Steel strip oil-removing rust-removing apparatus and method

A technology of steel belt and wire wheel, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of noise, dust pollution environment, dust pollution, etc., to prevent noise pollution, prevent dust pollution, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

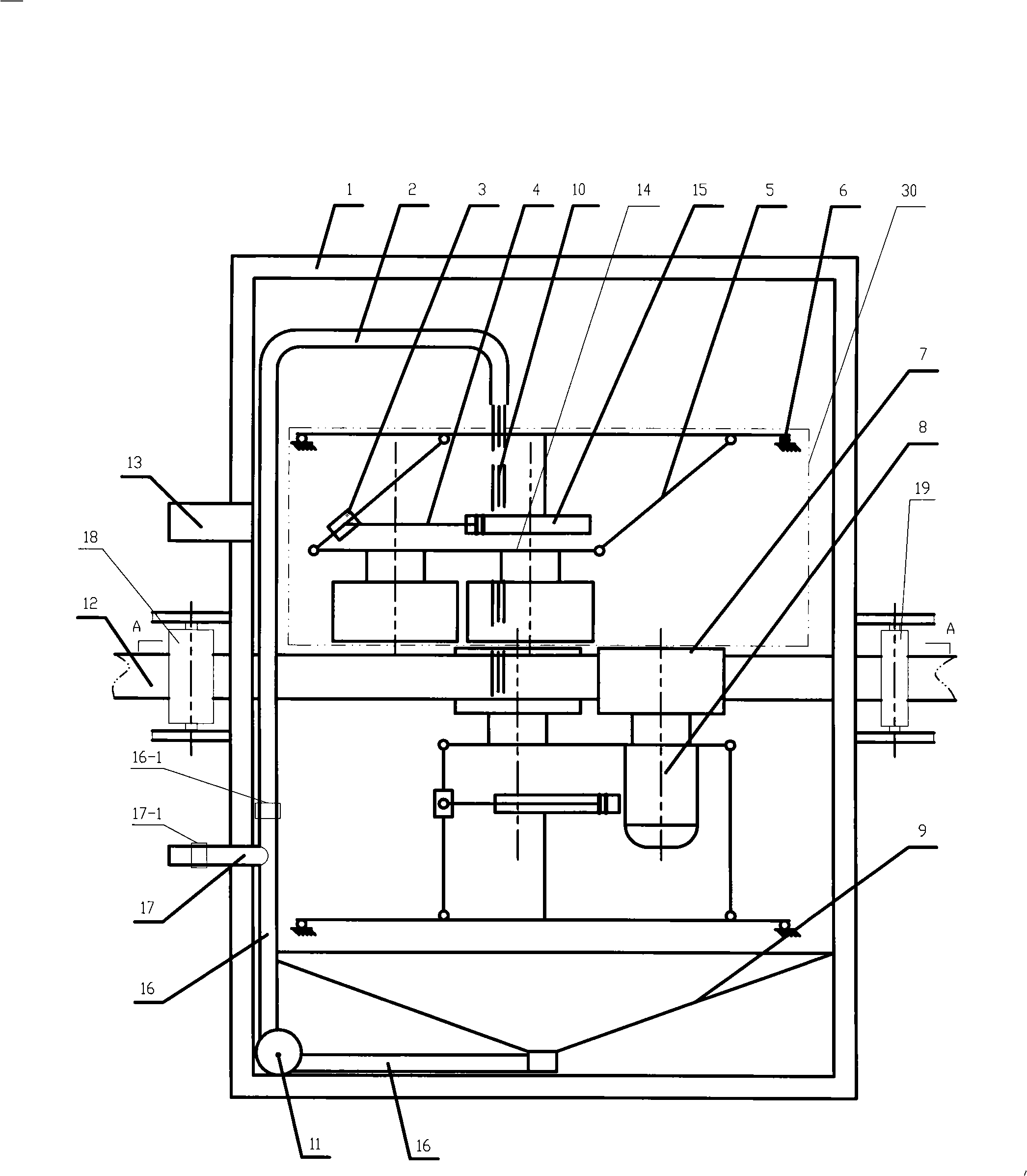

[0028] Such as figure 1 , figure 2 As shown, the steel strip degreasing and derusting device of the present invention includes a machine body 1 , a sand feeding system 2 and a sand grinding system 30 arranged inside the machine body 1 .

[0029] The body 1 adopts an airtight structure, including a body wall provided with a sound insulation layer, an equipment installation and operation door (not shown in the figure) arranged on the side wall of the body wall, and steel strips erected on the body walls on opposite sides of the body 1. , out of the groove (not shown in the figure).

