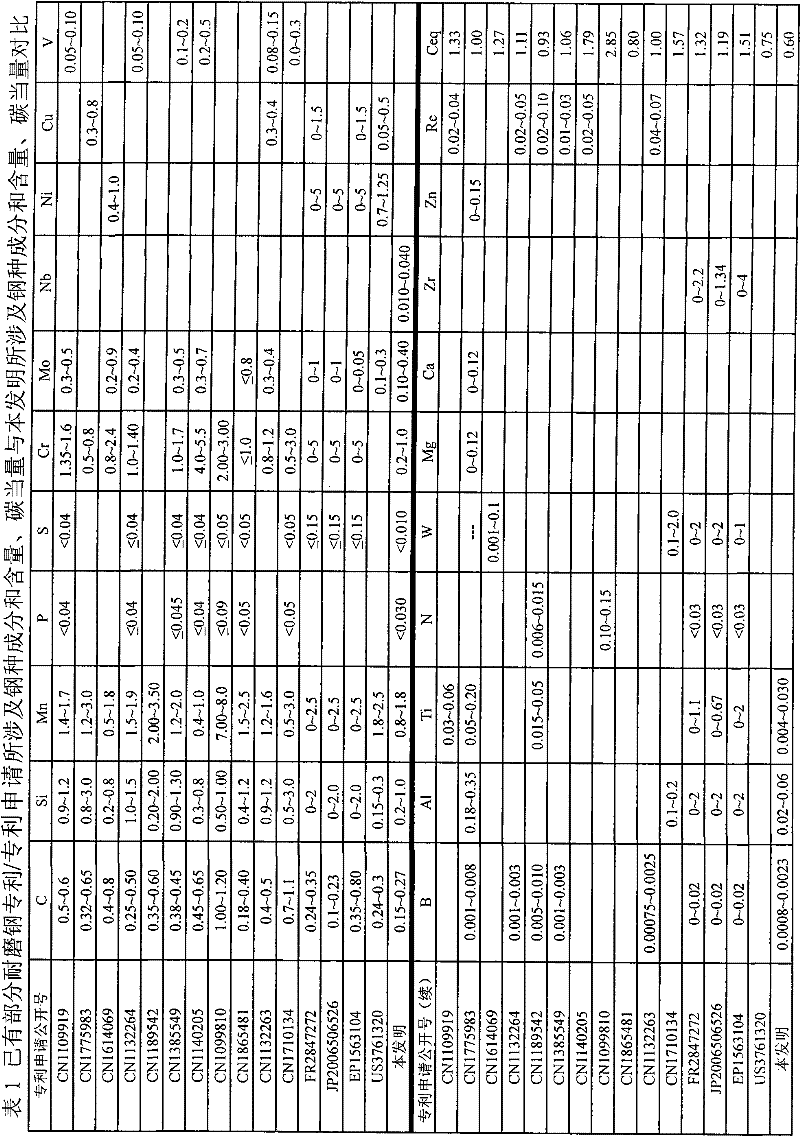

Patents

Literature

60results about How to "Loose craft system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

