Preparation method of V150-steel-grade high-strength high-toughness casing steel

A technology of high strength and toughness, casing steel, applied in the field of seamless petroleum casing steel smelting process, to achieve the effect of high steel purity, lightening of LF deep desulfurization load, and high strength and toughness matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

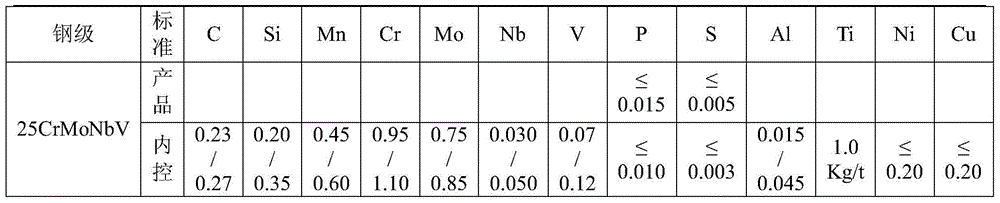

[0034] The preparation method of V150 steel grade high-strength toughness casing steel comprises the following steps:

[0035] a. Smelting: Using molten iron and steel scrap as raw materials, smelting in an electric arc furnace to obtain primary molten steel at a temperature of 1620-1640°C;

[0036] b. LF refining: Add molten steel smelted in step a to synthetic slag for LF refining. After the synthetic slag is basically melted, add refining agent and Al powder in batches to strengthen slag deoxidation and produce white slag, ensuring that the white slag time is ≥ 20 minutes; control Slag (FeO+MnO)≤0.5%, raise the temperature of molten steel, carry out alloying and desulfurization operations, adjust the alloy composition to meet the standard requirements and S≤0.003%; at the same time, perform the first calcium treatment after LF refining;

[0037] c. VD vacuum treatment: keep the vacuum degree of the molten steel refined in step b at normal pressure ~ 67pa, control the flow r...

Embodiment 1

[0051] ①Using molten iron and steel scrap as raw materials, molten iron composition: C: 3.80%, S: 0.030%, P: 0.100%, As: 0.008%, Sn: 0.004%, As+Sn+Pb+Sb+Bi: 0.017%, into Electric furnace molten iron temperature T: 1300°C; S in scrap steel: 0.008%, As: 0.007%, Sn: 0.004%, As+Sn+Pb+Sb+Bi: 0.016%; mix molten iron and scrap steel according to a certain ratio, control The carbon content is 1.7%.

[0052] ② Smelting in an electric arc furnace after loading molten iron and scrap steel to obtain primary molten steel with P: 0.002%, S: 0.009%, C: 0.08%, and molten steel temperature: 1635°C, and then poured the furnace back for tapping.

[0053] ③Add CaBaAlSi, Al block and ferroalloy during tapping, CaBaAlSi addition: 2.5kg / t, Al block addition: 3.0kg / t, high carbon ferromanganese: 4.5kg / t; add lime 3.0kg / t in the ladle before tapping kg / furnace, during the tapping process, adjust the intensity of argon blowing for stirring, and ensure the unimpeded bottom blowing before LF refining. ...

Embodiment 2

[0061] ①Using molten iron and steel scrap as raw materials, molten iron composition: C: 4.10%, S: 0.040%, P: 0.110%, As: 0.007%, Sn: 0.003%, As+Sn+Pb+Sb+Bi: 0.014%, into Electric furnace molten iron temperature T: 1310°C; S in scrap steel: 0.010%, As: 0.007%, Sn: 0.003%, As+Sn+Pb+Sb+Bi: 0.014%; mix molten iron and scrap steel according to a certain ratio, control The carbon content is 2.0%.

[0062] ② Smelting in an electric arc furnace after loading molten iron and scrap steel to obtain primary molten steel with P: 0.003%, S: 0.014%, C: 0.16%, and molten steel temperature: 1630°C, and then pour the furnace back for tapping.

[0063] ③ Add CaBaAlSi, Al block and ferroalloy during tapping, CaBaAlSi addition: 2.0kg / t, Al block addition: 3.0kg / t, high-carbon ferromanganese: 4.5kg / t; add lime 4.5kg / t to the ladle before tapping kg / furnace, during the tapping process, adjust the intensity of argon blowing for stirring, and ensure the unimpeded bottom blowing before LF refining.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com