Transparent conducting electrode based on graphene and manufacture method and applications thereof

A technology of transparent conductive electrodes and graphene, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as optical performance degradation, ion diffusion, device damage, etc., and achieve low cost and expand application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

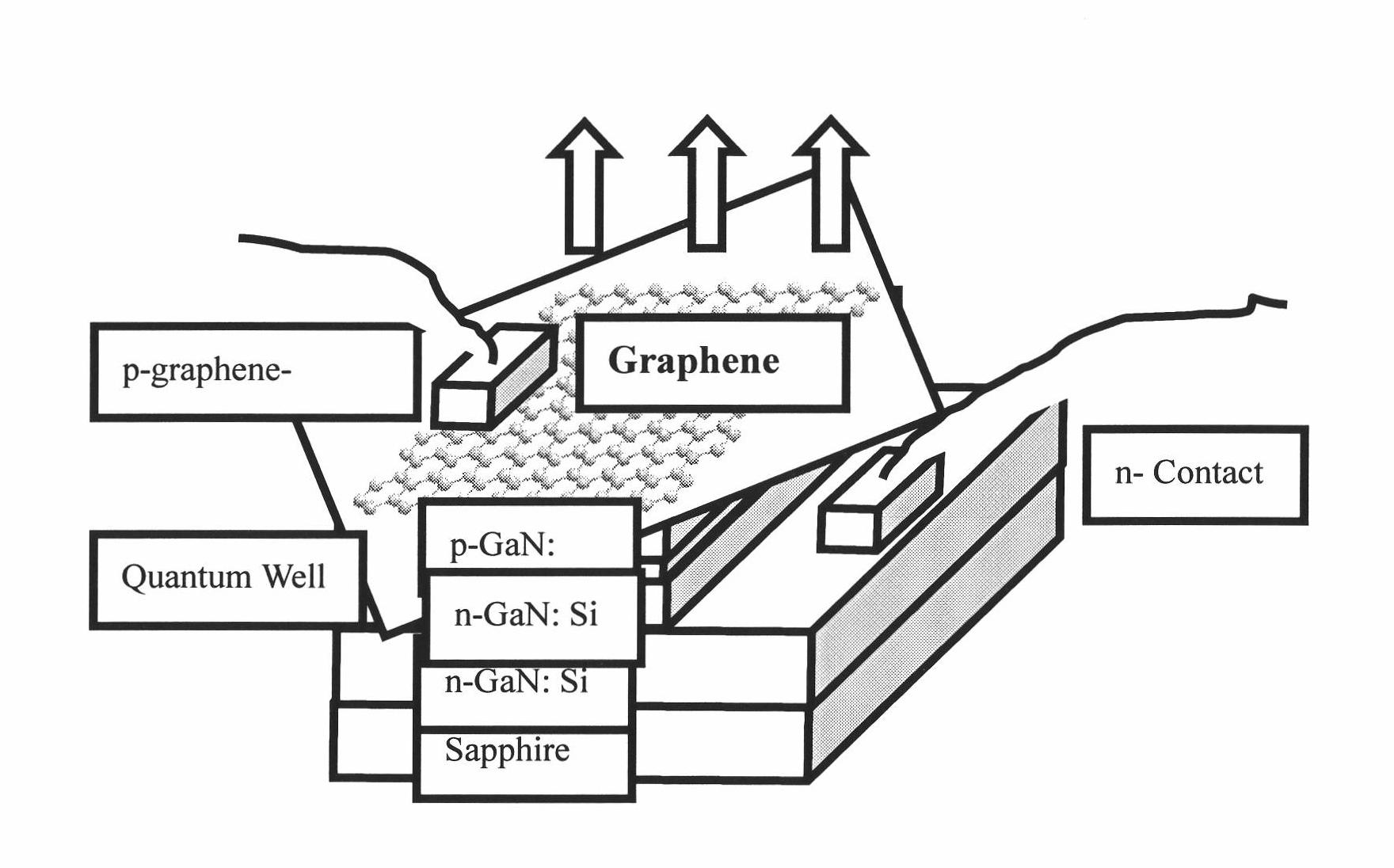

[0038] See attached description figure 1 , Graphene thin films make transparent conductive electrodes for GaN-based LEDs.

[0039] (1) on Si / SiO 2 Electron beam evaporation, magnetron sputtering or thermal evaporation of 100nm-500nm metal Ni film on the substrate is used as a catalyst for chemical vapor deposition and placed in a tube furnace. After reduction for 20 minutes, methane was introduced, the reaction time was 3-5 minutes, methane was stopped, the temperature was lowered under the protection of hydrogen, and the sample was taken out.

[0040] (2) Place the grown GaN epitaxial wafer containing quantum wells in a tube furnace, N 2 Keep at 750° C. for 15 minutes under ambient conditions to activate the Mg-doped P-type GaN layer.

[0041] (3) Place BOE(H 2 SO 4 :H 2 o 2 =3:1) in the solution at 70°C for 3 minutes, and keep at 120°C on the hot plate for 5 minutes to remove the residual solution.