600HB-grade wear resistant steel plate and its manufacturing method

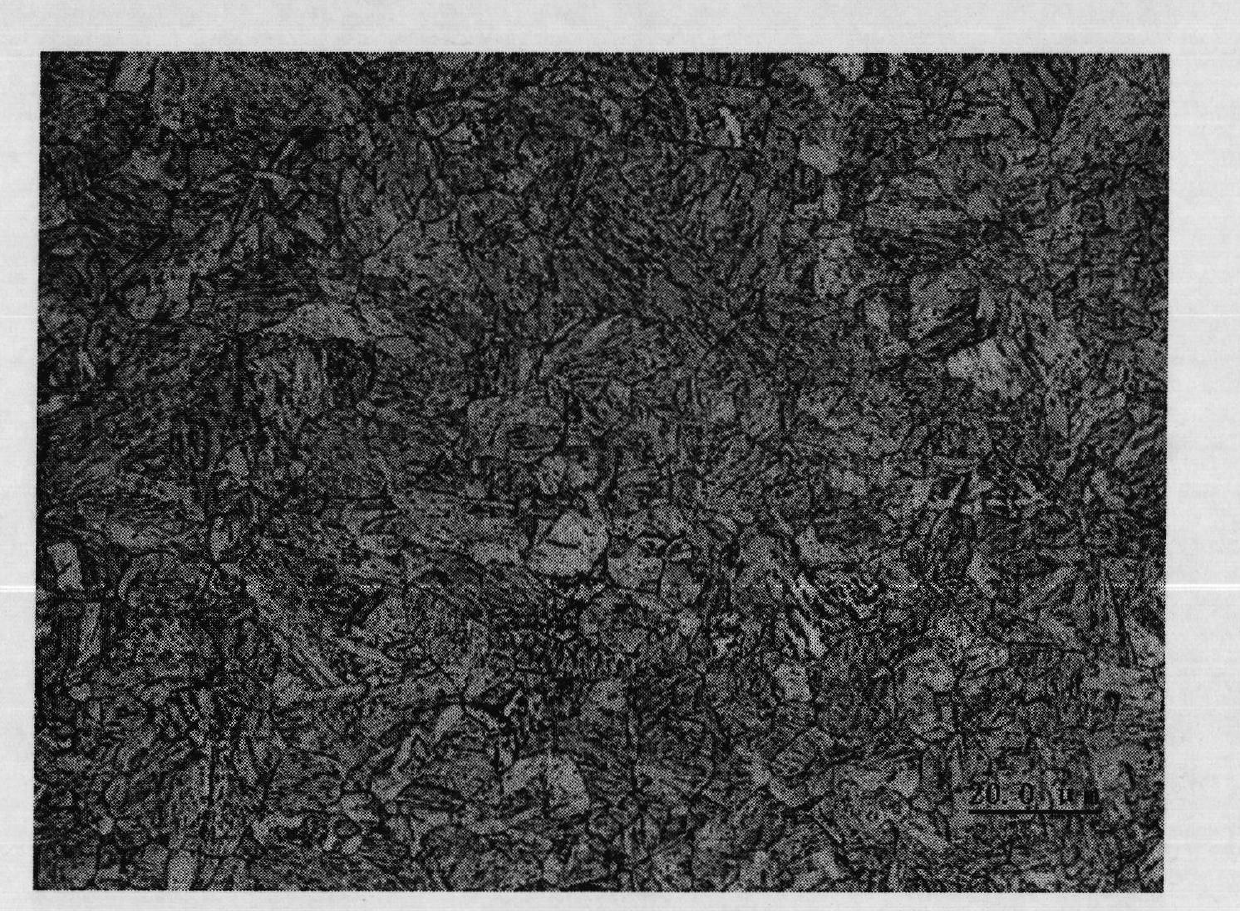

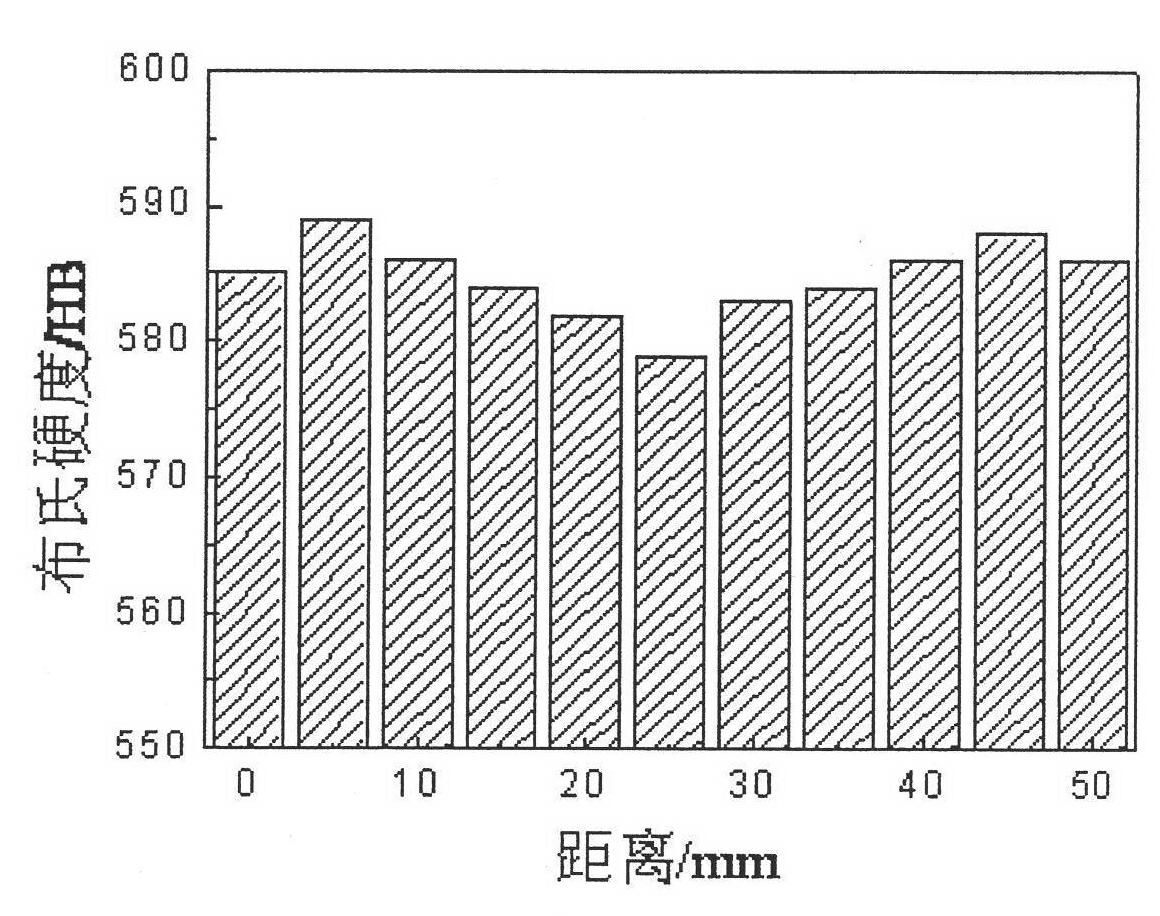

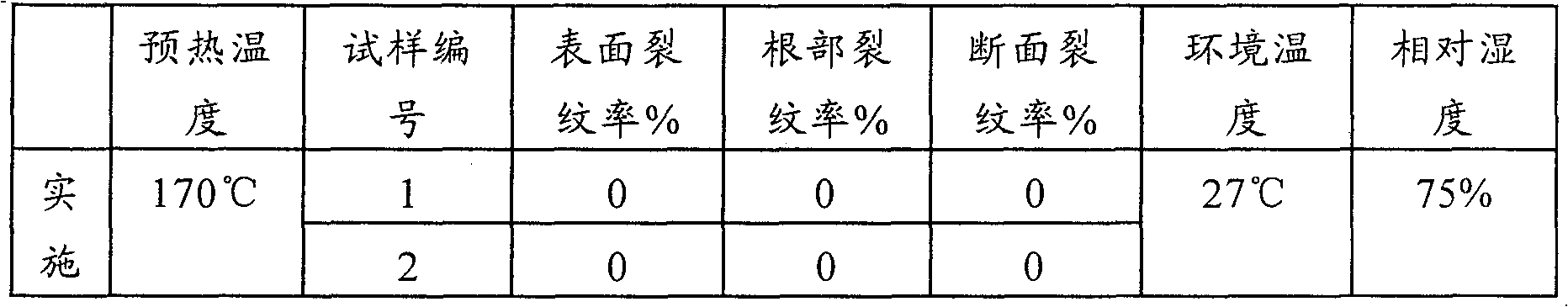

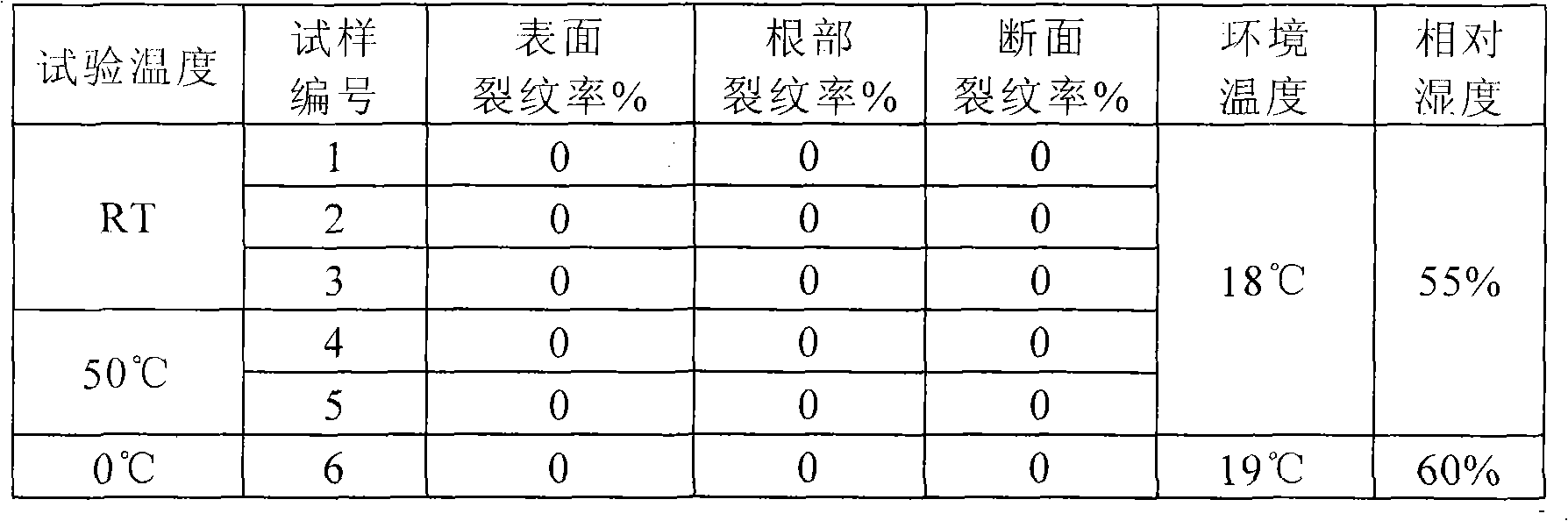

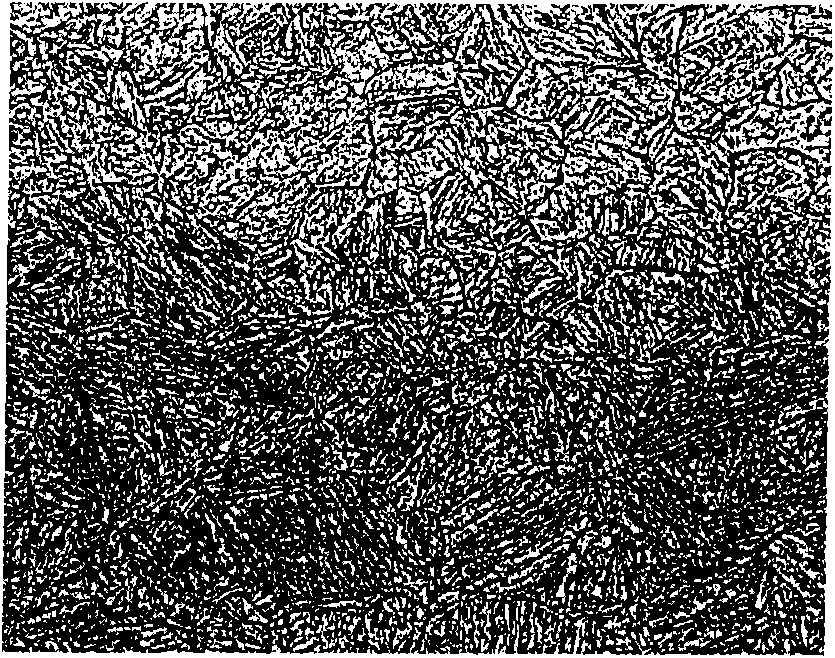

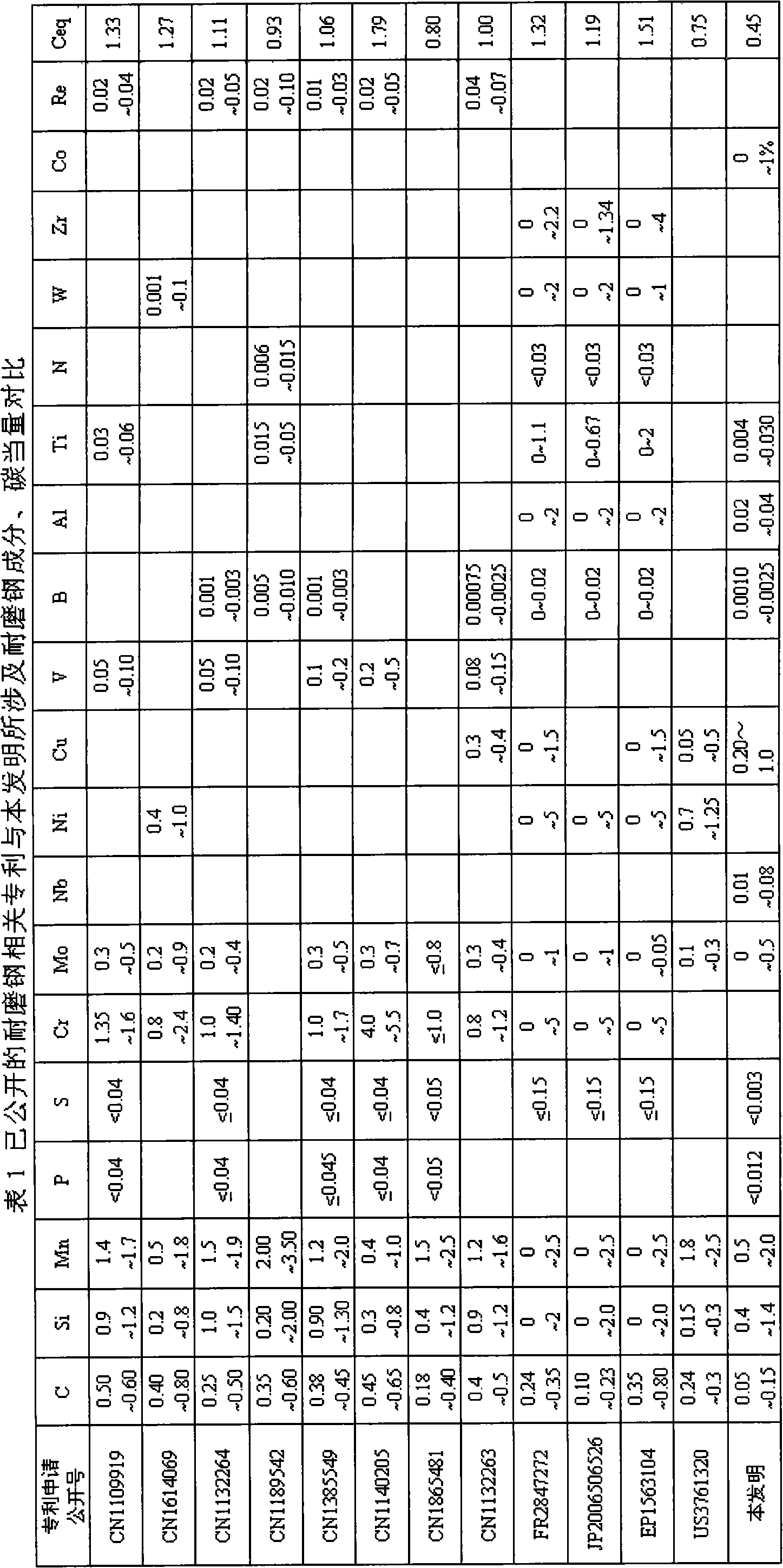

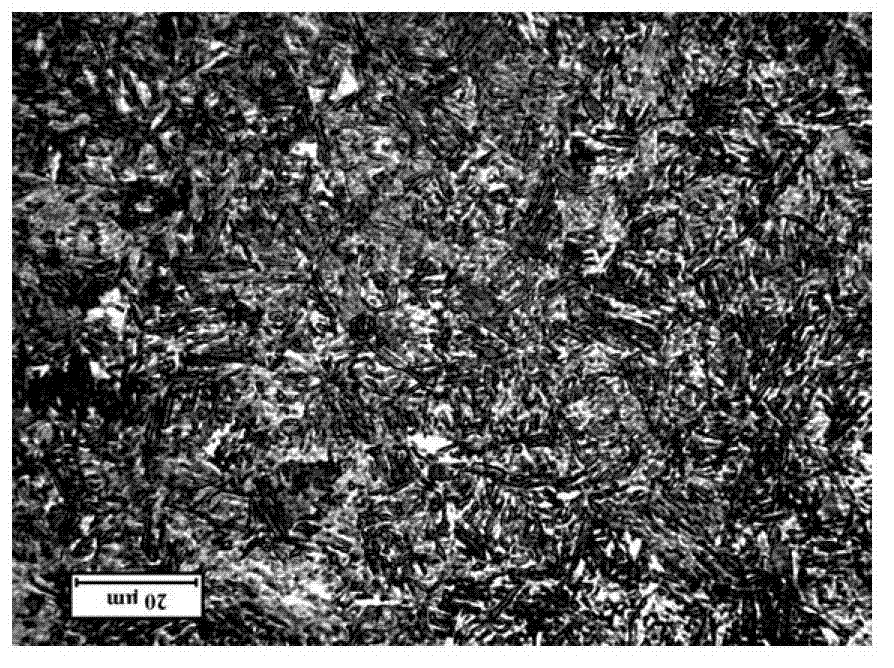

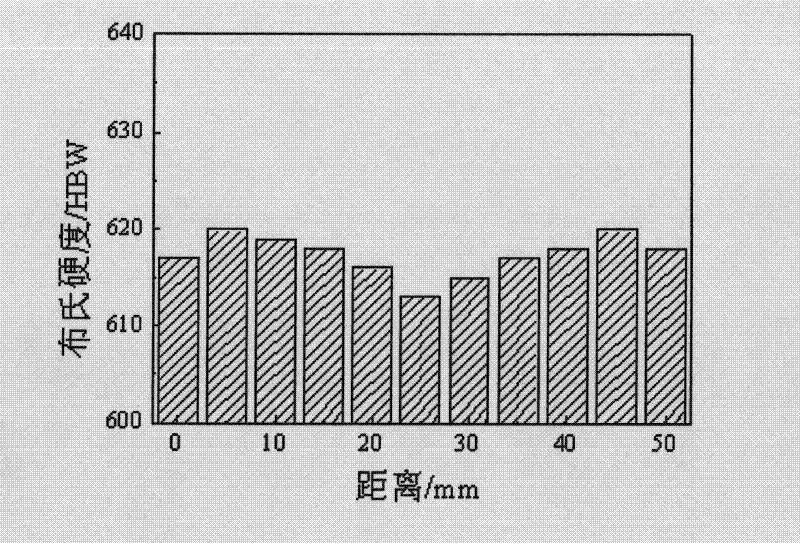

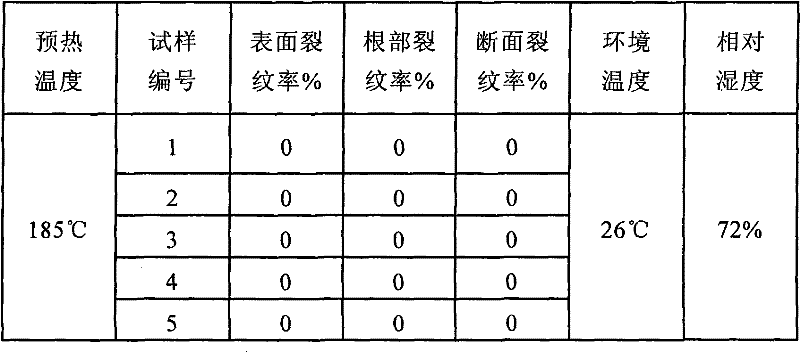

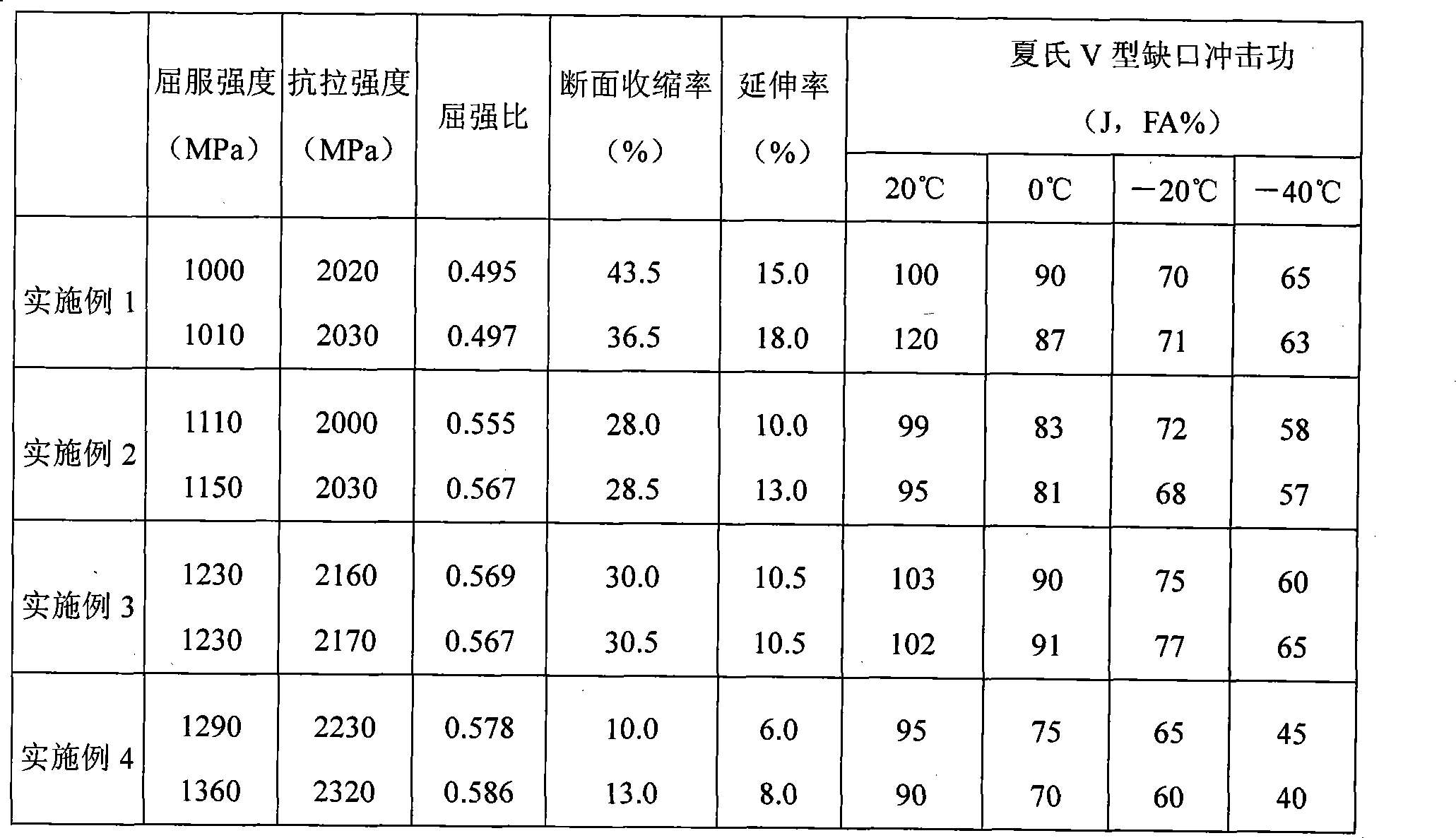

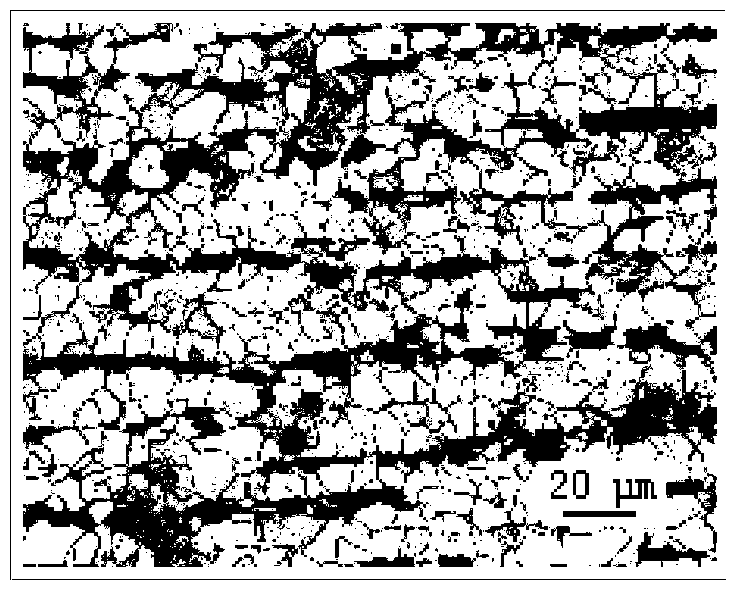

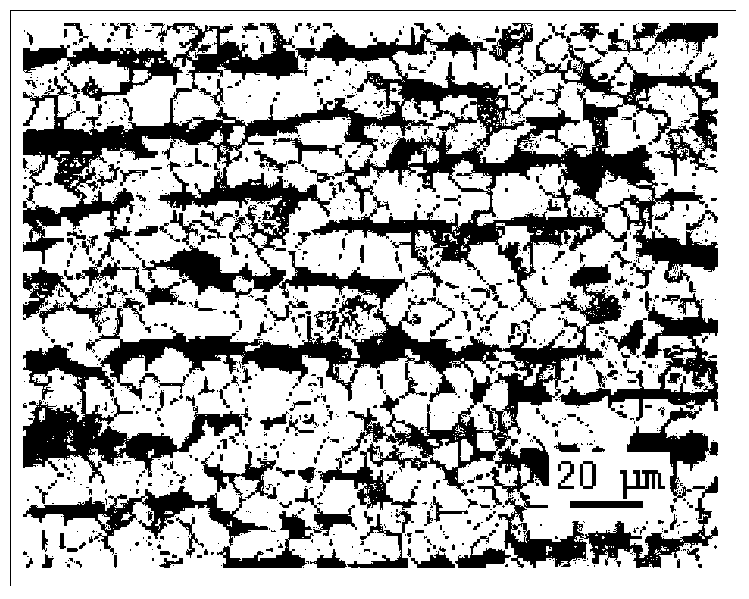

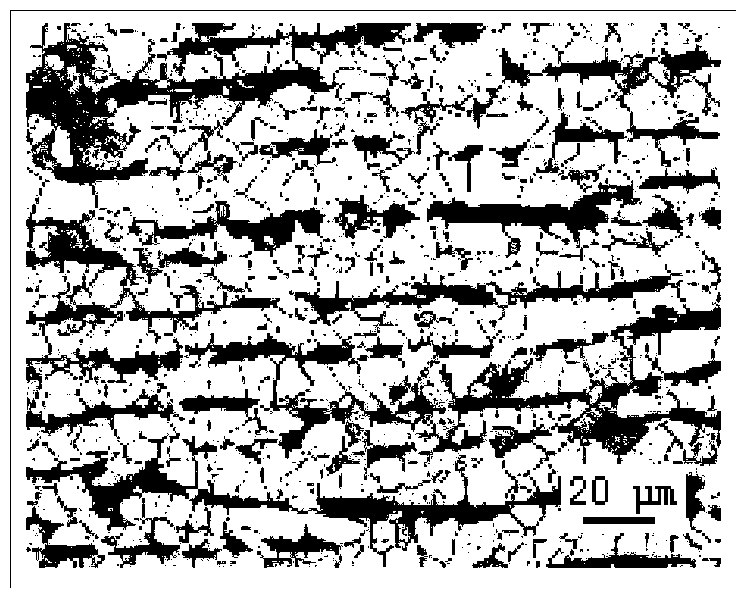

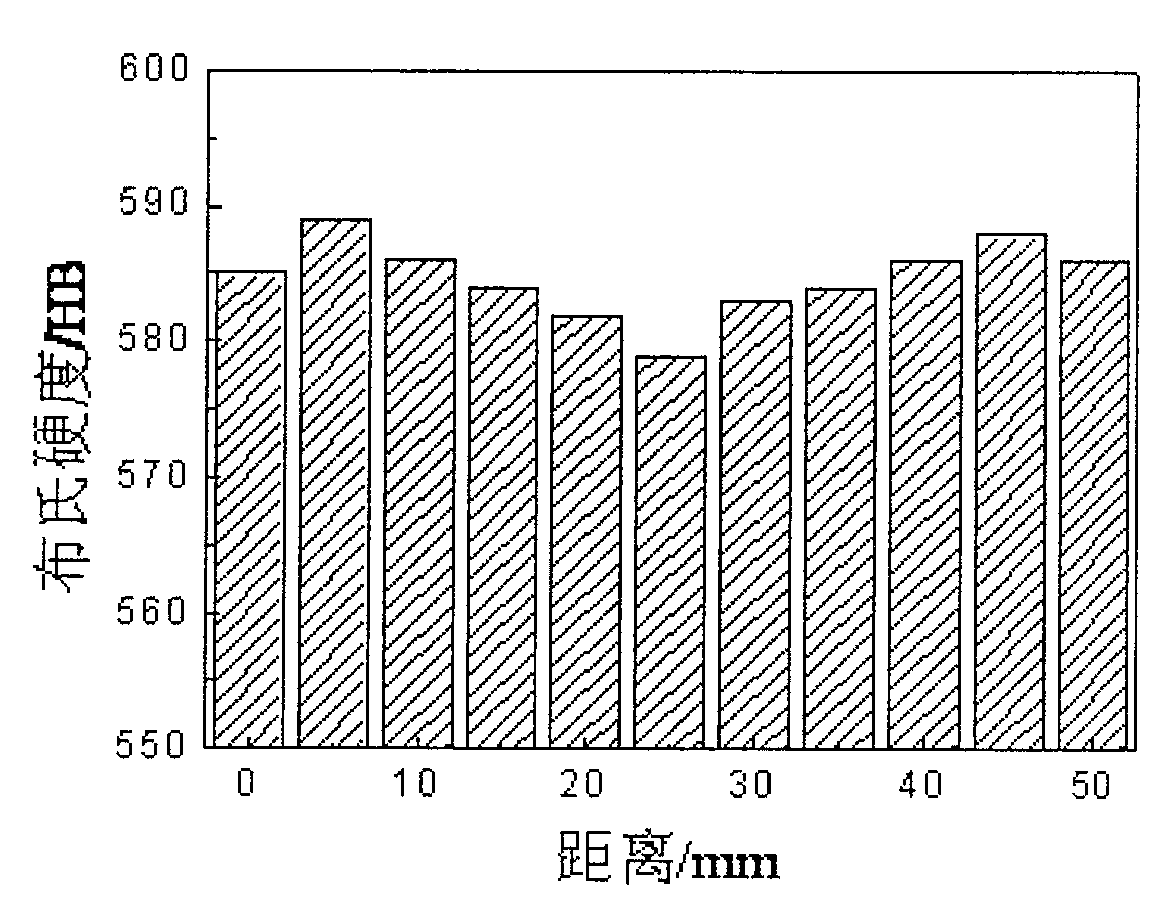

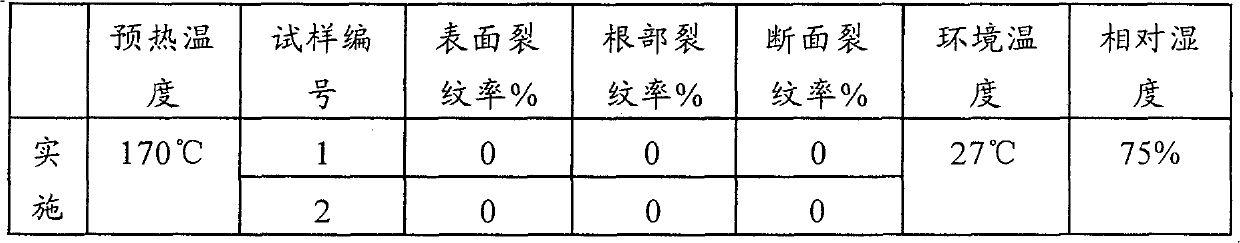

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balance Fe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance and excellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Wear resistant steel plate

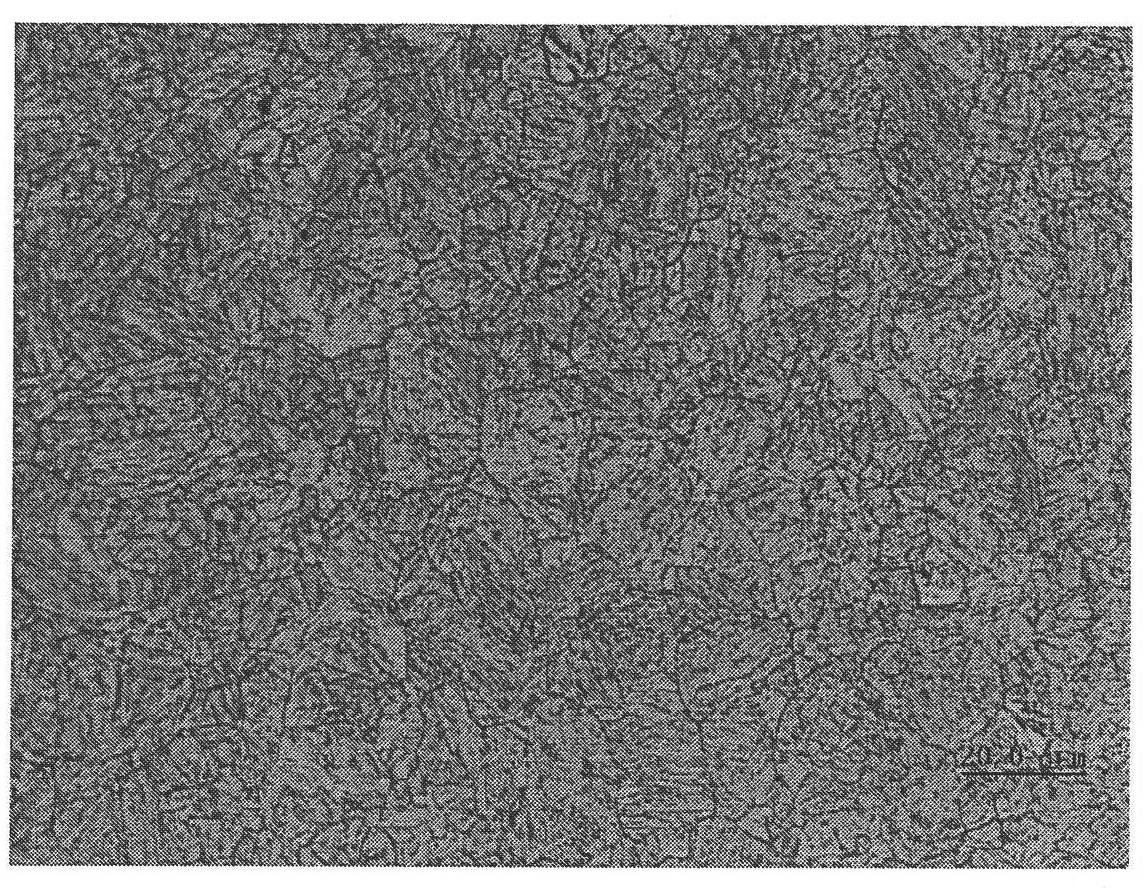

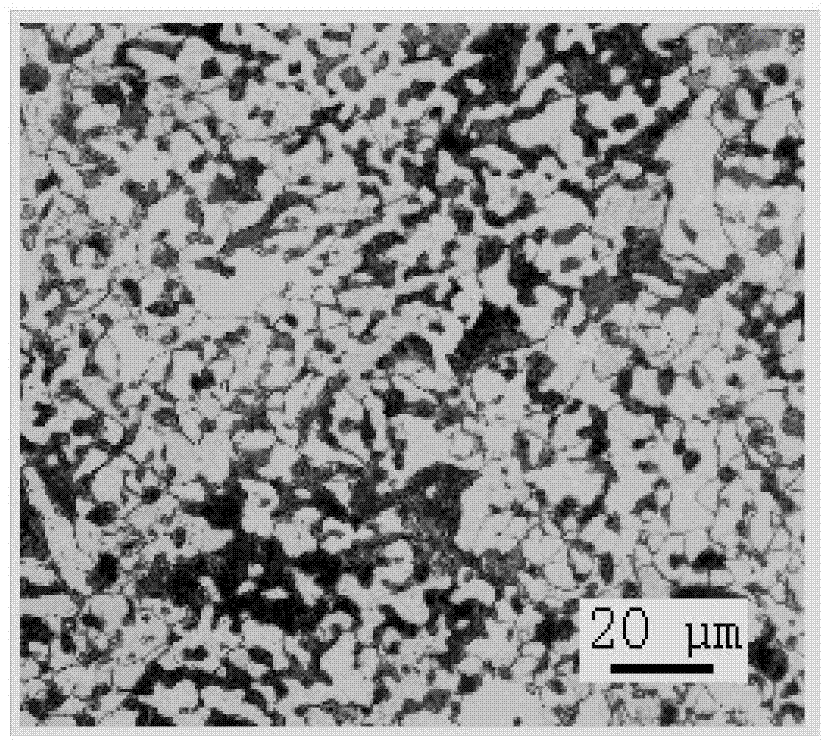

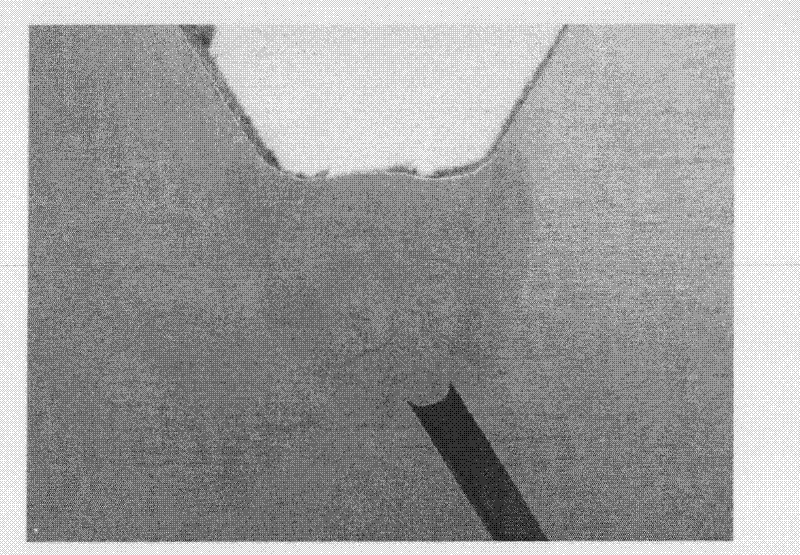

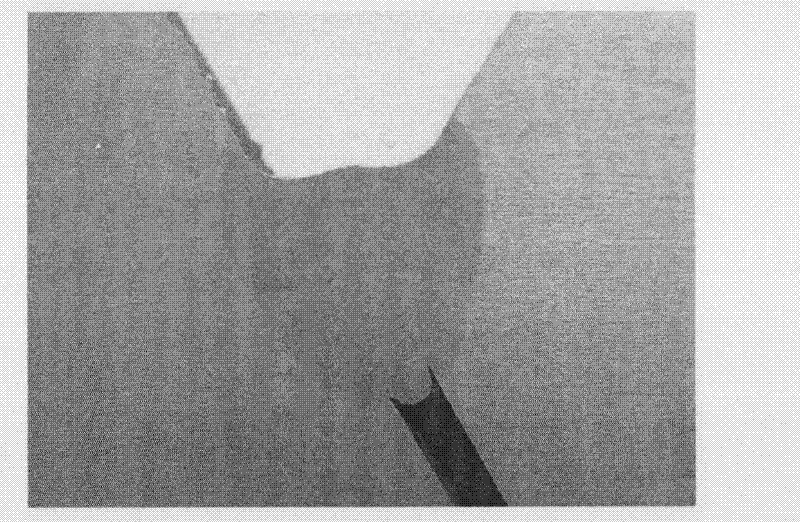

The invention provides a wear resistance steel plate, which contains the chemical ingredients (by weight percent) of: 0.31 to 0.40% of C, 0.10 to 0.80% of Si, 0.20 to 1.50% of Mn, not more than 0.050% of P, not more than 0.030% of S, 0 to 1.50% of Cr, 0 to 0.80% of Mo, 0.02 to 0.20% of Al, 0.0005 to 0.0040% of B, 0 to 0.10% of Ti, 0 to 0.030% of Ca, the balance of Fe and unavoidable impurities, wherein Cr+Mo is not less than 0.10% and not more than 1.80%, and Al+Ti not less than 0.05% and not more than 0.18%. A manufacturing method of the wear resistance steel plate comprises the steps of smelting, refining, casting, rolling, quenching, tempering and the like. The 550 HB-level wear resistance steel plate, which is obtained from the ingredients and process, has high hardness (not less than550 HB), can be welded and bent, and includes the microstructure of martensite or martensite and residual austenite. The steel plate has superior wear resistance and is extremely suitable for workingunder strong wear environment, especially on vehicles or facilities, like buckets, loaders, mining electric wheel dump tracks and the like, which come into contact with high-hardness materials, such as high strength ore and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

