Low welding crack sensitivity steel plate with yield strength of 690MPa grade and method for producing the same

A technology of yield strength and manufacturing method, applied in manufacturing tools, temperature control, metal rolling, etc., can solve the problems of complex manufacturing process, high Pcm value, and reduced steel strength, and achieve reasonable composition and process design, welding crack sensitivity The effect of low property and low alloying element content

Active Publication Date: 2010-11-24

BAOSHAN IRON & STEEL CO LTD

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As can be seen from Table 1, except for the ultra-high-strength welded steel disclosed in WO99 / 05334, the chemical composition of the steel disclosed in other patent applications has added alloy element Ni to varying degrees. Increase the cost of steel and reduce its market competitiveness, and Ni will form oxide skin on the surface of the steel plate, affecting the surface quality of the steel plate

Except for WO99 / 05334, WO99 / 05335 and CN1932064, Cu is added to the chemical composition of the steel disclosed in other patent applications, and the precipitation of Cu is used to increase the strength of the steel plate, but Ni needs to be added at the same time to avoid copper brittleness, which further increases the strength of the steel plate. manufacturing cost

Although the steel grades disclosed in WO99 / 05334 and WO99 / 05335 are relatively simple in composition, they all adopt quenching treatment, which increases the production process of the steel plate, causes an increase in the production cost of the steel plate, and their Pcm values are all relatively high, which has a great impact on weldability. have adverse effects

In addition, the steel types listed in Table 1 have been quenched + tempered or tempered, because the only way to reduce Pcm is to reduce the addition of carbon and alloy elements, and for high-strength steel produced by quenching + tempering process In general, reducing the addition of carbon and alloying elements will inevitably lead to a reduction in steel strength, and the manufacturing process is complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