[0042] (4) Take Si / SiO 2 After growing the graphene sample on the ...

Embodiment 2

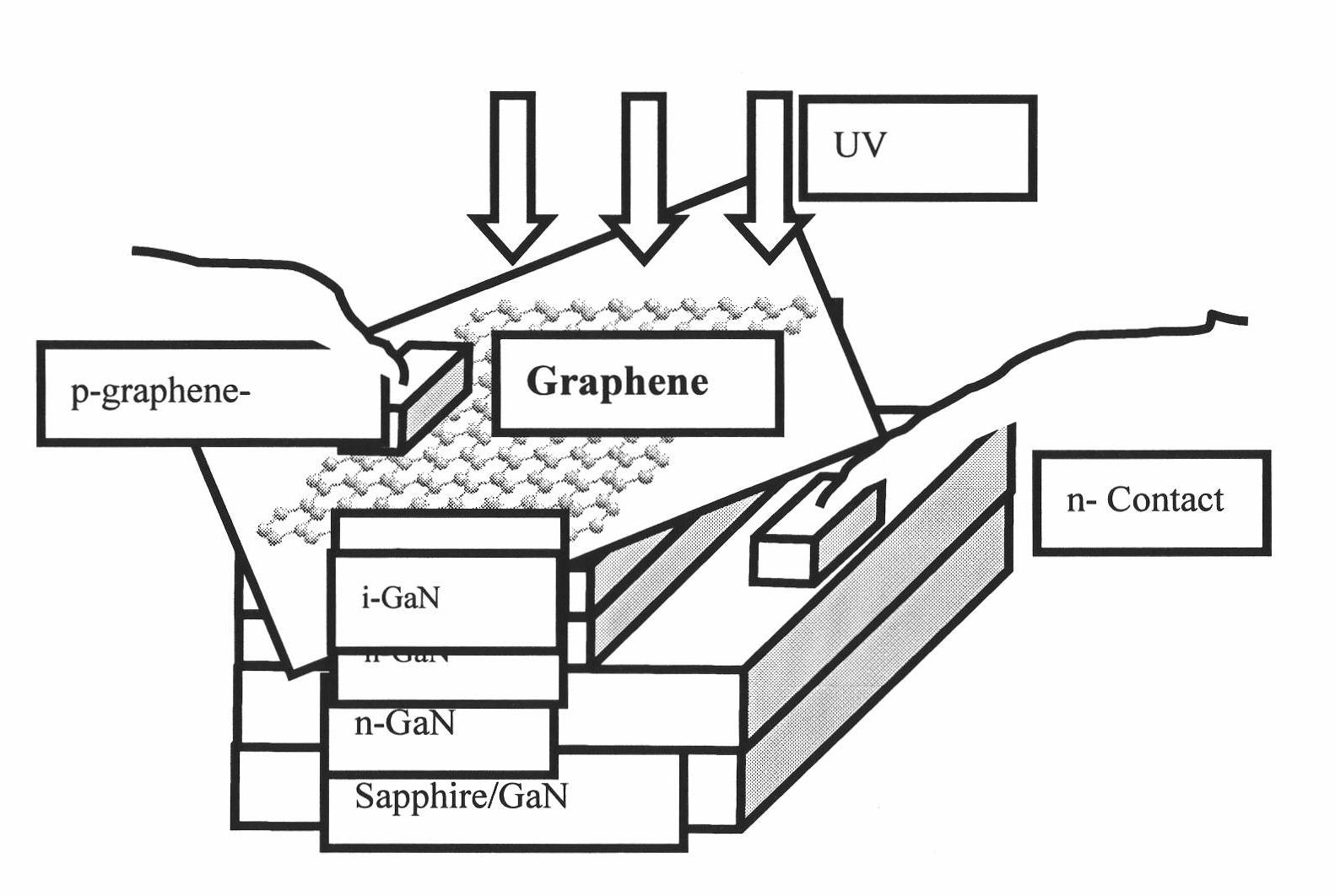

[0059] See attached description figure 2 , Graphene thin films make transparent conductive electrodes for GaN-based ultraviolet photodetectors.

[0060] (1) on Si / SiO 2 Electron beam evaporation, magnetron sputtering or thermal evaporation of 100nm-500nm metal Ni film on the substrate is used as a catalyst for chemical vapor deposition and placed in a tube furnace. After reduction for 20 minutes, methane was introduced, the reaction time was 3-5 minutes, methane was stopped, the temperature was lowered under the protection of hydrogen, and the sample was taken out.

[0061] (2) Place the p-i-n GaN epitaxial wafer in the tube furnace, N 2 Keep at 750° C. for 15 minutes under ambient conditions to activate the Mg-doped P-type GaN layer.

[0062] (3) Place BOE(H 2 SO 4 :H 2 o 2 =3:1) in the solution at 70°C for 3 minutes, and keep at 120°C on the hot plate for 5 minutes to remove the residual solution.

[0063] (4) Take Si / SiO 2 After growing the graphene sample on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com