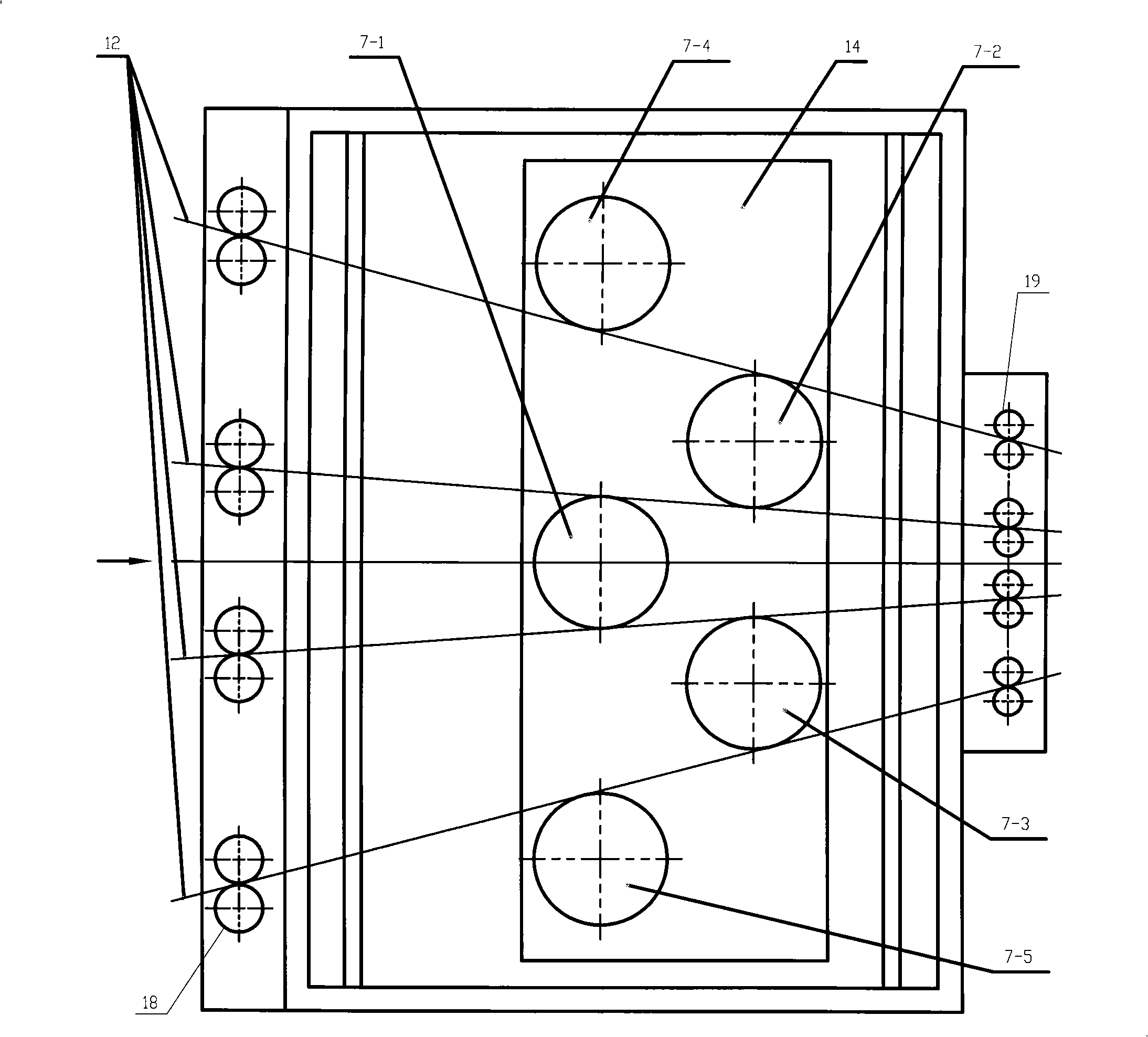

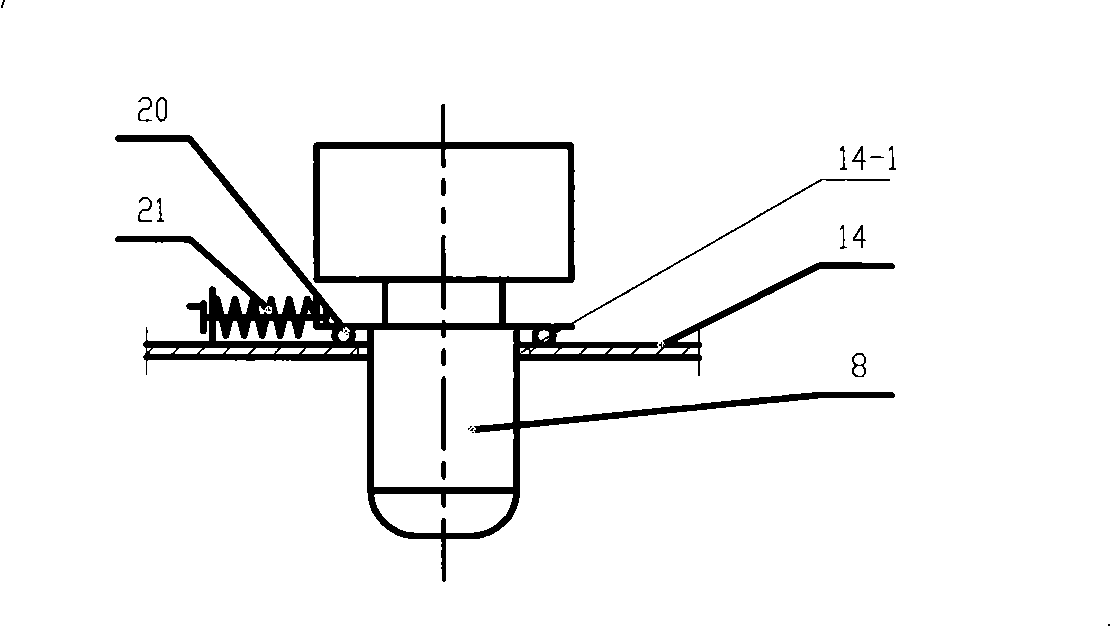

[0030] The sand grinding system 30 includes a grinding head mechanism, a mounting base 14, a quadrilateral mechanism 5 and a rotating device of the quadrilateral mechanism. The installation side of the quadrilateral mechanism 5 is provided with a sliding shoe or a pulley 6, and the inner wall structure of the body is provided with a sliding shoe or a pulley 6. Guide rail (the guide rail adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com