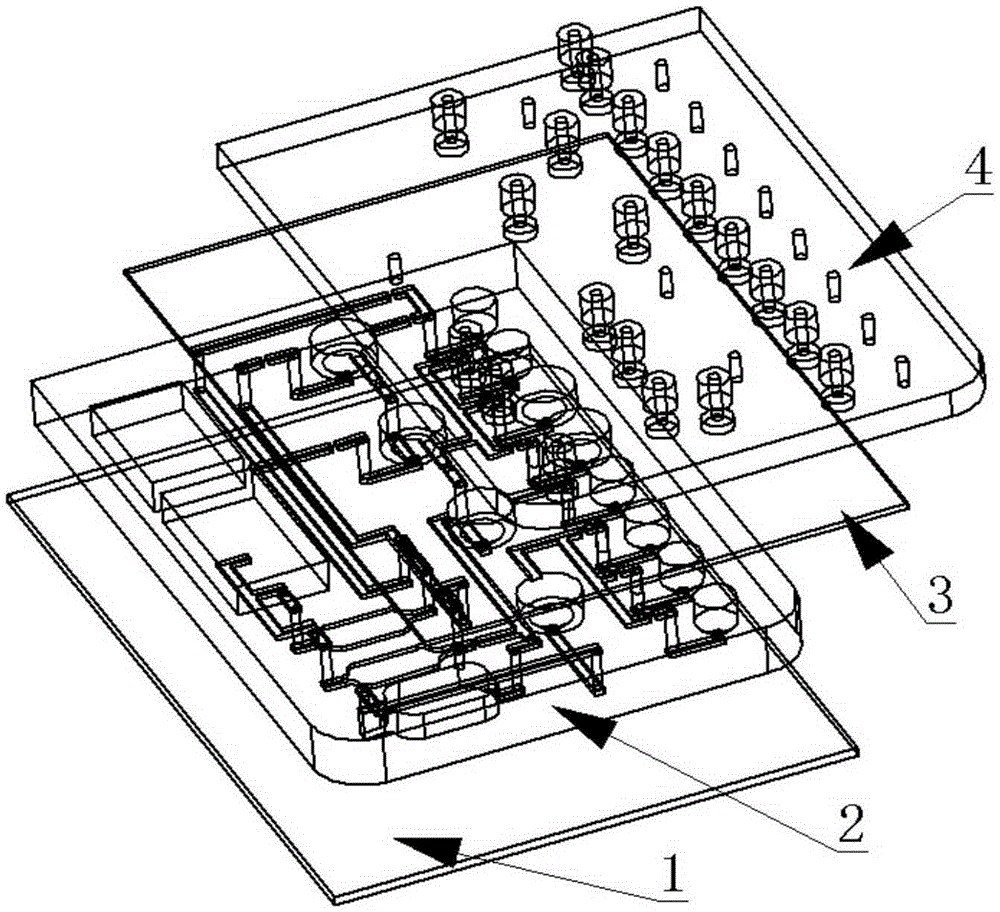

Multifunctional integrated microfluidic nucleic acid analysis chip and preparation and analysis method thereof

ActiveCN105349401AQuick buildEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsInjection mouldingMultiple layer

The invention provides a multifunctional integrated microfluidic nucleic acid analysis chip. The chip is prepared by preparing a combination mould according to 3D printing or micromachining technology, generating a microfluidic substrate according to an injection moulding method, and completing bonding of multiple layers including a chip substrate, a liquid circuit layer, an elastic film, a gas circuit layer and the like by means of plasma cleaning to finally obtain the complete chip. The chip integrates various structures including reagent cavities, mixing cavities, a splitting cavity, a DNA (deoxyribonucleic acid) extraction cavity, amplification reaction cavities, a microvalve, a microchannel and the like and has functions of sample loading, reagent mixing, heating for splitting, DNA adsorption, cleaning, eluting, amplification reaction and the like. The multifunctional integrated microfluidic nucleic acid analysis chip has the advantages that totally-closed automatic operation of 'sample input-result output' is realized, complicated manual operations are avoided, and detection efficiency is improved.

