Patents

Literature

69results about How to "Reduce external noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

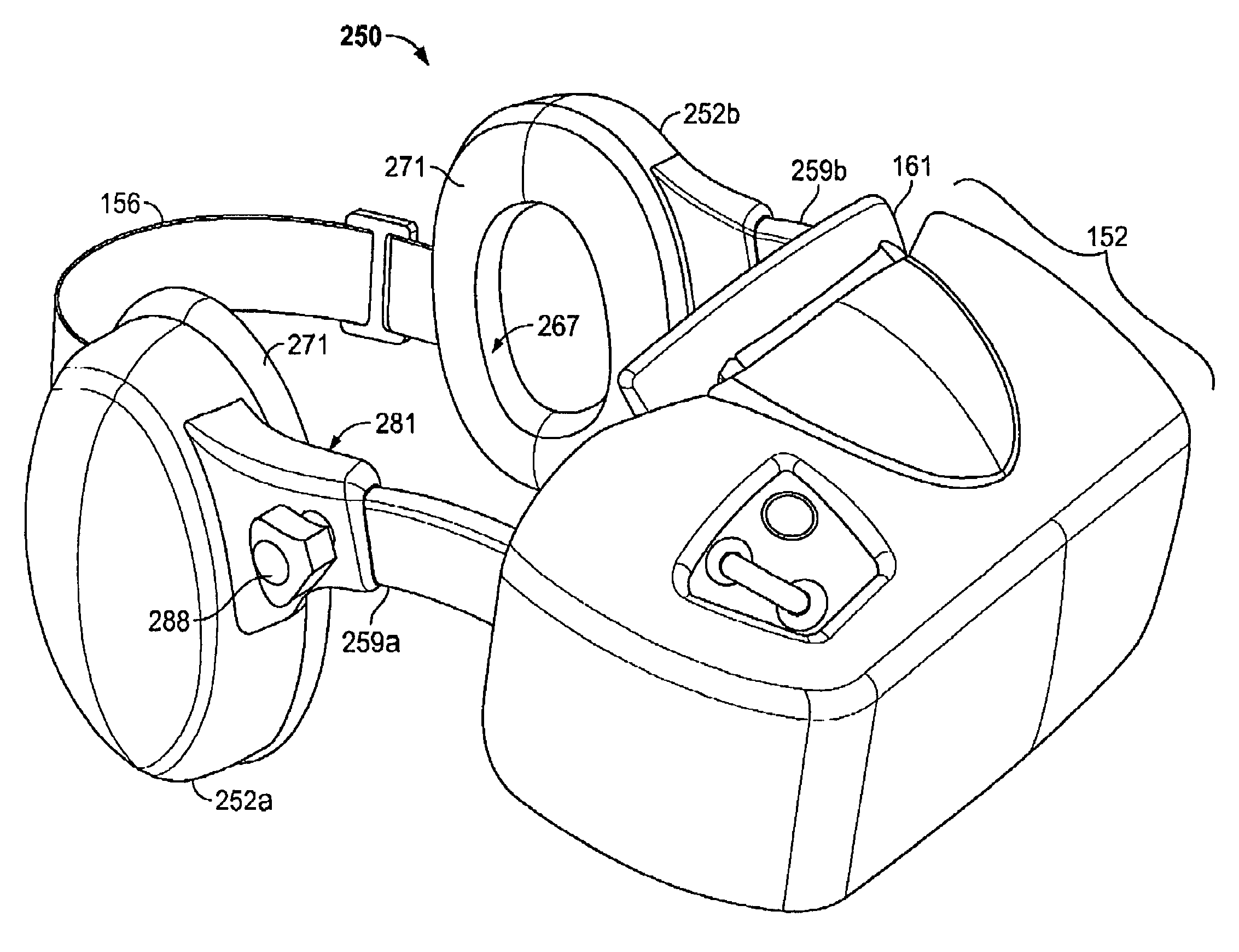

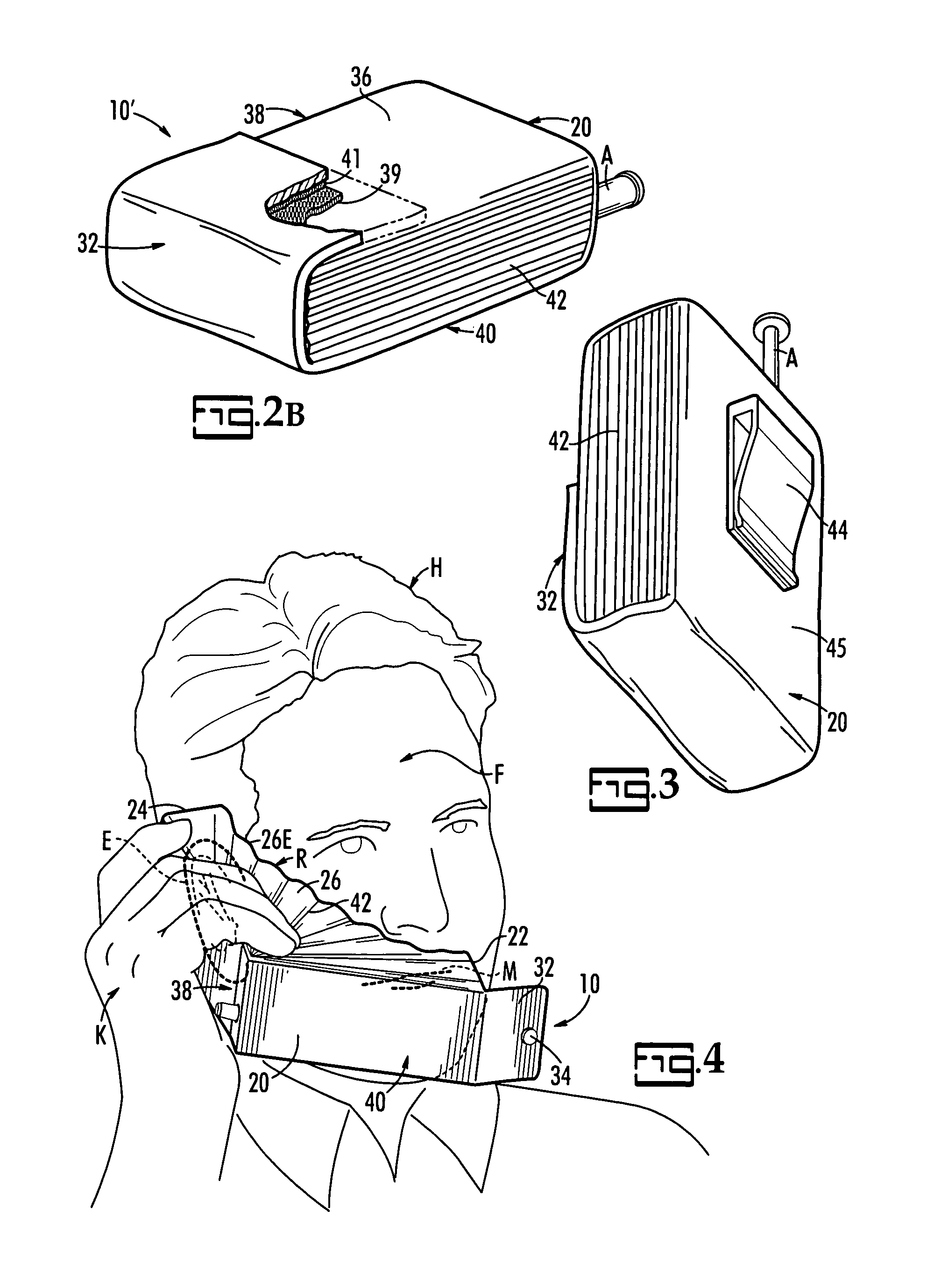

Audio/video system and method utilizing a head mounted apparatus with noise attenuation

InactiveUS7124425B1Reduce amountOvercomes inadequacy and deficiencyTelevision system detailsGHz frequency transmissionLoudspeakerImage based

A head mounted display in a video / audio system includes a display device, a head mount, noise reduction devices, and a speaker. The display device is coupled to the head mount and produces visual images based on received video signals. The head mount is mounted on the user's head and is coupled to the noise reduction devices, which cover the user's ears such that external noise is reduced. The noise reduction devices are coupled together via a strap that fits around the user head. The noise reduction devices are coupled to and house speakers that produce sound signals based on received audio signals. As a result, the user may see the video images produced by the display device and clearly hear the sounds produced by the speaker, and the external noise heard by the user is reduced.

Owner:IMMERSION ENTERTAINMENT L L C

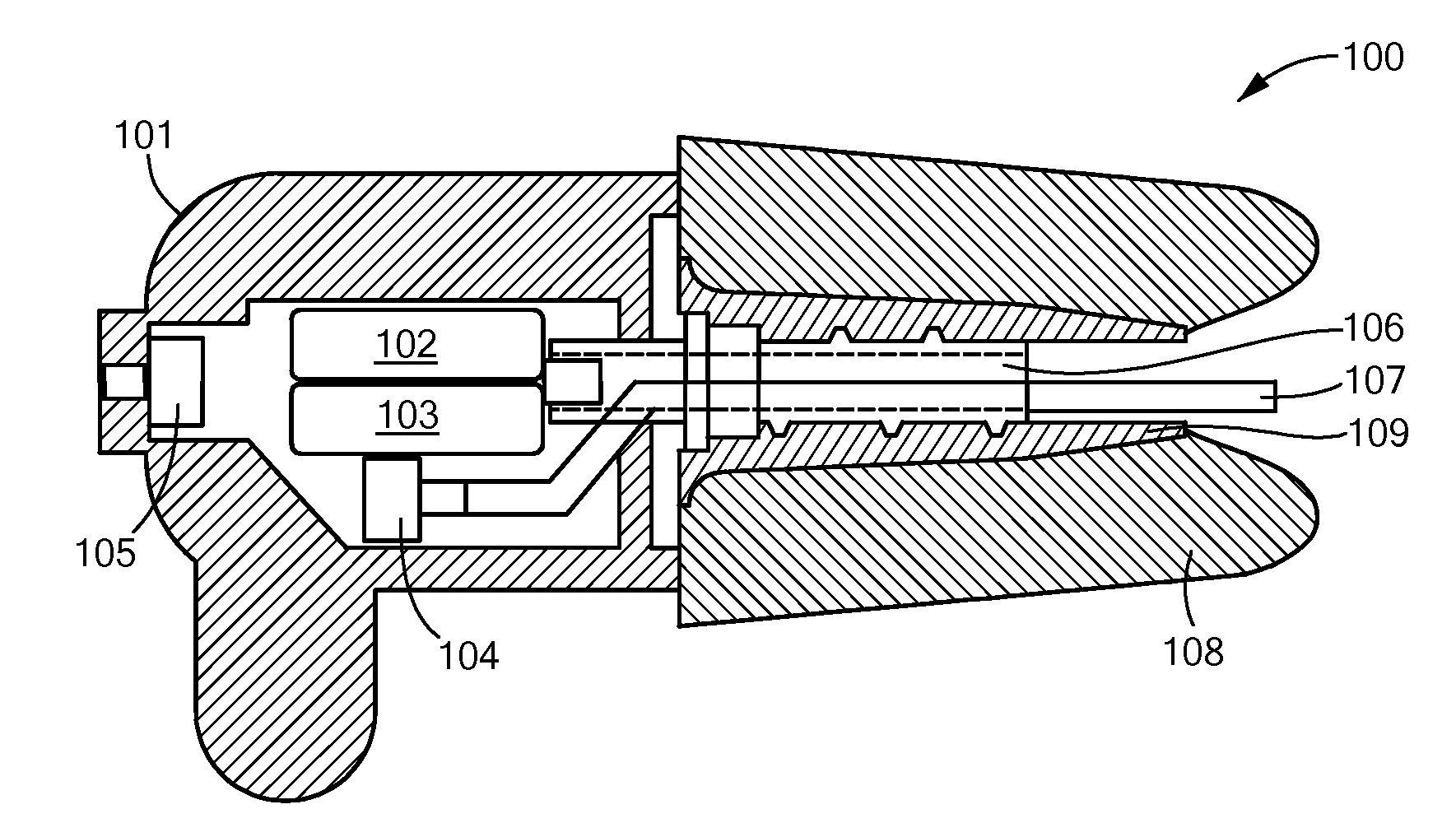

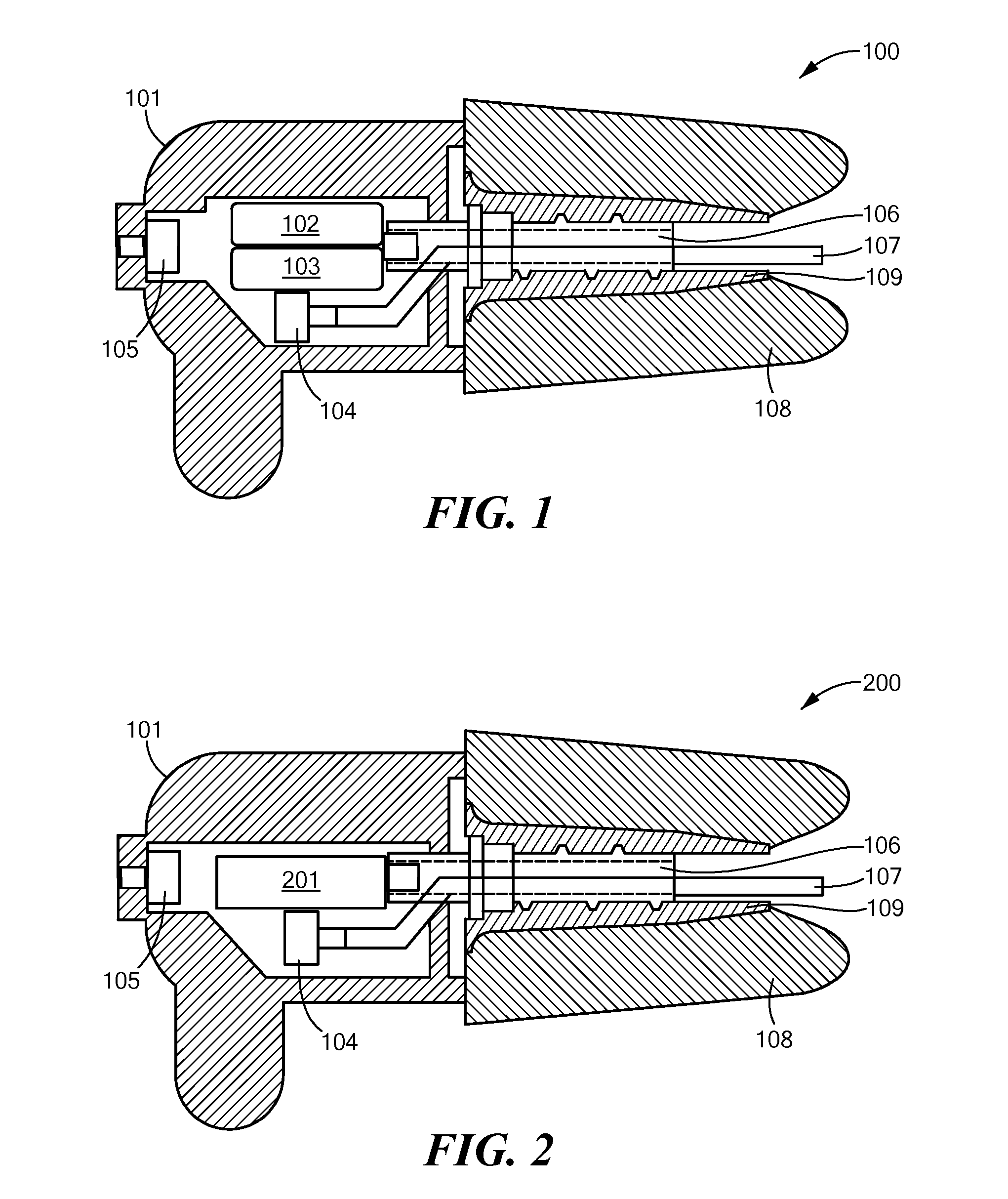

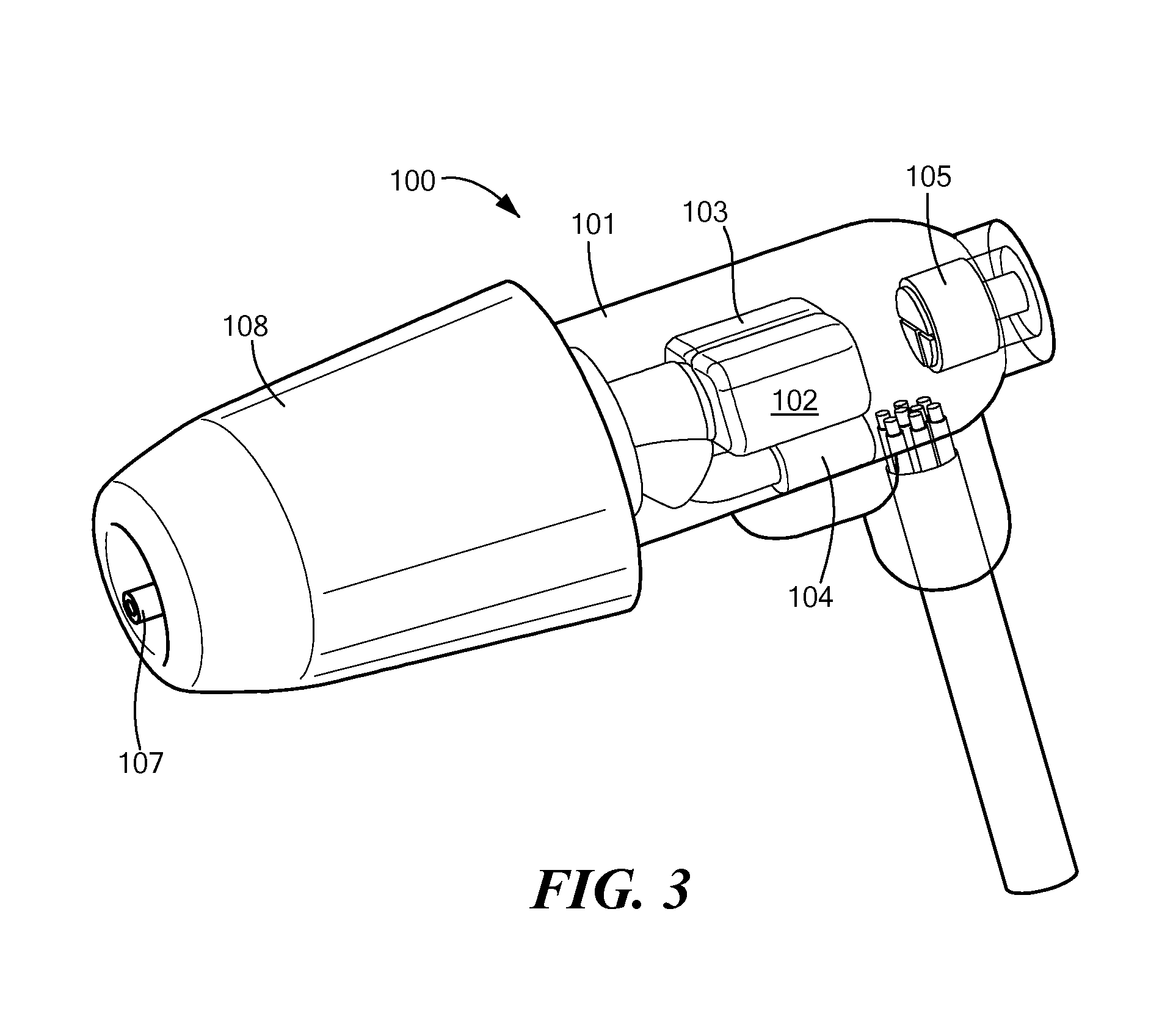

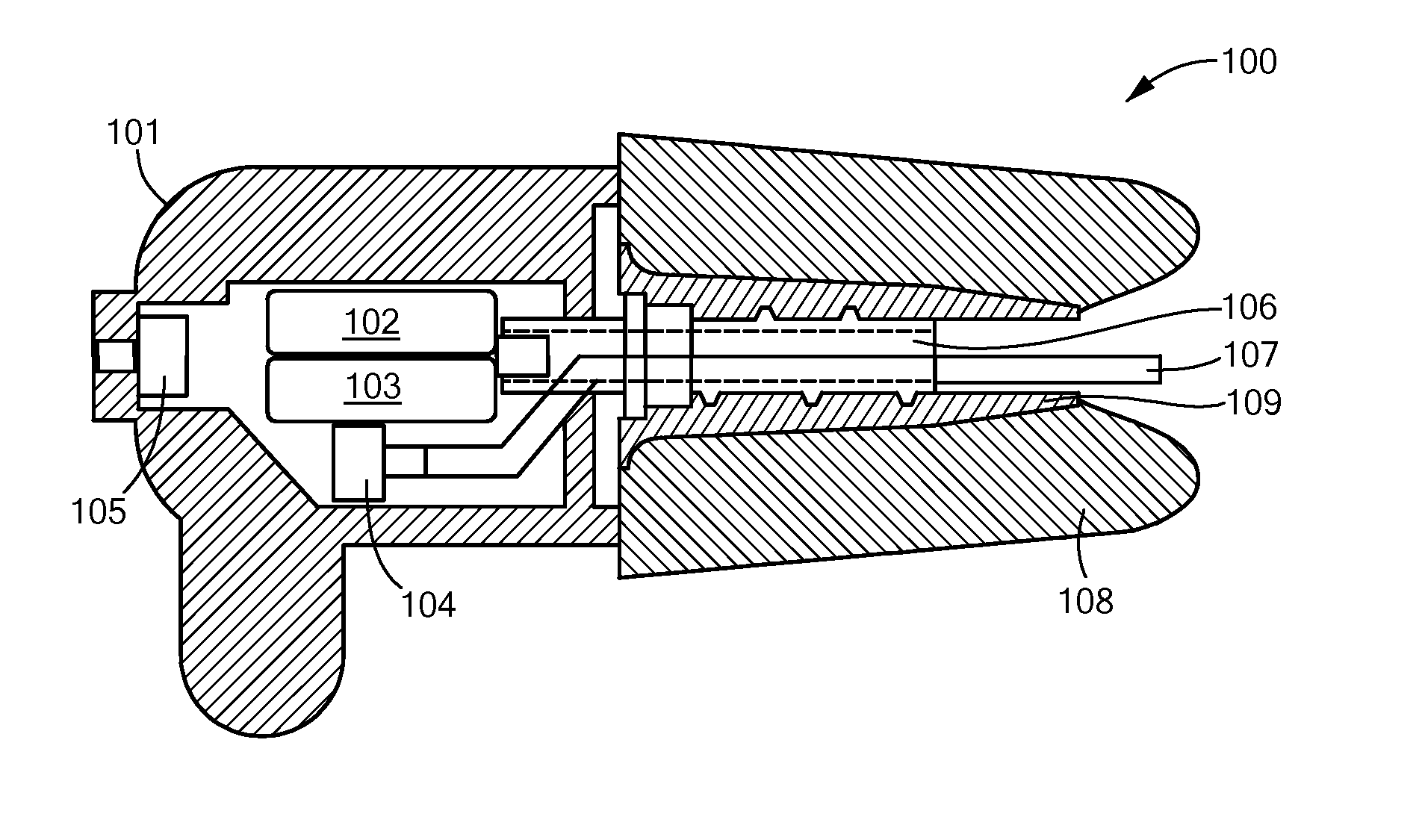

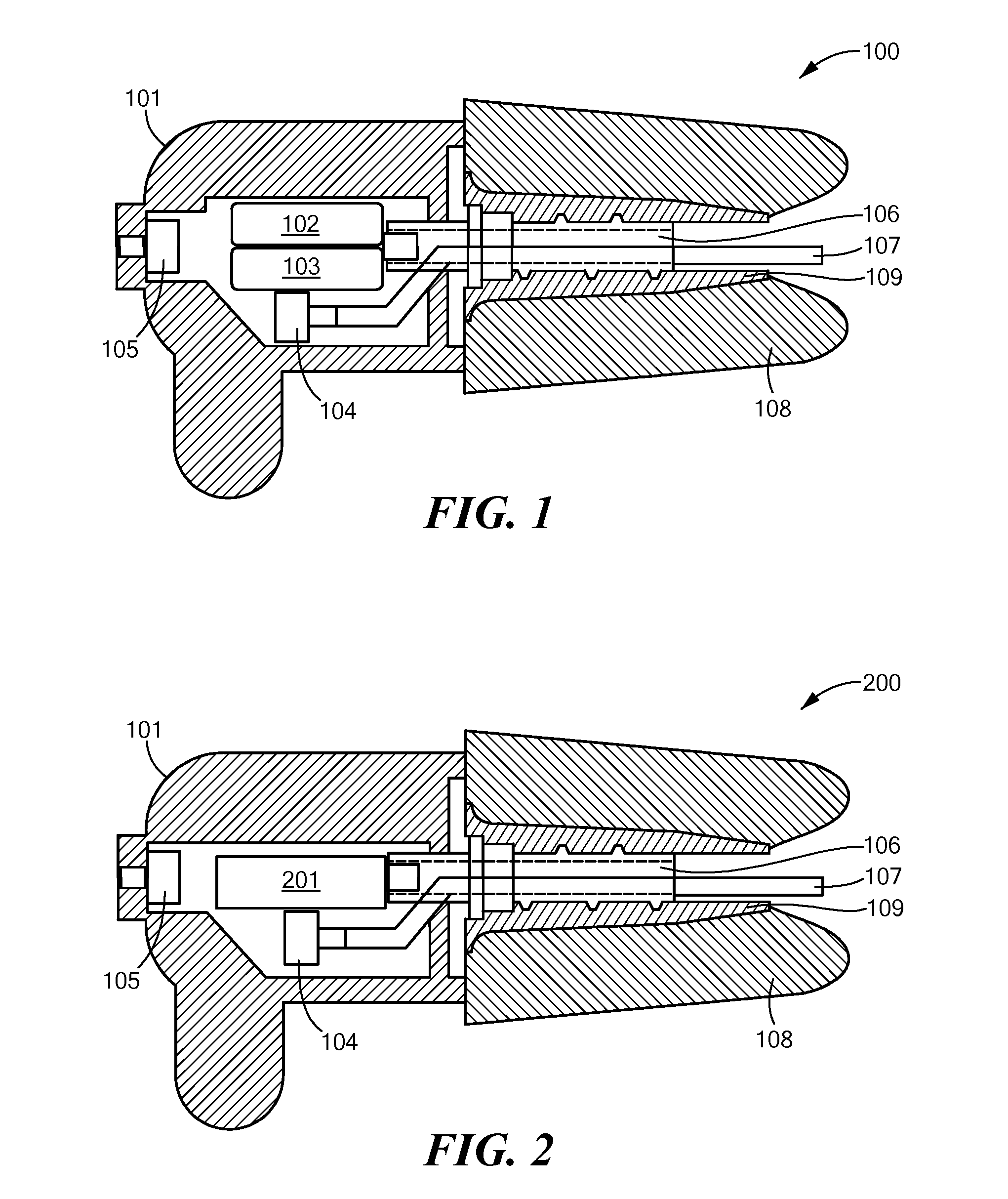

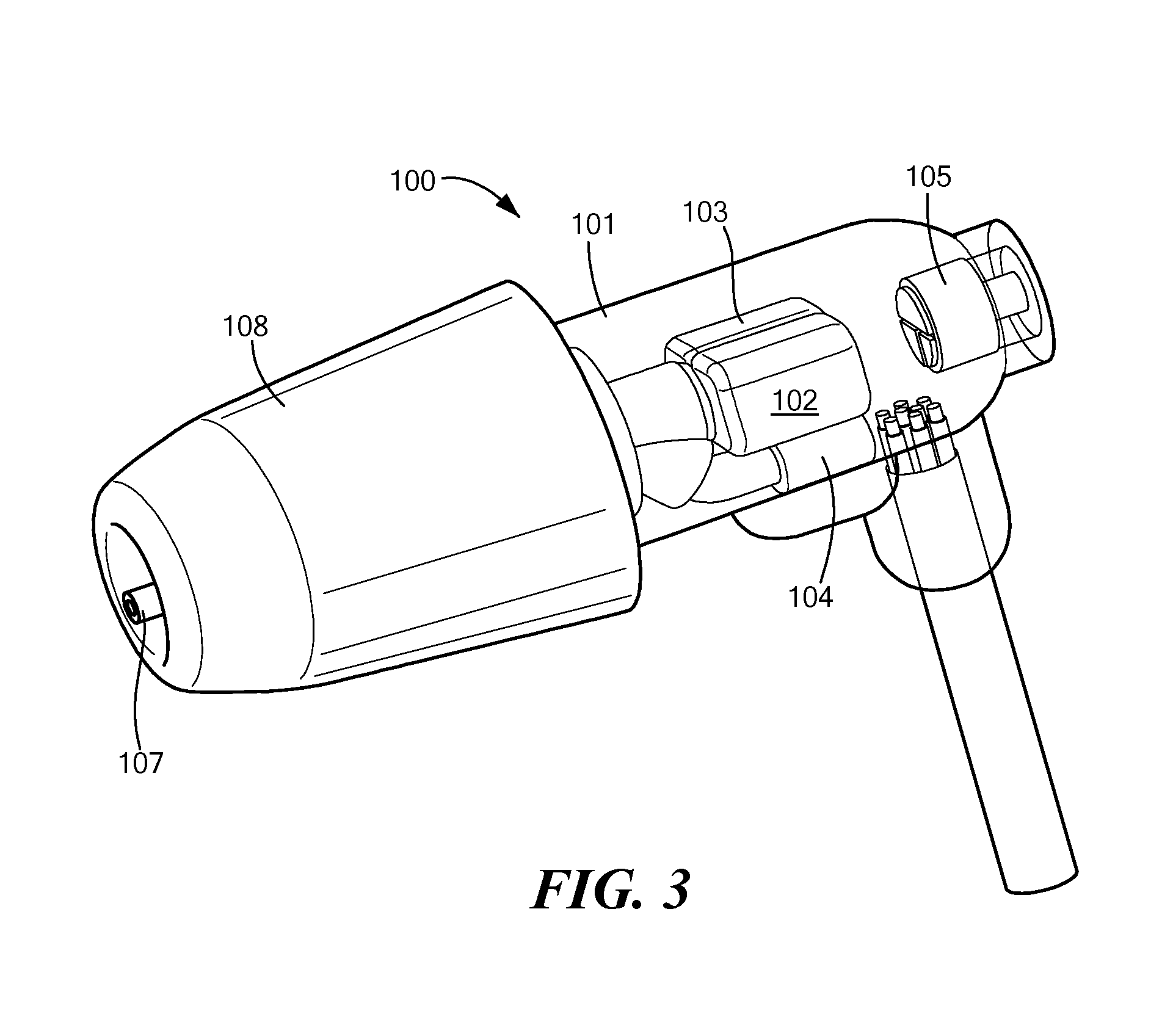

In-Ear Digital Electronic Noise Cancelling and Communication Device

ActiveUS20090080670A1Reduce external noiseEar treatmentHearing device active noise cancellationNoise reduction algorithmEngineering

A noise canceling and communication system is described. An in-ear device is adapted to fit in the ear canal of a device user. A passive noise reduction element reduces external noise entering the ear canal. An external microphone senses an external acoustic signal outside the ear canal to produce a representative external microphone signal. An internal microphone senses an internal acoustic signal proximal to the tympanic membrane to produce a representative internal microphone signal. One or more internal sound generators produce a noise cancellation signal and an acoustic communication signal, both directed towards the tympanic membrane. A probe tube shapes an acoustic response between the internal sound generator and the internal microphone to be relatively constant over a wide audio frequency band. An electronics module is located externally of the ear canal and in communication with the in-ear device for processing the microphone signals using a hybrid feed forward and feedback active noise reduction algorithm to produce the noise cancellation signal. The noise reduction algorithm includes a modeling component based on a transfer function associated with the internal sound generator and at least one of the microphones to automatically adjust the noise cancellation signal for fit and geometry of the ear canal of the user. The communication component also includes a modeling component based on a transfer function associated with the internal sound generator and at least one of the microphones to automatically adjust the communication signal for fit and geometry of the ear canal of the user and to assure that the communication signal does not interfere with the noise reduction algorithm and that the noise cancellation signal does not interfere with passing of the communication signal.

