Patents

Literature

58results about "Solid state device transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

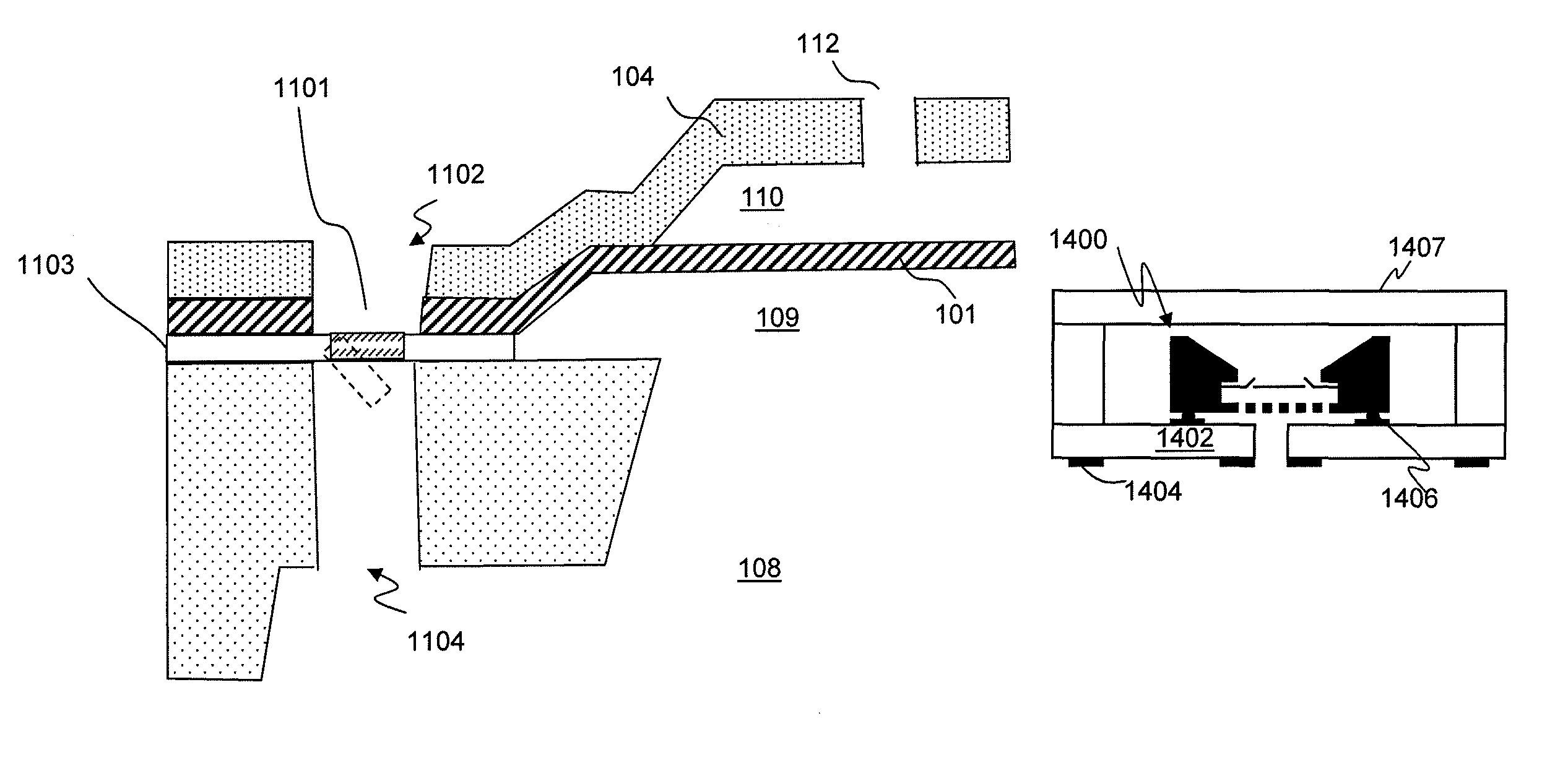

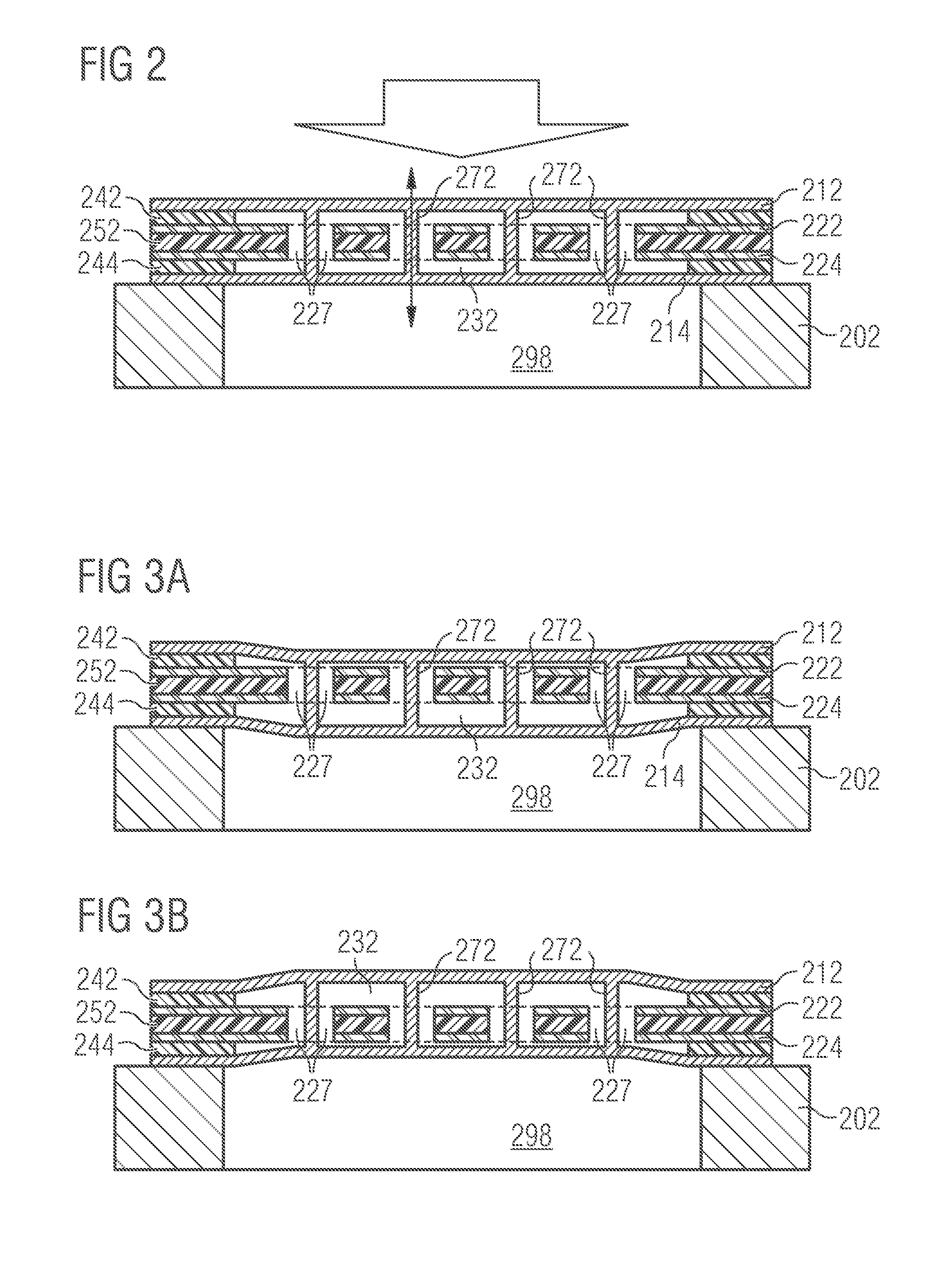

MEMS device and process

ActiveUS20140084396A1Improve robustnessEnhance resilienceSolid state device transducersDecorative surface effectsAir volumeAcoustic shock