Owner:合肥中科易康达生物医学有限公司

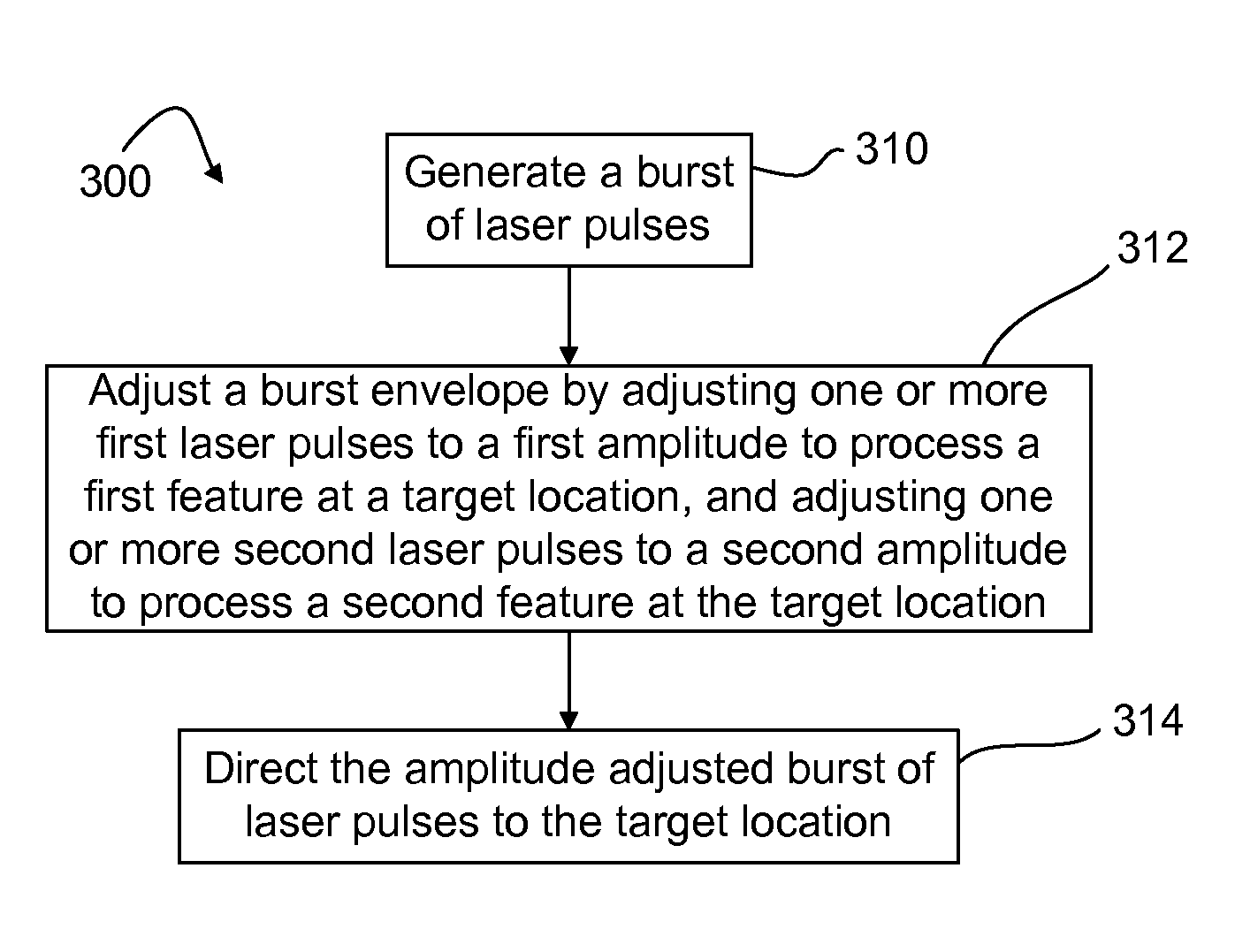

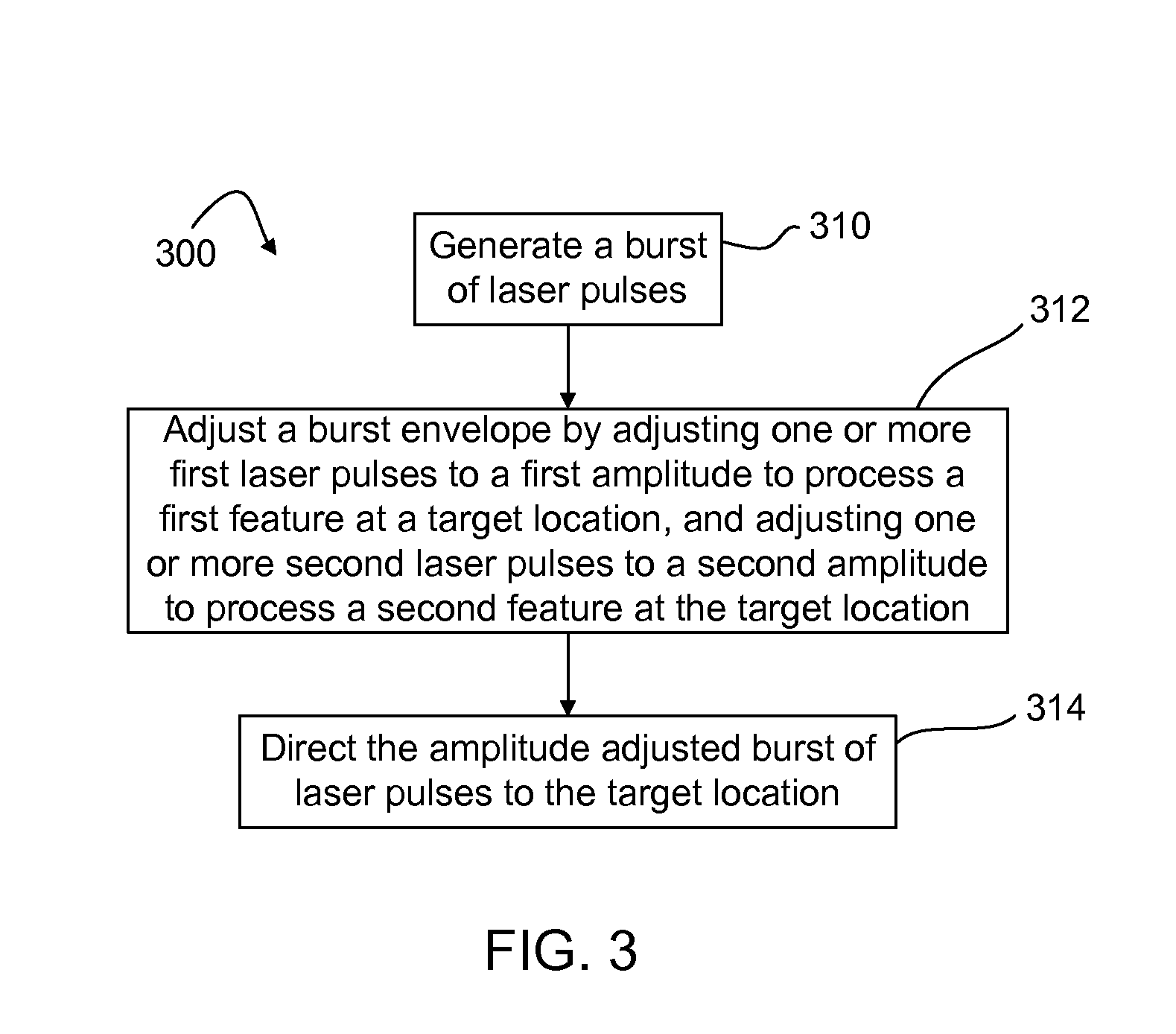

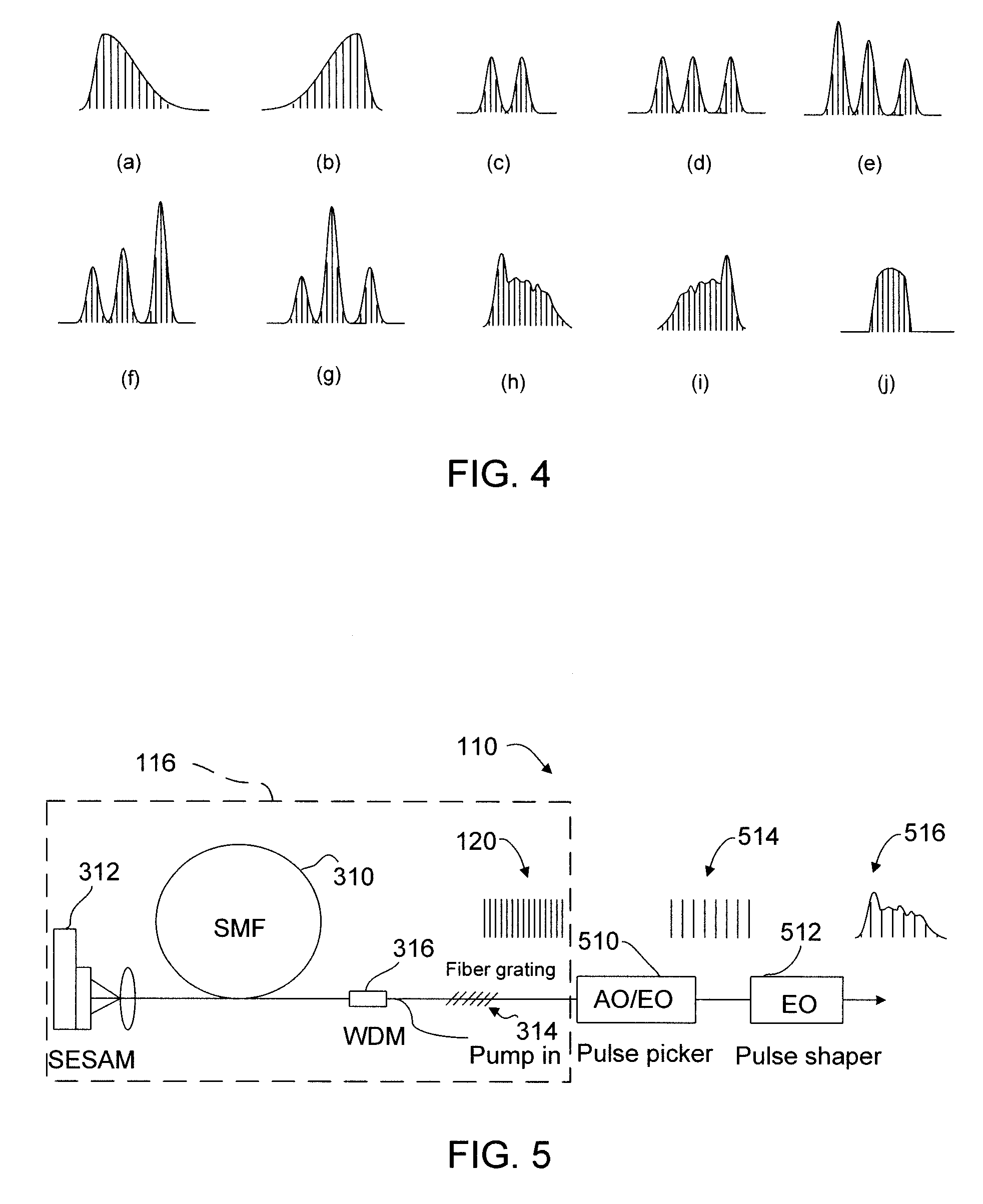

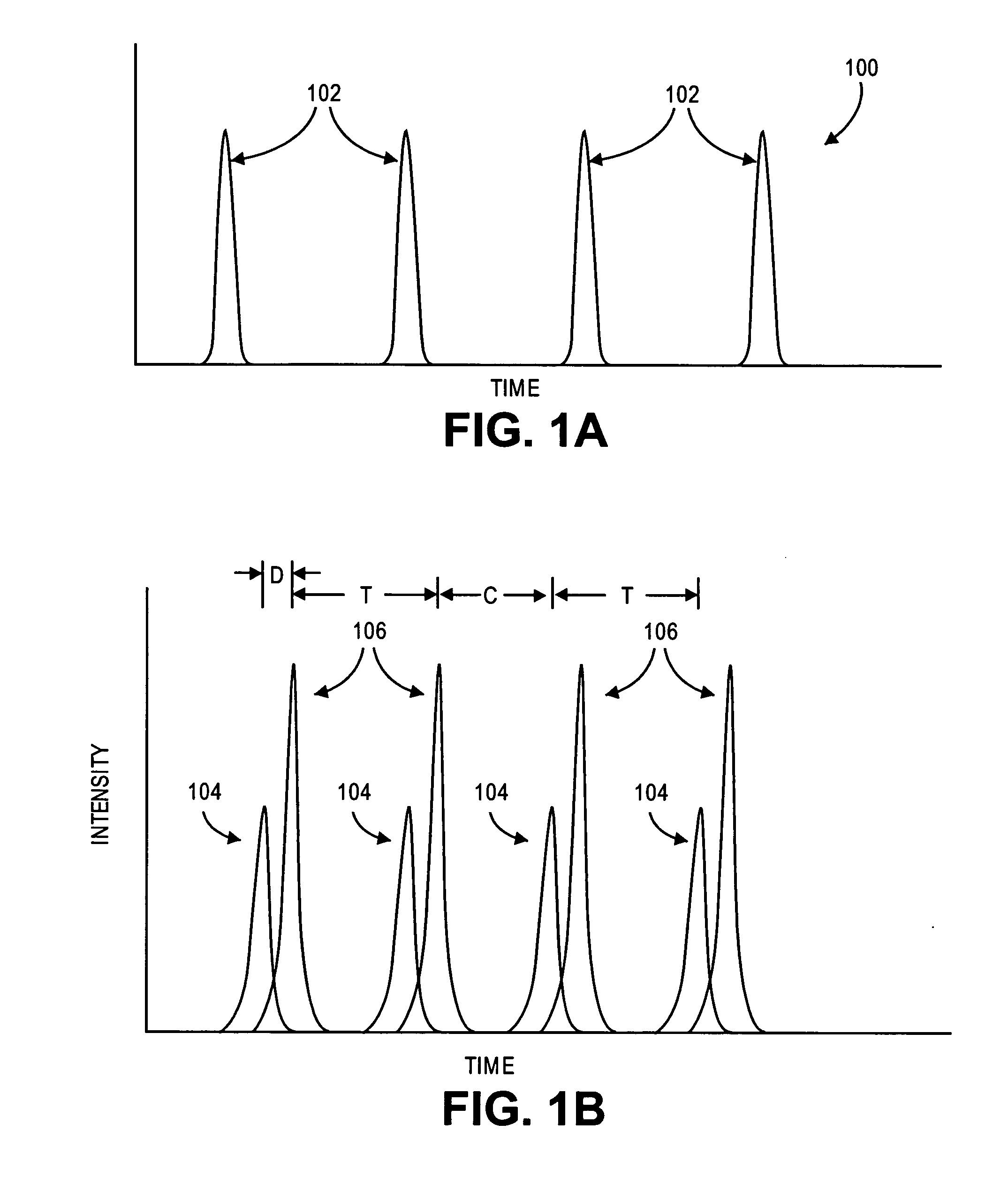

Laser micromachining with tailored bursts of short laser pulses

A series of laser pulse bundles or bursts are used for micromachining target structures. Each burst includes short laser pulses with temporal pulse widths that are less than approximately 1 nanosecond. A laser micromachining method includes generating a burst of laser pulses and adjusting an envelope of the burst of laser pulses for processing target locations. The method includes adjusting the burst envelope by selectively adjusting one or more first laser pulses within the burst to a first amplitude based on processing characteristics of a first feature at a target location, and selectively adjusting one or more second laser pulses within the burst to a second amplitude based on processing characteristics of a second feature at the target location. The method further includes directing the amplitude adjusted burst of laser pulses to the target location.