Owner:SOUND INNOVATIONS

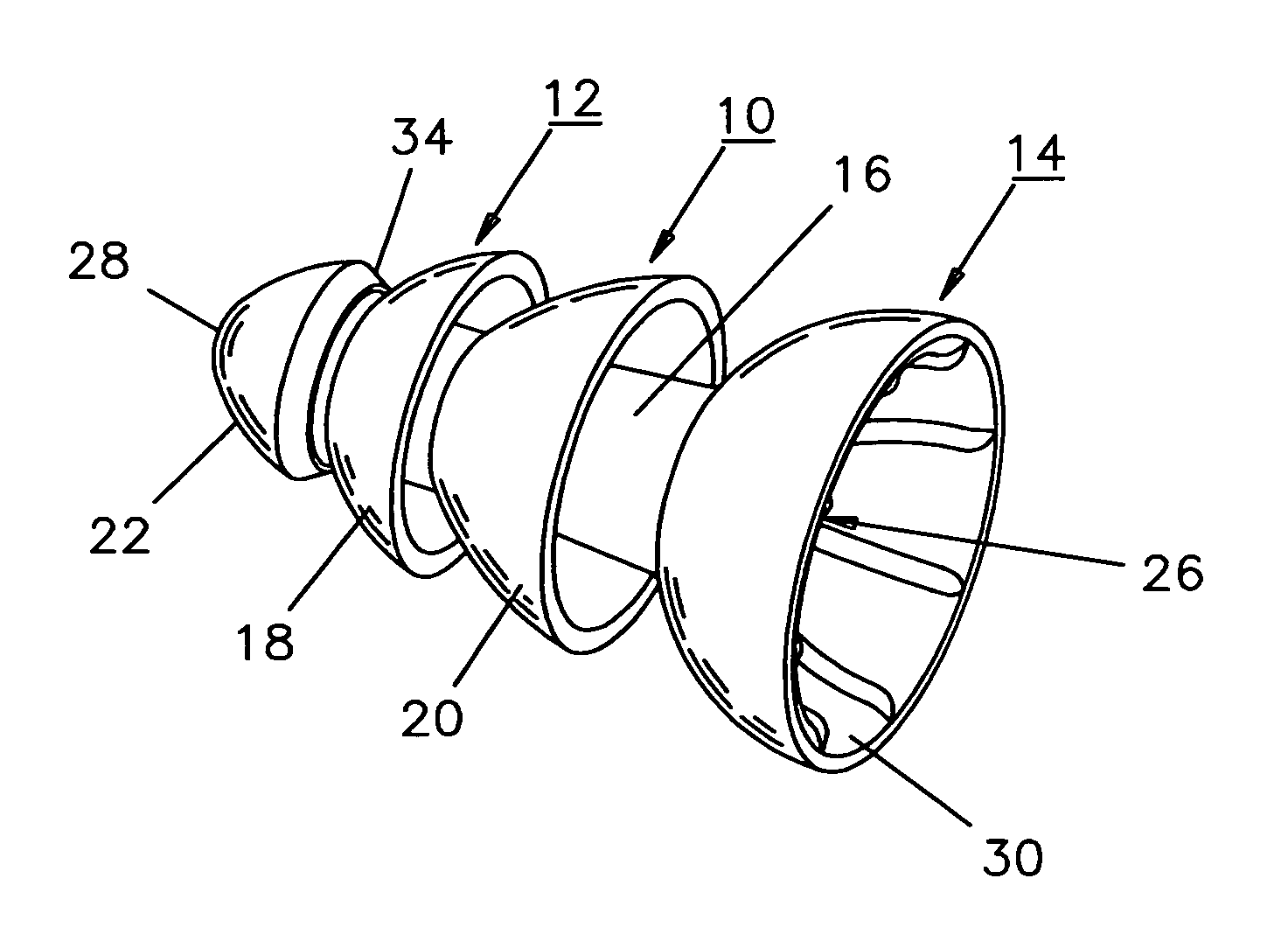

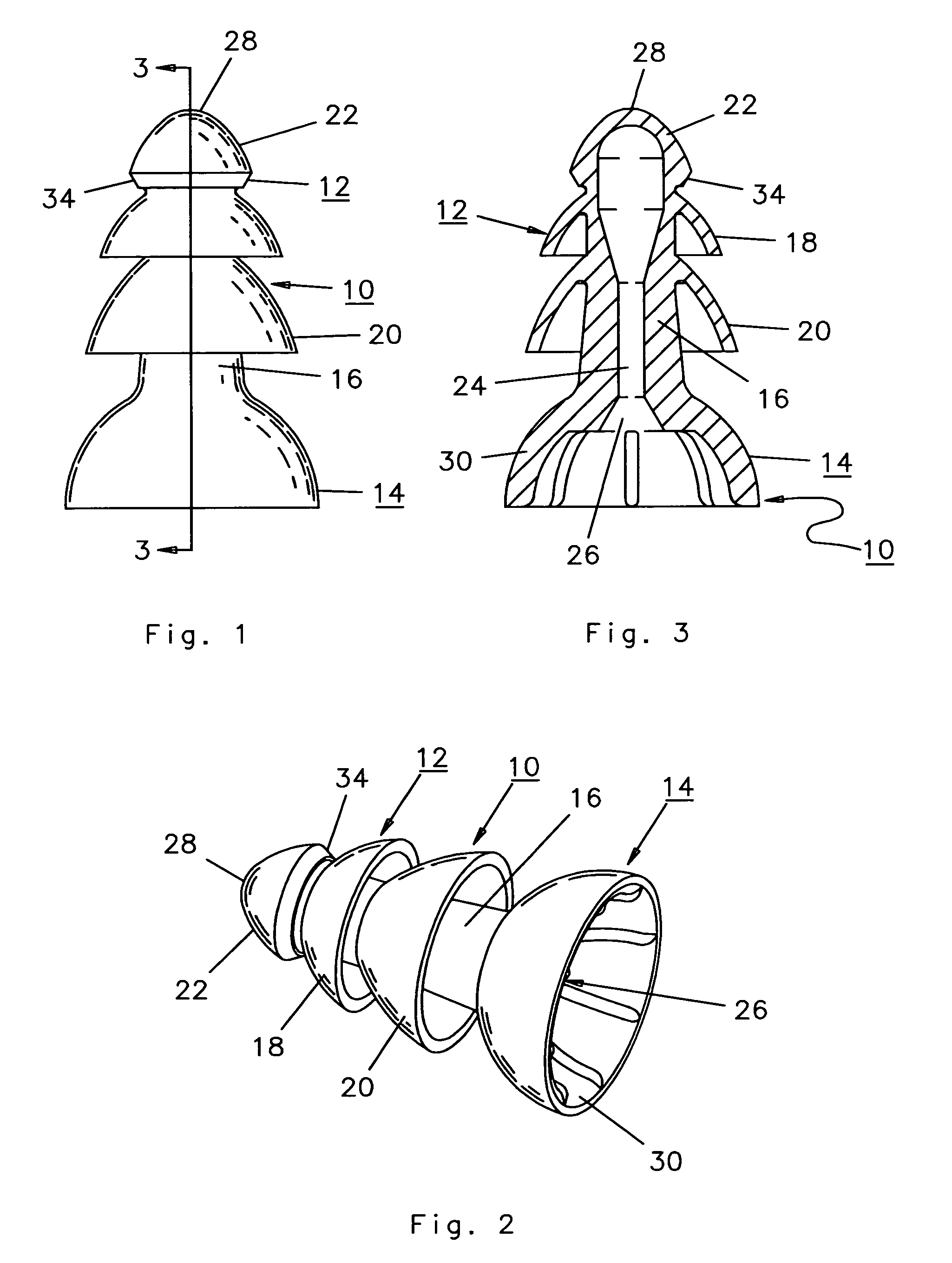

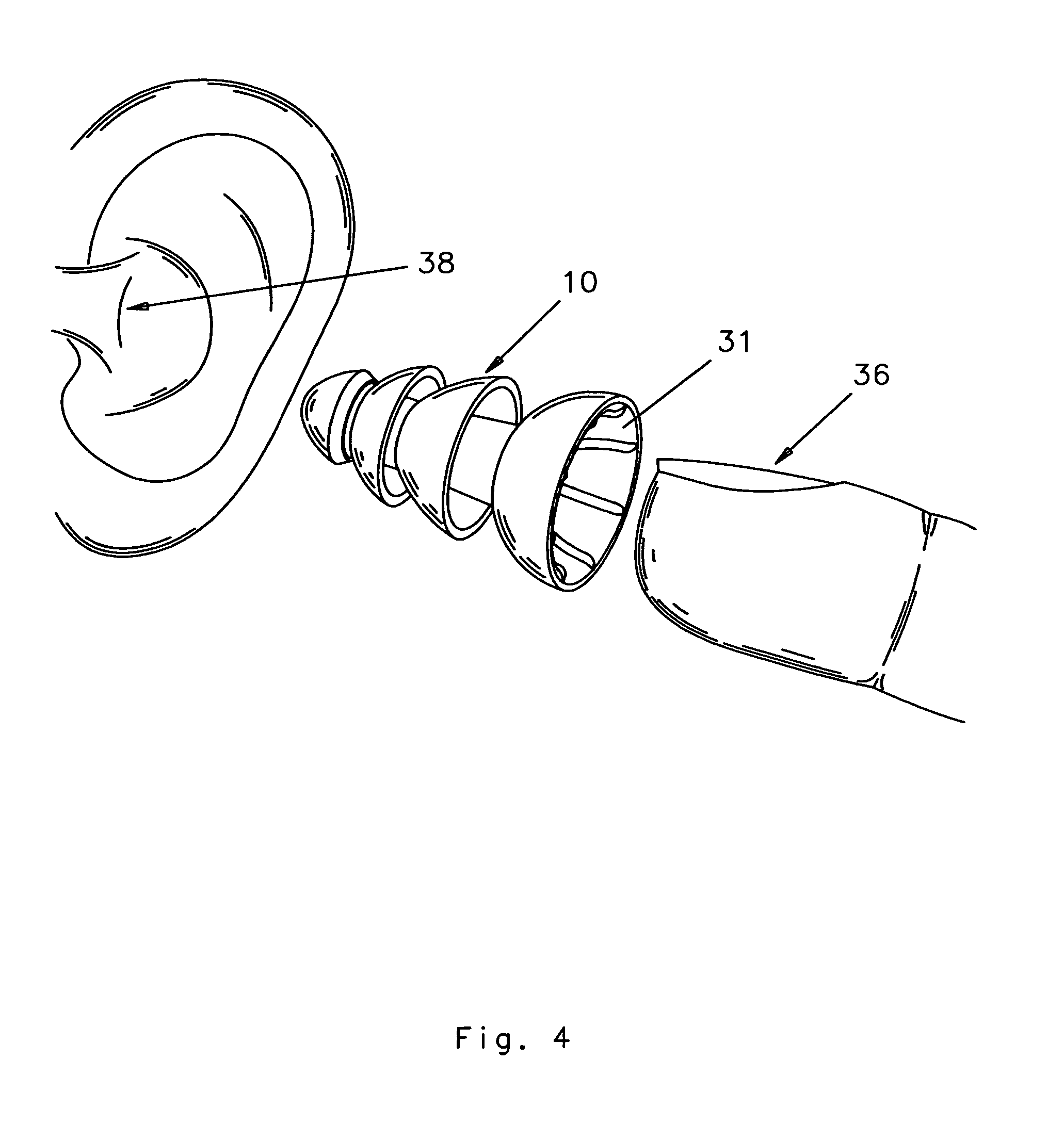

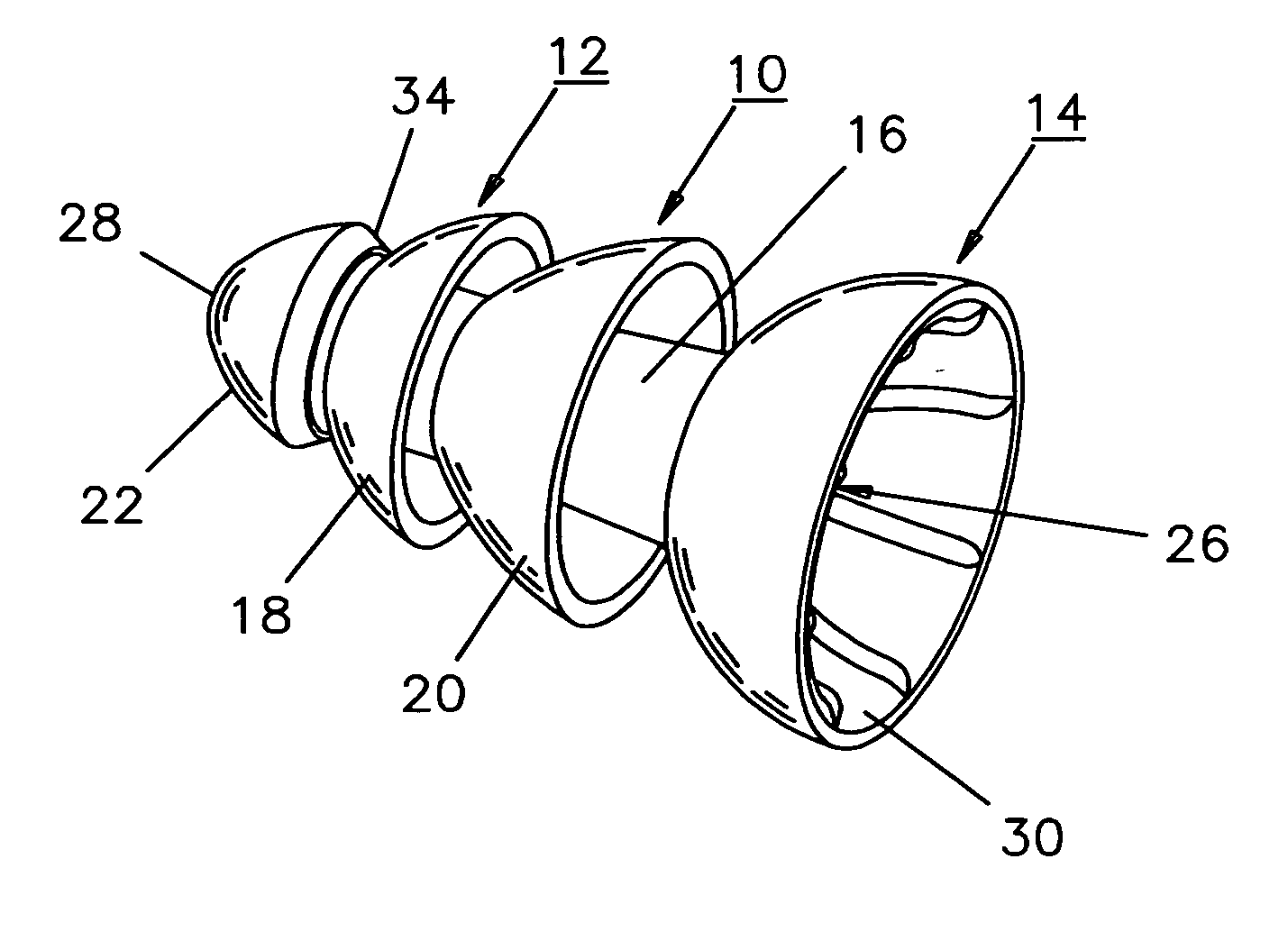

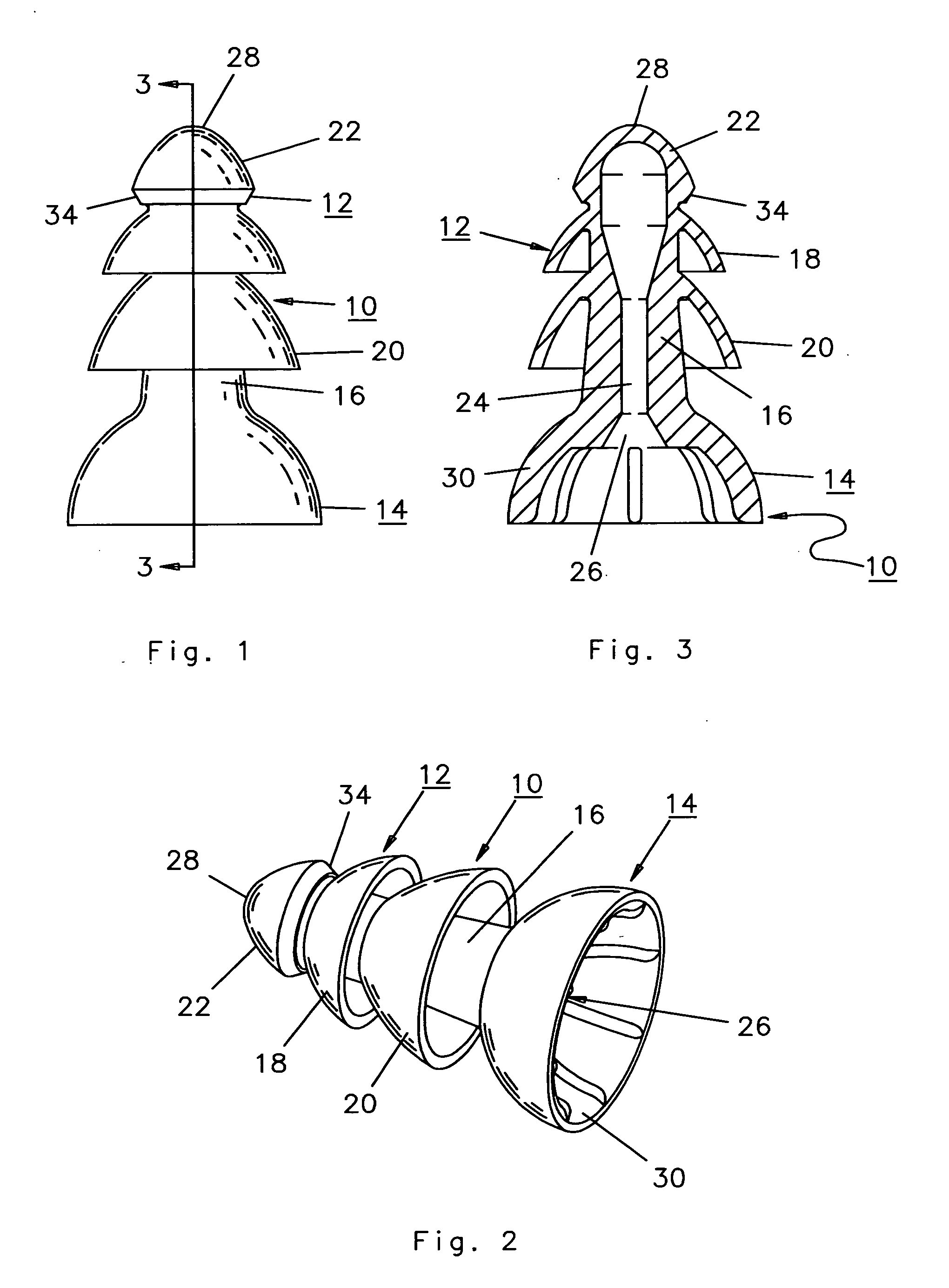

Earplug

ActiveUS7107993B2Inserted deeply and easily into the earReduce external noiseEar supported setsStethoscopeNoseCurve shape

An earplug composed of an injected molded resilient polymeric material for insertion into an ear canal by a fingertip of a user, including an elongated member having a nose portion formed as a curved front end. An open cup shaped rearward extending flange located at the end of the elongated member opposite to the nose portion and with the open cup shaped rearward extending flange configured to receive the fingertip of the user. The elongated member including at least one flange element located intermediate the nose portion and the open cup shape flange. The nose portion and the flange element having a generally curved shape to extend into and conform to the wall of the ear canal. The earplug composed of a resilient polymer material having a relatively low Shore A Durometer hardness value and the cup shape flange portion with the inserted fingertip of the user forming a handle of greater stiffness to enable the earplug with the relatively low Shore A Durometer hardness value to be more easily inserted into the ear canal.

Owner:MOLDEXMETRIC

In-ear digital electronic noise cancelling and communication device

ActiveUS8385560B2Reduce external noiseEar treatmentHearing device active noise cancellationNoise reduction algorithmEngineering

A noise canceling and communication system includes an in-ear device adapted to fit in the ear canal of a device user. A passive noise reduction element reduces external noise entering the ear canal. An external microphone senses an external acoustic signal outside the ear canal. An internal microphone senses an internal acoustic signal proximal to the tympanic membrane. One or more internal sound generators produce a noise cancellation signal and an acoustic communication signal, both directed towards the tympanic membrane. A probe tube shapes an acoustic response between the internal sound generator and the internal microphone to be relatively constant over a wide audio frequency band. An electronics module is located externally of the ear canal and in communication with the in-ear device for processing the microphone signals using a hybrid feed forward and feedback active noise reduction algorithm to produce the noise cancellation signal.

Owner:SOUND INNOVATIONS

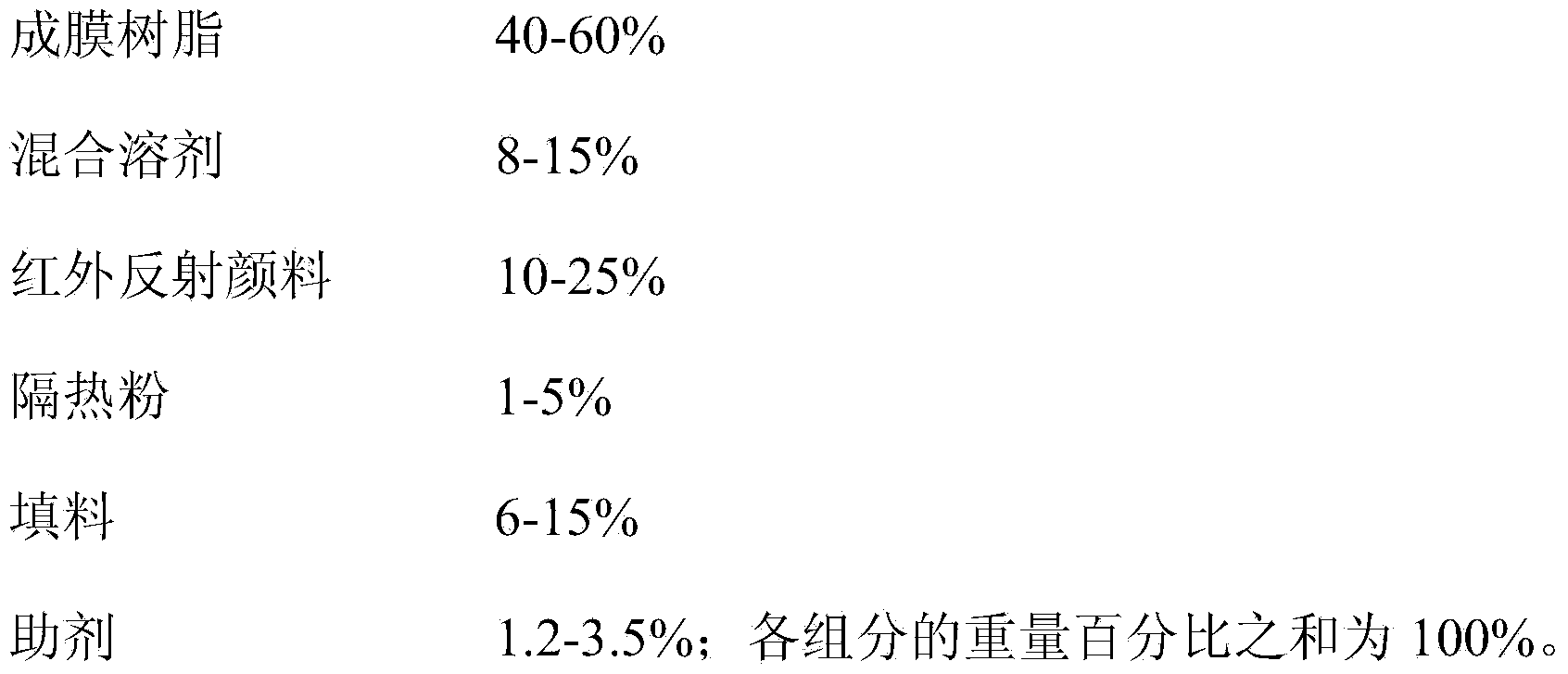

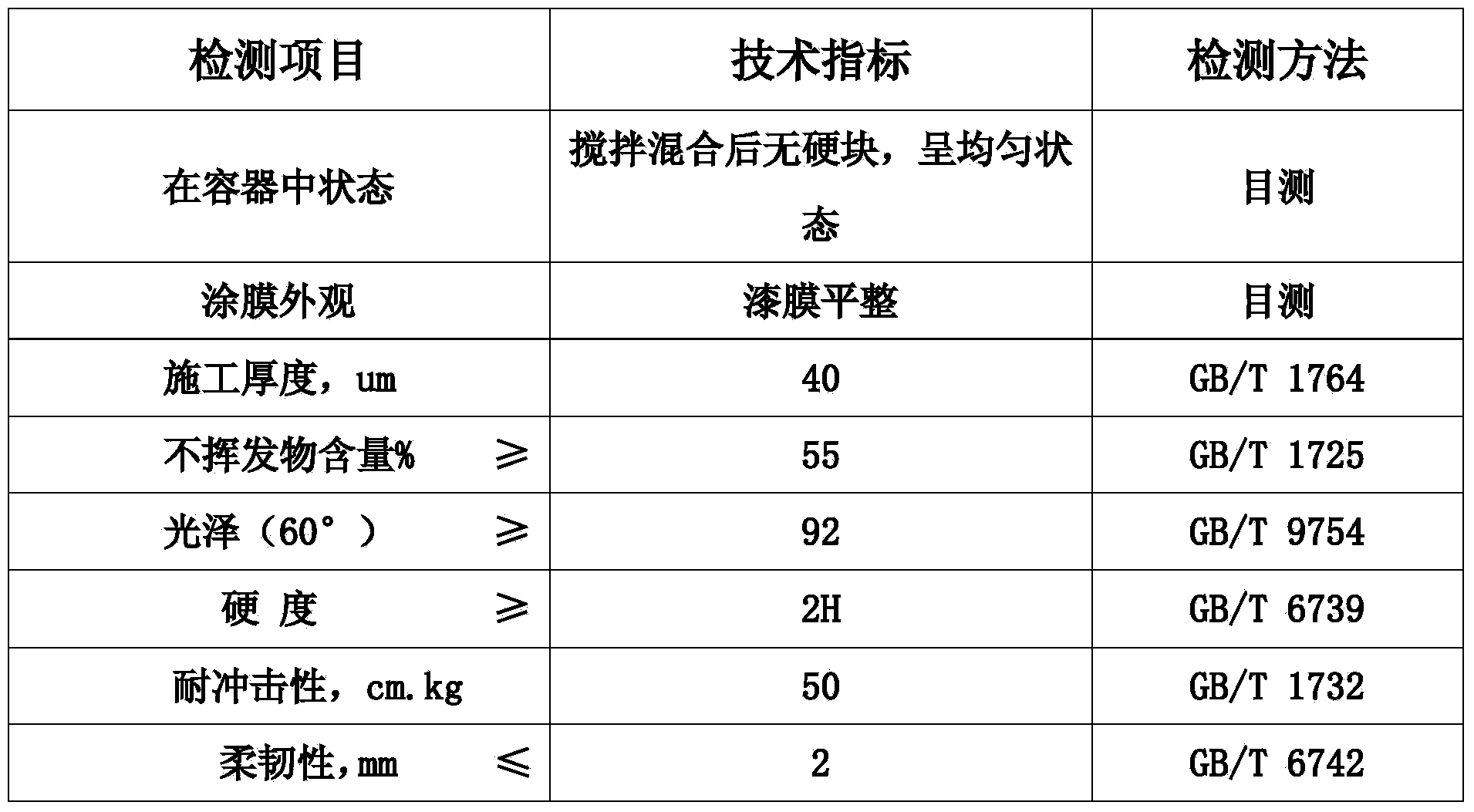

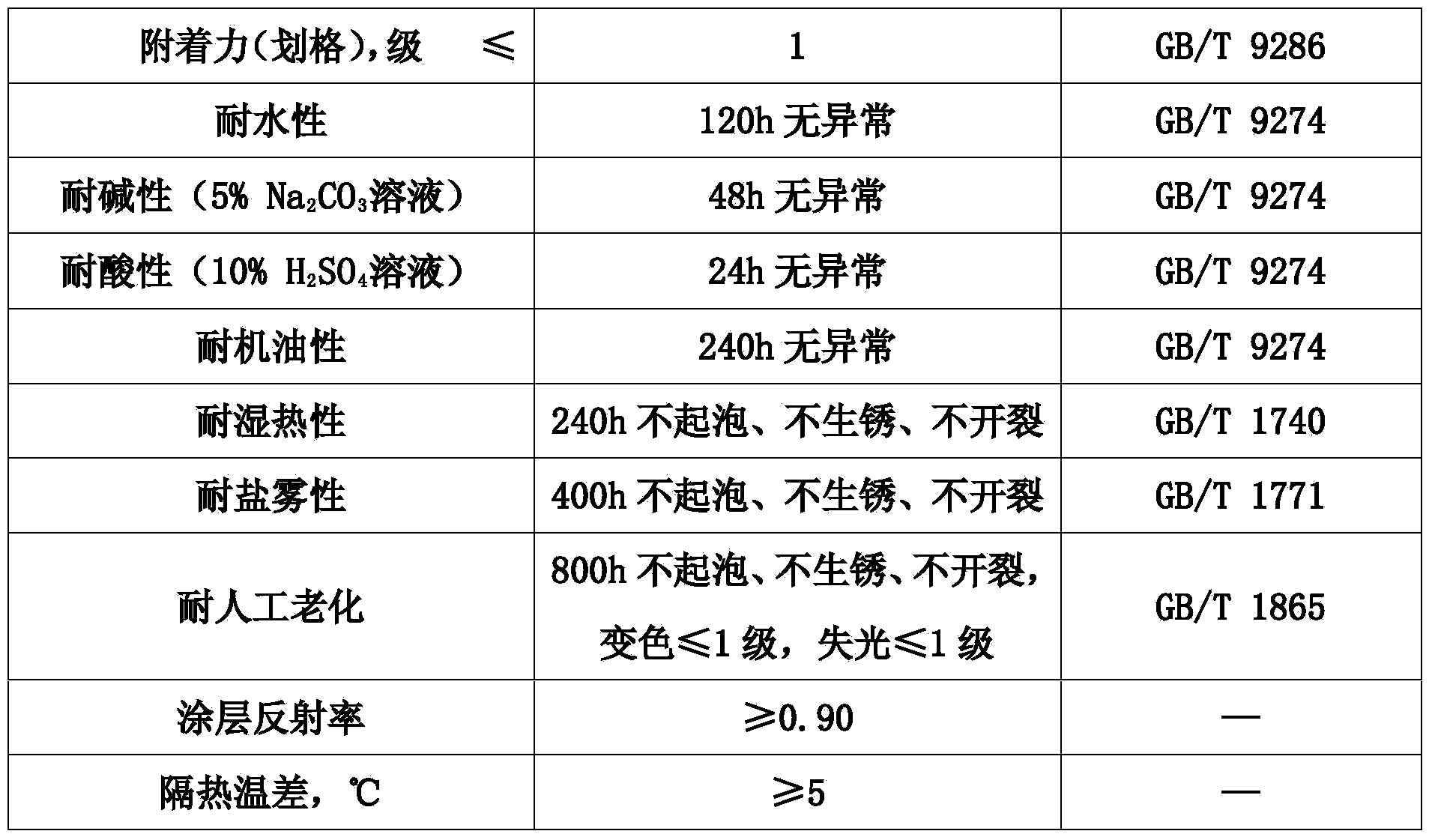

Heat reflective insulating stoving varnish coating and preparation method thereof

ActiveCN104109438AHigh strengthImprove impact resistancePolyester coatingsReflecting/signal paintsAcrylic resinSolvent

The invention discloses a heat reflective insulating stoving varnish coating and a preparation method thereof. The stoving varnish coating comprises the following components in percentage by weight: 40-60% of a film-forming resin, 8-15% of a mixed solvent, 10-25% of an infrared reflective pigment, 1-5% of insulating powder, 6-15% of filler and 1.2-3.5% of an auxiliary, totaling 100%, wherein the film-forming resin comprises a mixture of thermosetting acrylic resin, acrylic resin and amino resin. As the film-forming resin contains the above three main resins, the stoving varnish coating has good weather ability, mechanical property and chemical resistance. As the infrared reflective pigment and heat insulating powder are added into the raw material, the coating is high in reflection efficiency of sunlight and good in insulating effect.

Owner:ZHANG ZHOU SAN PAINTS

Earplug

ActiveUS20060102418A1Reduce external noiseInserted deeply and easily into the earEar supported setsStethoscopeCurve shapeNose

An earplug composed of an injected molded resilient polymeric material for insertion into an ear canal by a fingertip of a user, including an elongated member having a nose portion formed as a curved front end. An open cup shaped rearward extending flange located at the end of the elongated member opposite to the nose portion and with the open cup shaped rearward extending flange configured to receive the fingertip of the user. The elongated member including at least one flange element located intermediate the nose portion and the open cup shape flange. The nose portion and the flange element having a generally curved shape to extend into and conform to the wall of the ear canal. The earplug composed of a resilient polymer material having a relatively low Shore A Durometer hardness value and the cup shape flange portion with the inserted fingertip of the user forming a handle of greater stiffness to enable the earplug with the relatively low Shore A Durometer hardness value to be more easily inserted into the ear canal.

Owner:MOLDEXMETRIC

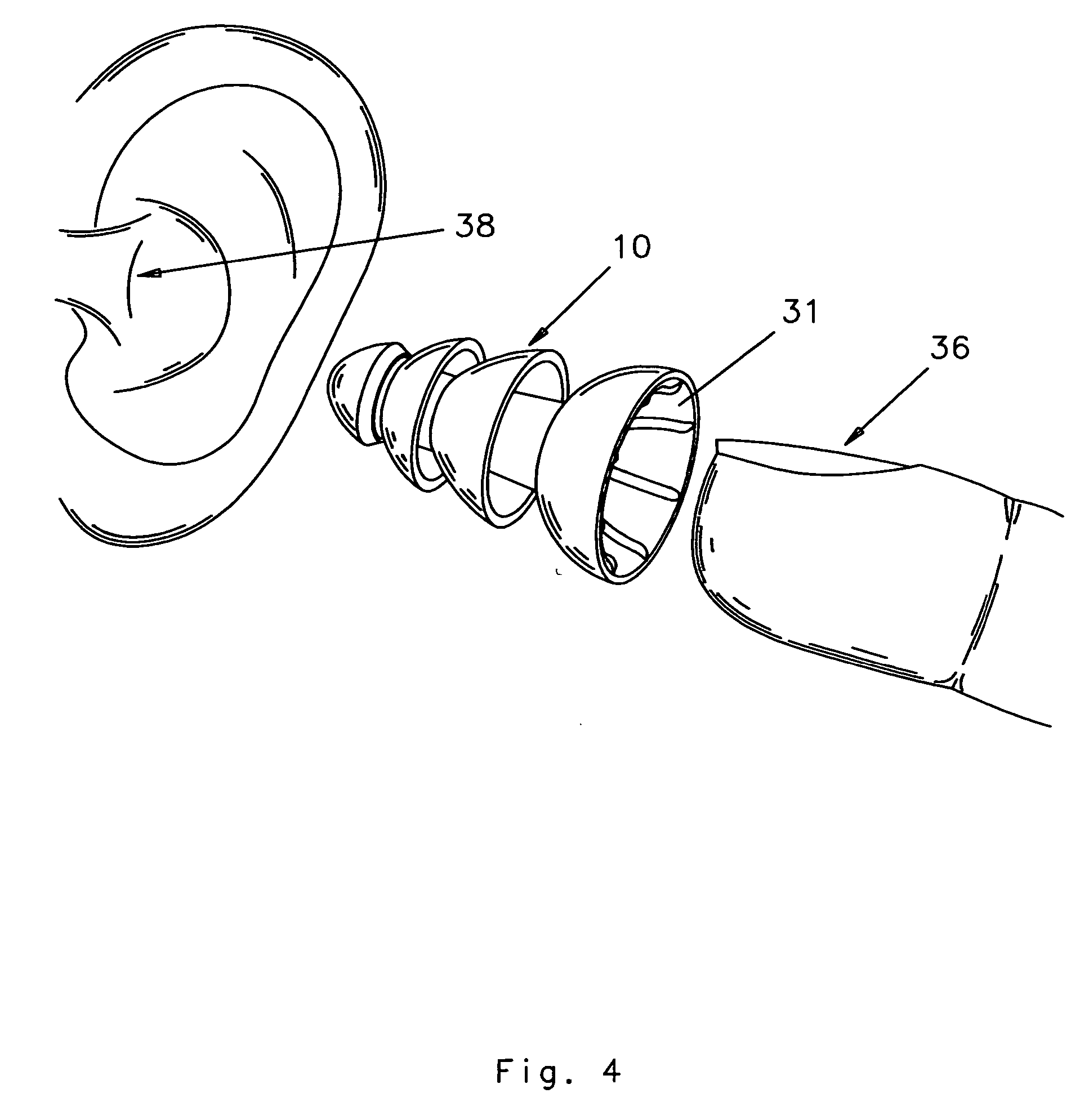

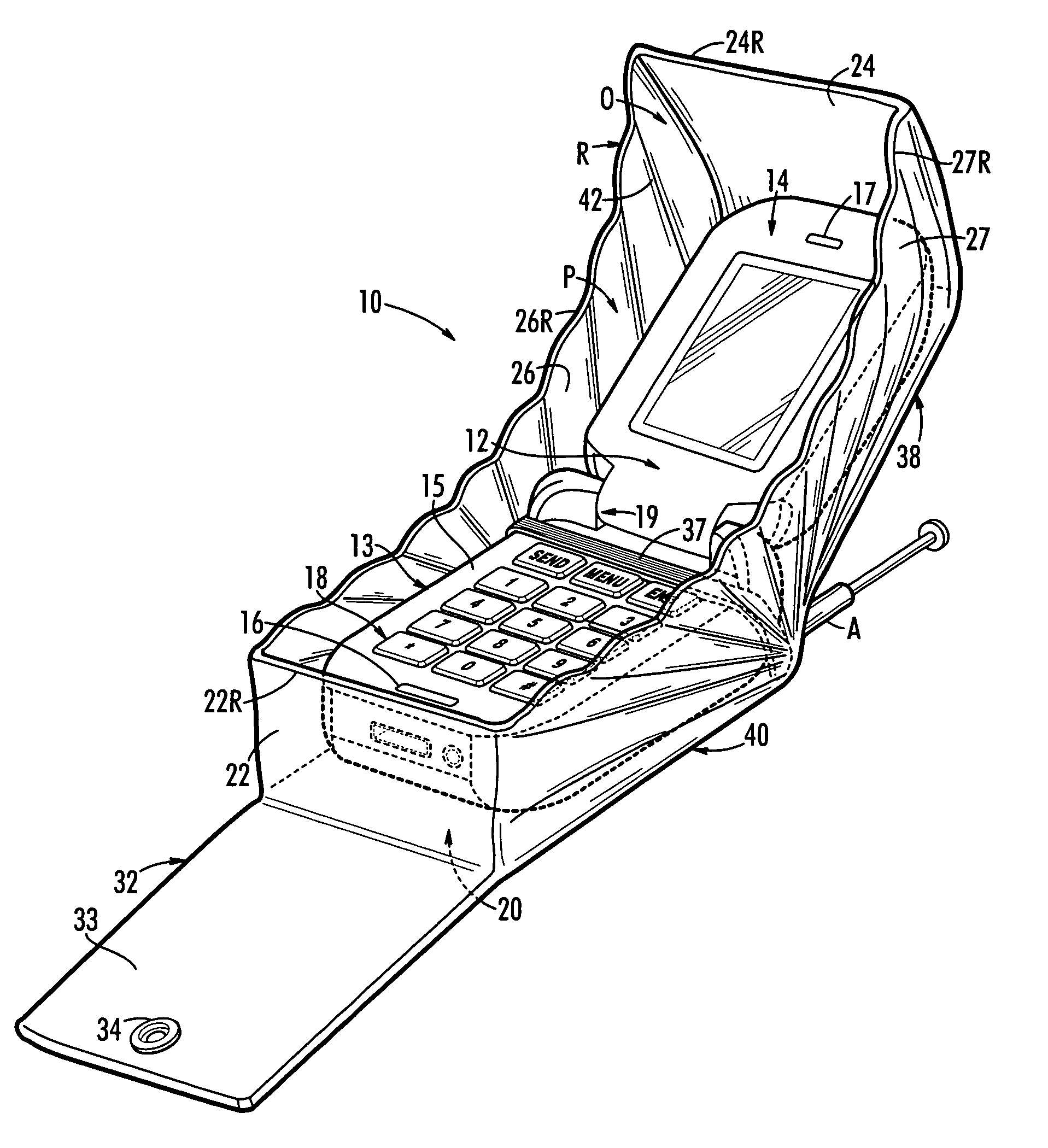

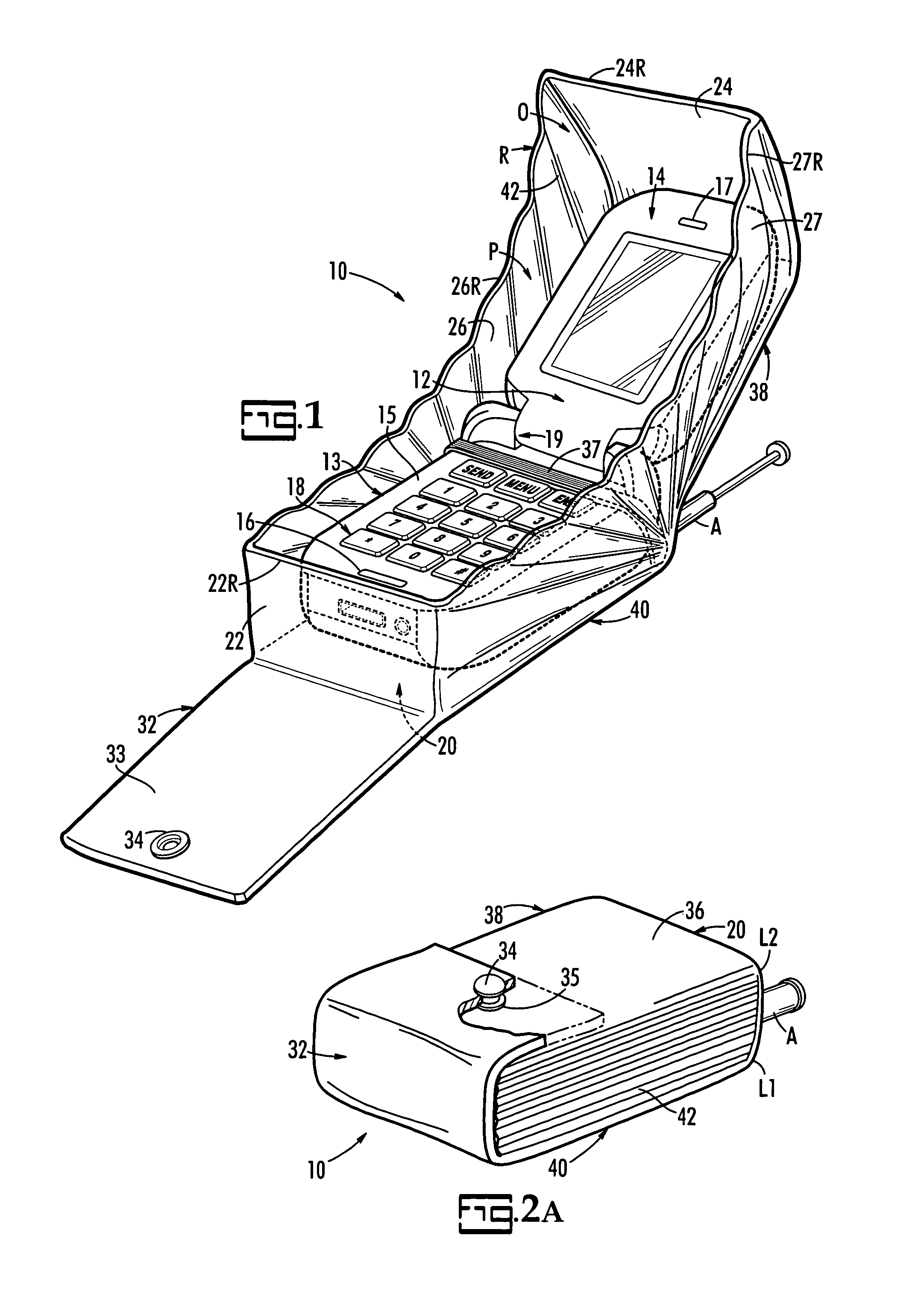

Privacy case for telephones

InactiveUS7515708B1Substantial sealEasy to foldInterconnection arrangementsTelephone set constructionsCurve shapeEngineering

A phone case having a bottom wall, opposing side walls, and mouth and ear end walls that form a pocket with an opening having a rim for extending from ear to mouth and around the mouth to hide it from view and to muffle and block beyond the case words spoken into a phone nested therein. A sidewall portion of the rim may have a curved shape conforming generally to the contour of a human face from ear to mouth, and the pocket walls may be made of a flexible, sound absorbing material so that the rim of the opening is sufficiently deformable to conform substantially to the ear to mouth contour and form a sound seal when pressed against a human face. The ear end wall may form an ear portion of the rim for placement over an ear lobe to reduce interfering external noise.