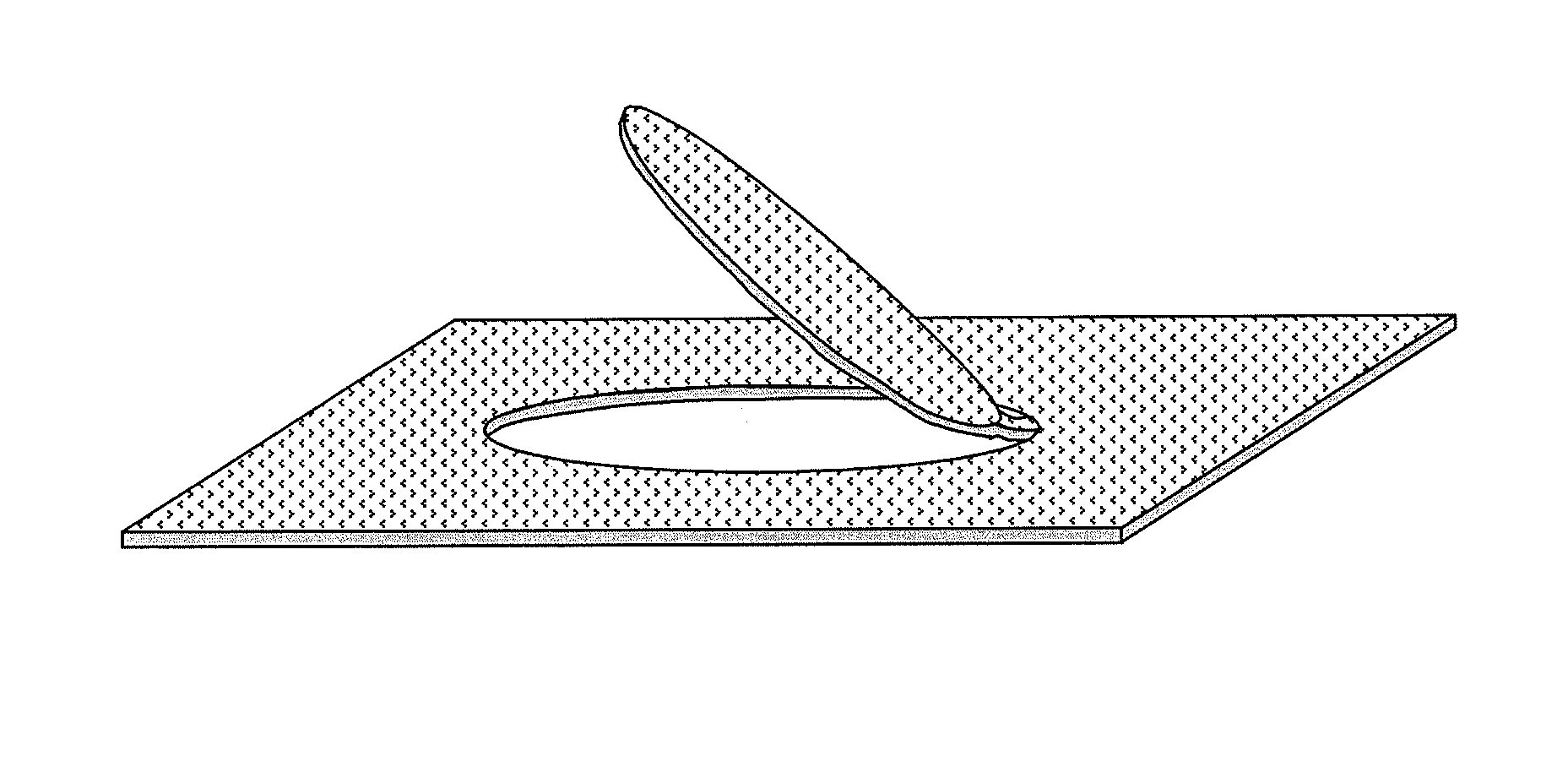

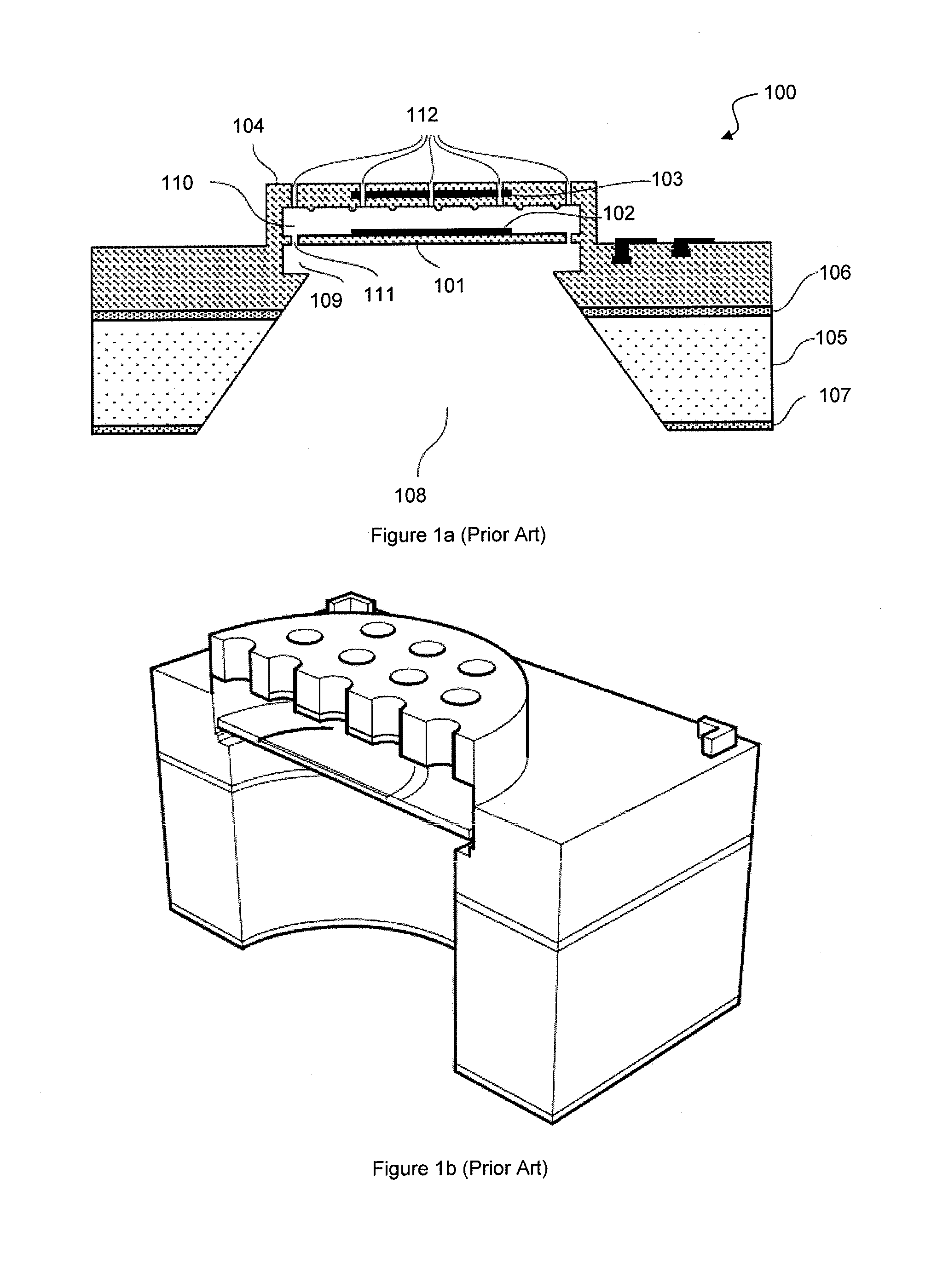

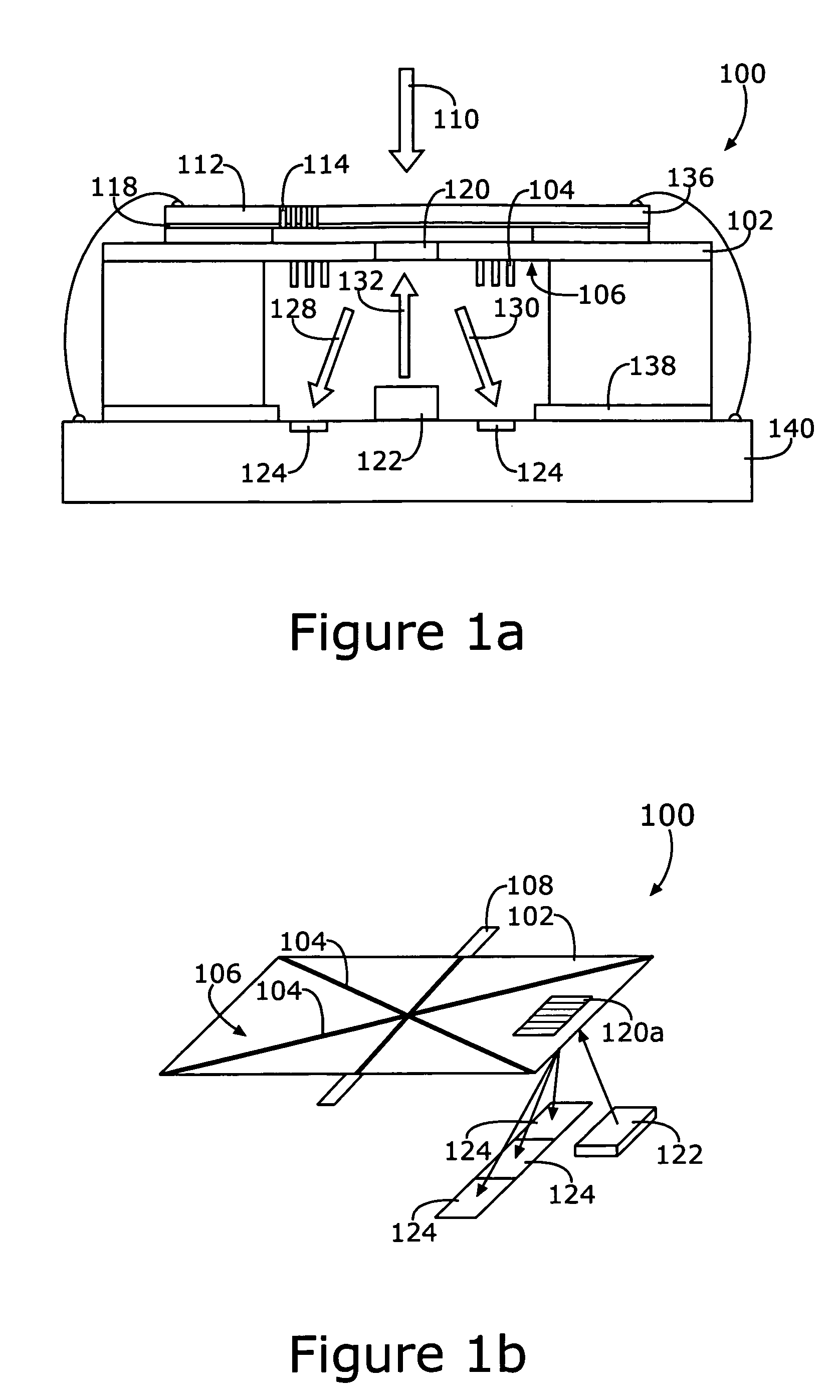

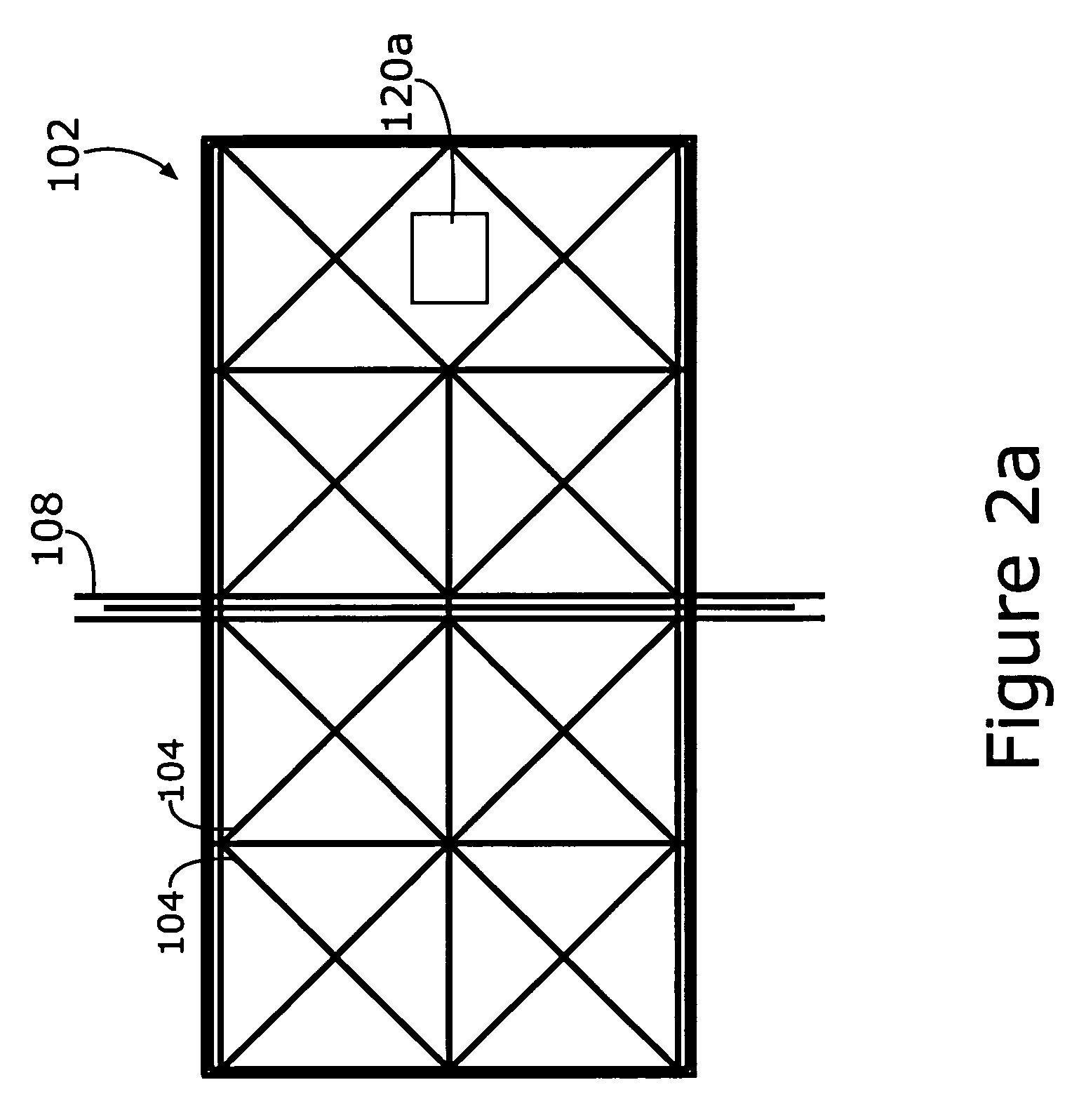

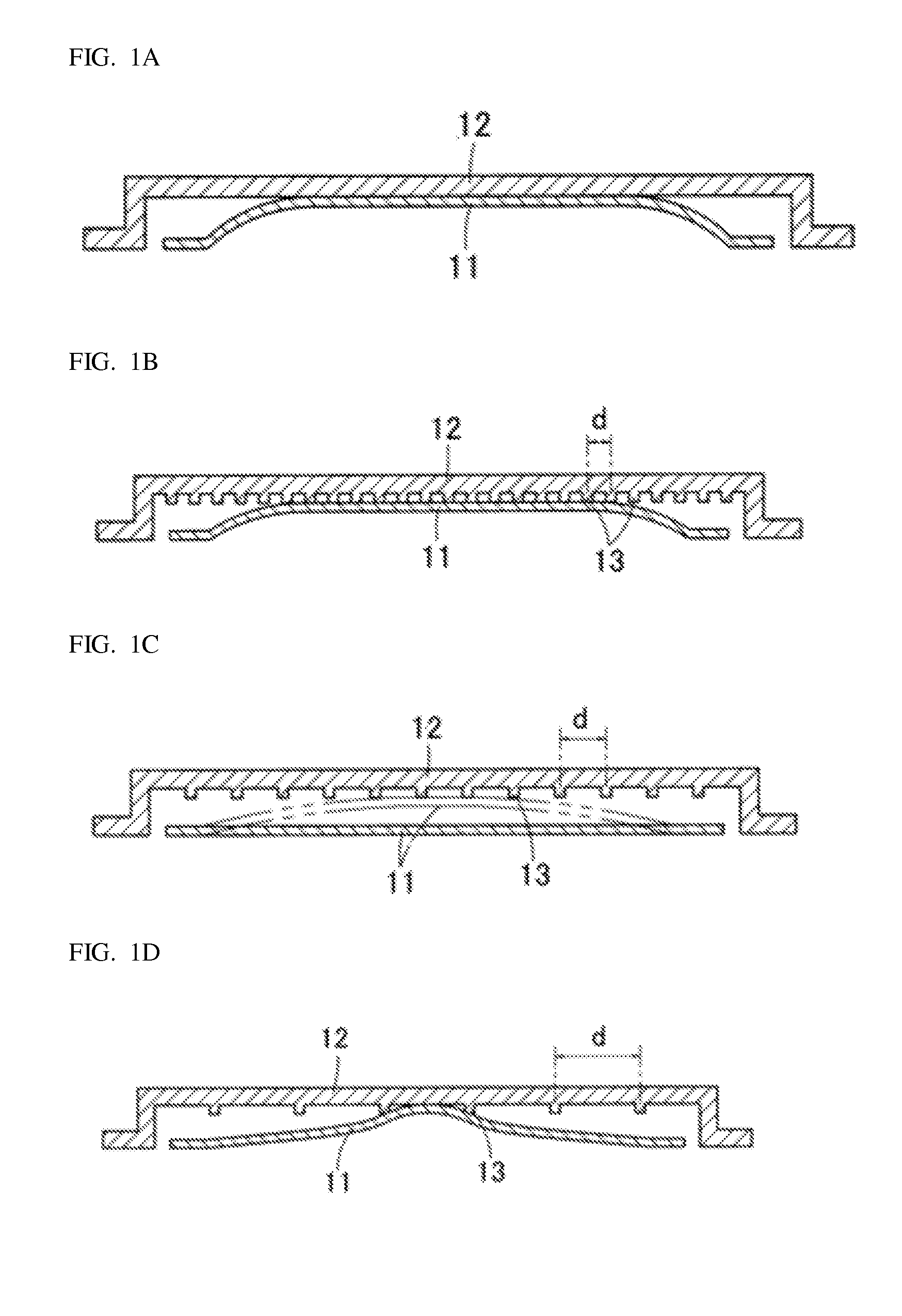

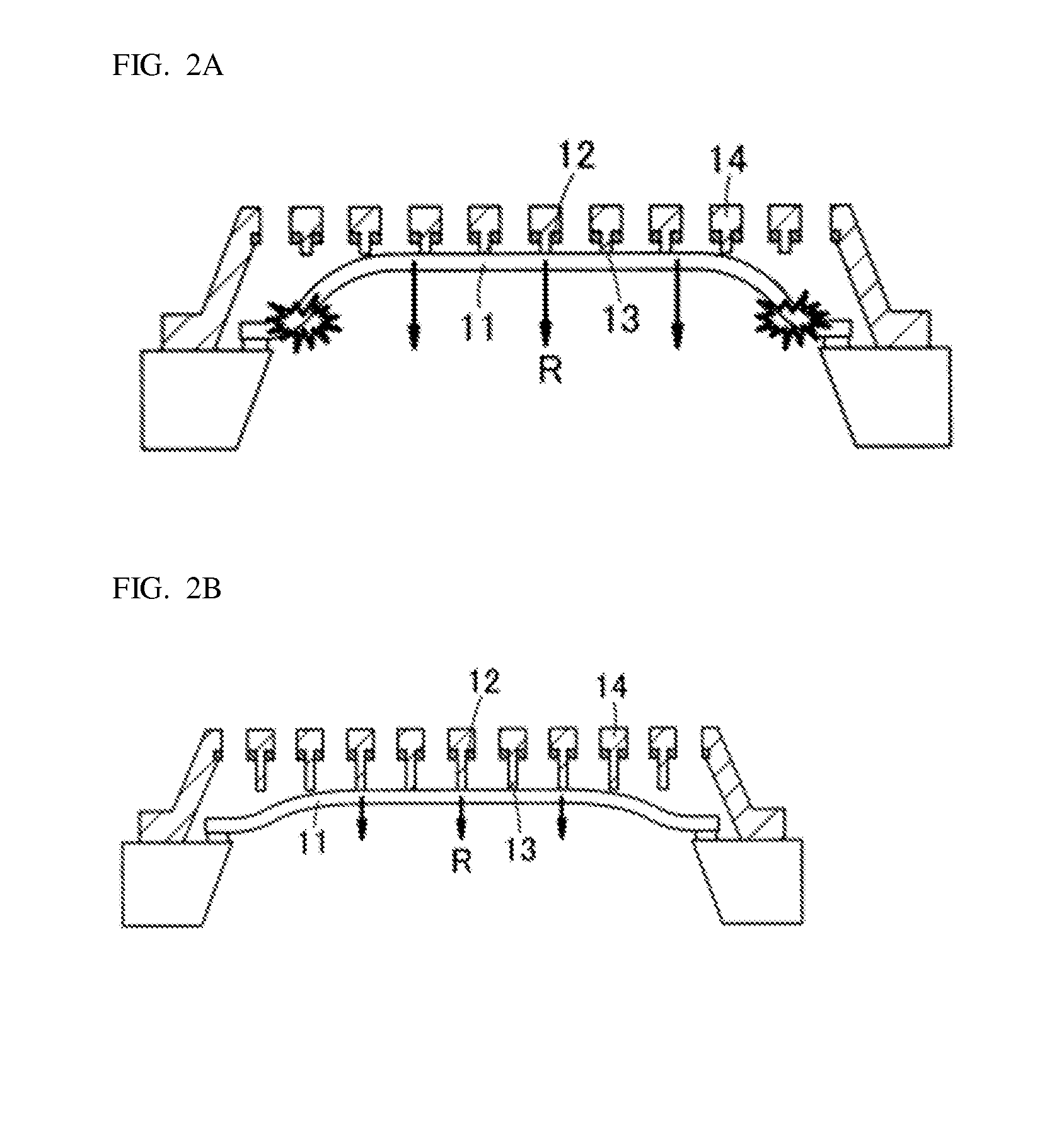

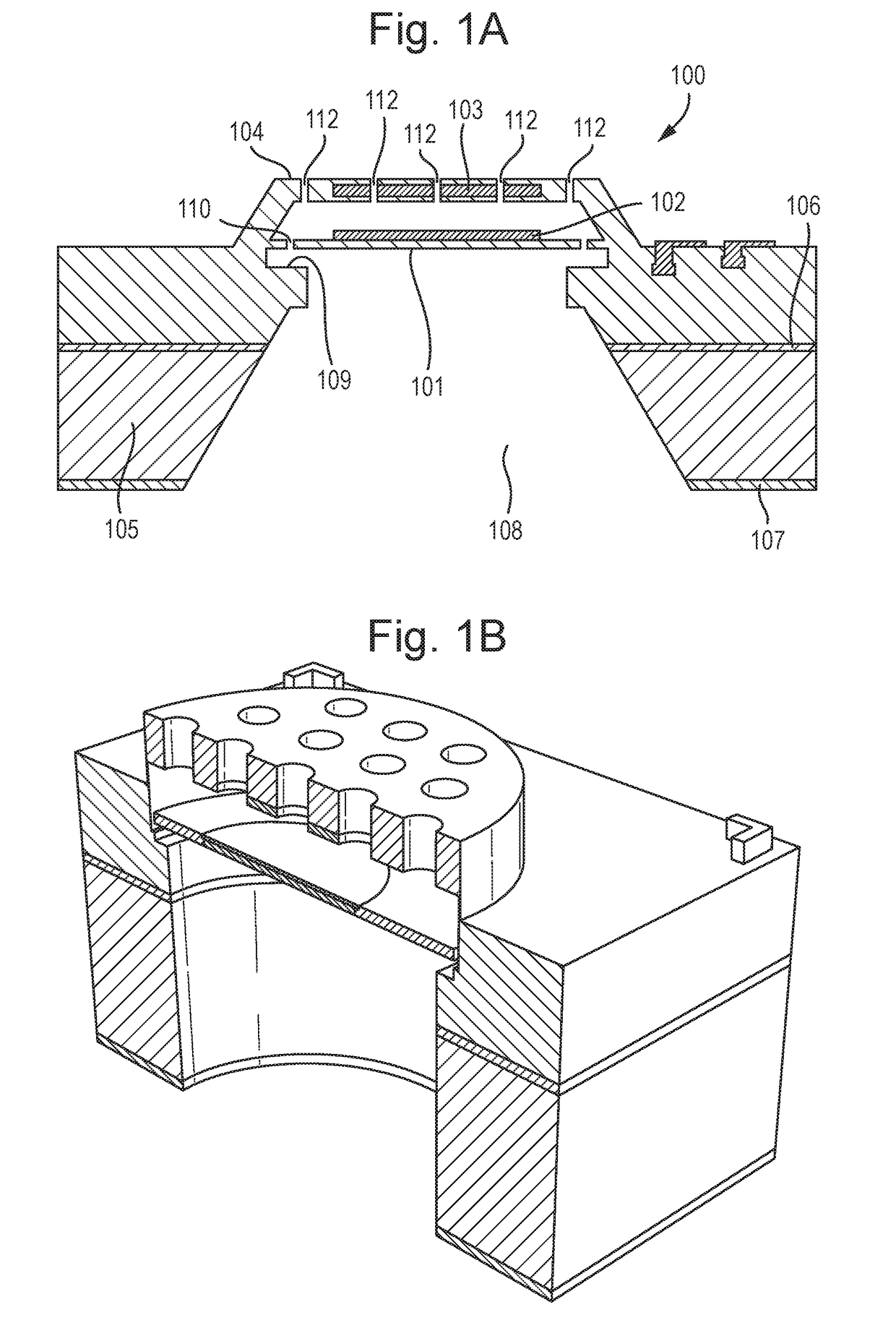

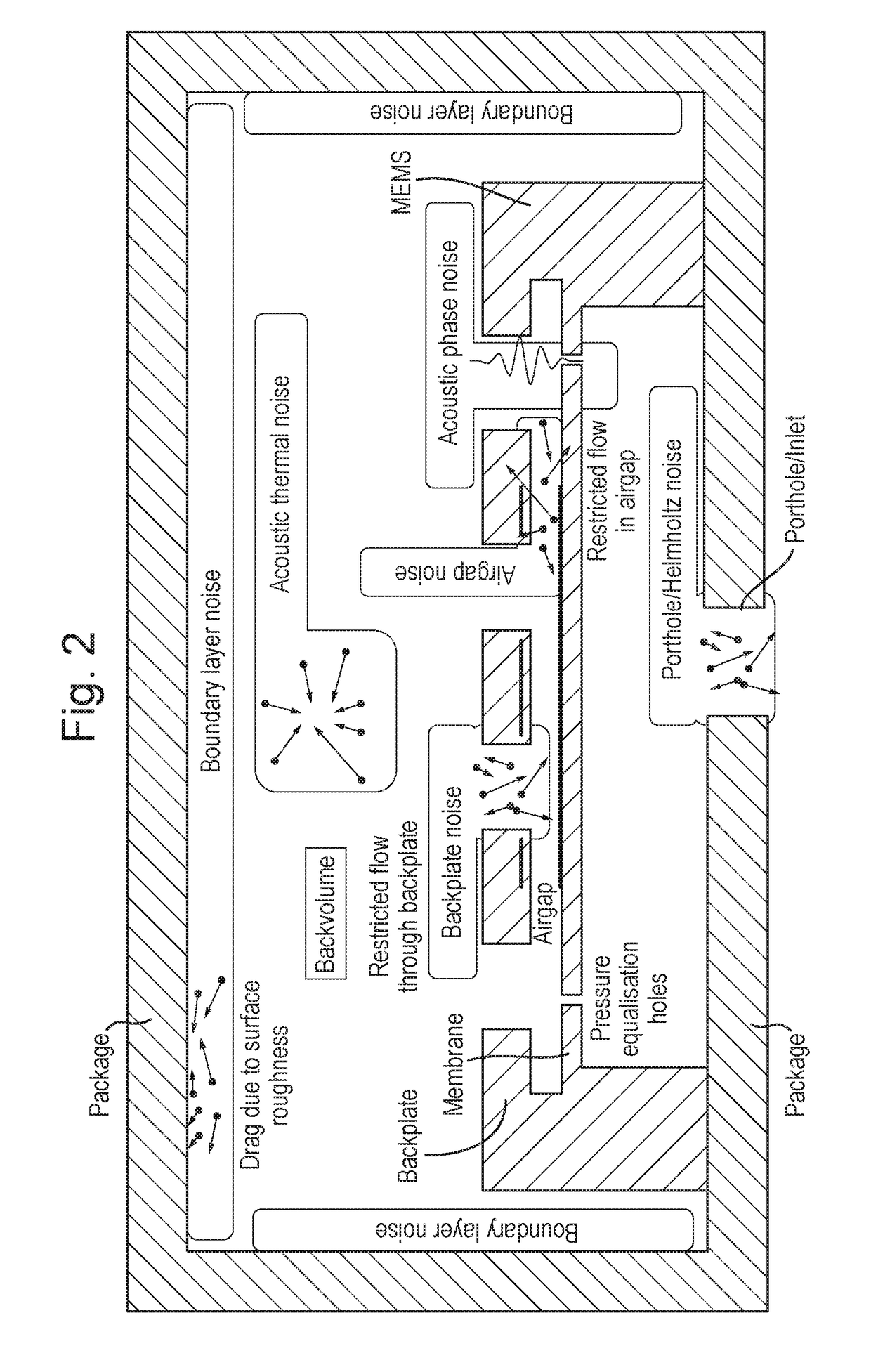

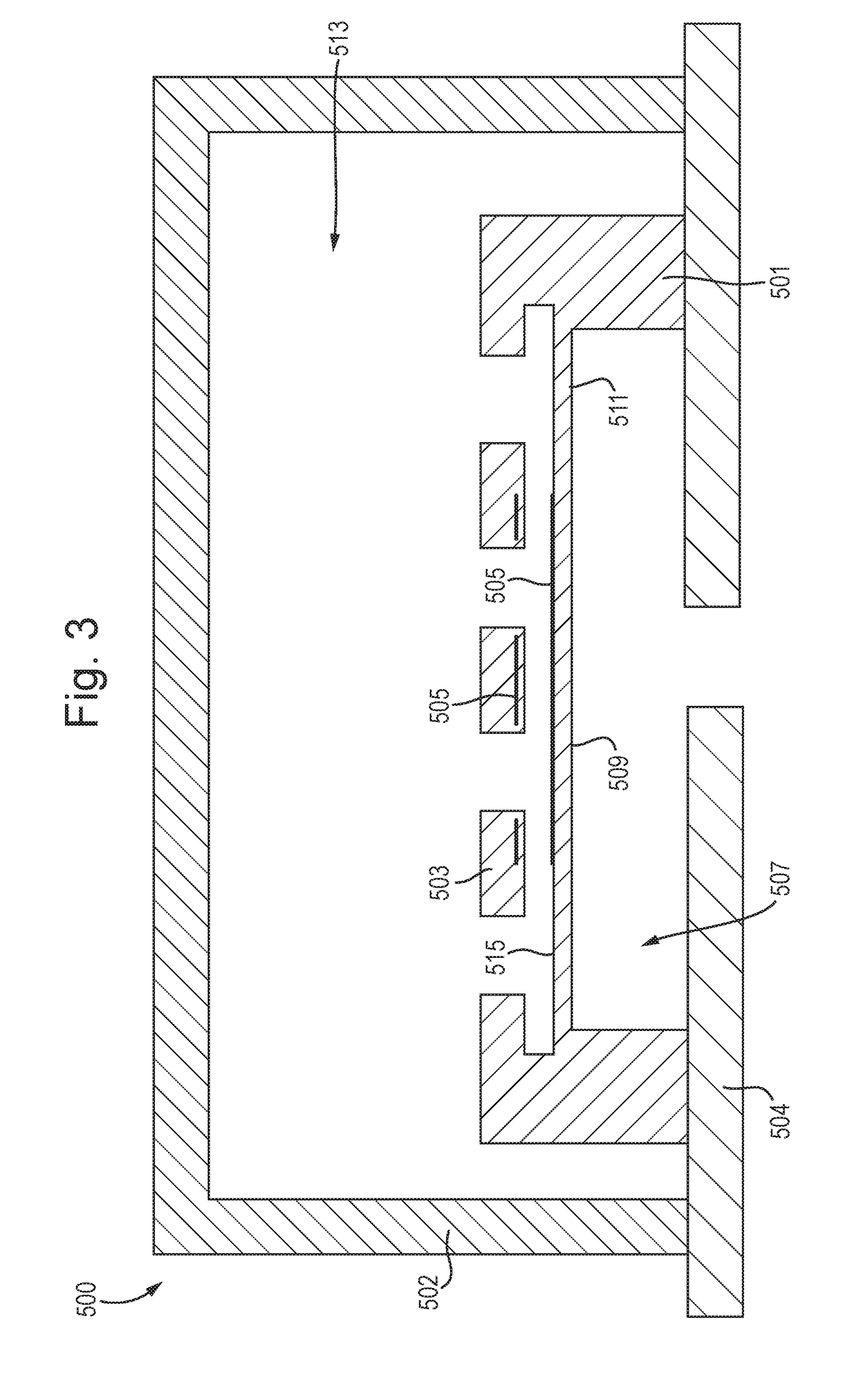

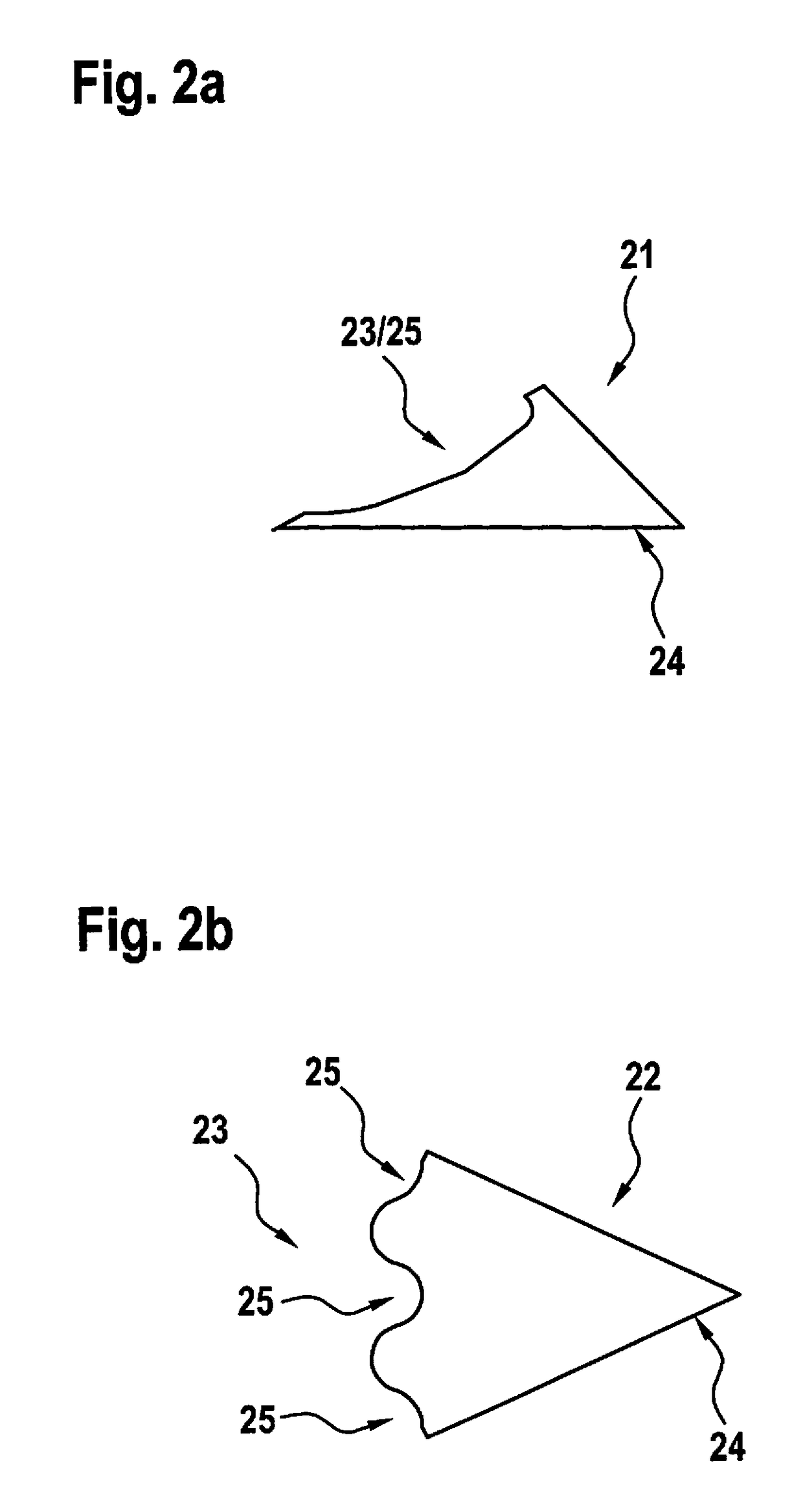

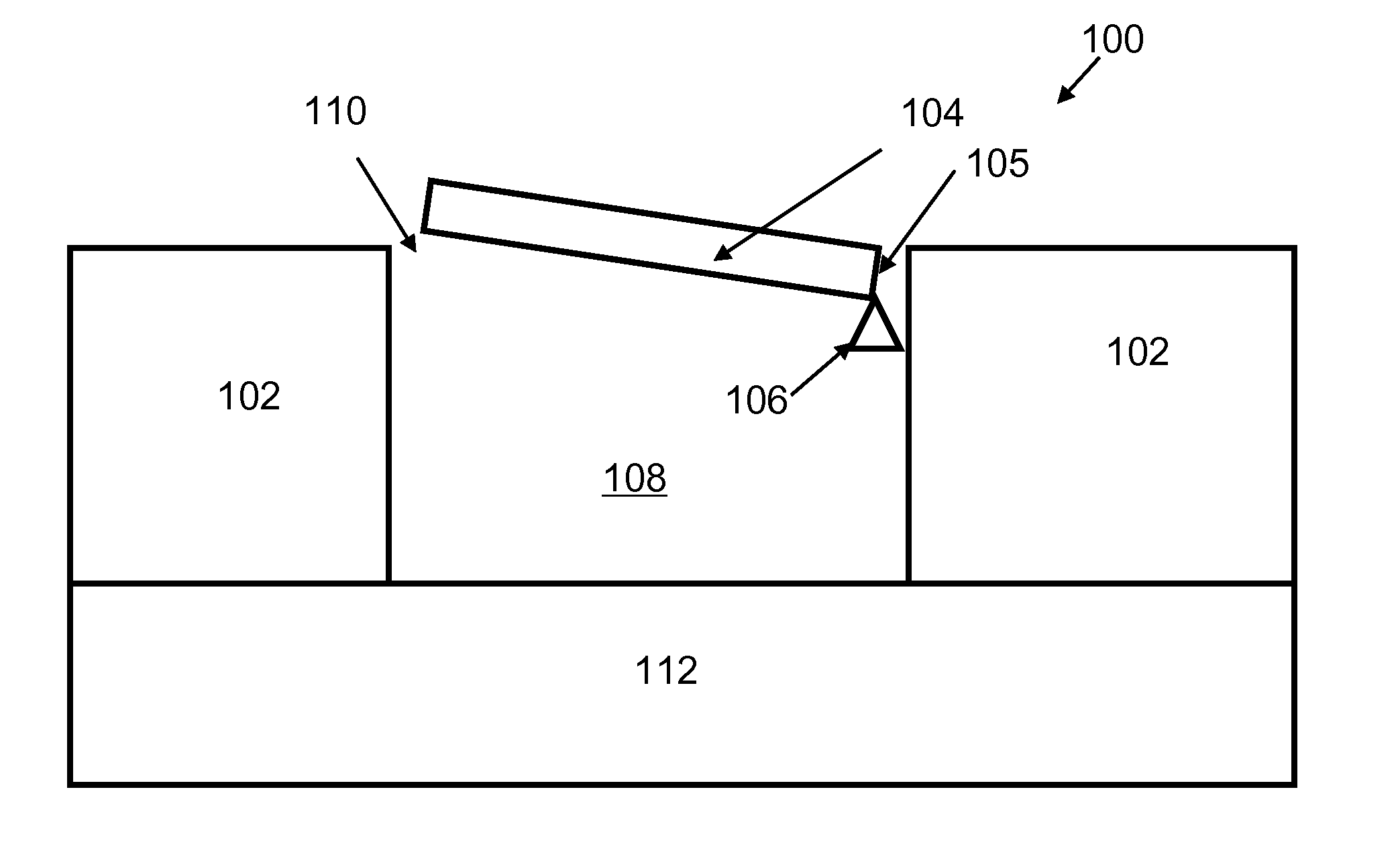

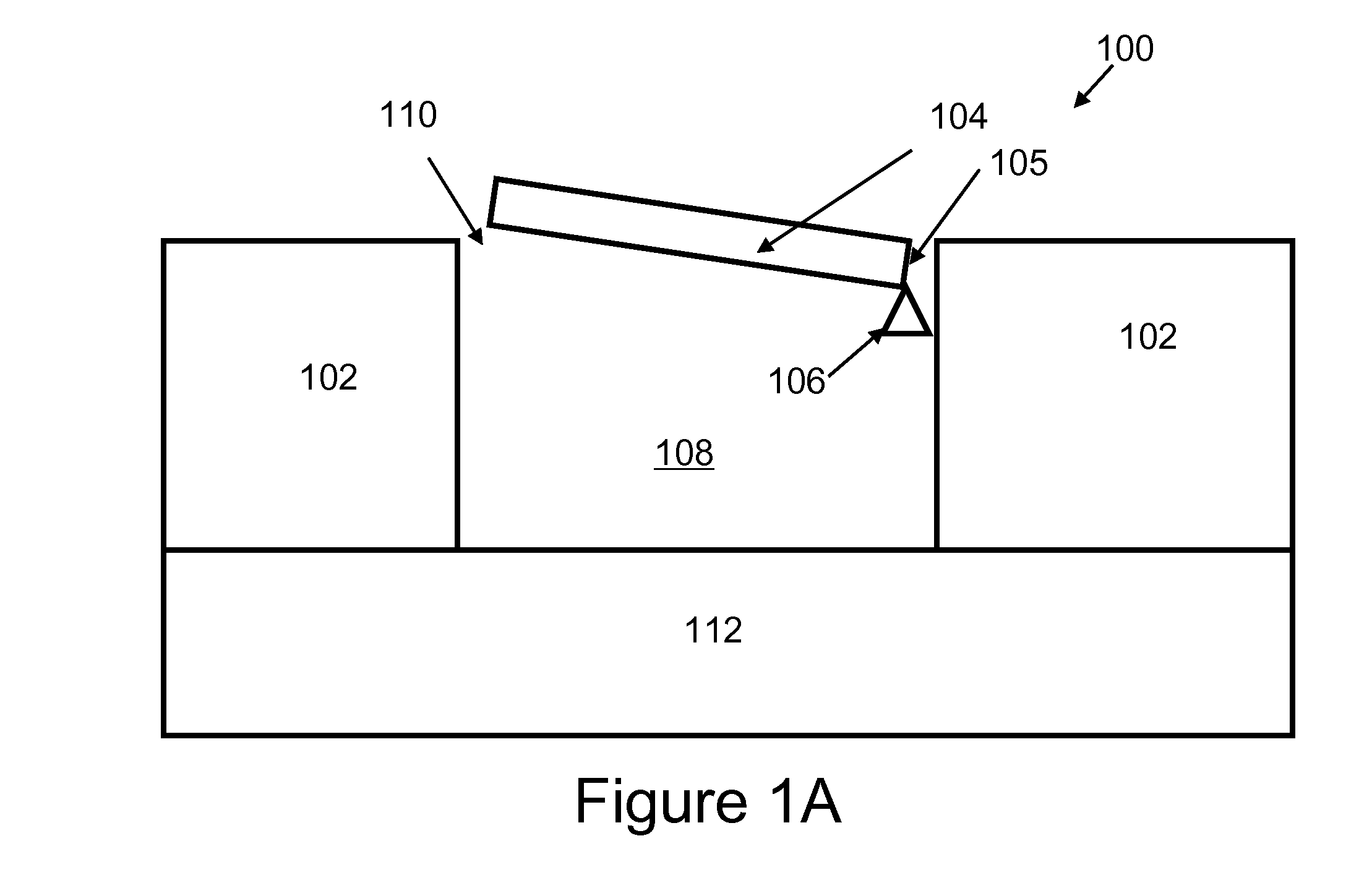

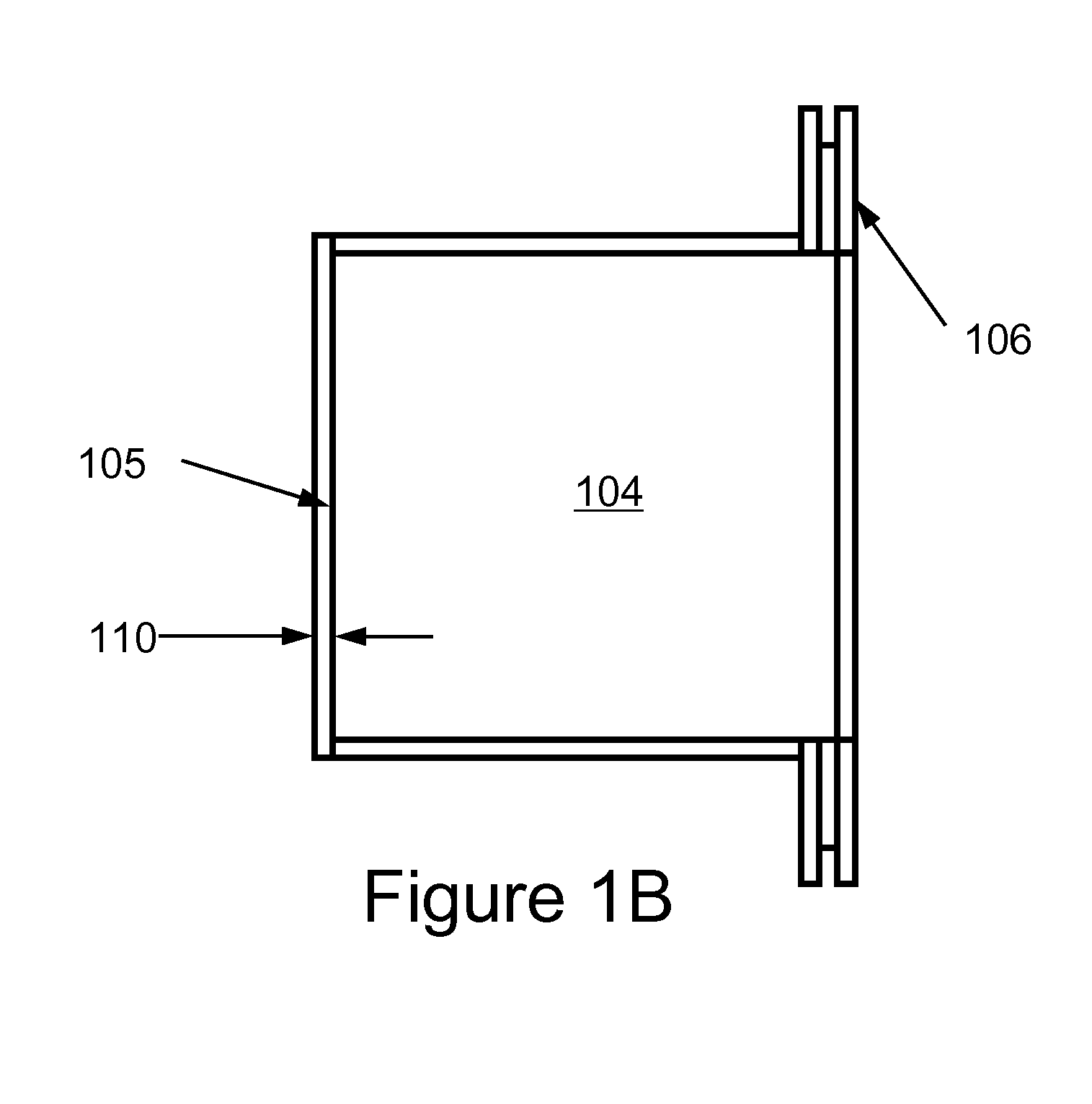

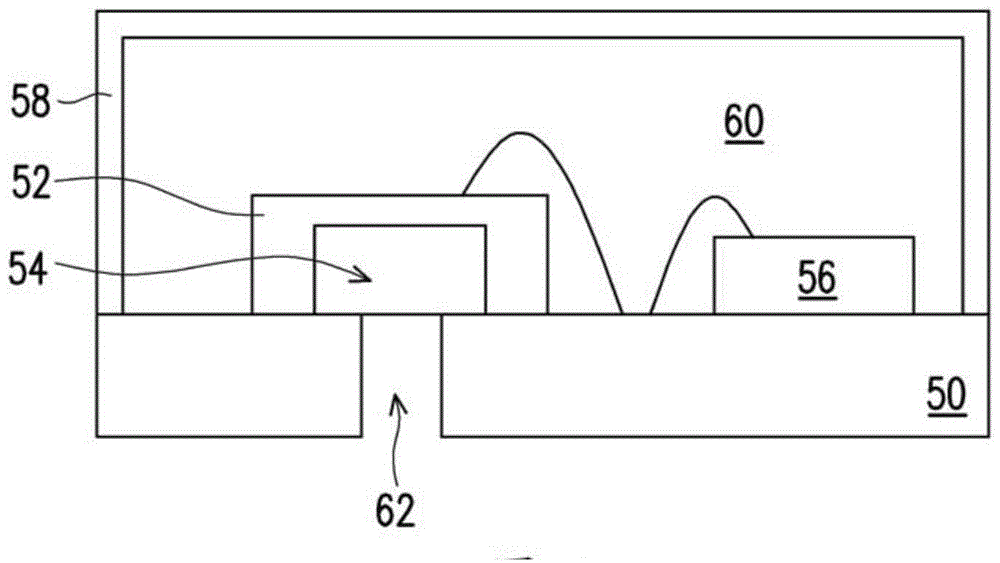

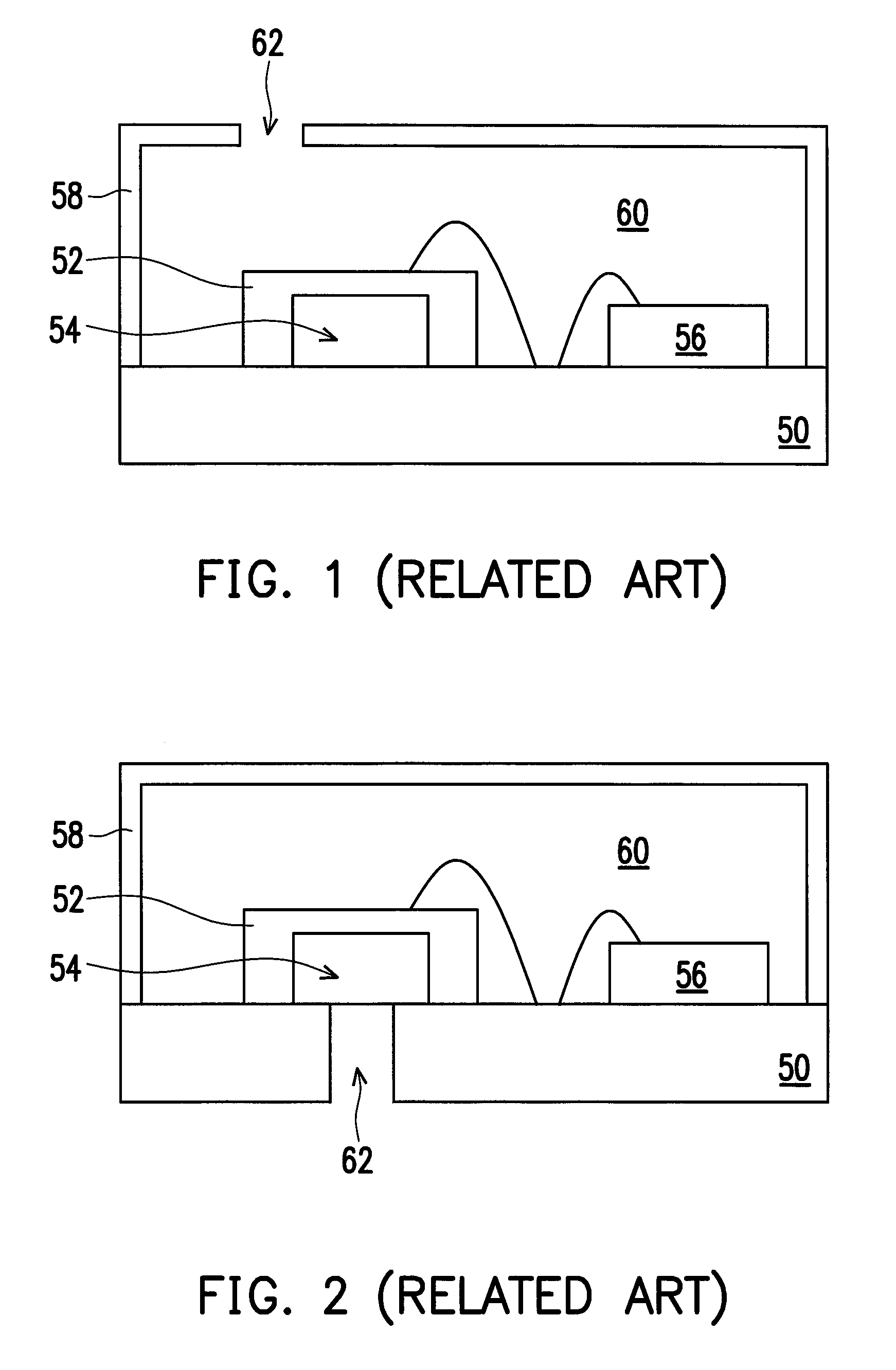

A MEMS capacitive transducer with increased robustness and resilience to acoustic shock. The transducer structure includes a flexible membrane supported between a first volume and a second volume, and at least one variable vent structure in communication with at least one of the first and second volumes. The variable vent structure includes at least one moveable portion which is moveable in response to a pressure differential across the moveable portion so as to vary the size of a flow path through the vent structure. The variable vent may be formed through the membrane and the moveable portion may be a part of the membrane, defined by one or more channels, that is deflectable away from the surface of the membrane. The variable vent is preferably closed in the normal range of pressure differentials but opens at high pressure differentials to provide more rapid equalisation of the air volumes above and below the membrane.

Owner:CIRRUS LOGIC INC

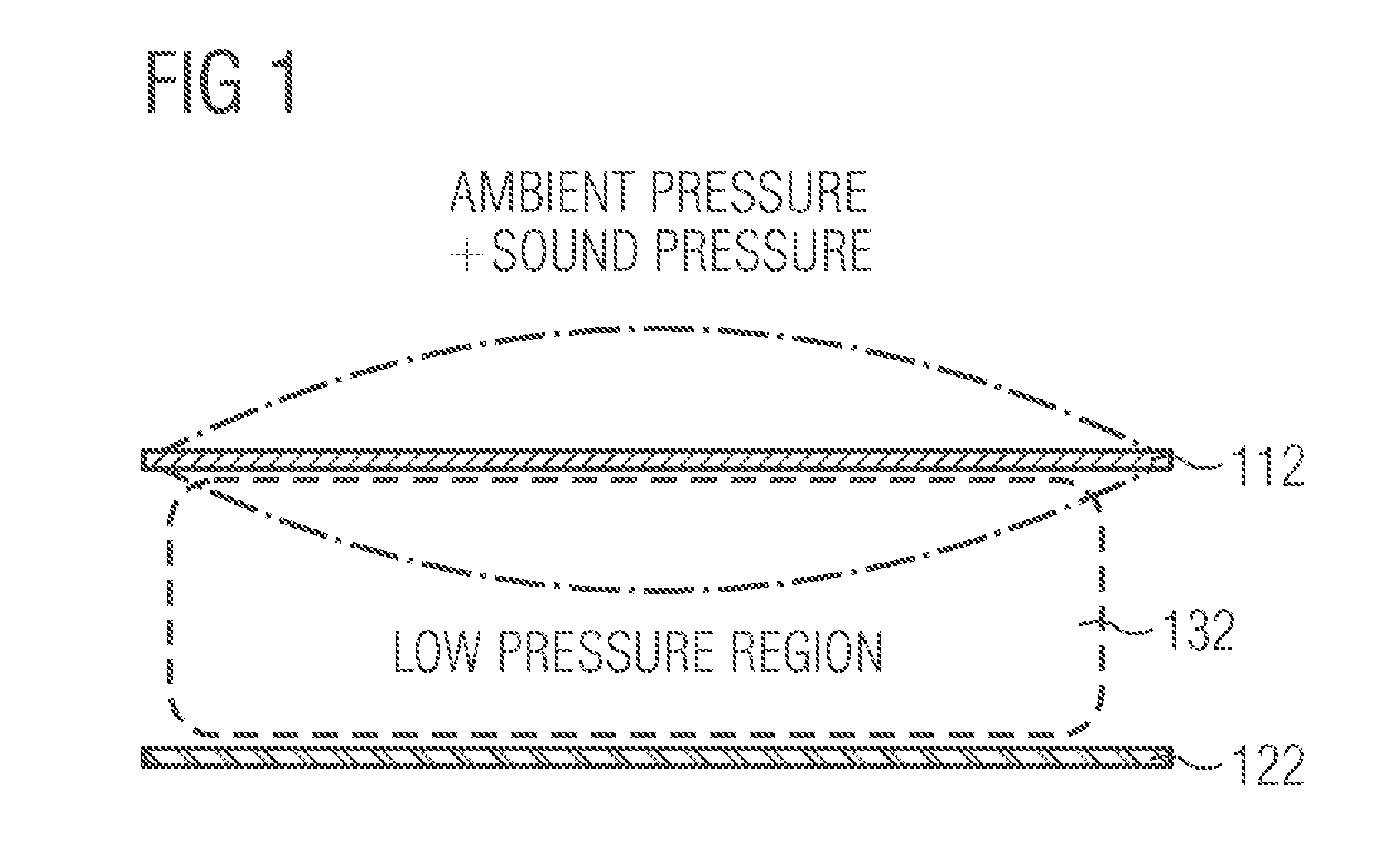

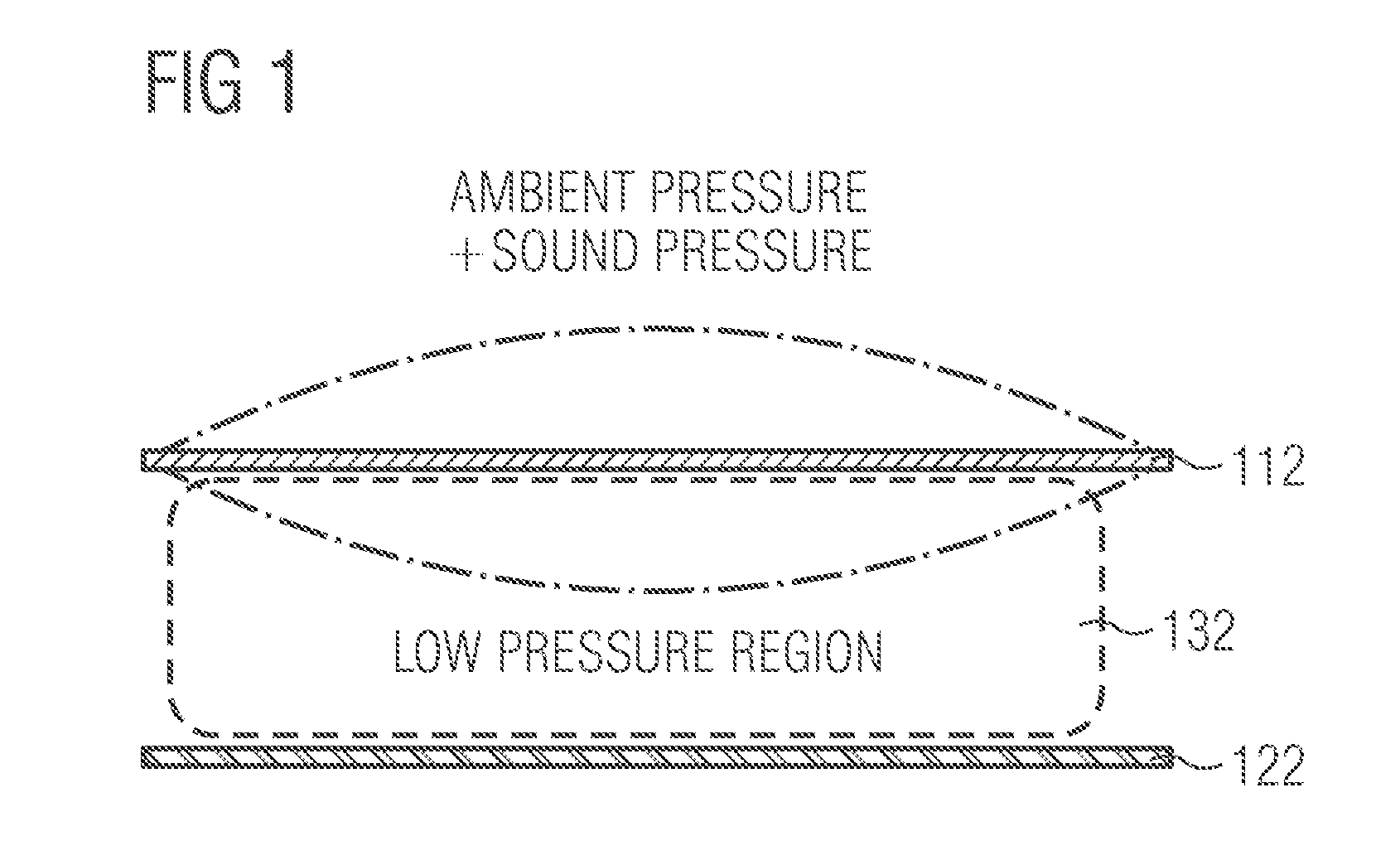

MEMS Microphone with Low Pressure Region Between Diaphragm and Counter Electrode

ActiveUS20150001647A1Avoid enteringSolid state device transducersDecorative surface effectsAmbient pressureMems microphone

A MEMS microphone includes a first diaphragm element, a counter electrode element, and a low pressure region between the first diaphragm element and the counter electrode element. The low pressure region has a pressure less than an ambient pressure.