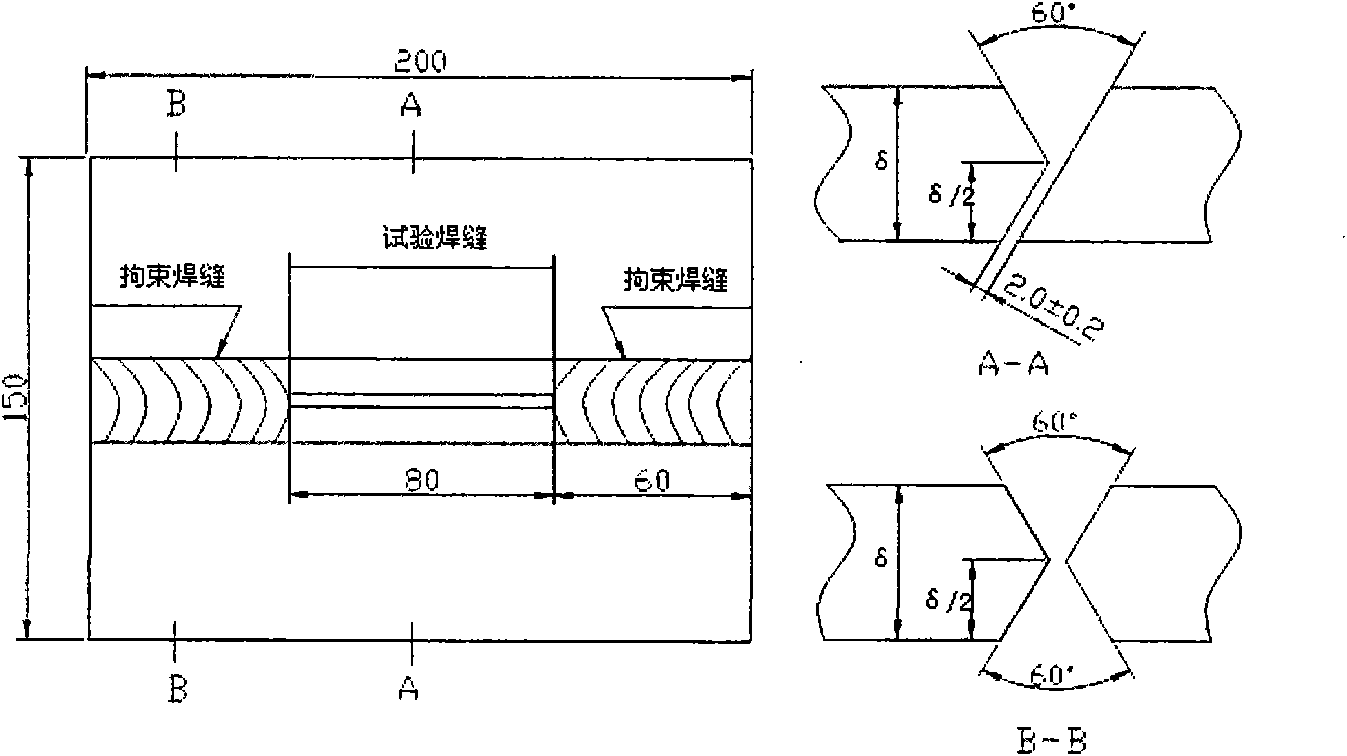

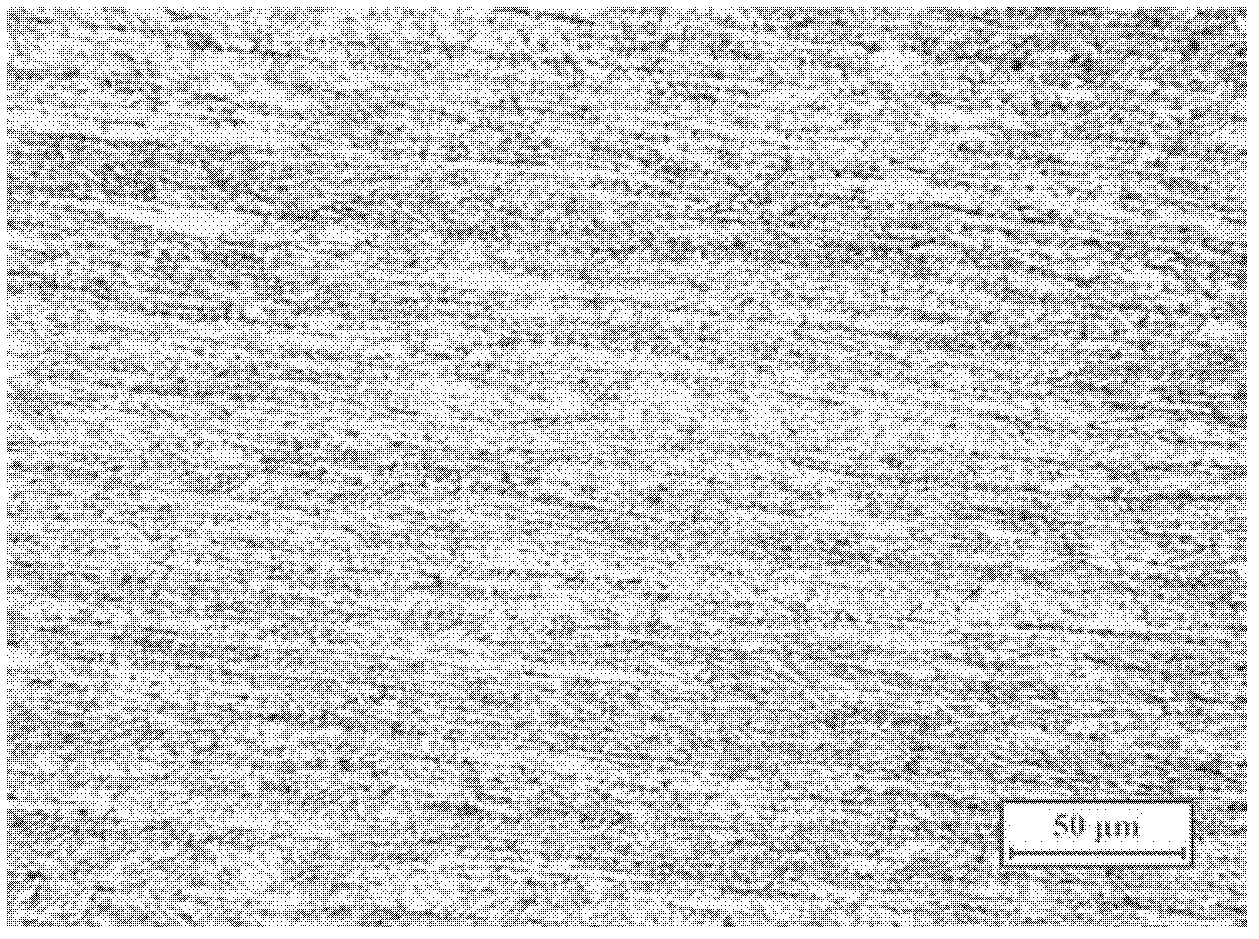

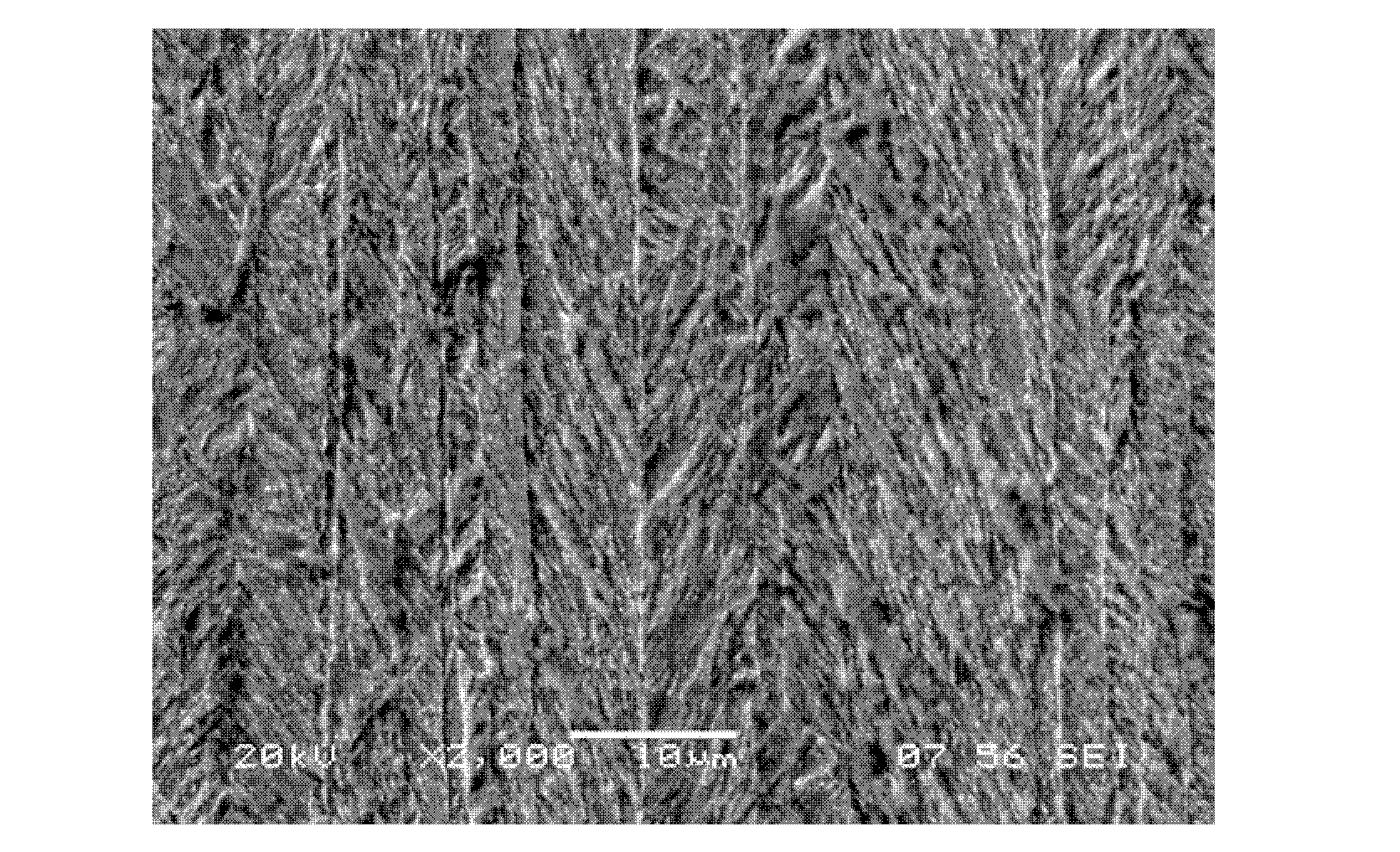

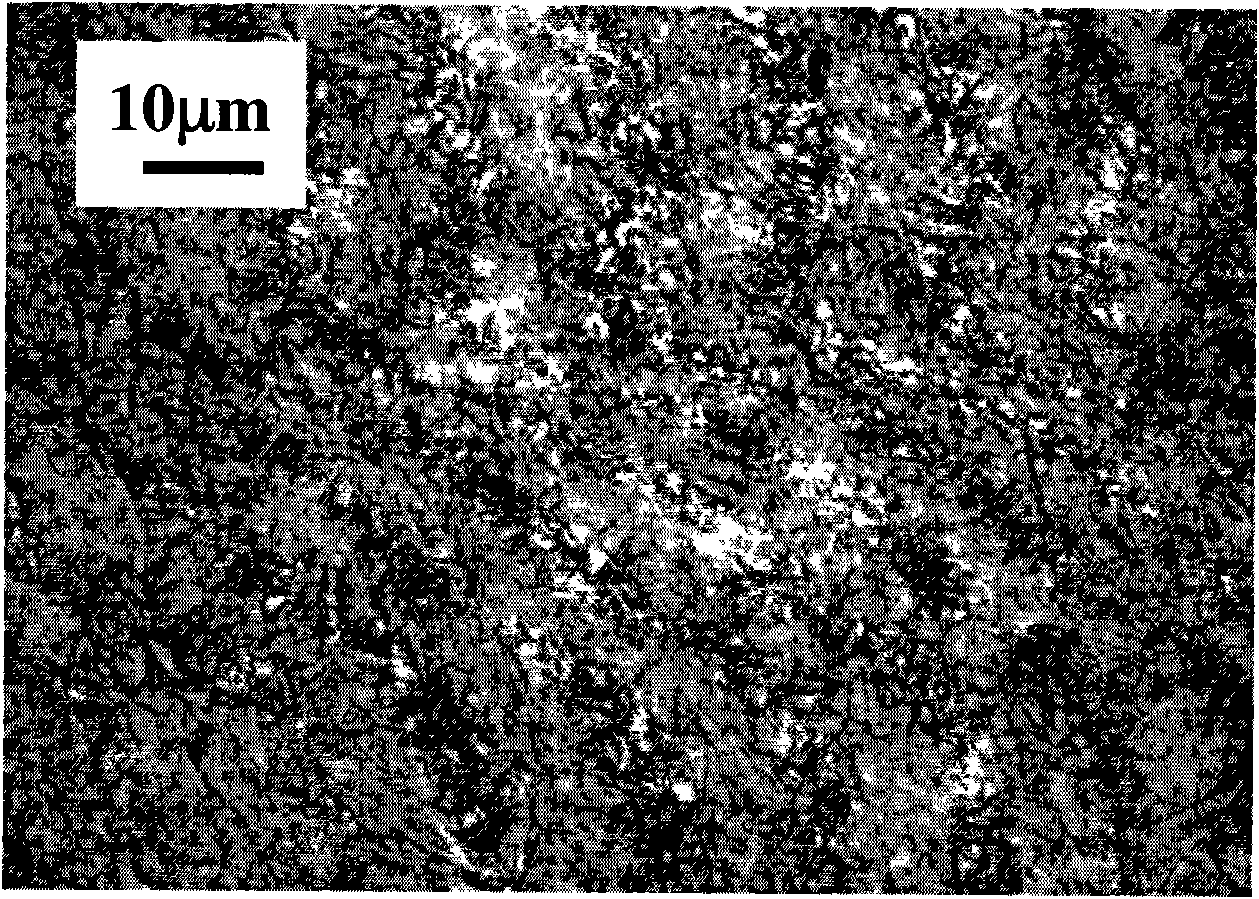

Ultrafine crystal bainite high-strength steel and manufacturing method thereof

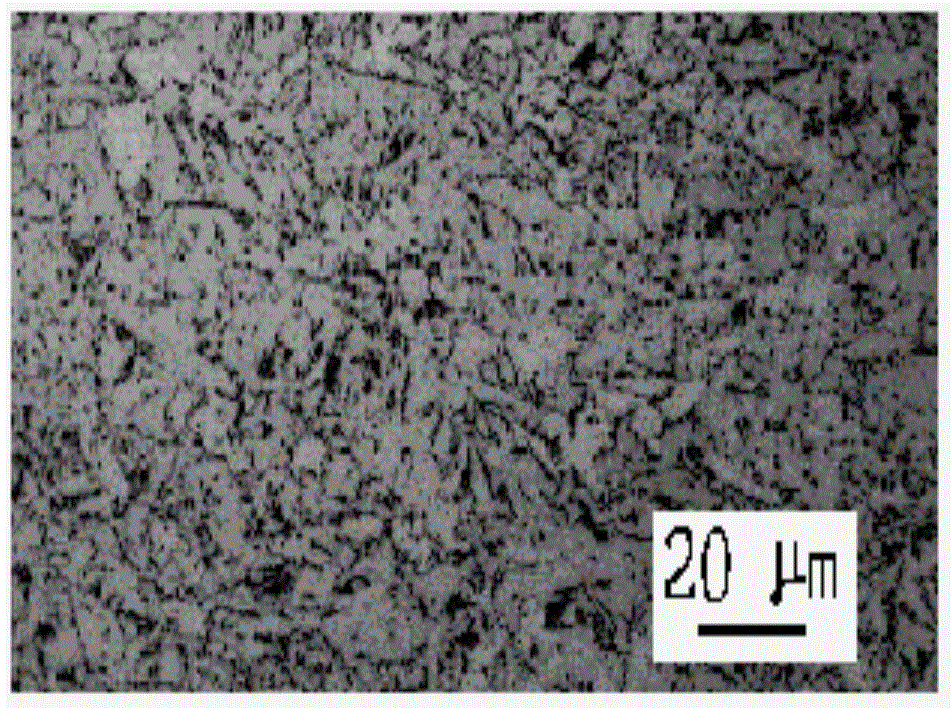

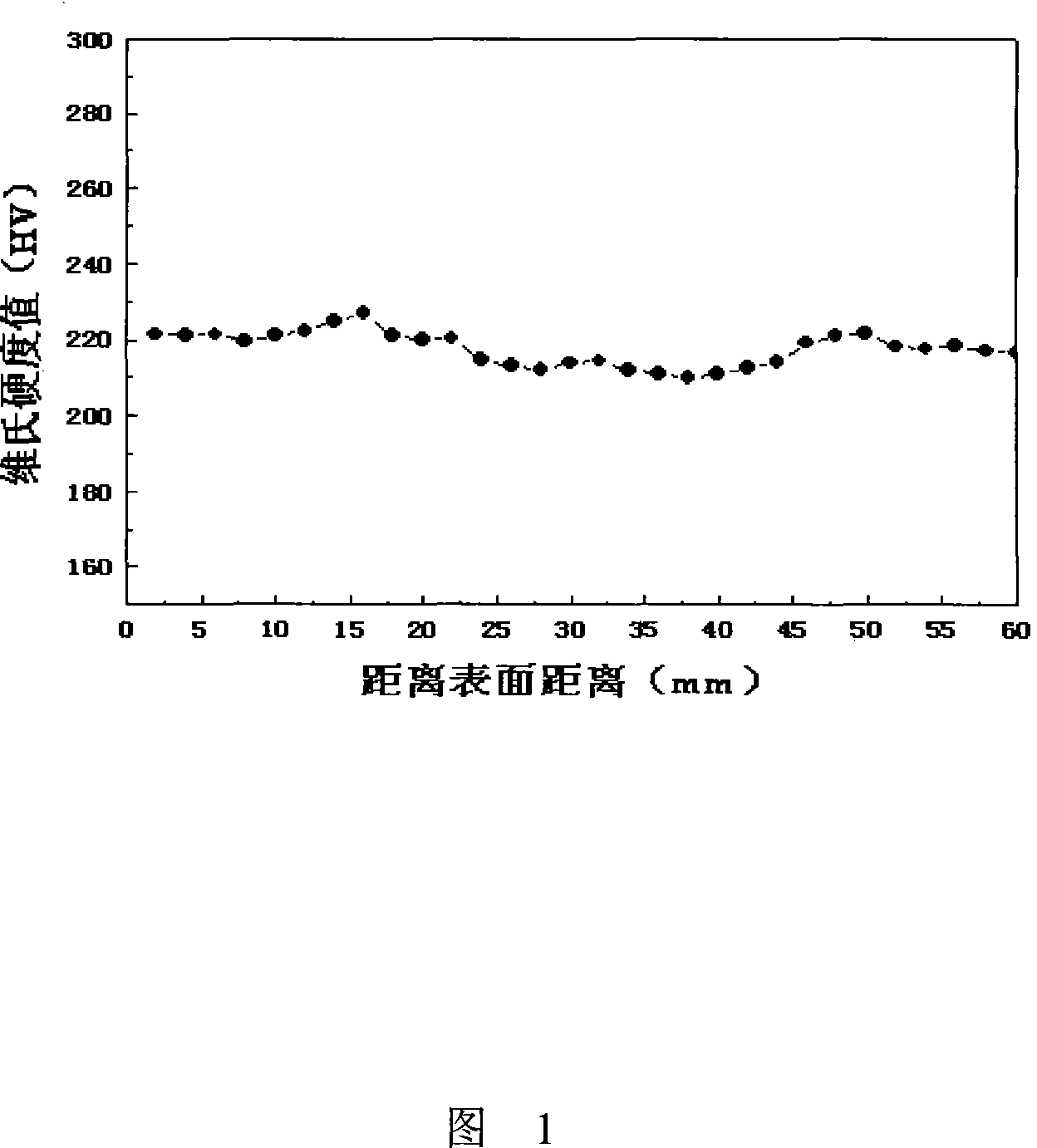

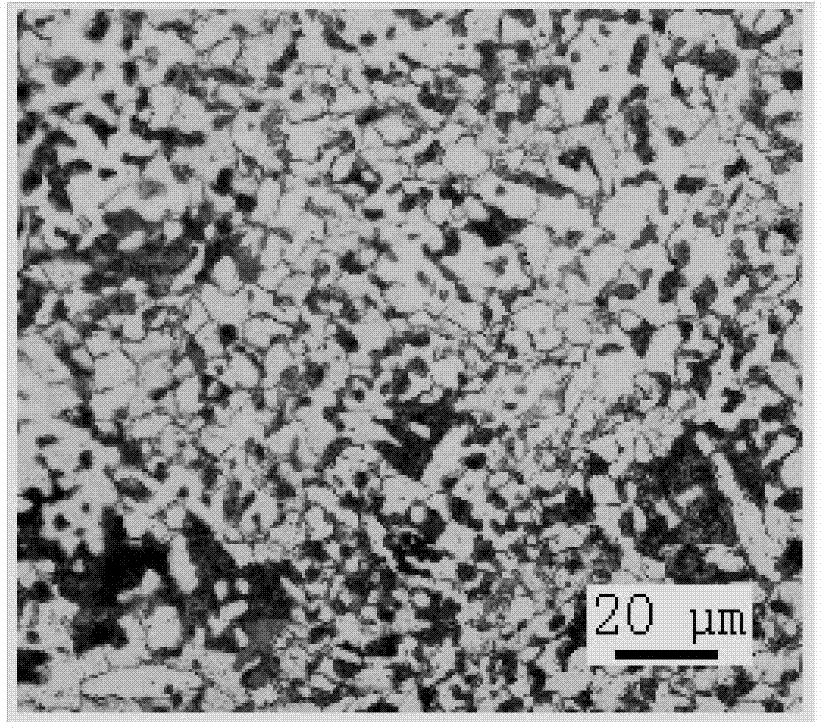

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Owner:BAOSHAN IRON & STEEL CO LTD

400HB-grade wear-resistant steel and method for manufacturing same

The invention provides a wear-resistant steel which comprises the following chemical components by weight percent (wt%): 0.08-0.24% of C, 0.10-0.30% of Si, 0.70-1.70% of Mn, 0.050% of P or less, 0.030% of S or less, 1.00% of Cr or less, 0.60% of Mo or less, 0.01-0.10% of Al, 0.0005-0.0040% of B, 0.005-0.06% of Ti and the balance of Fe and inevitable impurities, wherein the total weight percent of the Cr and the Mo is more than or equal to 0.15% and less than or equal to 1.20%, and the total weight percent of the Al and the Ti is more than or equal to 0.011% and less than or equal to 0.15%. A method for manufacturing the wear-resistant steel comprises the steps of smelting, casting, rolling, quenching and tempering. The 400HB-grade wear-resistant steel which is obtained by adopting the components and the process has high strength, good toughness and excellent machining performance, is easy to weld and bend and is suitable for the easily-worn equipment such as the bucket, the scraper conveyor and the mining electric-wheel dumper carriage of the engineering machinery.

Owner:BAOSHAN IRON & STEEL CO LTD

High-flexibility wear-resistant steel plate and manufacturing method thereof

ActiveCN101775539AImprove wear resistanceImprove low temperature toughnessMicro structureForeign matter

The invention provides a high-flexibility wear-resistant steel plate, which is characterized by comprising the following chemical components by weight percent: 0.04 to 0.11 percent of C, 0.10 to 0.50 percent of Si, 0.50 to 1.50 percent of Mn, less than 0.015 percent of P, less than 0.010 percent of S, 0 to 0.60 percent of Cr, 0 to 0.50 percent of Mo, 0 to 0.80 percent of Ni, 0 to 0.050 perent of Nb, 0.005 to 0.0040 percent of B, 0.010 to 0.060 percent of Al and 0.005 to 0.060 percent of Ti, and the surplus is Fe and inevitable foreign matters; and the content of Si, Mn and Cr satisfies that: Si+Mn+Cr is less than or equal to 2.4 percent and more than or equal to 1.30 percent; and the content of Mo, Ni and Nb satisfies that: Mo+Ni+Nb is less than or equal to 1.10 percent more than or equal to 0.10 percent. The hardness of the high-flexibility wear-resistant steel plate is more than 350 HB, the longitudinal impact power is more than 100J at the temperature of minus 40 DEG C, the micro-structure is of bainite or martensite, and the welding performance is excellent. The wear-resistant steel plate has simple and easy production technology and excellent low-temperature flexibility and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate with yield strength of 960MPa and manufacturing method thereof