Owner:TURKEWITZ ROBERT M

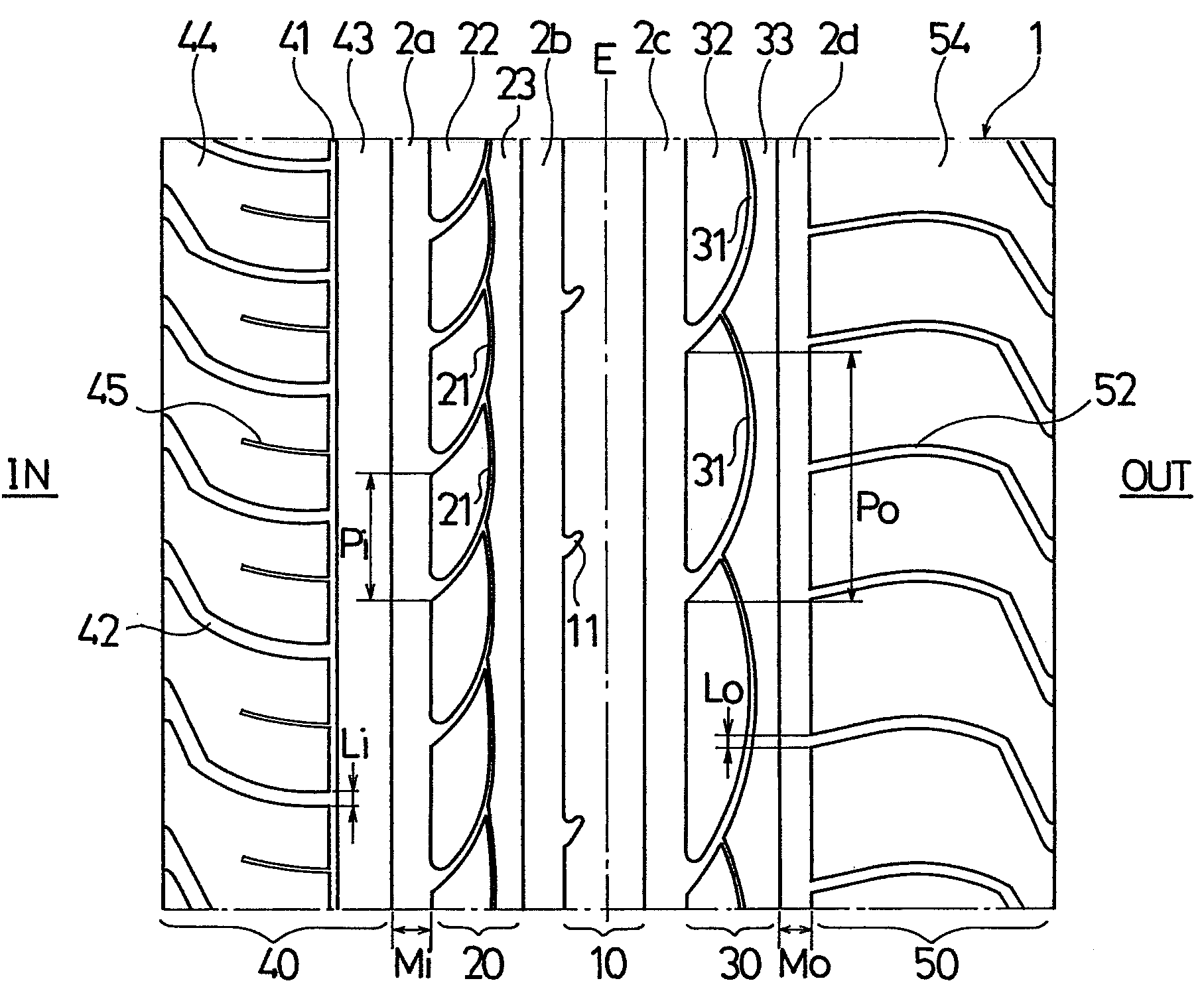

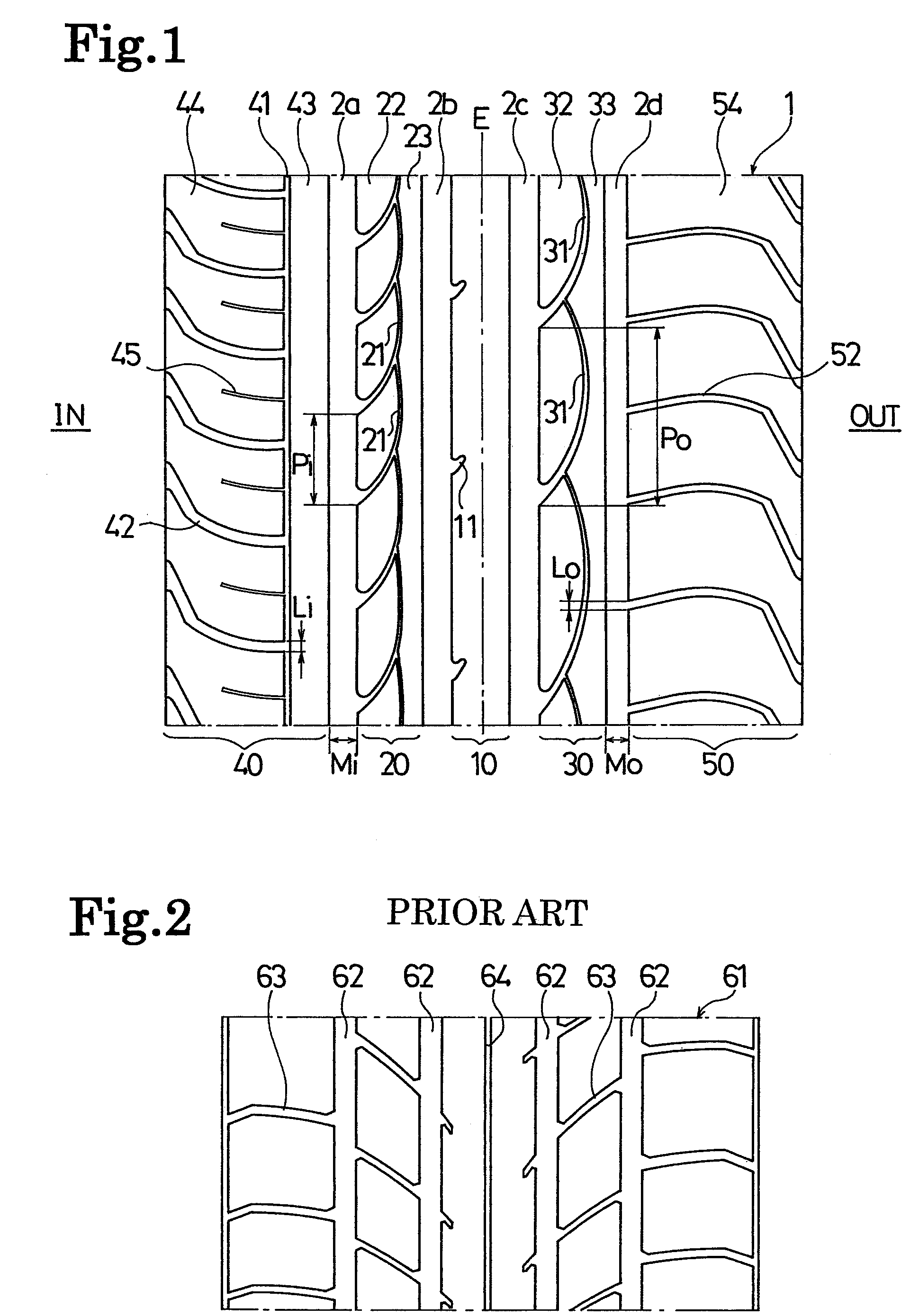

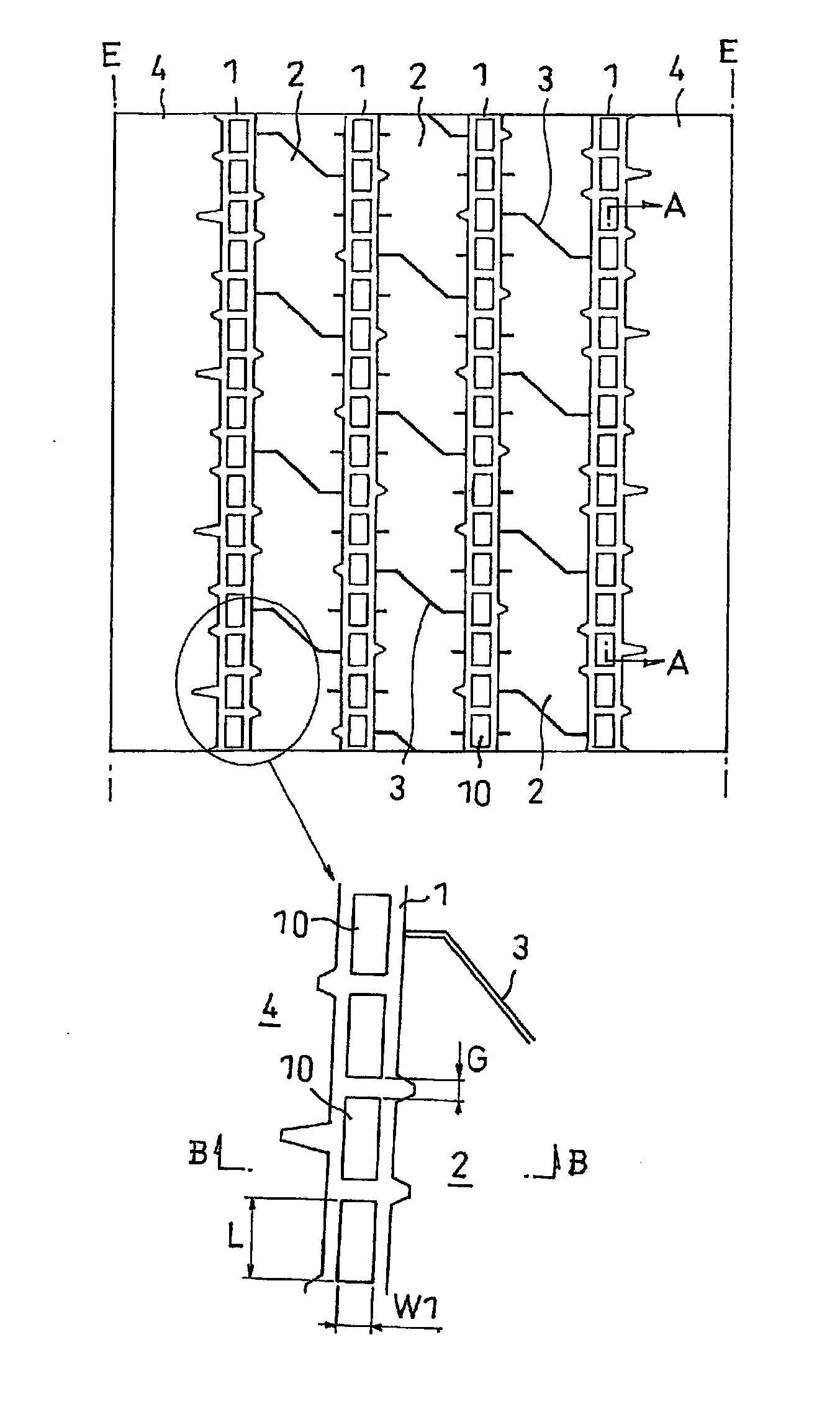

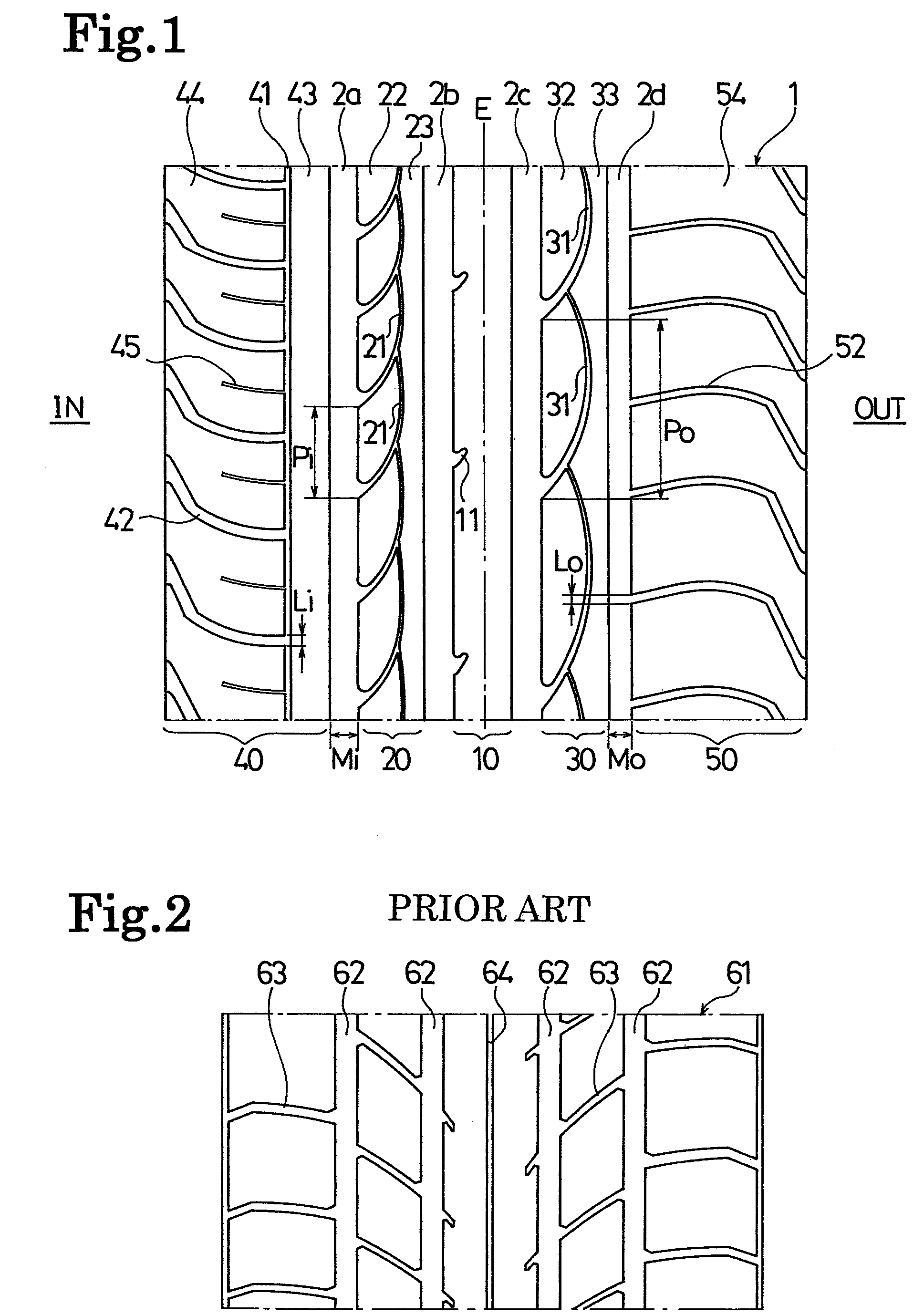

Pneumatic tire

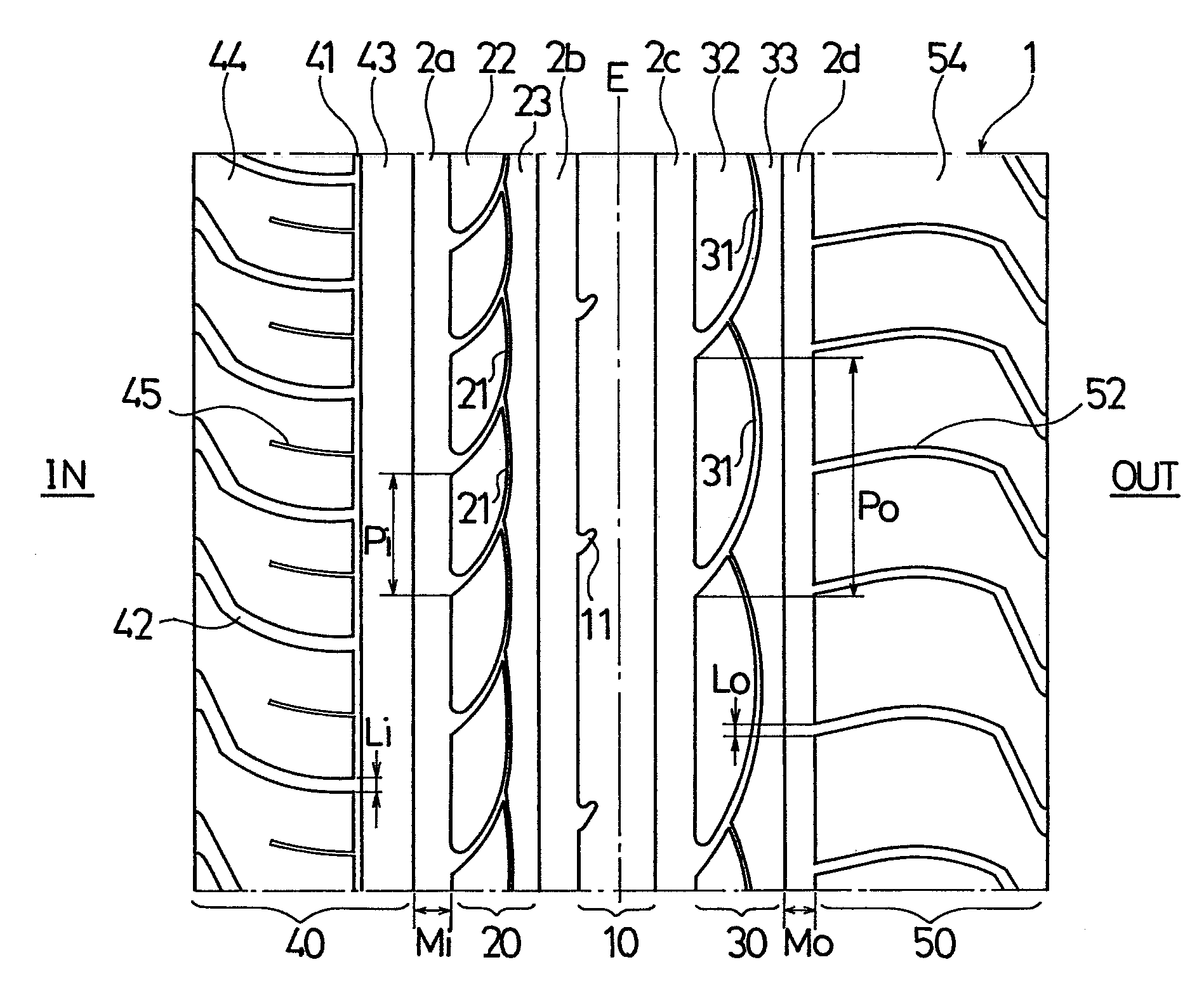

ActiveUS20090178745A1Improve wettabilityReduce external noiseTyre tread bands/patternsNon-skid devicesIn vehicleEngineering

Provided is a pneumatic tire in which improvement is achieved in a wet performance and reduction in vehicle exterior noise while ensuring a dry performance. The pneumatic tire has a designated fitting direction relative to a vehicle, in which four main grooves extending in a circumferential direction of the tire are provided on a tread portion, two grooves out of these main grooves are located on each of both sides of a tire equator, five lines of land portions are defined by the main grooves, a center land portion located on the tire equator is a rib which continuously extends in the circumferential direction of the tire without being sectioned, a plurality of arcuate grooves each extending in an arc shape are provided on each of a pair of second land sections located respectively on both sides of the center land section, an end of each of the arcuate grooves is connected to the main groove on an inner side of the vehicle, another end of the arcuate groove is connected to the adjacent arcuate groove, a repeat pitch Po of the arcuate grooves on the second land portion located on an outer side of the vehicle is set greater than a repeat pitch Pi of the arcuate grooves on the second land portion located on the inner side of the vehicle, and a proportion Po / Pi of the pitches is set in a range from 1.5 to 3.0.

Owner:THE YOKOHAMA RUBBER CO LTD

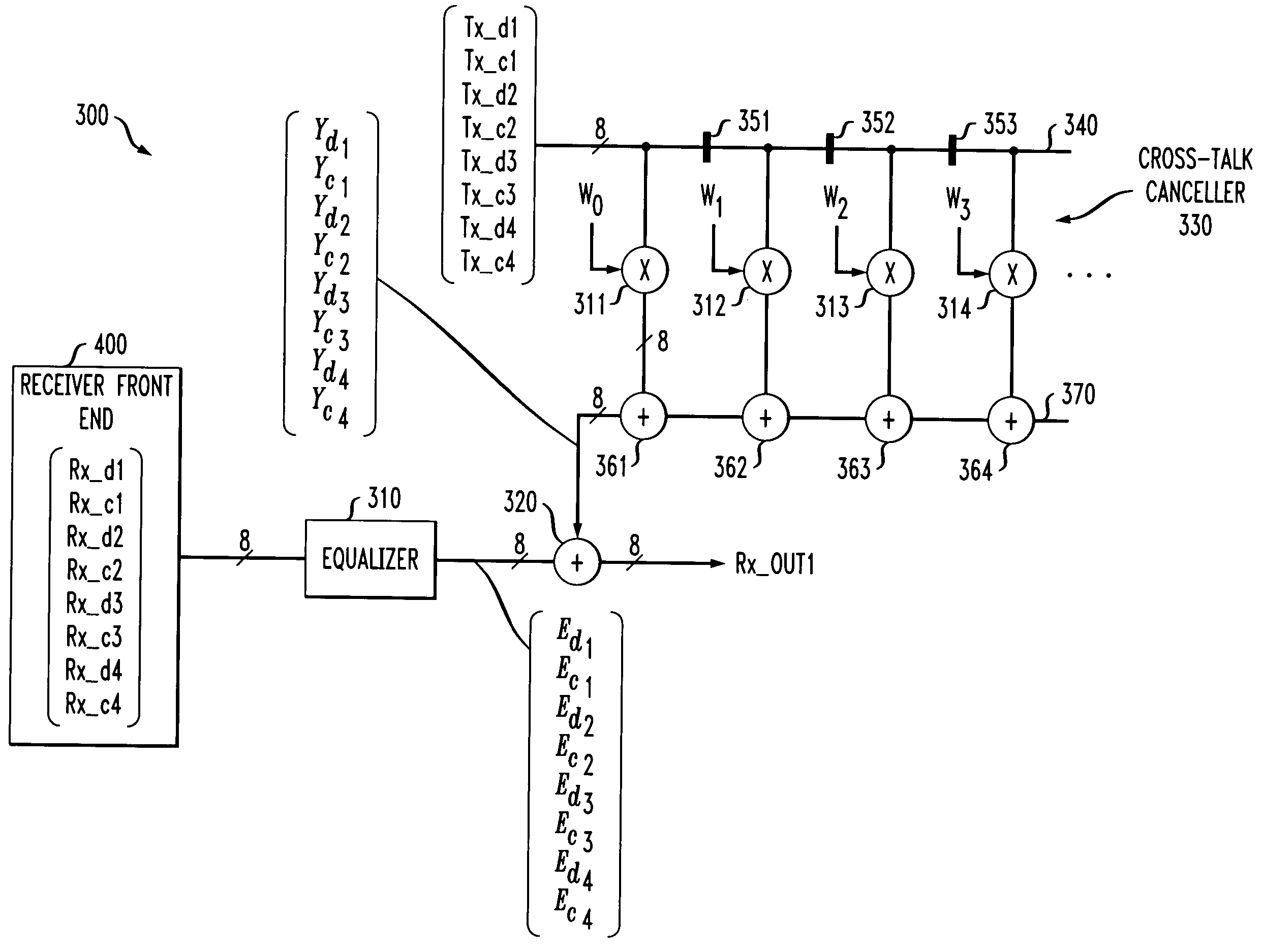

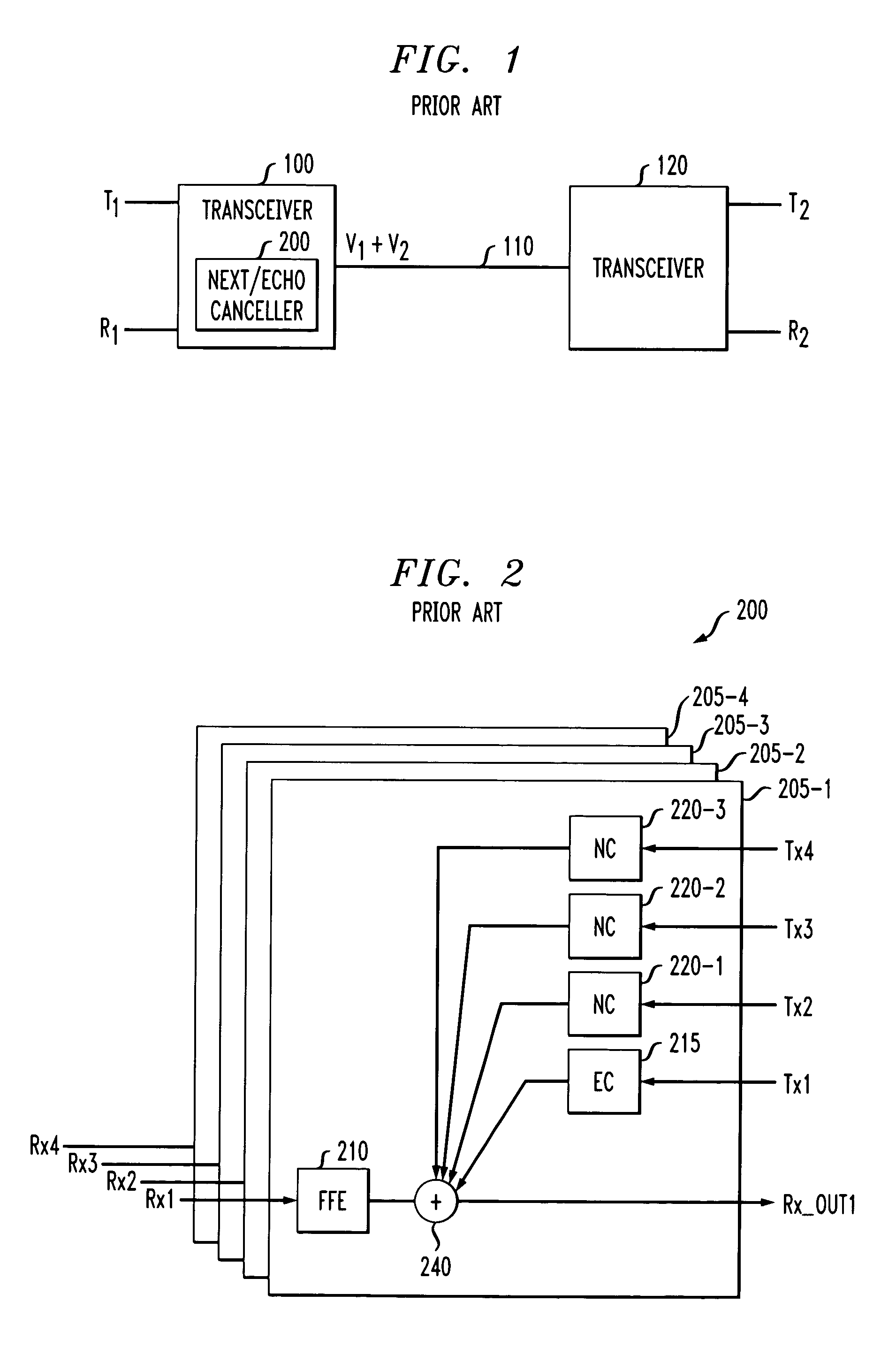

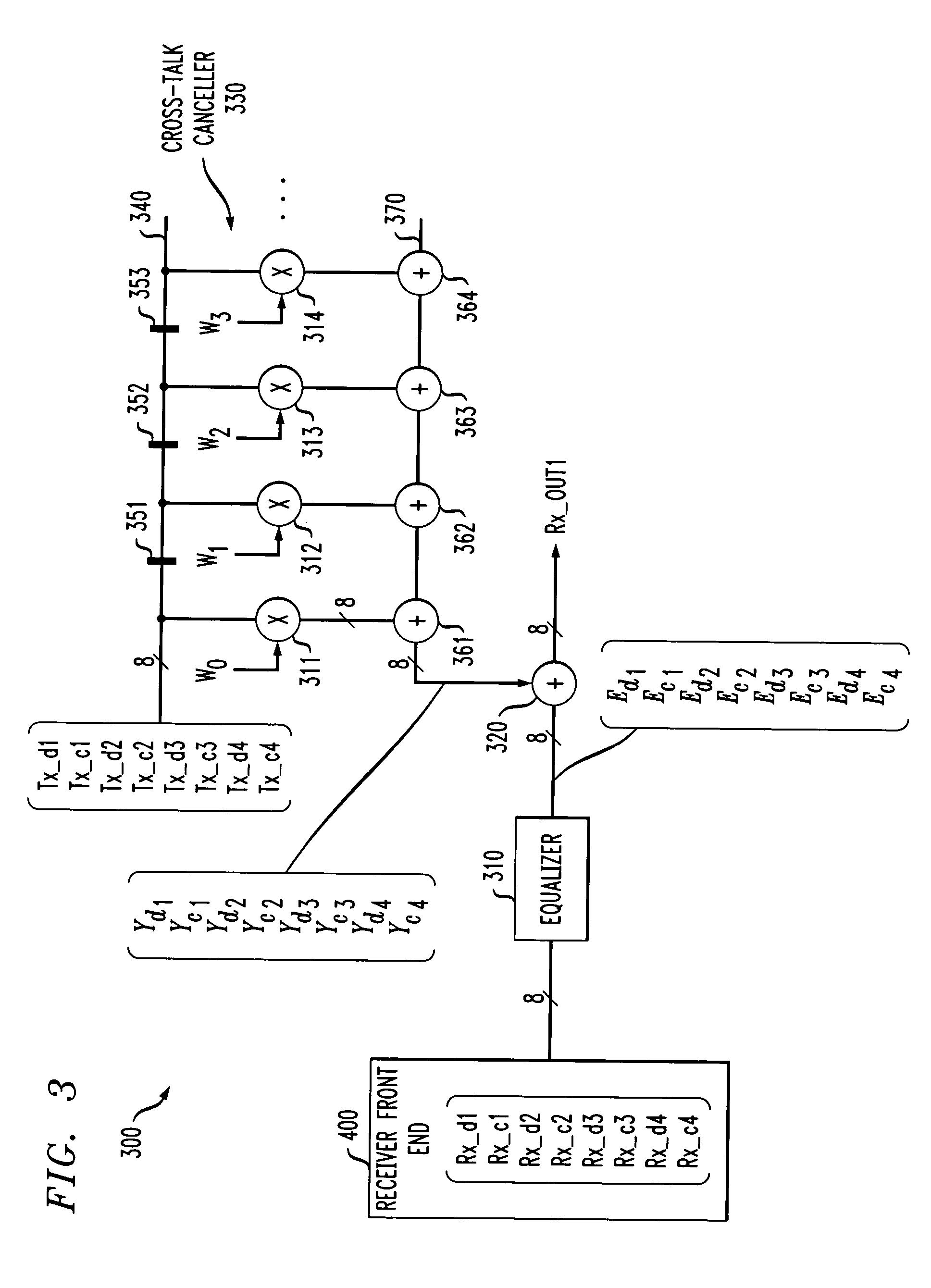

Method and apparatus for reducing noise in an unbalanced channel using common mode component

ActiveUS20050018777A1Reduce noiseReduce the impactMultiple-port networksError preventionFinite impulse responseProximal point

A method and apparatus are disclosed for reducing noise, such as external noise, cross-talk and echo, in an unbalanced channel. A cross-talk canceller is disclosed that uses a multi-dimensional finite impulse response filter to process both the differential, d, and common-mode, c, components of a received signal. Recovery of the differential mode component of the received signal is improved by reducing the contribution of the common mode component. The common mode component of a received signal may be expressed, for example, as the average of two voltages or two current signals. The differential and common mode components of the received signal are equalized. The disclosed multi-dimensional cross-talk canceller reduces external noise; near-end crosstalk resulting from differential and common mode components on one twisted pair interfering with another twisted pair; and echo crosstalk resulting from differential and common mode cross-talk components on the same twisted pair.

Owner:AVAGO TECH INT SALES PTE LTD

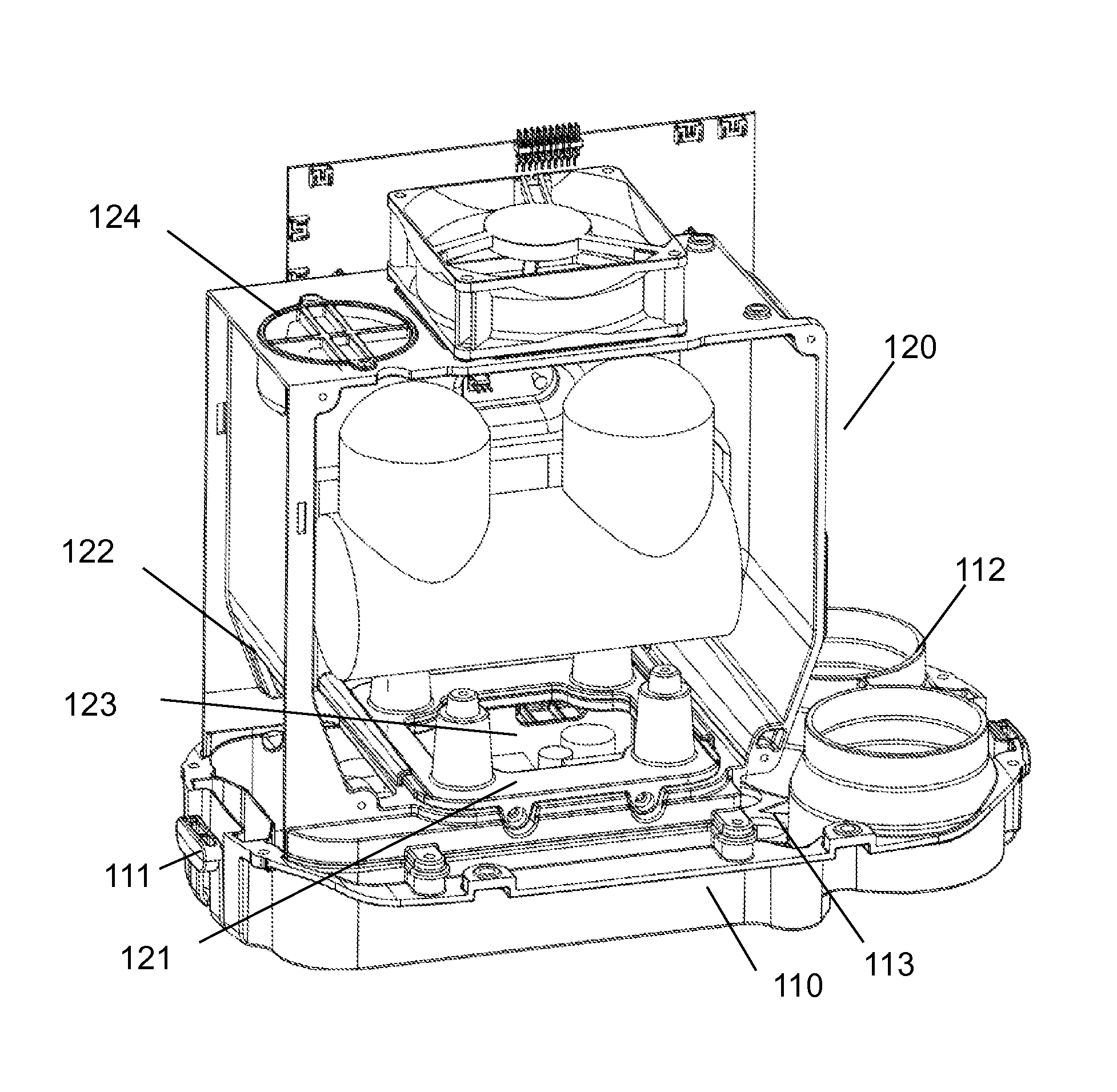

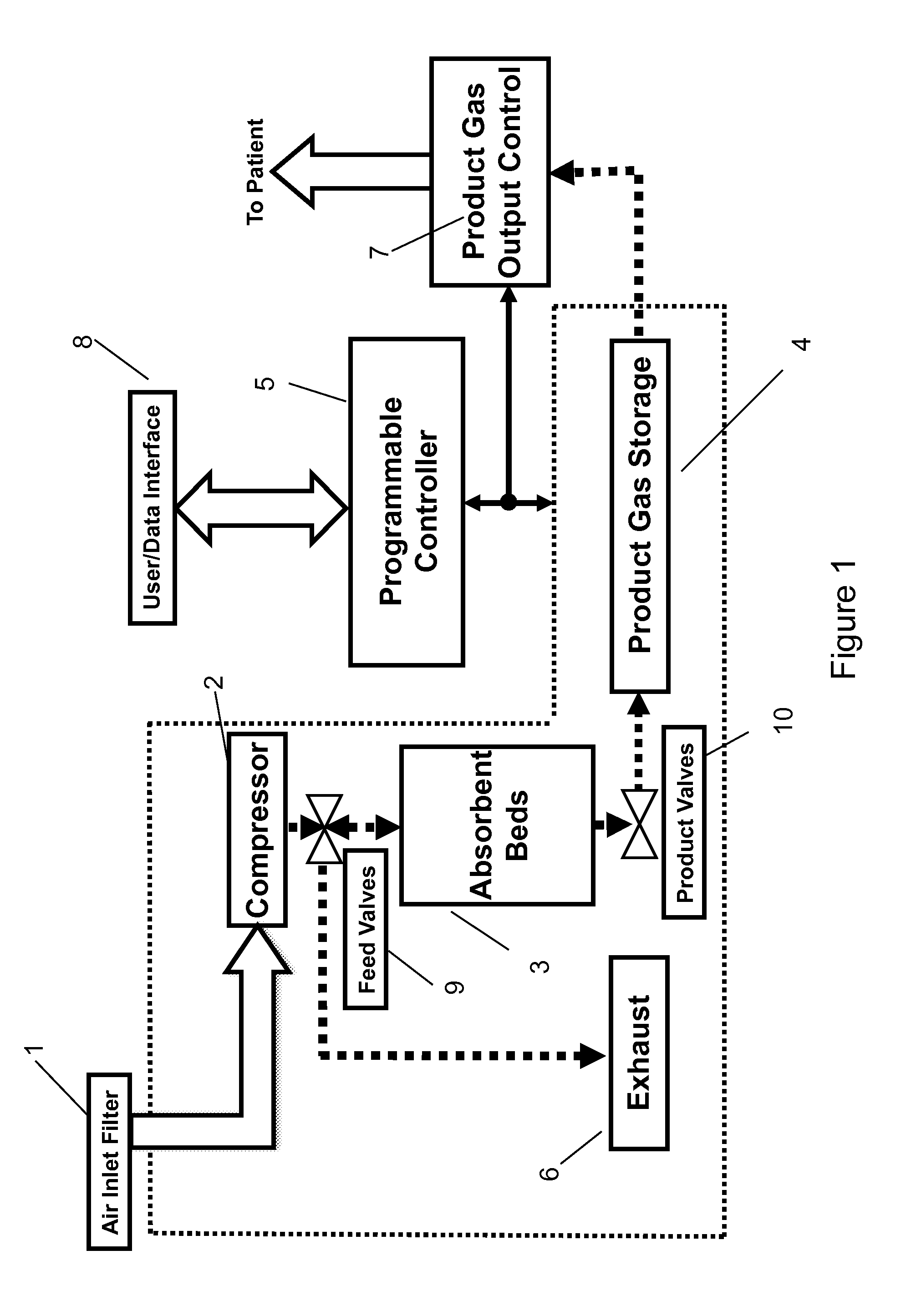

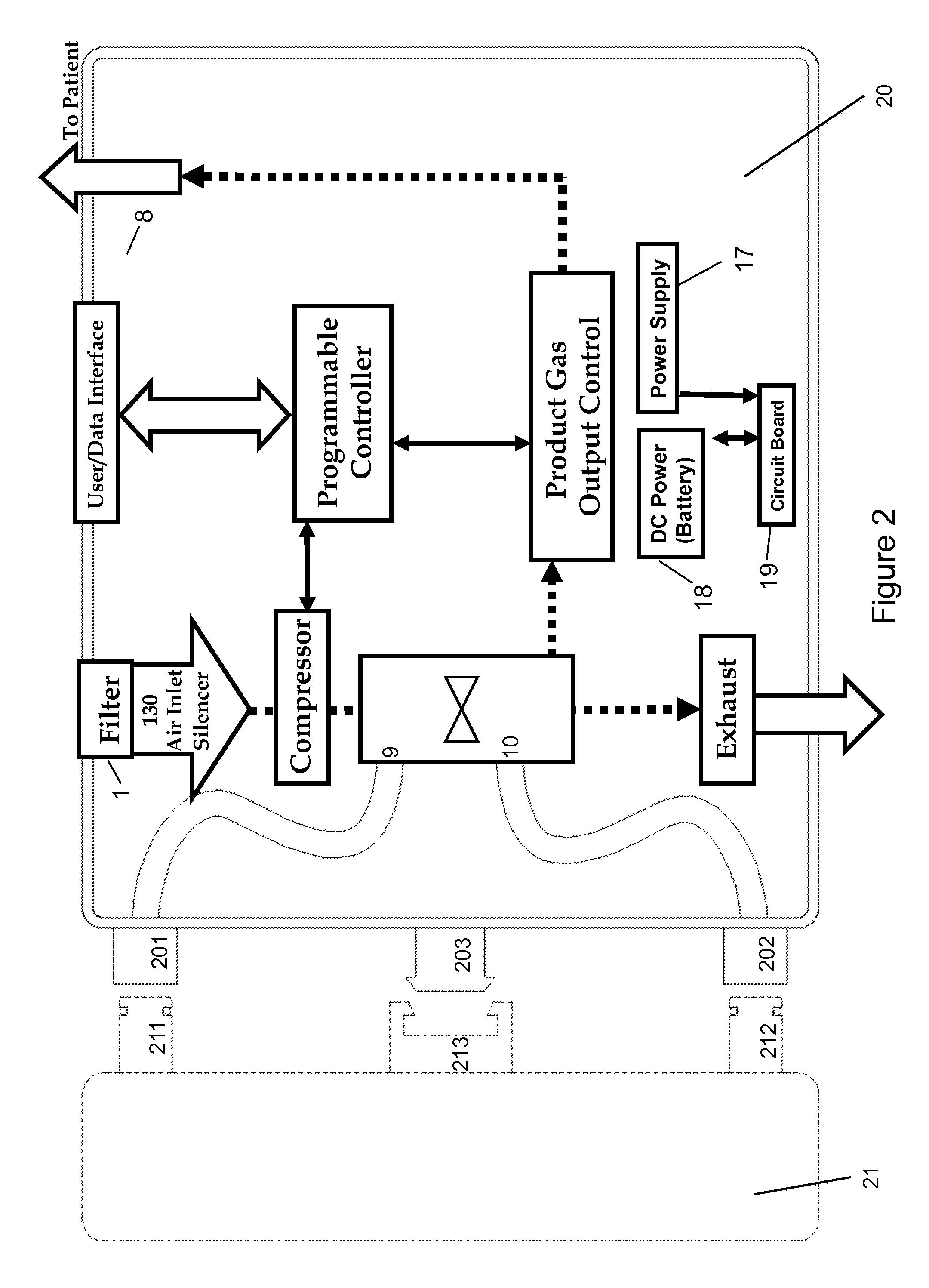

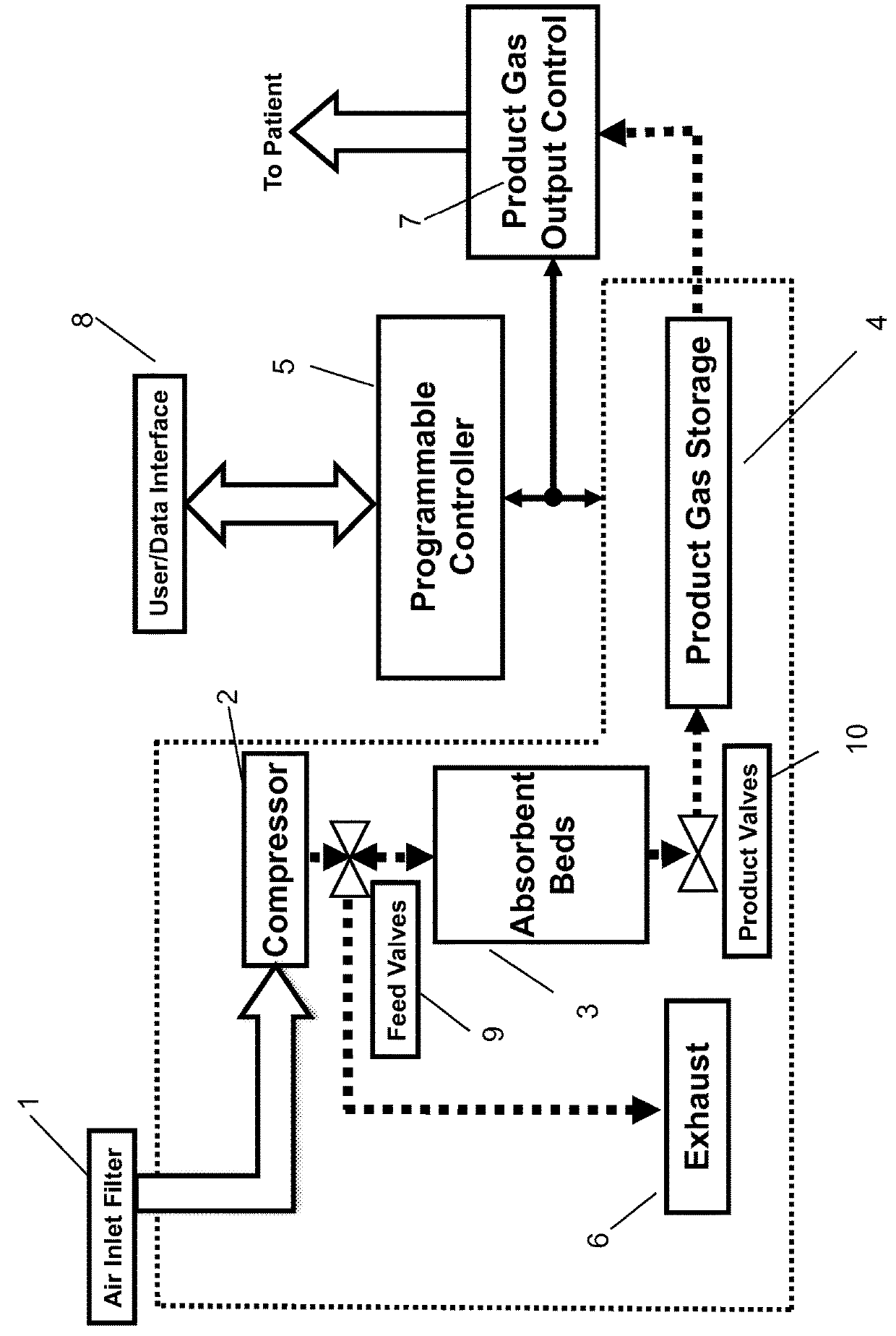

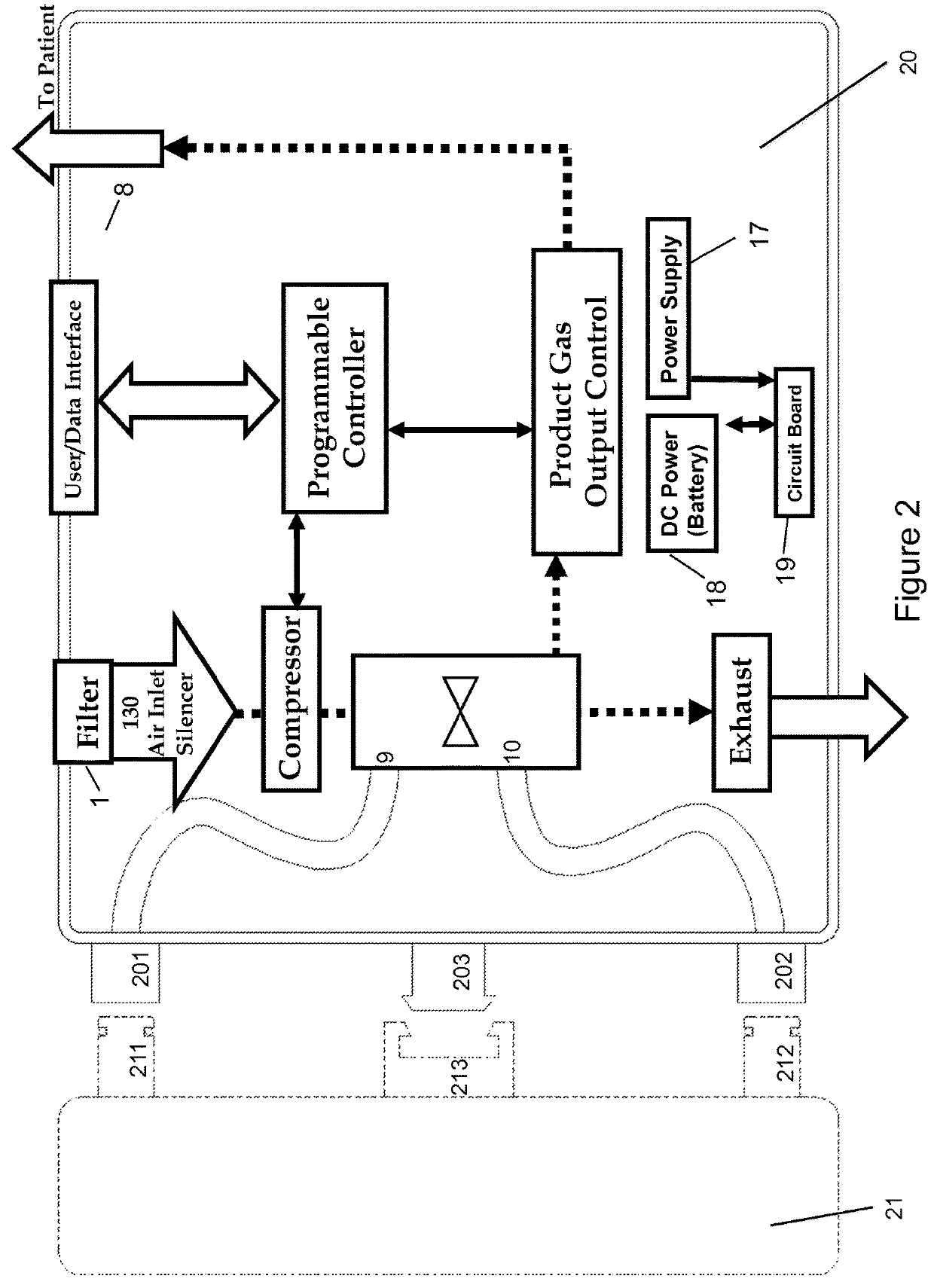

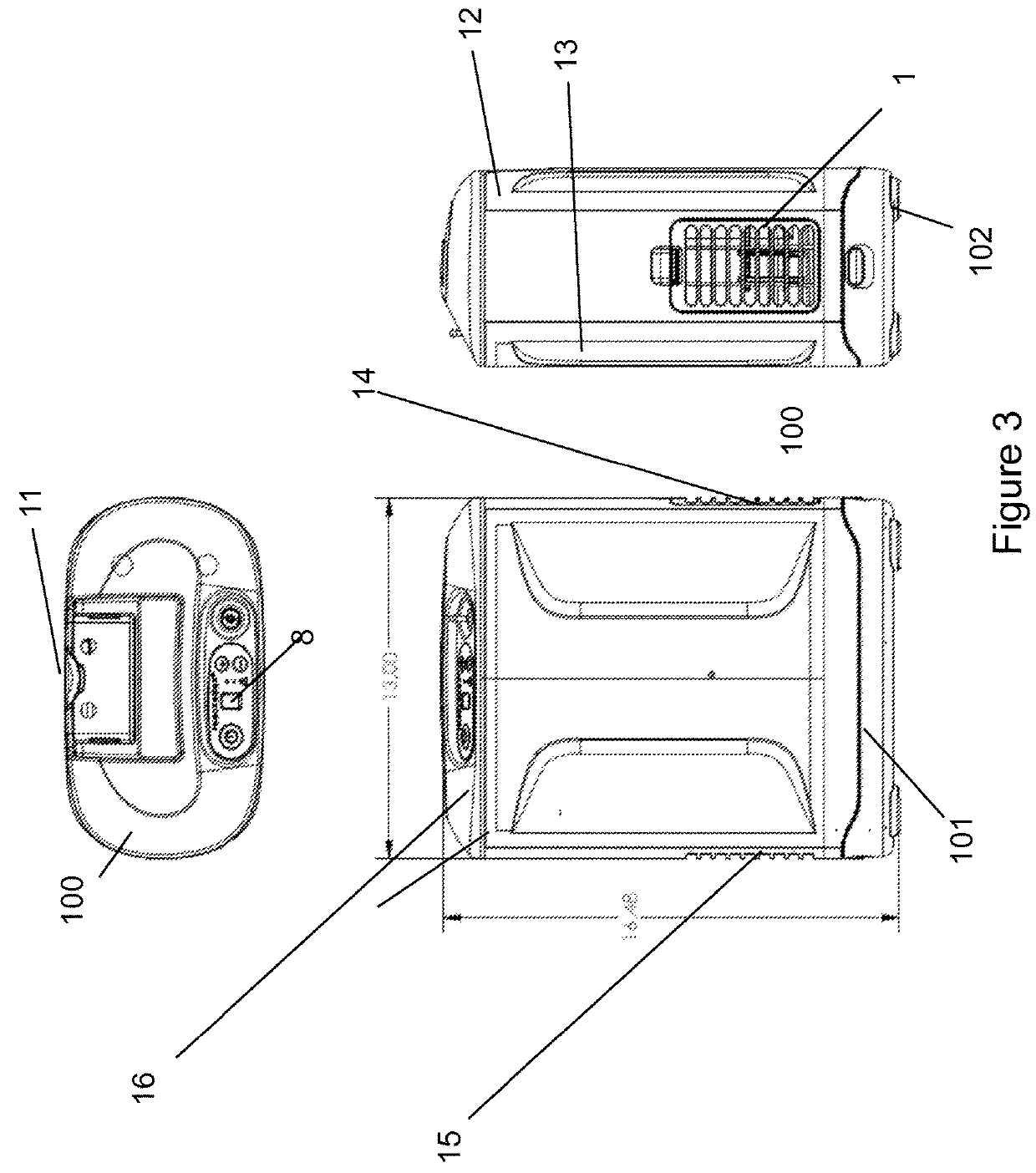

Gas Concentrator with Removable Cartridge Adsorbent Beds

ActiveUS20150182720A1Reduce external noiseAvoid breakingRespiratorsGas treatmentAir filterEngineering

A portable oxygen concentrator designed for medical use where the adsorbent beds, are designed to be replaced by a patient. The concentrator is designed so that the power supply and adsorbent bed mount is one module and the compressor and air filter are part of another module configured to provide a unitary cooling and air supply system. Replacement beds may be installed easily by patients, and all gas seals will function properly after installation.