Owner:INFINEON TECH AG

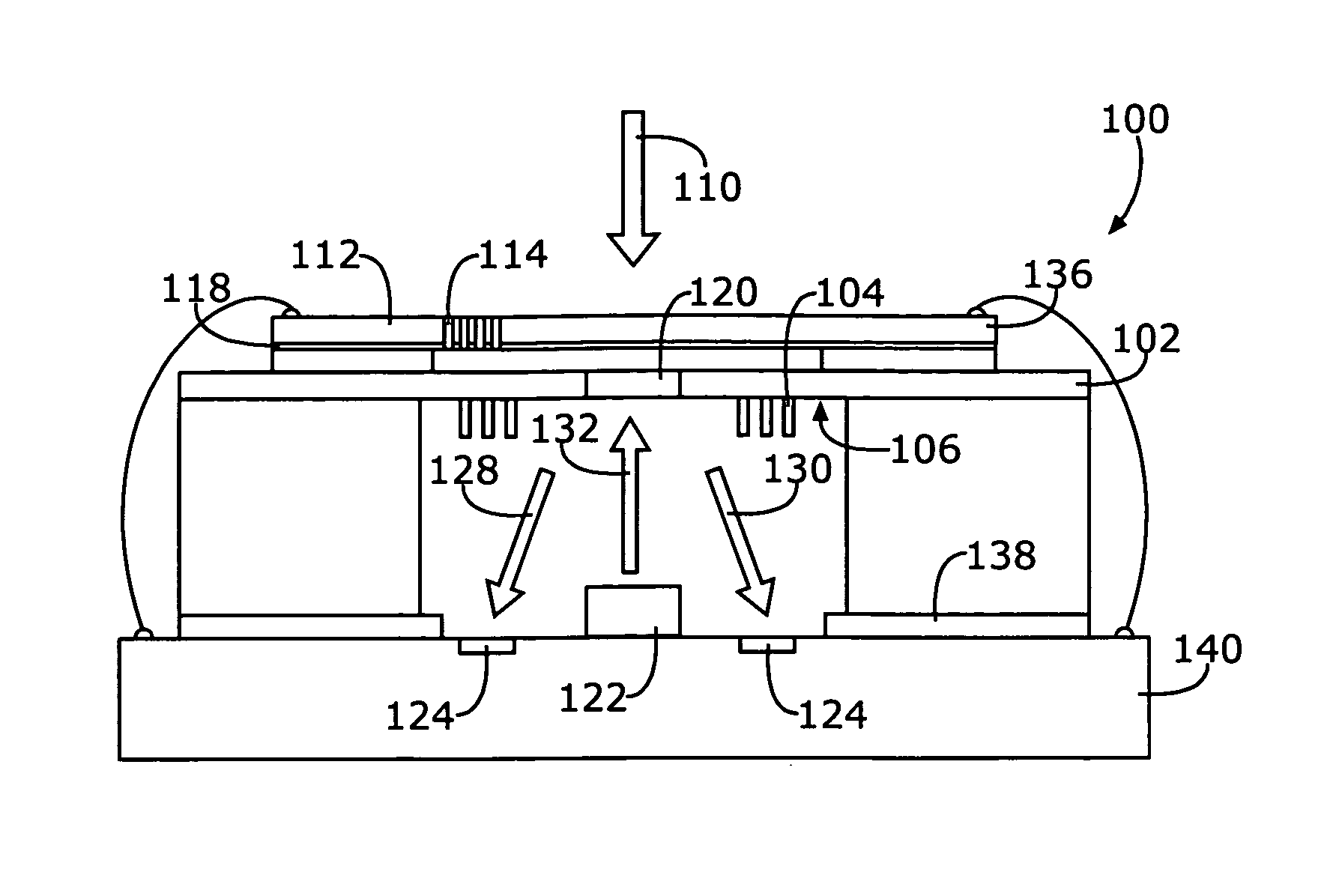

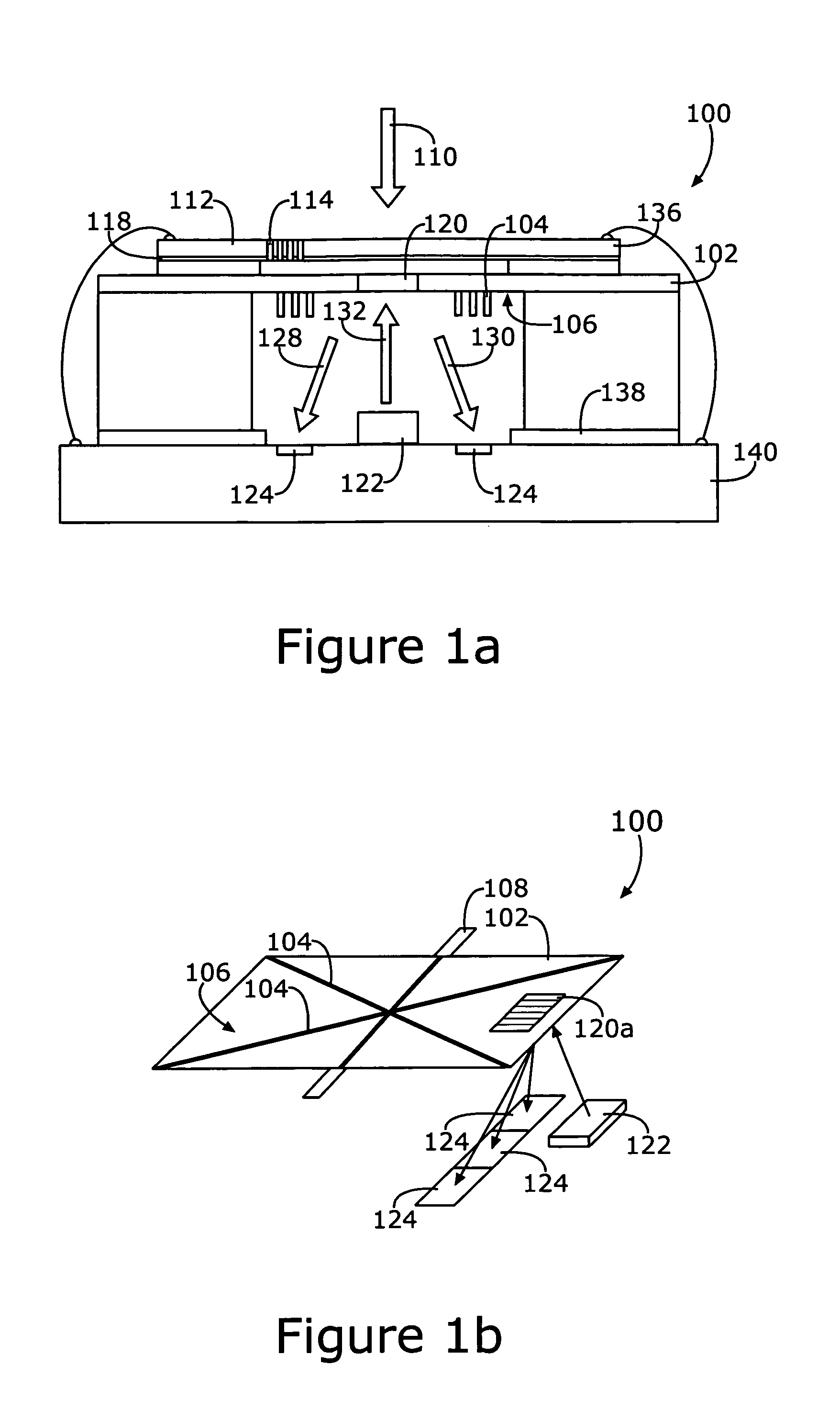

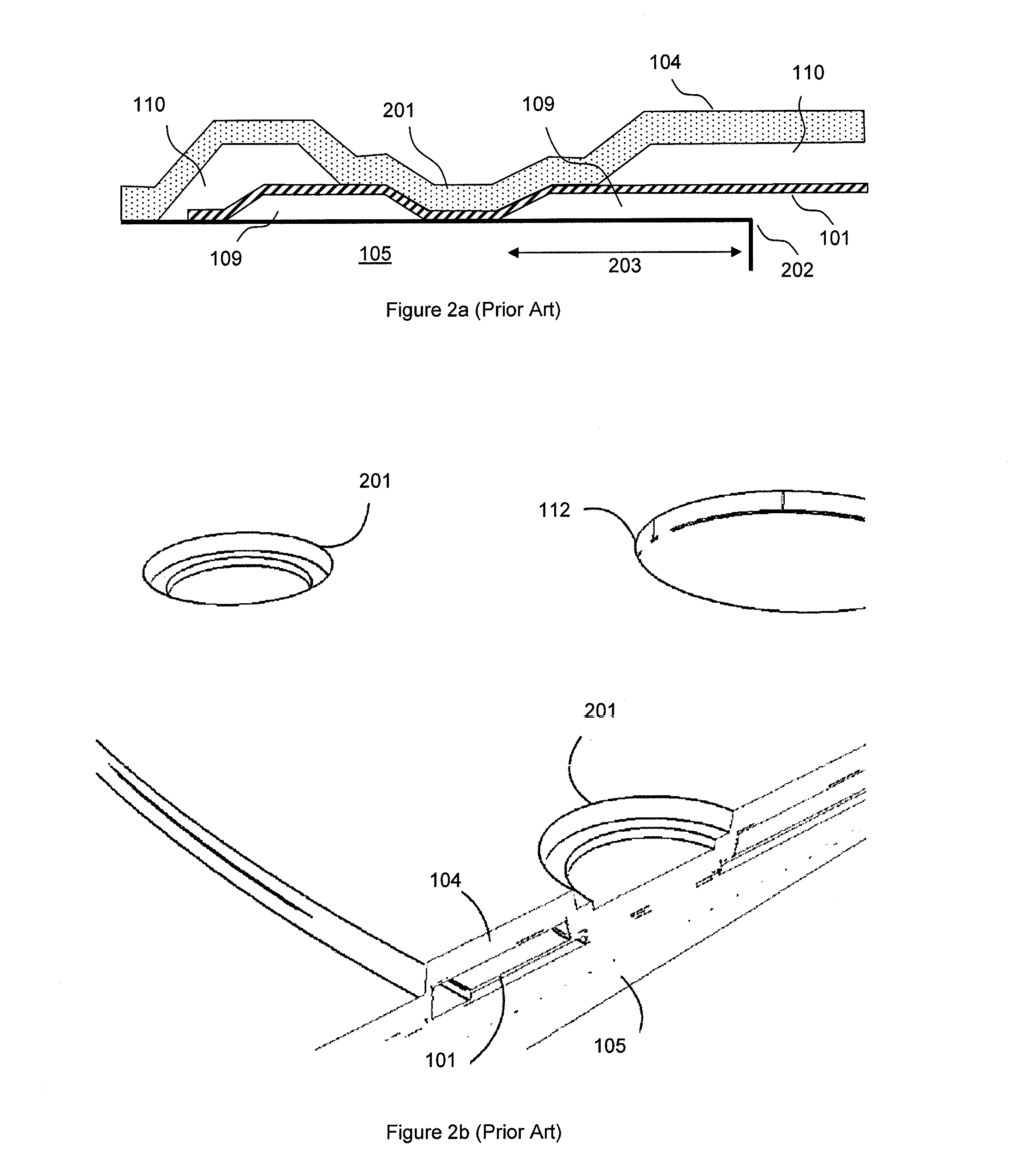

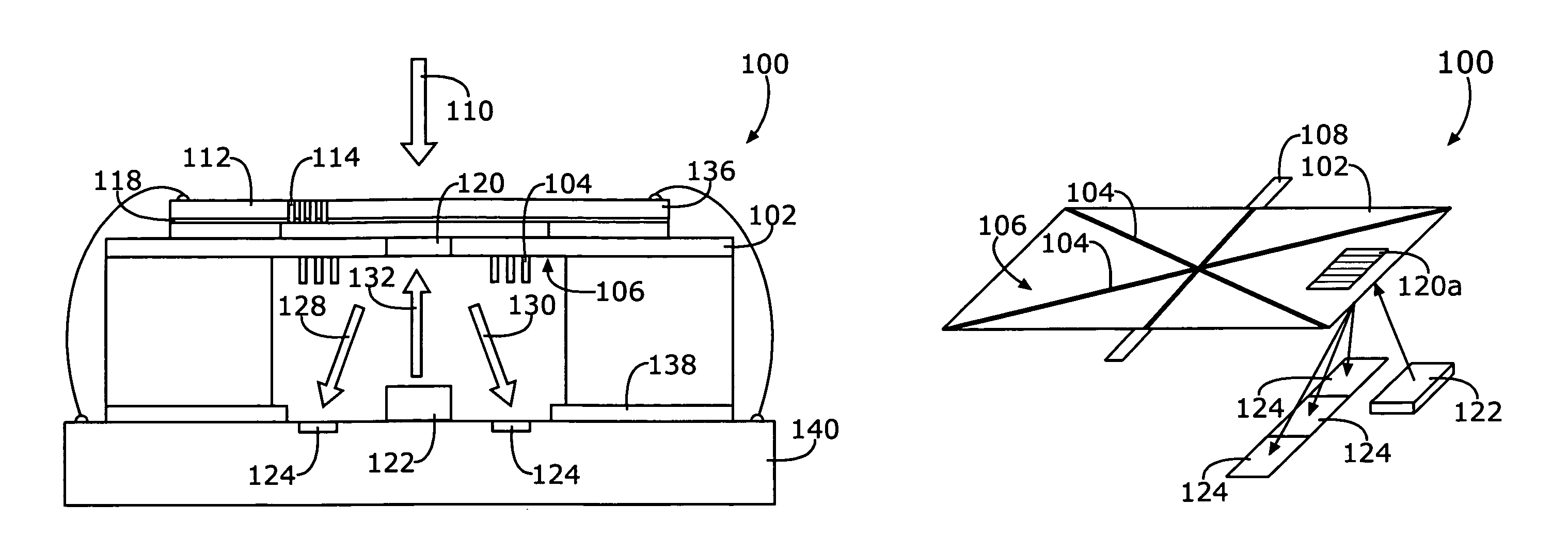

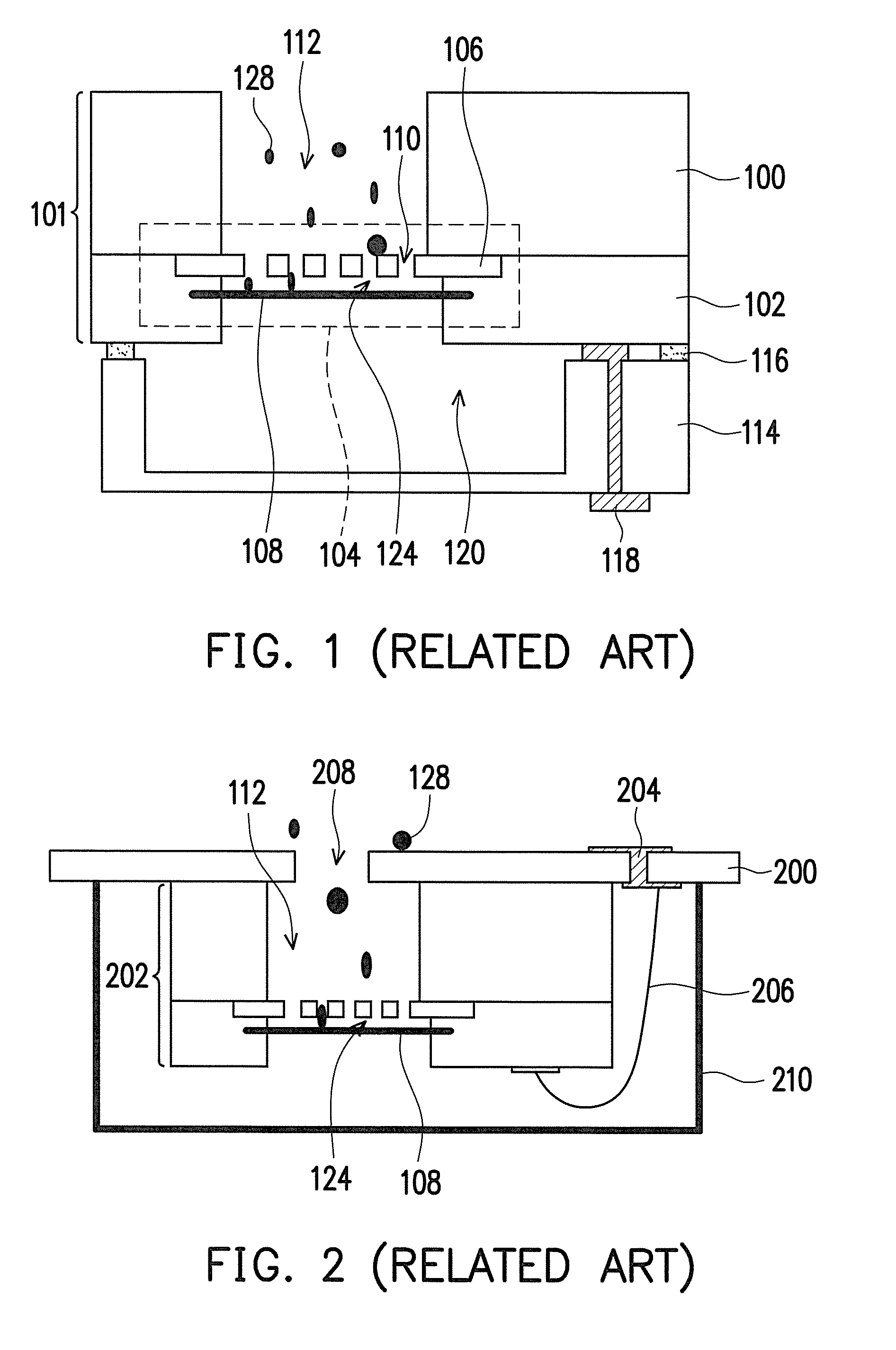

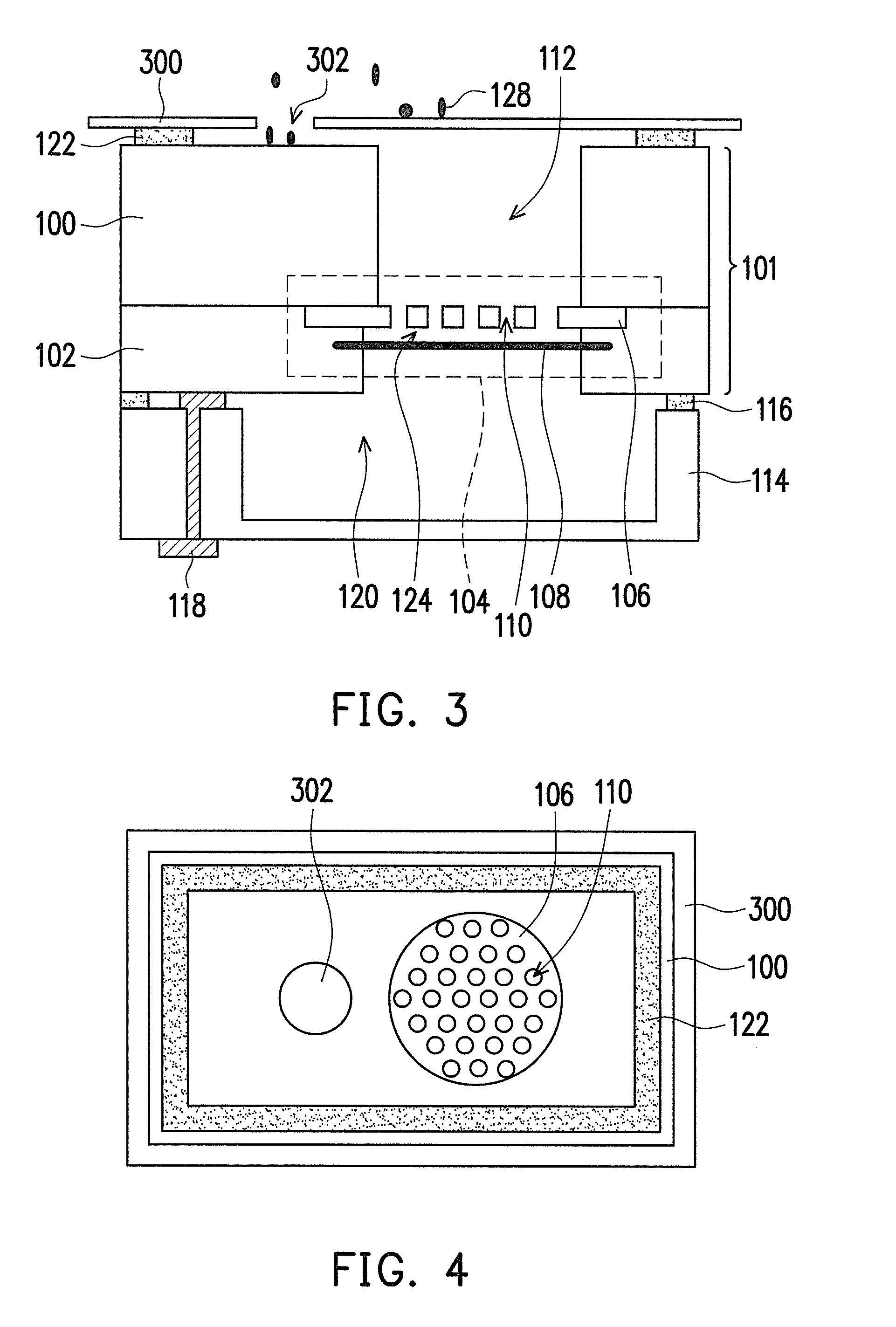

Optical sensing in a directional MEMS microphone

InactiveUS20070165896A1Bulky and heavyReduce external noiseVibration measurement in solidsSolid state device transducersEngineeringMems microphone

A microphone having an optical component for converting the sound-induced motion of the diaphragm into an electronic signal using a diffraction grating. The microphone with inter-digitated fingers is fabricated on a silicon substrate using a combination of surface and bulk micromachining techniques. A 1 mm×2 mm microphone diaphragm, made of polysilicon, has stiffeners and hinge supports to ensure that it responds like a rigid body on flexible hinges. The diaphragm is designed to respond to pressure gradients, giving it a first order directional response to incident sound. This mechanical structure is integrated with a compact optoelectronic readout system that displays results based on optical interferometry.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

MEMS device and process

ActiveUS8737171B2Improving robustness and resilienceSolid state device transducersSemiconductor electrostatic transducersAir volumeAcoustic shock

A MEMS capacitive transducer with increased robustness and resilience to acoustic shock. The transducer structure includes a flexible membrane supported between a first volume and a second volume, and at least one variable vent structure in communication with at least one of the first and second volumes. The variable vent structure includes at least one moveable portion which is moveable in response to a pressure differential across the moveable portion so as to vary the size of a flow path through the vent structure. The variable vent may be formed through the membrane and the moveable portion may be a part of the membrane, defined by one or more channels, that is deflectable away from the surface of the membrane. The variable vent is preferably closed in the normal range of pressure differentials but opens at high pressure differentials to provide more rapid equalization of the air volumes above and below the membrane.

Owner:CIRRUS LOGIC INC

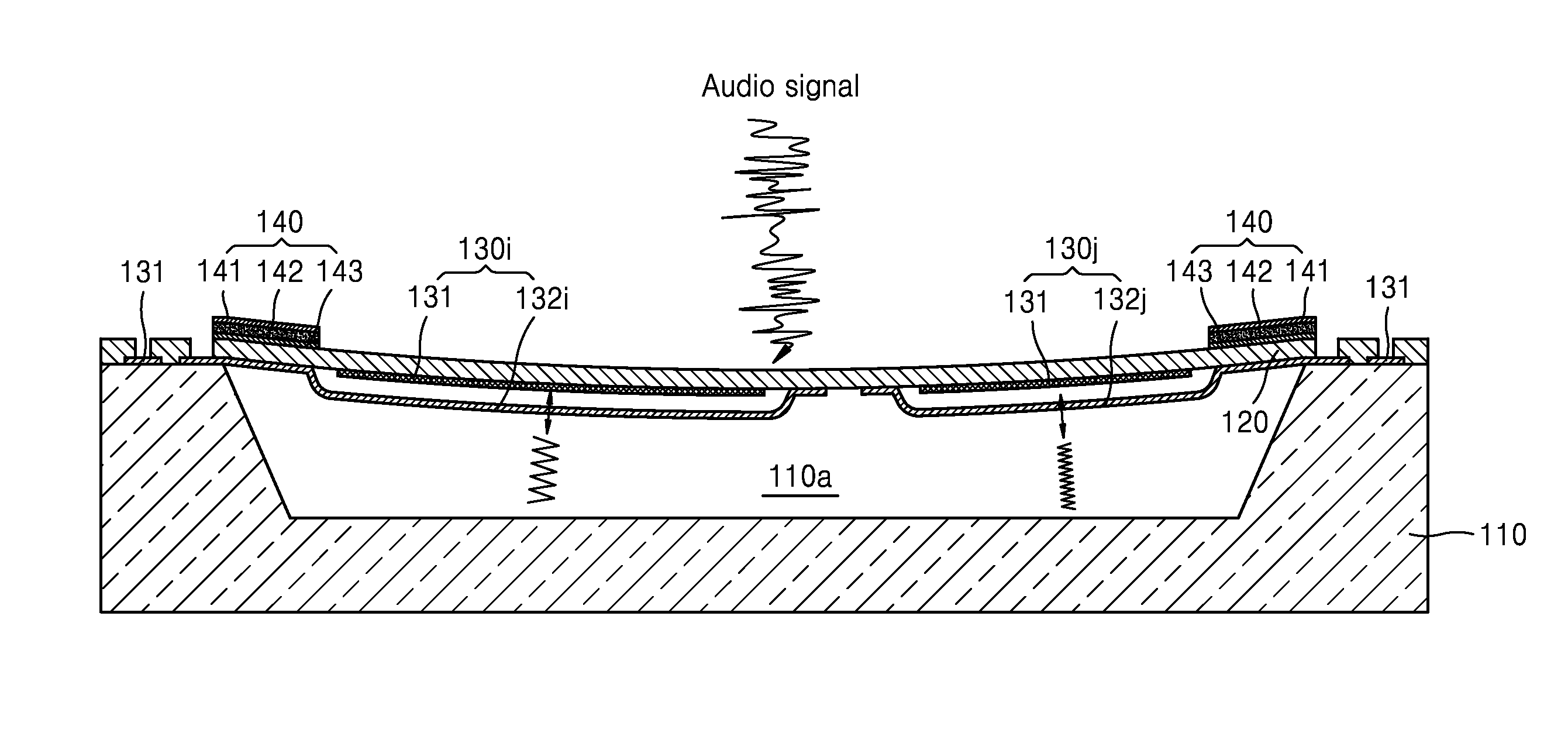

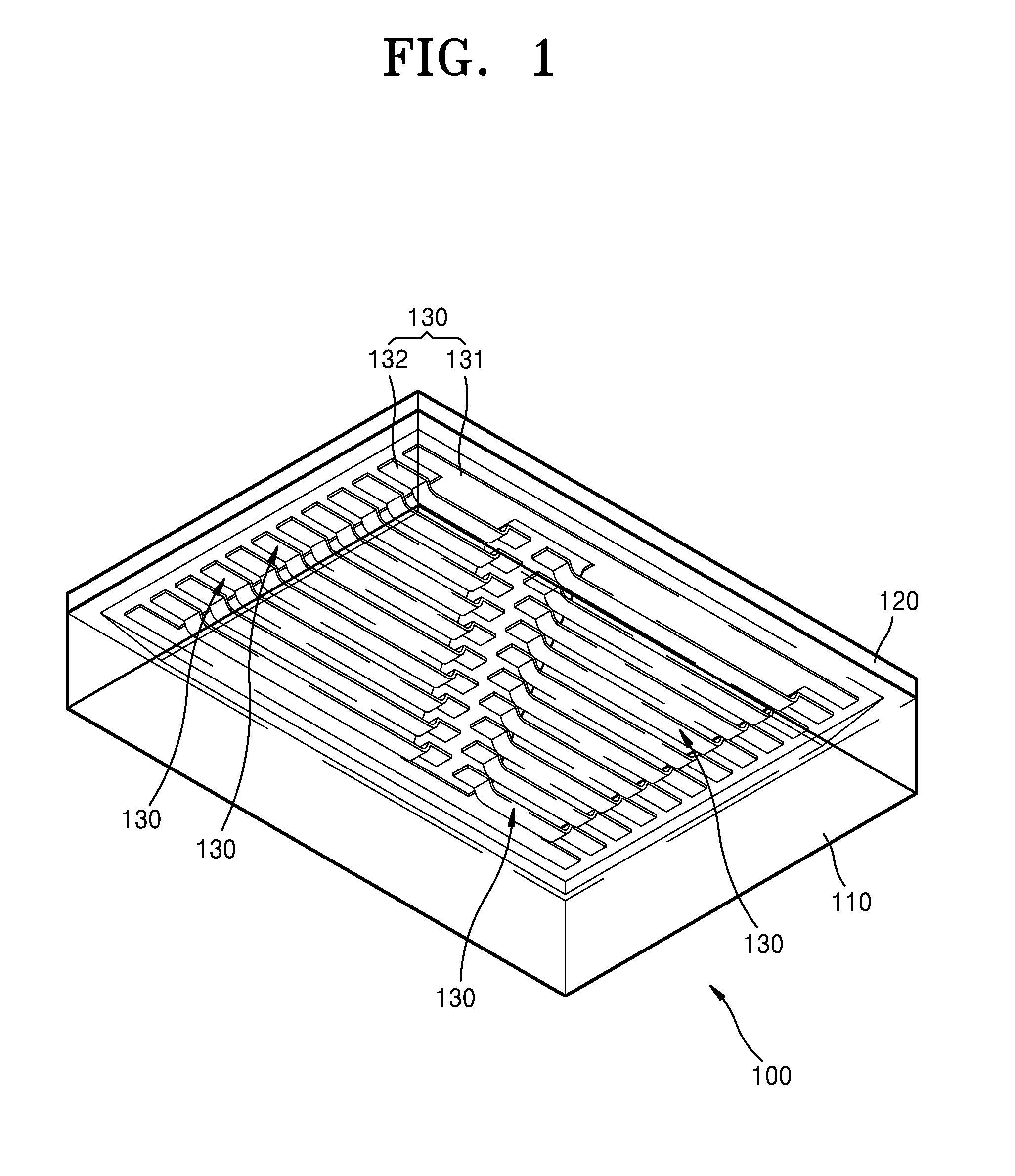

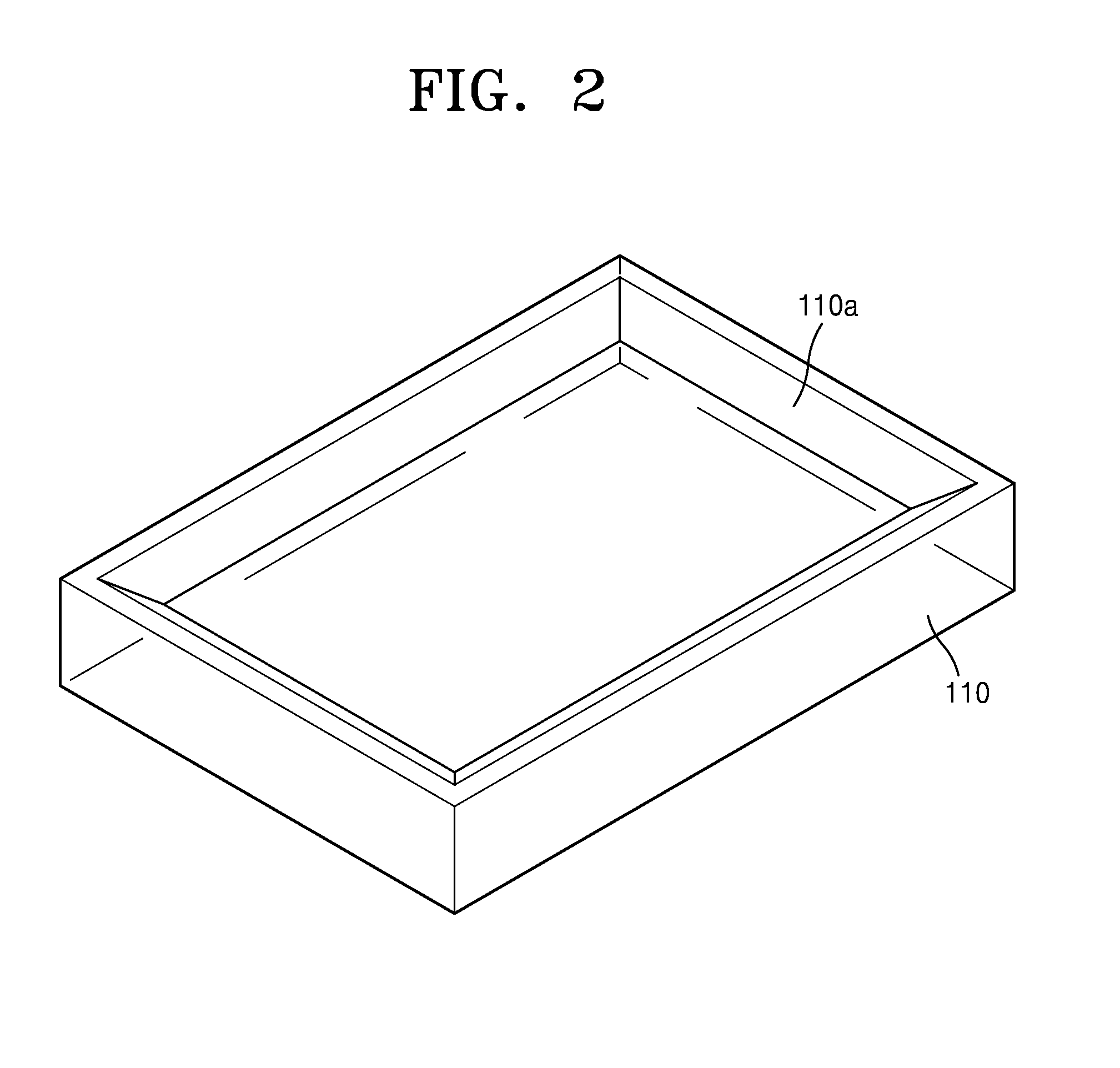

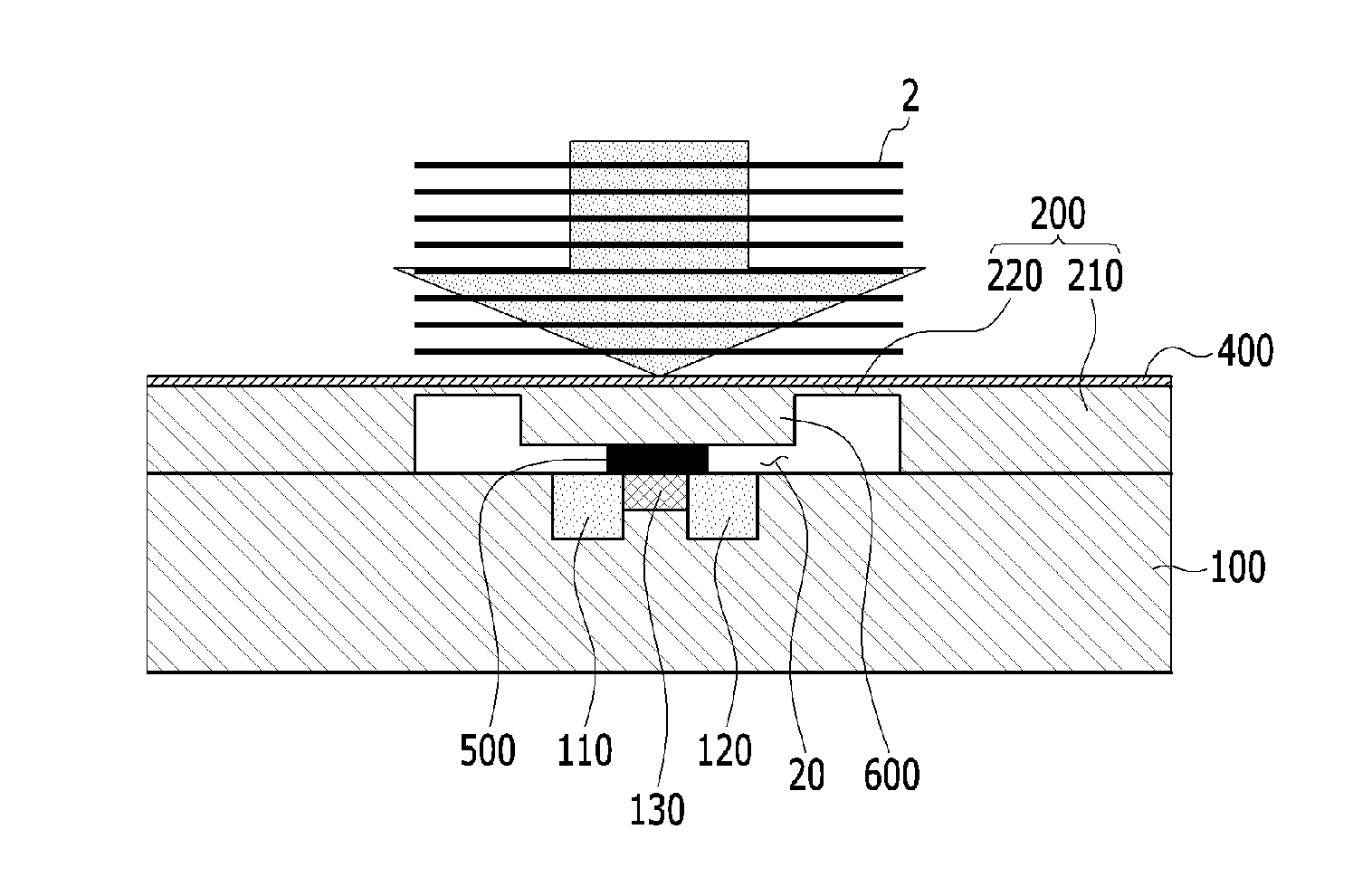

Audio sensing device and method of acquiring frequency information

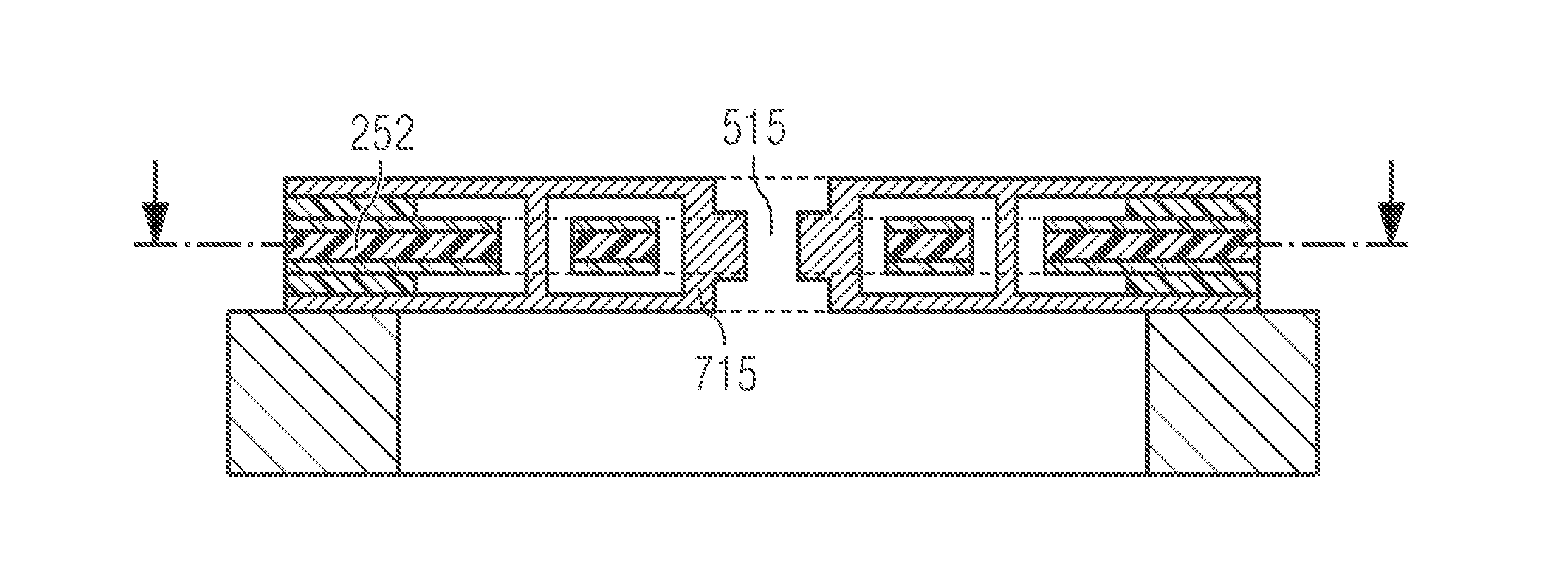

ActiveUS20160050506A1Piezoelectric/electrostrictive microphonesSolid state device transducersComputer scienceAudio frequency

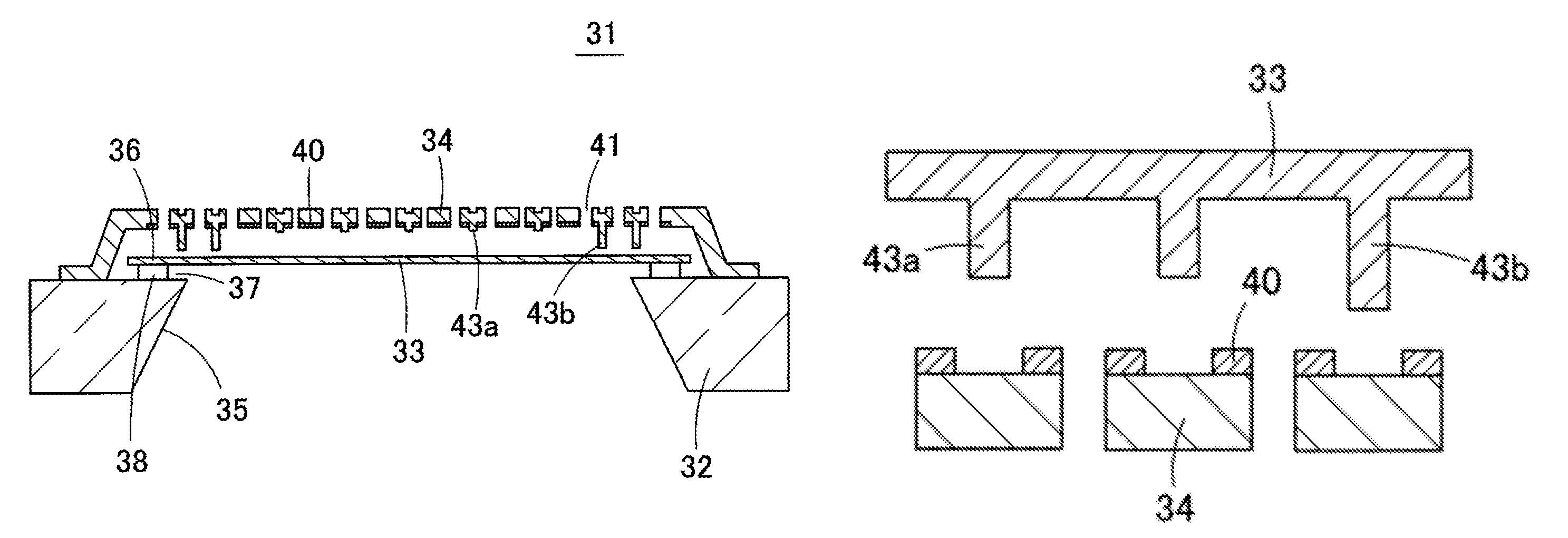

An audio sensing device having a resonator array and a method of acquiring frequency information using the audio sensing device are provided. The audio sensing device includes a substrate having a cavity formed therein, a membrane provided on the substrate and covering the cavity, and a plurality of resonators provided on the membrane and respectively sensing sound frequencies of different frequency bands.