Owner:ELECTRO SCI IND INC

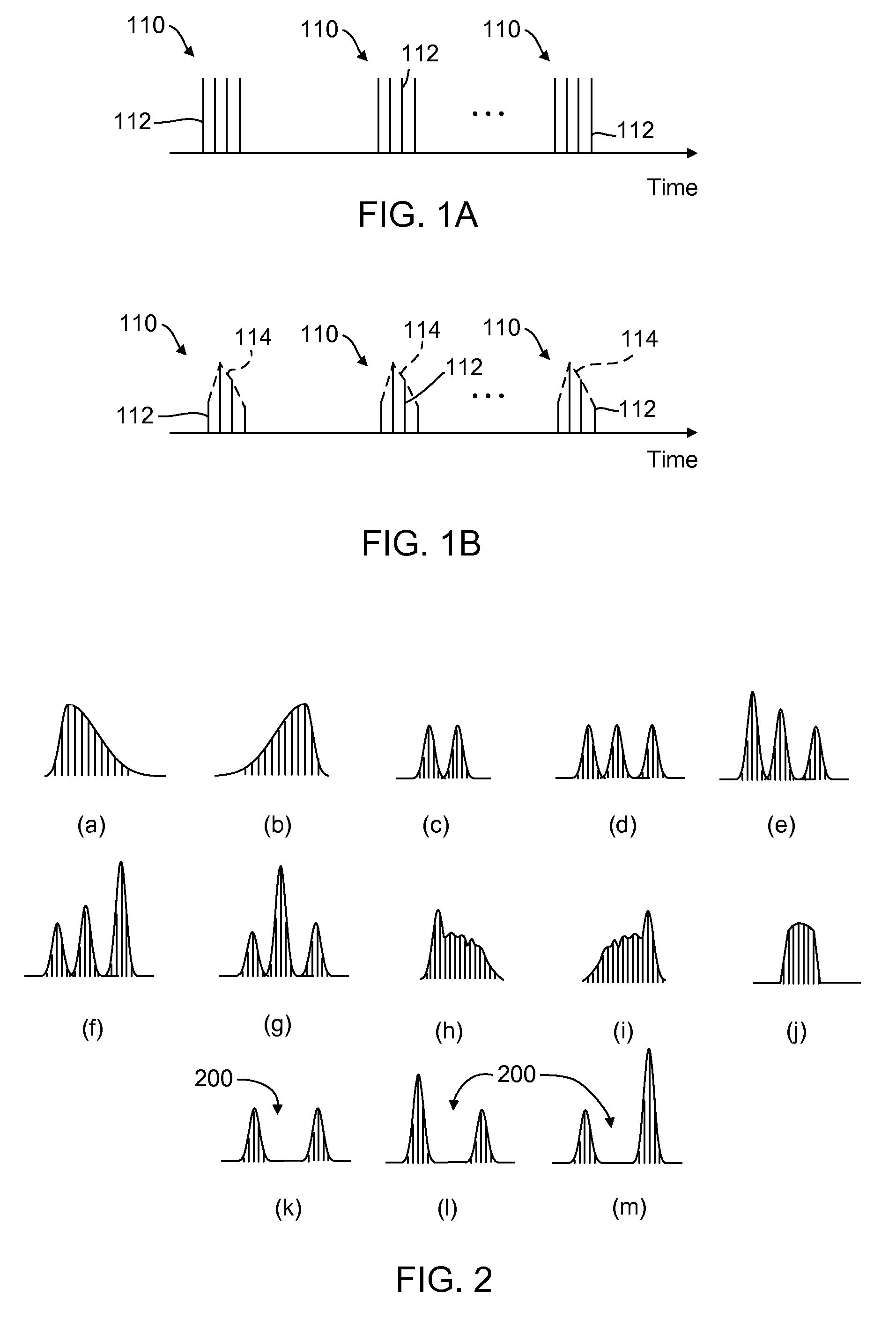

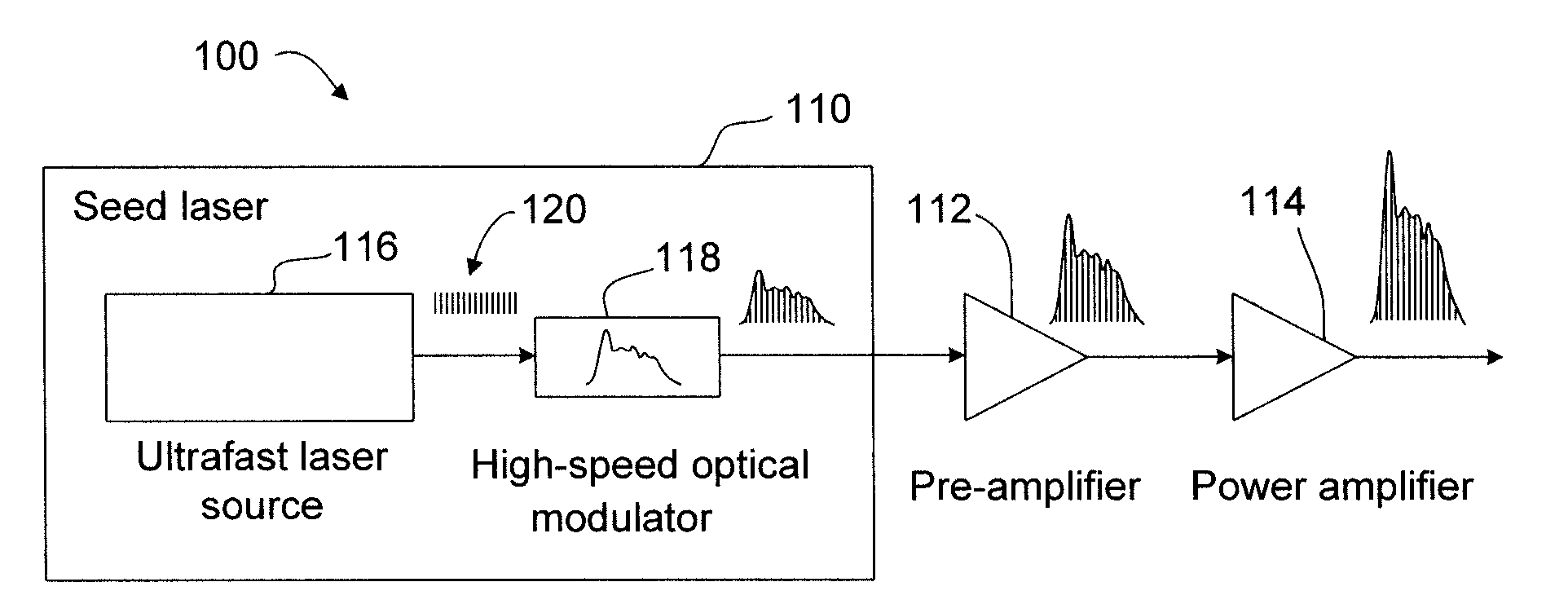

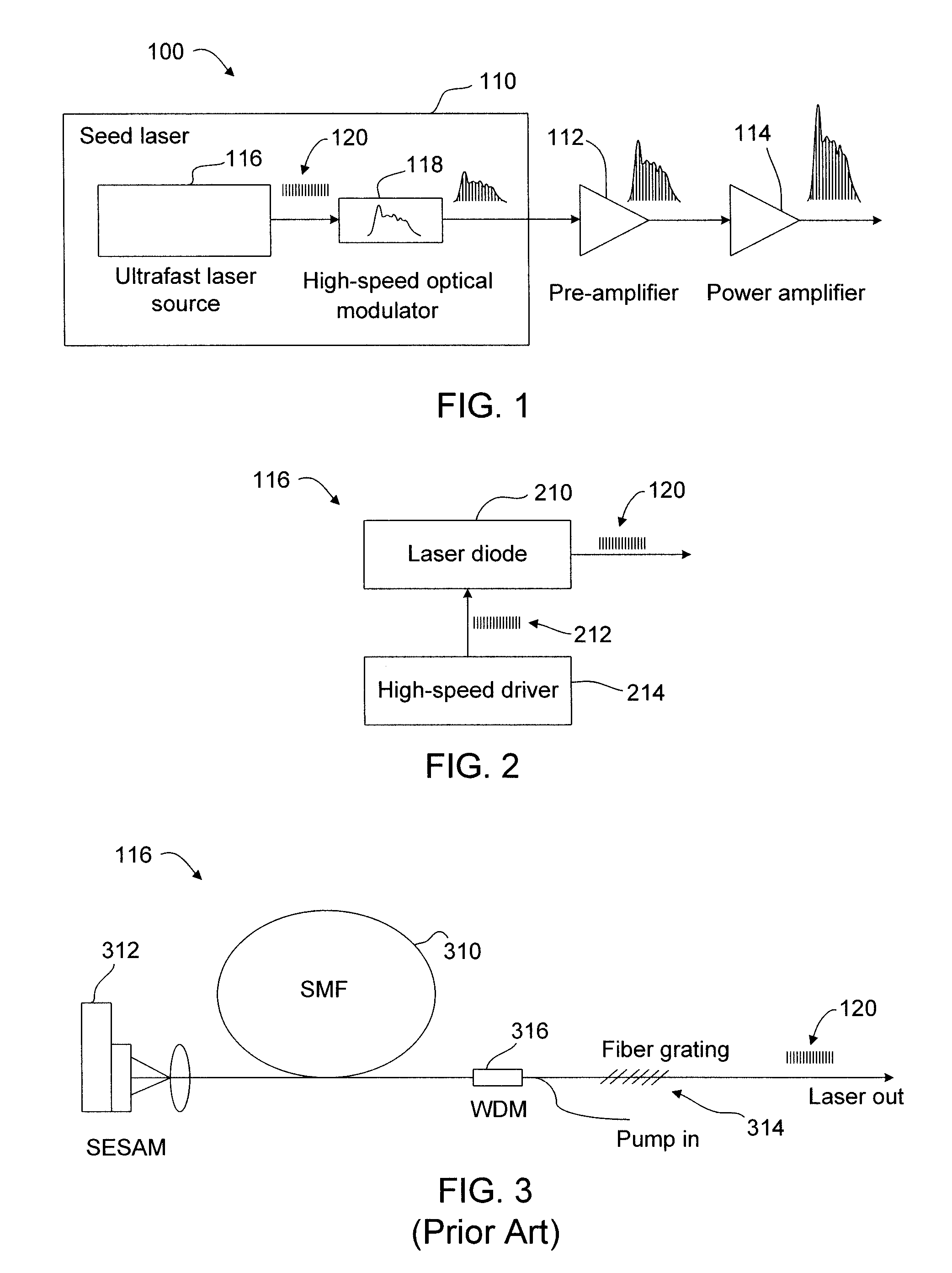

Pulse temporal programmable ultrafast burst mode laser for micromachining

InactiveUS20100177794A1Laser detailsLaser optical resonator constructionLaser processingOptoelectronics

A laser processing system provides a burst of ultrafast laser pulses having a selectively shaped burst envelope. A burst pulse laser includes a high repetition rate ultrafast laser to deliver a pulse train with each pulse in the train having an independently controlled amplitude. The respective amplitudes of each ultrafast pulse in a group define a “burst envelope.” In addition to independently controlling the amplitude of each ultrafast pulse within the burst envelope, the system may also provide selective control of spacing between each ultrafast pulse and / or the overall temporal width of the burst envelope. Thus, the system provides selective shaping of the burst envelope for particular laser processing applications.

Owner:ELECTRO SCI IND INC

Dual pulsed beam laser micromachining method

InactiveUS20060249816A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsLaser scribing

Owner:INTEL CORP

Delivery of therapeutic biologicals from implantable tissue matrices

InactiveUS20020031500A1Many of effectMany of inconveniencePowder deliveryBiocideProgenitorActive agent

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com