Owner:INOGEN INC

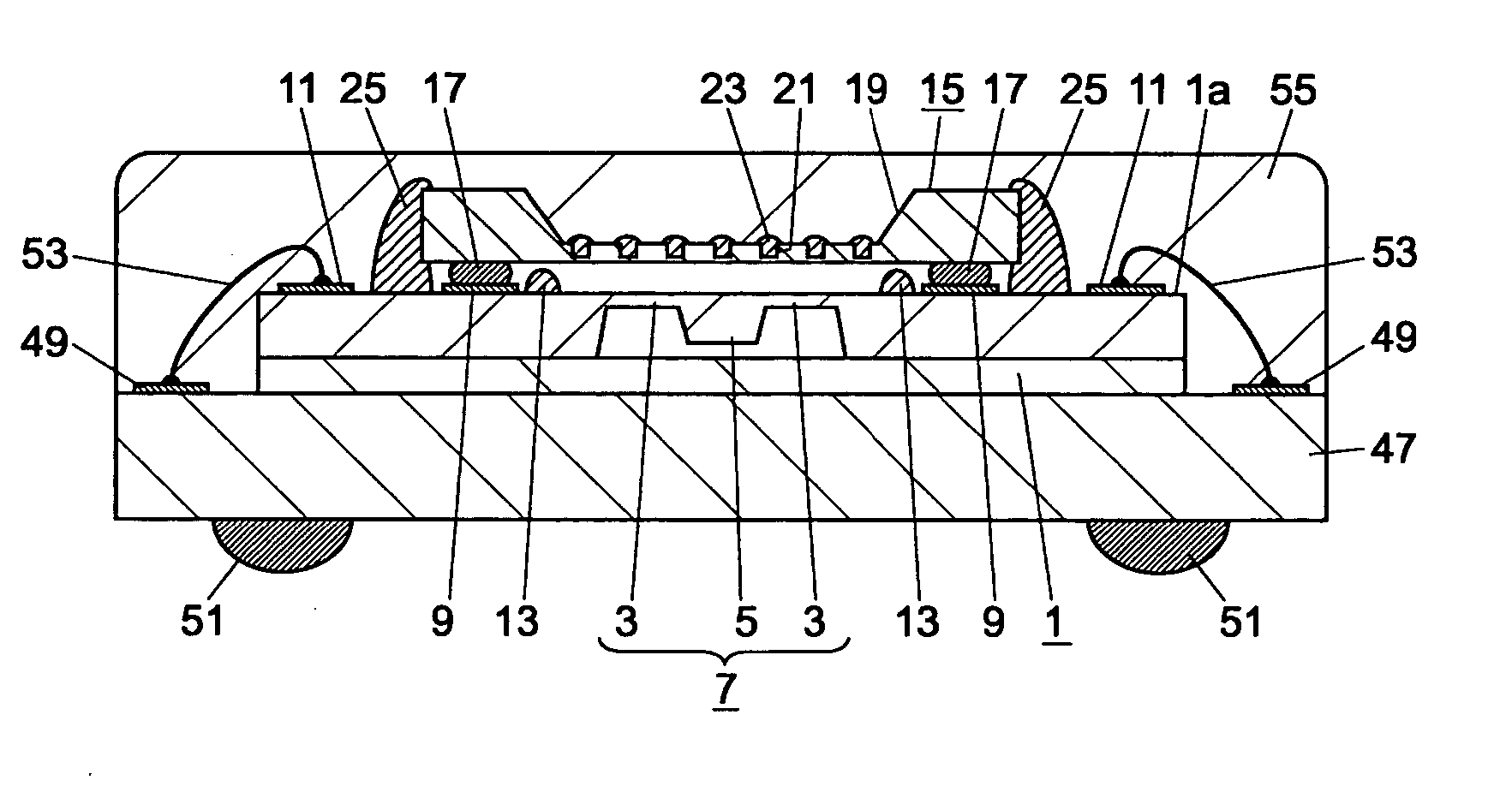

Semiconductor sensor device and method of producing the same

InactiveUS20050146004A1Adjusting output characteristicAvoid encapsulationAcceleration measurement using interia forcesSemiconductor/solid-state device detailsSemiconductor sensorSignal processing

A semiconductor sensor device is provided with a semiconductor sensor chip having a plurality of electrodes formed on a substrate surface and a semiconductor sensor, and a signal processing IC chip mounted on the semiconductor sensor chip by flip-chip bonding.

Owner:RICOH KK

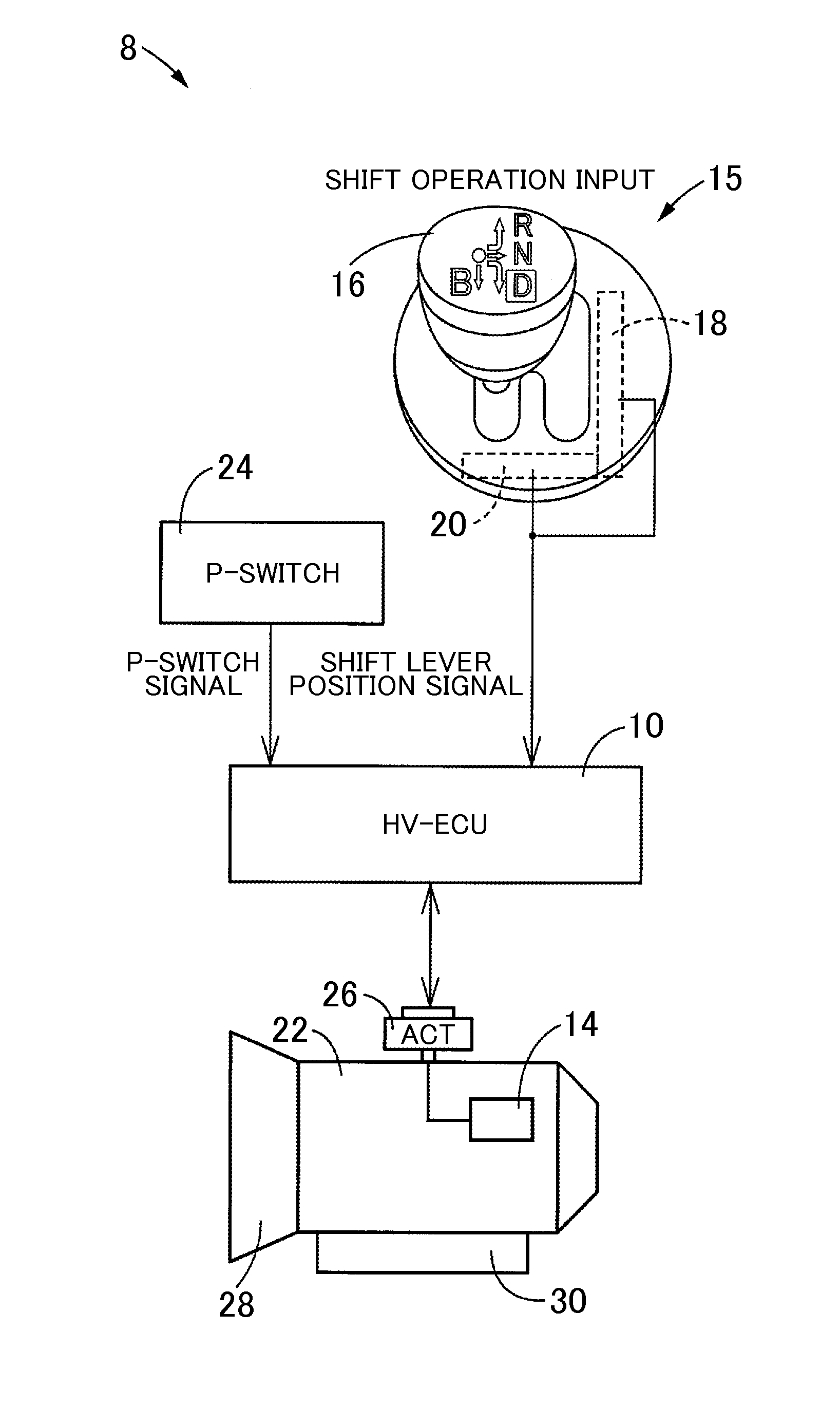

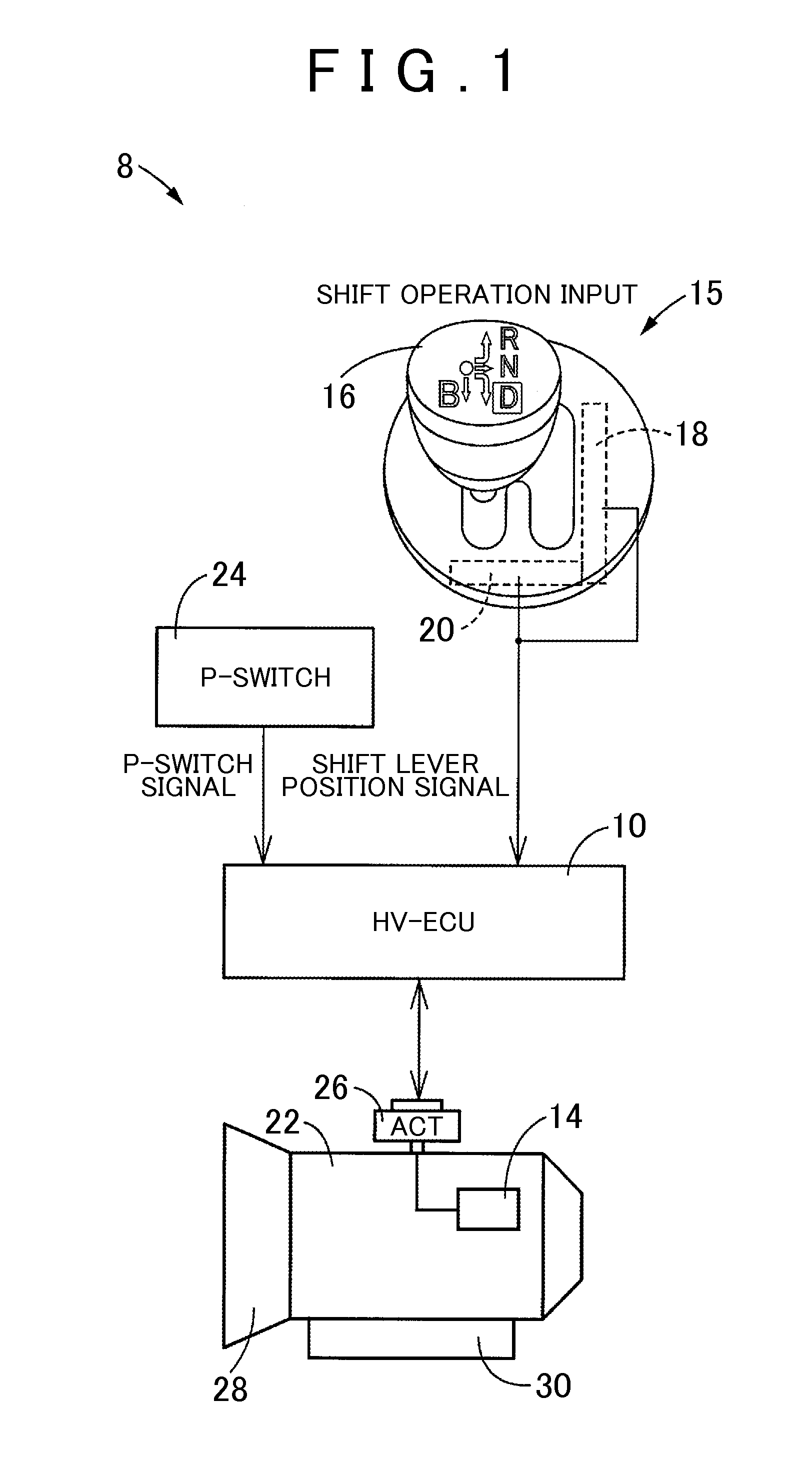

Control system for vehicle

ActiveUS20160152224A1Reduce torqueReduce external noiseHybrid vehiclesElectrical controlControl systemInternal combustion engine

A control system is for a vehicle that includes an internal combustion engine. The control system includes an electronic control unit. The electronic control unit is configured to limit an output of the internal combustion engine when the electronic control unit determines that the vehicle runs in an unmanned state, such that the output of the internal combustion engine is lower the vehicle runs in the unmanned state than when the vehicle runs in a manned state.

Owner:TOYOTA JIDOSHA KK

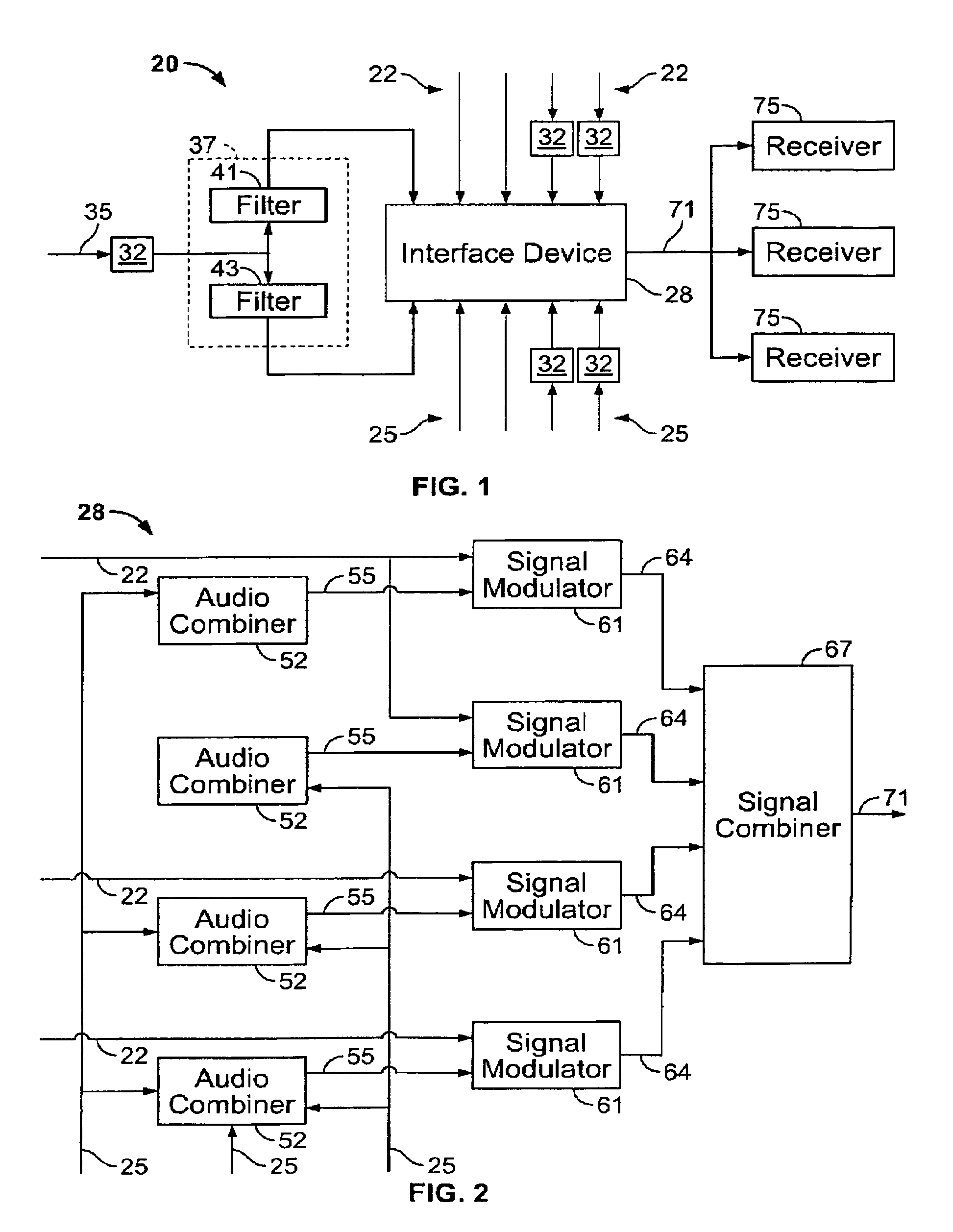

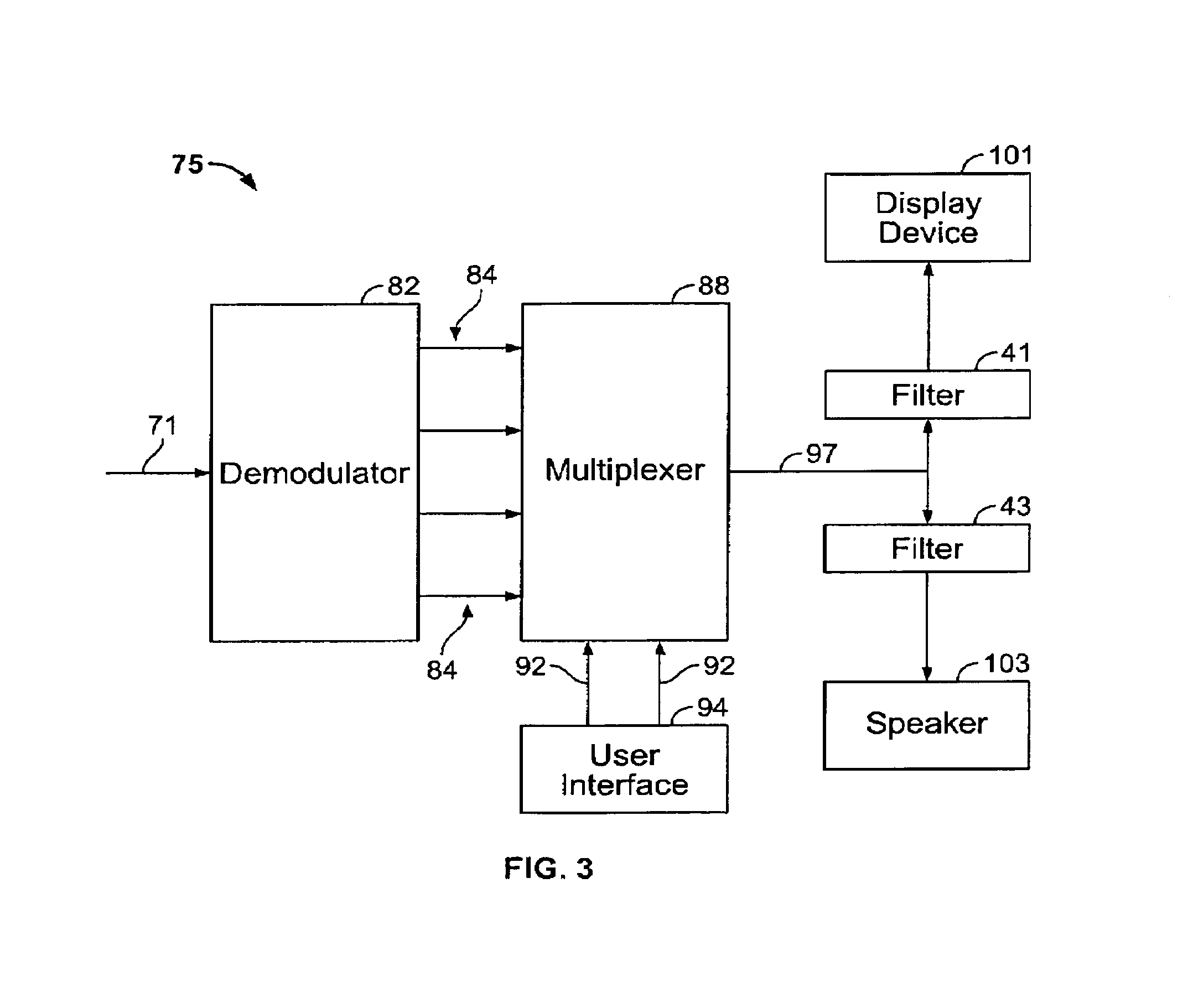

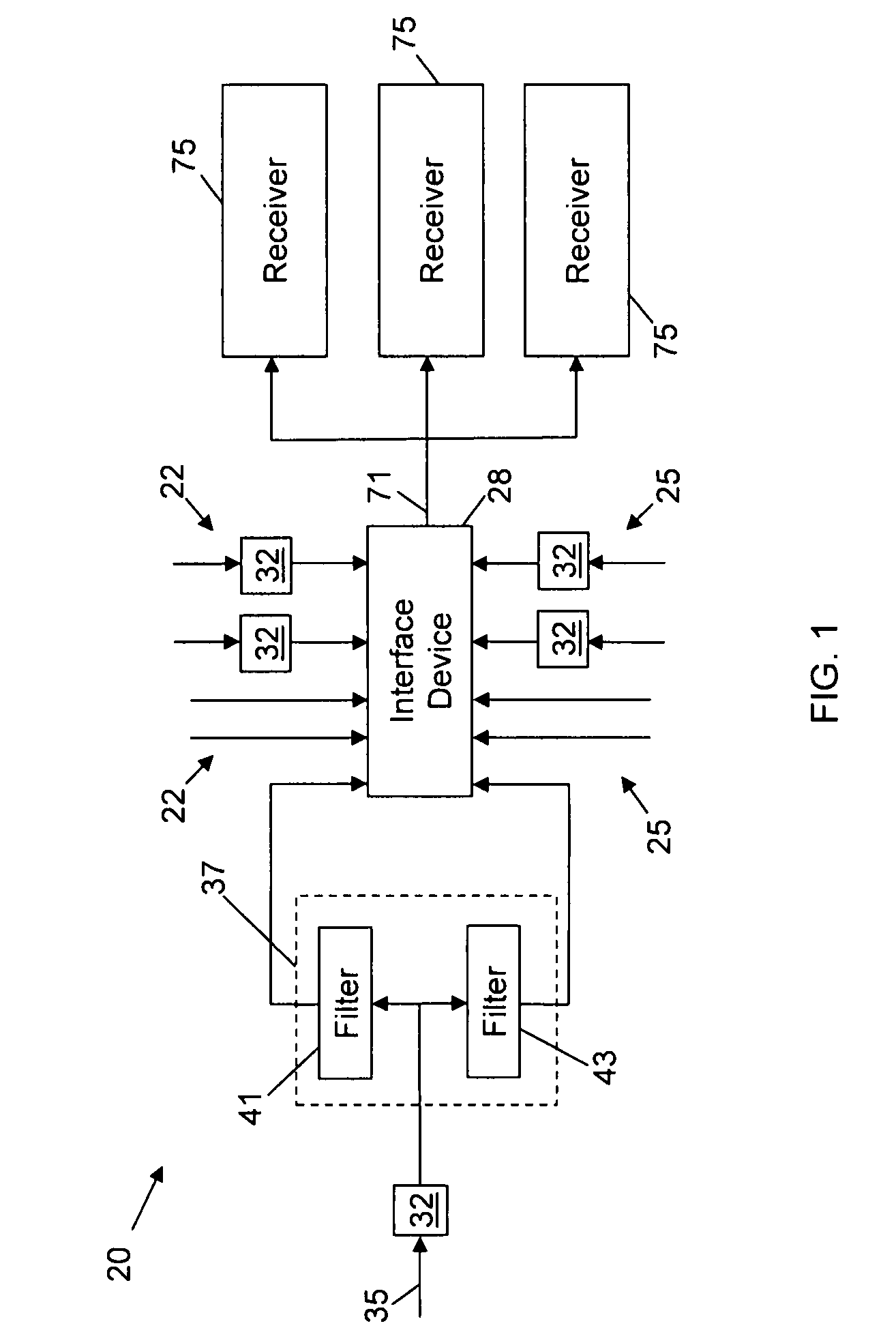

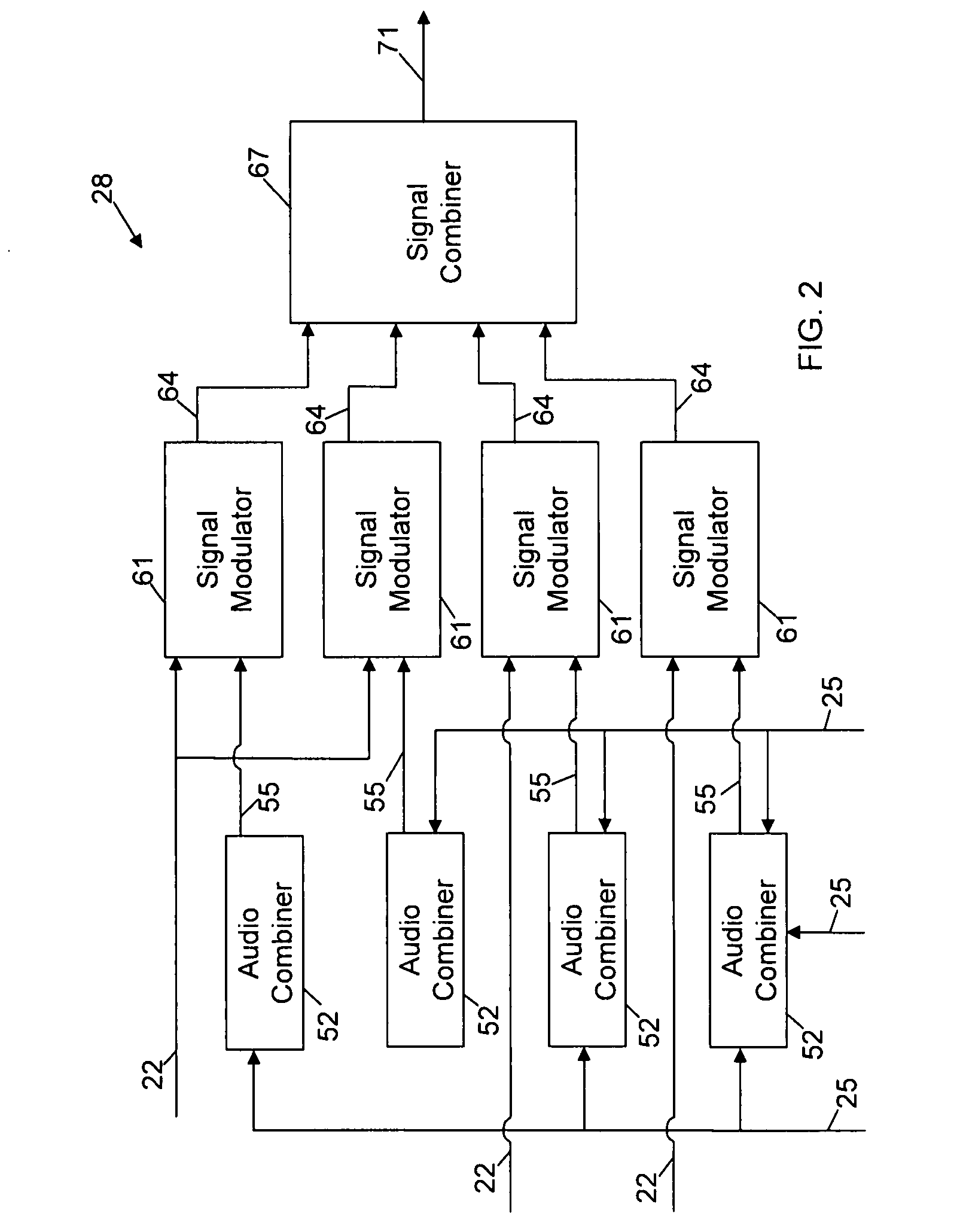

Audio/video entertainment system and method

InactiveUS20070256107A1Reduce the amount requiredReduce external noiseTelevision system detailsBroadcast information characterisationDisplay deviceProgram logic

The preferred embodiment of the present invention provides a system and method for programming and / or charging one or more audio / video devices such that the audio / video devices will be programmed and charged to receive transmitted audio and video signals associated with an event, allowing a user to use the audio / video device to observe the sights and sounds of the event. A preferred embodiment of the present invention includes a cart with a docking port for each of a plurality of personal audio / video devices, a charger configured to charge the power source of each personal audio / video display device, and programming logic configured to program each of the personal audio / video devices.