Owner:SAMSUNG ELECTRONICS CO LTD

Optical sensing in a directional MEMS microphone

InactiveUS7826629B2Bulky and heavyReduce noiseVibration measurement in solidsSolid state device transducersEngineeringMems microphone

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

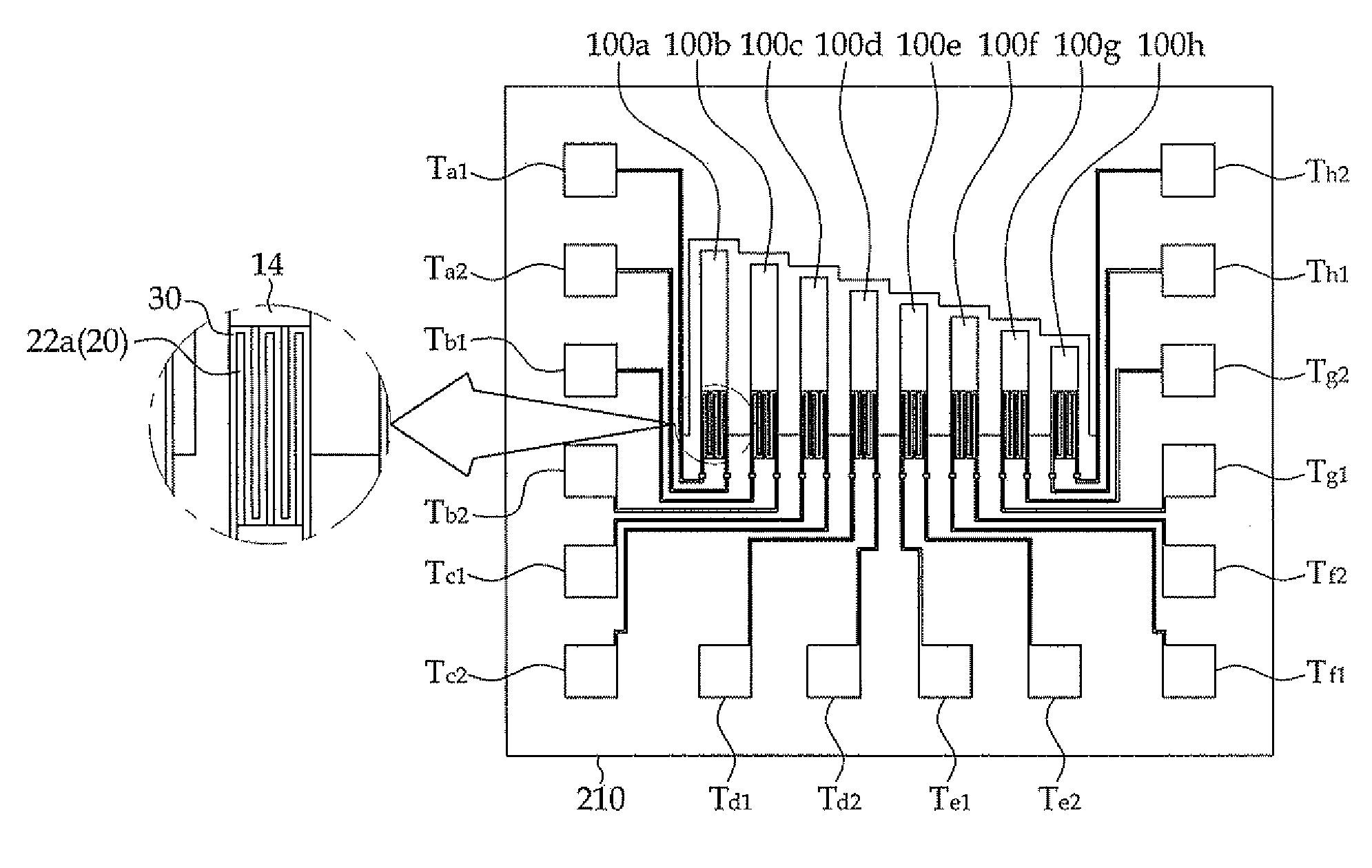

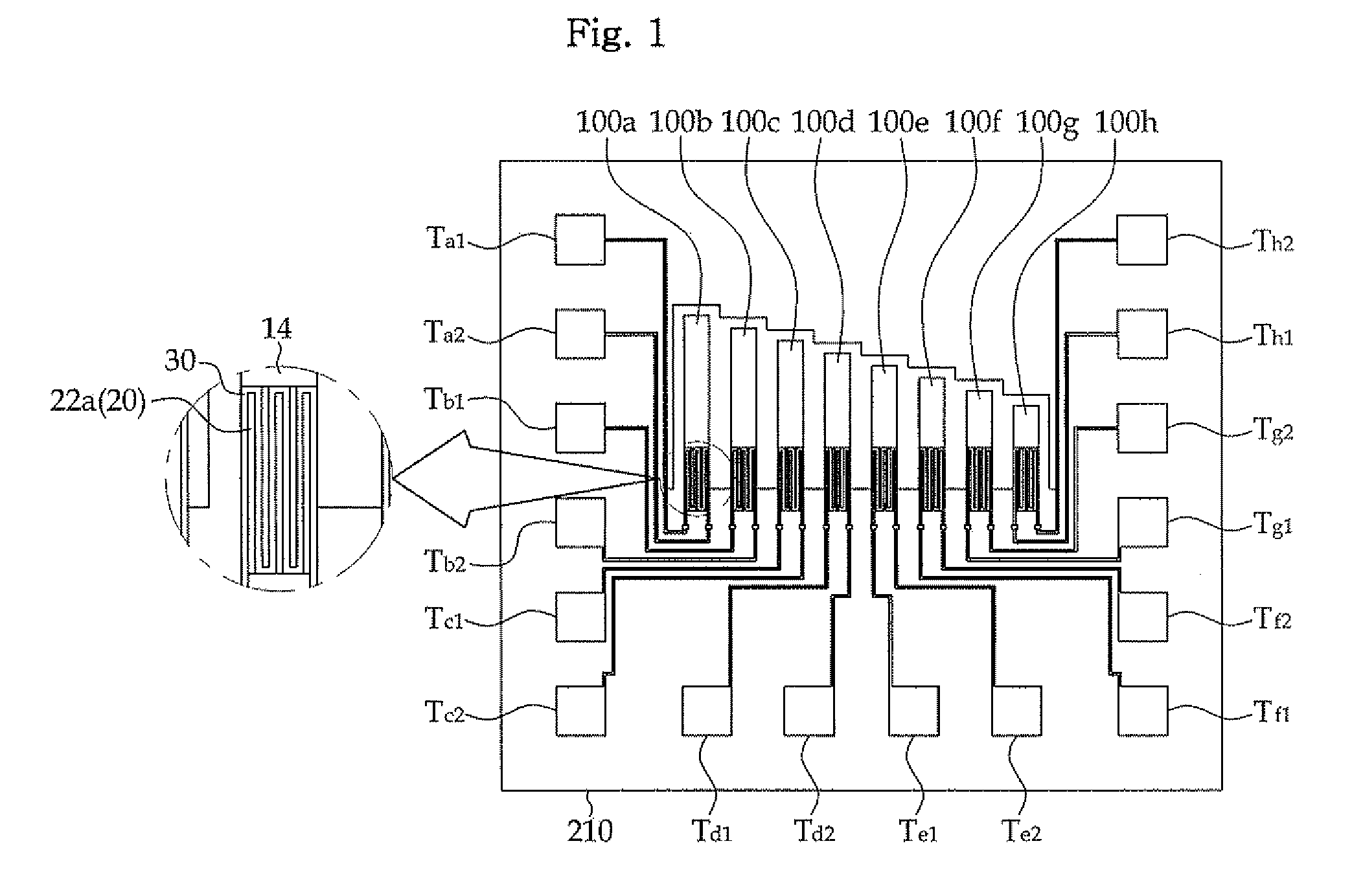

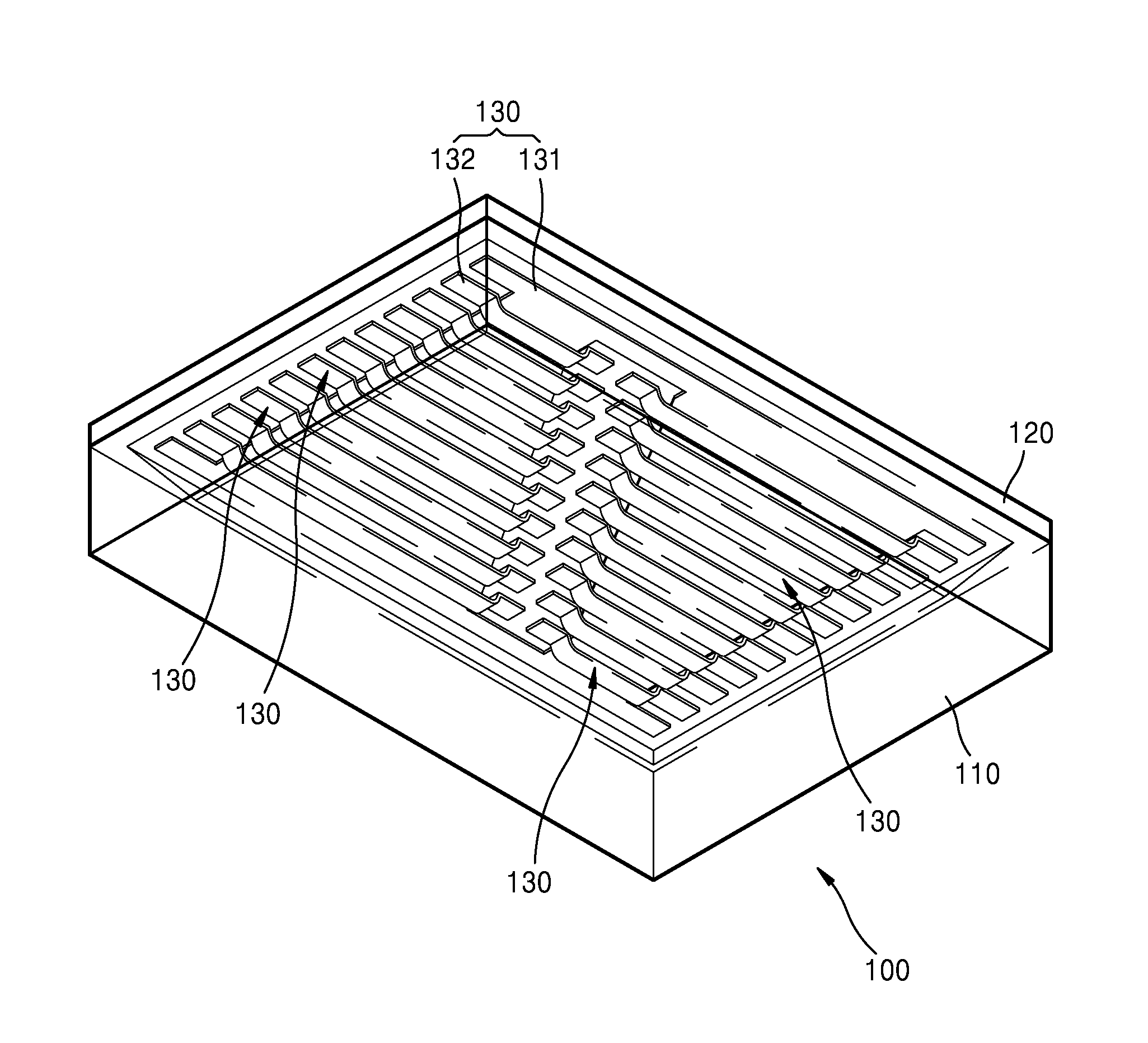

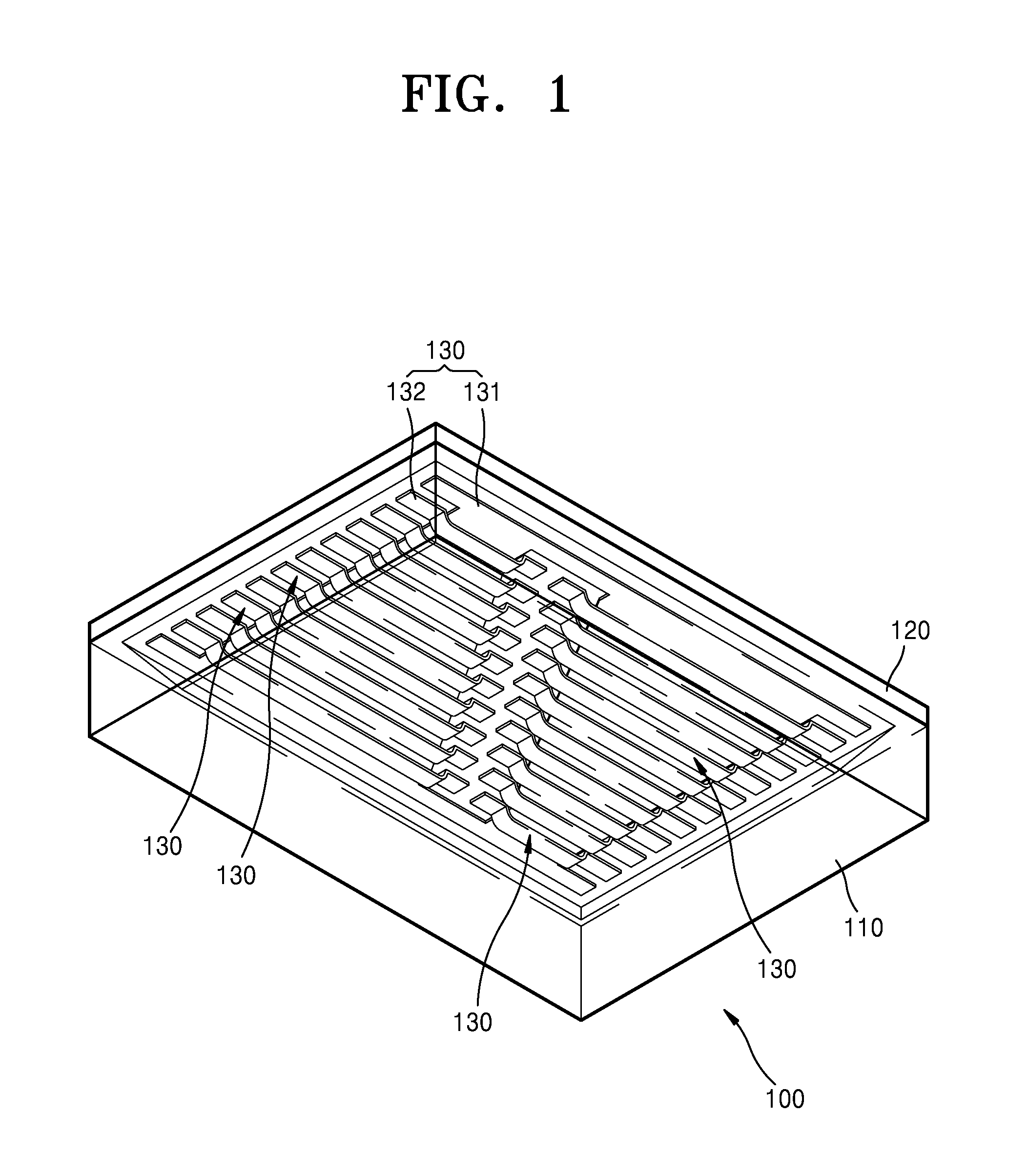

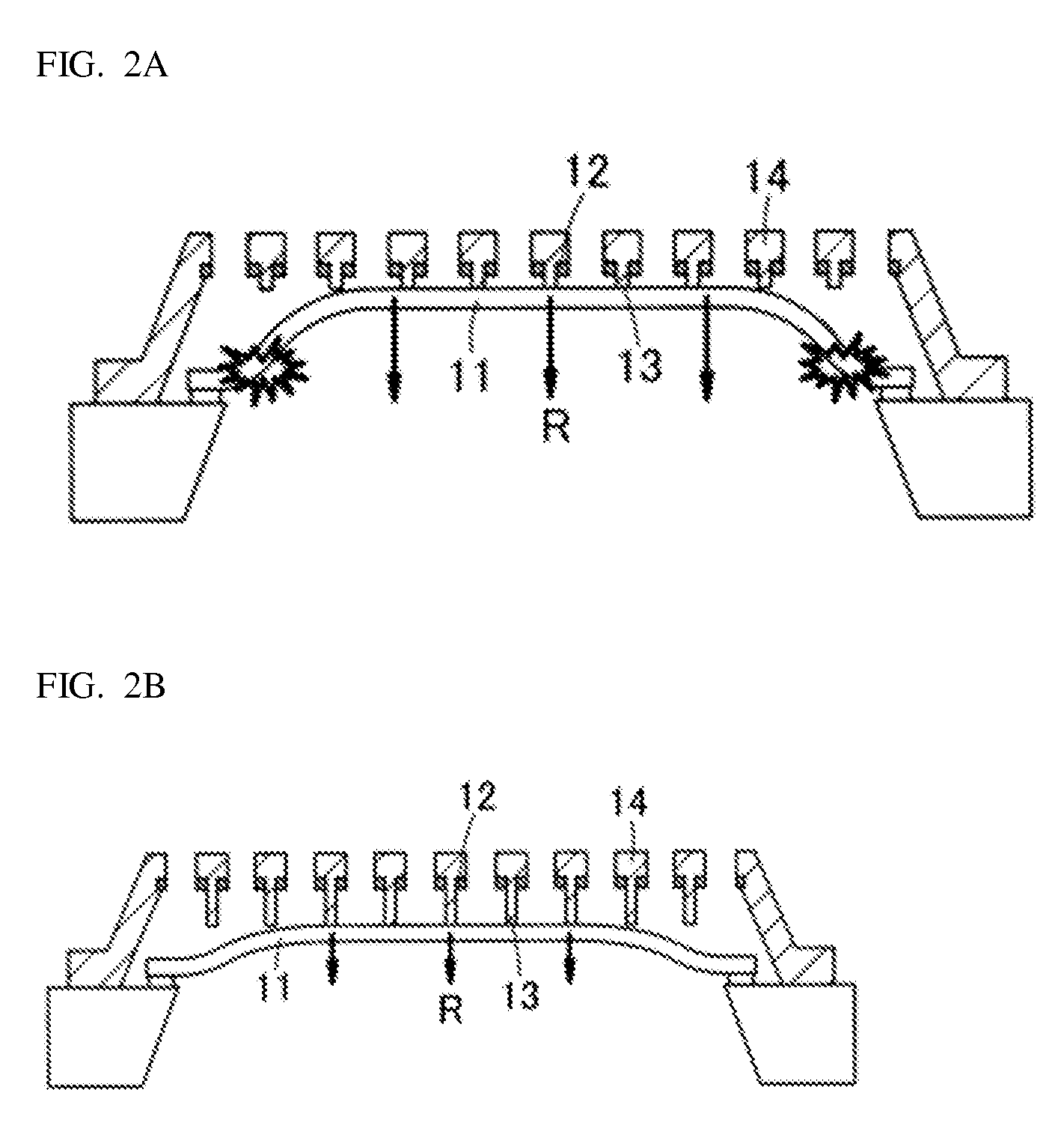

Multi-cantilever MEMS sensor, manufacturing method thereof, sound source localization apparatus using the multi-cantilever MEMS sensor, sound source localization method using the sound source localization apparatus

InactiveUS20090079298A1Fast processingReduce manufacturing costSolid state device transducersMicrophonesSound sourcesMems sensors

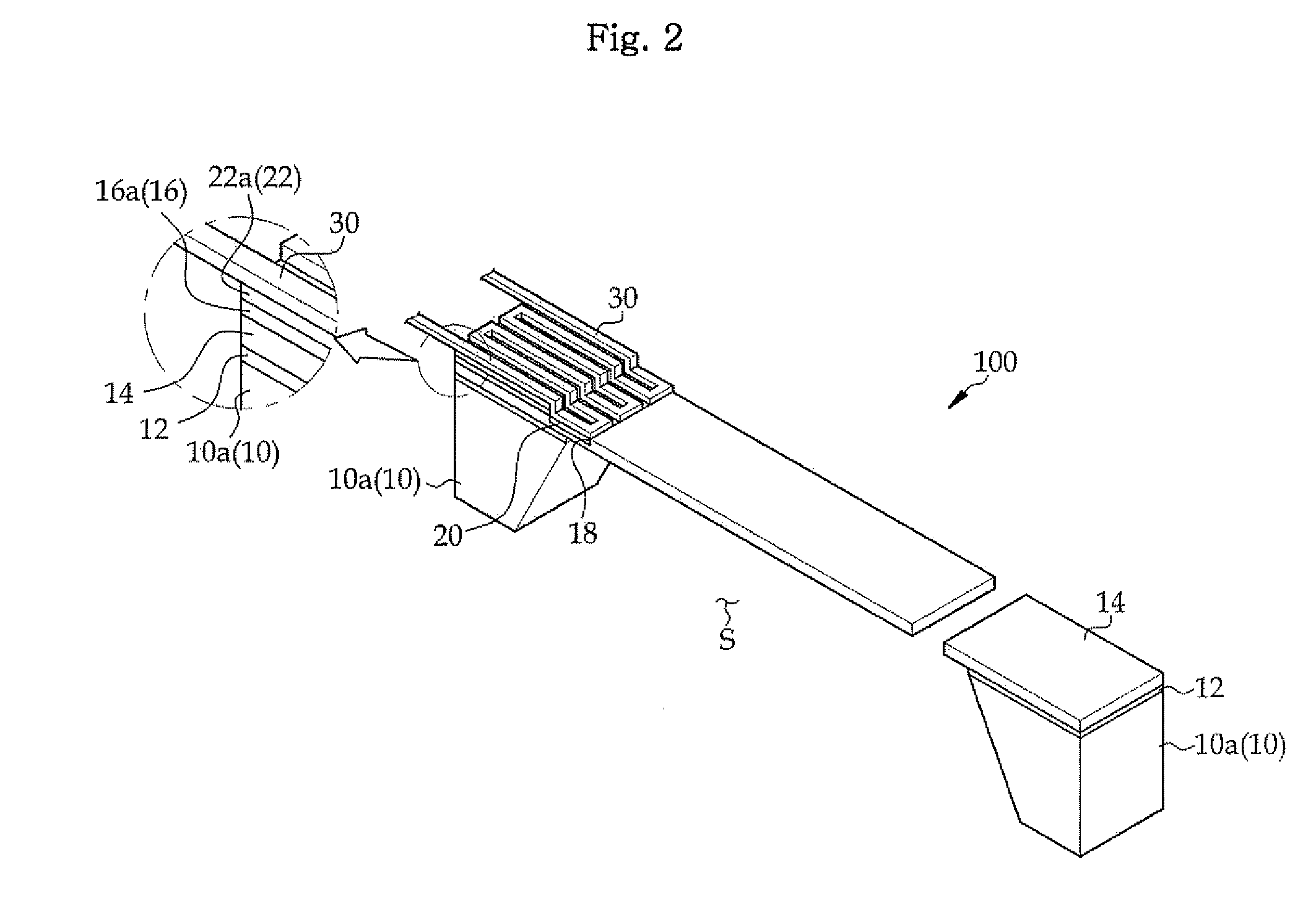

Disclosed herein is a multi-cantilever MEMS sensor functioning as a mechanical sensor having a plurality of cantilevers, replacing a conventional DSP based sound source localization algorithm and reducing production cost when the MEMES sensor applied to mass-produced robots, a manufacturing method thereof, a sound source localization apparatus using the multi-cantilever MEMS sensor and a sound source localization method using the sound source localization apparatus. The multi-cantilever MEMS sensor comprises a plurality of cantilevers 100 each of which includes a piezoresistor 20 and a sensing part 30 for sensing a predetermined signal generated according to the piezoresistor 20l; and a terminal T for detecting the signal generated according to the piezoresistor 20, wherein one end of each cantilever is a free end and the other end thereof is a fixed end of each cantilever, the piezoresistor 20 and the sensing part 30 are formed at the fixed end, and the free ends of the plurality of cantilevers 100 have different lengths. A method of manufacturing the multi-cantilever MEMS sensor is provided. Furthermore, a method of using the multi-cantilever MEMS sensor and a sound source localization apparatus are provided.

Owner:KOREA ADVANCED INST OF SCI & TECH

MEMS device and process

ActiveUS20140161290A1Improving robustness and resilienceSolid state device transducersDecorative surface effectsAir volumeAcoustic shock

A MEMS capacitive transducer with increased robustness and resilience to acoustic shock. The transducer structure includes a flexible membrane supported between a first volume and a second volume, and at least one variable vent structure in communication with at least one of the first and second volumes. The variable vent structure includes at least one moveable portion which is moveable in response to a pressure differential across the moveable portion so as to vary the size of a flow path through the vent structure. The variable vent may be formed through the membrane and the moveable portion may be a part of the membrane, defined by one or more channels, that is deflectable away from the surface of the membrane. The variable vent is preferably closed in the normal range of pressure differentials but opens at high pressure differentials to provide more rapid equalisation of the air volumes above and below the membrane.

Owner:CIRRUS LOGIC INC

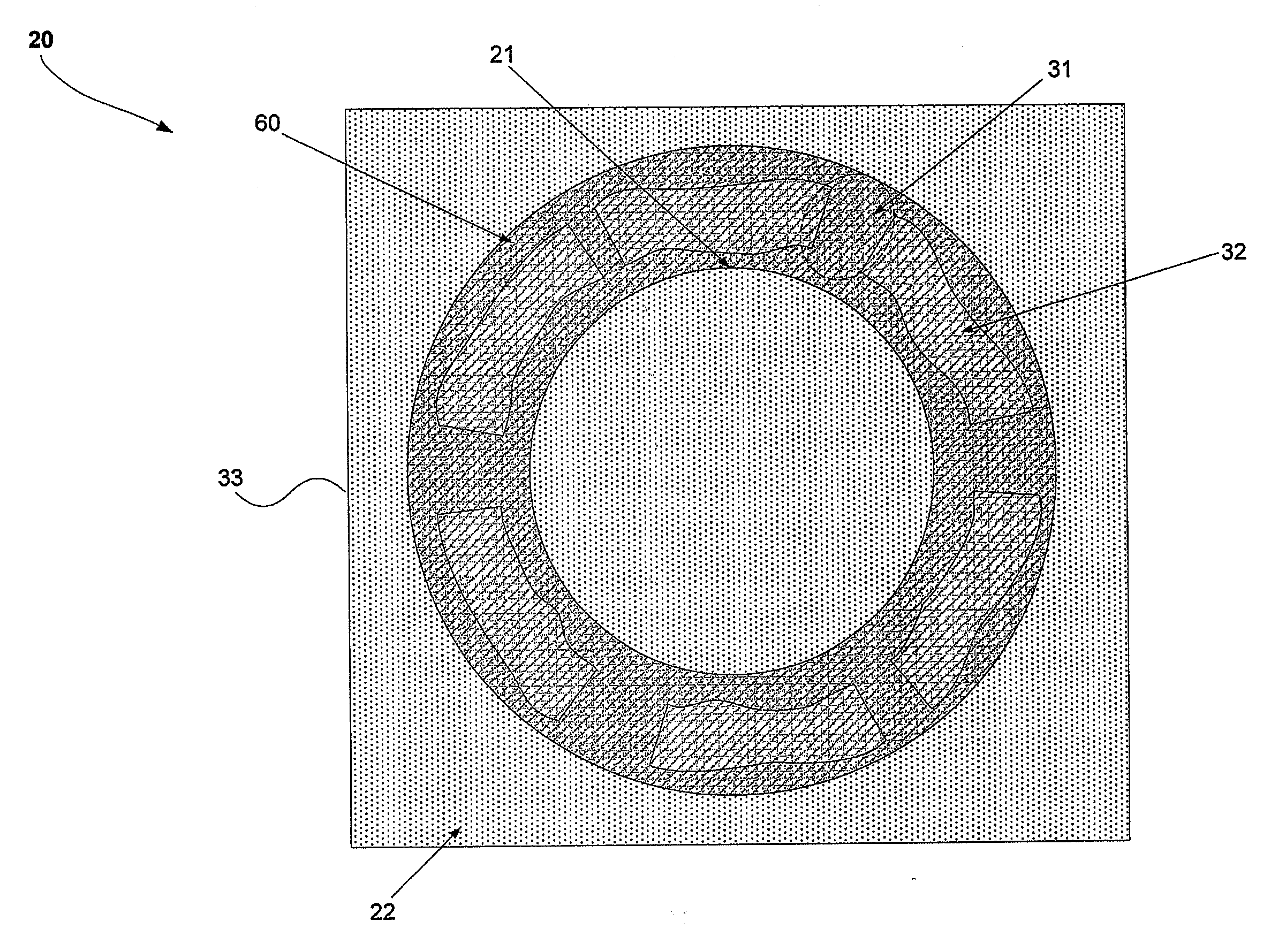

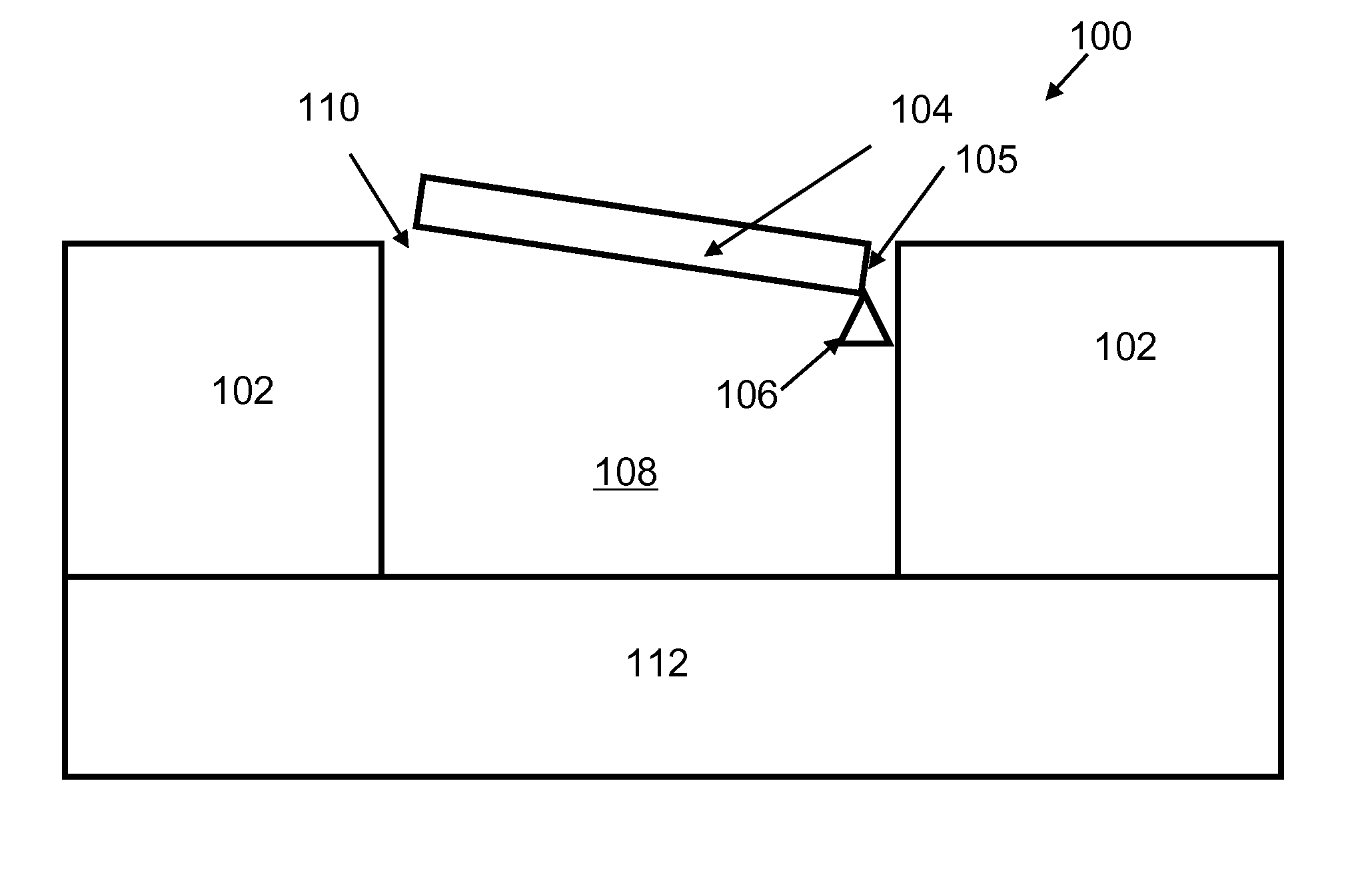

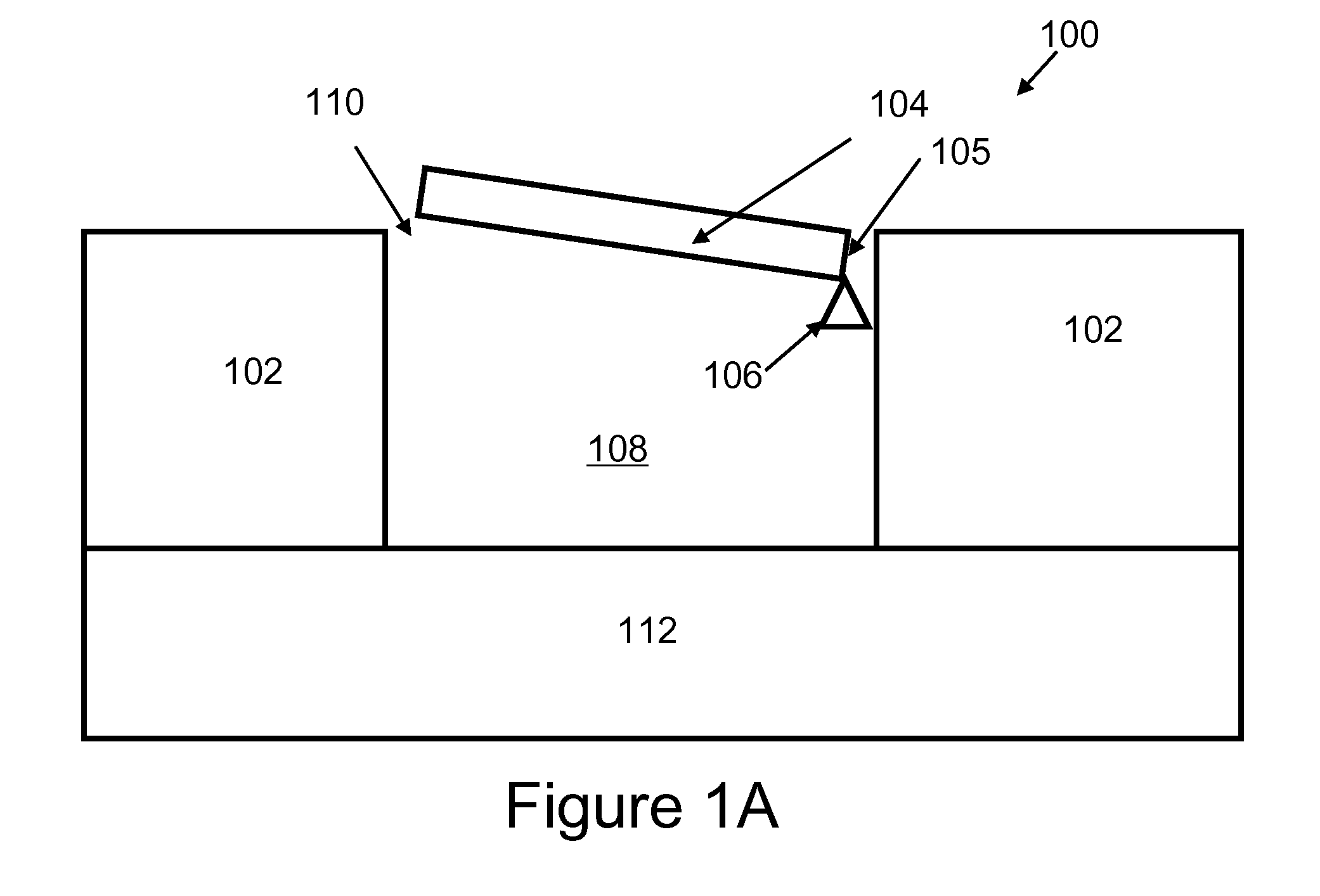

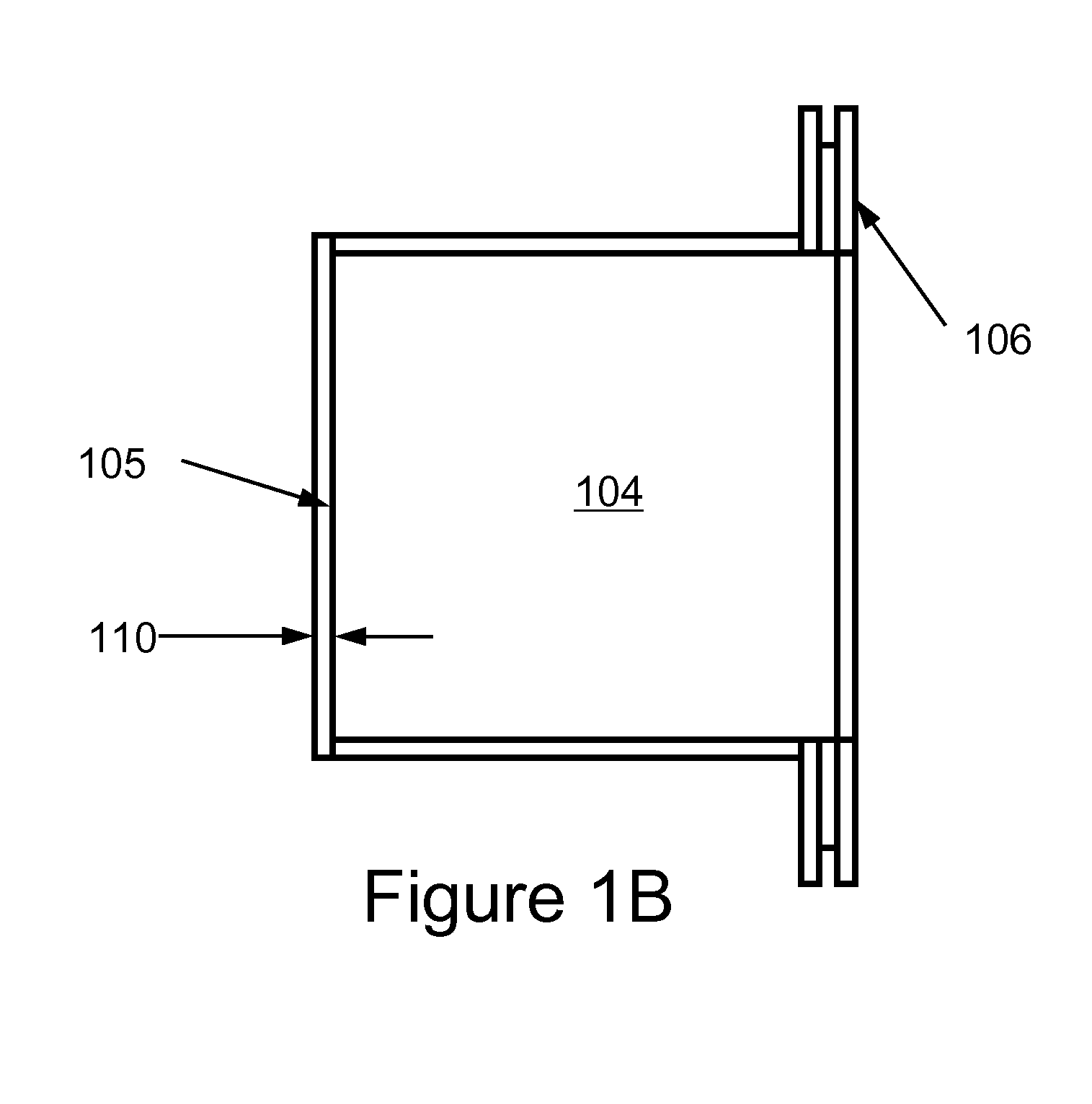

MEMS stress concentrating structure for MEMS sensors

ActiveUS20110048138A1The process steps are simpleSolid state device transducersPiezoelectric/electrostrictive device manufacture/assemblyStress concentrationEngineering

A stress concentrating apparatus and a method for a MicroElectroMechanical System (MEMS) sensors is provided. The apparatus includes a plate having an inner region and outer region, the inner region being separated from the outer region by slits defined in the plate. A stress concentrator bridge connects the inner region to the outer region, and to mechanically amplify stress applied on the inner region of the plate. At least one stress sensor is operatively connected to the stress concentrator bridge, whereby the at least one stress sensor converts the mechanically amplified stress applied on the inner region into an electrical signal.

Owner:KONTEL DATA SYST

MEMS microphone with low pressure region between diaphragm and counter electrode

A MEMS microphone includes a first diaphragm element, a counter electrode element, and a low pressure region between the first diaphragm element and the counter electrode element. The low pressure region has a pressure less than an ambient pressure.

