Thick-gauge steel plate with excellent low-temperature aging performance, and manufacturing method thereof

A low-temperature aging and manufacturing method technology, applied in the field of metallurgy, can solve the problems of increasing the yield strength of steel plates and decreasing low-temperature impact toughness, and achieve the effects of excellent low-temperature aging performance, reducing low-temperature brittleness, and reducing low-temperature brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

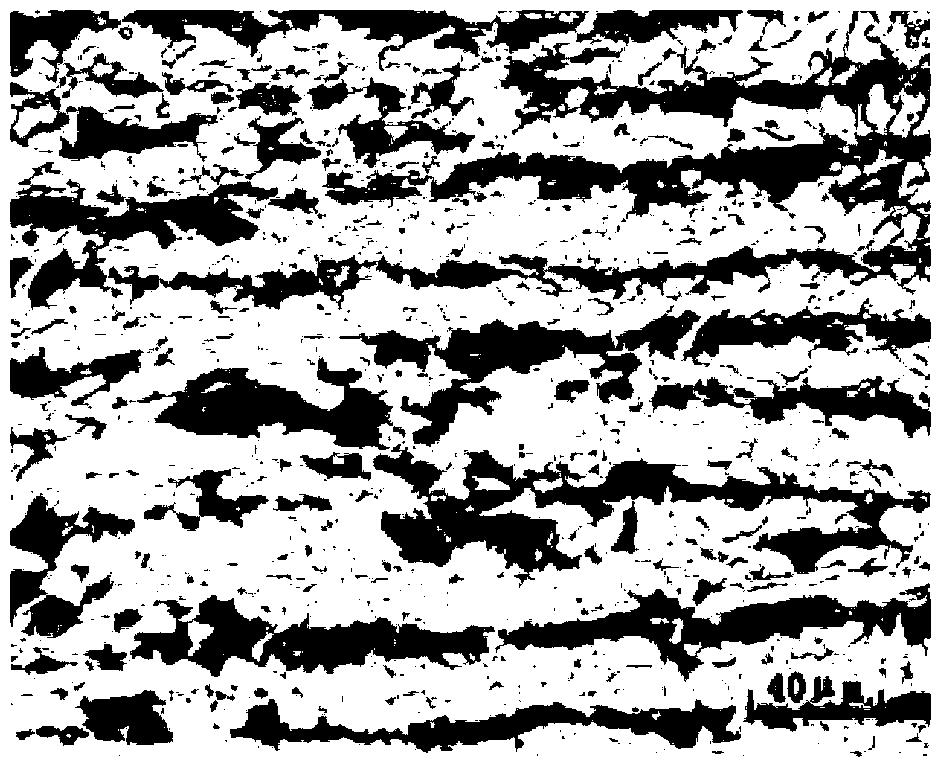

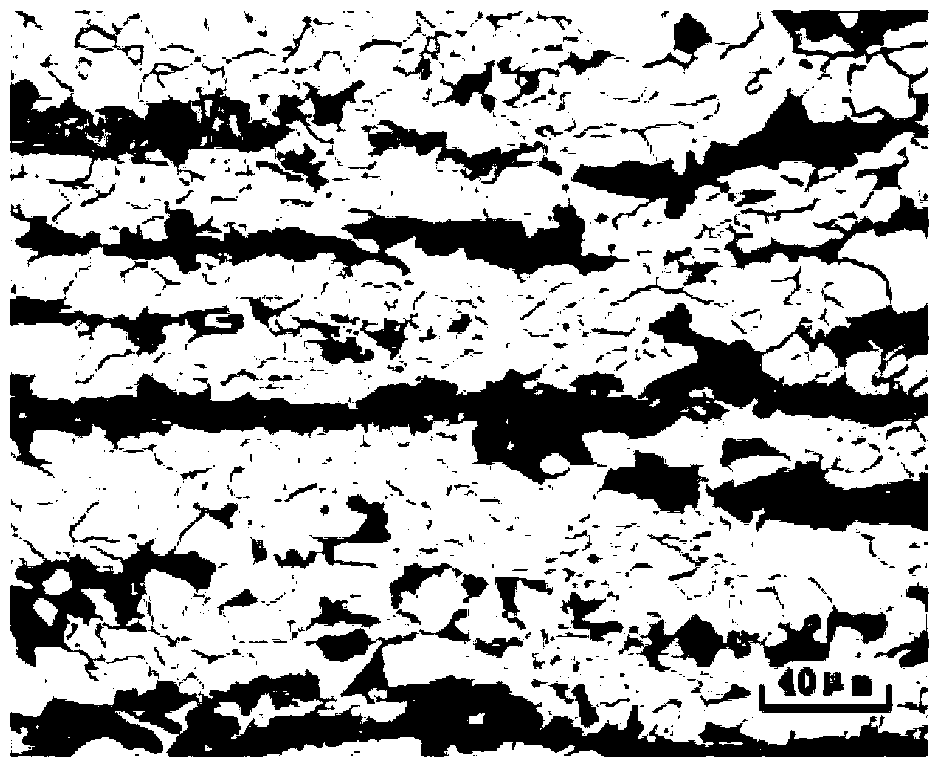

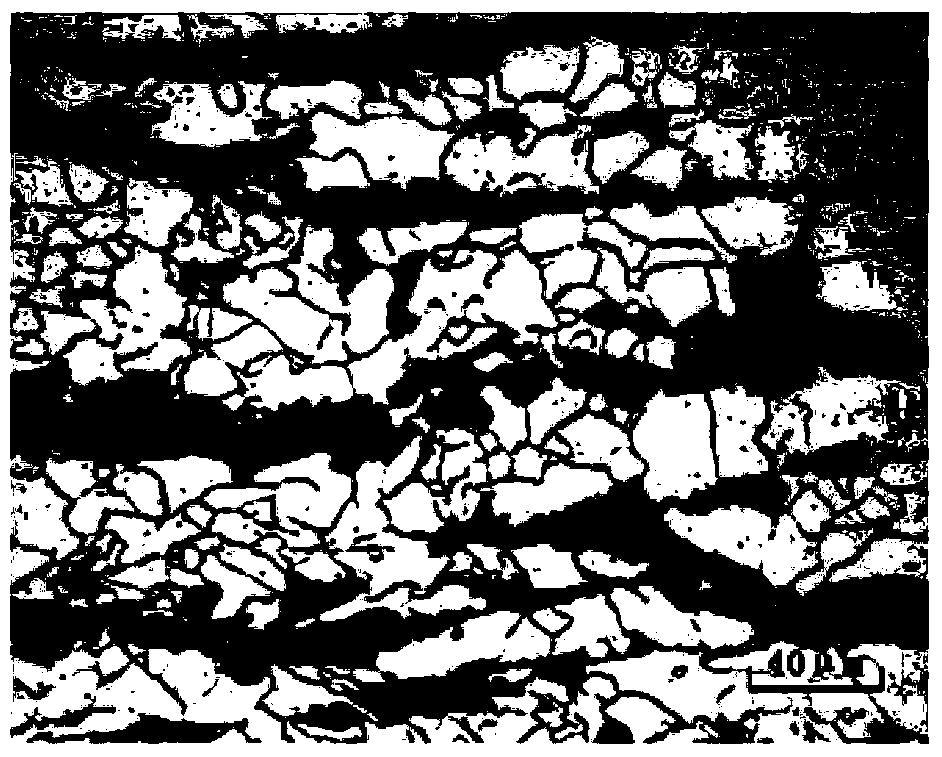

Image

Examples

Embodiment 1

[0042] A thick-gauge steel plate excellent in low-temperature aging performance of Example 1 having the chemical composition shown in Table 3 below was produced. Among them, No. 1 represents a steel plate with a thickness of 63.5 mm, and No. 2 represents a steel plate with a thickness of 75 mm.

[0043] Table 3 Chemical composition (wt%) of thick-gauge steel plate with excellent low-temperature aging performance in Example 1

[0044]

[0045] The thick-gauge steel plate excellent in low-temperature aging performance of Example 1 was manufactured by the following method. Specifically, the molten iron pretreatment process is carried out first, the molten iron is desulfurized, the sulfur content in the molten iron is controlled at 0.012wt%, the temperature is controlled at about 1270°C, and the slag on the surface of the molten iron is removed after desulfurization.

[0046] In the steelmaking process, the top-bottom double blowing converter is used for smelting. The pretreat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com