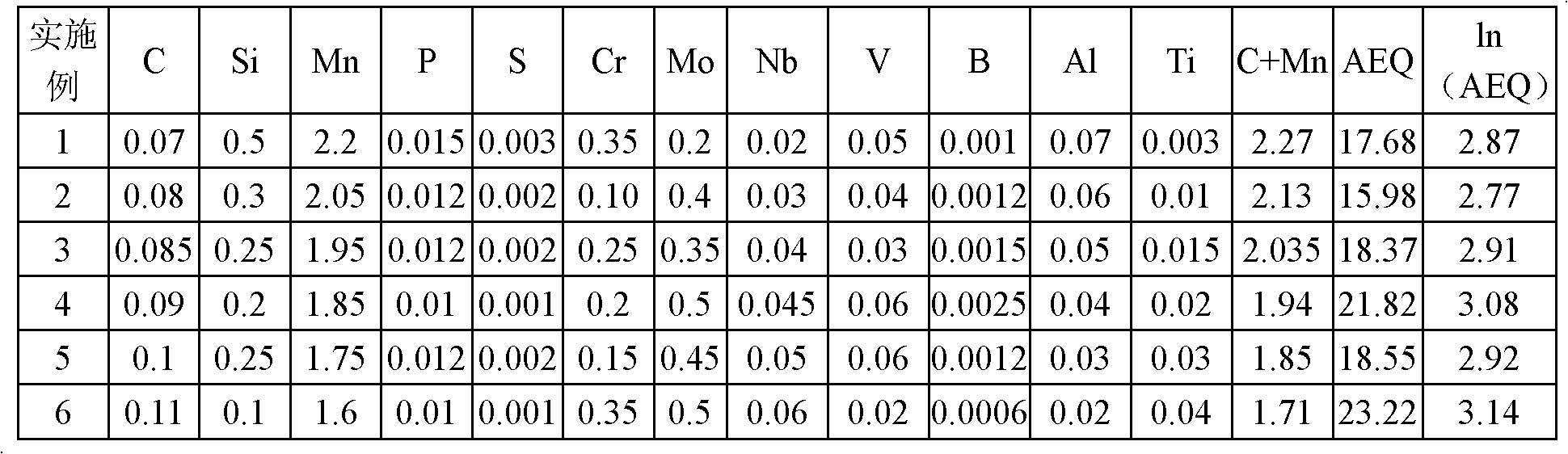

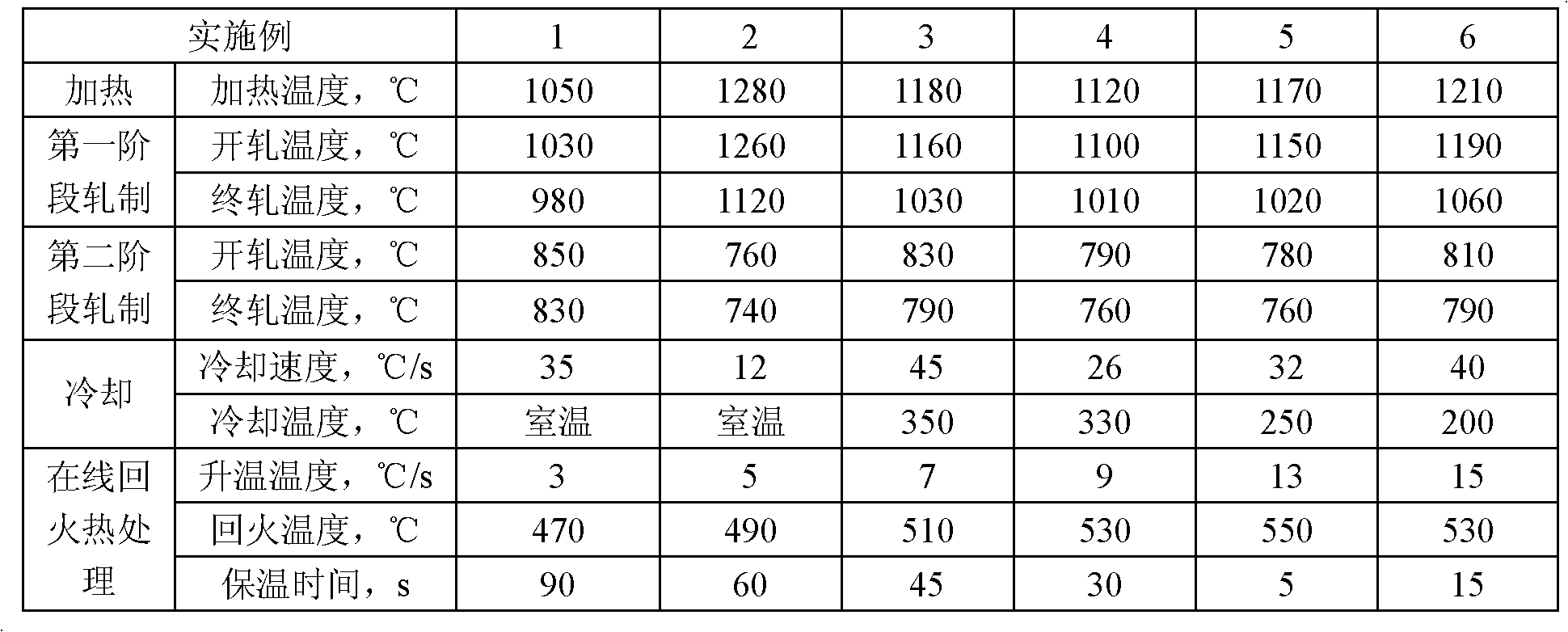

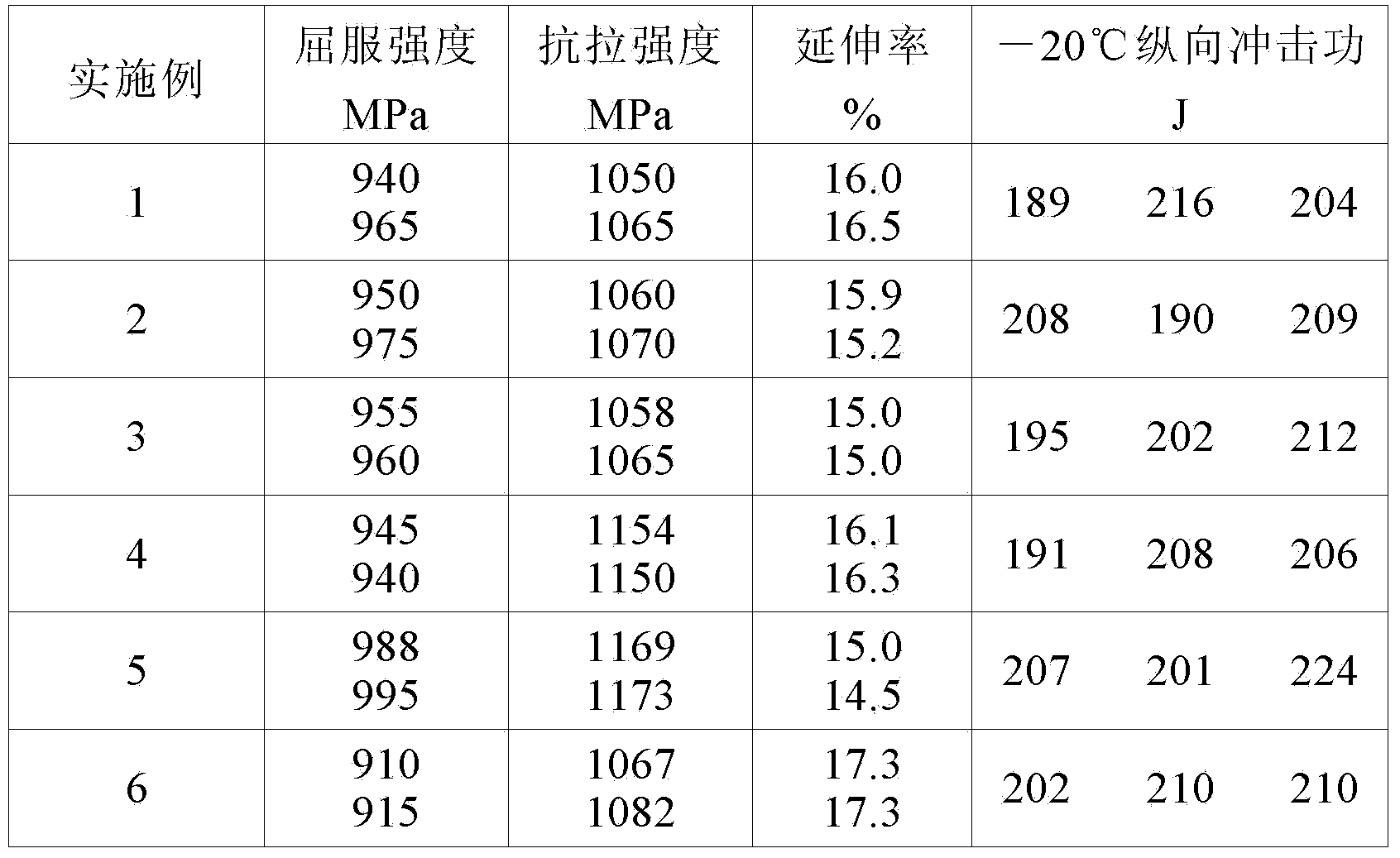

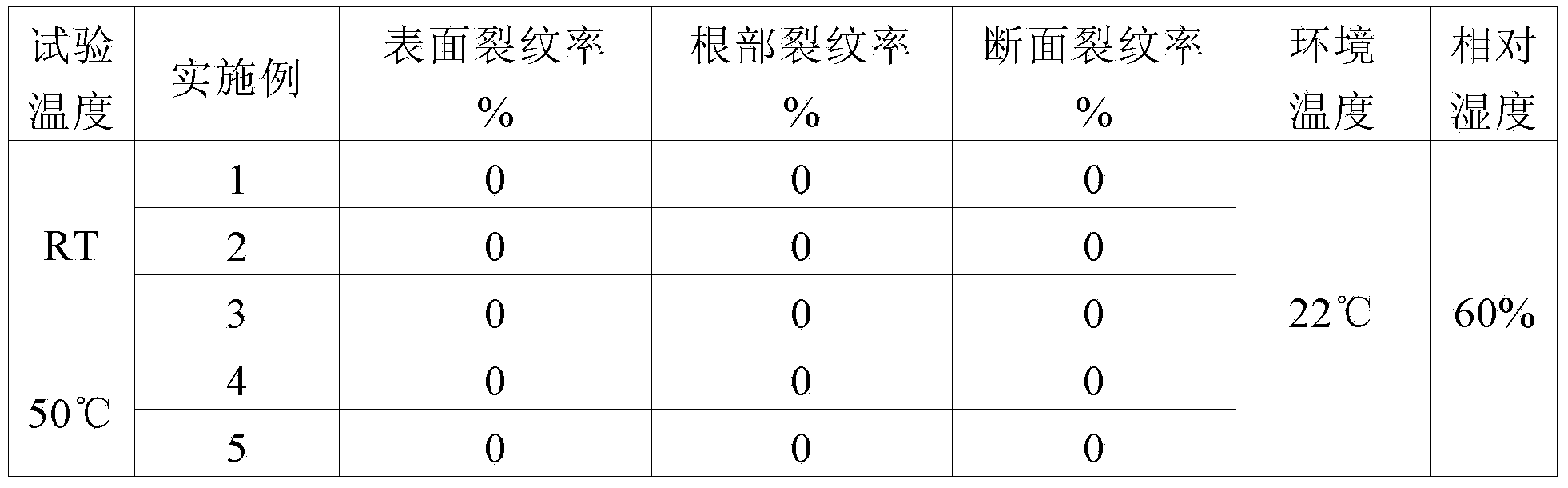

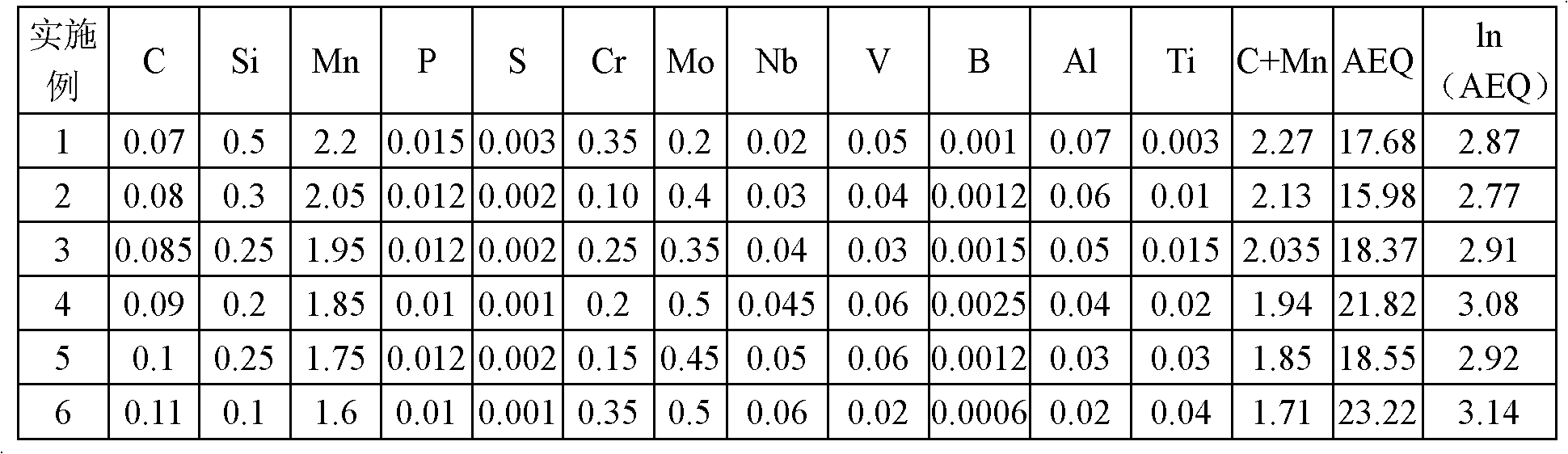

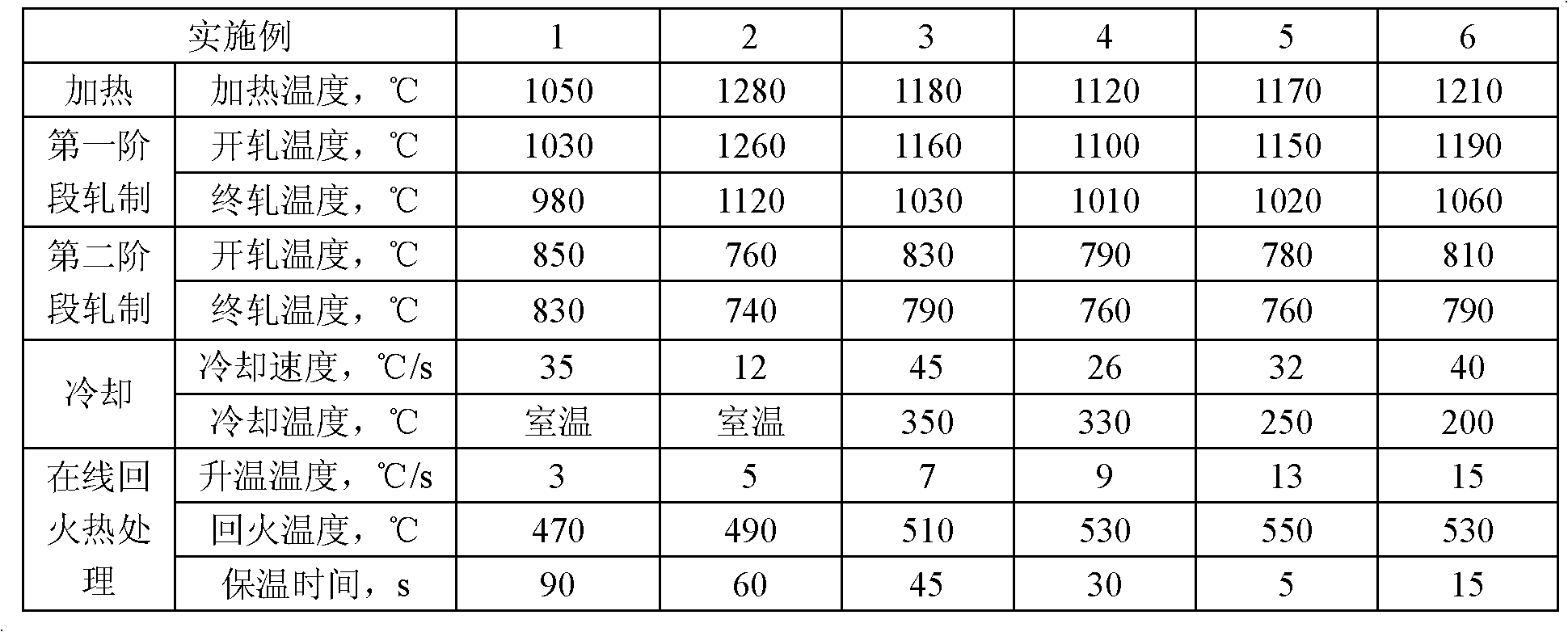

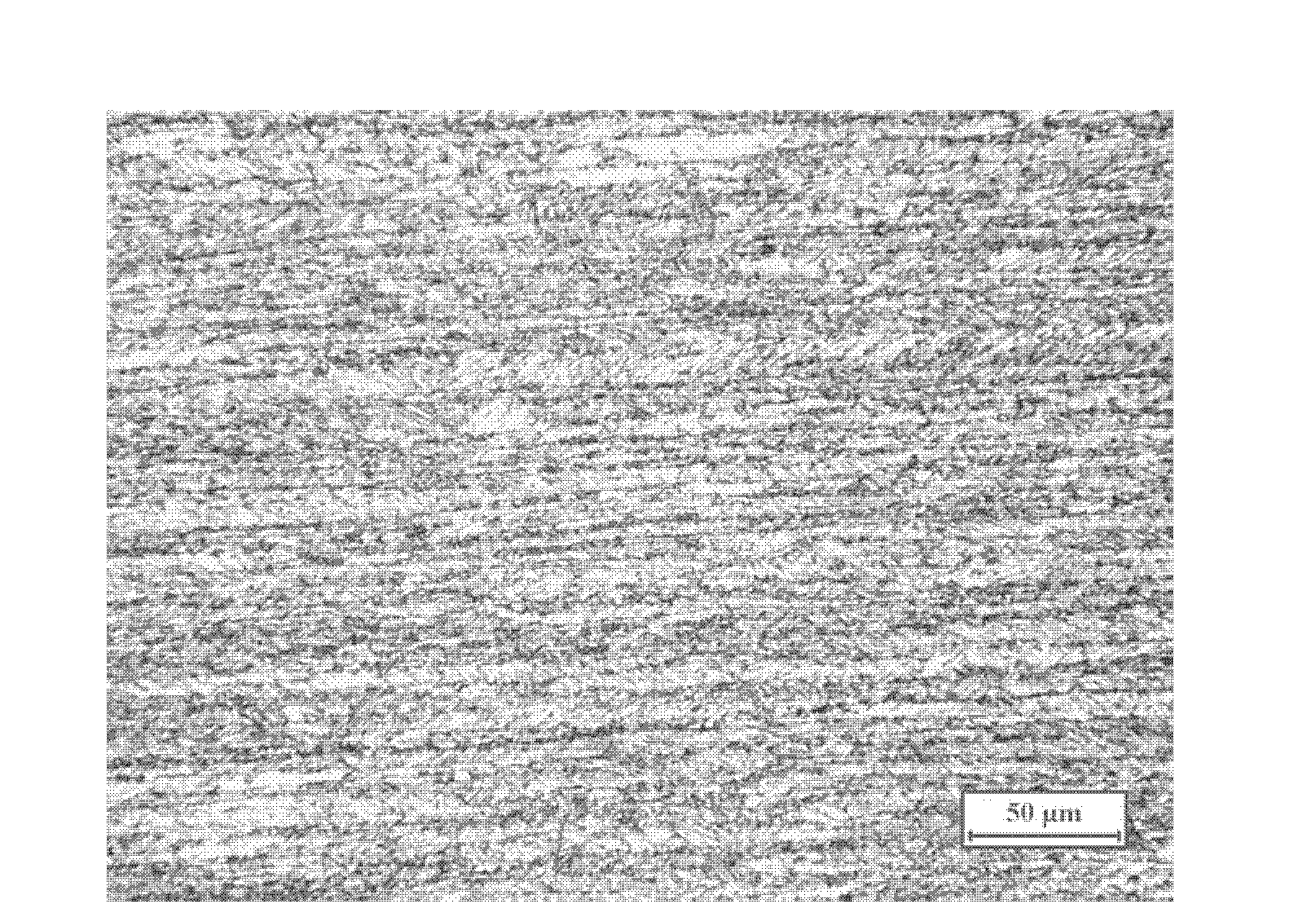

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate with 890MPa-grade yield strength and low welding crack sensitivity and manufacturing method thereof

ActiveCN103898406AReduce C contentLow costFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

The invention discloses a steel plate with 890MPa-grade yield strength and low welding crack sensitivity and a manufacturing method thereof. The steel plate comprises the following components by weight percent: 0.06-0.13wt.% of C, 0.05-0.70wt.% of Si, 1.20-2.30wt.% of Mn, 0-0.25wt.% of Mo, 0.03-0.11wt.% of Nb, 0.002-0.050wt.% of Ti, 0.02-0.15wt.% of Al, 0-0.0020wt.% of B, no more than 8.5% of 2Si+3Mn+4Mo, and the balance being Fe and inevitable impurities. The tissue of taking a super-fine bainitic lath as a matrix is obtained by adopting a technology of controlling hot mechanical rolling and cooling, so as to improve the strength, the plasticity and the toughness of the steel plate. The yield strength of the steel plate with low welding crack sensitivity is greater than 800MPa, the tensile strength is greater than 900MPa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 150J, the welding crack sensitivity index Pcm is smaller than or equal to 0.20%, and the welding property is good.

Owner:BAOSHAN IRON & STEEL CO LTD

HB400-grade wear-resisting steel plate and production method thereof

The invention discloses an HB400-grade wear-resisting steel plate and a production method thereof. The steel plate comprises the following chemical components in percentage by weight: C 0.05-0.15wt%, Si 0.4-1.4wt%, Mn 0.5-2.0wt%, P <0.012wt%, S <0.003wt%, Mo 0-0.5%, Nb 0.01-0.08%, Cu 0.20-1.0%, Co 0-1.0%, B 0.0010-0.0025wt%, Al 0.02-0.04wt%, Ti 0.004-0.030wt%, and the balance of Fe and inevitable impurities, wherein the content of Mo and Nb needs to satisfy the condition that the Mo+Nb is not less than 0.023C+0.059Ti+1.71B and not more than 2.574C+0.62Mn+10.36Ti +2.11B. The invention reduces production cost by adding some cheap alloy elements; and when the value of carbon equivalent Ceq is not more than 0.45, the HB400-grade wear-resisting steel plate has good welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Easy welding steel plate with yield strength of 550MPa and high toughness and manufacturing method thereof

The invention discloses an easy welding steel plate with yield strength of 550MPa and high toughness and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05 to 0.08 percent of C, 0.25 to 0.50 percent of Si, 1.65 to 1.90 percent of Mn, 0.03 to 0.07 percent of Nb, 0.03 to 0.07 percent of V, 0.0006 to 0.002 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, and the balance of Al and inevitable impurities, wherein the content of Fe accords with the following relation that: Mn is more than or equal to 3.01Si +12.8Nb+6.65V-12.12C and less than or equal to 4.78Si+13.8Nb+12.72V-10.13C. A tissue with a bainite strip serving as a substrate is obtained by a control rolling and control cooling technology. The yield strength of the easy welding thick plate with yield strength is more than 550MPa, the tensile strength is more than 670MPa, the Charpy impact power Akv(-20 DEG C) is more than 150 J, and the sensitivity index Pcm of welding cracks is less than or equal to 0.19 percent. The steel plate has high welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

High-hardness wear-resistant steel plate and manufacturing method thereof