Owner:INFINEON TECH AG

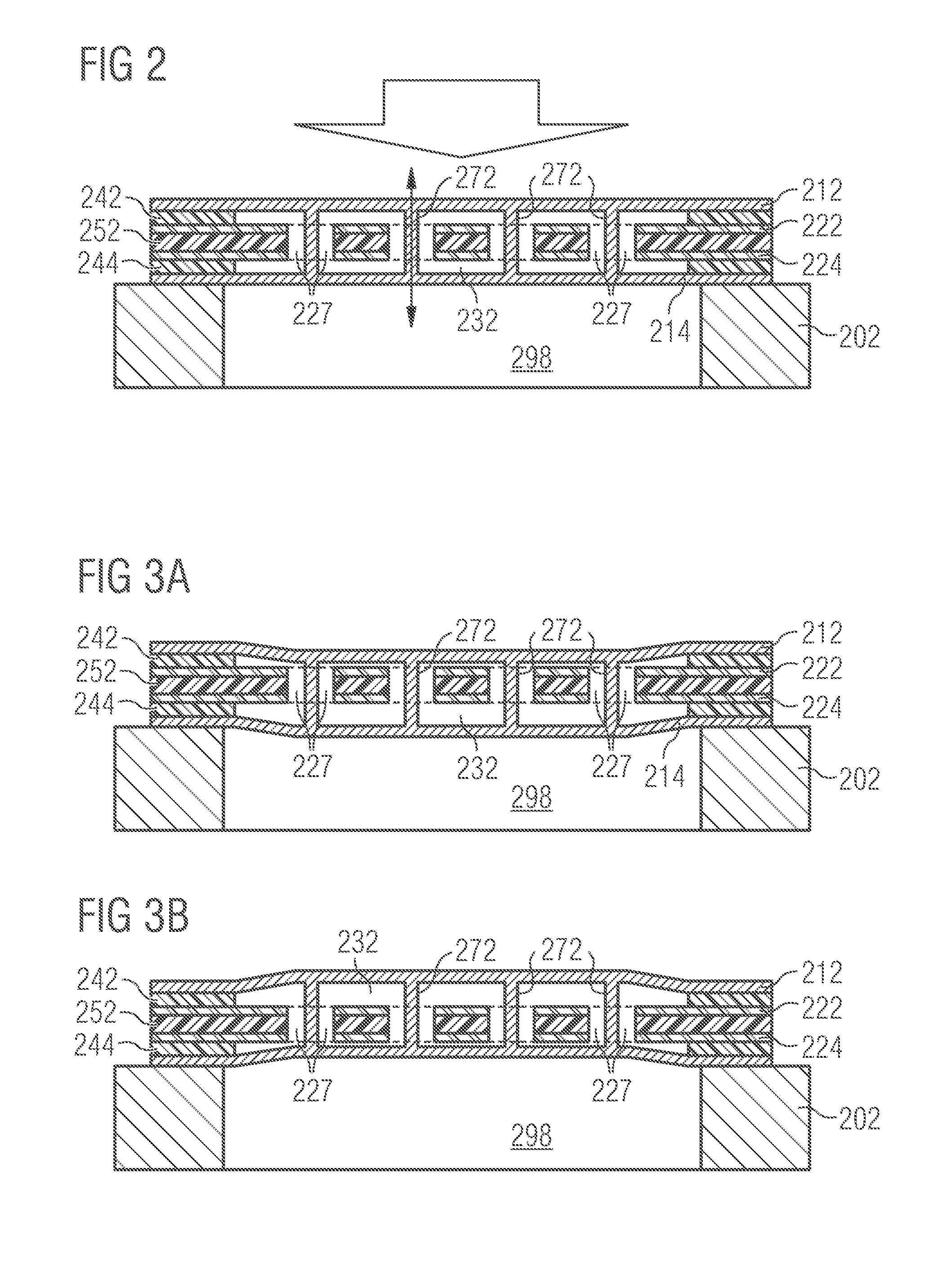

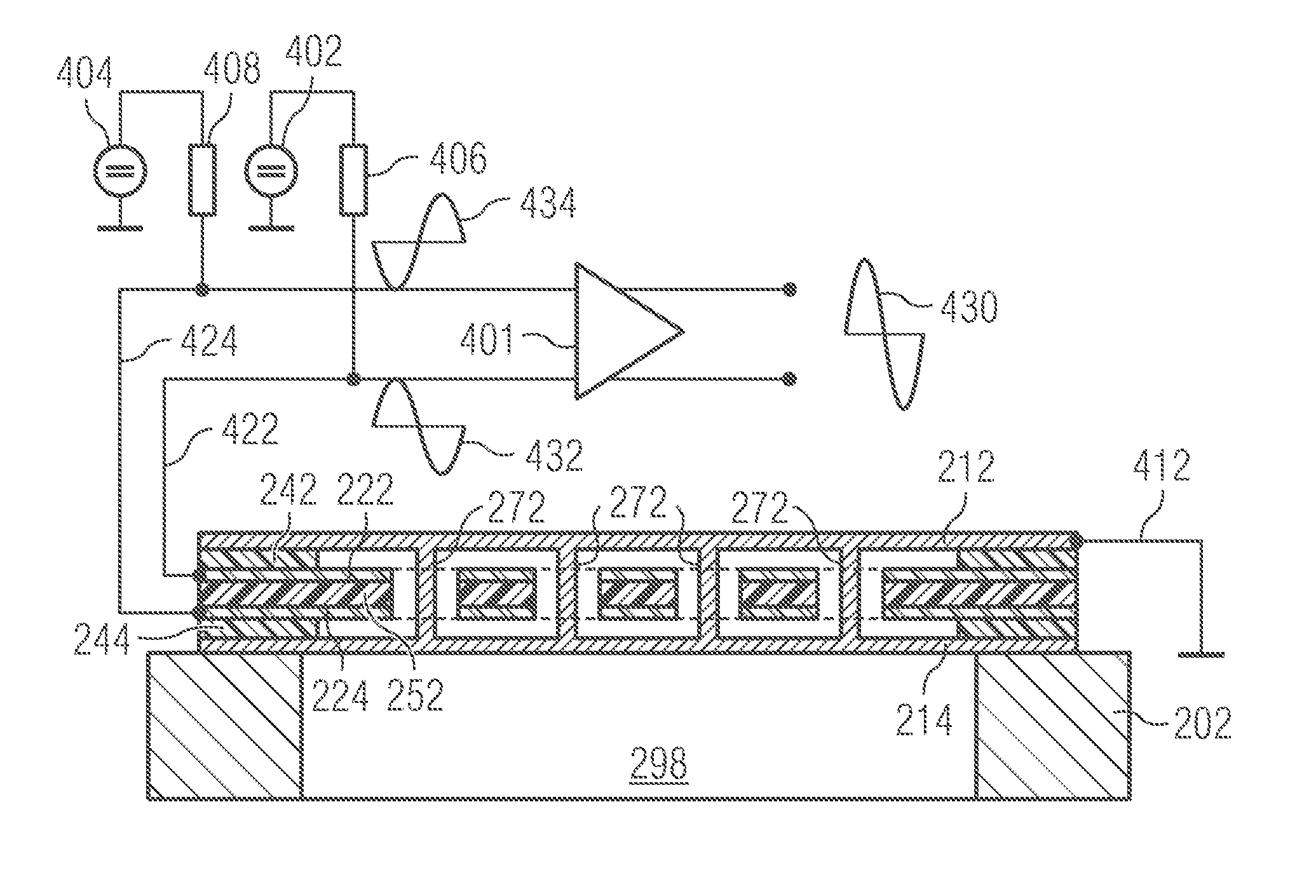

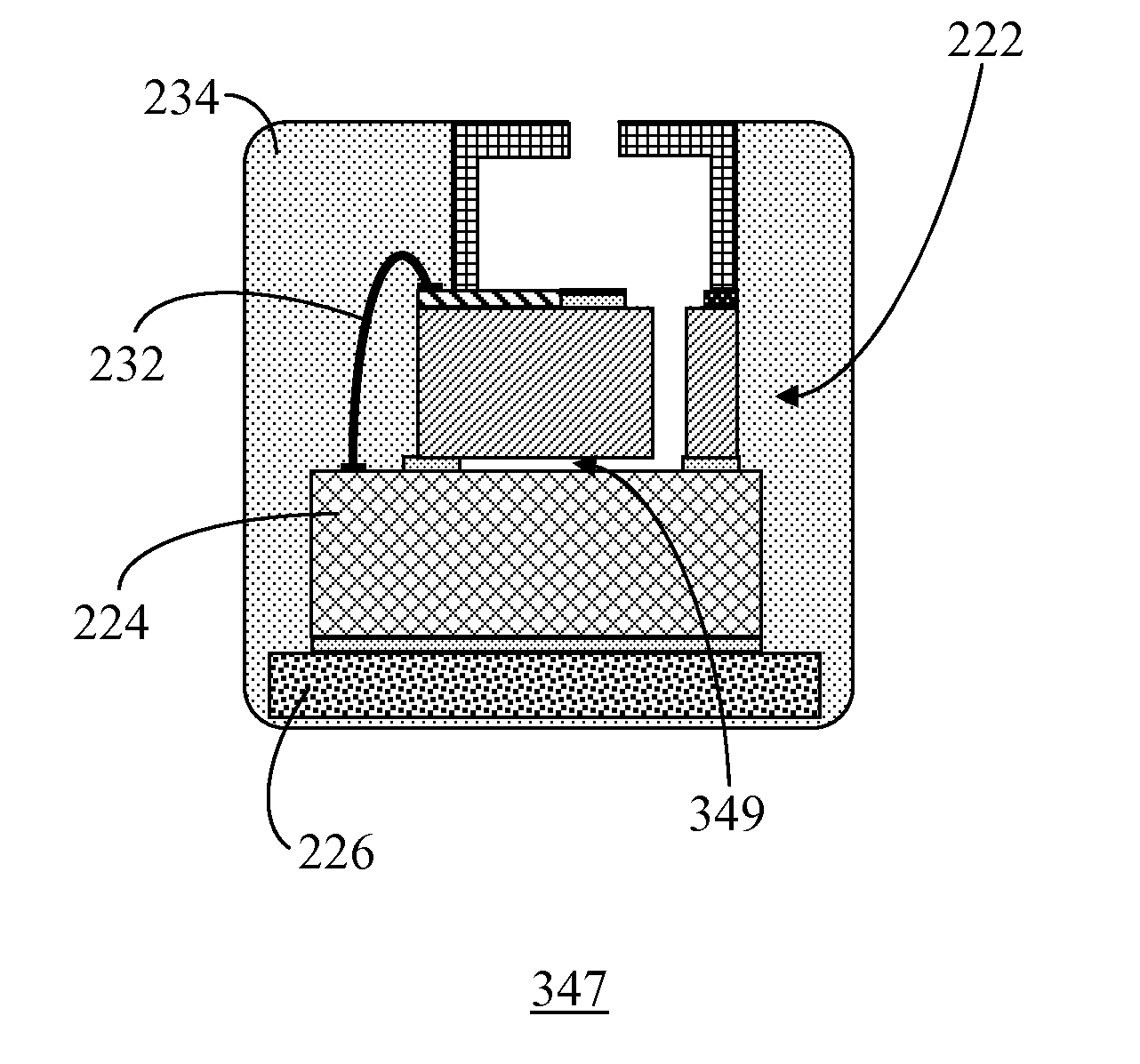

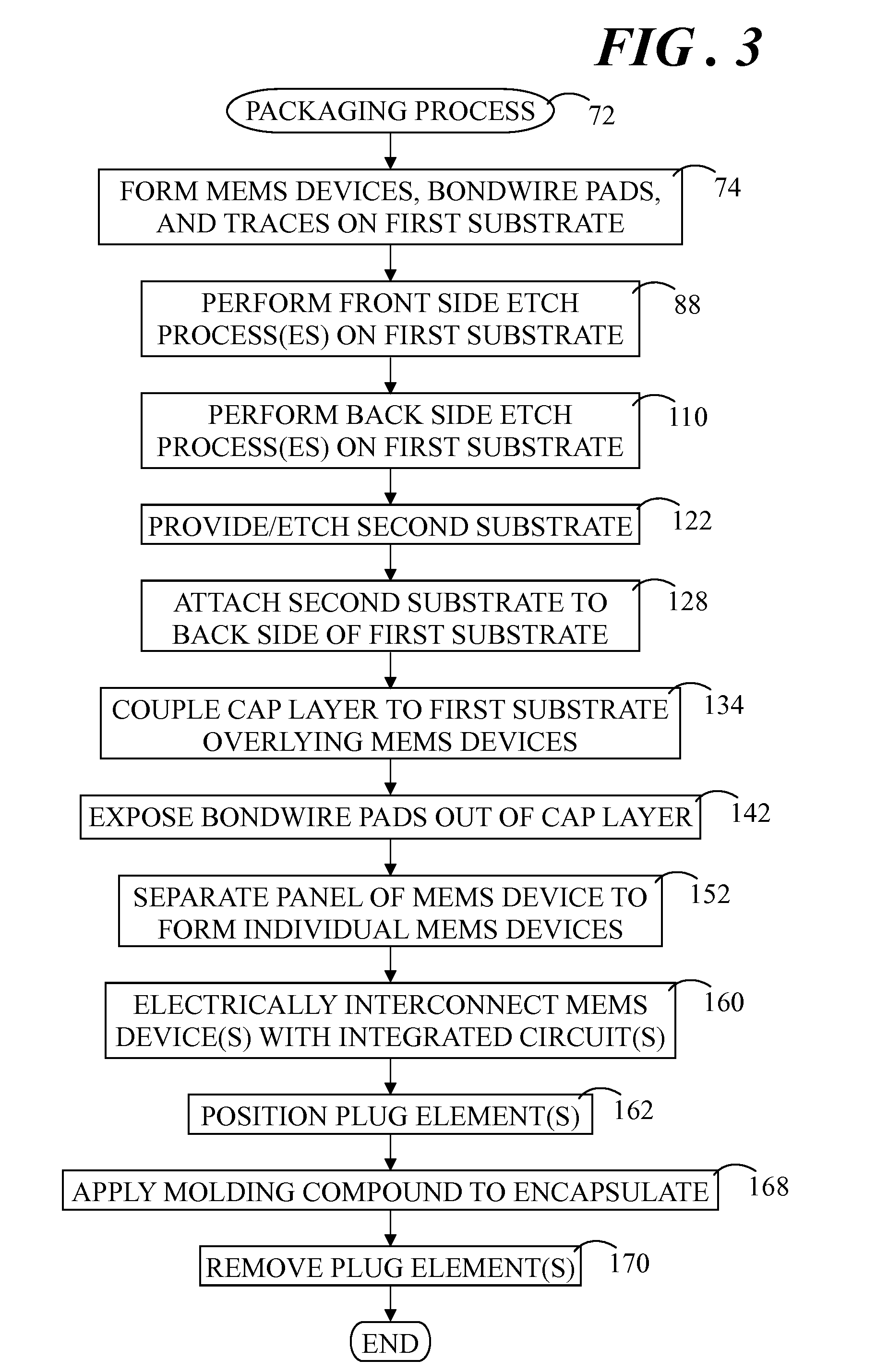

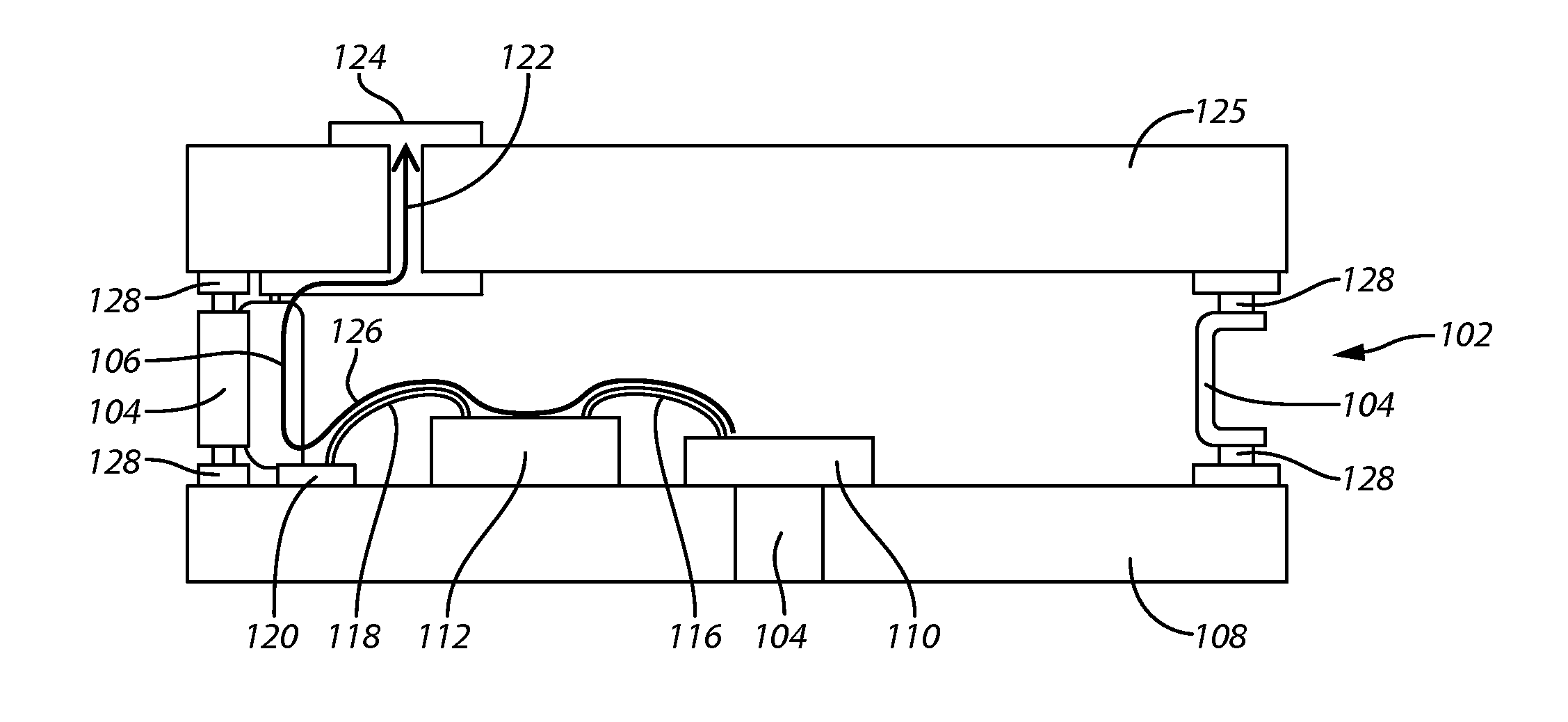

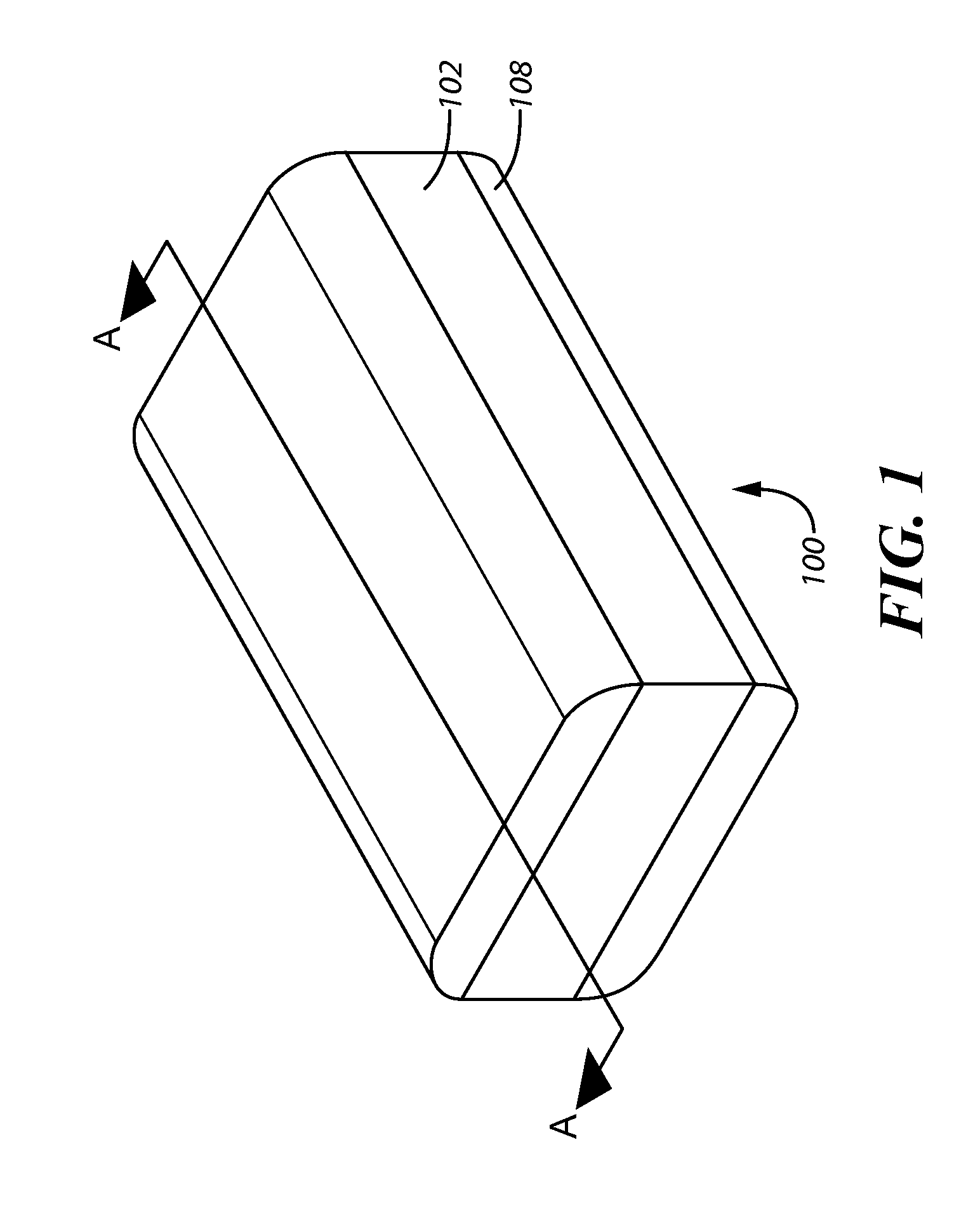

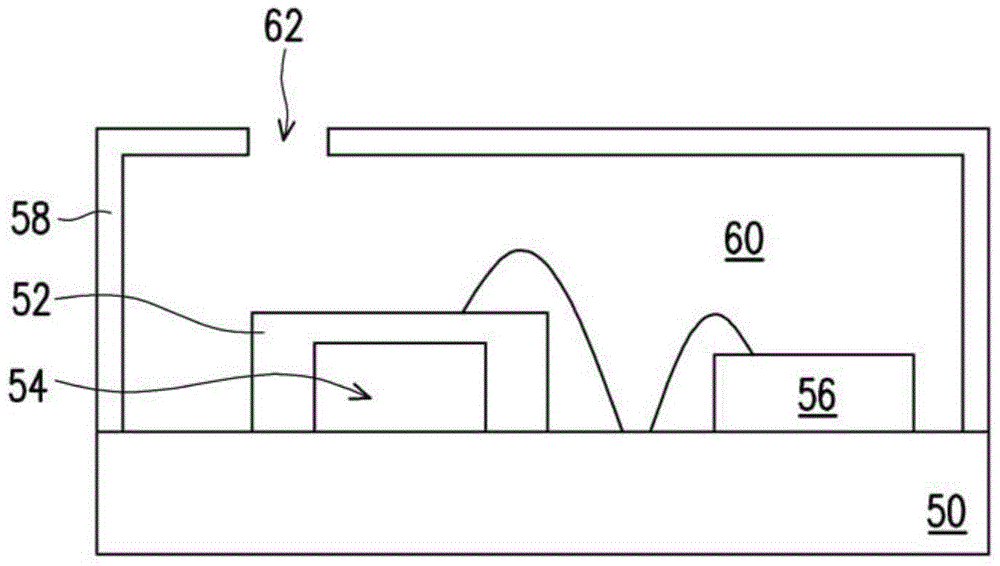

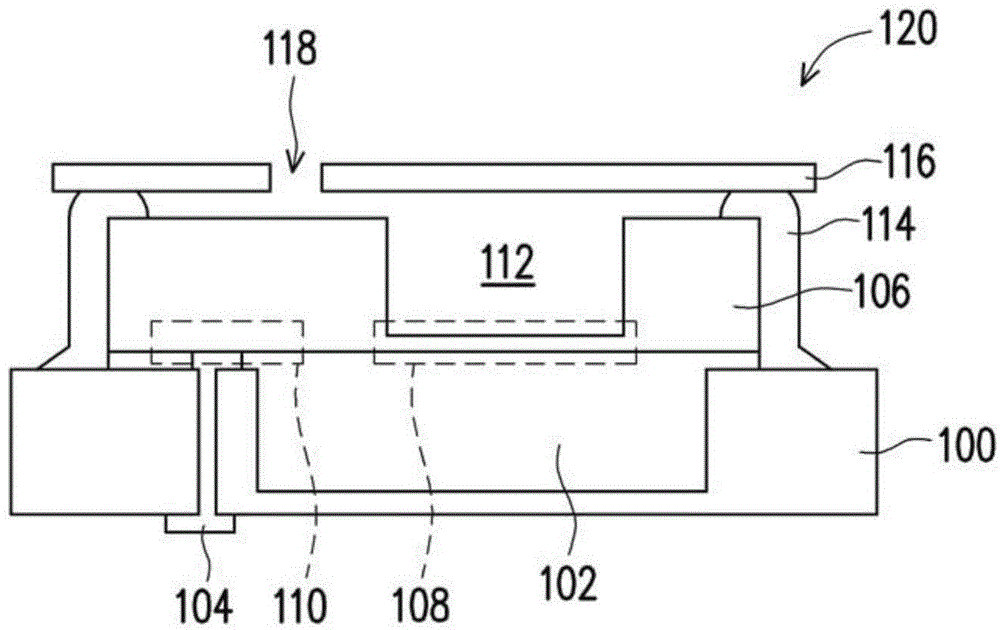

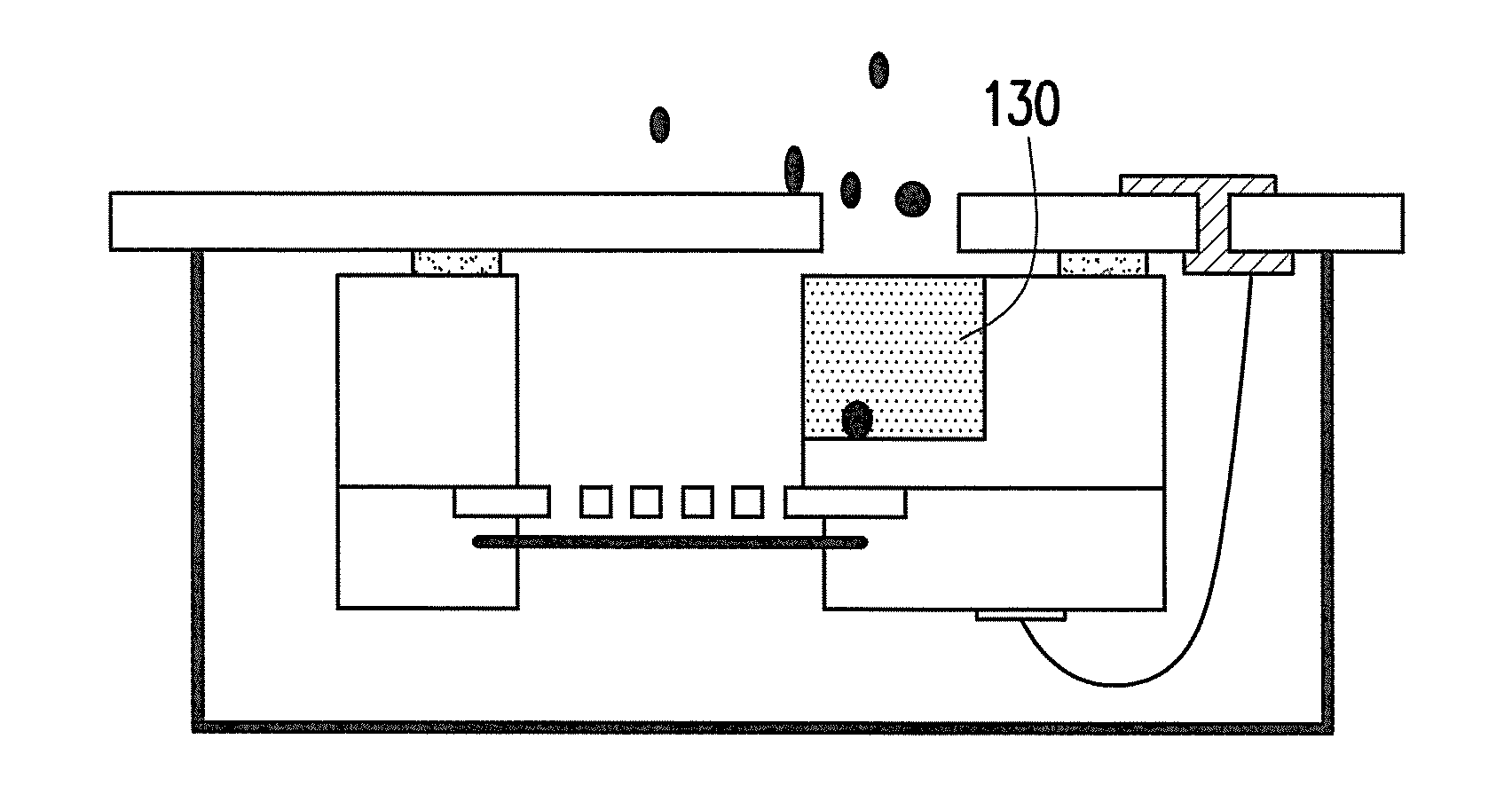

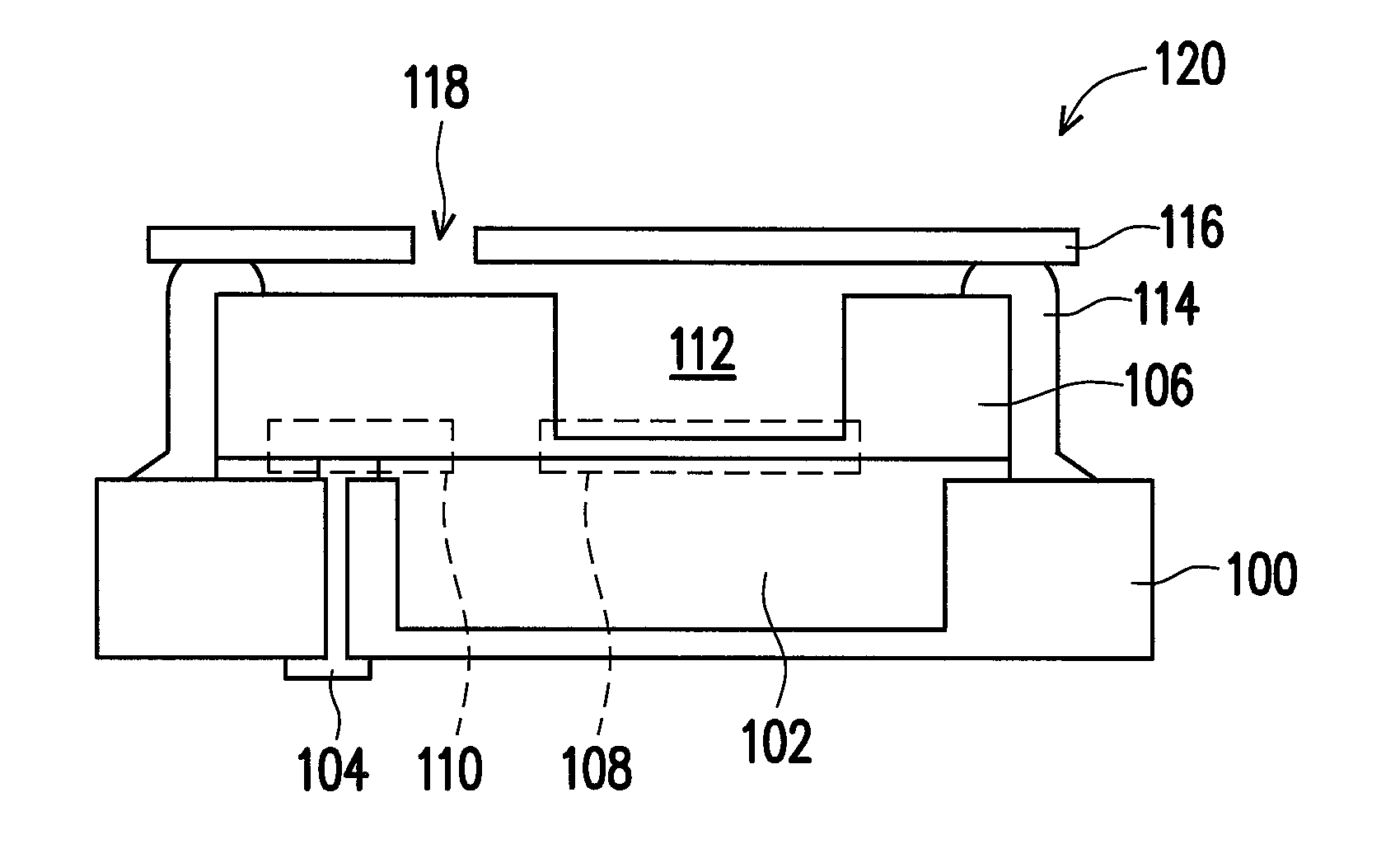

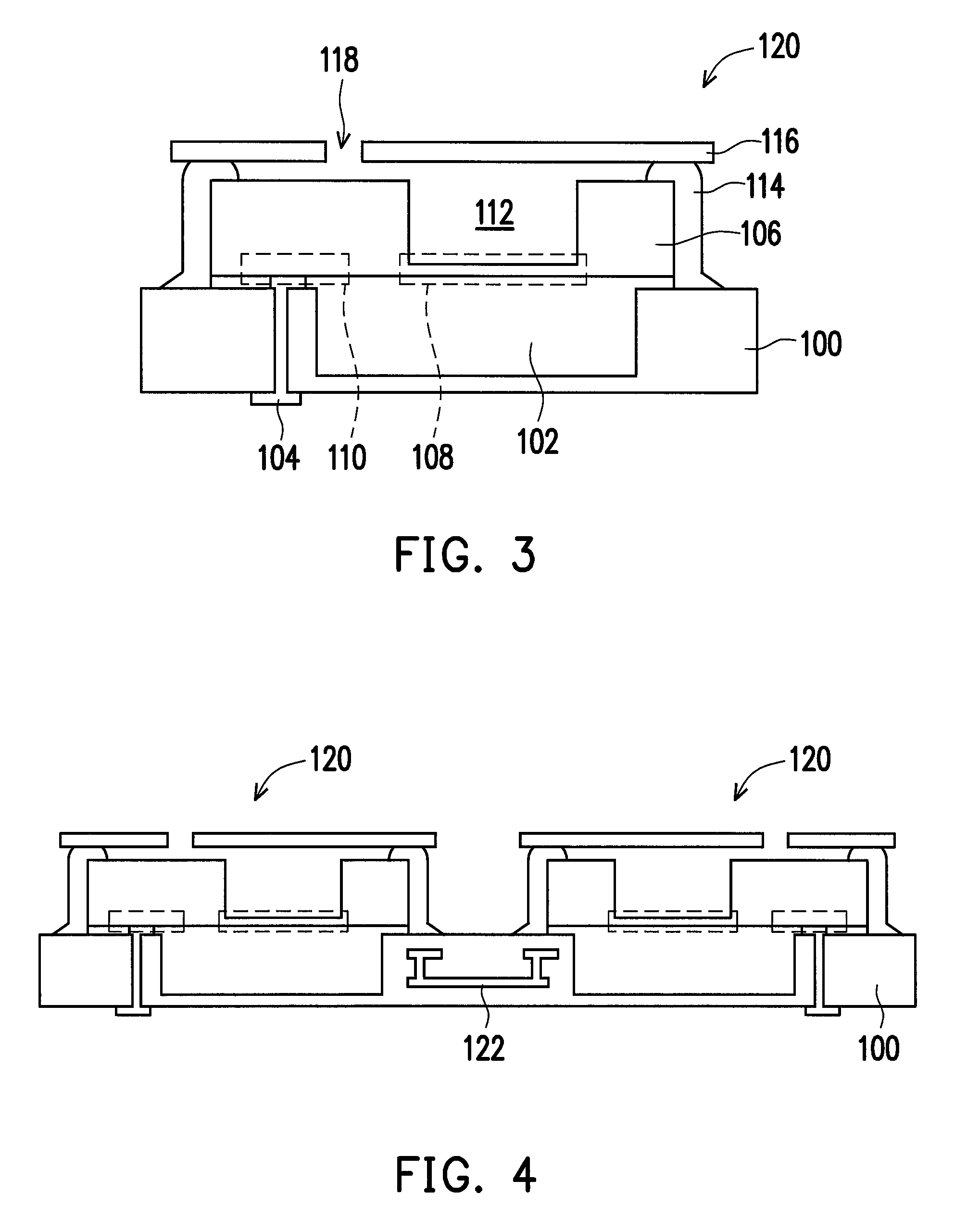

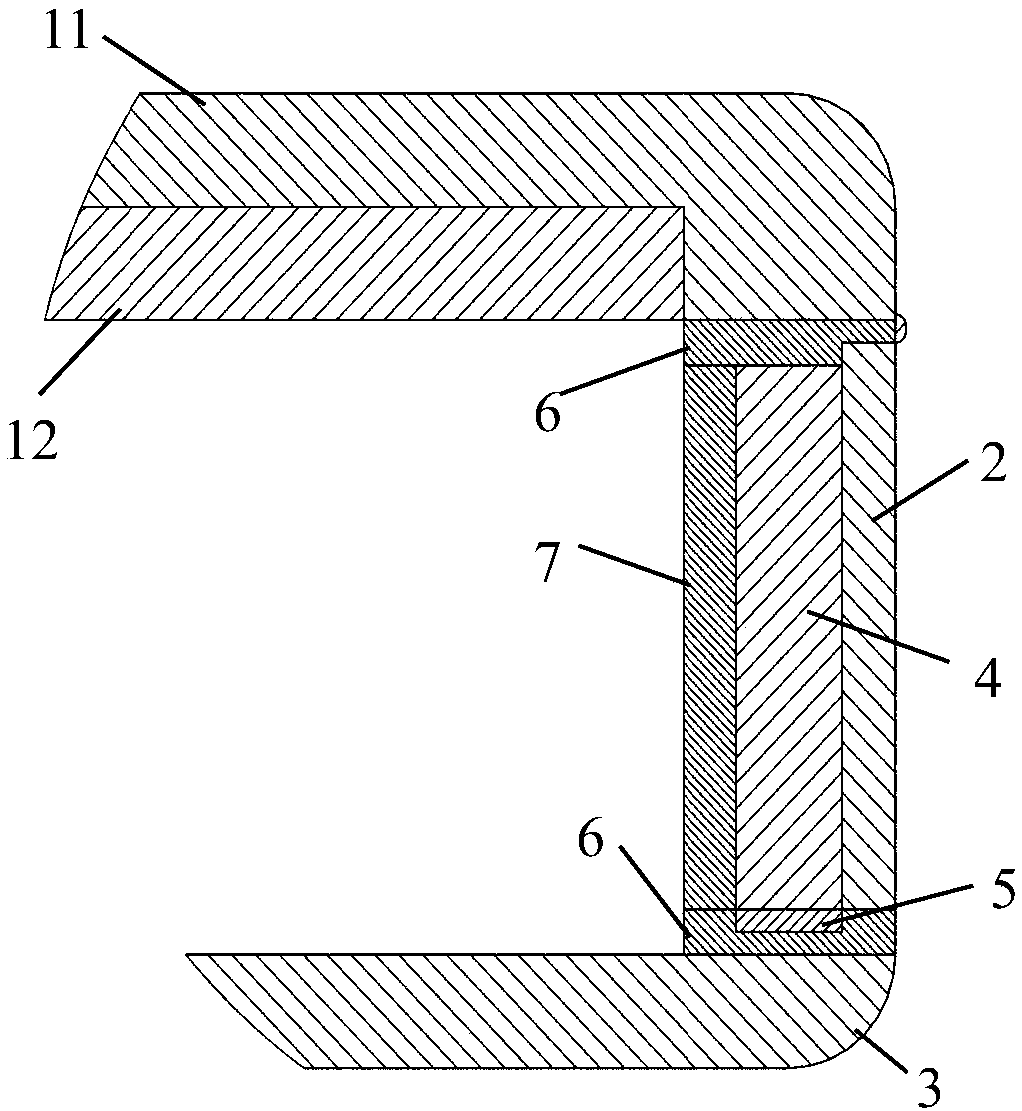

MEMS device assembly and method of packaging same

An assembly (220) includes a MEMS die (222) and an integrated circuit (IC) die (224) attached to a substrate (226). The MEMS die (222) includes a MEMS device (237) formed on a substrate (242). A packaging process (264) entails forming the MEMS device (237) on the substrate (242) and removing a material portion of the substrate (237) surrounding the device (237) to form a cantilevered substrate platform (246) suspended above the substrate (226) at which the MEMS device (237) resides. The MEMS die (222) is electrically interconnected with the IC die (224). A plug element (314) can be positioned overlying the platform (246). Molding compound (32) is applied to encapsulate the die (222), the IC die (224), and substrate (226). Following encapsulation, the plug element (314) can be removed, and a cap (236) can be coupled to the substrate (242) overlying an active region (244) of the MEMS device (237).

