Thermal processing method of chromium-containing ferrite refractory steel

A heat treatment method and heat-resistant steel technology, applied in the field of thermal processing of metal materials, can solve the problems of small grain size unfavorable long-term creep, lack of application prospects, etc., and achieve the effect of easy operation and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The heat treatment method of the chromium-containing ferritic heat-resistant steel proposed by the present invention, the weight percentage of each element in the ferritic heat-resistant steel is:

[0019]

[0020]

[0021] Surplus is Fe, it is characterized in that this heat treatment method comprises the following steps:

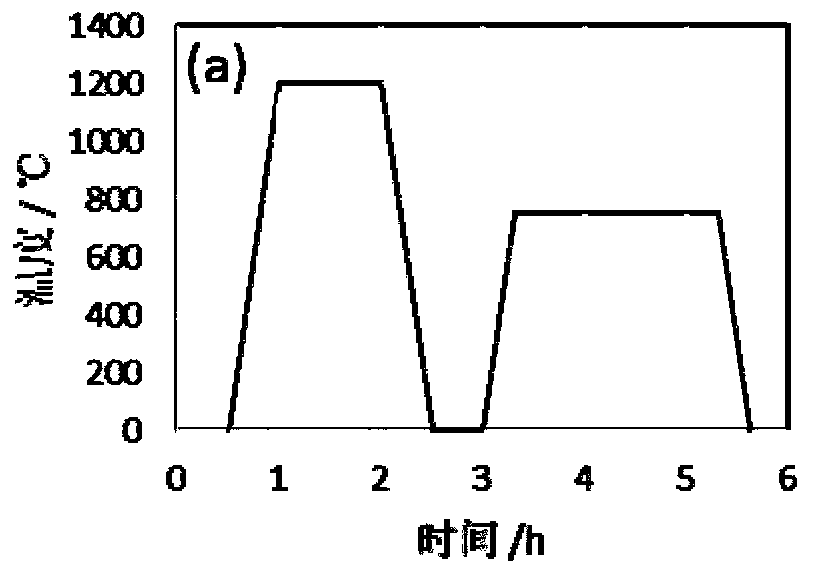

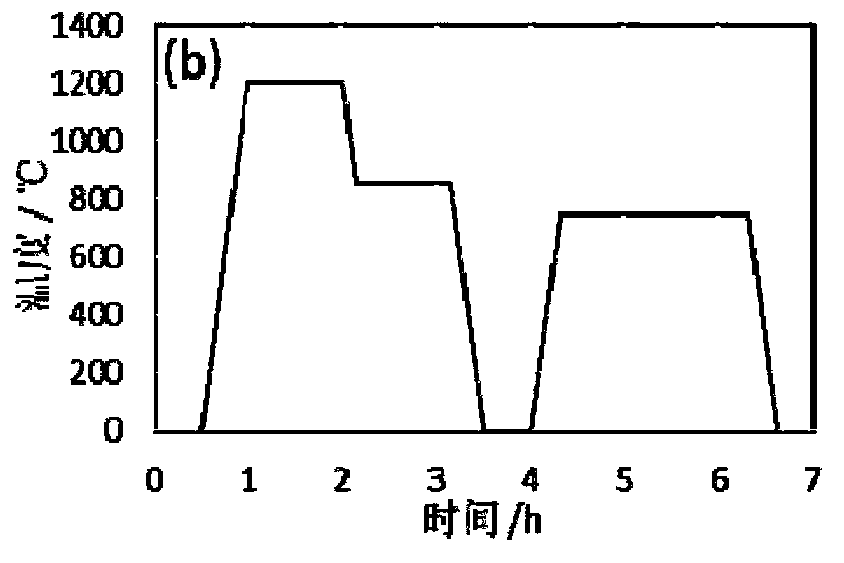

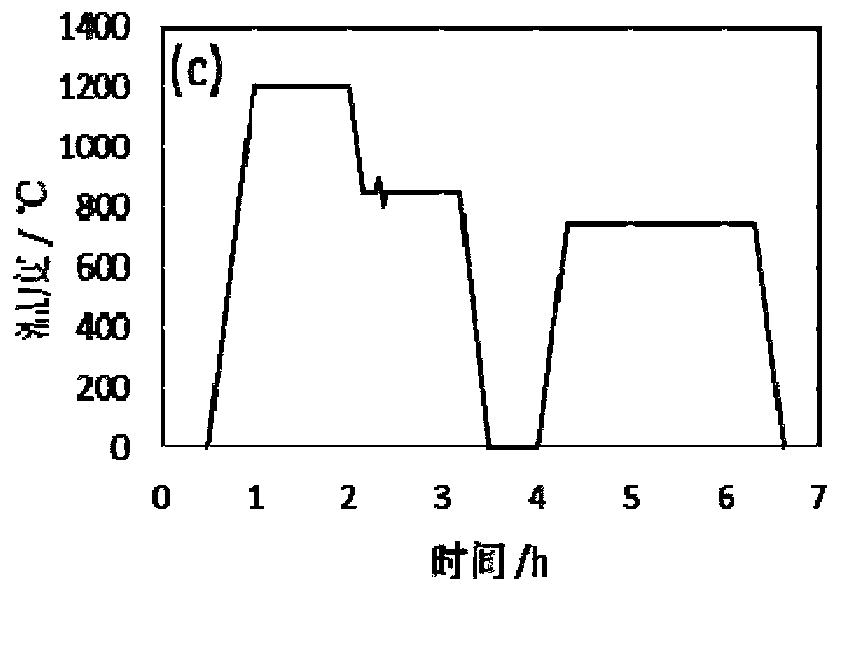

[0022] (1) Heat the ferritic heat-resistant steel parts to 1050 ° C ~ 1250 ° C, and keep it warm for 1 to 2 hours;

[0023] (2) Cooling the ferritic heat-resistant steel part in step (1) to 800°C-900°C, keeping it warm for 1-2 hours, and water quenching to room temperature;

[0024] Or: cooling the ferritic heat-resistant steel parts in step (1) to 800°C-900°C, deforming the ferritic heat-resistant steel parts to reduce the thickness of the ferritic heat-resistant steel parts by 20%-70 %, heat preservation for 1 to 2 hours, water quenching to room temperature; (3) heat the ferritic heat-resistant steel parts in step (2) to 700°C to 800°C, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com