ActiveCN103205643AImprove mechanical propertiesImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionWear resistant

The present invention provides a high-hardness wear-resistant steel plate and a manufacturing method thereof. The high-hardness wear-resistant steel plate comprises the following chemical compositions (wt%) of 0.60-0.75% of C, 0.10-0.40% of Si, 0.60-1.30% of Mn, 0-0.020% of P, 0-0.010% of S, 0.10-0.50% of Cu, 0.10-0.50% of Ni, 0.0030-0.0100% of N, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following steps of smelting, casting, hot rolling, annealing, pipe making, welding, quenching and tempering and other steps. The wear-resistant steel plate obtained by the above compositions and through the above process has high hardness and high wear resistance, with typical Rockwell hardness of HRC 62 to 66, and is suitable for easy-to-wear parts in various mechanical equipments, such as concrete pump delivery pipes.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength steel plate and plate shape control method thereof

ActiveCN106987773AGuaranteed straightnessSimple processTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention relates to a high-strength steel plate and a plate shape control method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.4-1.5% of Mn, 0.015% or less of P, 0.005% or less of S, 0.015-0.03% of Als, 0.03-0.04% of Nb, 0.001-0.0015% of Ca, and the balance of iron and inevitable impurities. According to the method, through appropriate heating, rolling, cooling and straightening technology design, the straightness of the steel plate can be guaranteed to meet requirements, and the degree of unstraightness of the steel plate is smaller than 3.2mm / m; and a cold straightening machine for re-straightening is not needed, so that manufacturing cost is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low-cost Q345R steel plate and production method thereof

The invention discloses a low-cost Q345R steel plate which comprises the following chemical components in percentage by weight: 0.16-0.18% of C, 0.2-0.3% of Si, 1.3-1.5% of Mn, at most 0.02% of P, at most 0.005% of S, 0.0015-0.003% of Ca, 0.017-0.027% of Als, and the balance of iron and impurities. The invention also discloses a production method of the low-cost Q345R steel plate. The low-cost Q345R steel plate can be produced by proper heating, controlled rolling and controlled cooling; and no expensive alloy elements, such as Nb, V, Ti and the like, are added to the steel plate, so the production cost is low.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Steel plate with yield strength of 960MPa and manufacturing method thereof

The invention discloses a steel plate with yield strength of 960MPa, which comprises the following chemical components in weight percent: 0.07-0.11 percent of C, 0.10-0.50 percent of Si, 1.60-2.20 percent of Mn, not greater than 0.015 percent of P, not greater than 0.003 percent of S, 0.10-0.35 percent of Cr, 0.20-0.50 percent of Mo, 0.02-0.06 percent of Nb, 0.02-0.06 percent of V, 0.003-0.04 percent of Ti, 0.02-0.07 percent of Al, 0.0006-0.0025 percent of B and the balance of Fe and other inevitable impurities. The steel plate with the yield strength of 960MPa also meets the following relational expressions: C+Mn is not less than 1.853Si+2.078Cr+3.112Mo-1298.532B but is not greater than 5.891Si+4.115Cr+4.797Mo-398.532B, and ln(AEQ) is not less than 2.08 but is not greater than 3.41. The invention also discloses a manufacturing method for the steel plate. The tensile strength of the obtained steel plate is not less than 980MPa, the Charpy impact power Akv (-40 DEG C) is not less than 80J, and the carbon equivalent (CEV) is not greater than 0.58 percent. The steel plate is excellent in welding property.