Owner:NORTH STAR INNOVATIONS

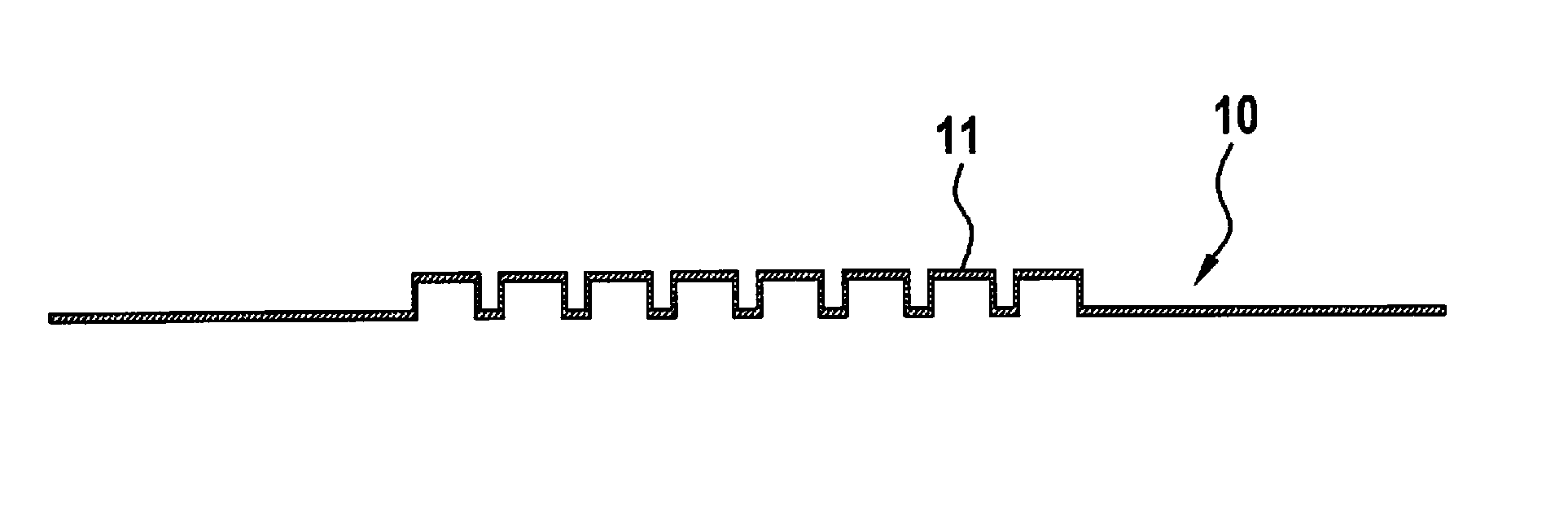

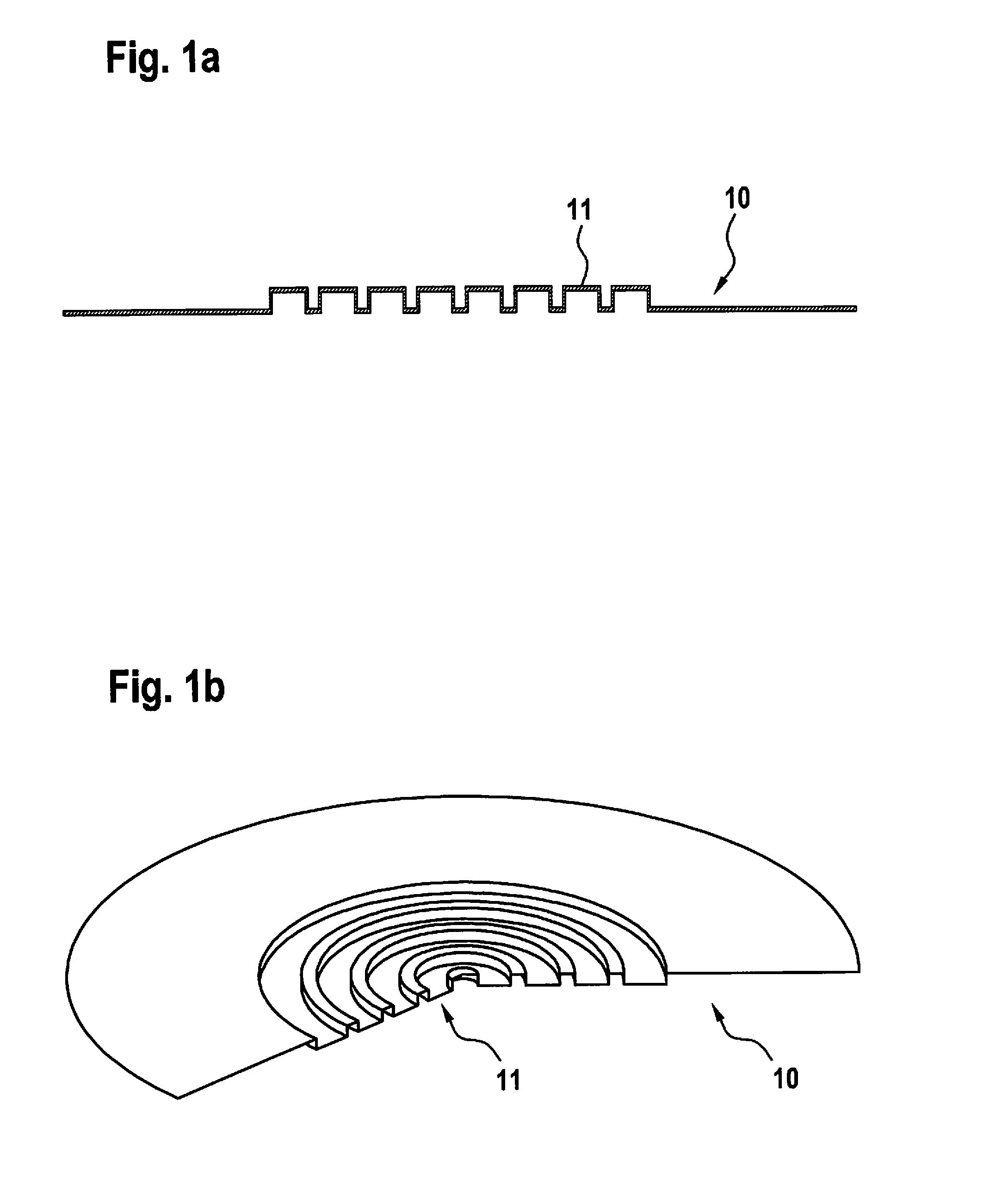

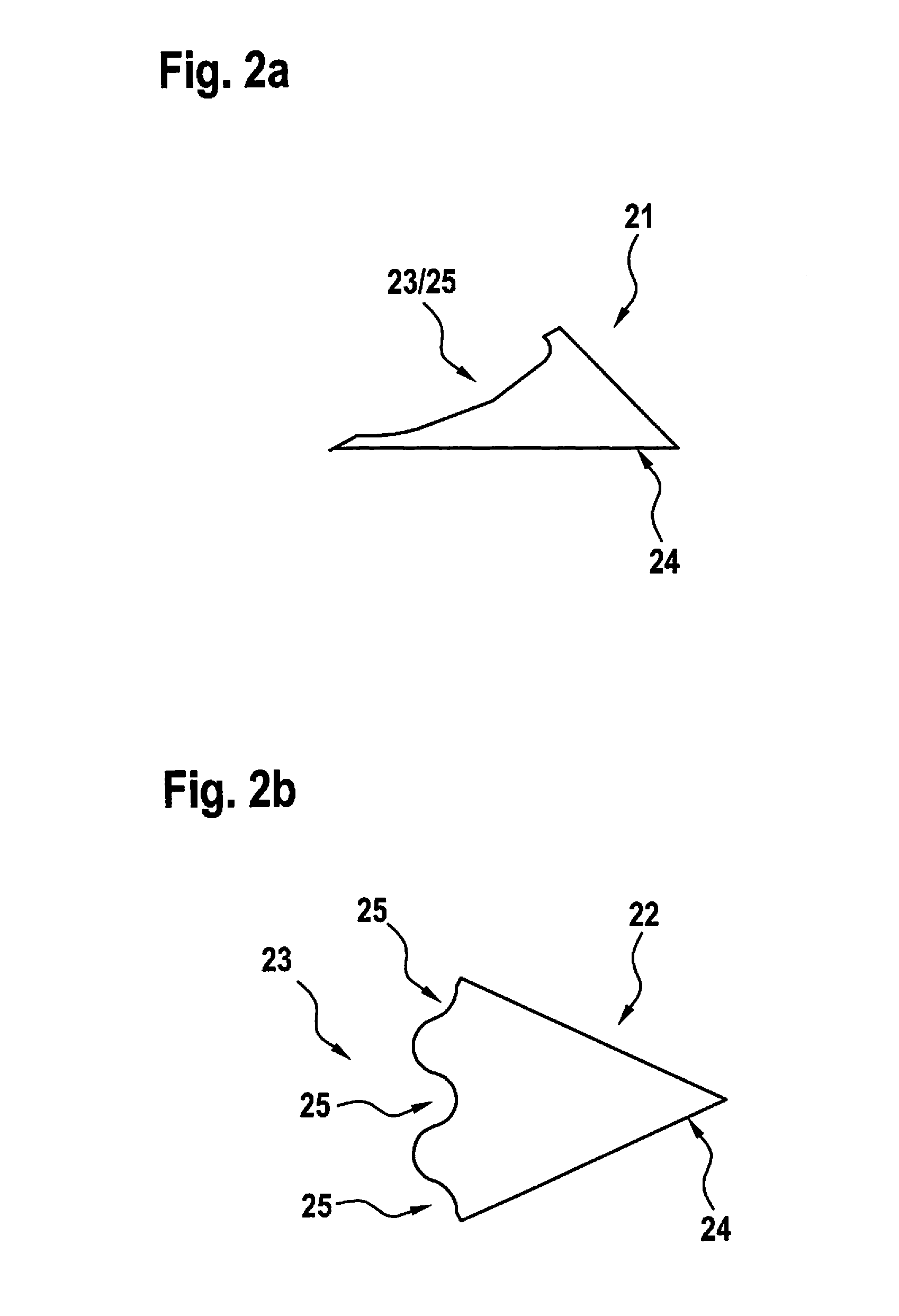

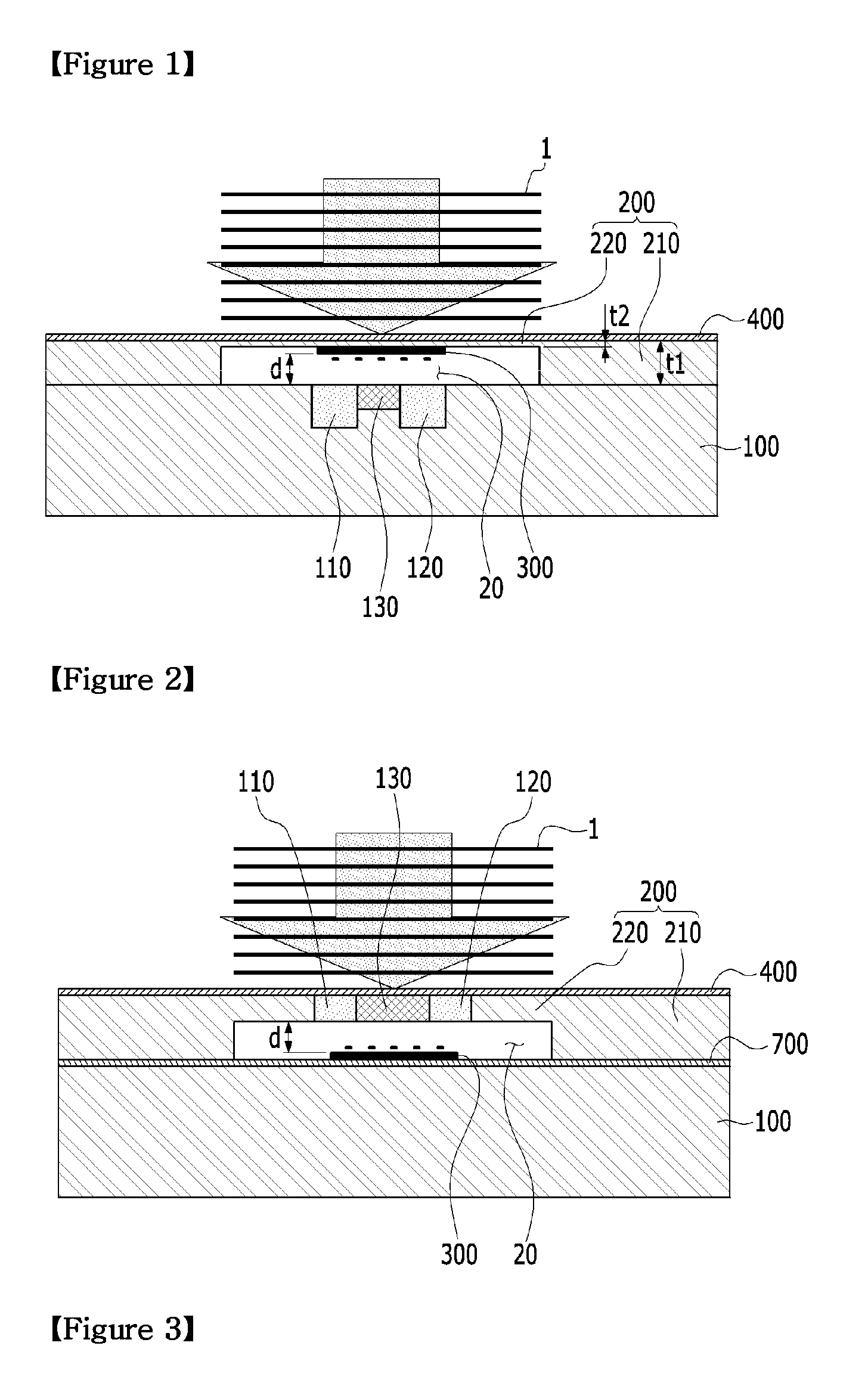

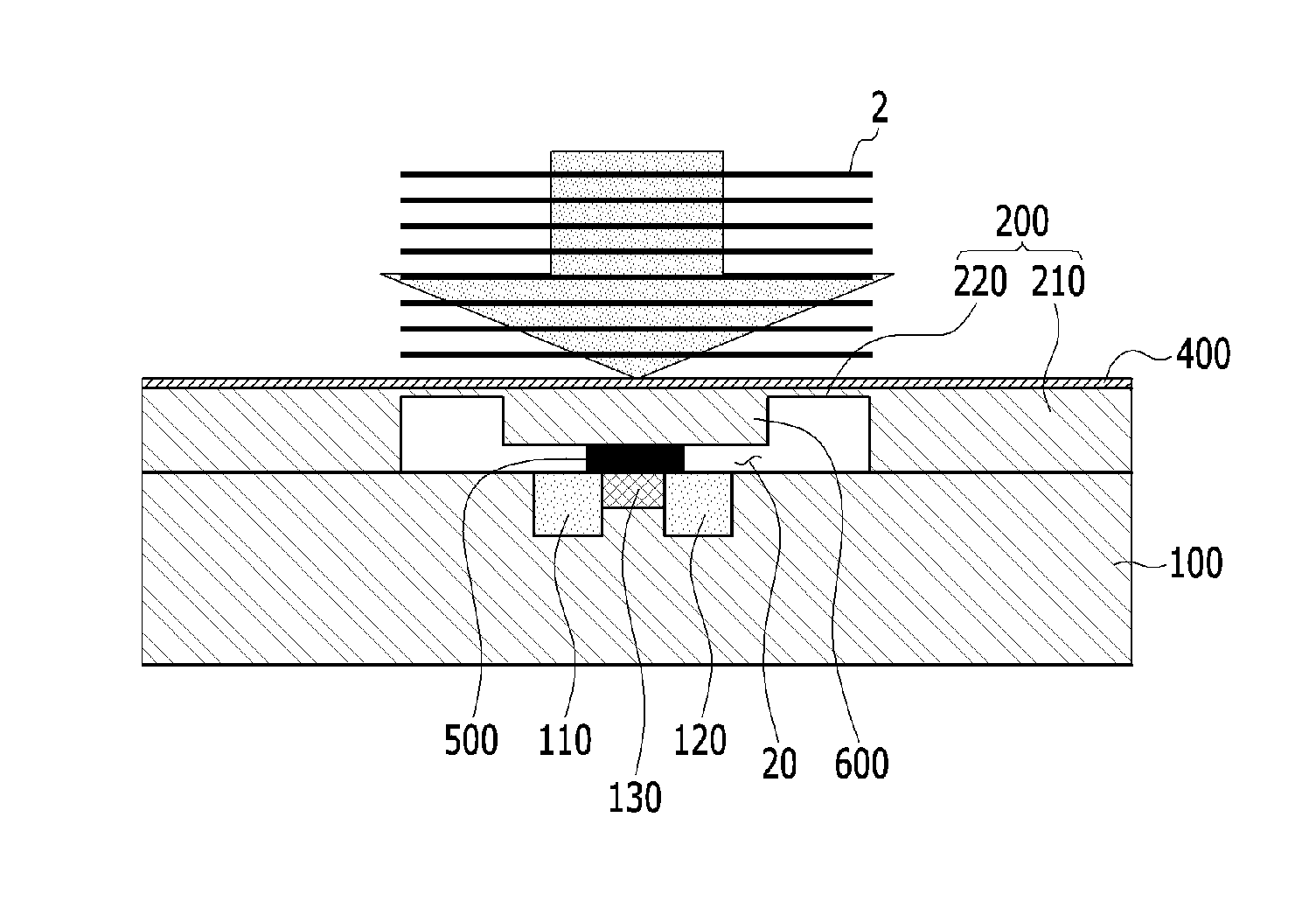

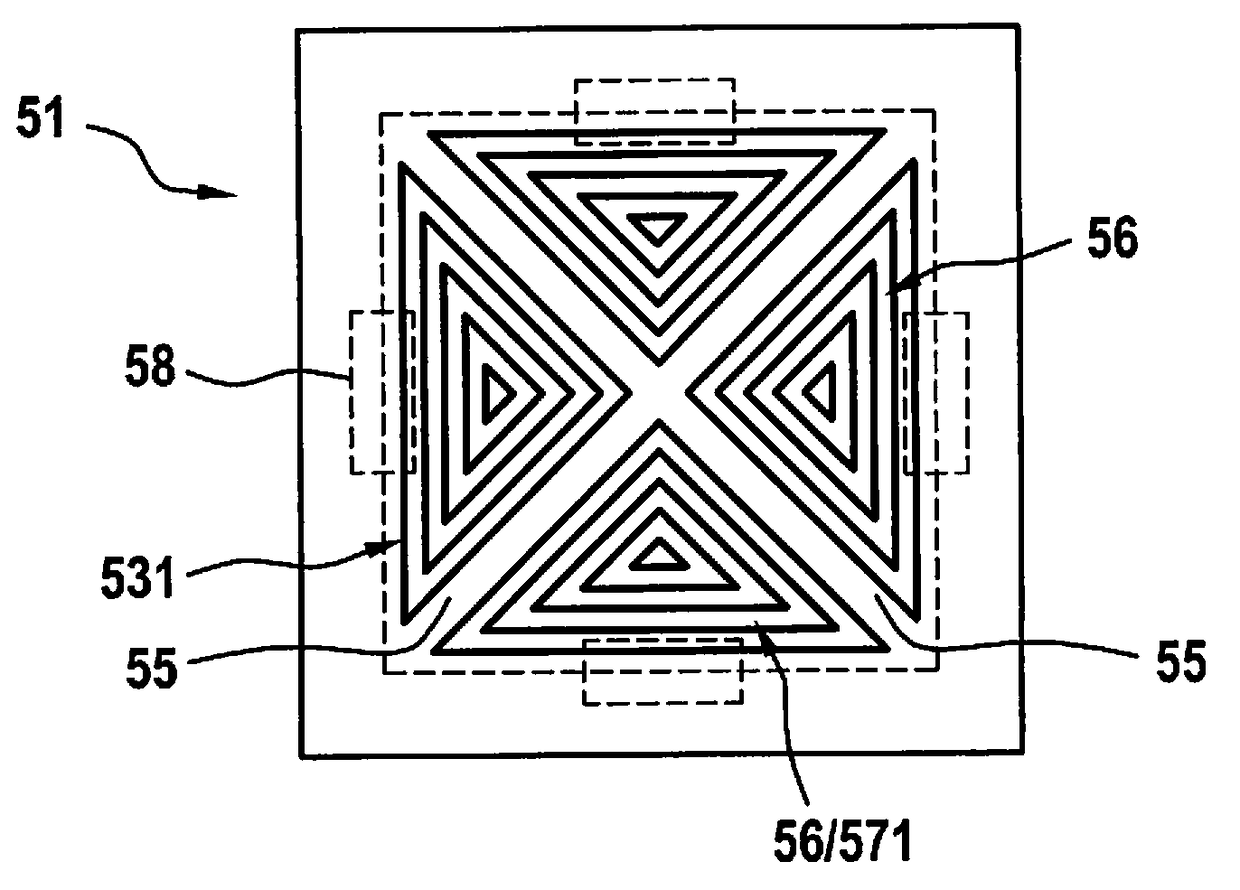

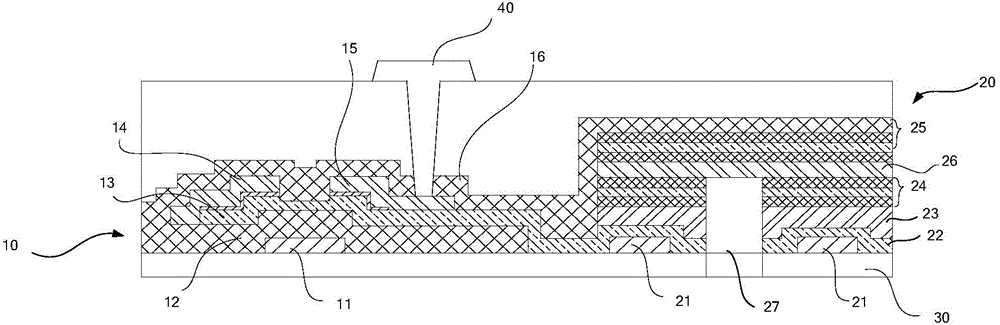

MEMS component including a sound-pressure-sensitive diaphragm element and piezosensitive signal detection

ActiveUS20170026754A1Enhanced signalPiezoelectric/electrostrictive microphonesSolid state device transducersStress distributionEngineering

For a MEMS component, in the layer structure of which at least one sound-pressure-sensitive diaphragm element is formed, which spans an opening or cavity in the layer structure and the deflections of which are detected with the aid of at least one piezosensitive circuit element in the attachment area of the diaphragm element, design measures are provided, by which the stress distribution over the diaphragm surface may be influenced intentionally in the event of deflection of the diaphragm element. In particular, measures are provided, by which the mechanical stresses are intentionally introduced into predefined areas of the diaphragm element, to thus amplify the measuring signal. For this purpose, the diaphragm element includes at least one designated bending area, which is defined by the structuring of the diaphragm element and is more strongly deformed in the event of sound action than the adjoining diaphragm sections.

Owner:ROBERT BOSCH GMBH

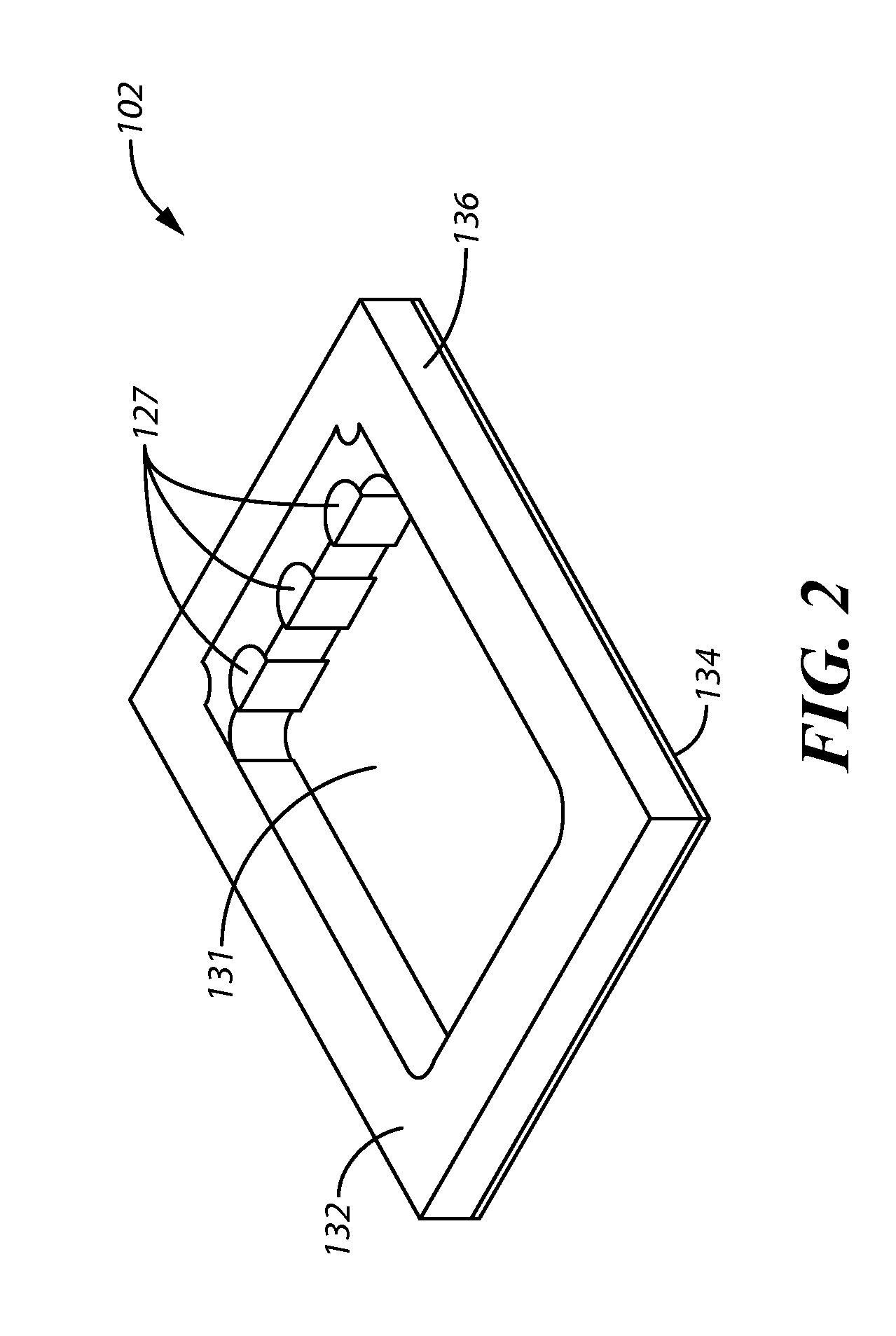

Interposer For MEMS-On-Lid MIcirophone

ActiveUS20150195659A1Solid state device transducersMicrophonesInterposerMicroelectromechanical systems

A microphone includes an interposer, a lid, and a base. The interposer includes at least one wall portion that forms a cavity. The wall portion includes a first side and a second side that are opposite from each other. The lid is coupled to the first side of the interposer and the base is coupled to the second side of the interposer such that the lid and the base enclose the cavity. A microelectromechanical system (MEMS) device is disposed in the cavity. The interposer structurally supports one or both of the lid and the base. The interposer includes a plurality of plated regions that are configured to electrically connect the lid and the base. The plated regions are configured to at least partially be exposed and open to the cavity.

Owner:KNOWLES ELECTRONICS INC

Capacitive transducer

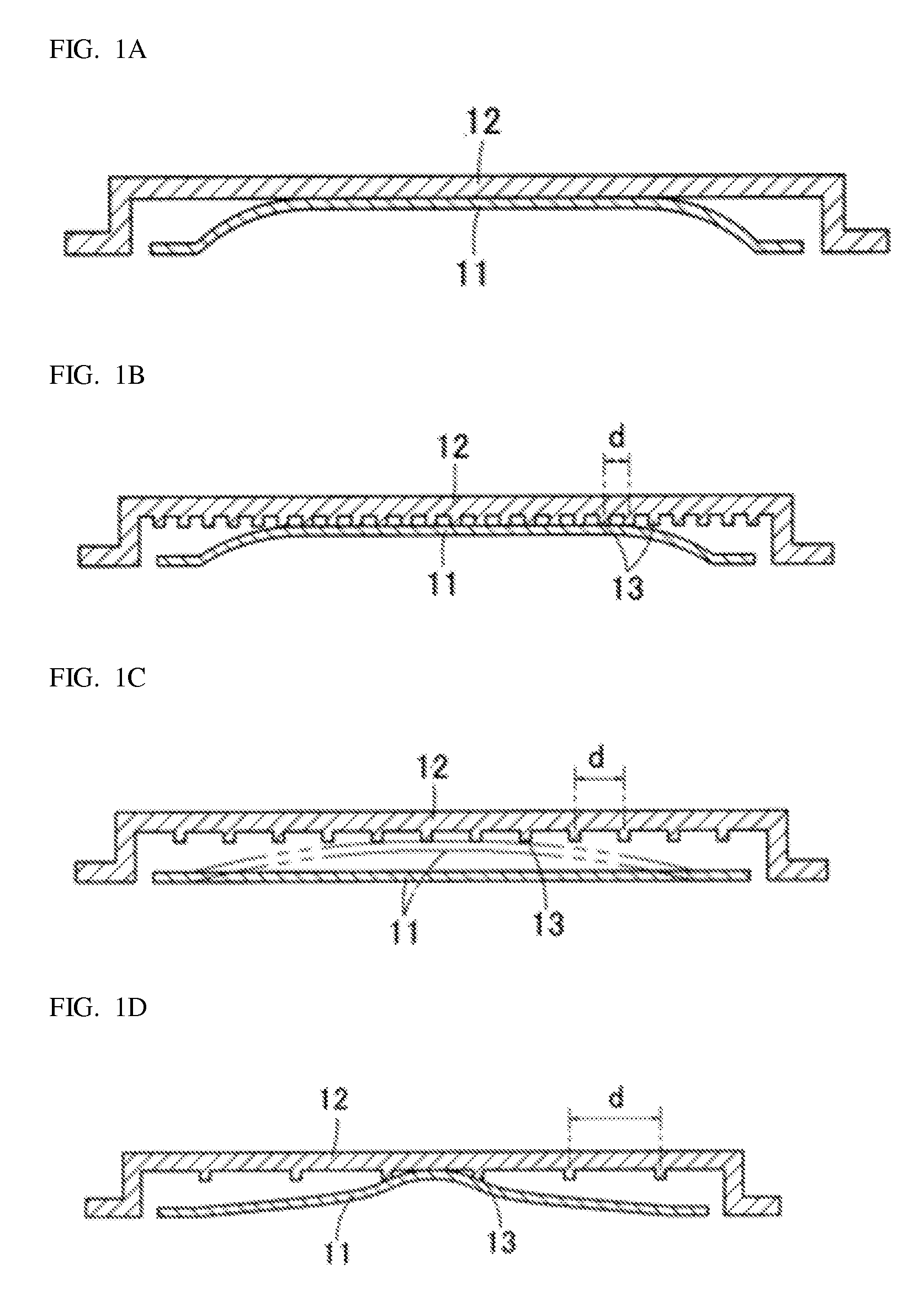

ActiveUS20150264462A1Good anti-adhesionAvoid a lotSolid state device transducersMicrophonesEngineeringElectrode

A capacitive transducer has a back plate including a fixed electrode, a diaphragm facing the back plate with an air gap interposed therebetween, the diaphragm acting as a movable electrode, at least a first stopper of a first protruding length, and a second stopper of a second protruding length. The first and second stoppers protrude from at least either the surface on the back plate near the air gap or the surface on the diaphragm near the air gap. The first stopper is provided at a position corresponding to a first position on the diaphragm. The second the stopper is provided at a position corresponding to a second position on the diaphragm. An amount of displacement of the diaphragm at the first position is greater than an amount of displacement of the diaphragm at the second position. The protruding length of the first stopper is shorter than the protruding length of the second stopper.