Owner:IMMERSION ENTERTAINMENT L L C

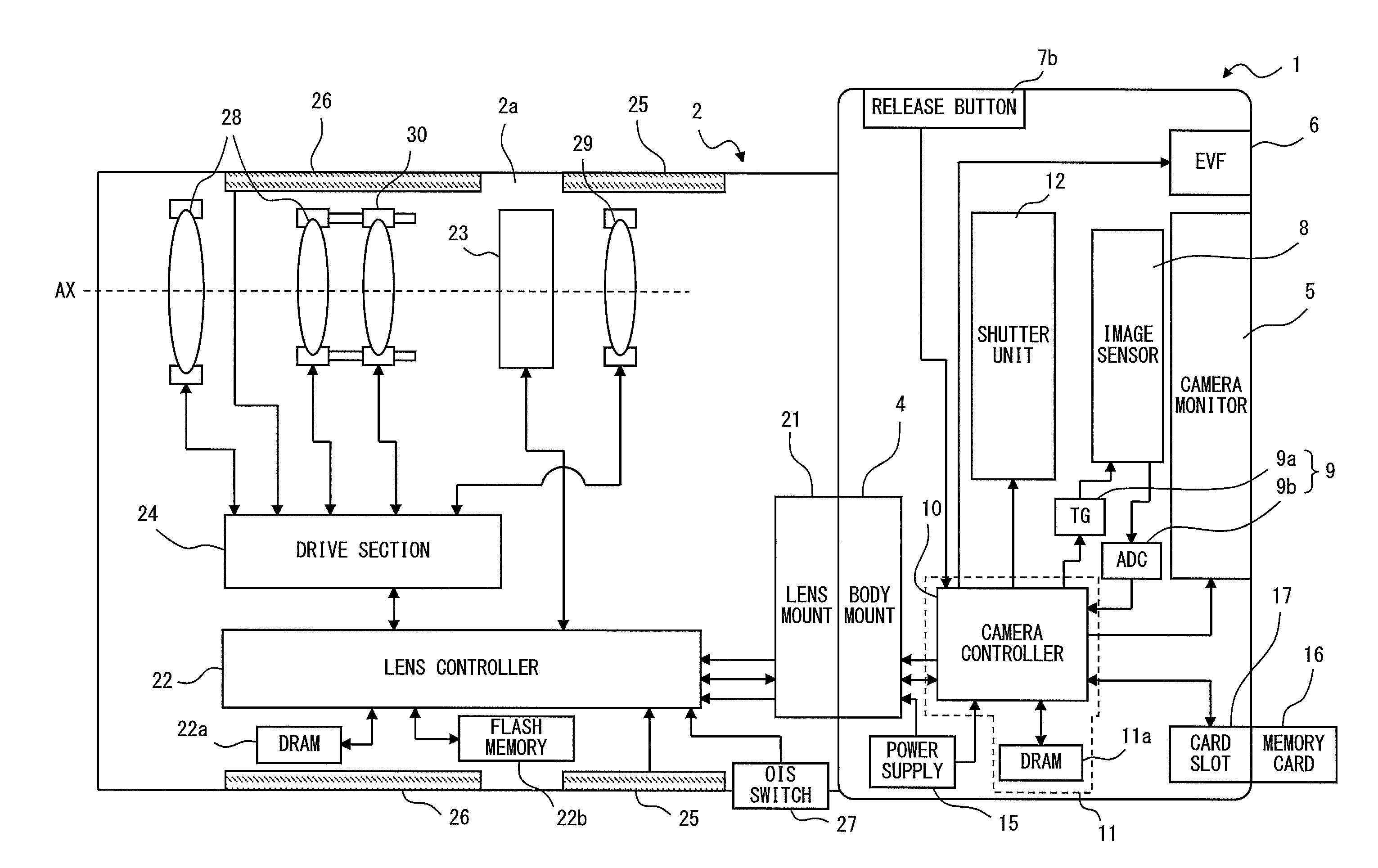

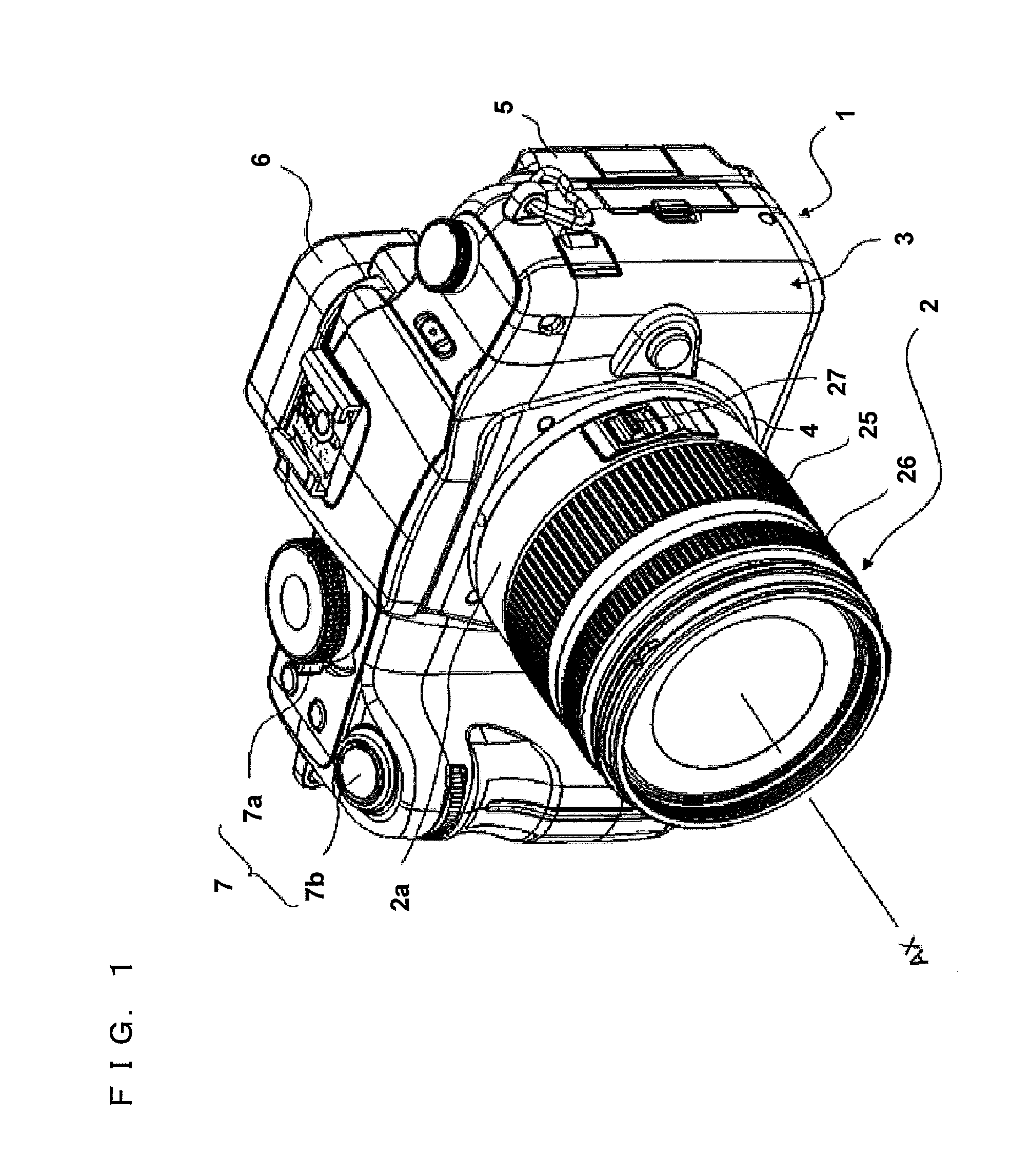

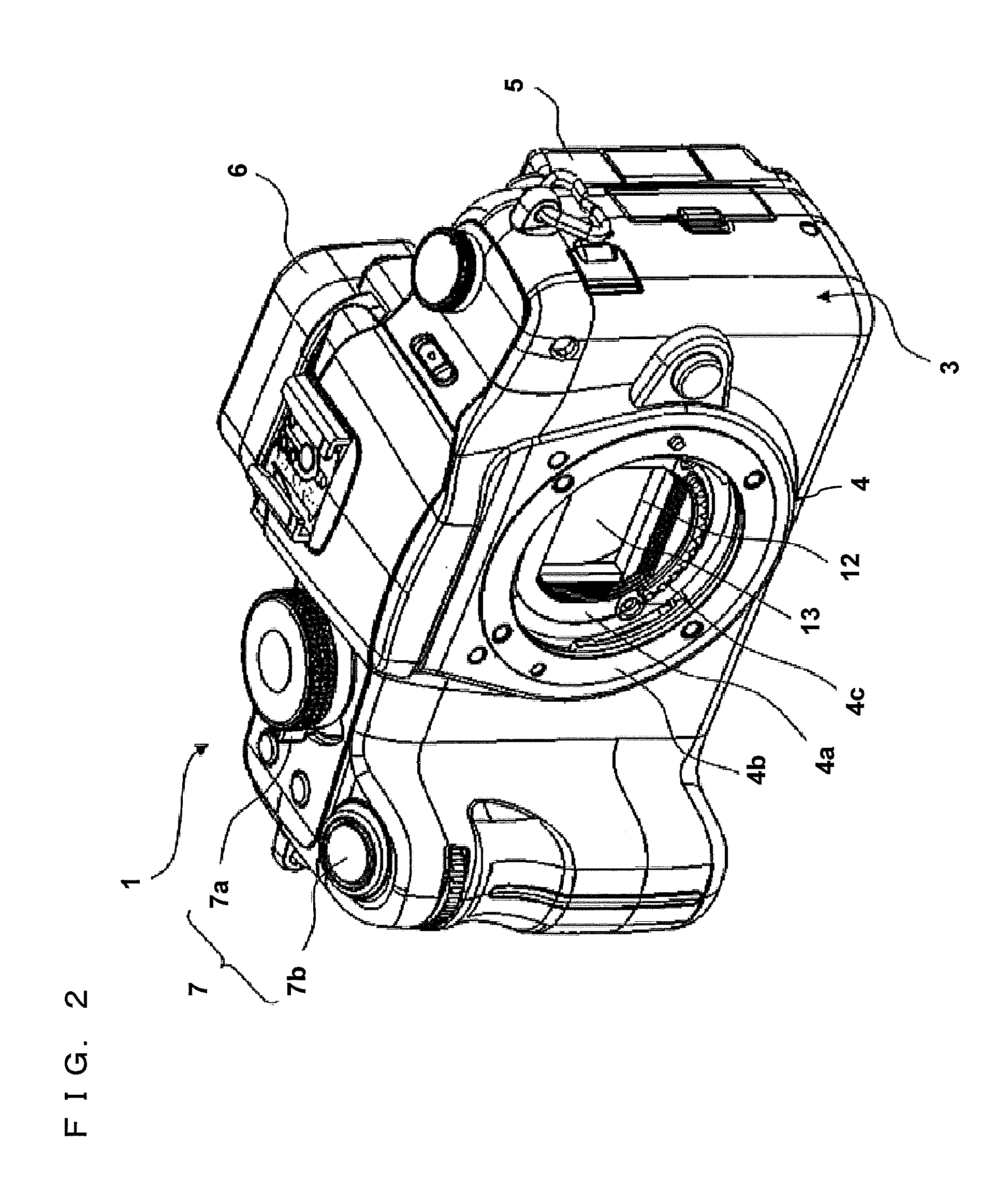

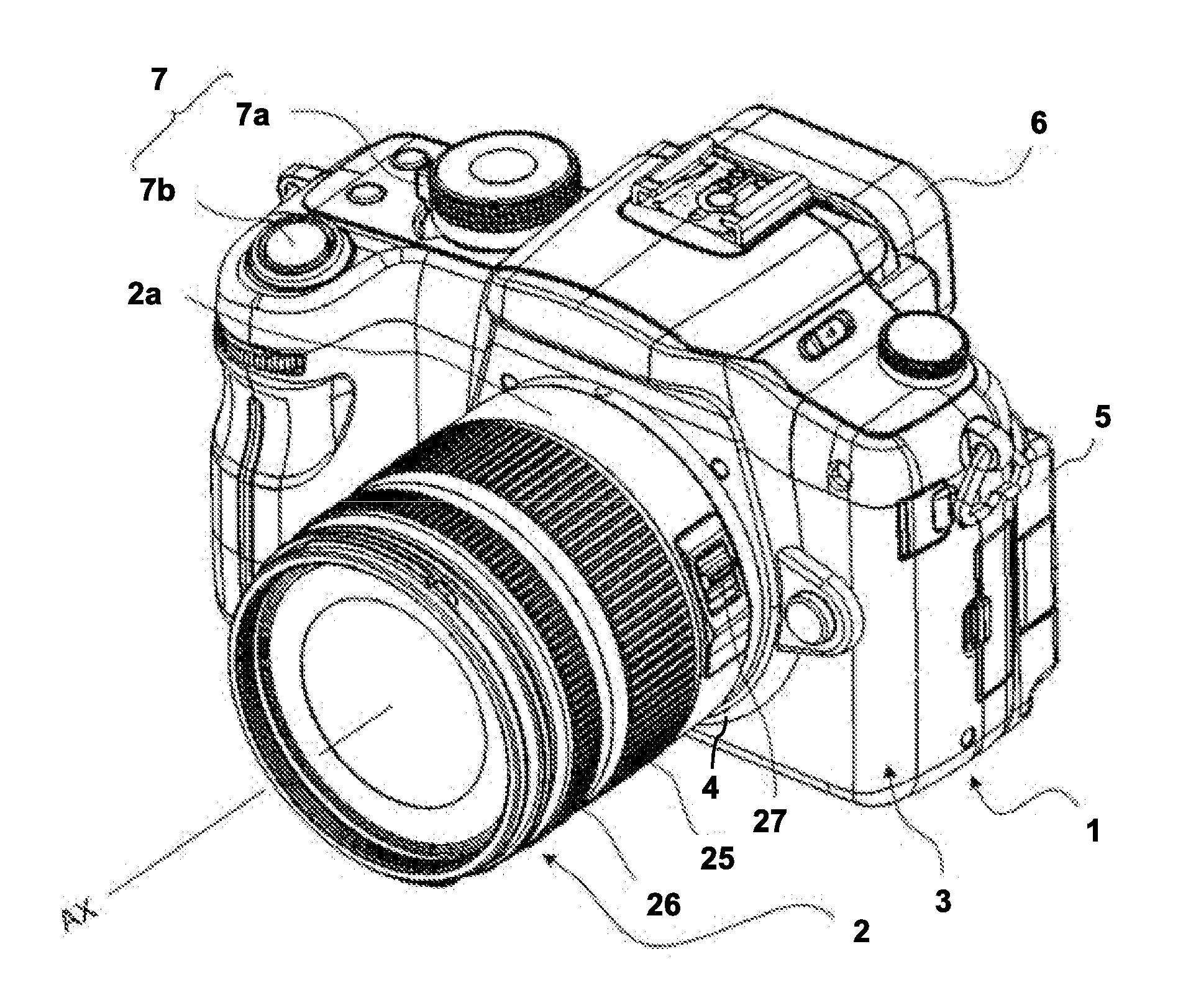

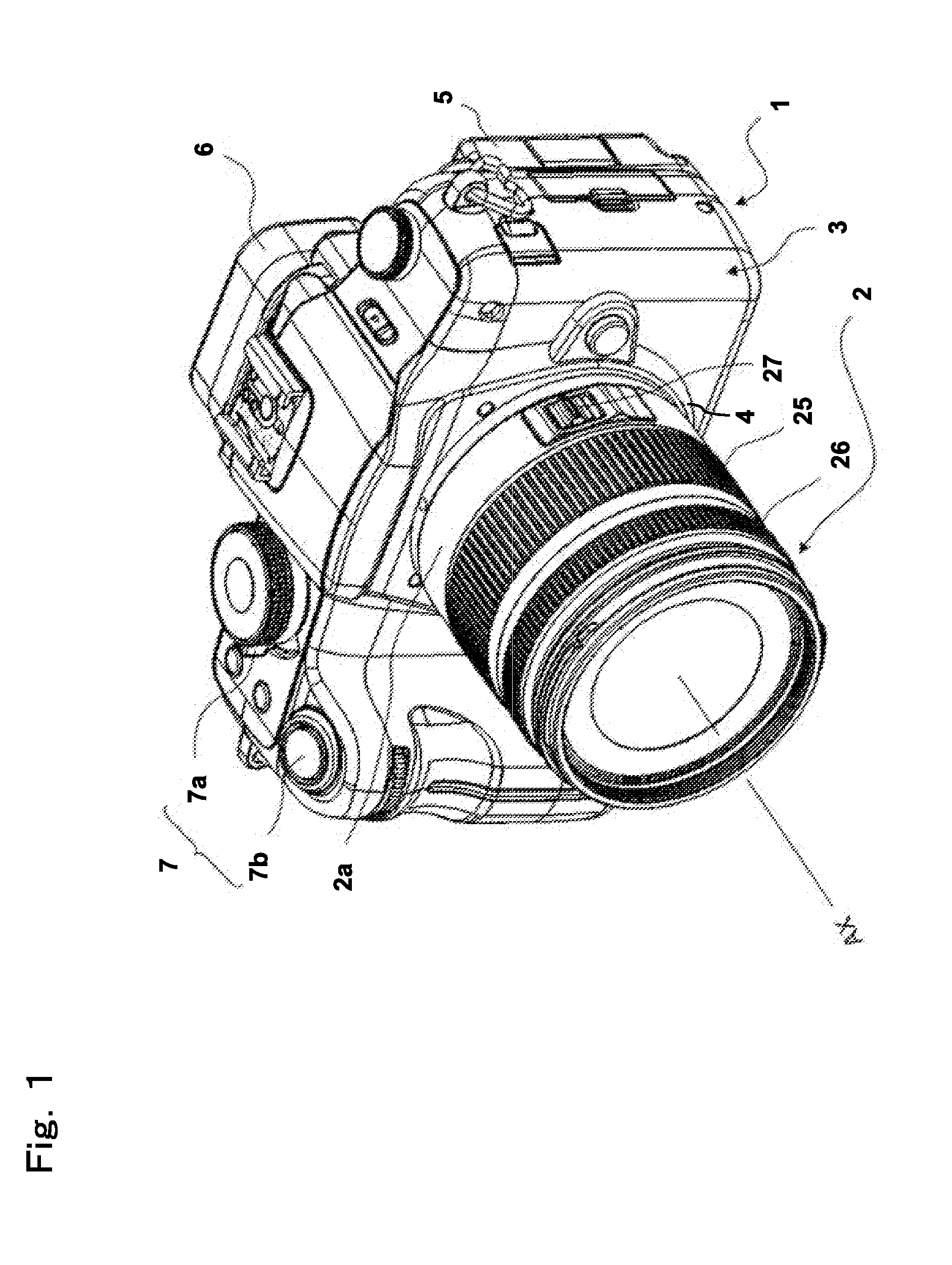

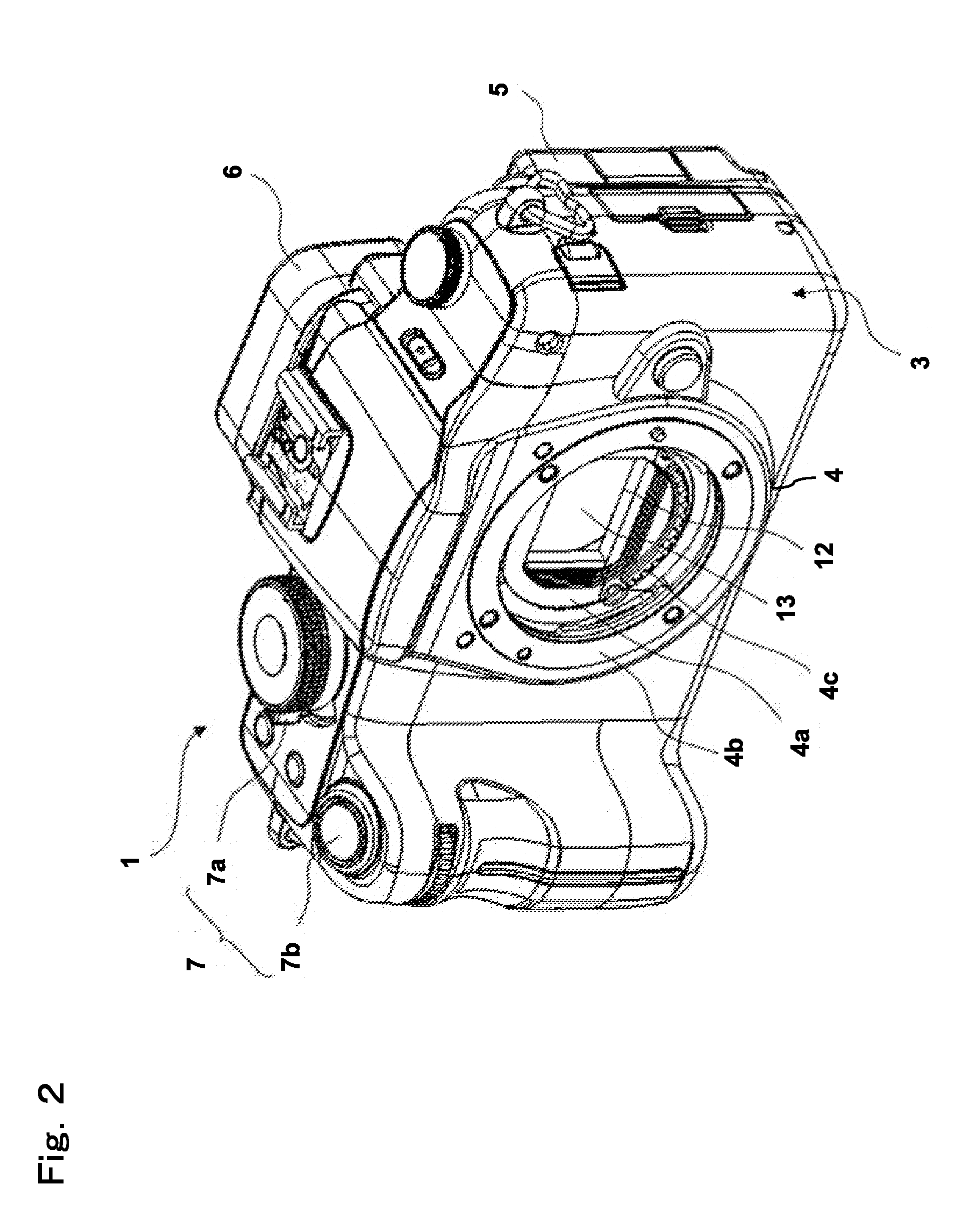

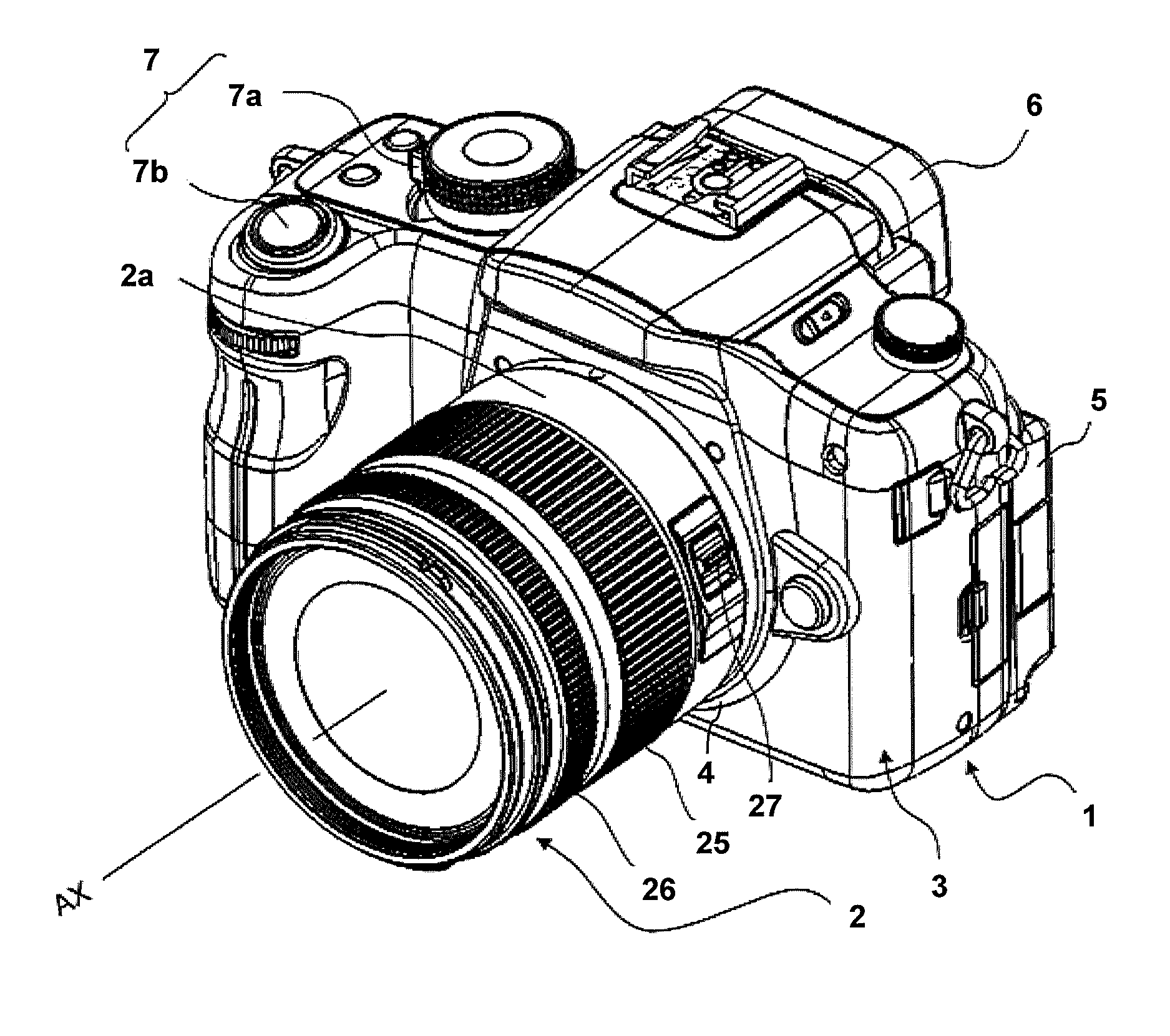

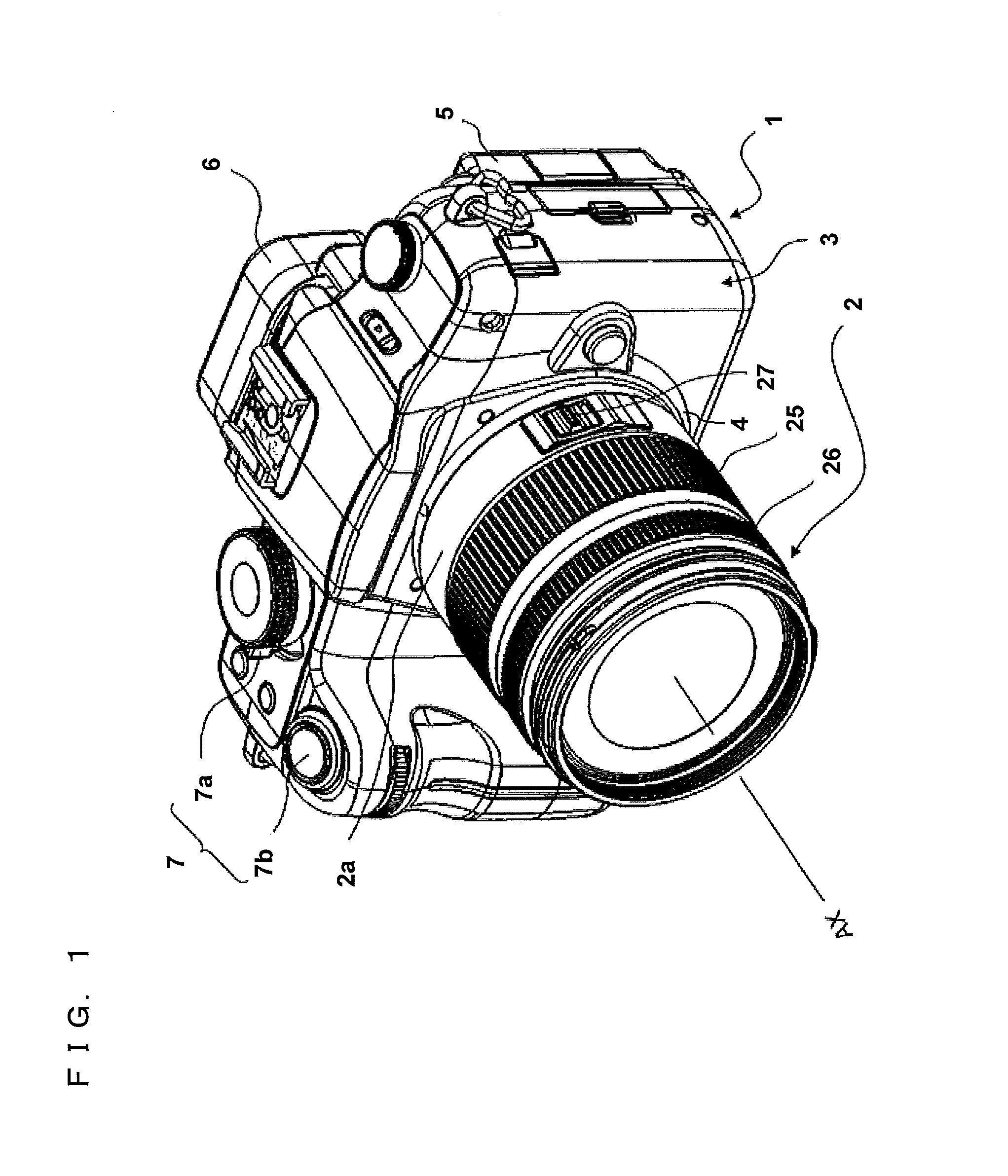

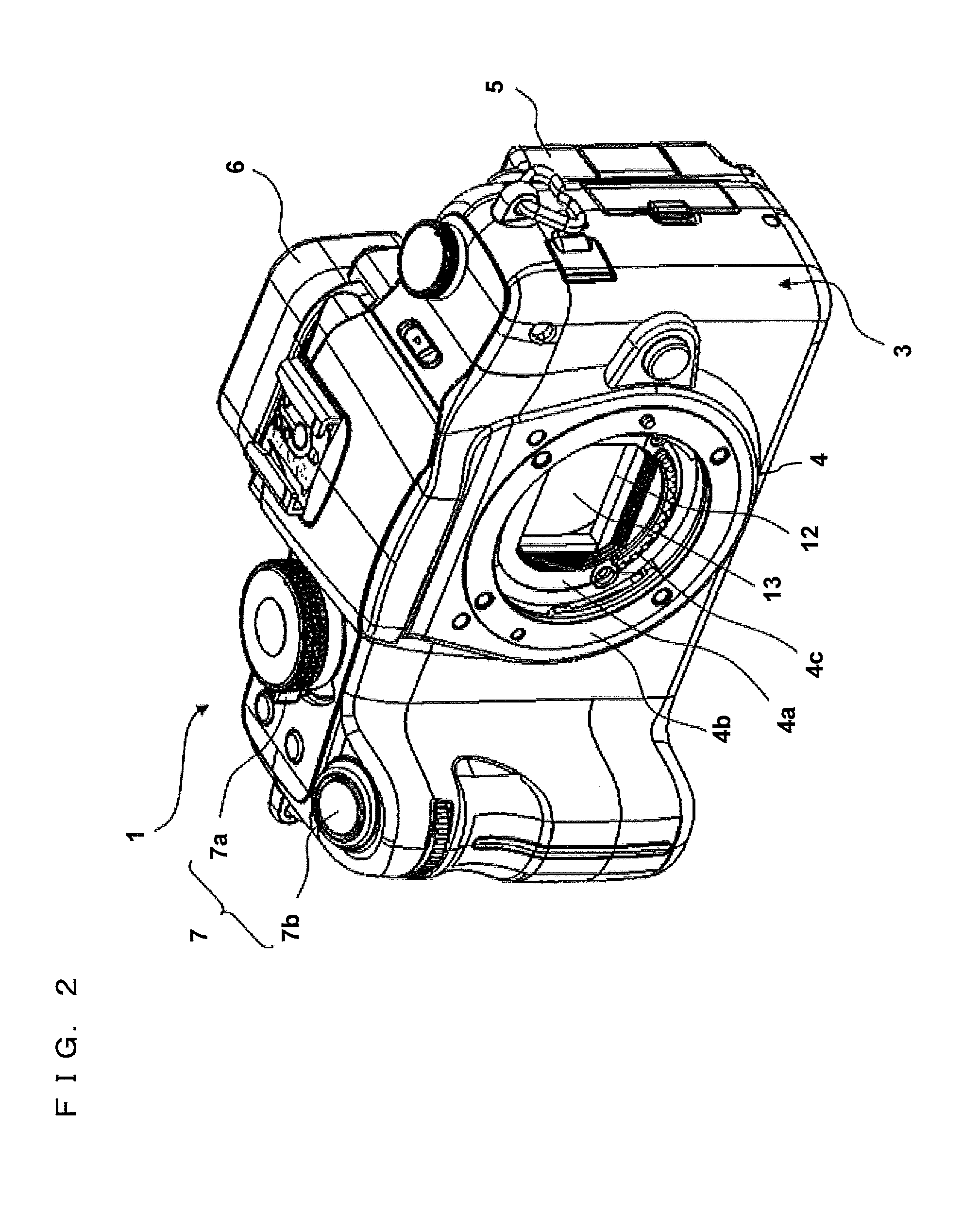

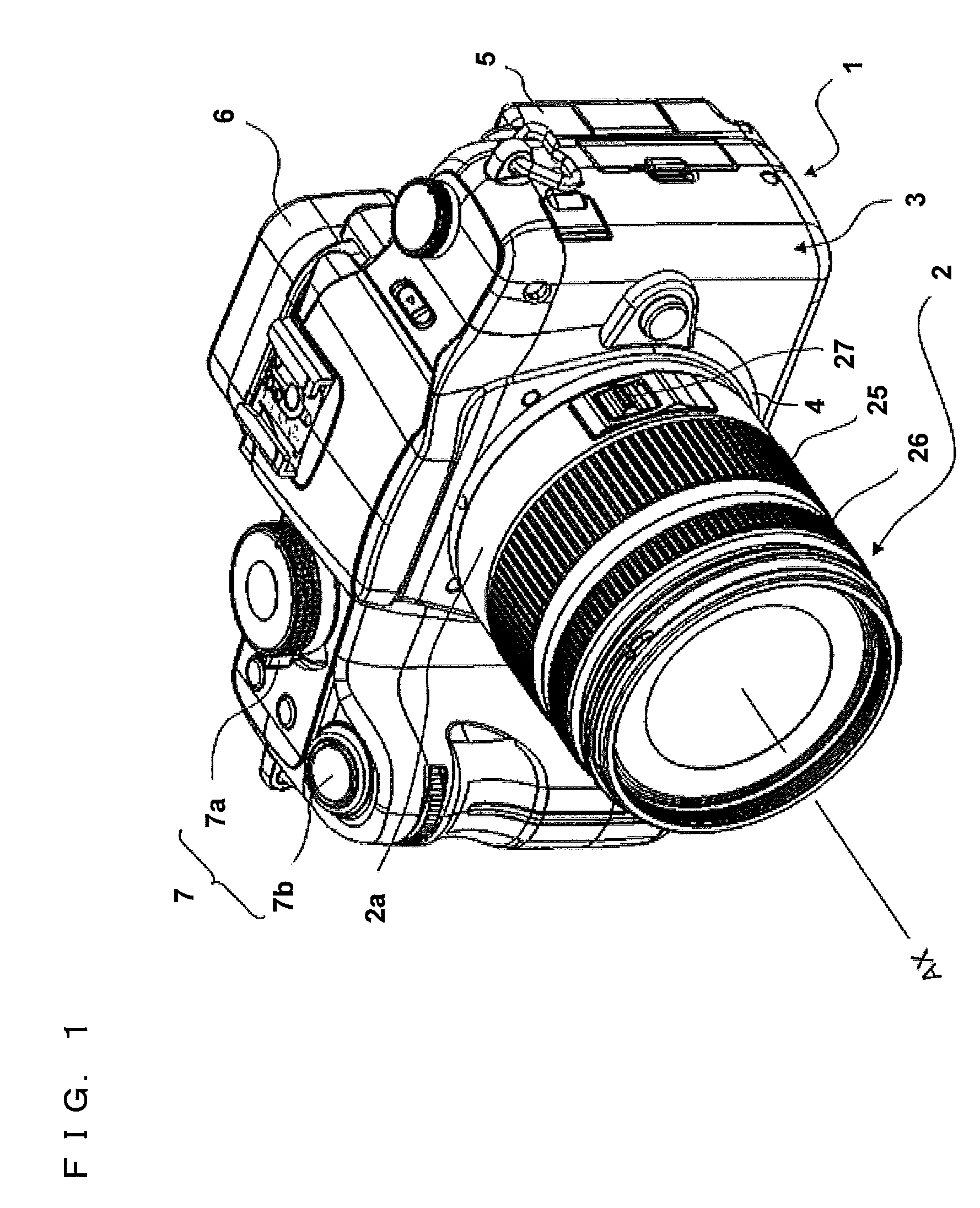

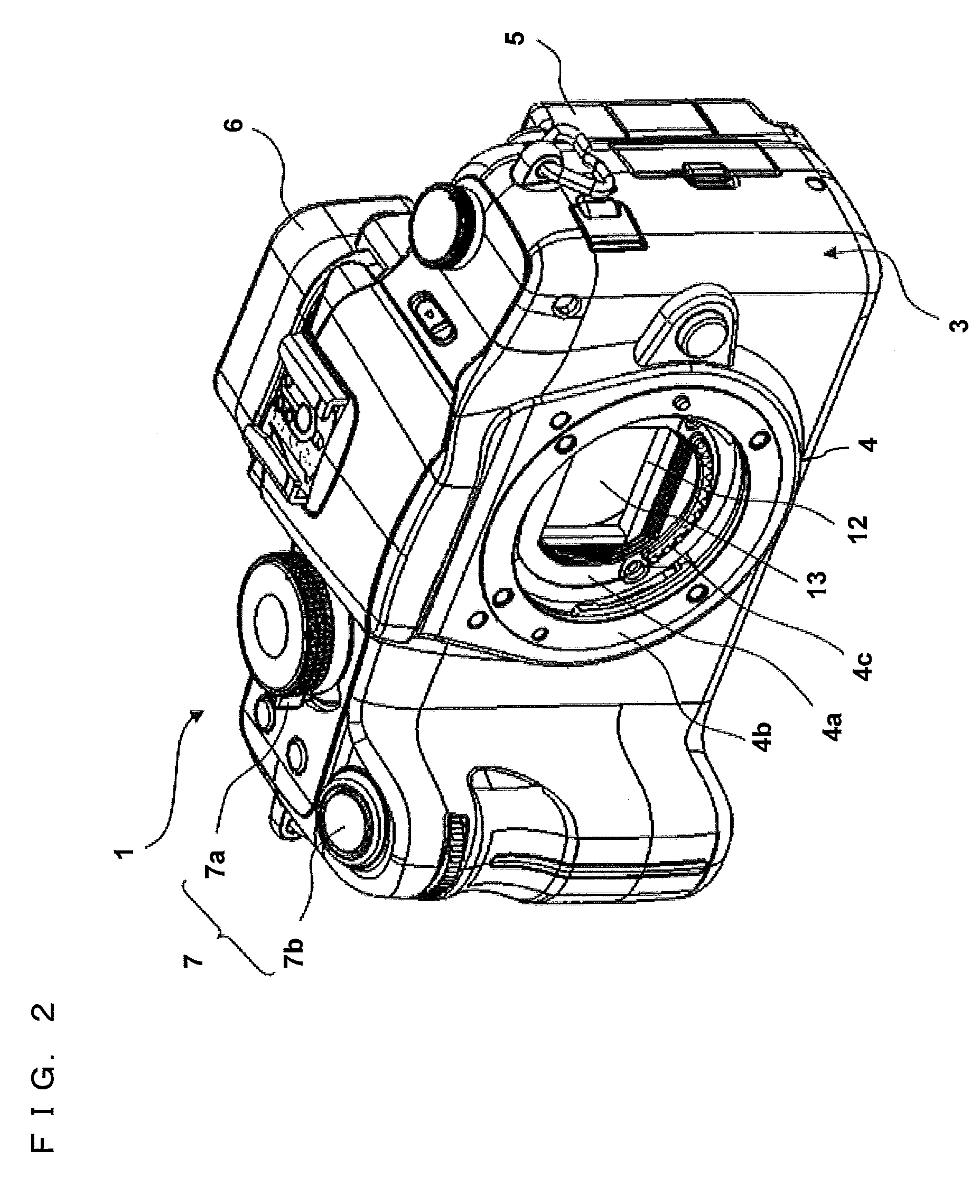

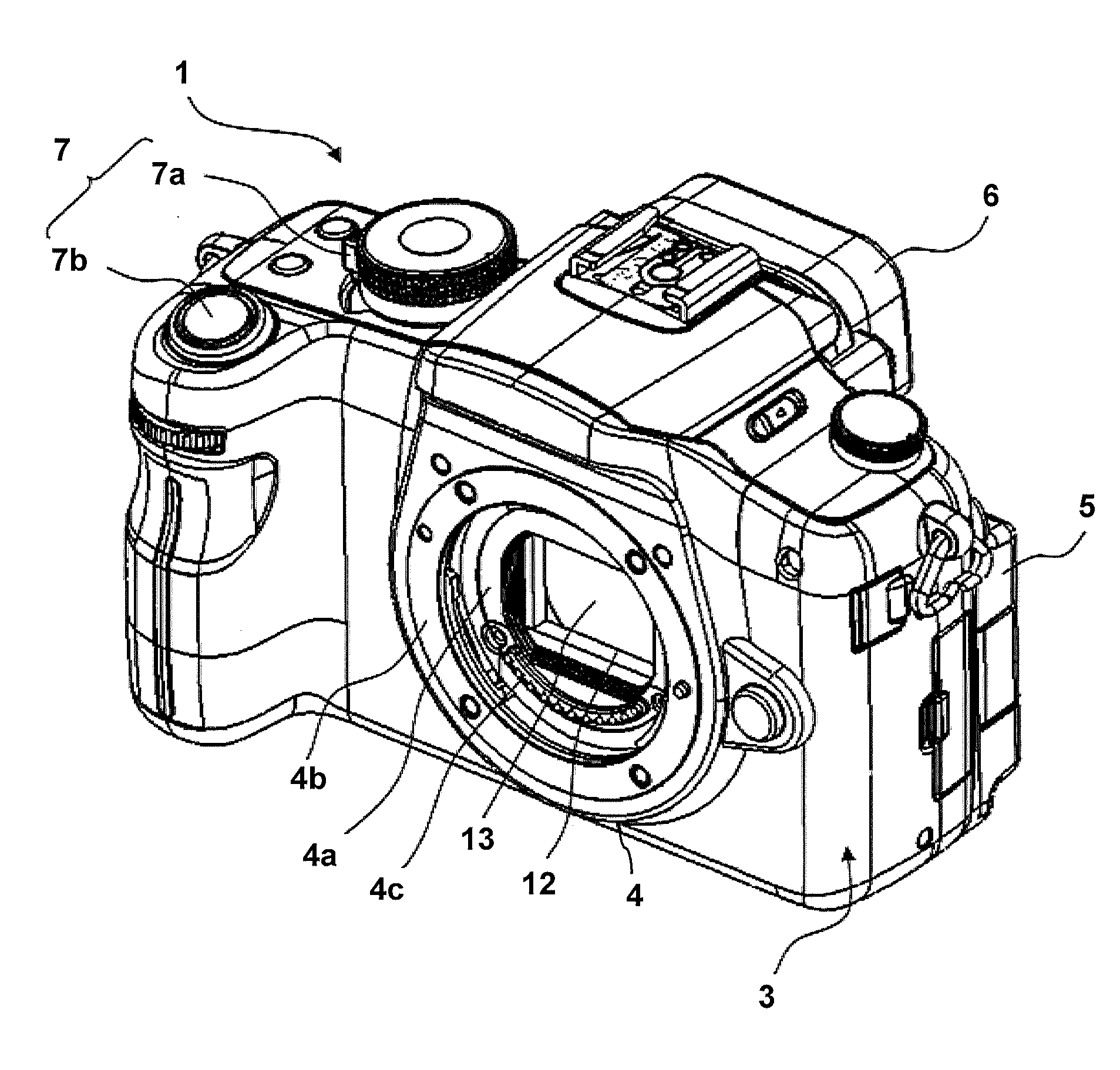

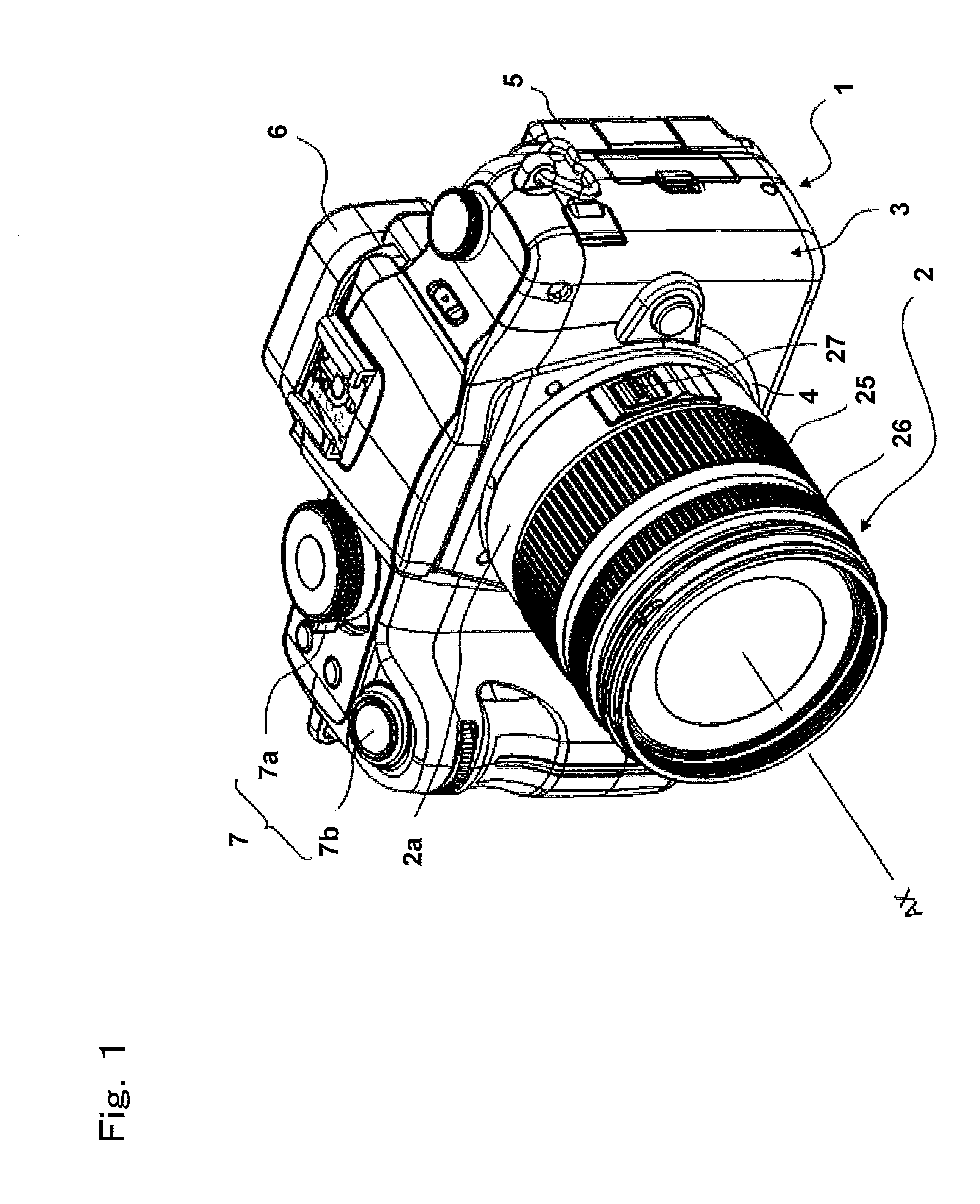

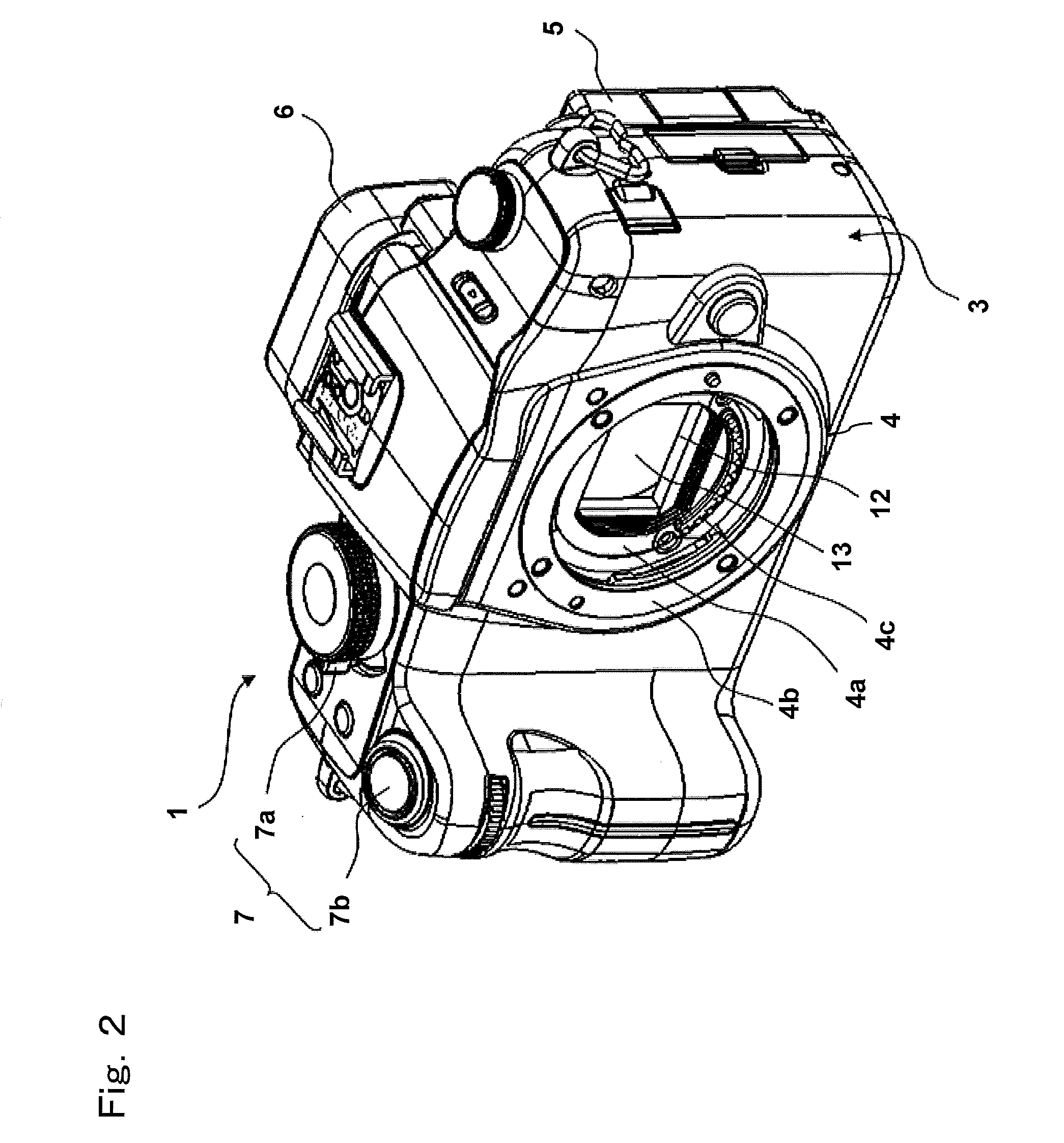

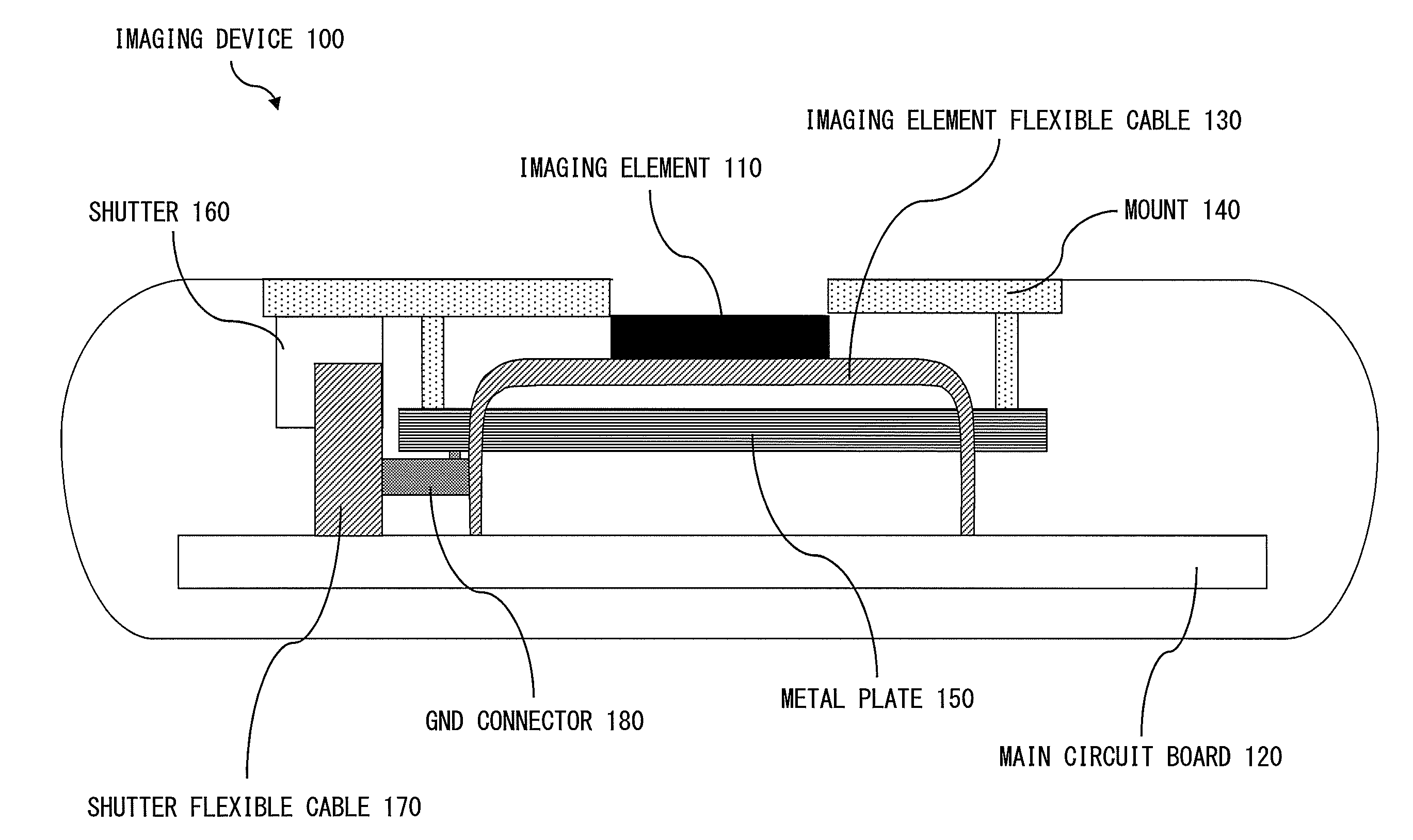

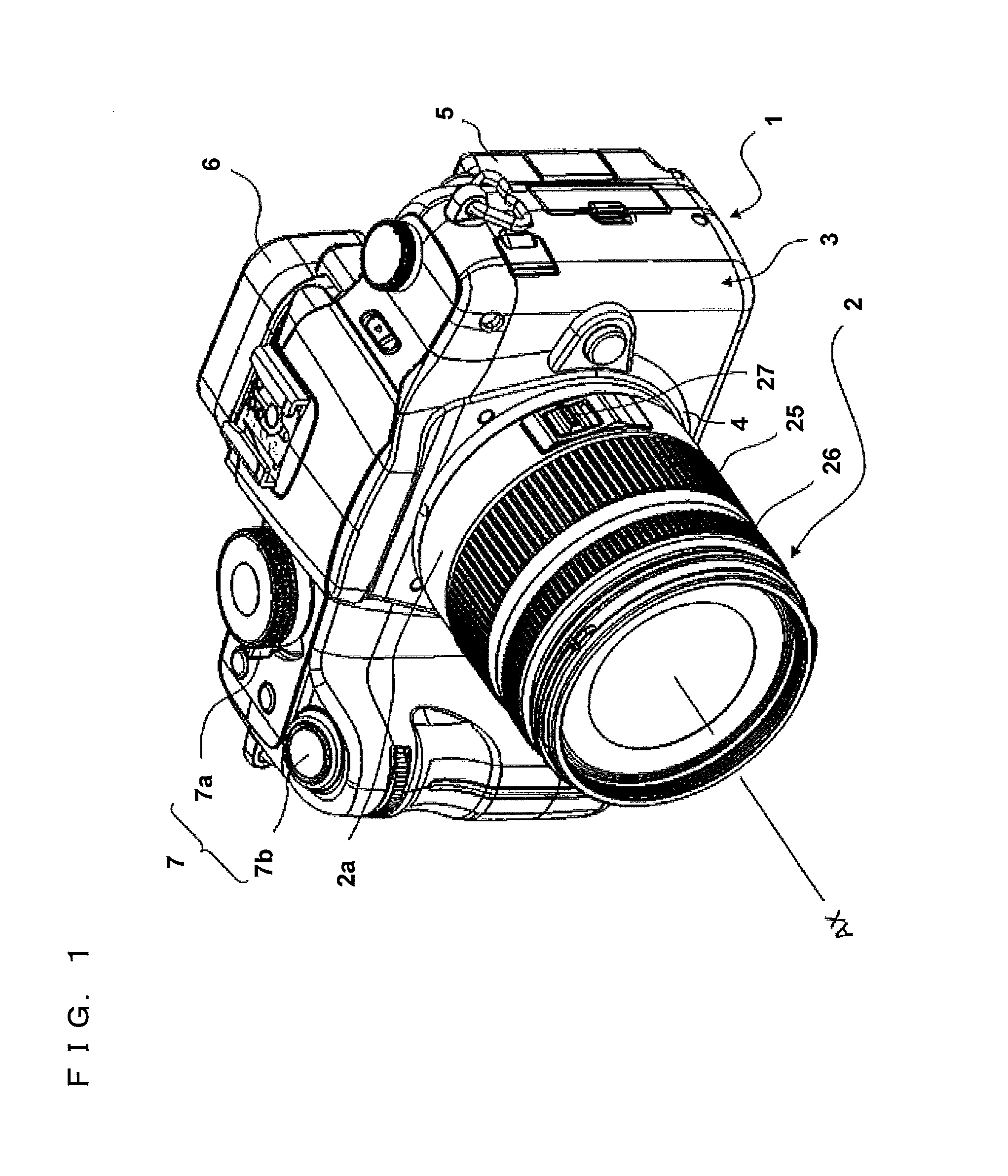

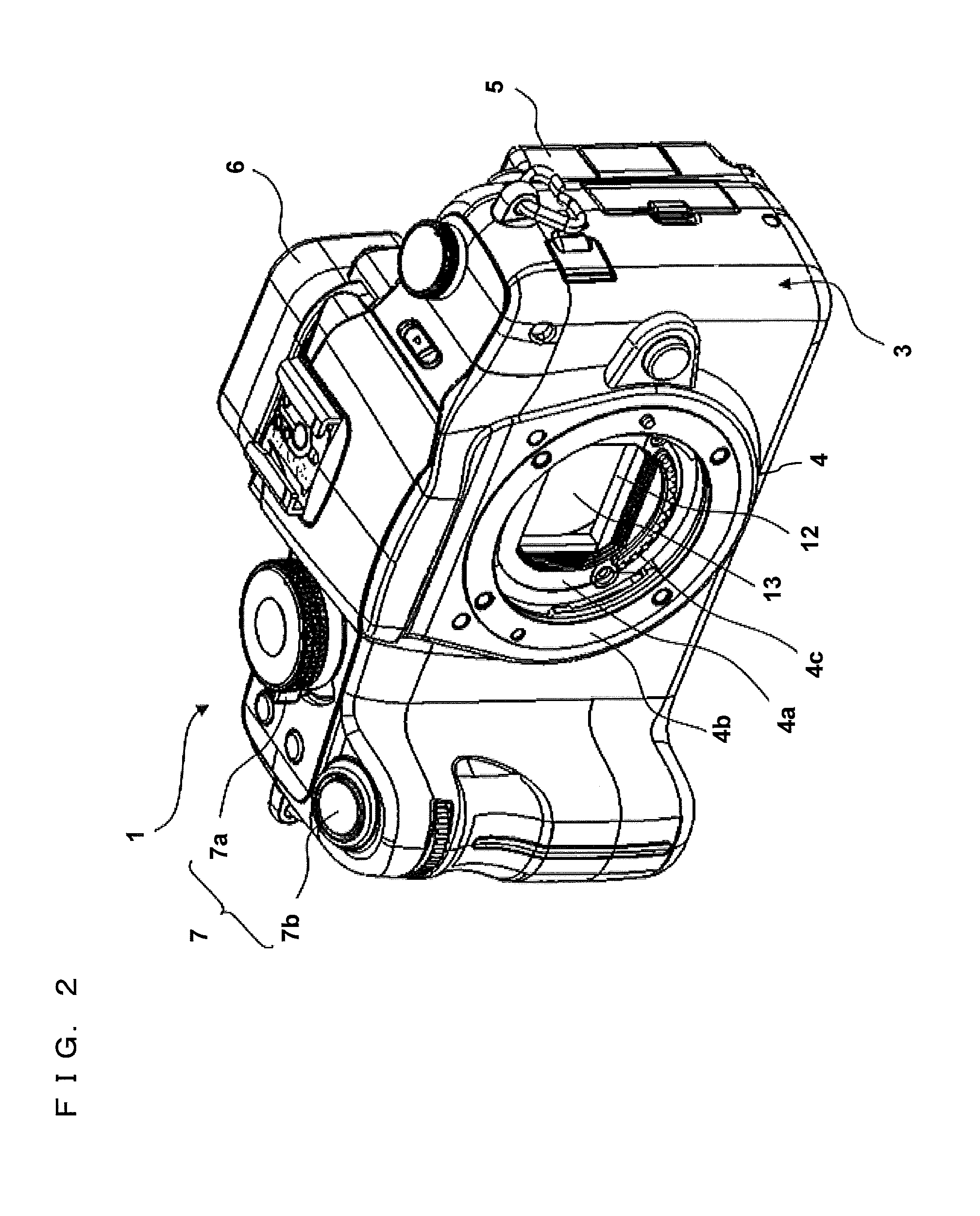

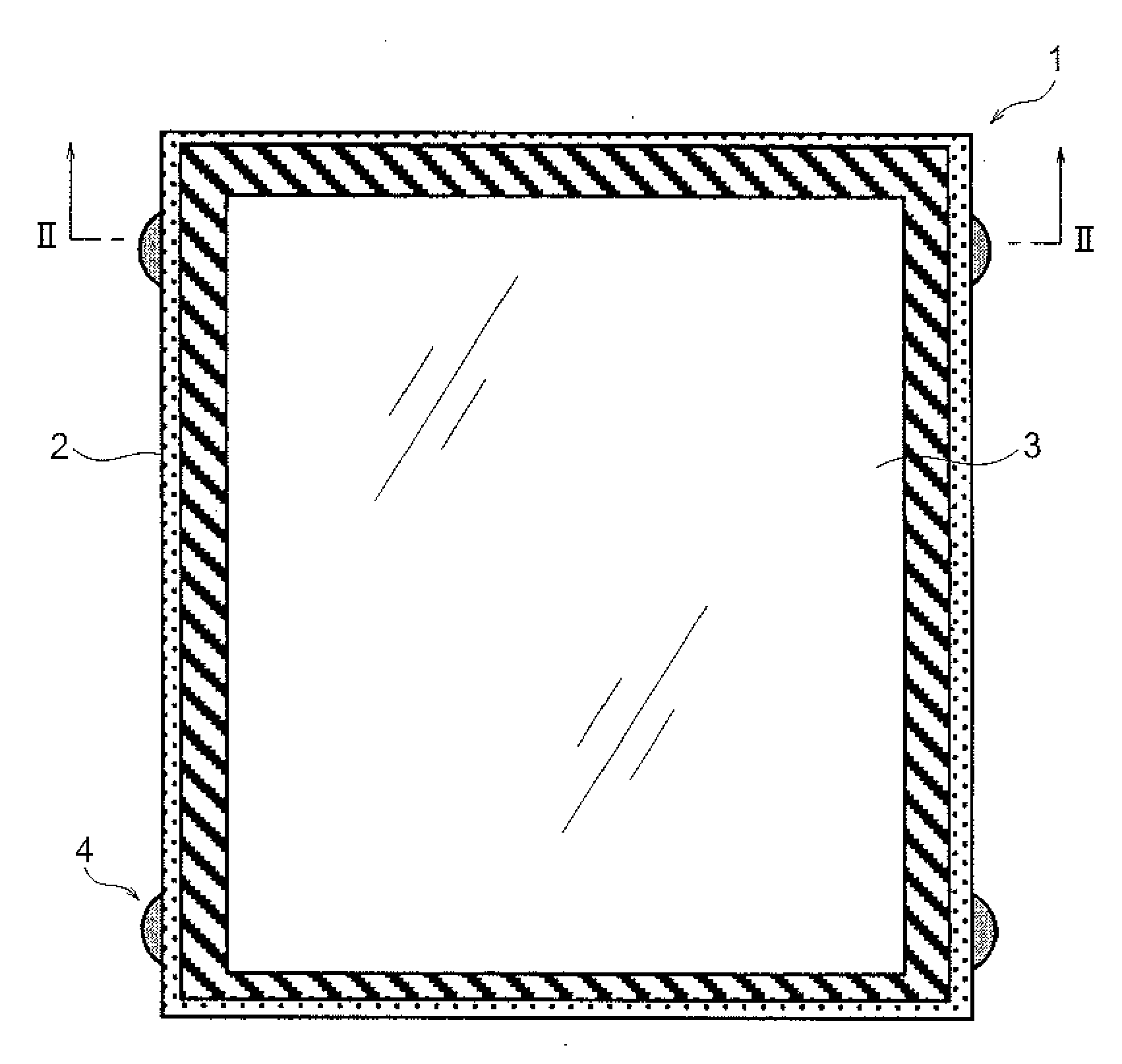

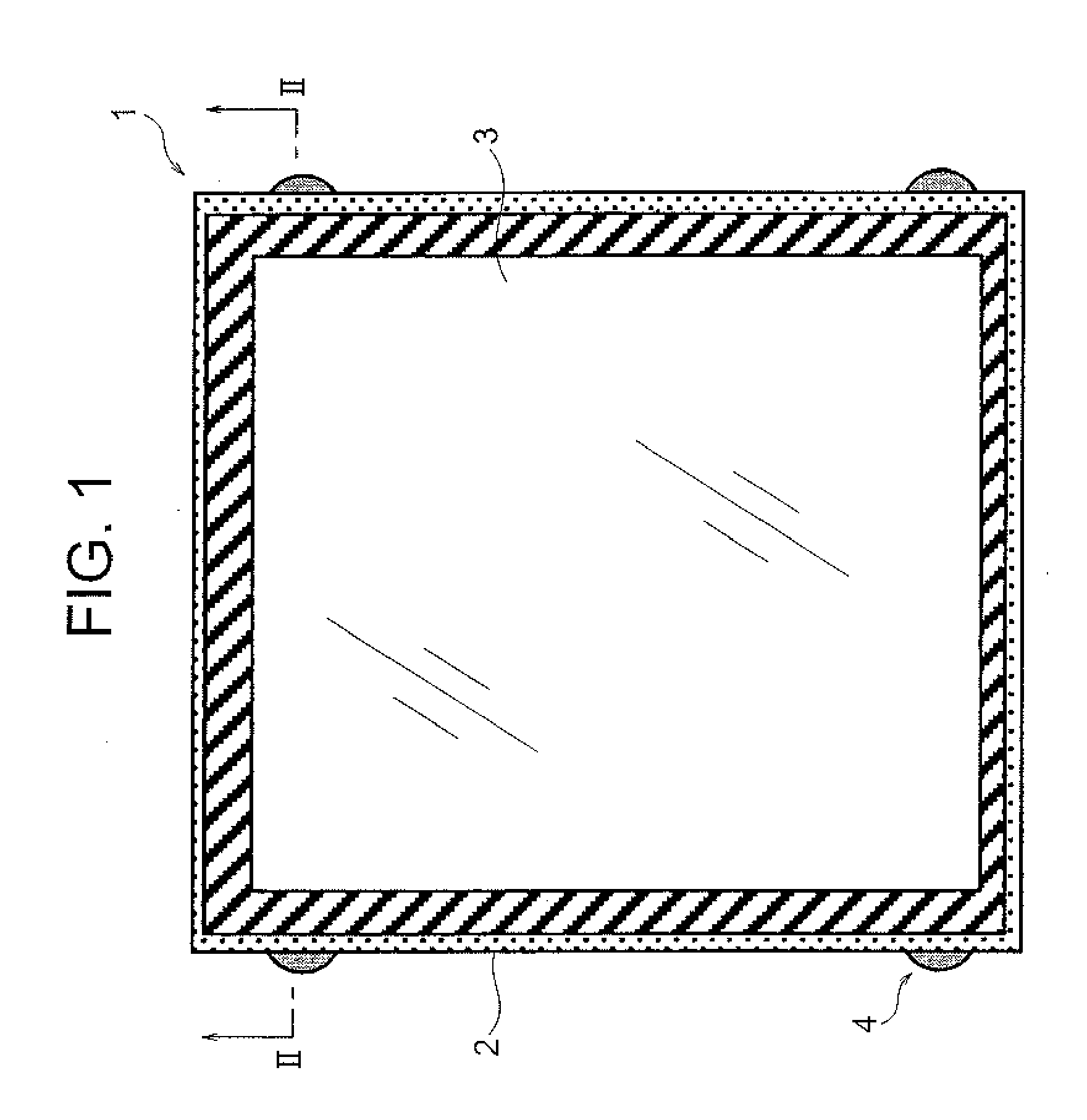

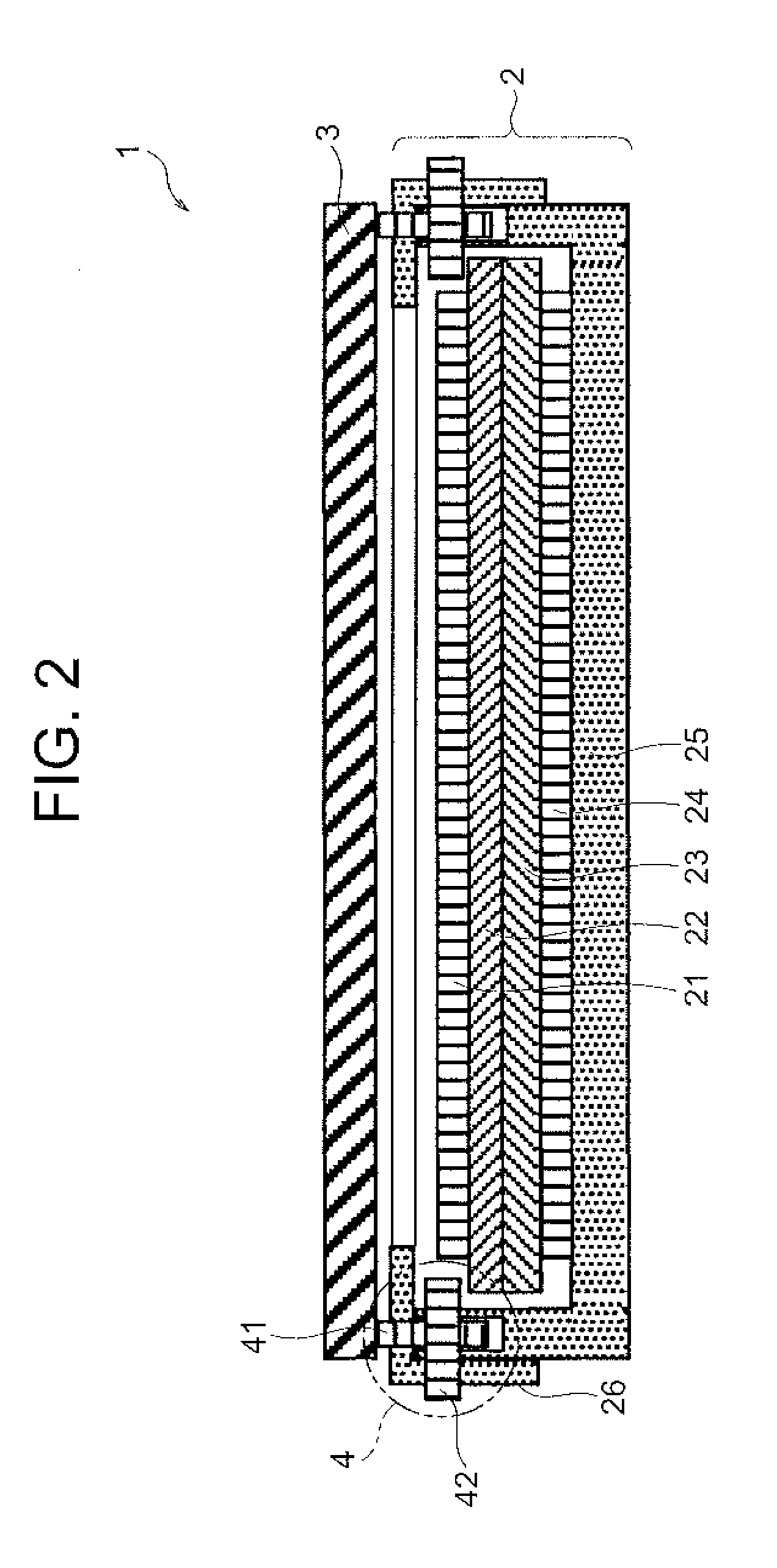

Imaging Device

InactiveUS20120287317A1Reduce external noiseSimple internal configurationTelevision system detailsTelevision system scanning detailsElectricityEngineering

An imaging device of the present invention, which is an imaging device for shooting images or video of a photographic subject, includes: an imaging element for taking an optical image of the photographic subject and generating image data therefrom; a main circuit board that is for conducting signal processing on the image data generated by the imaging element and that includes a main circuit board ground (“GND”) having a ground potential; an imaging element flexible cable that is connected to the main circuit board and on which the imaging element is mounted; a mount for fixing the imaging element and that includes a metallic component; and a metal plate that is connected to the mount and is disposed between the imaging element and the main circuit board. Wherein, the mount and the main circuit board GND are electrically connected.

Owner:PANASONIC CORP

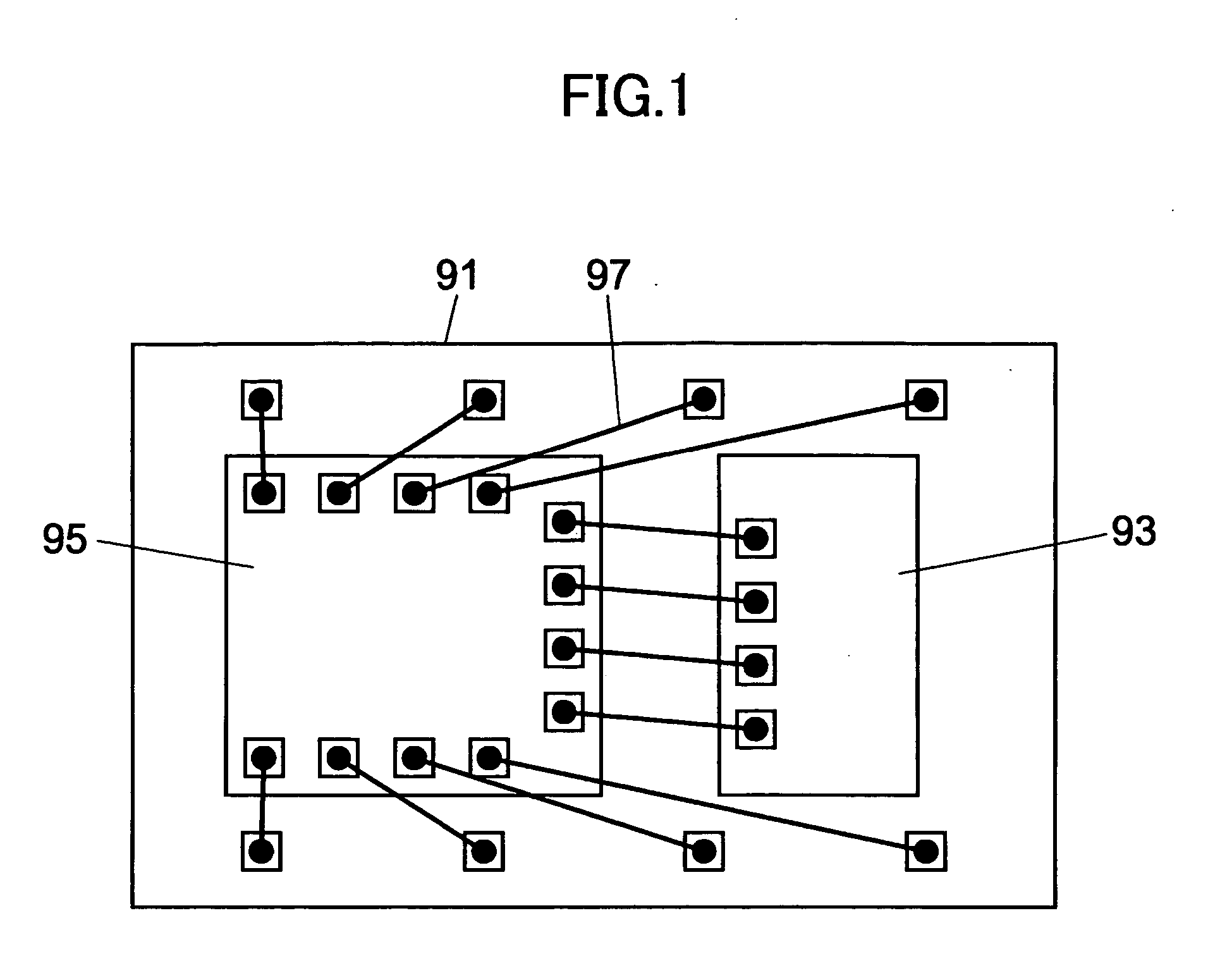

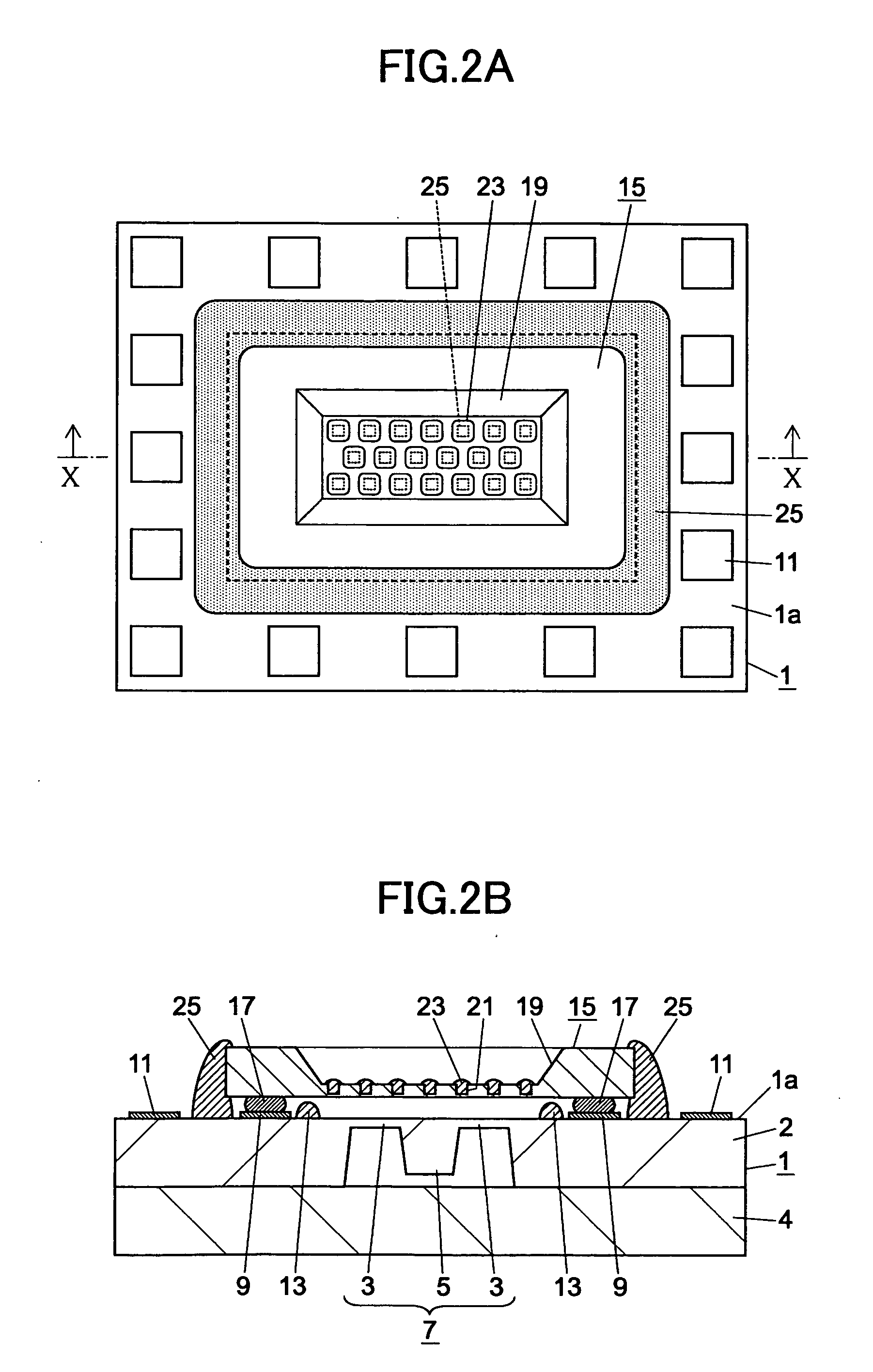

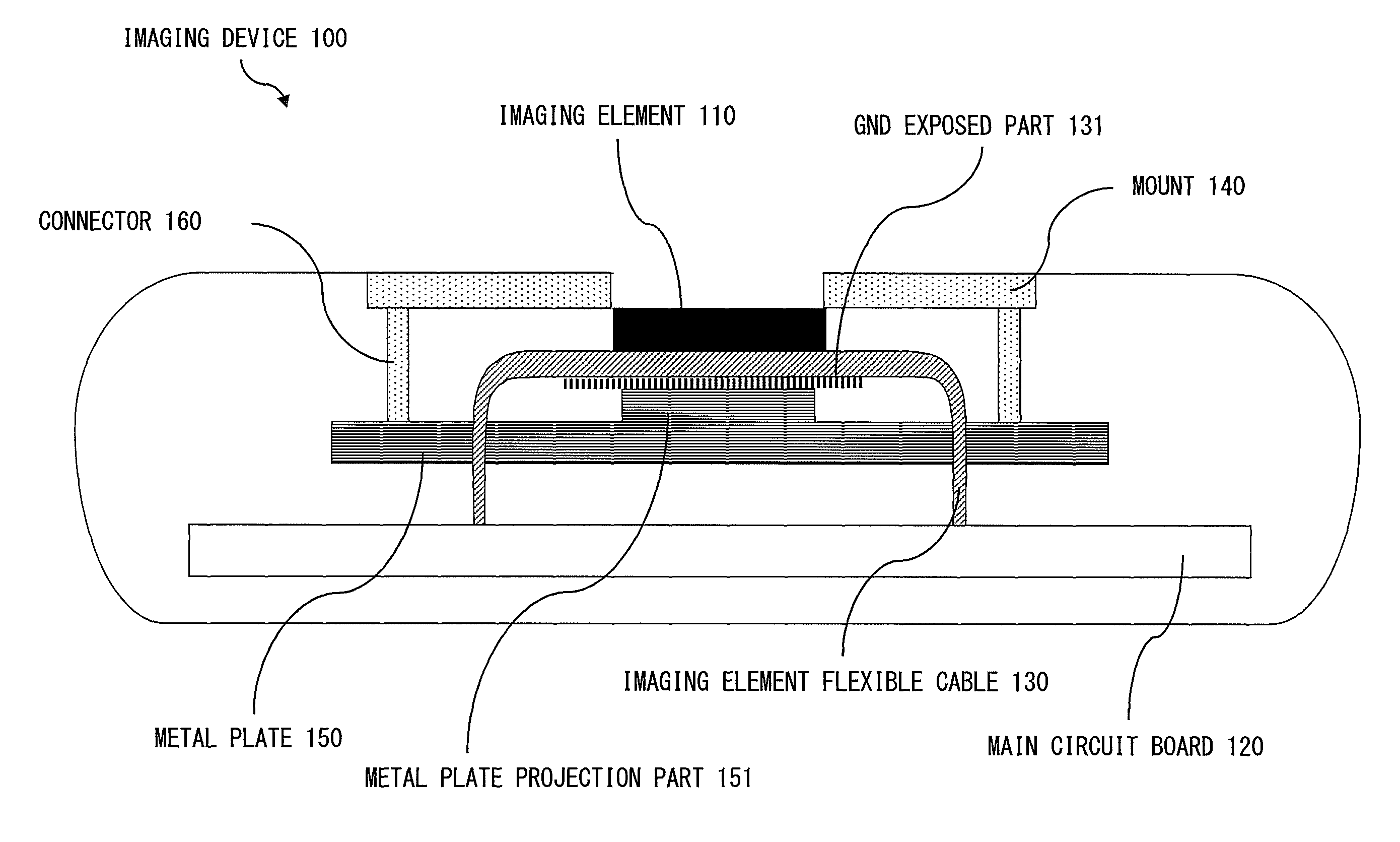

Imaging device

ActiveUS20130107115A1Reduce external noiseQuality improvementTelevision system detailsColor television detailsPhysicsImaging equipment

An imaging device includes: an imaging sensor 110; a main circuit substrate 120 includes a first ground conductor; an imaging sensor cable 130 that includes a second ground conductor, has the imaging sensor 110 mounted thereon, and is connected to the main circuit substrate 120; a metal plate 150 that is disposed between the main circuit substrate 120 and an area of the imaging sensor cable 130 where the imaging sensor 110 is mounted thereon, and that is electrically connected to the second ground conductor; and a ground connection conductor 190 that electrically connects between the first ground conductor and the metal plate 150. The ground connection conductor 190 is disposed in an area where the imaging sensor 110 and the imaging sensor cable 130 overlap each other or in an area where the imaging sensor 110 and the main circuit substrate 120 overlap each other.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