Owner:BAOSHAN IRON & STEEL CO LTD

High-tenacity steel and steel plate adaptive to high heat input welding and production method thereof

ActiveCN101724779AReduce contentLow carbon equivalentTemperature control deviceMetal rolling arrangementsUltimate tensile strengthContinuous casting

The invention provides a high-tenacity steel and a steel plate adaptive to high heat input welding and a production method thereof. The high-tenacity steel and steel plate comprise the following compositions by weight percent: 0.045-0.075% of C, 0.20-0.40% of Si, 1.20-1.60% of Mn, 0.015-0.025% of Nb, 0.02-0.06% of Al, 0.006-0.020% of Ti, 0.020-0.060% of N, P is no more than 0.015%, S is no more than 0.003% and the balance Fe and inevitable impurities. The invention also provides a production method for the steel plate, including smelting, continuous casting, heating, rolling and cooling. The invention adopts low C-moderate Mn-low Si-micro Nb and Ti-no B series of steel grade, and improves the strength, low-temperature tenacity and weldability of the steel plate by strengthening the control of thermo-mechanical rolling and post-rolling accelerated cooling technology.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate with 115 MPa grade yield strength and manufacturing method thereof

InactiveCN102618800AGrain refinementImprove low temperature impact toughnessChemical compositionUltimate tensile strength

The invention discloses a steel plate with the 115 MPa grade yield strength. The steel plate comprises the following chemical compositions in percentage by weight: 0.14-0.17wt% of C, 0.10-0.30wt% of Si, 0.80-1.20wt% of Mn, less than or equal to 0.015wt% of P, less than or equal to 0.003wt% of S, 0.30-0.50wt% of Cr, 0.40-0.70wt% of Mo, 1.1-2.2wt% of Ni, 0.01-0.06wt% of Nb, 0.04-0.06wt% of V, 0.003-0.02wt% of Ti, 0.03-0.07wt% of Al, 0.0006-0.0020wt% of B, the rest of Fe and other inevitable impurities. The steel plate with the 115 MPa grade yield strength also meets the following conditions: C+Mn / 2 is greater than or equal to 0.23Ni+0.32Mo+0.49Si+0.17Cr-153.21B and is less than or equal to 0.49Ni+0.64Mo+0.76Si+0.53Cr-132.61B, and Qm is greater than or equal to 2.77 and is less than or equal 4.92. The steel plate has the advantages that the yield strength is greater than or equal to 1150MPa, the tensile strength is greater than or equal to 1200MPa, the charpy impact energy (Akv) (minuse 40 DEG C) is greater than or equal to 60 J, and the carbon equivalent (CEV) is less than or equal to 0.60%, and the steel plate has excellent welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Production method of low-cost and high-strength steel plate

The invention discloses a low-cost and high-strength steel plate. A material of the steel plate includes the following chemical components by weight: 0.08-0.10% of C, 0.3-0.5% of Si, 1.5-1.8% of Mn, no more than 0.015% of P, no more than 0.007% of S, 0.2-0.4% of Cr, 0.04-0.06% of Nb, 0.04-0.07% of V, 0.008-0.02% of Ti, 0.0010-0.0025% of Ca, 0.015-0.03% of Als and the balance of iron and impurities. The invention also discloses a production method of the low-cost and high-strength steel plate. The method comprises the steps of continuous casting heating, rolling, cooling and heat treatment. The steel plate provided by the invention has yield strength and impact toughness met the requirements and eliminates expensive alloy like Mo; and a TMCP and tempering process are employed for production to realize simple process and low cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low welding crack sensitivity steel plate with yield strength of 690MPa grade and method for producing the same

ActiveCN101418418BReduce C contentLow costTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD

Low-yield-ratio thick Q345R steel plate for pressure vessels and production method thereof

ActiveCN104120339AImprove surface qualityImprove mechanical propertiesChemical compositionSheet steel

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Low-carbon bainite thick steel plate with high strength and toughness and manufacturing method thereof

ActiveCN102162061AReduce contentLow costTemperature control deviceMetal rolling arrangementsSheet steelUltimate tensile strength

The invention relates to a low-carbon bainite thick steel plate with high strength and toughness and a manufacturing method thereof. The steel plate comprises the following components in percentage by mass: 0.02 to 0.09 percent of C, 0.35 to 0.60 percent of Si, 1.50 to 1.85 percent of Mn, 0.15 to 0.30 percent of Mo, 0.04 to 0.07 percent of Nb, 0.04 to 0.07 percent of V, 0.0010 to 0.0020 percent of B, 0.01 to 0.04 percent of Al, 0.01 to 0.03 percent of Ti, less than or equal to 0.0030 percent of Zr, Mo in an amount which is more than or equal to 0.55-0.181Mn-1.51C and less than or equal to 8.7-3.69 Mn-29.18C, and the balance of Fe and inevitable impurities. The steel plate does not need quenching and heat treatment, so the manufacturing process is simplified, and the manufacturing cost of steel is reduced. The yield strength of the steel plate with low welding crack sensitivity is more than 690MPa, the tensile strength is more than 770MPa, the Charpy impact power Akv (-20 DEG C) is more than or equal to 180J, and the thickness of the plate can reach 80 millimeters. The welding crack sensitivity index Pcm is less than or equal to 0.20 percent, and the steel plate has excellent welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Large, thick, high-strength and high-toughness TMCP type steel plate and production method thereof

The invention discloses a large, thick, high-strength and high-toughness TMCP type steel plate and a production method thereof. The large, thick, high-strength and high-toughness TMCP type steel plate is composed of, by weight, 0.06%-0.08% of C, 0.20%-0.40% of Si, 1.40%-1.50% of Mn, 0.015% or less of P, 0.005% or less of S, 0.020-0.030% of Nb, 0.030%-0.050% of Alt, the balance Fe and inevitable impurities and 0.20% or less of Pcm. According to the steel plate, the components are simple, only a proper amount of microalloy Nb is added, and the precious elements such as V, Ti and Ni are not added; production cost is low, and the probability of large-scale production is increased. The steel plate is of a mixed structure mainly containing bainite, ferrite, pearlite and martensite and has a good comprehensive mechanical property; the steel plate is better in matching of the components and the strength and toughness, and it is guaranteed that the steel plate has the excellent comprehensive mechanical property; particularly, the impact performance of half of the plate in the thickness direction is good at the low temperature of minus 40 DEG C, and the method can be widely used for producing low-temperature-resistant building steel and engineering steel used in extremely cold climate. The method has the advantages that the production cost is low, and the technique is simple; the performance of products is excellent, and the comprehensive mechanical property of the products is stable.

Owner:WUYANG IRON & STEEL

Low alloy and high strength Q420C medium steel plate and production method thereof

The invention discloses a low alloy and high strength Q420C medium steel plate. The low alloy and high strength Q420C medium steel plate comprises the following chemical components by weight percent: 0.16-0.18% of C, 0.35-0.45% of Si, 1.45-1.55% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 0.015-0.03% of Als, and the balance of iron and impurities. The invention also discloses a production method for the low alloy and high strength Q420C medium steel plate. The production method is simple, and has a short production cycle and low production cost; and the strength of the steel plate is moderate, the yield strength is 430-460MPa, and the tensile strength is 540-590MPa.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

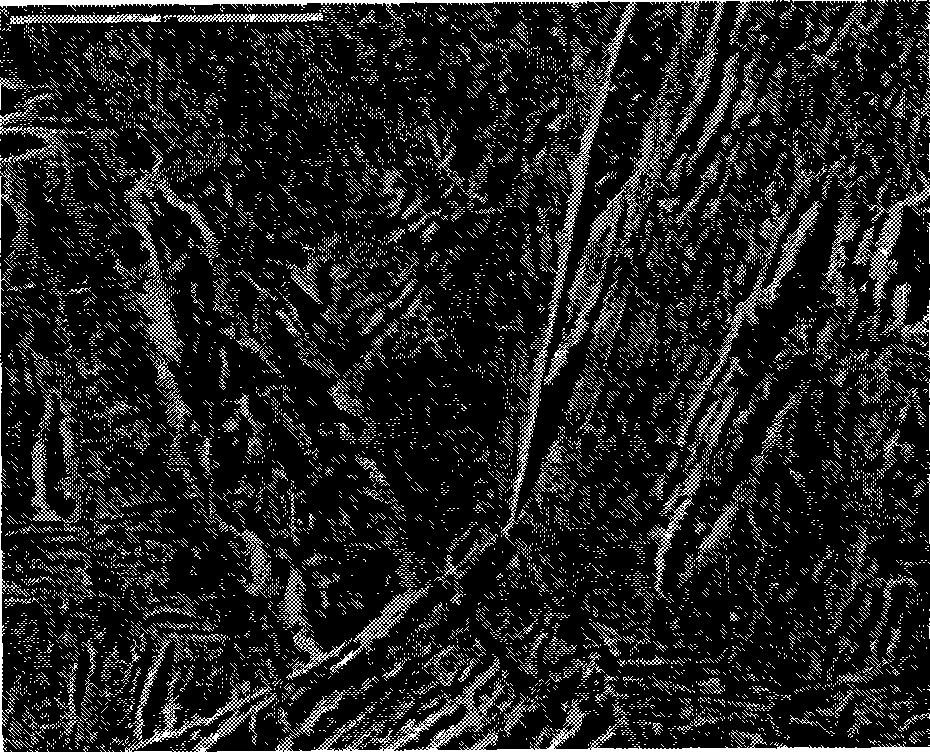

Ultra-high strength hot rolling wire rod of 2200 Mpa level and manufacture method thereof

ActiveCN101586208ALow content of alloying elementsSave resourcesTemperature control deviceWork treatment devicesWire rodChemical composition