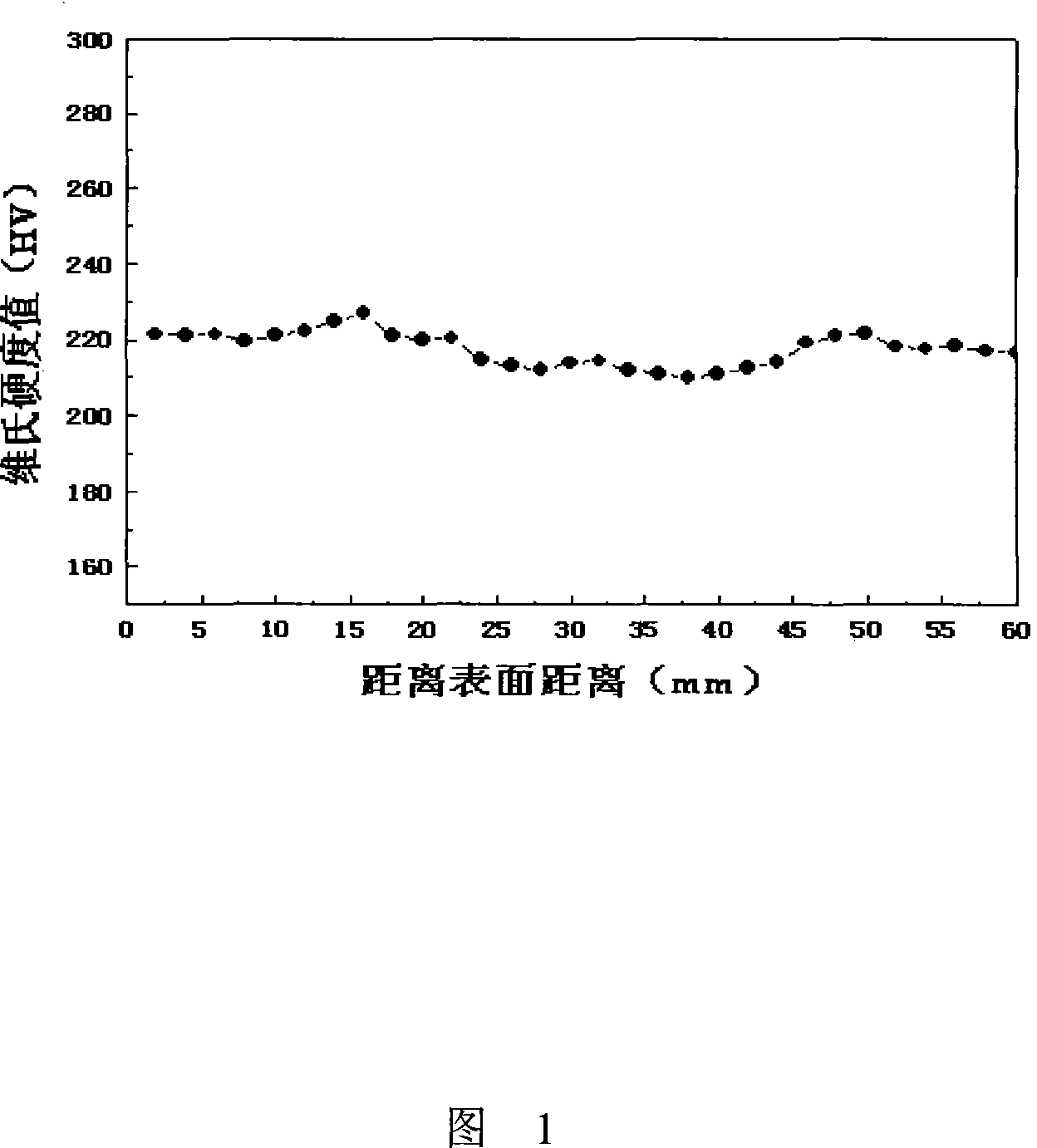

The invention provides a low crack sensitivity steel plate with the yield strength of 690MPa grade and a method for manufacturing the same. The chemical components of the low crack sensitivity steel plate are as follows: 0.03 to 0.06 weight percent of C, 0.05 to 0.40 weight percent of S, 1.30 to 2.00 weight percent of Mn, 0.05 to 0.15 weight percent of Cr, 0.10 to 0.25 weight percent of Mo, 0.03 to 0.08 weight percent of Nb, 0.04 to 0.12 weight percent of V, 0.02 to 0.04 weight percent of Al, 0.004 to 0.030 weight percent of Ti, 0.0010 to 0.0020 weight percent of B, and the balance being Fe and inevitable impurities, wherein the weld crack sensitivity index Pcm is less than or equal to 0.20 percent. The invention adopts a controlled thermo-mechanical rolling and cooling technology to obtain a matrix structure mainly based on a thinned bainite, which is advantageous for improving the steel strength, the plasticity and the toughness of the steel plate. The yield strength of the low weldcrack sensitivity steel plate is greater than 690 MPa; the tensile strength is greater than 700 MPa; the Charpy impact energy Akv (20 DEG C below zero) is more than or equal to 150 J; the plate thickness can reach 60 millimeters; and the welding performance is good.

Description

Yield strength 690MPa grade low crack sensitivity steel plate and its manufacturing method technical field The invention relates to high-strength structural steel, in particular, the invention relates to a steel plate with a yield strength of 690 MPa and low crack sensitivity. Background technique Welding cold cracks are the most common welding process defects, especially when welding low- and medium-alloy strength steels. As the strength level increases, the tendency of cold cracks to appear is increasing. In order to prevent cold cracks, it is usually preheated before welding and heat treated after welding. The greater the strength, the higher the preheating temperature, which causes the complexity of the welding process and inoperability under special circumstances, endangering the safety of the welded structure Reliability, especially for large steel structures. In view of the characteristics of petrochemical, high-rise buildings, bridges, shipbuilding and other indus...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/32C22C38/38C21D8/02B21B37/16B21B37/74

Inventor 姚连登赵小婷

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com