Owner:MMI SEMICON CO LTD

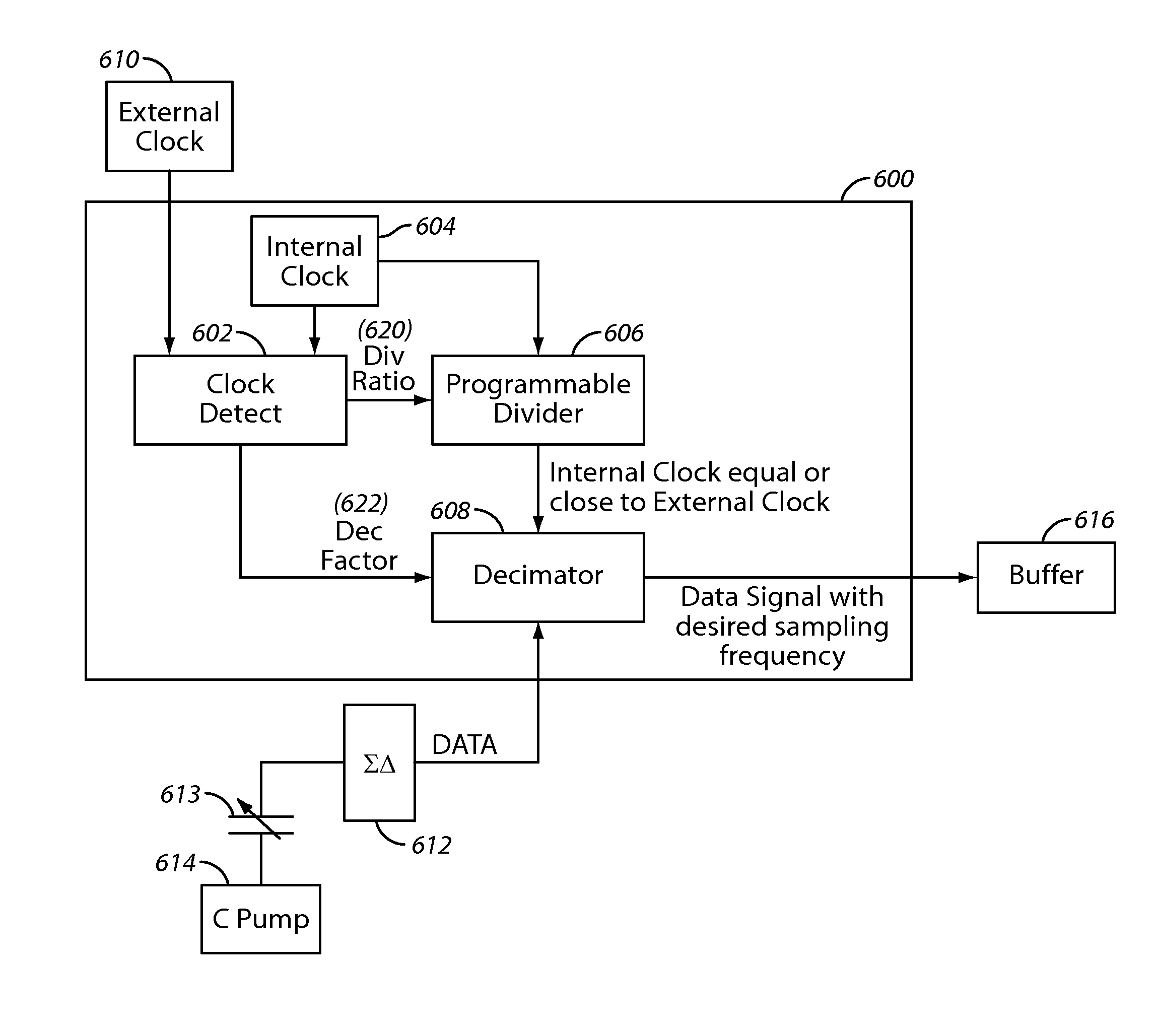

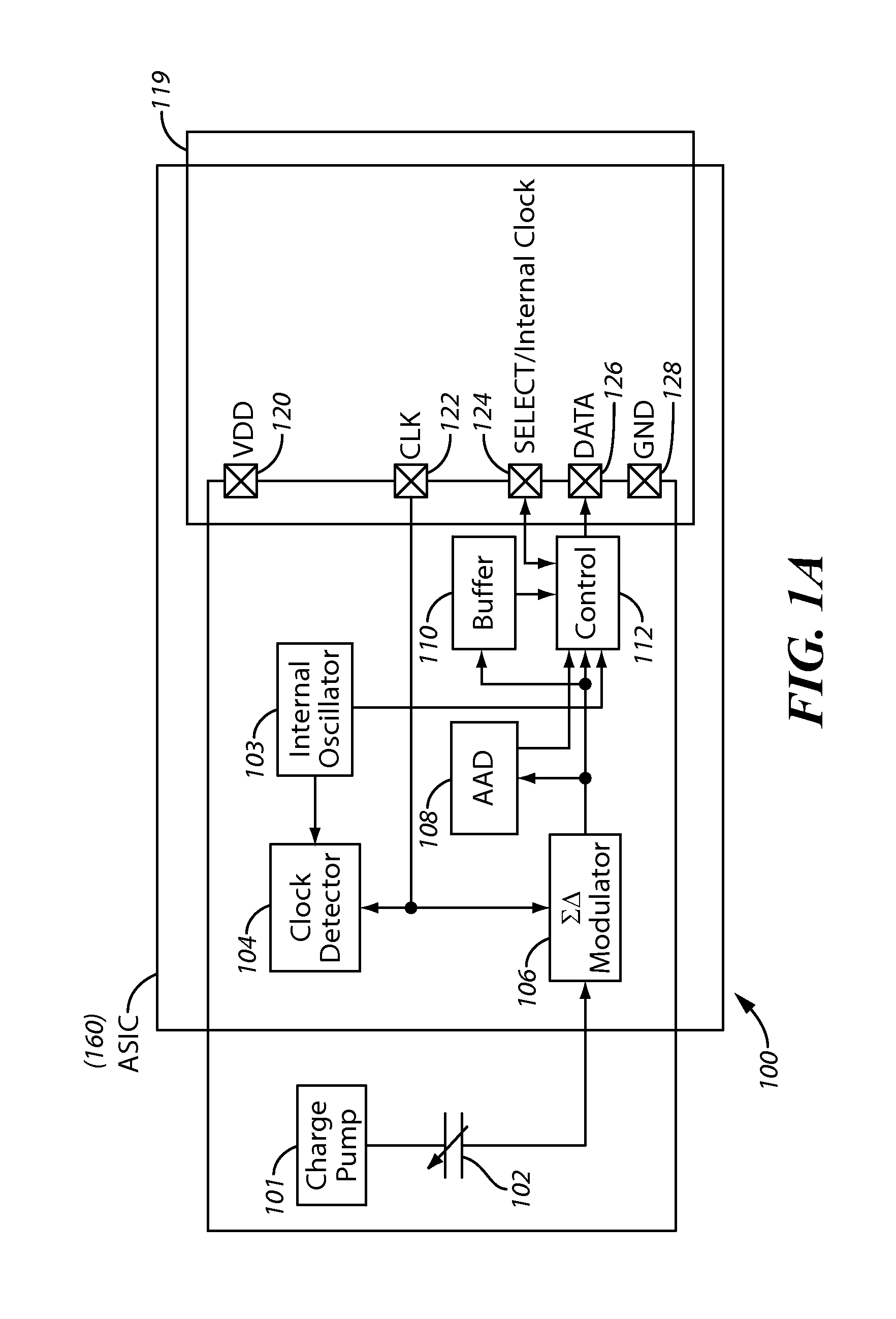

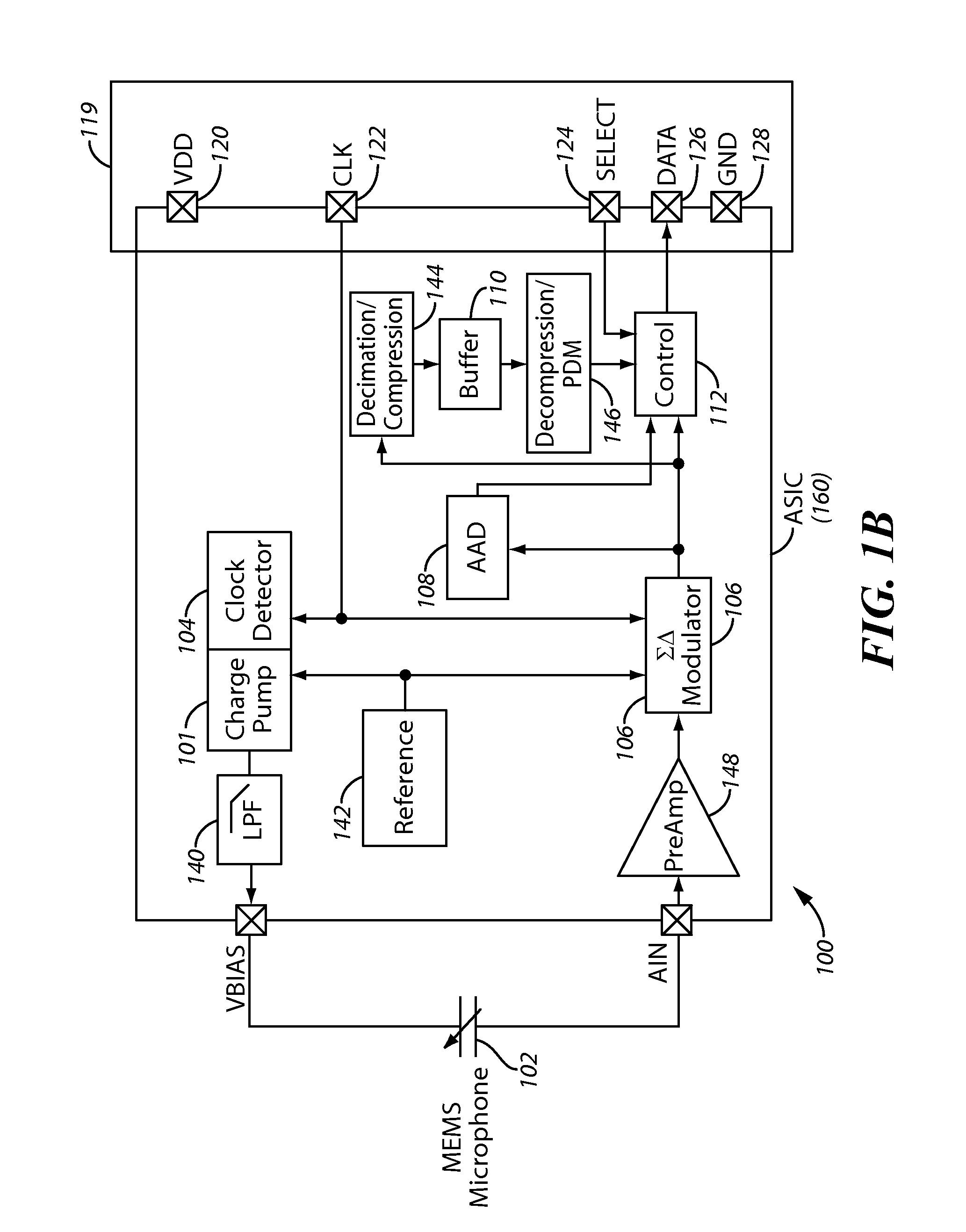

Decimation Synchronization in a Microphone

An external clock signal having a first frequency is received. A division ratio is automatically determined based at least in part upon a second frequency of an internal clock. The second frequency is greater than the first frequency. A decimation factor is automatically determined based at least in part upon the first frequency of the external clock signal, the second frequency of the internal clock signal, and a predetermined desired sampling frequency. The division ratio is applied to the internal clock signal to reduce the first frequency to a reduced third frequency. The decimation factor is applied to the reduced third frequency to provide the predetermined desired sampling frequency. Data is clocked to a buffer using the predetermined desired sampling frequency.

Owner:KNOWLES ELECTRONICS INC

Audio sensing device and method of acquiring frequency information

ActiveUS9479884B2Solid state device transducersPiezoelectric/electrostrictive microphonesComputer scienceAudio frequency

An audio sensing device having a resonator array and a method of acquiring frequency information using the audio sensing device are provided. The audio sensing device includes a substrate having a cavity formed therein, a membrane provided on the substrate and covering the cavity, and a plurality of resonators provided on the membrane and respectively sensing sound frequencies of different frequency bands.

Owner:SAMSUNG ELECTRONICS CO LTD

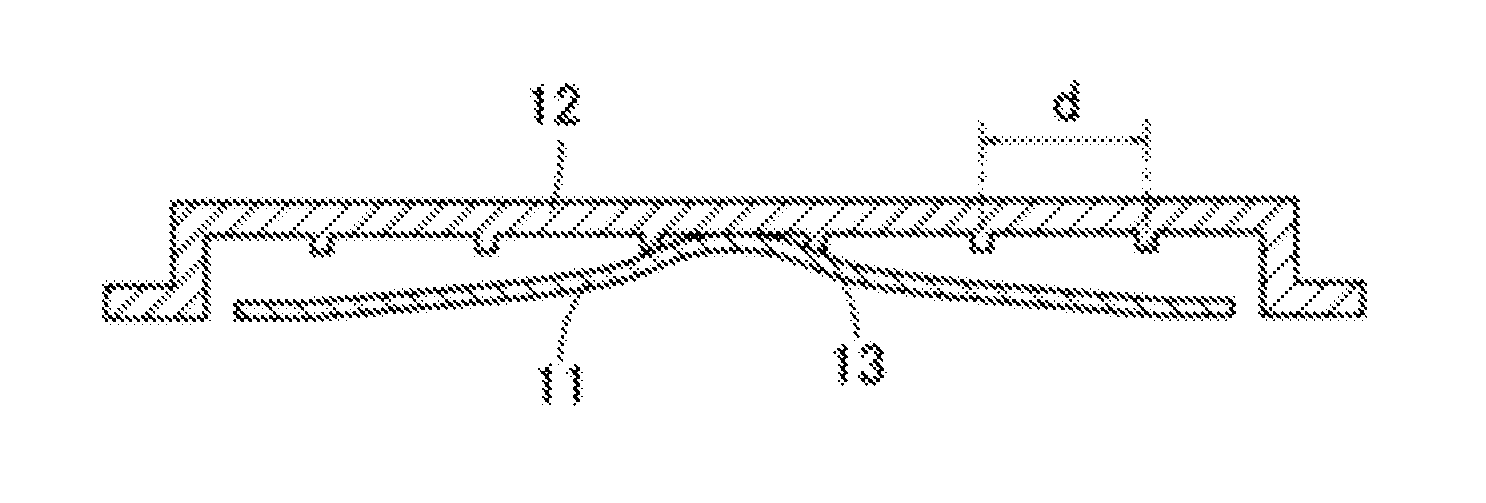

Micromechanical Sound Transducer Arrangement and a Corresponding Production Method

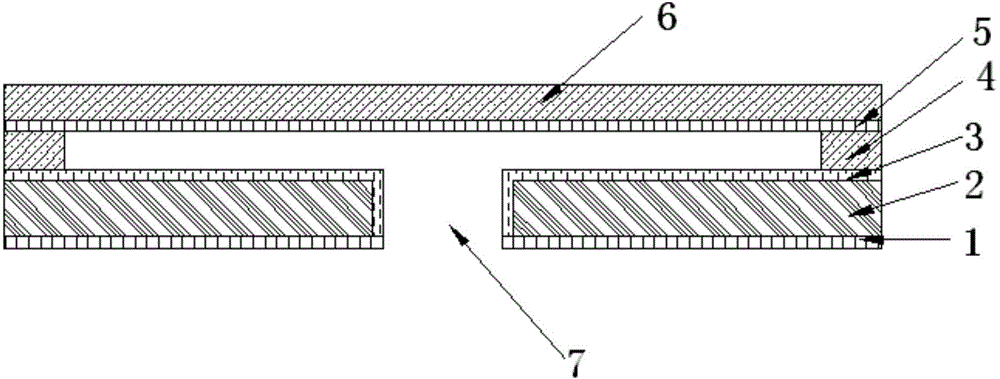

ActiveCN103313172AEffective Packaging TechnologyImprove integration densitySolid state device transducersLoudspeaker screensTransducerAcoustic wave

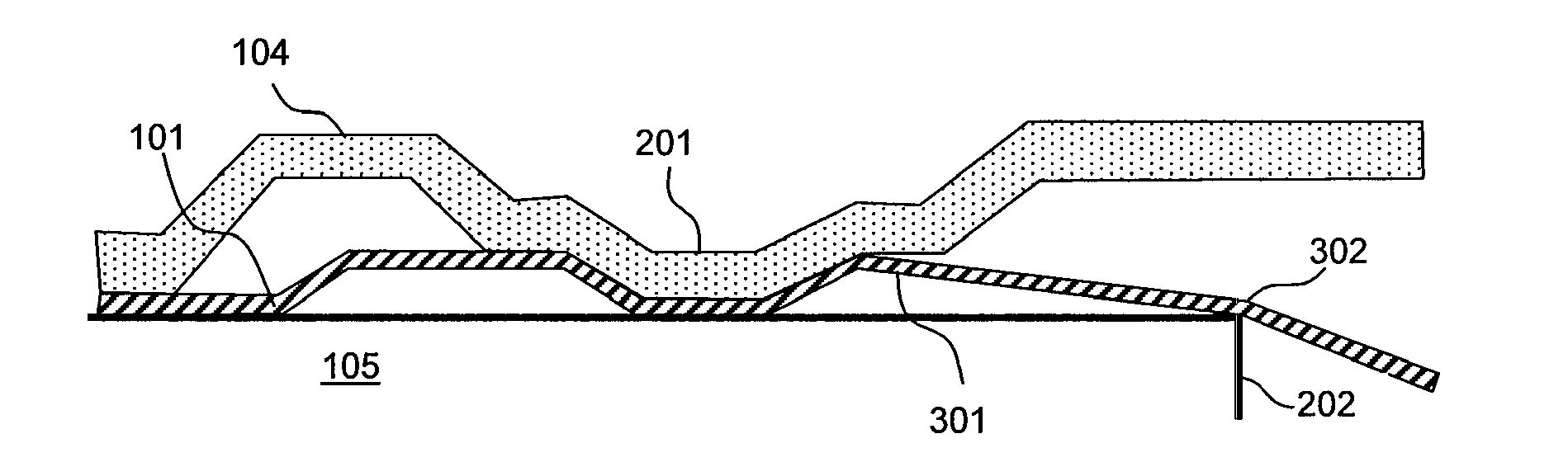

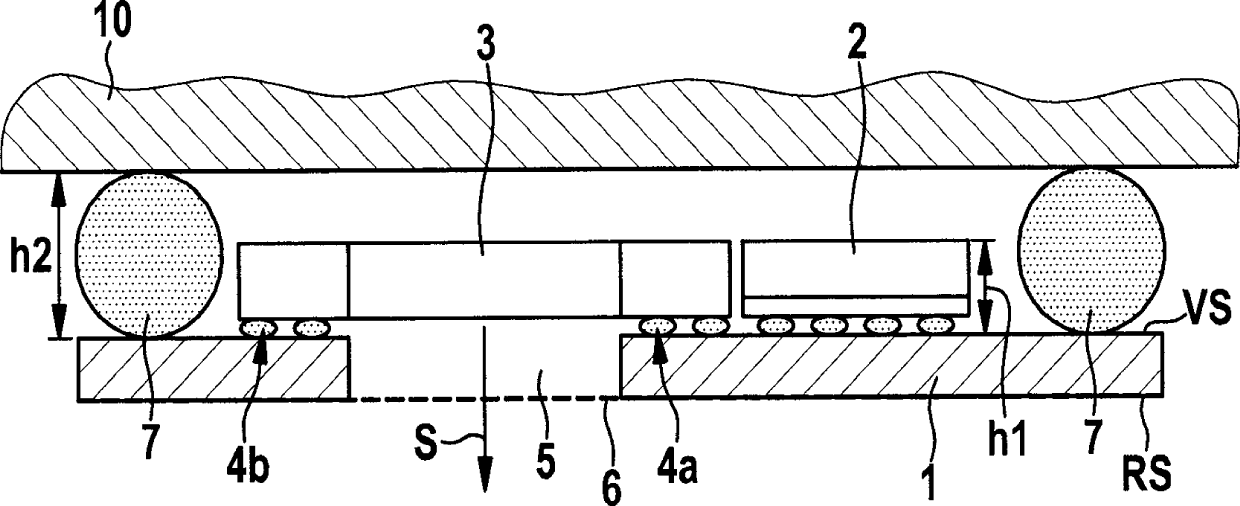

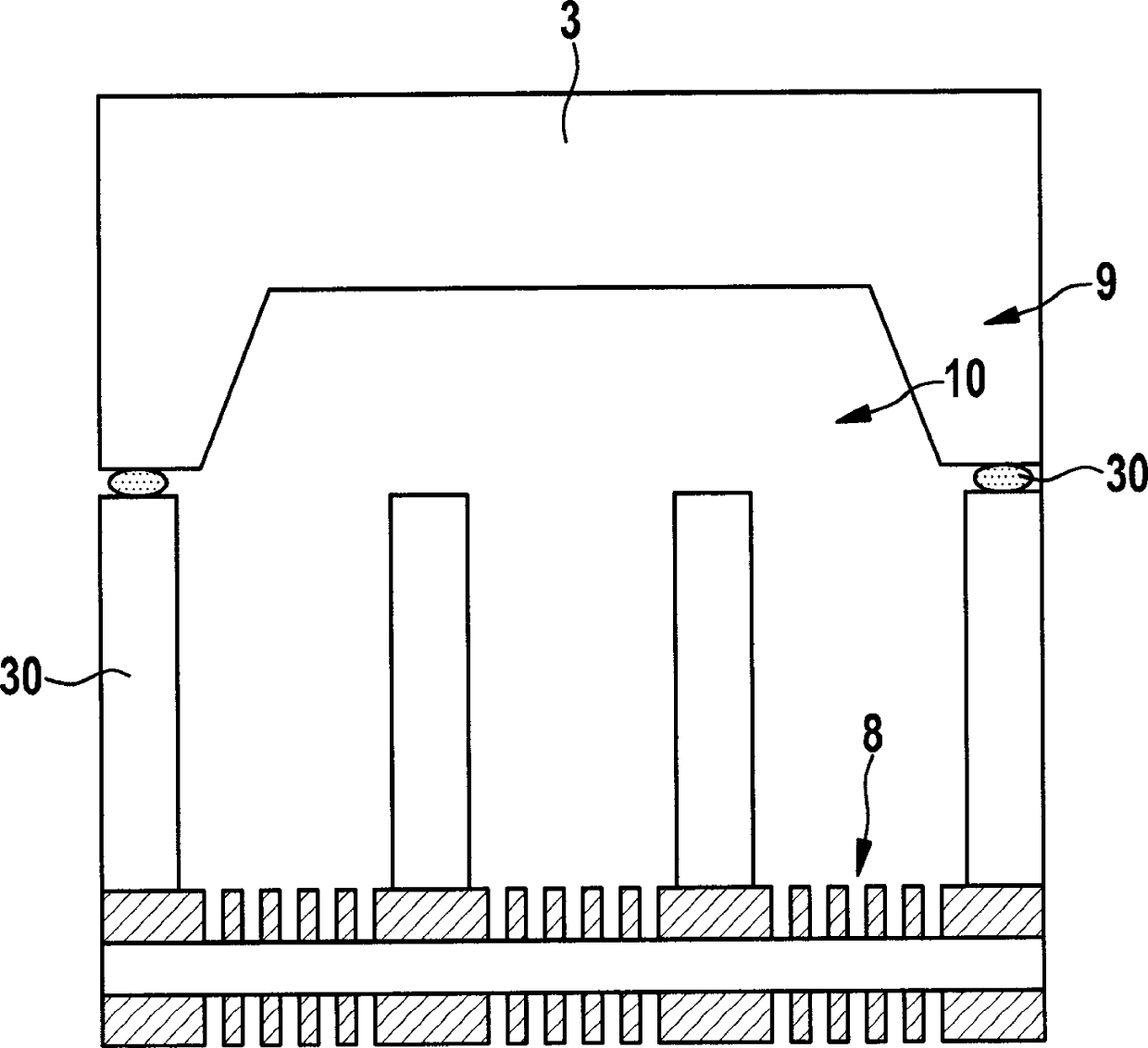

A micromechanical sound transducer arrangement includes an electrical printed circuit board (1) having a front side (VS) and a rear side (RS). A micromechanical sound transducer structure (3) is applied to the front side (VS) using the flip-chip method. The printed circuit board (1) defines an opening (5) for emitting soundwaves (S) in the region of the micromechanical sound transducer structure (3).

Owner:ROBERT BOSCH GMBH

Capacitive transducer

ActiveUS9319798B2Improve propertiesPreventing the diaphragm from breakingSolid state device transducersMicrophonesEngineeringElectrode

Owner:MMI SEMICON CO LTD

Sensor using sensing mechanism having combined static charge and field effect transistor

InactiveUS20150115331A1Simple configurationSolid state device transducersMicrophonesEngineeringField effect

The present invention relates to a sensor that uses a sensing mechanism having a combined static charge and a field effect transistor, the sensor including: a substrate; source and drain units formed on the substrate and separated from each other; a channel unit interposed between the source and drain units; a membrane separated from the channel unit, disposed on a top portion and displaced in response to an external signal; and a static charge member formed on a bottom surface of the membrane separately from the channel unit and generating an electric field. Accordingly, since the sensor using a sensing mechanism having a combined static charge and a field effect transistor according to an embodiment of the present invention can measure the displacement or movement of the sensor by measuring a change of the electric field of the channel unit of the field effect transistor by using a static member, the electric field can be formed so as to be proportional to an amount of charge and inversely proportional to a squared distance regardless of the intensity and distribution of an external electric field. Therefore, sensitivity is improved without being affected by an external electric field.

Owner:POSTECH ACAD IND FOUND

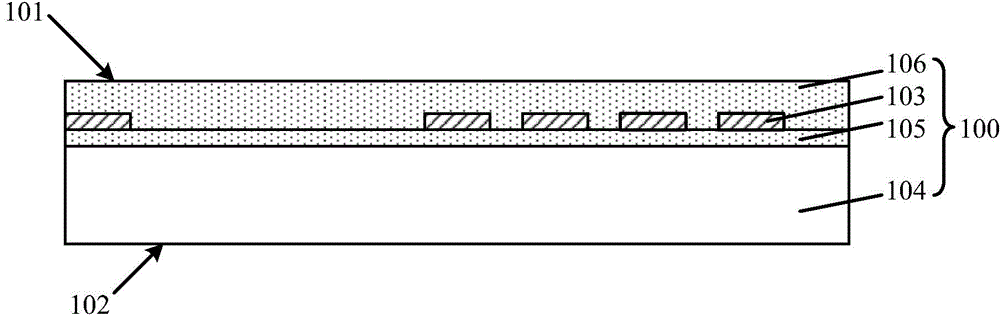

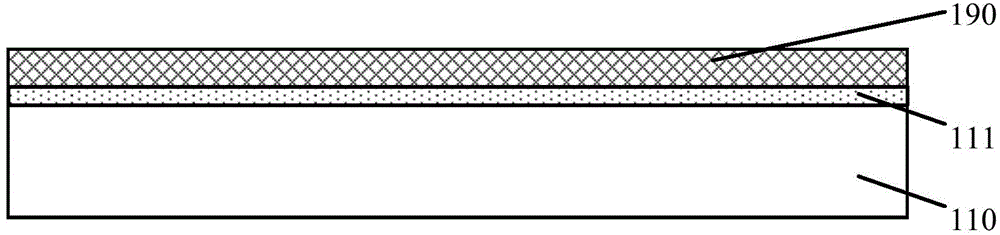

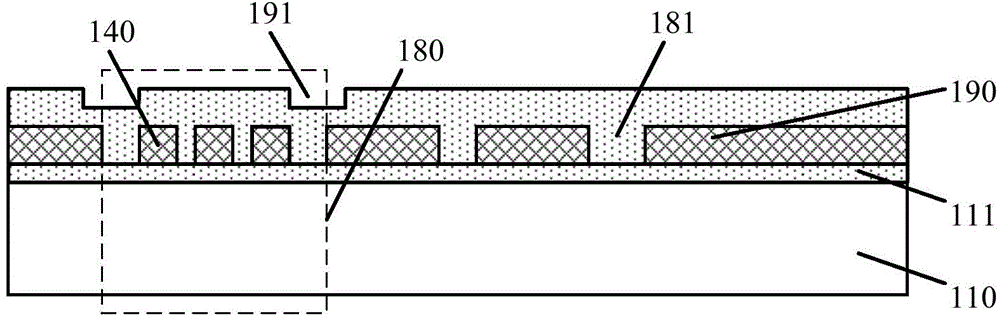

A MEMS microphone and a formation method thereof

ActiveCN104796832AAchieve electrical connectionAffect the manufacturing processSolid state device transducersMicrophonesFistOptoelectronics

Provided are a MEMS microphone and a formation method thereof. The formation method comprises: providing a first substrate comprising a first surface and a second surface, wherein, the first substrate comprises at least one conductive layer, which is located at a side of the first surface of the first substrate; providing a second substrate comprising a third surface and a fourth surface, wherein, the second substrate comprises a second base and a sensitive electrode, and comprises a sensitive area, in which the sensitive electrode is located at a side of the third surface of the second substrate; fixing the first surface of the fist substrate and the third surface of the second substrate each other; thereafter, removing the second base, and forming a fifth surface opposite to the third surface of the second substrate; forming an empty cavity between the first substrate and the sensitive area of the second substrate; and forming, from a side of the fifth surface of the second substate, a first conductive plug penetrating to the at least one conductive layer. The MEMS microphone is improved in performance and reliability, is reduced in size, and is lowed in process cost.

Owner:MEMSEN ELECTRONICS

MEMS devices and processes

InactiveUS20190047847A1Reduce the impactImprove signal-to-noise ratioTelevision system detailsSolid state device transducersTransducerEngineering

A MEMS transducer configured to operate as a microphone, the MEMS transducer comprising a flexible membrane, the flexible membrane having a first surface and a second surface, wherein the first surface of the flexible membrane is fluidically isolated from the second surface of the flexible membrane. Also, a MEMS device comprising a MEMS transducer, an electronic device comprising a MEMS transducer and / or a MEMS device, and a method for forming a MEMS device.

Owner:CIRRUS LOGIC INT SEMICON

MEMS component including a sound-pressure-sensitive diaphragm element and piezosensitive signal detection

ActiveUS9936298B2Enhanced signalSolid state device transducersPiezoelectric/electrostrictive microphonesEngineeringSounding - action

For a MEMS component, in the layer structure of which at least one sound-pressure-sensitive diaphragm element is formed, which spans an opening or cavity in the layer structure and the deflections of which are detected with the aid of at least one piezosensitive circuit element in the attachment area of the diaphragm element, design measures are provided, by which the stress distribution over the diaphragm surface may be influenced intentionally in the event of deflection of the diaphragm element. In particular, measures are provided, by which the mechanical stresses are intentionally introduced into predefined areas of the diaphragm element, to thus amplify the measuring signal. For this purpose, the diaphragm element includes at least one designated bending area, which is defined by the structuring of the diaphragm element and is more strongly deformed in the event of sound action than the adjoining diaphragm sections.