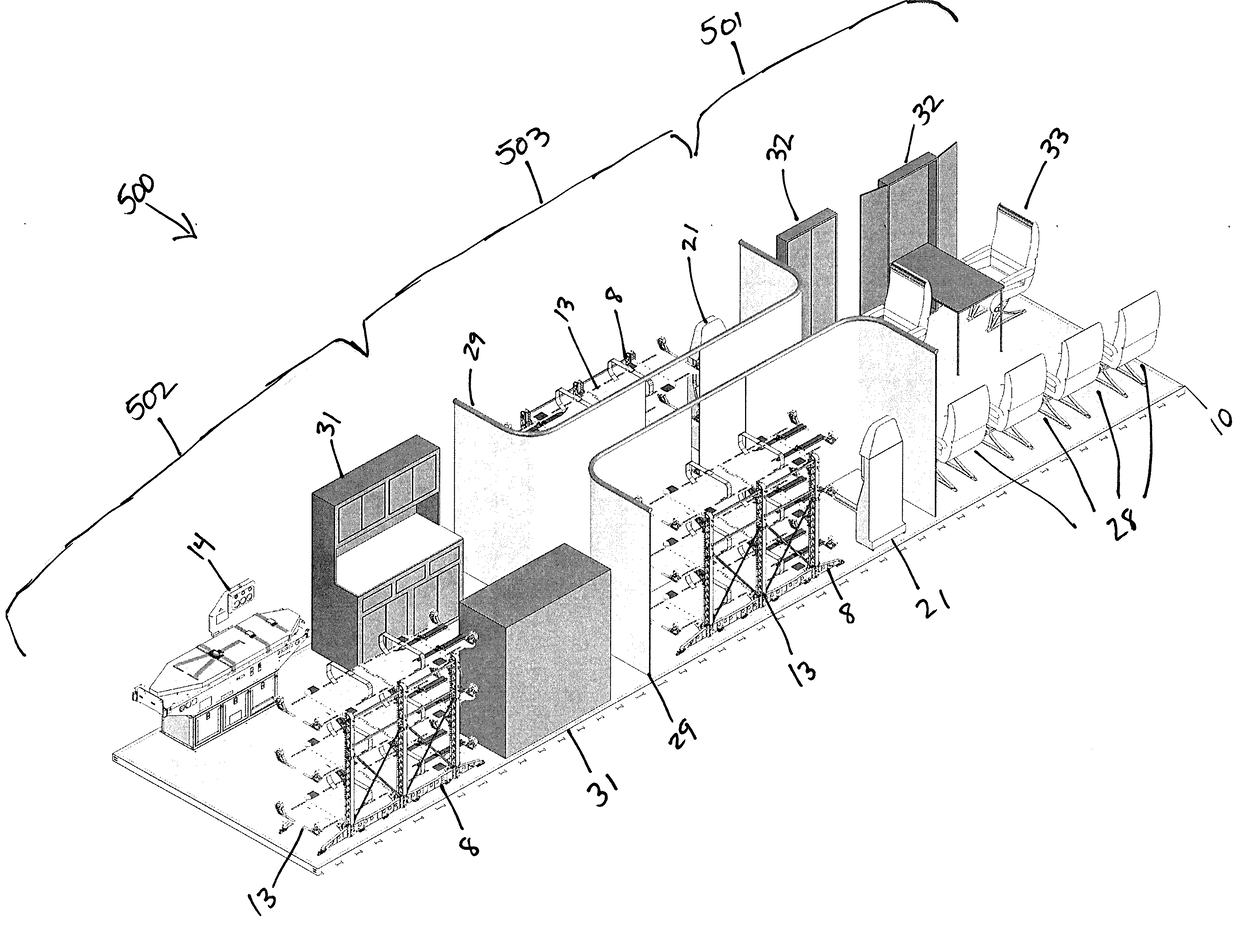

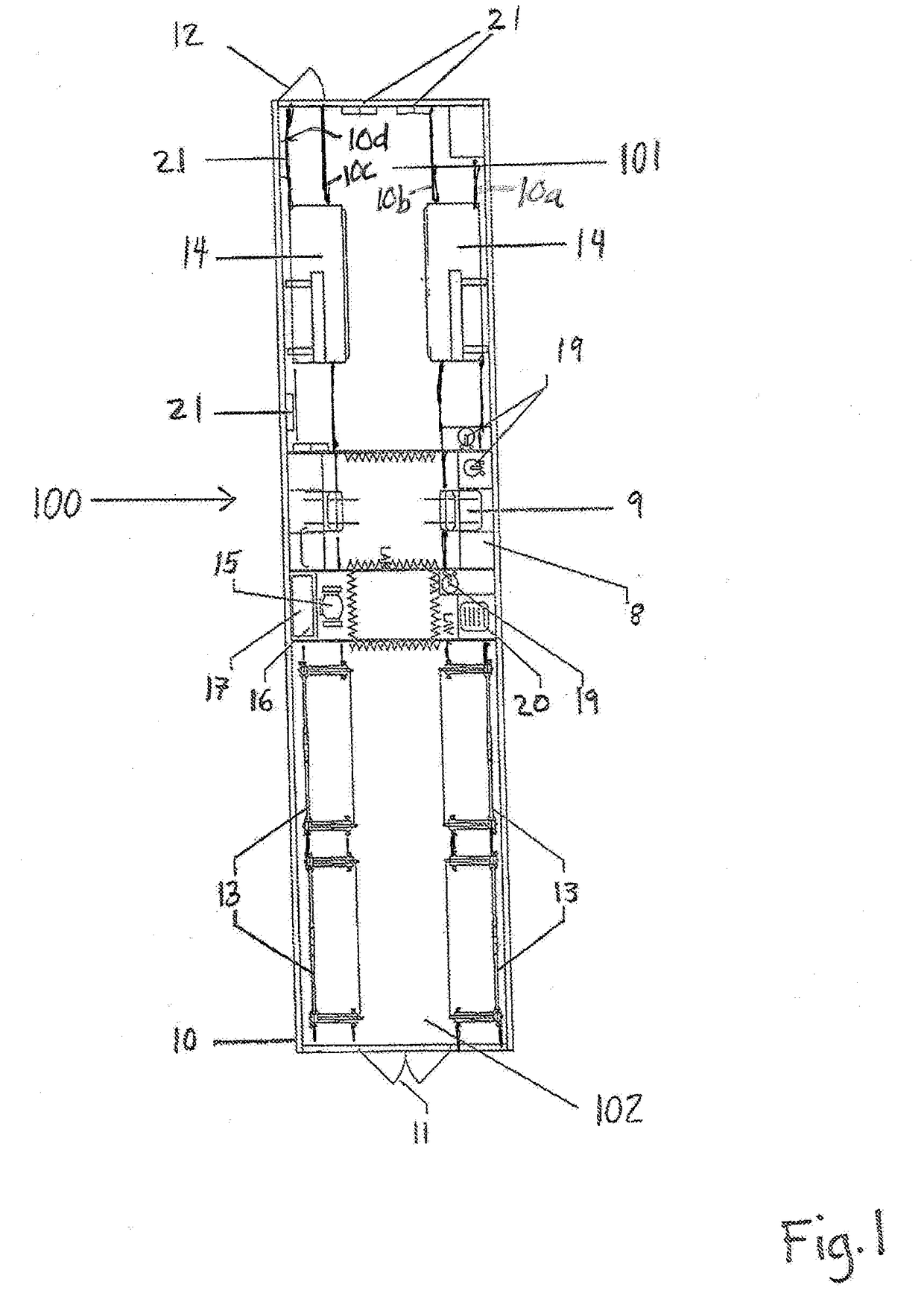

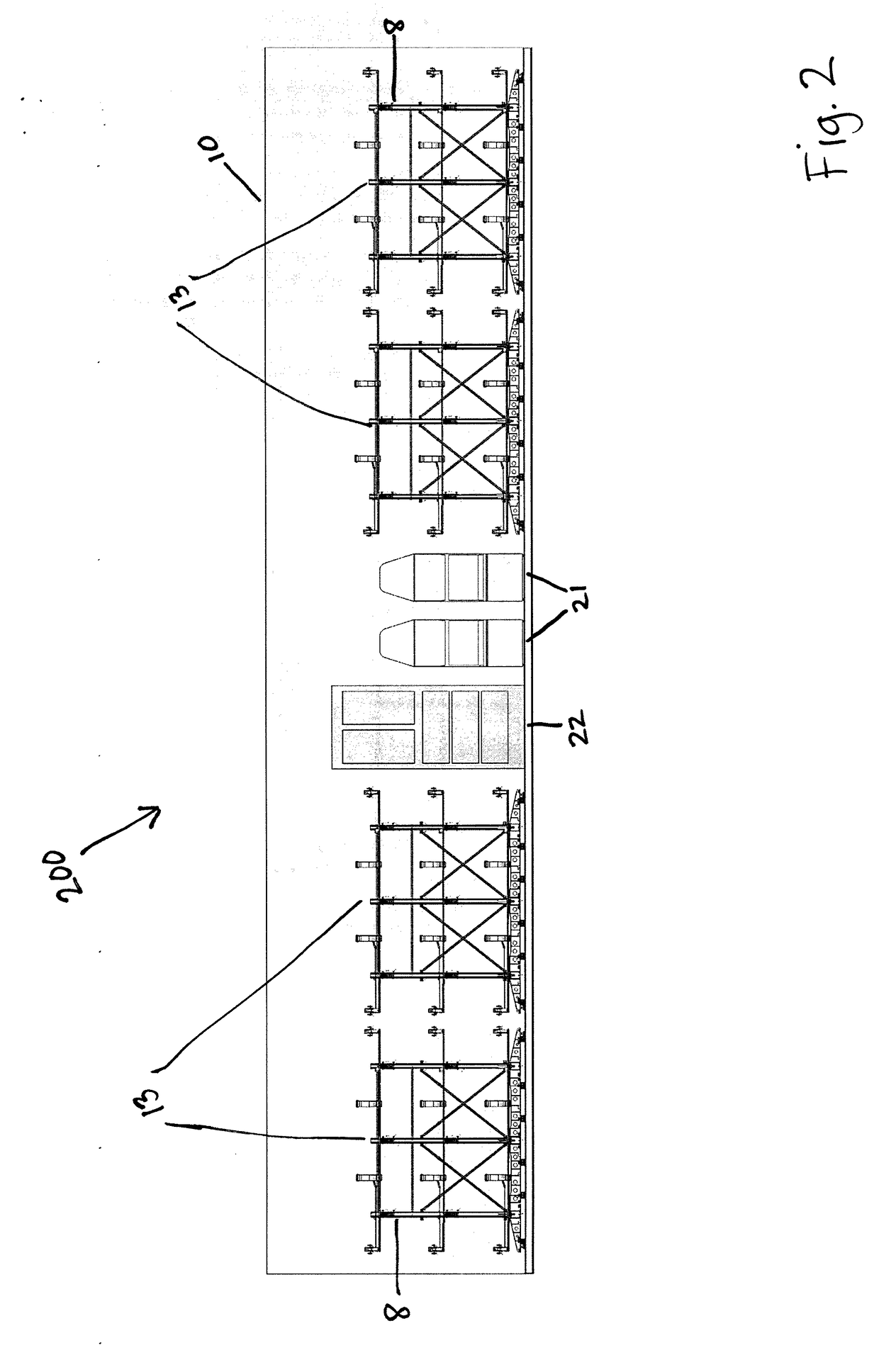

Portable Modularized Medical Unit and System

The invention includes a portable modularized medical unit that may be transported by airplane, helicopter, truck, rail, or ship to and from any location where emergency medical care, trauma care, surgical care, intensive care, isolation care, critical care, mass casualty, exam treatment or emergency medical evacuation are needed. The unit includes a rigid parallelepipedal frame that serves as the rigid exoskeleton of the unit that is a rigid aluminum parallelepipedal frame with a plurality of longitudinal metal tracks in the unit to provide the attachment or connection points for various medical components inside the internal portion of the portable modularized medical unit and that are rigidly attached to the interior surface of the base structure of the rigid parallelepipedal frame to provide multiple connection and attachment points for the components in an airworthy but removable manner to the base structure, walls, or roof of the rigid parallelepipedal frame so that the components internal to the unit may be attached, removed, relocated, replaced, and rearranged inside of the portable modularized medical unit.

Owner:KNIGHT AEROSPACE MEDICAL SYST LLC

Imaging Device

InactiveUS20120314118A1Reduce external noiseSimple configurationTelevision system detailsColor television detailsControl signalEngineering

An imaging device of the present invention includes: an imaging element for taking an optical image of a photographic subject and generating image data therefrom; a main circuit board for conducting signal processing on the image data, an imaging element flexible cable on which the imaging element is mounted and that has a ground potential; a shutter that opens and closes timed on the shooting of images or video of the photographic subject; a shutter flexible cable that transfers a control signal for controlling the shutter and that has a ground potential; a mount for fixing the imaging element and that includes a metallic component; and a metal plate that is connected to the mount and is disposed between the imaging element and the main circuit board. Therein, the ground potential of the imaging element and the shutter flexible cable are connected.