Owner:ROBERT BOSCH GMBH

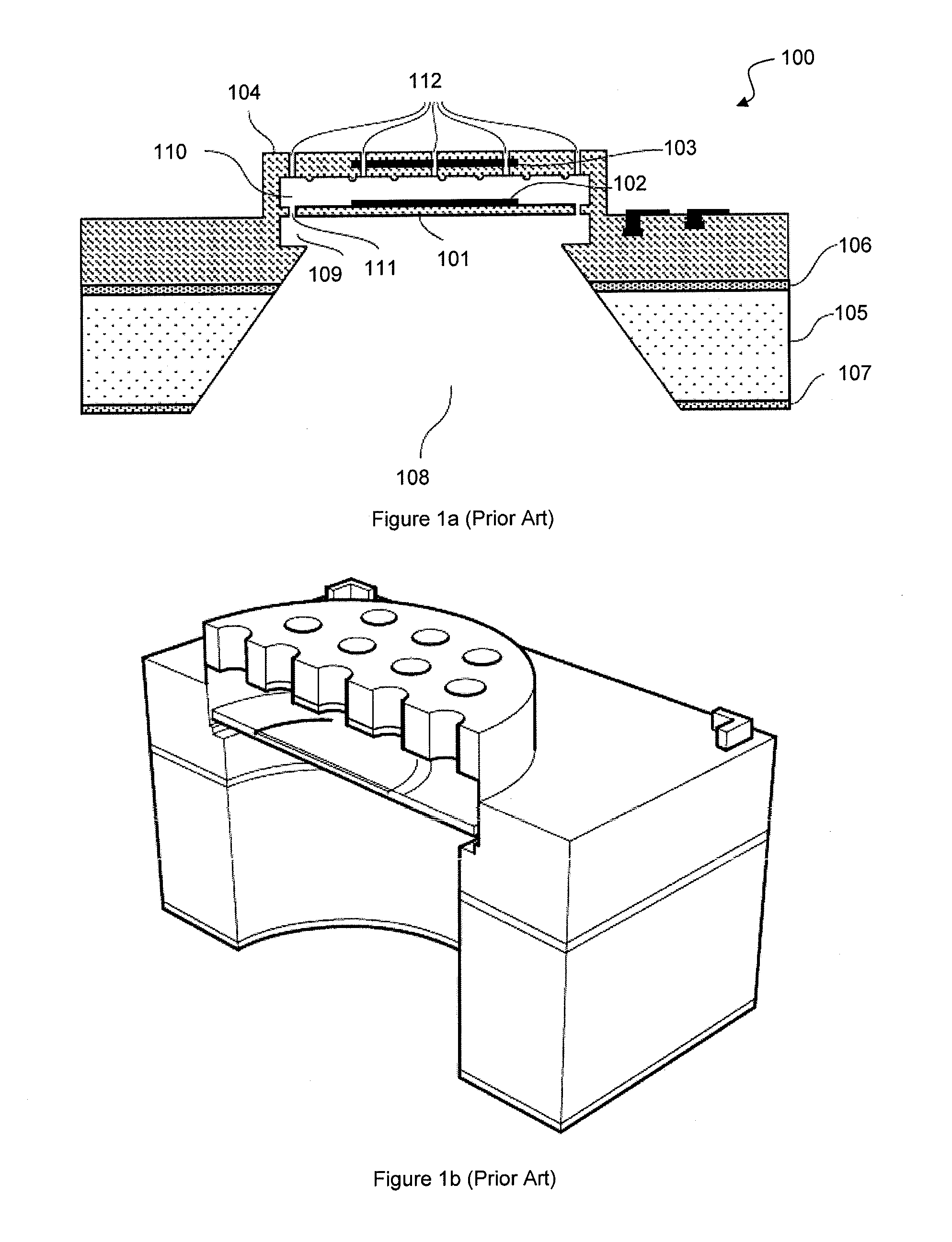

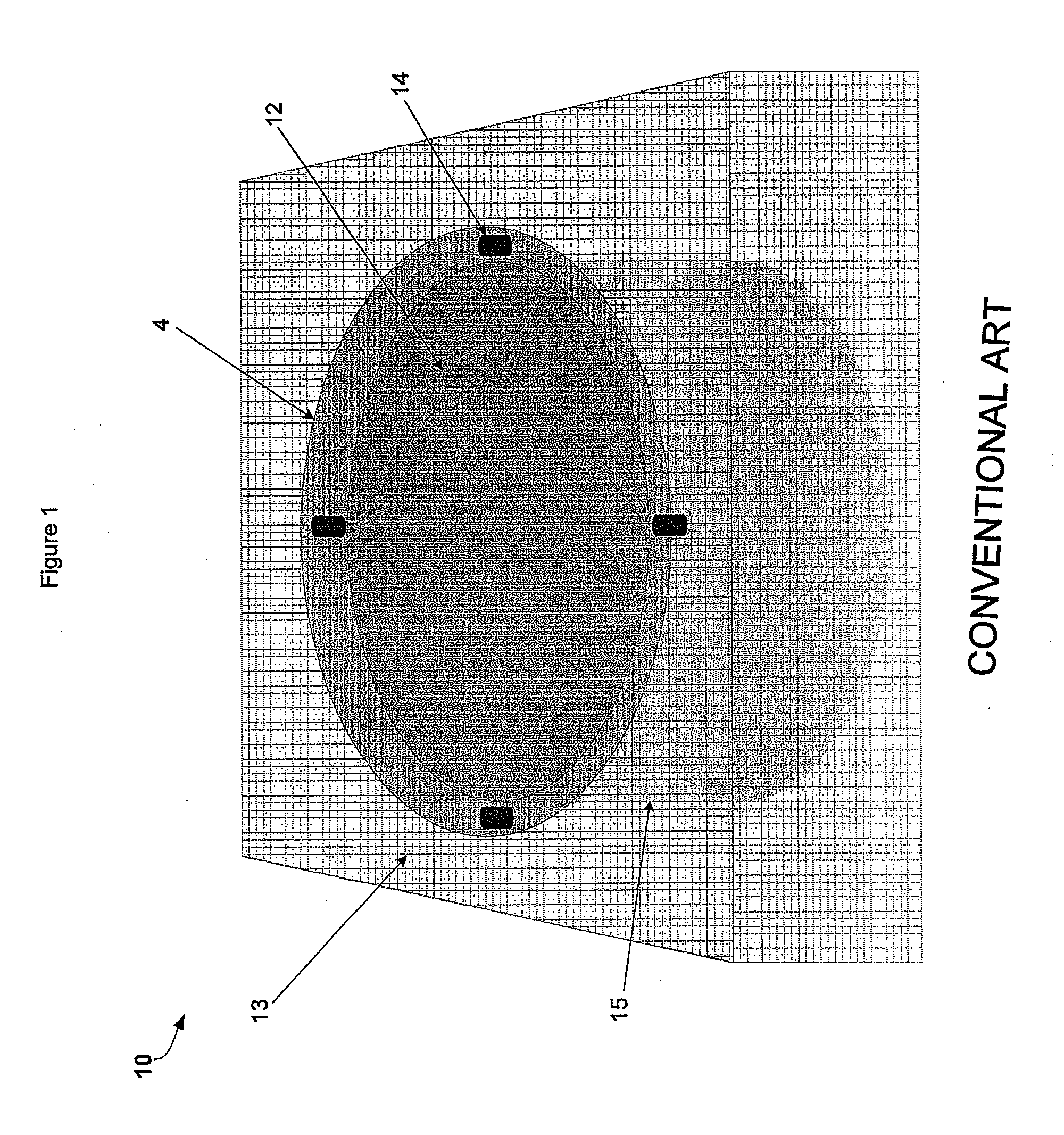

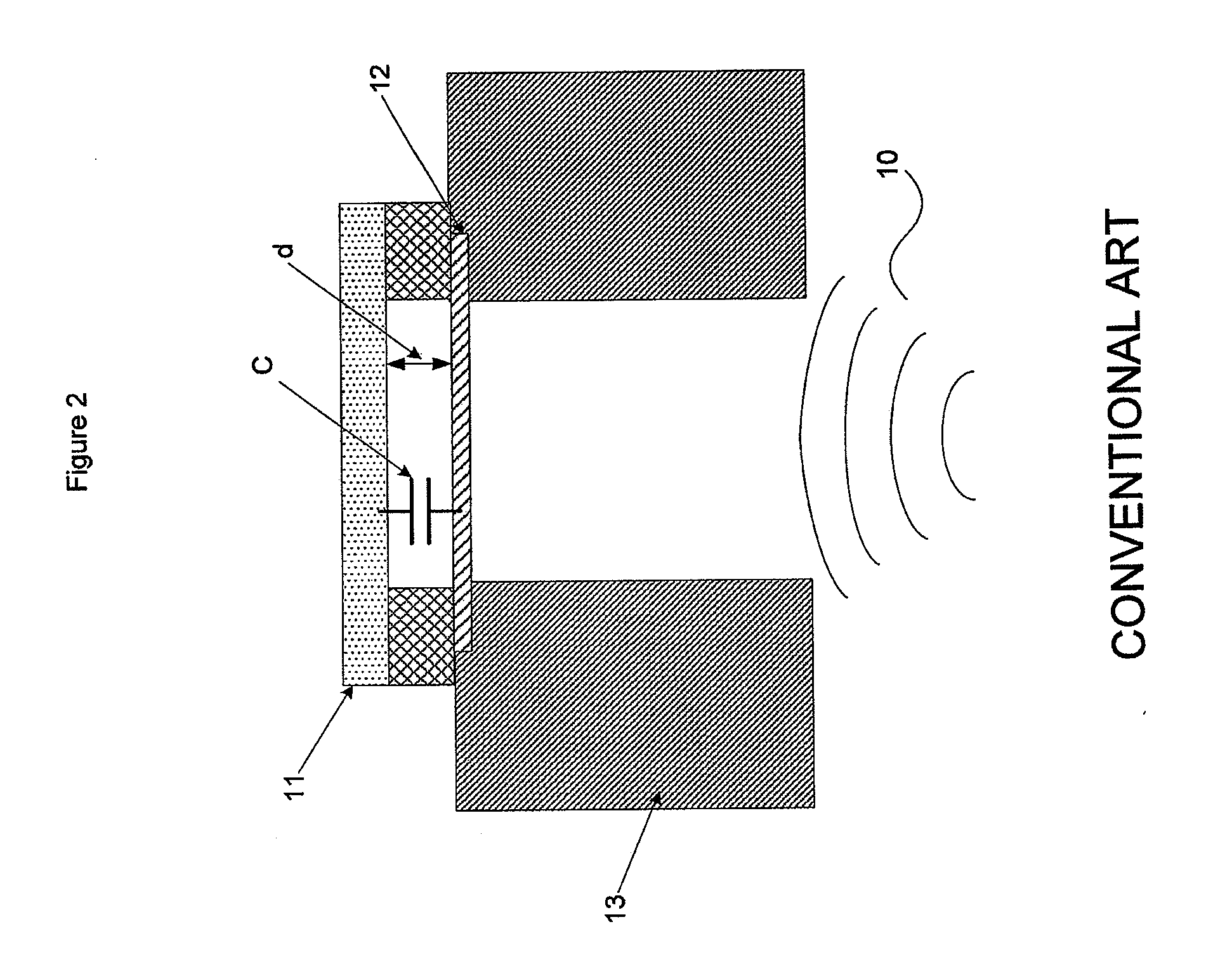

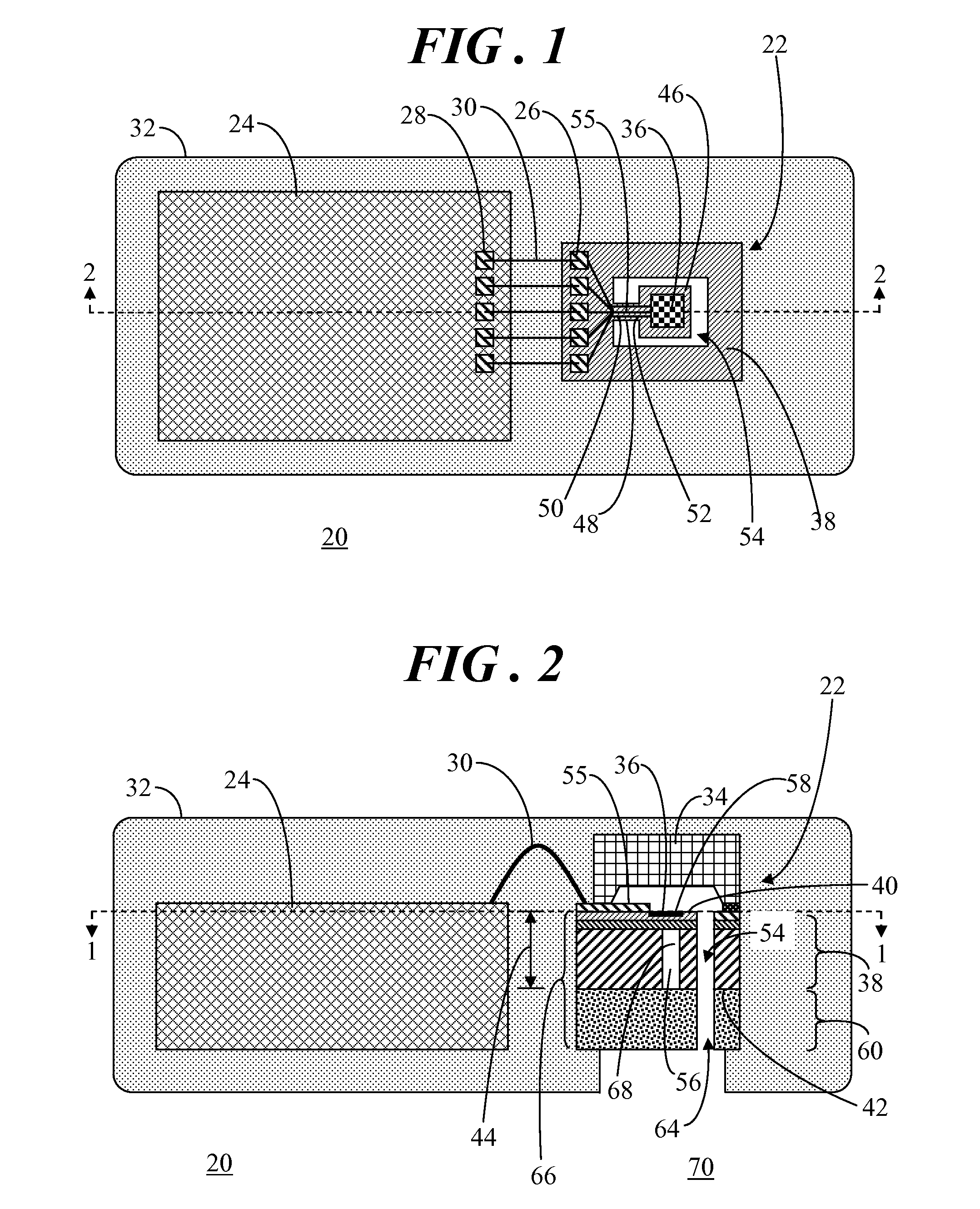

Miniature non-directional microphone

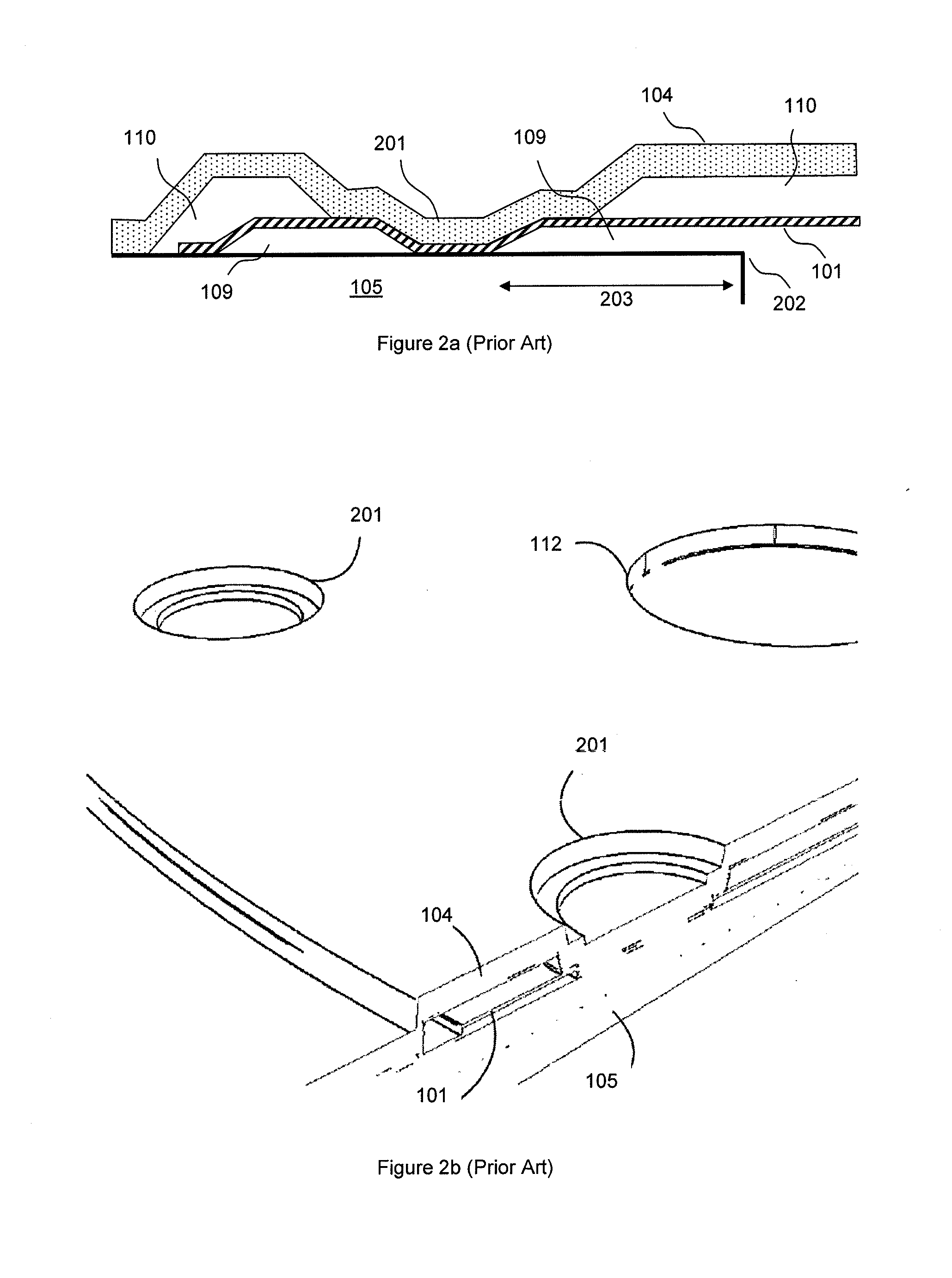

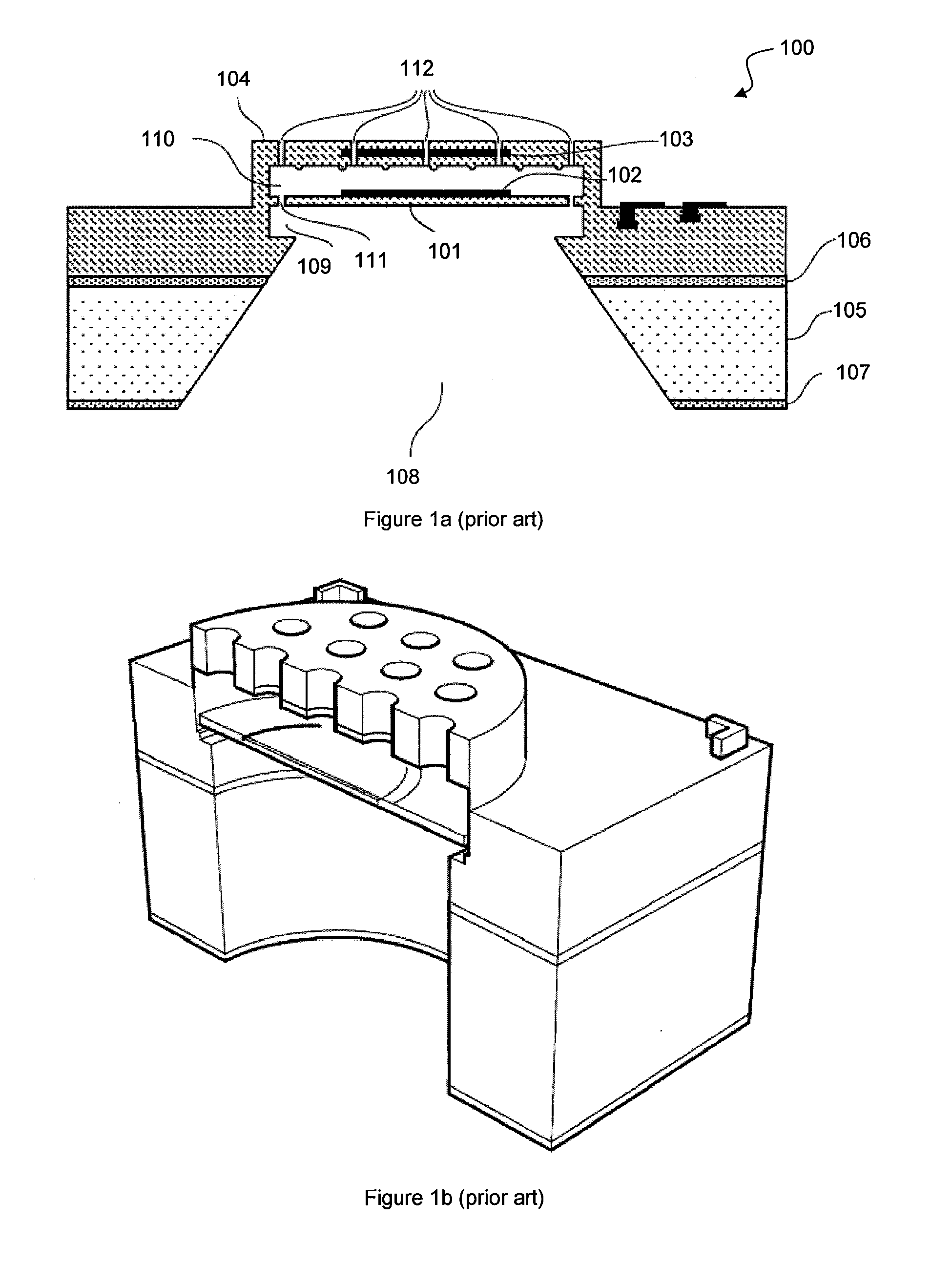

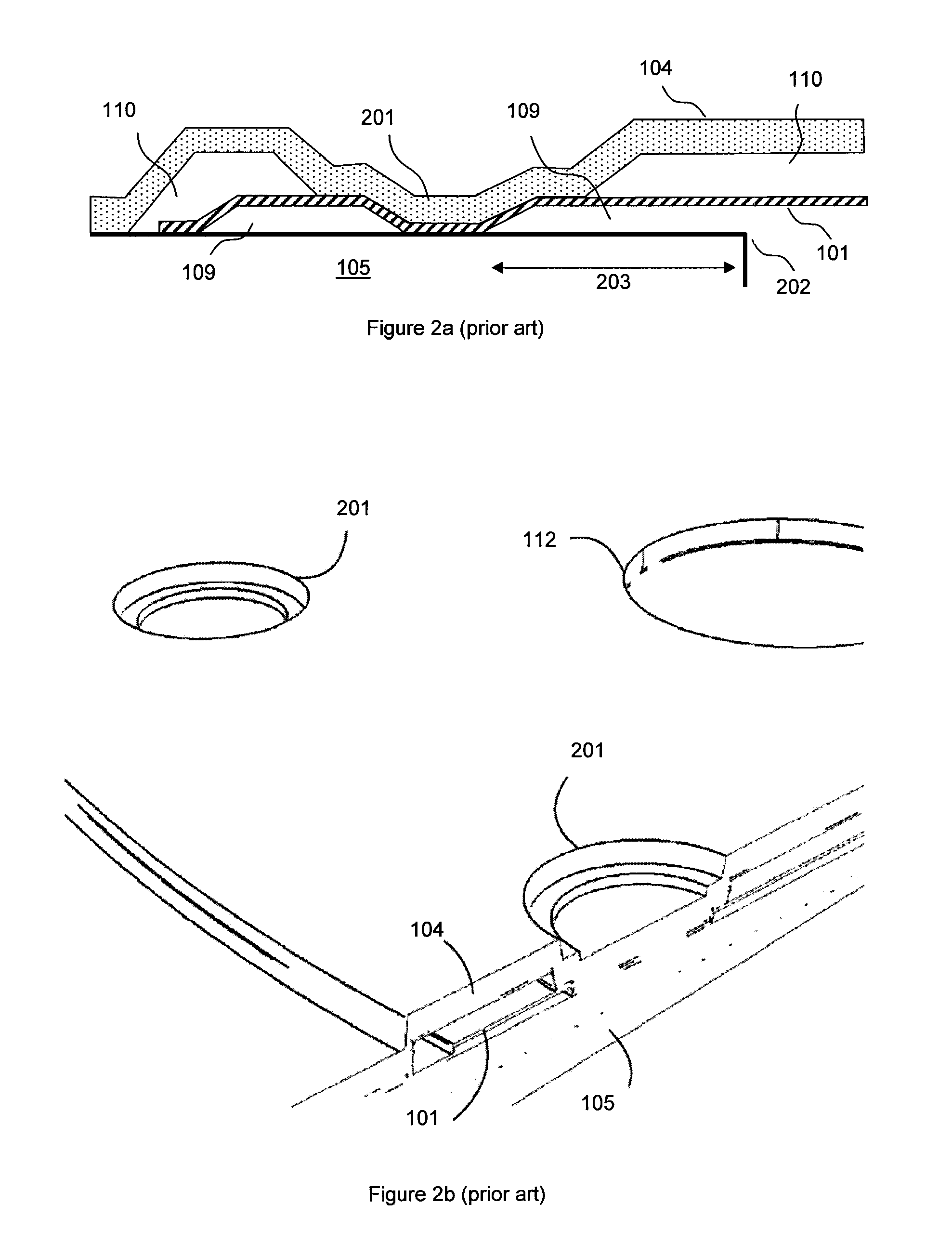

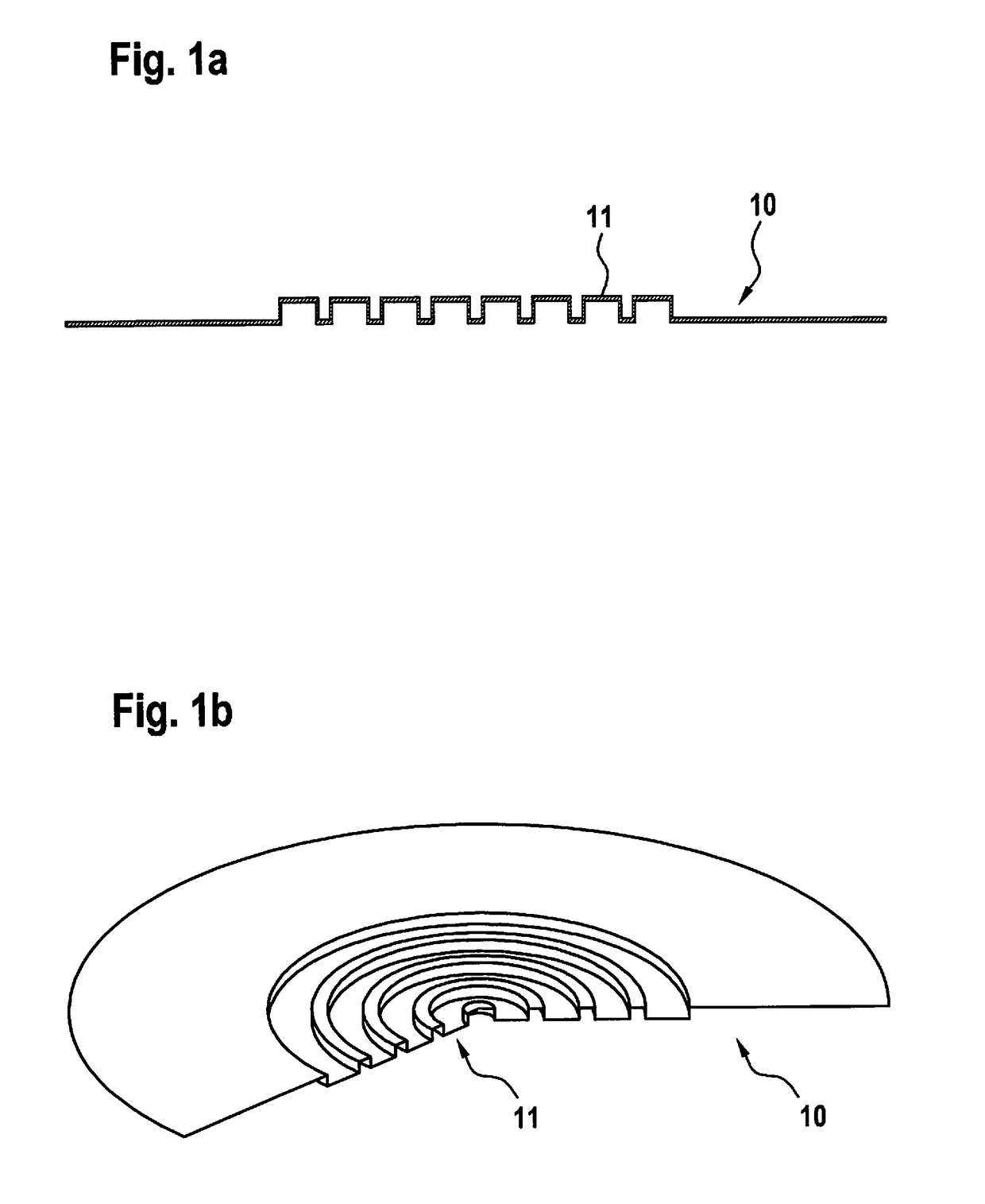

InactiveUS7903835B2Improve responseHigh sensitivityPiezoelectric/electrostrictive microphonesSolid state device transducersAir volumeMicrofabrication

A miniature microphone comprising a diaphragm compliantly suspended over an enclosed air volume having a vent port is provided, wherein an effective stiffness of the diaphragm with respect to displacement by acoustic vibrations is controlled principally by the enclosed air volume and the port. The microphone may be formed using silicon microfabrication techniques and has sensitivity to sound pressure substantially unrelated to the size of the diaphragm over a broad range of realistic sizes. The diaphragm is rotatively suspend for movement through an arc in response to acoustic vibrations, for example by beams or tabs, and has a surrounding perimeter slit separating the diaphragm from its support structure. The air volume behind the diaphragm provides a restoring spring force for the diaphragm. The microphone's sensitivity is related to the air volume, perimeter slit, and stiffness of the diaphragm and its mechanical supports, and not the area of the diaphragm.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Miniature non-directional microphone

InactiveUS20080101641A1Less stiffImprove responsePiezoelectric/electrostrictive microphonesSolid state device transducersAir volumeSpring force

A miniature microphone comprising a diaphragm compliantly suspended over an enclosed air volume having a vent port is provided, wherein an effective stiffness of the diaphragm with respect to displacement by acoustic vibrations is controlled principally by the enclosed air volume and the port. The microphone may be formed using silicon microfabrication techniques and has sensitivity to sound pressure substantially unrelated to the size of the diaphragm over a broad range of realistic sizes. The diaphragm is rotatively suspend for movement through an arc in response to acoustic vibrations, for example by beams or tabs, and has a surrounding perimeter slit separating the diaphragm from its support structure. The air volume behind the diaphragm provides a restoring spring force for the diaphragm. The microphone's sensitivity is related to the air volume, perimeter slit, and stiffness of the diaphragm and its mechanical supports, and not the area of the diaphragm.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Microelectro-mechanical systems (MEMS) microphone package device and MEMS packaging method thereof

The present invention discloses a microelectro-mechanical systems (MEMS) microphone package device and a MEMS packaging method thereof. A MEMS microphone package device includes a MEMS microphone chip as an integrated circuit chip. An acoustic sensing structure is embedded in the integrated circuit chip. An adhesive structure adheres on outer sidewall of the microphone chip. A bottom portion of the adhesive structure protrudes out from first surface of the microphone chip and adheres on a surface of a substrate, having interconnection structure, to form a first seal ring. A space between the acoustic sensing structure and the substrate and sealed by the first seal ring forms a second chamber. A cover adheres to top portion of the adhesive structure, covering over the cavity on the second surface of the microphone chip. The top portion of the adhesive structure forms as a second seal ring. A space between the cover and the second surface of the microphone chip and sealed by the second seal ring forms a first chamber.

Owner:SOLID STATE SYST

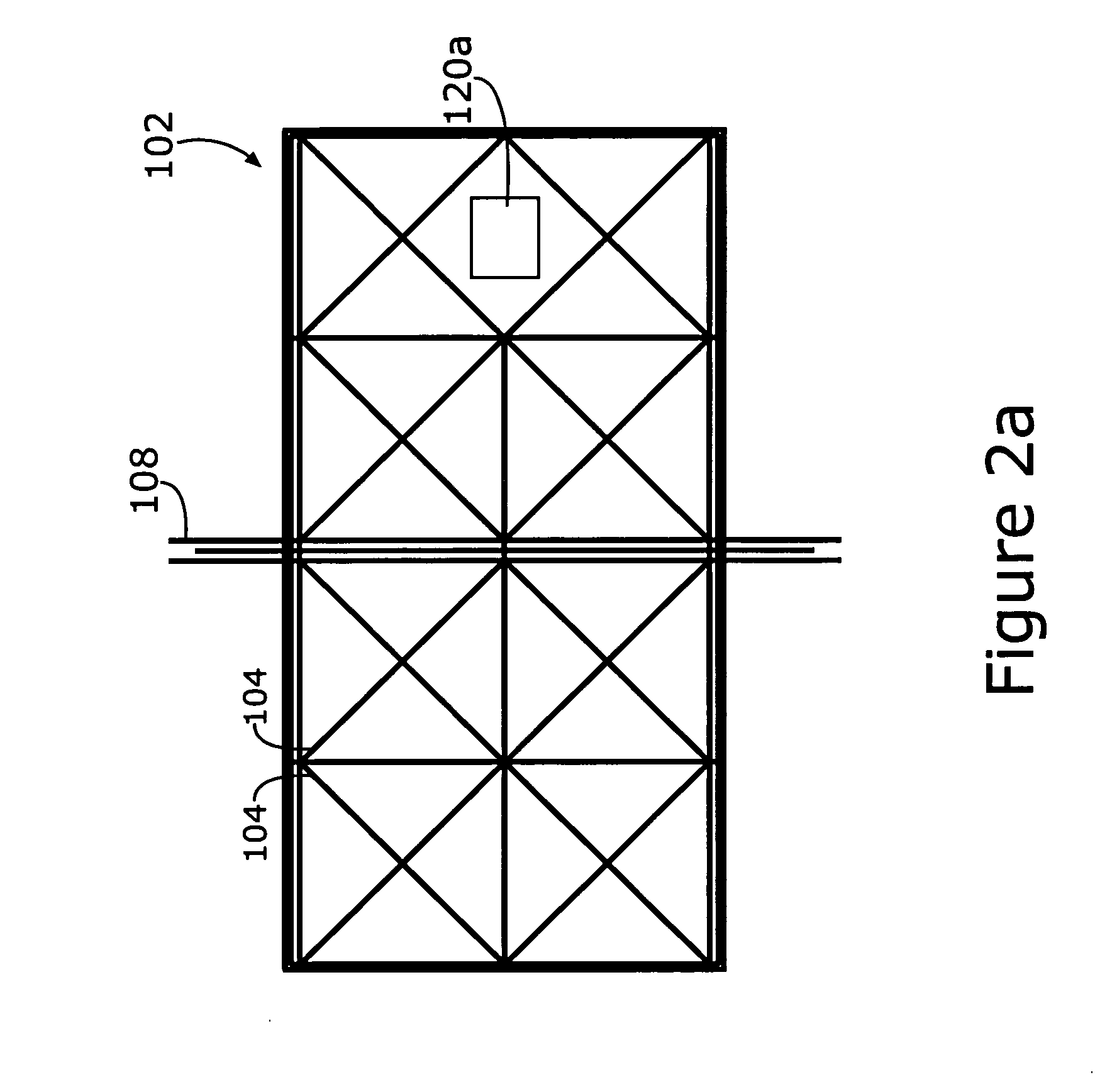

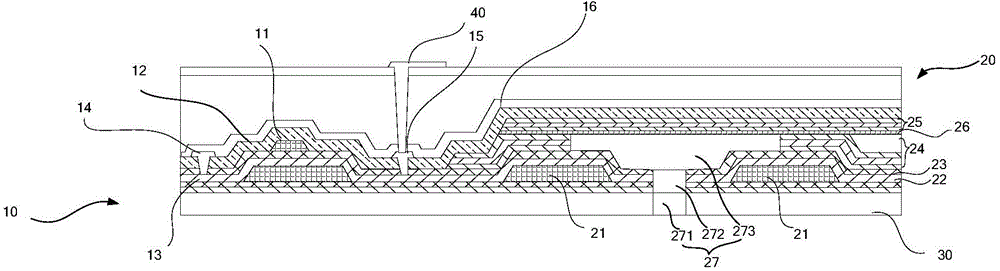

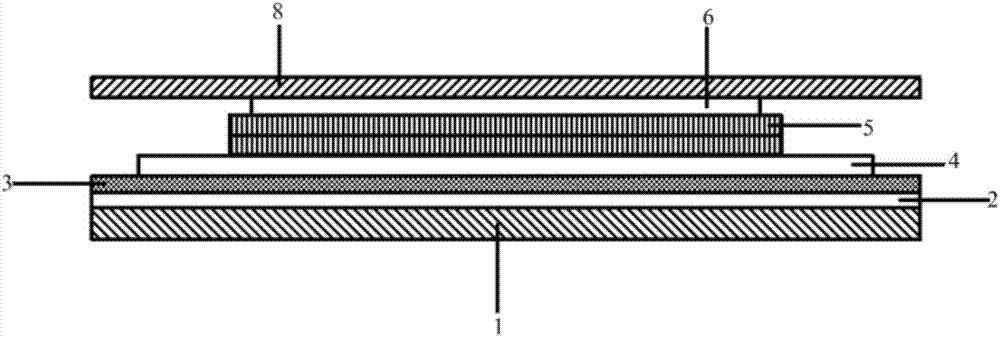

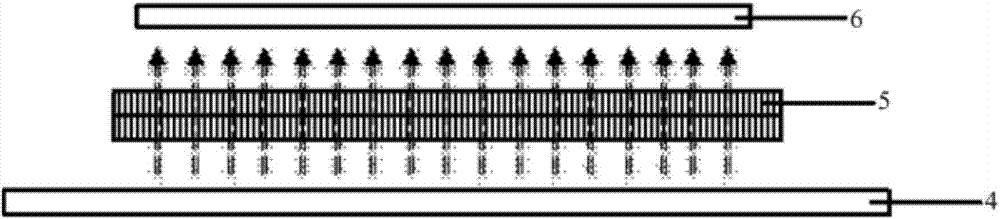

Display panel, preparation method of display panel, display device and health monitoring method of display device

ActiveCN105182583AIncrease volumeSolid state device transducersVibration measurement in fluidDisplay deviceAcoustic wave

The invention relates to the technical field of display devices and discloses a display panel, a preparation method of the display panel, a display device and a health monitoring method of the display device. The display panel comprises a substrate and a sonic sensor arranged on the substrate. According to the technical scheme, the sonic sensor is directly formed on the substrate, the sonic sensor can be formed while other structures of the display panel are prepared, and the preparation efficiency of the display device is improved; meanwhile, the thickness of the formed display device is reduced, and thin type development of the display device is convenient.

Owner:BOE TECH GRP CO LTD +1

Micro-electrical-mechanical system (MEMS) microphone

ActiveUS20150315013A1Reduce probabilitySolid state device transducersMicrophonesEngineeringBackplane

A micro-electrical-mechanical system (MEMS) microphone includes a MEMS structure, having a substrate, a diaphragm, and a backplate, wherein the substrate has a cavity and the backplate is between the cavity and the diaphragm. The backplate has multiple venting holes, which are connected to the cavity and allows the cavity to extend to the diaphragm. Further, an adhesive layer is disposed on the substrate, surrounding the cavity. A cover plate is adhered on the adhesive layer, wherein the cover plate has an acoustic hole, dislocated from the cavity without direct connection.

Owner:SOLID STATE SYST

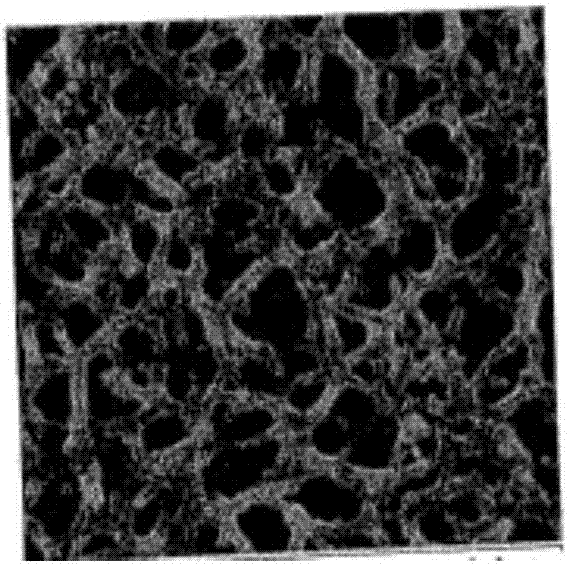

Transistor acoustic sensing element, preparation method thereof, acoustic sensor and portable device

ActiveCN107478320AHigh sensitivityEnhanced Sensing CapabilitiesSolid state device transducersMicrophonesInsulation layerEngineering

The present invention provides a transistor acoustic sensing element, a preparation method thereof, an acoustic sensor and a portable device. The transistor acoustic sensing element comprises a gate, a gate insulation layer, a first pole, an active layer and a second pole which are all arranged on a substrate; the active layer is of a nanometer fine wire three-dimensional mesh structure; and the active layer generates vibration under the action of sound signals, so that the output current of the transistor acoustic sensing element changes correspondingly. According to the transistor acoustic sensing element, the active layer of the nanometer fine wire three-dimensional mesh structure is adopted, so that the detection of the sound signals can be realized; since the active layer of such kind structure can sense the weak vibration of acoustic waves sensitively, the active layer of such kind structure can improve the sensitivity of the transistor acoustic sensing element to the sound signals, and therefore, the sensing performance of the transistor acoustic sensing element to sound can be improved.

Owner:BOE TECH GRP CO LTD +1

Microelectro-mechanical systems (MEMS) microphone package device and MEMS packaging method thereof

A MEMS microphone package device includes a MEMS microphone chip as an integrated circuit chip. An acoustic sensing structure is embedded in the integrated circuit chip. An adhesive structure adheres on outer sidewall of the microphone chip. A bottom portion of the adhesive structure protrudes out from first surface of the microphone chip and adheres on a surface of a substrate, having interconnection structure, to form a first seal ring. A space between the acoustic sensing structure and the substrate and sealed by the first seal ring forms a second chamber. A cover adheres to top portion of the adhesive structure, covering over the cavity on the second surface of the microphone chip. The top portion of the adhesive structure forms as a second seal ring. A space between the cover and the second surface of the microphone chip and sealed by the second seal ring forms a first chamber.

Owner:SOLID STATE SYST

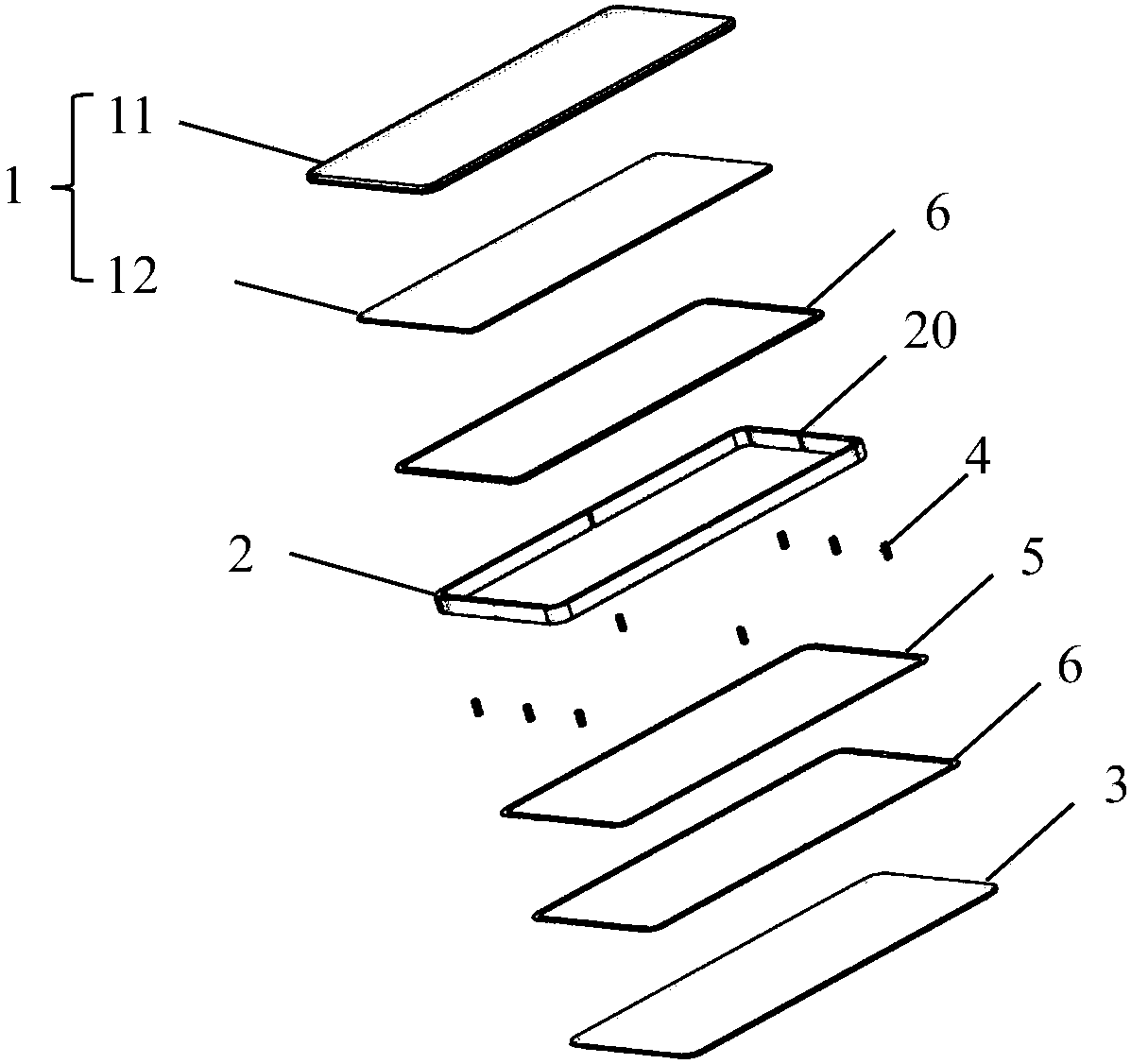

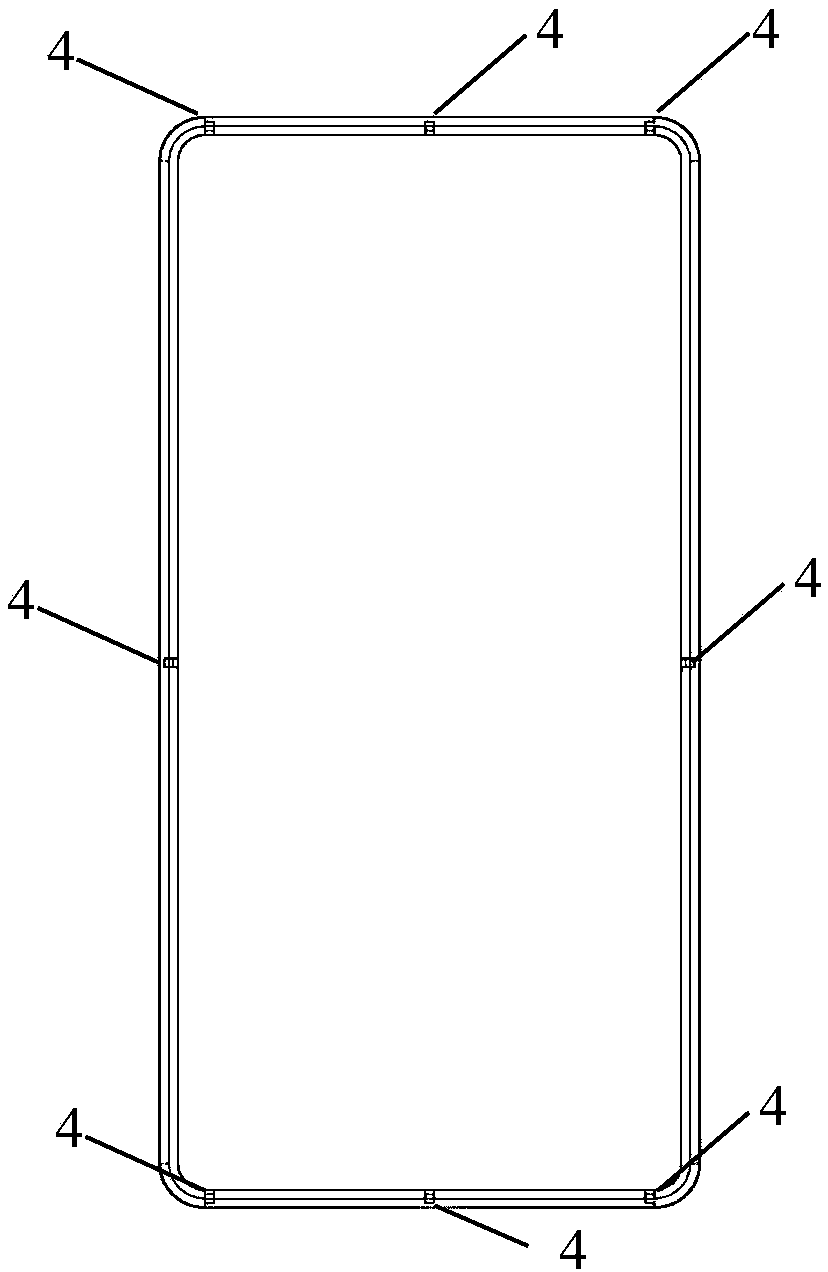

Electronic assembly

PendingCN108337618AHigh sensitivityImprove sound qualitySolid state device transducersLoudspeakerElectric energy

The invention discloses an electronic assembly. The electronic assembly comprises a display screen assembly, a side frame, a back casing, a plurality of piezoelectric transducers and a flexible circuit board. The plurality of piezoelectric transducers are arranged in a groove of the side frame; and through electric connection of the flexible circuit board and the piezoelectric transducers, the piezoelectric transducers can mutually convert electric energy and mechanical energy, so that the electronic assembly can realize different functions. The electronic assembly is simple in structure, canreplace the traditional loudspeaker or telephone receiver which is arranged on multimedia equipment, and can improve the sensitivity and the tone quality of the loudspeaker. Meanwhile, the piezoelectric transducers can be arranged on an edge of the display screen, so that a full screen can be matched and the application range of the piezoelectric transducers can be increased.

Owner:KINGTONE INNOVATION BEIJING TECH +1

Popular searches

Fluid pressure measurement by electric/magnetic elements Solid-state devices Semiconductor/solid-state device manufacturing Electrostatic transducer microphones Flexible microstructural devices Microstructural device manufacture Semiconductor devices Microelectromechanical systems Loudspeakers Chemical vapor deposition coating

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com