Owner:PANASONIC CORP

Imaging device

ActiveUS8421912B2Reduce external noiseSimple configurationTelevision system detailsColor television detailsEngineeringImaging equipment

Owner:PANASONIC CORP

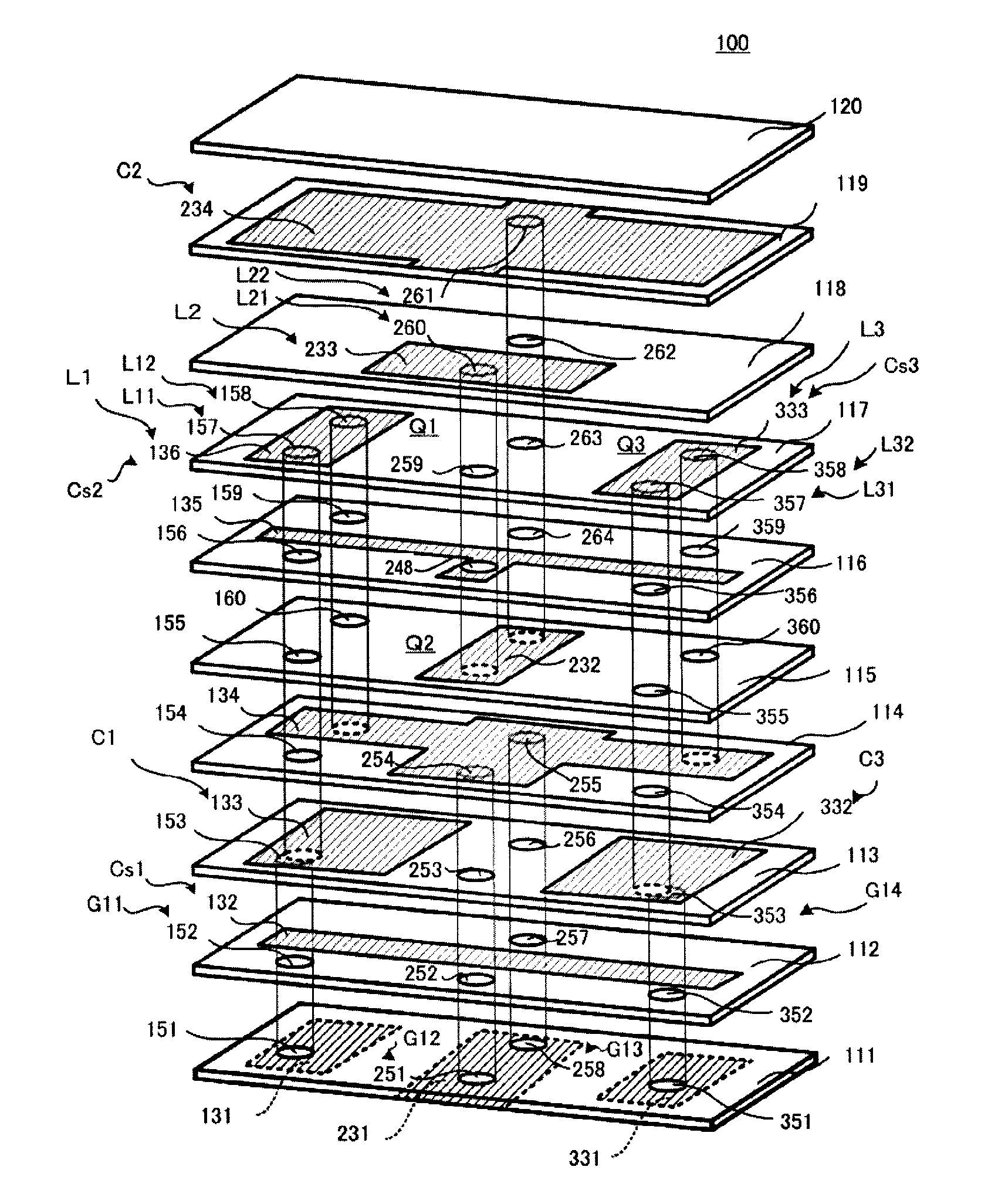

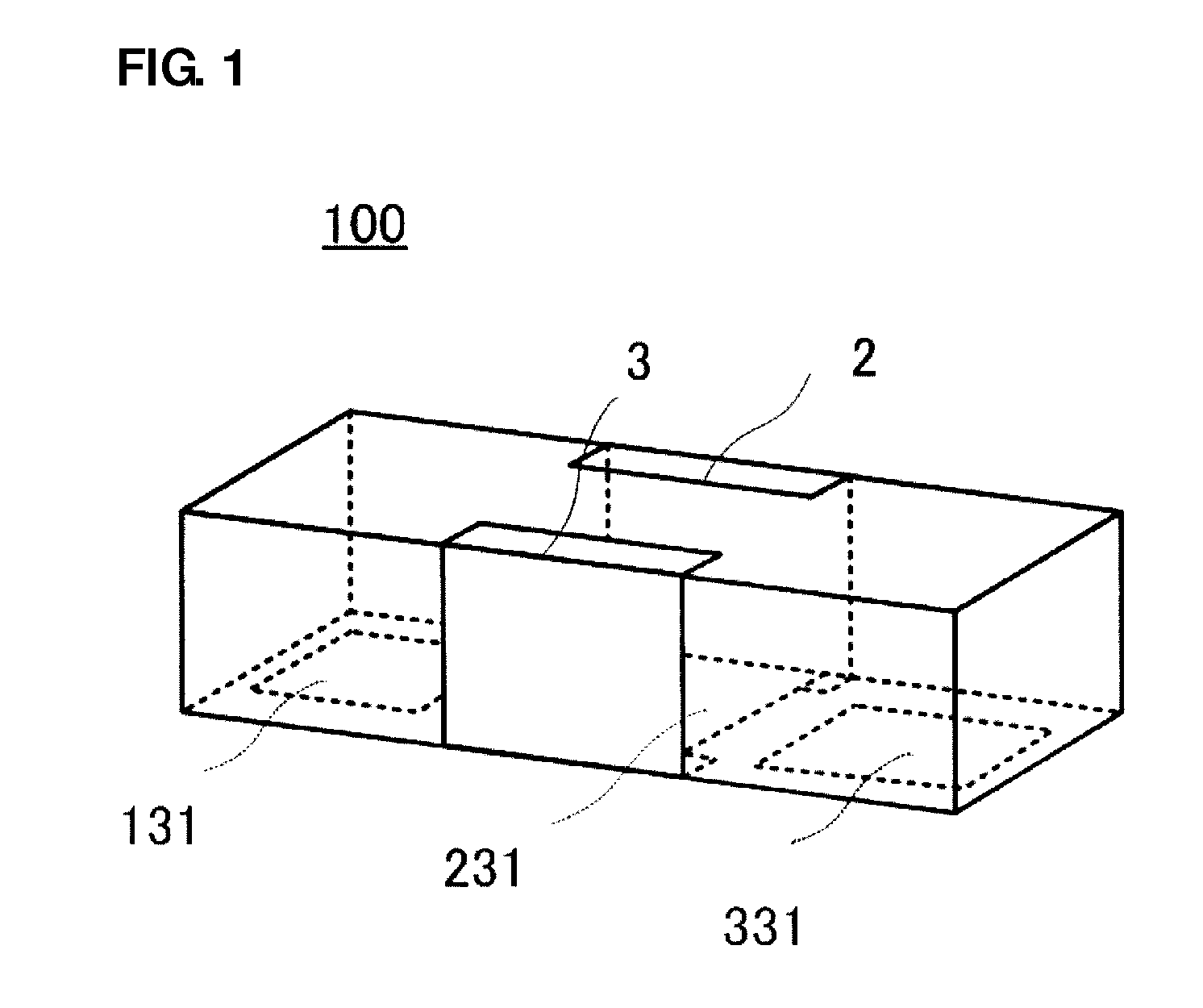

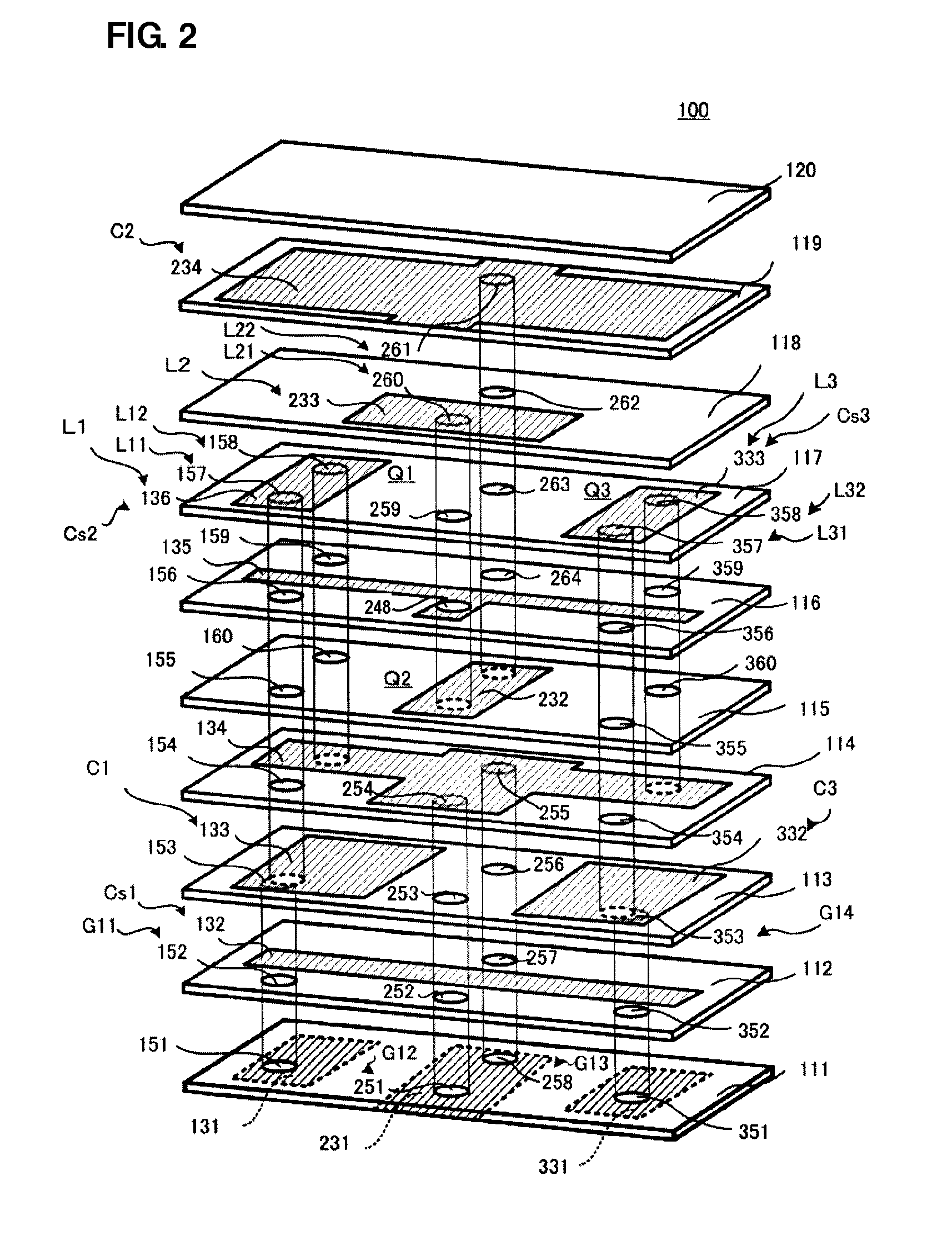

Band-pass filter

ActiveUS20130154769A1Improve featuresIncrease capacitanceMultiple-port networksResonatorsLc resonatorBand-pass filter

A capacitor of a certain LC resonator, among multiple LC resonators in a band-pass filter, is arranged at a side of one main surface in a stacking direction of a multilayer body of the band-pass filter and the capacitors of the remaining LC resonators are arranged at a side of the other main surface in the stacking direction of the multilayer body. One of a pair of capacitor electrodes of the capacitor of the certain LC resonator is grounded. The one capacitor electrode that is grounded covers at least the plurality of LC resonators, as viewed from the stacking direction of the multilayer body.

Owner:MURATA MFG CO LTD

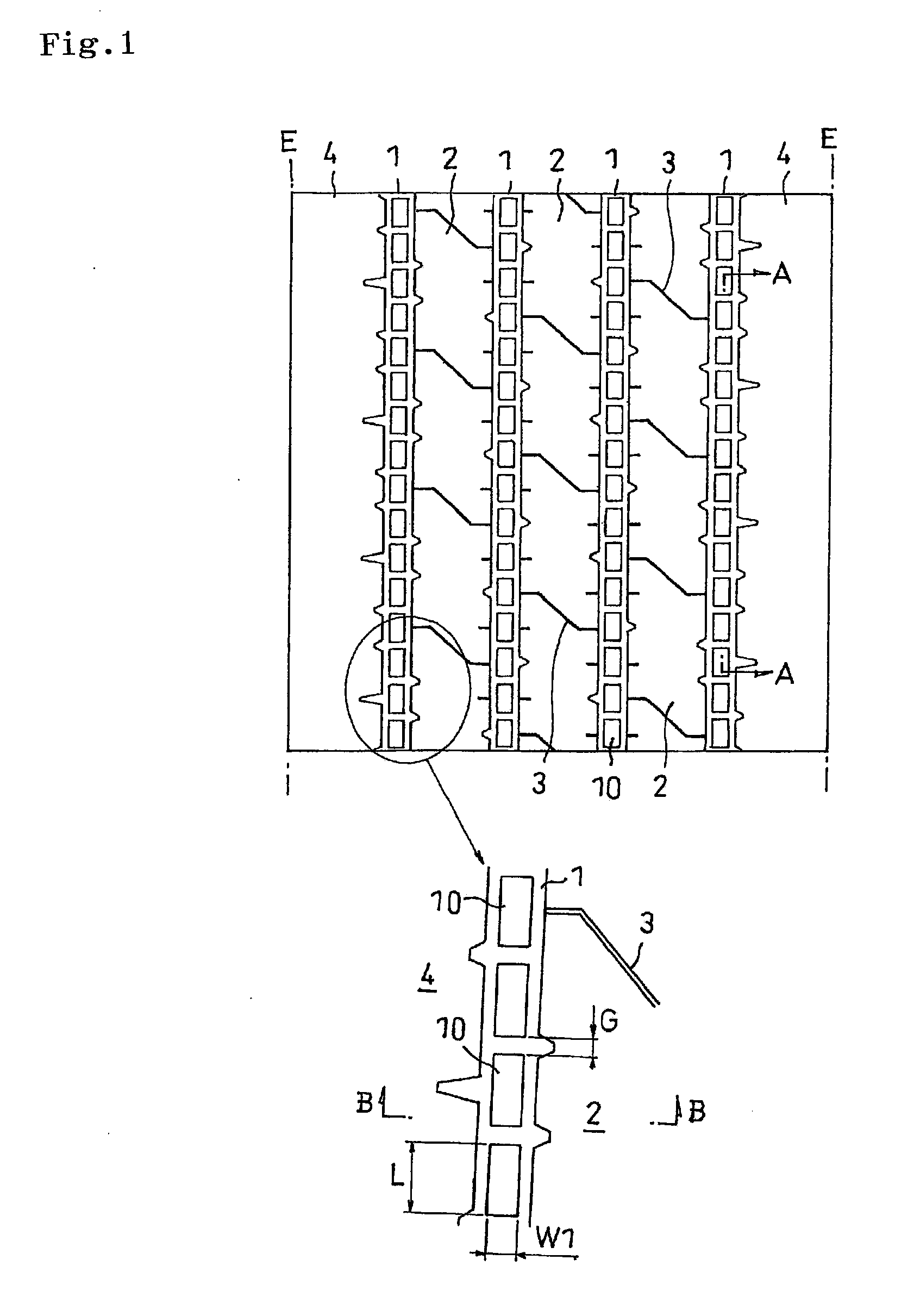

Pneumatic Tire

InactiveUS20100212793A1Reduce car exterior noiseReduce marginTyre tread bands/patternsNon-skid devicesEngineeringMechanical engineering

A pneumatic tire has a main groove extending along a tire circumferential direction in a tread surface. A plurality of projections having different heights are provided in a groove bottom of the main groove in such a manner that an outer peripheral surface is inclined so as to repeat trough portions depressed to an inner side in a tire diametrical direction and peak portions protruding to an outer side in the tire diametrical direction along the tire circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

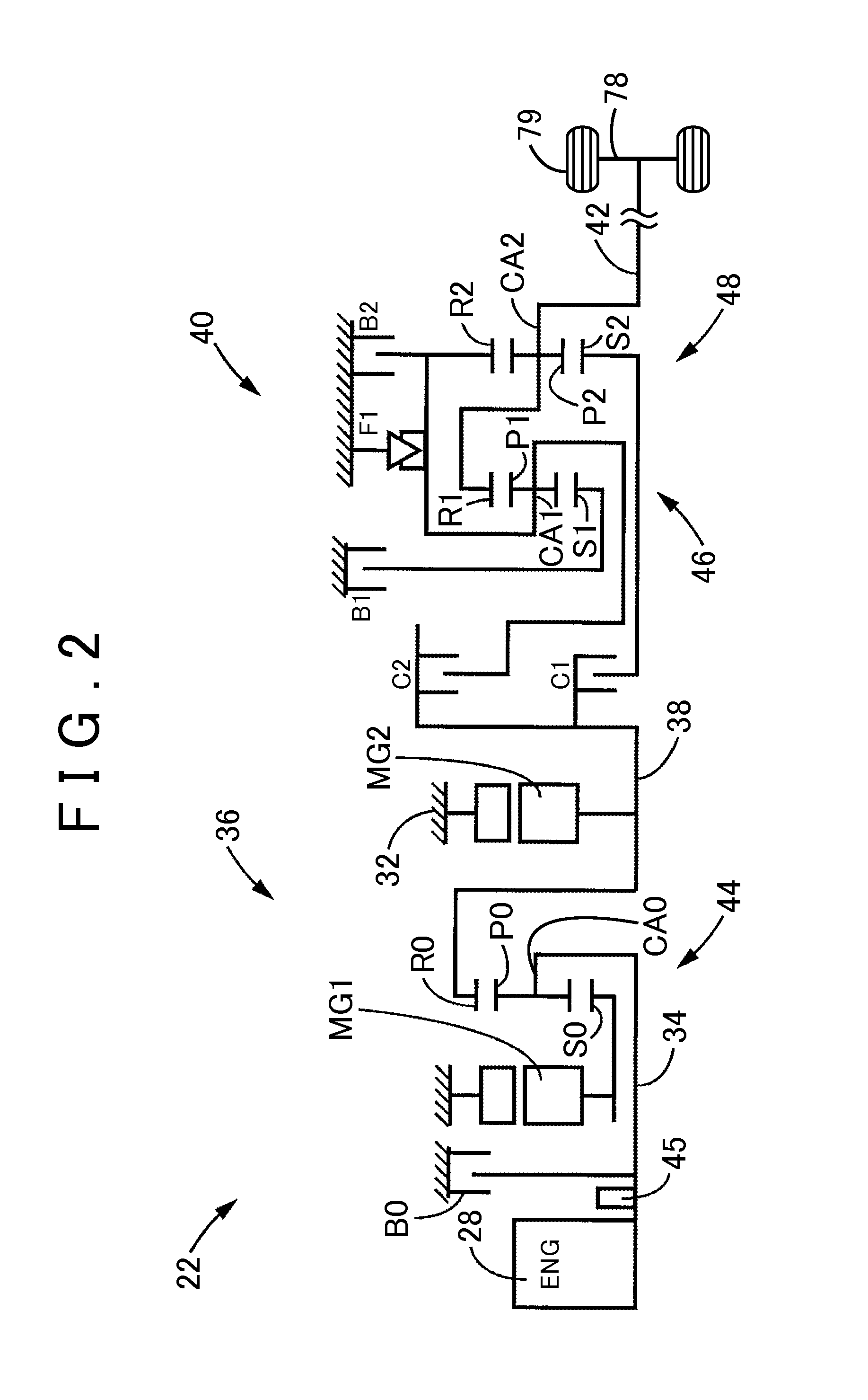

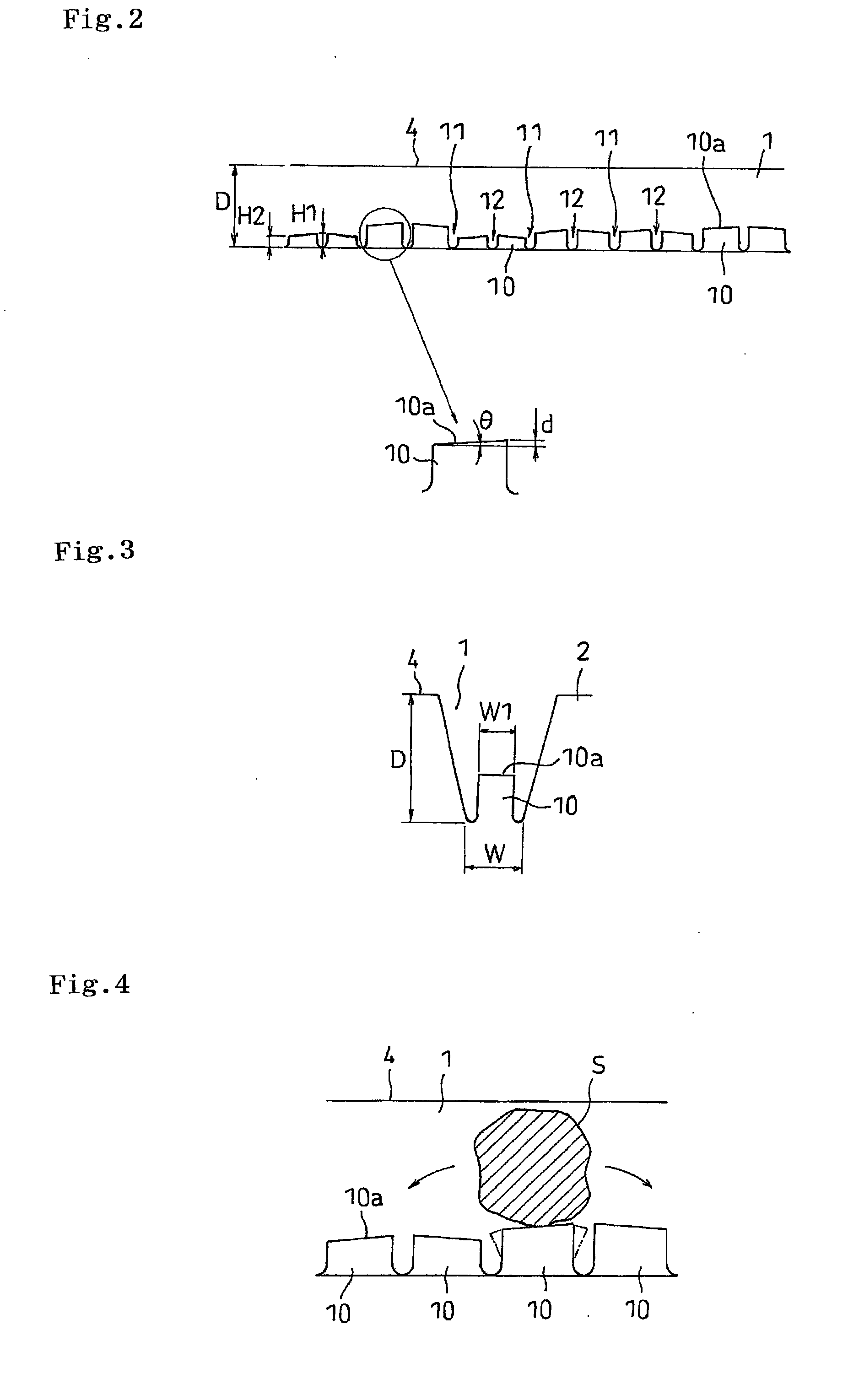

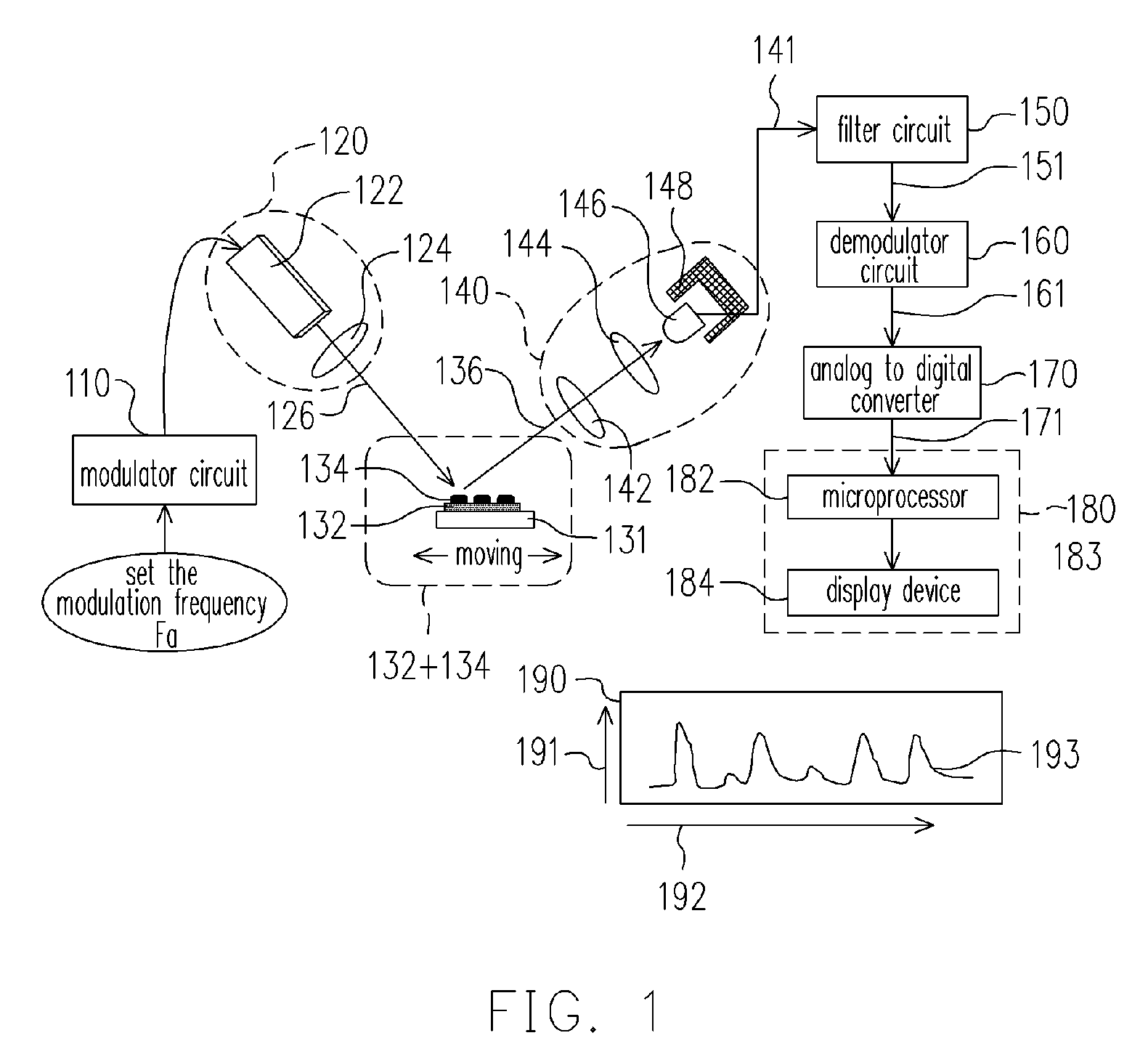

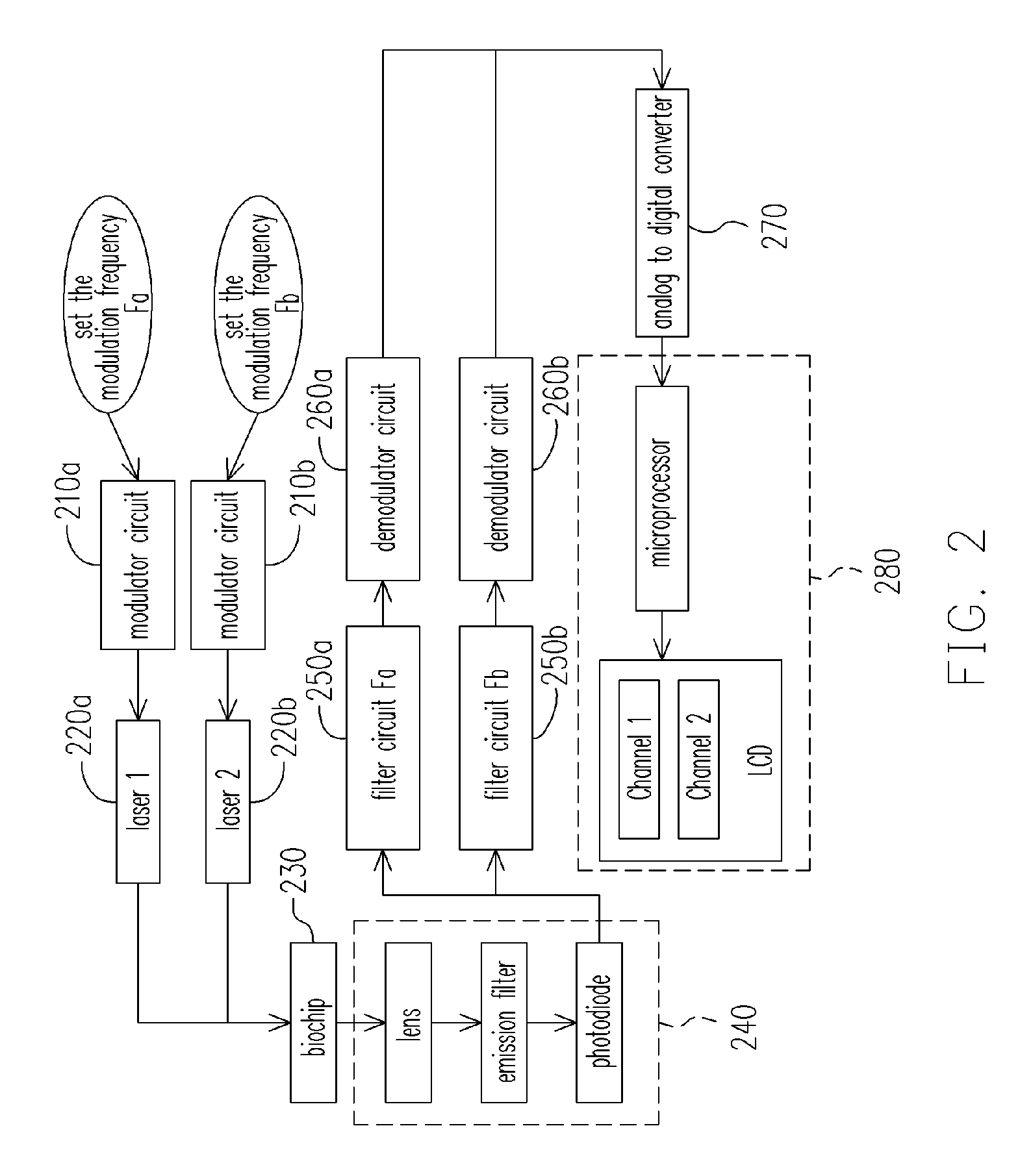

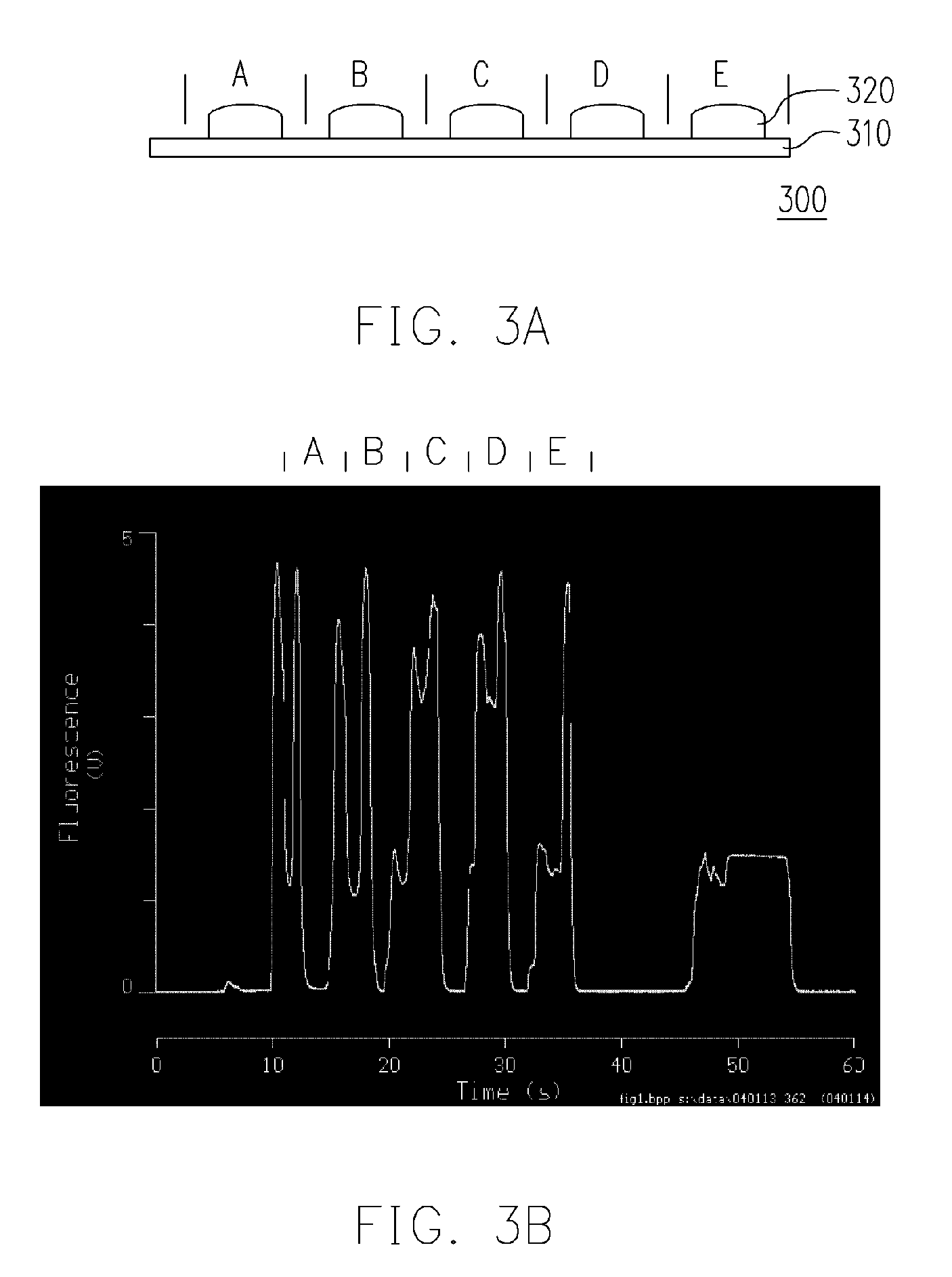

System and method for analyzing biochip

InactiveUS20050214931A1Reduce external noiseBioreactor/fermenter combinationsBiological substance pretreatmentsOptical sensingDigital converter

A system and method for analyzing a biochip are provided. Wherein, a first modulator circuit outputs a first modulated signal with a first frequency. A first light source module output a first light beam based on the first modulated signal. A first optical signal is generated after the first light beam being emitted onto the biochip. An optical sensing module sense the first optical signal and outputting a first sensing signal. A first filter circuit filters the first sensing signal and outputting a first portion sensing signal. A first demodulator circuit demodulates the first portion sensing signal and outputting a first demodulated signal. An analog to digital converter convert the first demodulated signal to a first digital signal. A signal display module receives and display the first digital signal.

Owner:NATIONAL YANG MING UNIVERSITY

Imaging device

InactiveUS20130076975A1Image can be preventedReduce external noiseTelevision system detailsColor television detailsElectrical conductorEngineering

An imaging device 100 includes: an imaging element 110; a main circuit substrate 120; a mounting component 130 mounting the imaging element 110; a metal plate 150 disposed between the mounting component 130 and the main circuit substrate 120; a mount 140 supporting the metal plate 150 by connection sections 160 being fixed at at least three fixing points; elastic components 165 urging the connection sections 160 at each fixing point of the mount 140; and an electrically-conductive component 190 electrically connecting between a ground conductor of the main circuit substrate 120 and the metal plate 150. The electrically-conductive component 190 is disposed such that a connection point with the metal plate 150 is positioned in a area formed by the at least three fixing points being sequentially connected in the case of a back surface of the metal plate 150 being viewed in a direction orthogonal thereto.

Owner:PANASONIC CORP

Gas concentrator with removable cartridge adsorbent beds

ActiveUS10004869B2Reduce external noiseAvoid breakingRespiratorsGas treatmentAir filterComputer module

Owner:INOGEN INC

Imaging device

InactiveUS8786772B2Reduce external noiseSimple configurationTelevision system detailsColor television detailsControl signalEngineering

An imaging device of the present invention includes: an imaging element for taking an optical image of a photographic subject and generating image data therefrom; a main circuit board for conducting signal processing on the image data, an imaging element flexible cable on which the imaging element is mounted and that has a ground potential; a shutter that opens and closes timed on the shooting of images or video of the photographic subject; a shutter flexible cable that transfers a control signal for controlling the shutter and that has a ground potential; a mount for fixing the imaging element and that includes a metallic component; and a metal plate that is connected to the mount and is disposed between the imaging element and the main circuit board. Therein, the ground potential of the imaging element and the shutter flexible cable are connected.

Owner:PANASONIC CORP

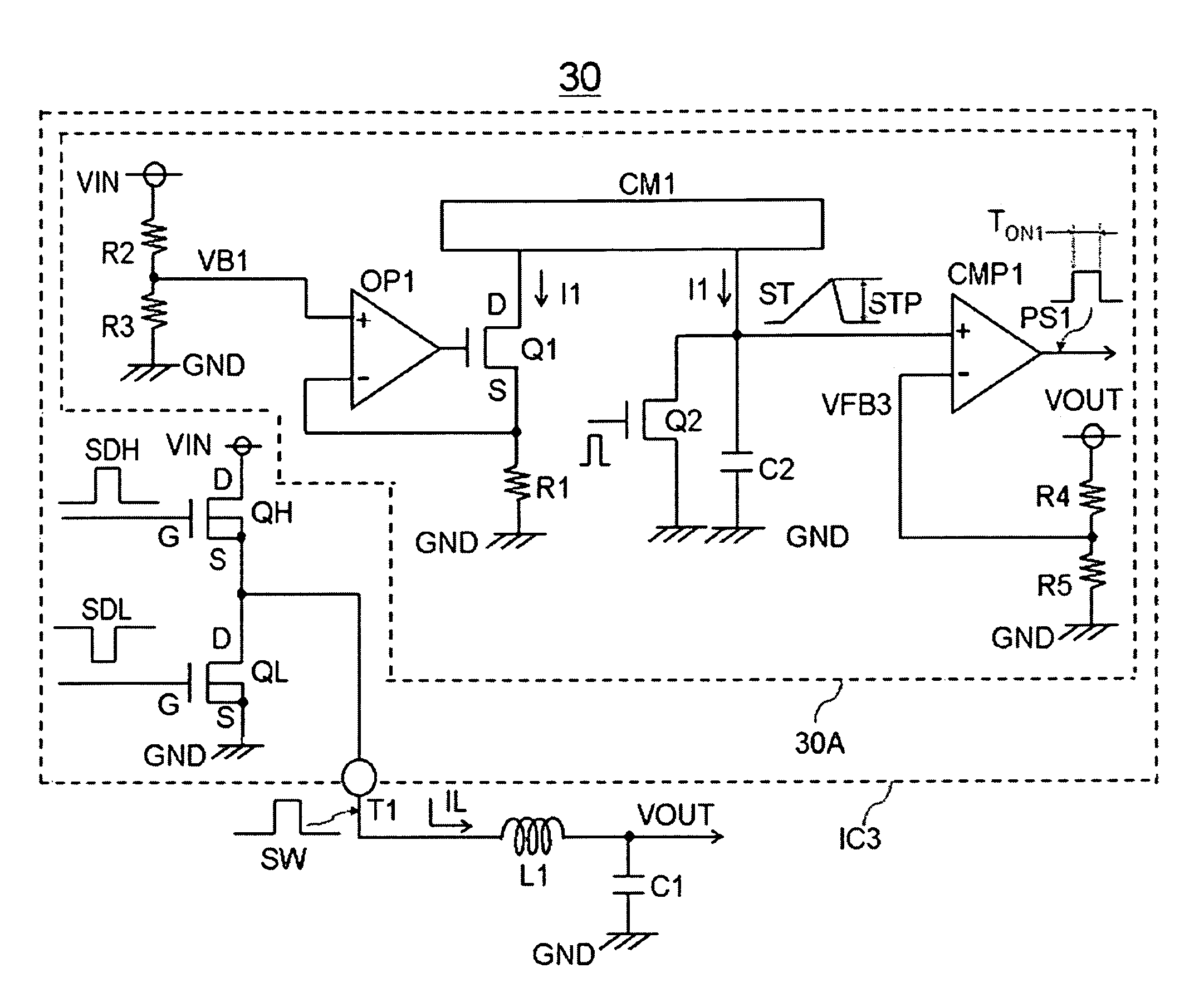

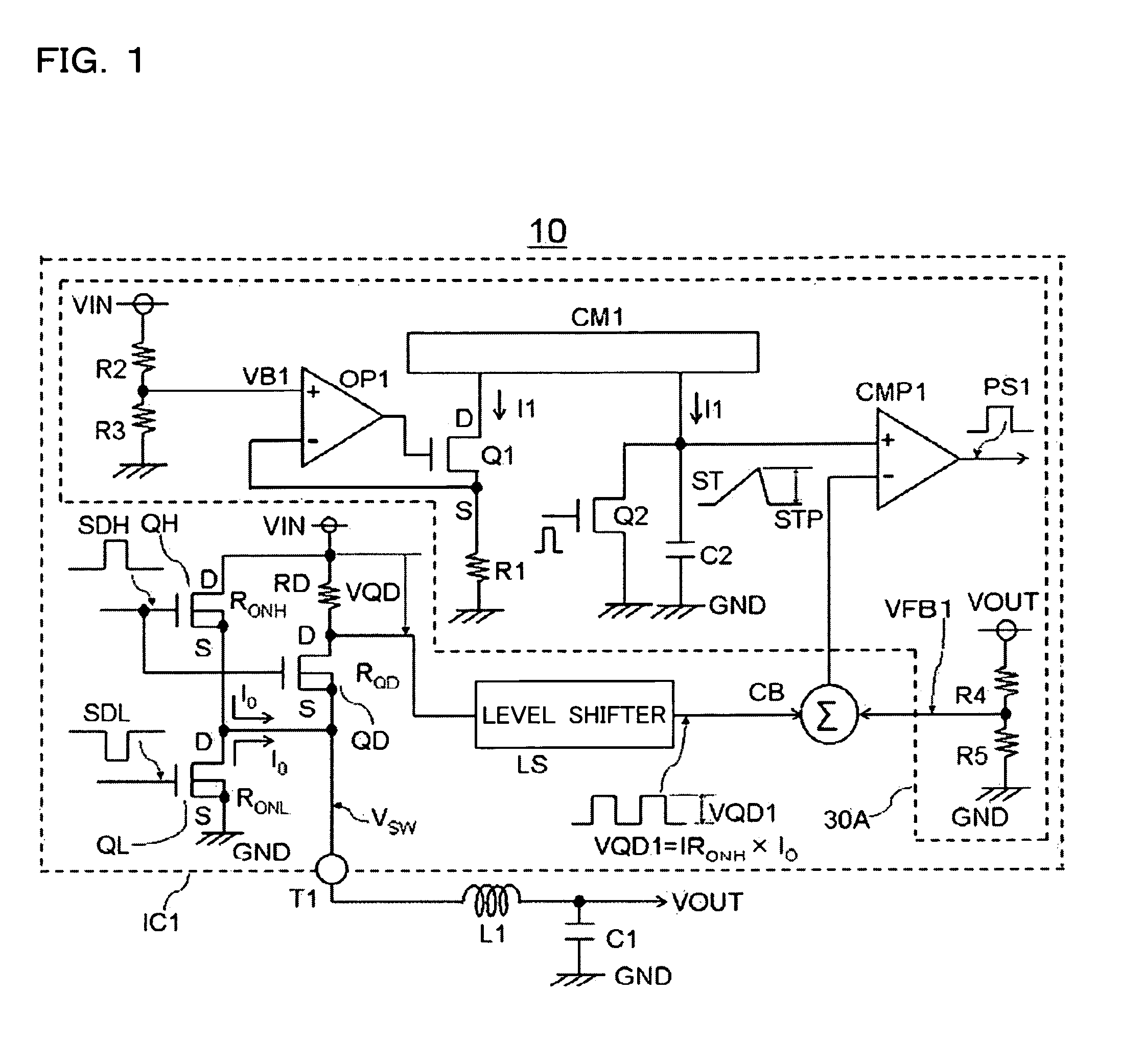

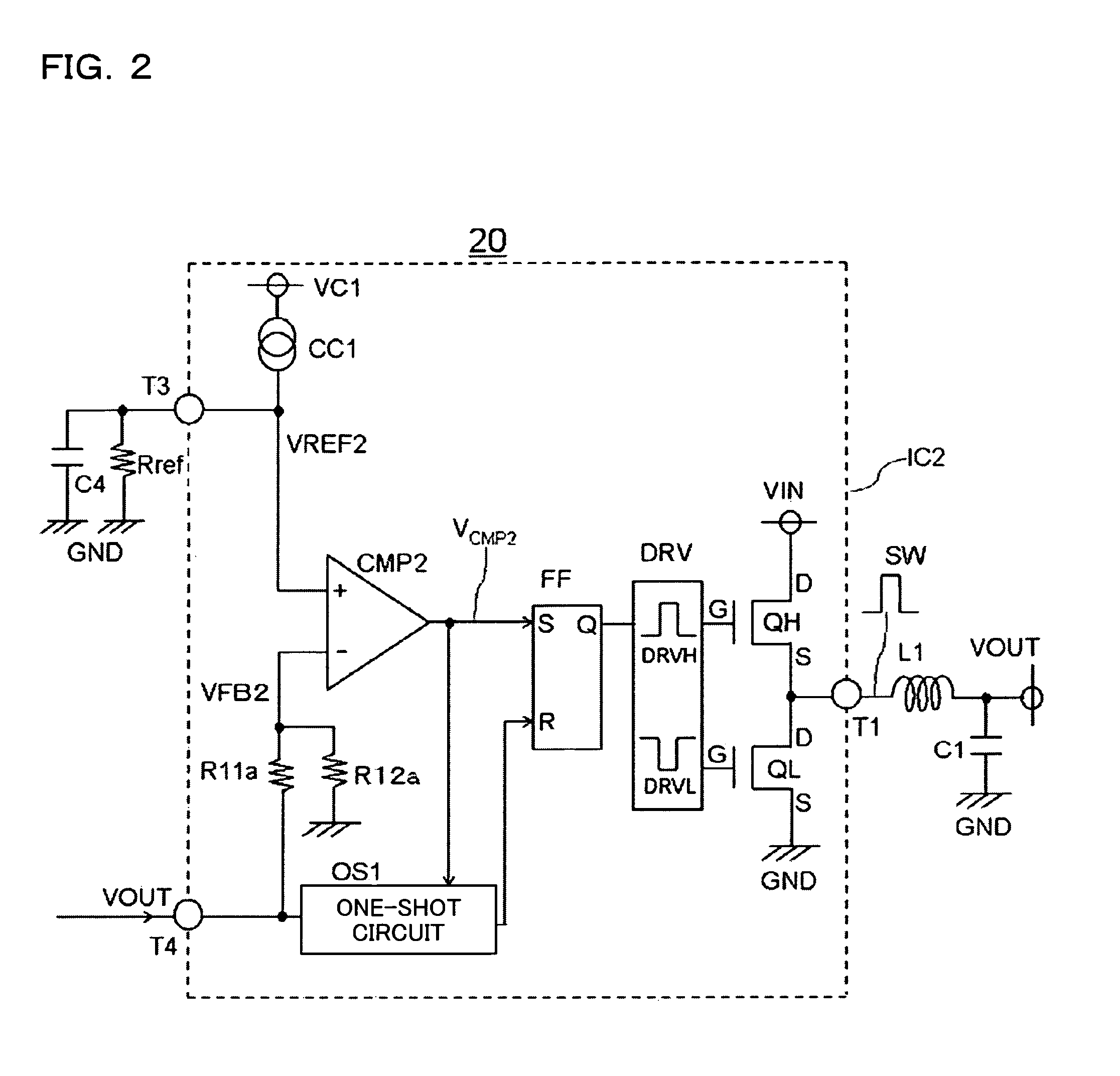

DC/DC converter and television using same

ActiveUS8830405B2Raise the ratioReduce noiseTelevision system detailsElectric signal transmission systemsEngineeringOne shot

A DC / DC converter 10 has a high-side transistor QH as a switching element and a low-side transistor QL as a synchronous rectifier element. A first primary electrode D and secondary primary electrode S of the high-side transistor QH are connected to an input voltage VIN and an external terminal T1, respectively. A detection transistor QD is provided in a row with the high-side transistor QH, and the ON voltage of the high-side transistor QH when ON is output as detection voltage VQD from the detection transistor QD. The output detection voltage VQD is added to a feedback voltage VFB1 by an adder CB, and inputted to a comparator CMP1. The ON period of a one-shot pulse PS1 outputted from the comparator CMP1 is regulated so as to be in direct proportion to the sum of the detection voltage VQD and the feedback voltage VFB1.

Owner:ROHM CO LTD

Display device with touch sensor, control system and control method thereof

InactiveUS20140232683A1Reduce external noiseInput/output processes for data processingCapacitanceControl system

A display device with a touch sensor and the like, capable of adjusting the external noise even in a state where the touch sensor is being placed on a display panel or a state where the display device with the touch sensor is being mounted into an electronic apparatus, includes a display panel, a capacitance type touch sensor provided by being superimposed on the display panel, and a distance variable mechanism which changes the distance between the touch sensor and the display panel.

Owner:NEC LCD TECH CORP

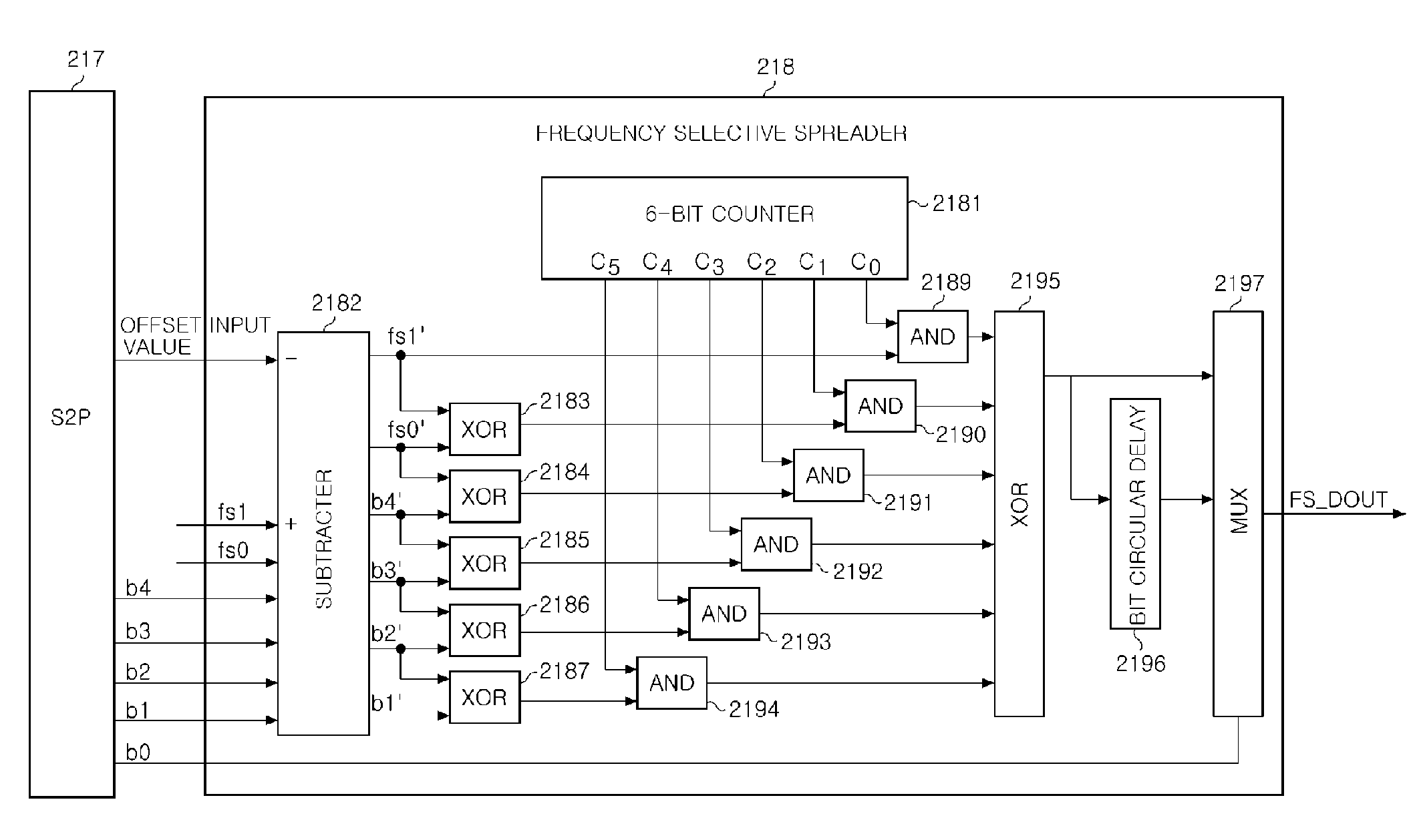

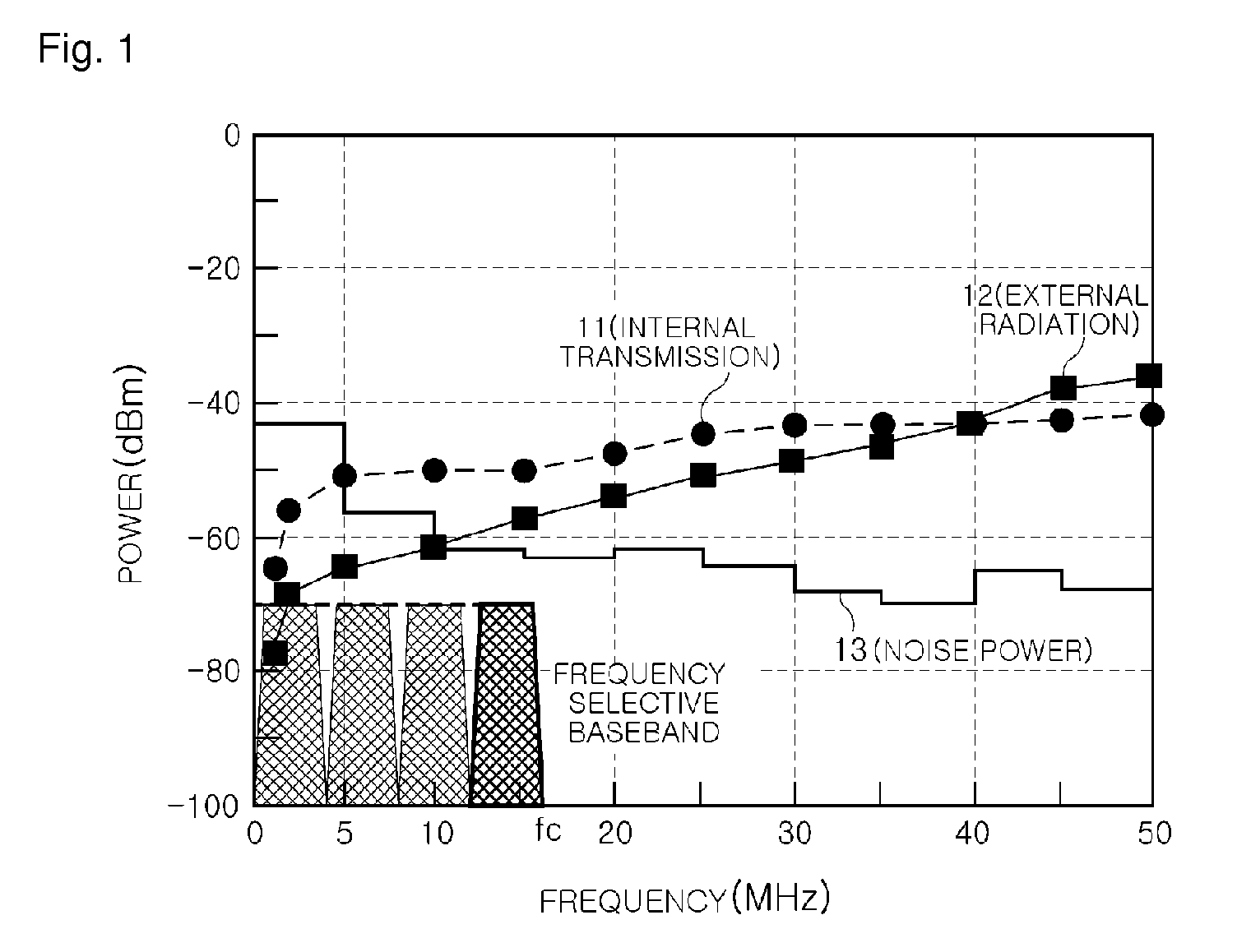

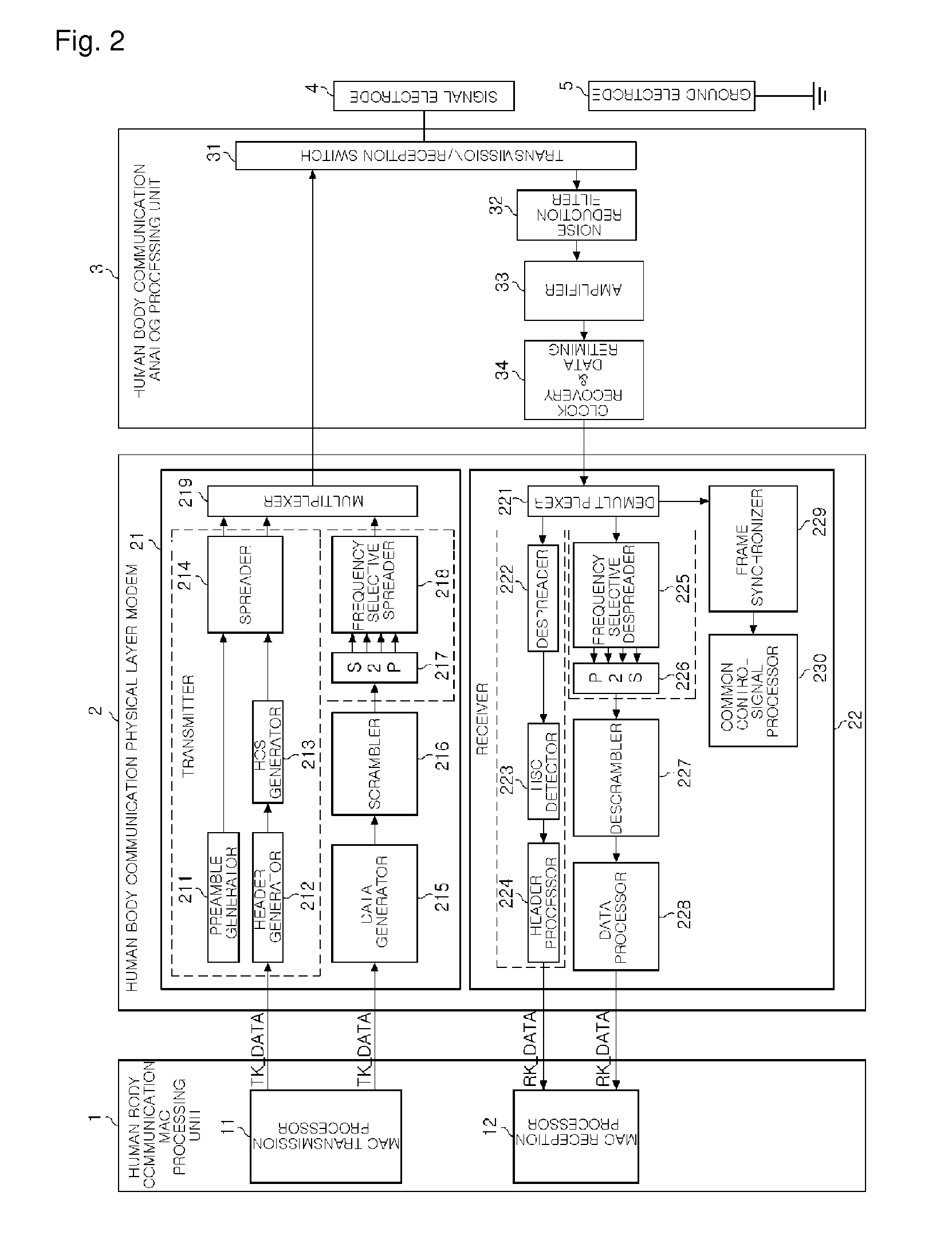

Modulation and demodulation apparatus using frequency selective baseband and transmission and reception apparatus using the same

InactiveUS8345735B2Increase processing gainReduce external noiseTransmission monitoringLine-transmission monitoring/testingData rateEngineering

There is provided a communication method using a human body as a medium. A modulation apparatus using a frequency selective baseband according to an aspect of the invention may include: a serial-to-parallel conversion unit converting serial data supplied from an upper layer into parallel data consisting of M+1 number of data input bits; and a frequency selective spreader selecting one subgroup among a plurality of subgroups obtained by dividing 2N number (where N is a positive integer) of spreading codes used for frequency spreading by 2M (where M is a positive integer, and M<N is satisfied), and selecting and outputting one spreading code among 2M number of spreading codes of the one subgroup by using the M number of data input bits, and spreading codes obtained by performing bit circular shifts on the 2M number of spreading codes. Accordingly, the number of transmission data is increased to improve a transmission data rate, strong interference induced from users and other electronic devices is reduced, and stable human body communication having low power consumption is performed.

Owner:ELECTRONICS & TELECOMM RES INST

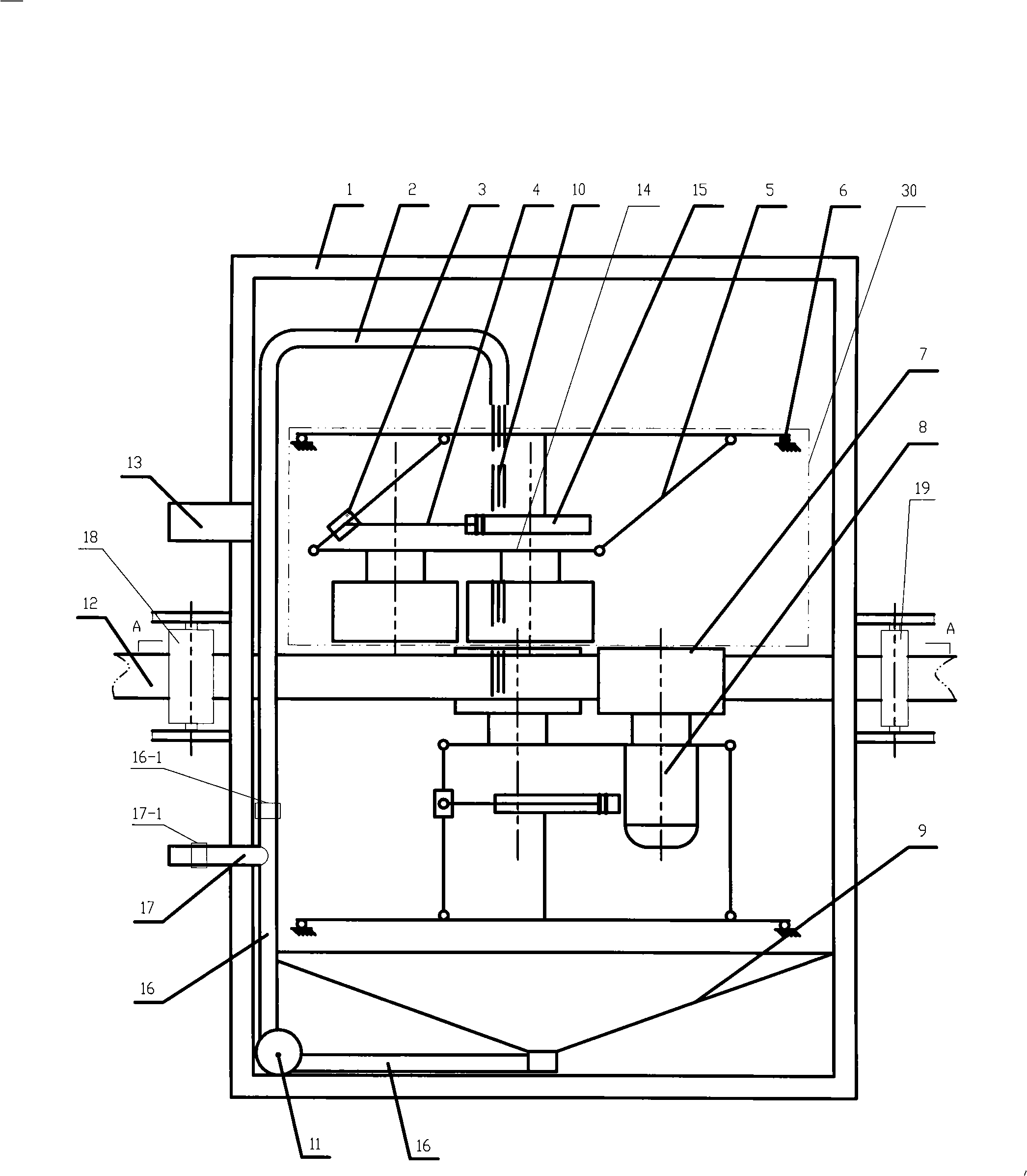

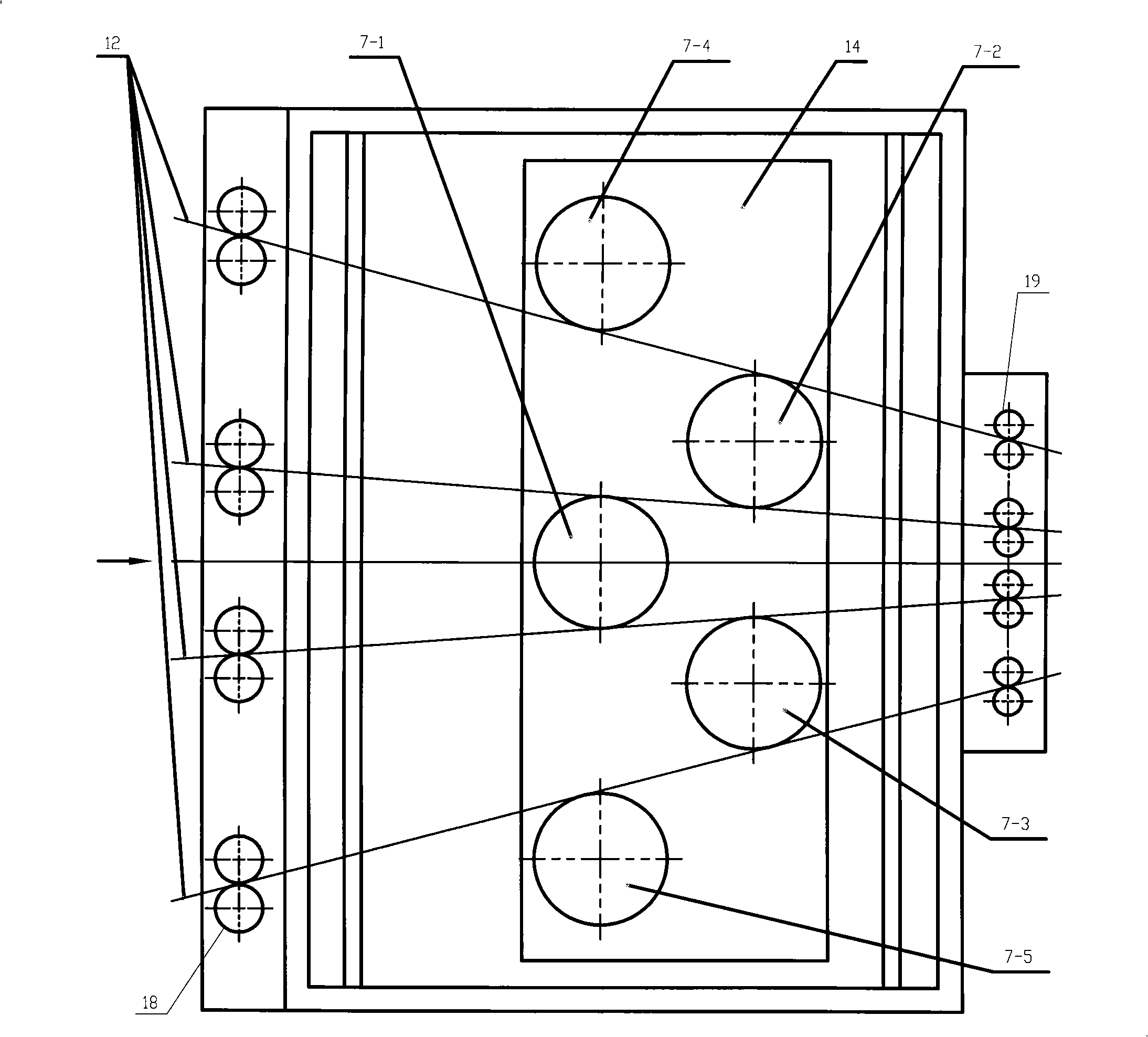

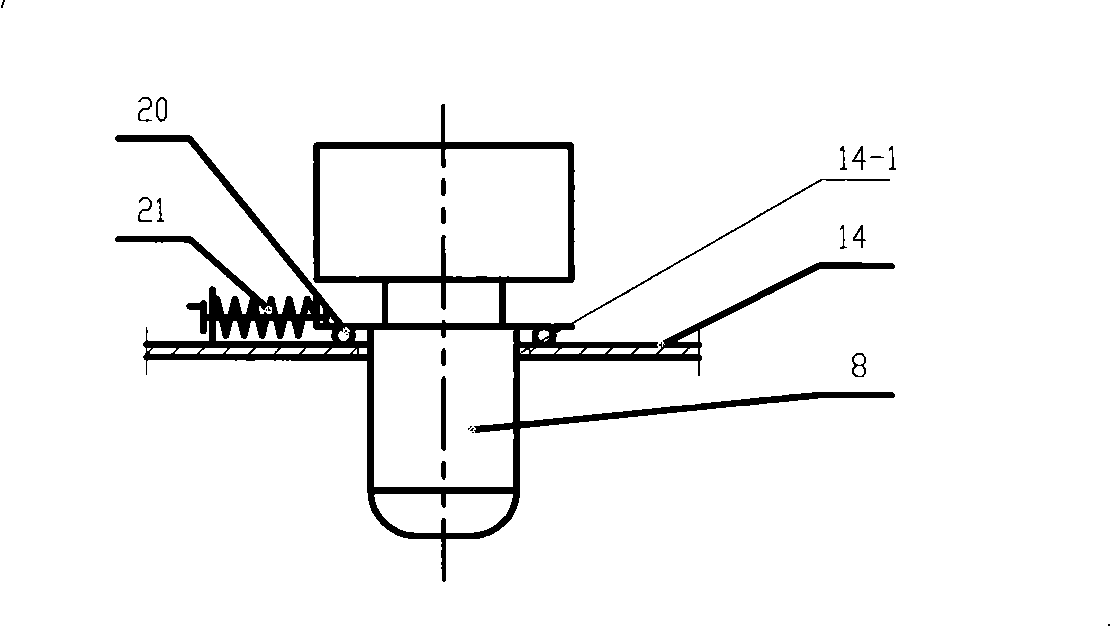

Steel strip oil-removing rust-removing apparatus and method

The invention provides a steel strip oil-removal and rust-removal device and a steel strip oil-removal and rust-removal method. The device comprises an enclosed soundproof engine body, and a sand feeding system and a sand grinding system which are arranged in the engine body; the engine body wall is provided with an equipment installation operation door, a vertical steel strip inlet trough and a vertical steel strip outlet trough; the sand grinding system comprises a grinding head mechanism and an installation base; the grinding head mechanism comprises a motor, a steel wire wheel and a couple; the motor is connected with the installation base; the steel wire wheel is respectively tangent to or locally attached to two sides of the steel strip; the sand feeding system comprises a sand hopper, a sand pipe and a sand feeding machine; the sand outlet of the sand pipe is arranged above the steel wire wheel and leads the sand flow to flow through the screw-in contact inlet of the steel wire wheel and the steel strip at least; the method comprises the steps as follows: sand loading, steel strip piercing, adjusting the sand grinding system to lead the steel wire wheel to be tangent to or partly attached to the steel strip, starting the sand feeding machine for sand feeding, starting the sand grinding system to remove the oil and rust, and continuously conveying the steel strips, etc. The device and method of the invention can realize dual types of oil-removal and rust-removal: friction type and impact type, have high efficiency, low noise, no pollution, and comply with the continuous oil-removal and rust-removal disposal to the steel strips.

Owner:四川江瀚工业股份有限公司

Pneumatic tire with tread having circumferential grooves and arcuate grooves

ActiveUS7631675B2Improve wettabilityReduce external noiseTyre tread bands/patternsNon-skid devicesIn vehicleEngineering

Provided is a pneumatic tire in which improvement is achieved in a wet performance and reduction in vehicle exterior noise while ensuring a dry performance. The pneumatic tire has a designated fitting direction relative to a vehicle, in which four main grooves extending in a circumferential direction of the tire are provided on a tread portion, two grooves out of these main grooves are located on each of both sides of a tire equator, five lines of land portions are defined by the main grooves, a center land portion located on the tire equator is a rib which continuously extends in the circumferential direction of the tire without being sectioned, a plurality of arcuate grooves each extending in an arc shape are provided on each of a pair of second land sections located respectively on both sides of the center land section, an end of each of the arcuate grooves is connected to the main groove on an inner side of the vehicle, another end of the arcuate groove is connected to the adjacent arcuate groove, a repeat pitch Po of the arcuate grooves on the second land portion located on an outer side of the vehicle is set greater than a repeat pitch Pi of the arcuate grooves on the second land portion located on the inner side of the vehicle, and a proportion Po / Pi of the pitches is set in a range from 1.5 to 3.0.

Owner:THE YOKOHAMA RUBBER CO LTD

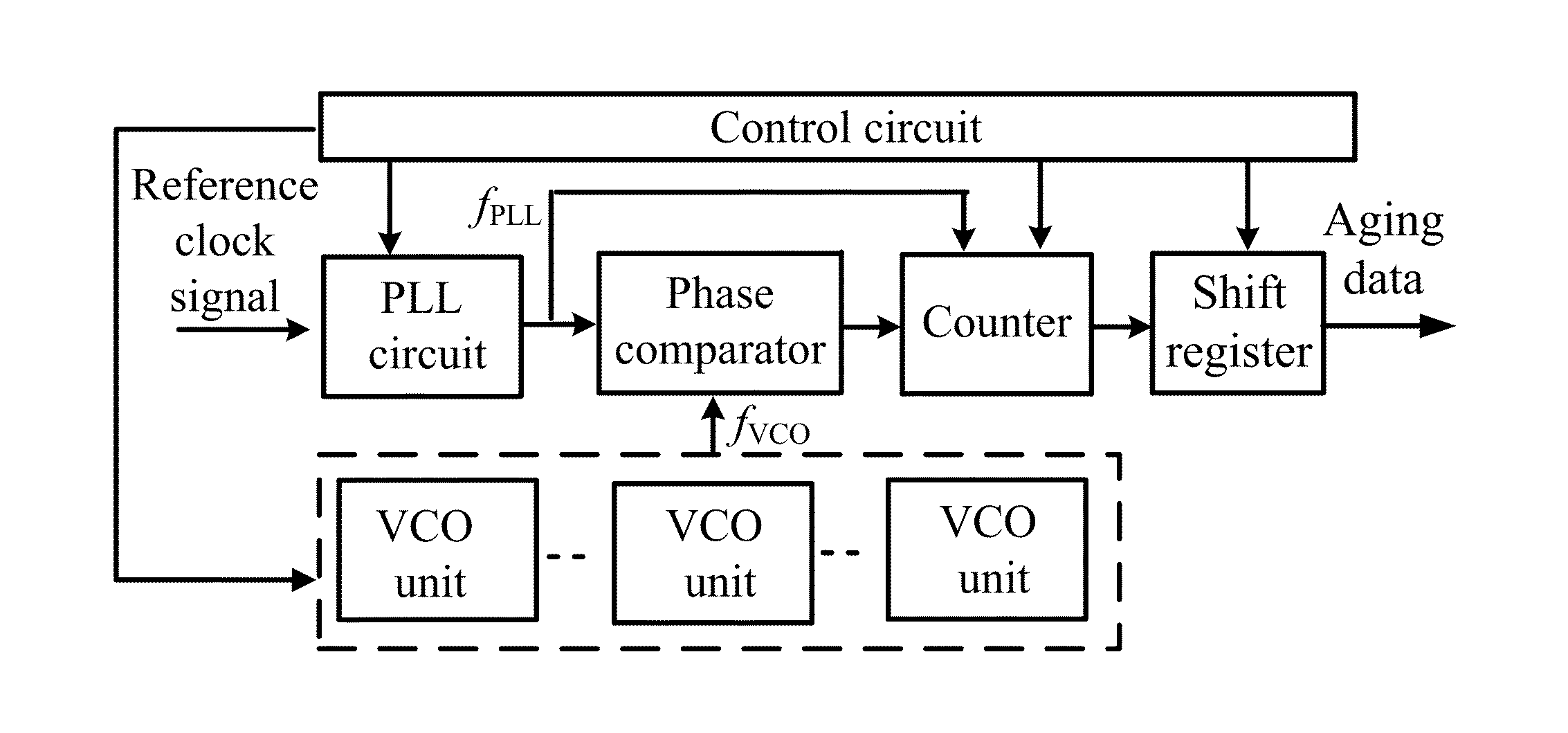

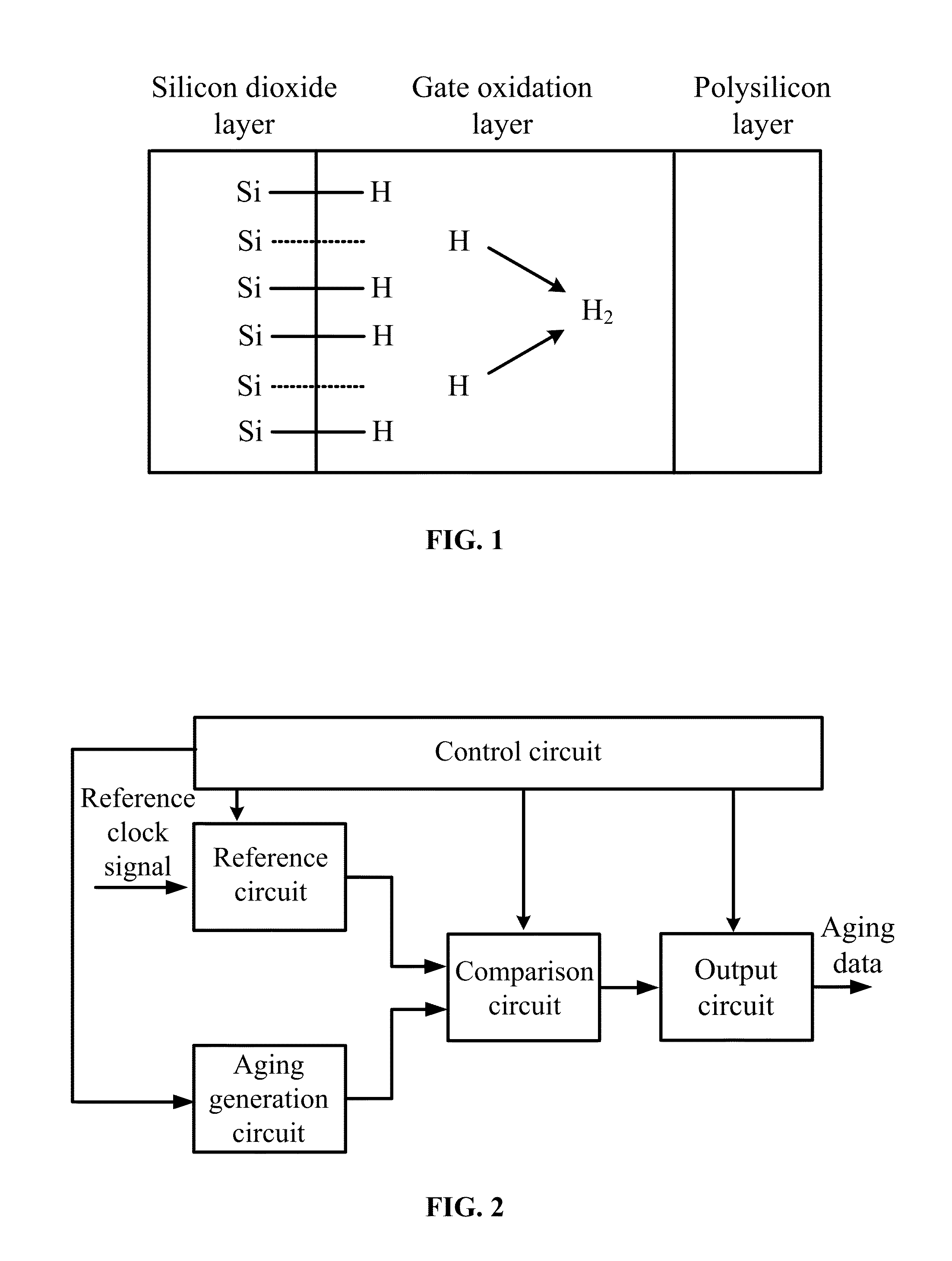

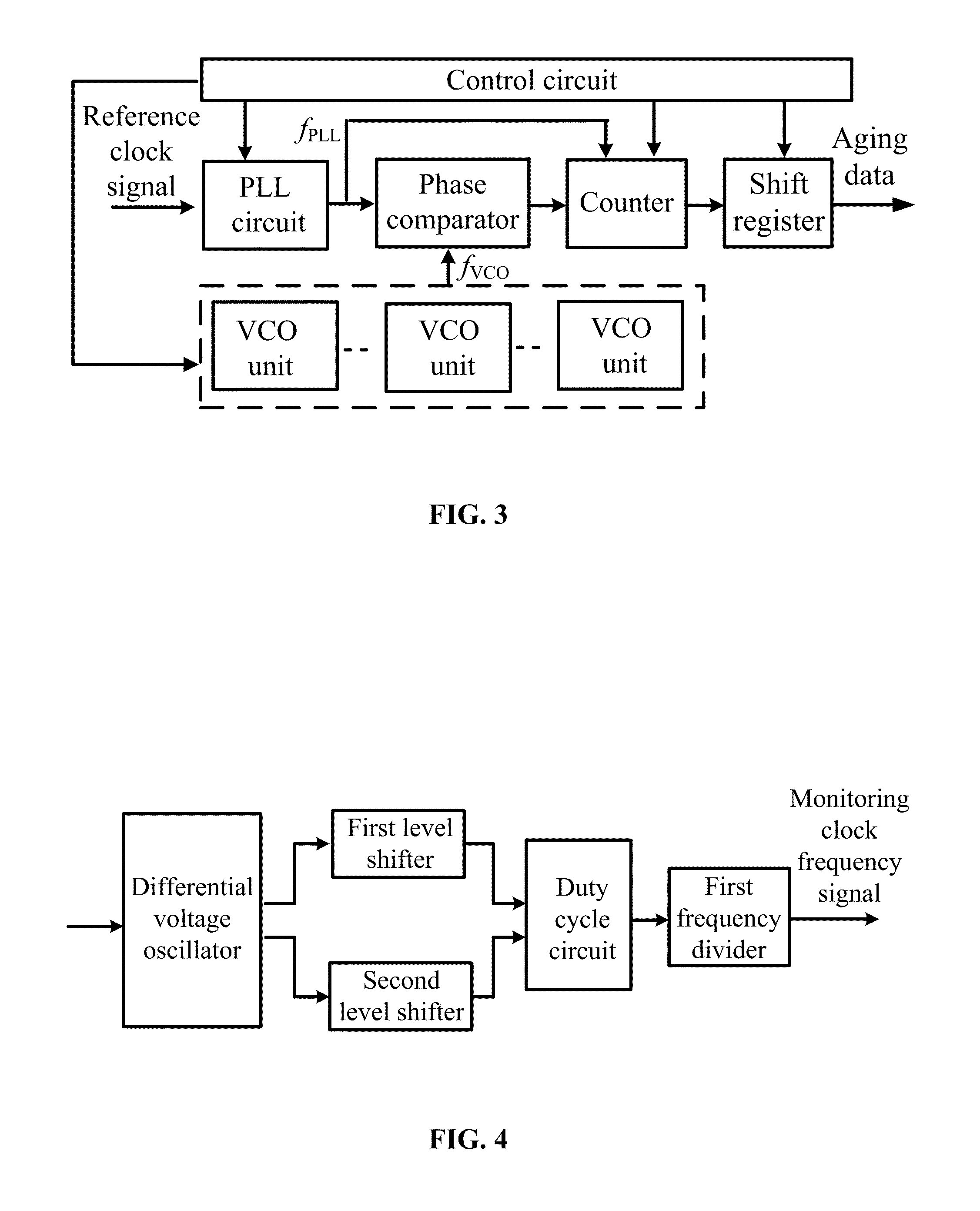

Pll-vco based integrated circuit aging monitor

InactiveUS20160087640A1Reduce harmful effectsImprove accuracyPulse automatic controlEngineeringReference circuit

A PLL-VCO based integrated circuit aging monitor, including: a control circuit, a monitoring circuit, and an output circuit. The monitoring circuit includes a reference circuit, an aging generation circuit, and a comparison circuit. The reference circuit is a PLL circuit insensitive to a parameter error caused by the aging of circuit. The aging generation circuit is a VCO circuit sensitive to the parameter error. The control circuit is connected to the PLL circuit, the VCO circuit, the comparison circuit, and the output circuit. The output end of the PLL circuit is connected to a first input end of the comparison circuit, and the output end of the VCO circuit is connected to a second input end of the comparison circuit. The output end of the comparison circuit is connected to the input end of the output circuit. The input end of the PLL circuit inputs a reference clock signal.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com