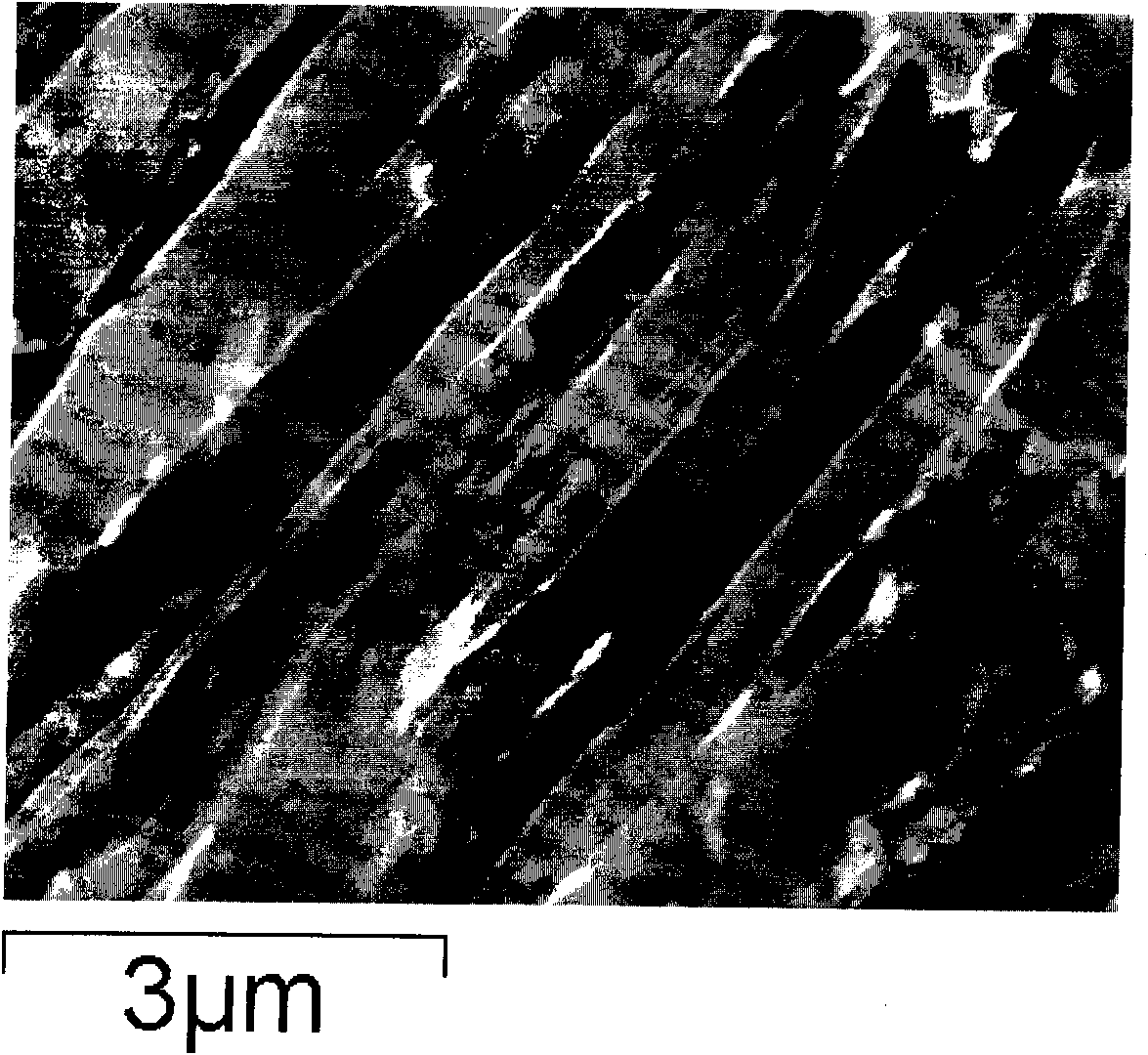

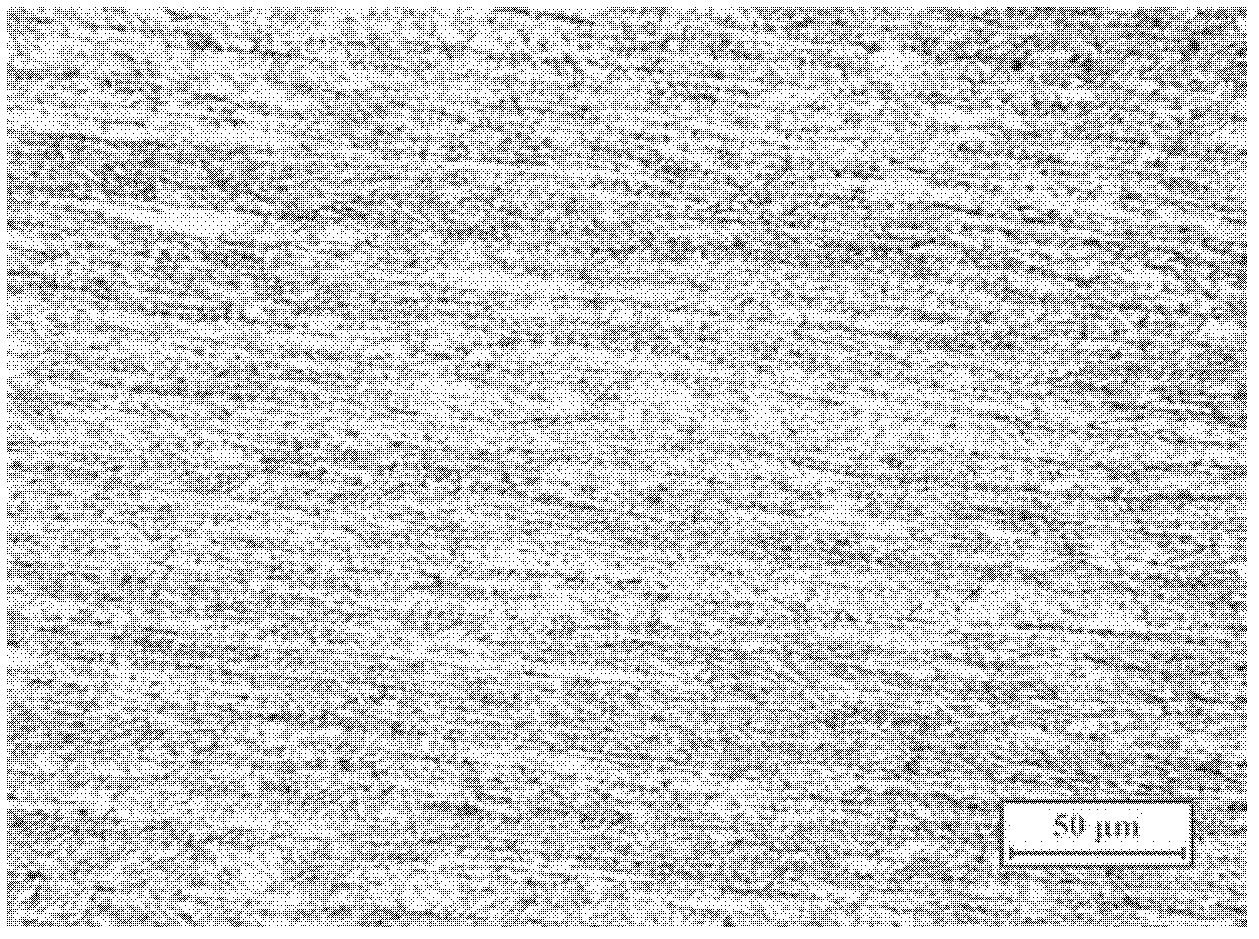

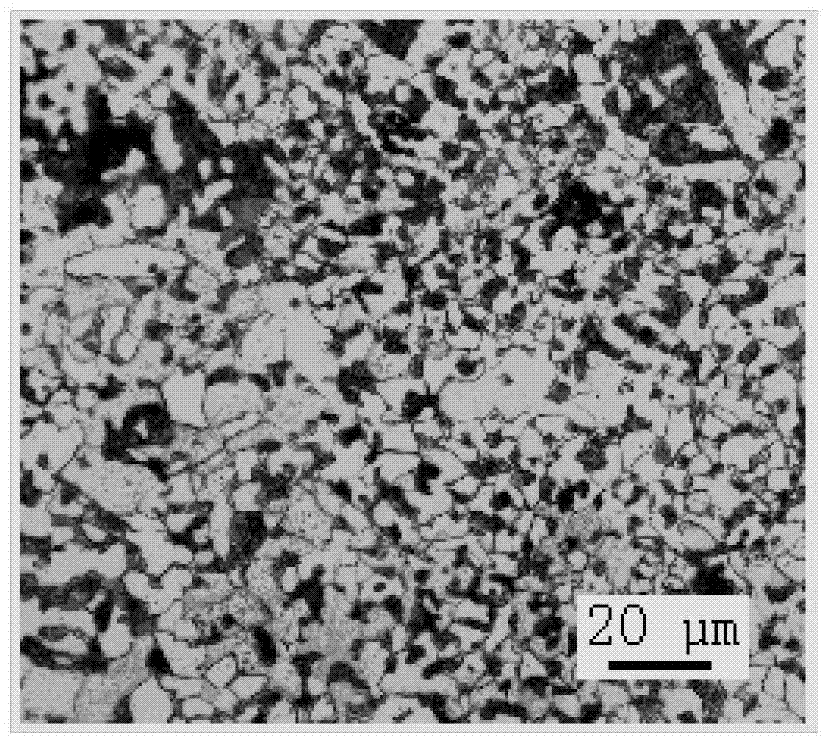

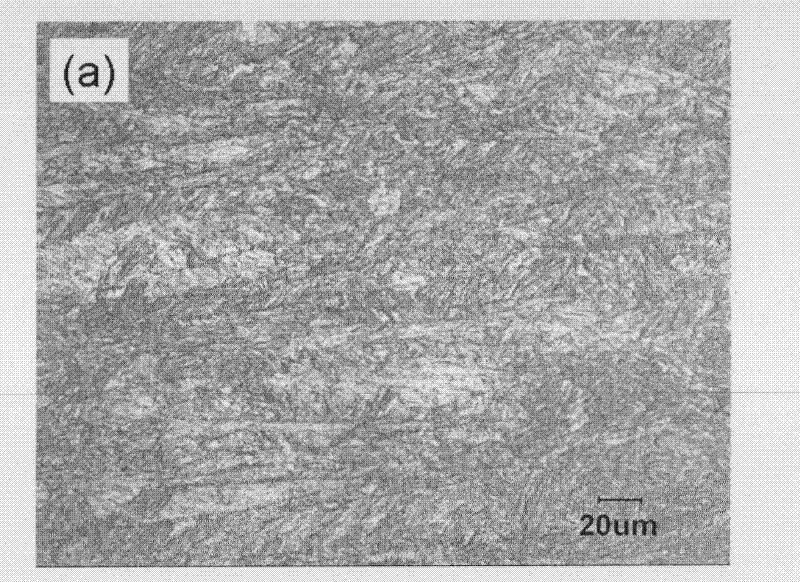

The invention provides an ultra-high strength hot rolling wire rod of 2200 Mpa level and a manufacture method thereof. The ultra-high strength hot rolling wire rod of 2200 Mpa level comprises the following chemical components by weight percentage: 0.40 to 0.60 percent of C, 2.5 to 4.0 percent of Si, 3.0 to 5.0 percent of Mn, 0.40 to 0.60 percent of Mo, and the balance of Fe and unavoidable impurities. The invention adopts Mn-Si-Mo line components, and obtains the hot rolling wire rod taking a nanometer scale martensite structure as the characteristic through purification smelting, forging, rough rolling, finish rolling and the silking technology with the width of a martensite slab of about 5 to 15 nm. The ultra-high strength hot rolling wire rod has the steel yield strength no less than 1900 Mpa, the tensile strength no less than 2200 Mpa, the yield ratio no less than 0.85 percent, the elongation no less than 8.0 percent and the reduction of area no less than 40 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

High-flexibility wear-resistant steel plate and manufacturing method thereof

ActiveCN101775539BImprove low temperature toughnessGood welding performanceForeign matterMicro structure

The invention provides a high-flexibility wear-resistant steel plate, which is characterized by comprising the following chemical components by weight percent: 0.04 to 0.11 percent of C, 0.10 to 0.50 percent of Si, 0.50 to 1.50 percent of Mn, less than 0.015 percent of P, less than 0.010 percent of S, 0 to 0.60 percent of Cr, 0 to 0.50 percent of Mo, 0 to 0.80 percent of Ni, 0 to 0.050 percent of Nb, 0.005 to 0.0040 percent of B, 0.010 to 0.060 percent of Al and 0.005 to 0.060 percent of Ti, and the surplus is Fe and inevitable foreign matters; and the content of Si, Mn and Cr satisfies that: Si+Mn+Cr is less than or equal to 2.4 percent and more than or equal to 1.30 percent; and the content of Mo, Ni and Nb satisfies that: Mo+Ni+Nb is less than or equal to 1.10 percent more than or equalto 0.10 percent. The hardness of the high-flexibility wear-resistant steel plate is more than 350 HB, the longitudinal impact power is more than 100J at the temperature of minus 40 DEG C, the micro-structure is of bainite or martensite, and the welding performance is excellent. The wear-resistant steel plate has simple and easy production technology and excellent low-temperature flexibility and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

High-tenacity steel and steel plate adaptive to high heat input welding and production method thereof

ActiveCN101724779BReduce contentLow carbon equivalentTemperature control deviceMetal rolling arrangementsSheet steelUltimate tensile strength

Owner:BAOSHAN IRON & STEEL CO LTD

600HB-grade wear resistant steel plate and its manufacturing method

Disclosed is a 600HB-grade wear resistant steel plate, comprising, by weight, 0.41 to 0.50% of C, 0.10 to 0.60% of Si, 0.20 to 1.20% of Mn, no more than 0.050% of P, no more than 0.030% of S, 0.01 to 1.50% of Cr, 0.01 to 1.00% of Mo, 0.01 to 1.50% of Ni, 0.001 to 0.10% of Ti, 0.001 to 0.10% of Al, 0.001 to 0.10% of RE, 0.01 to 1.00% of W, 0.0005 to 0.0040% of B, 0.001 to 0.010% of Ca, the balanceFe and unavoidable impurities. The 600HB-grade wear resistant steel plate provided in the invention has high hardness (no less than 600HB), good toughness and plasticity, high abrasion resistance andexcellent processability and weldability; the microstructure is martensite or martensite and retained austenite. Therefore, the 600HB-grade wear resistant steel plate is extremely suitable for being used in high abrasion environment, especially for being used in vehicles or equipment which contact with such materials of high hardness as high strength ores, for example, a bucket, or the compartment of an electric wheel self-discharging truck for mining, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

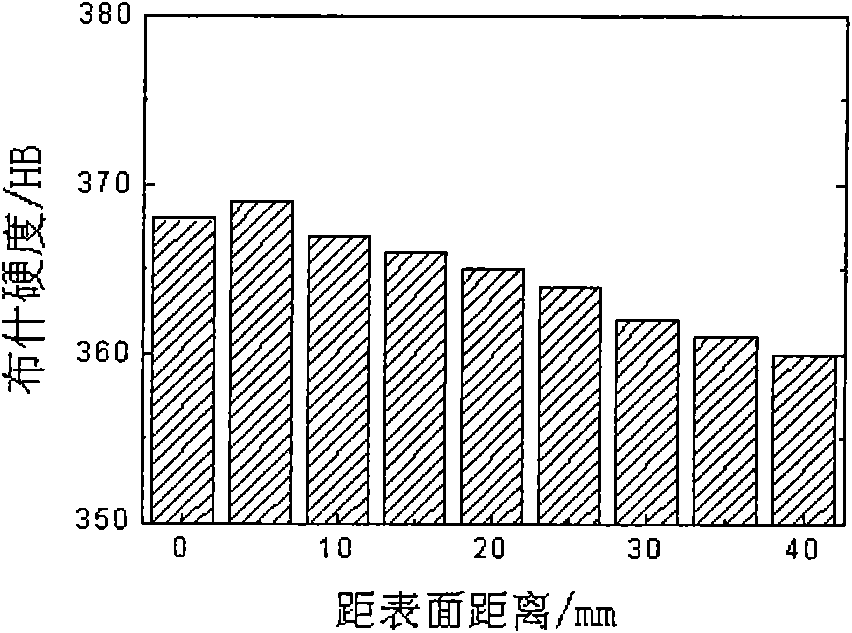

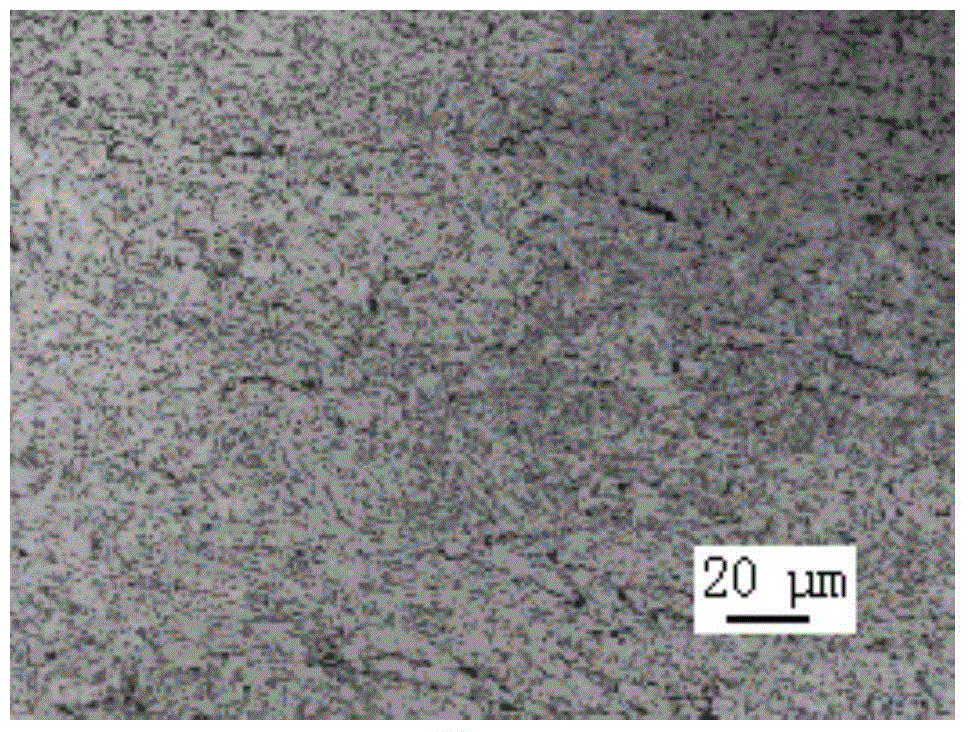

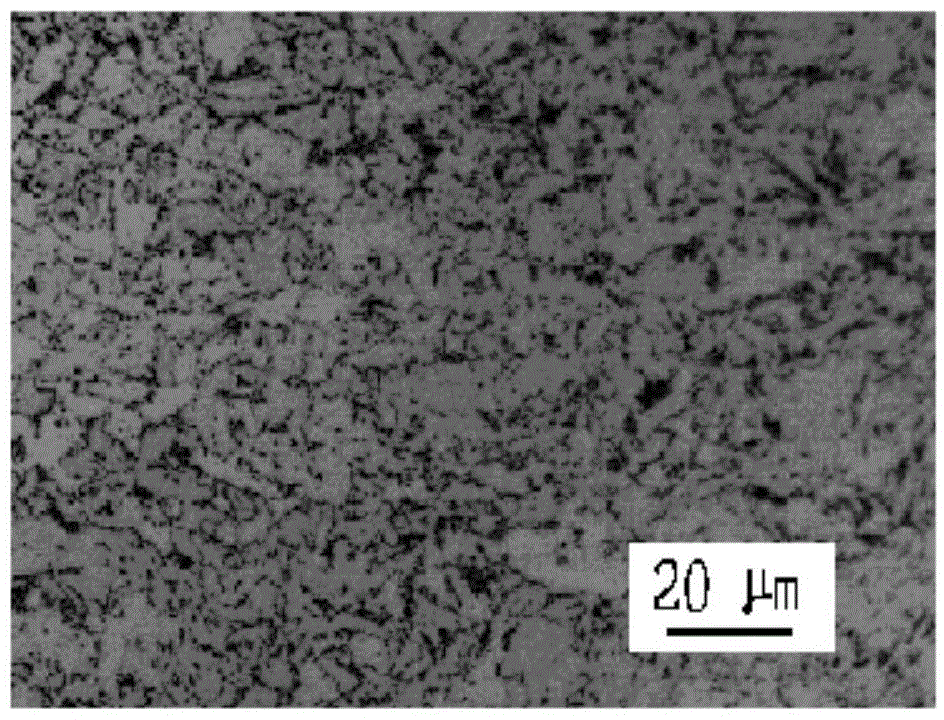

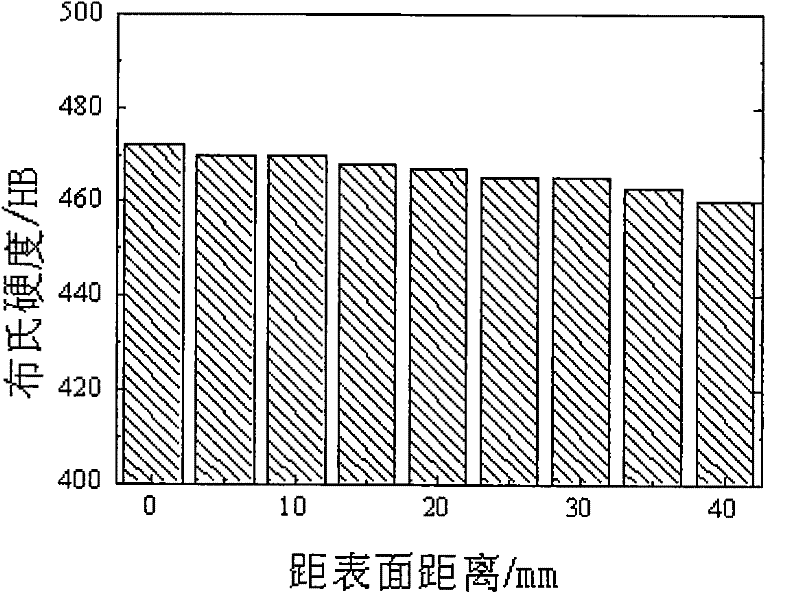

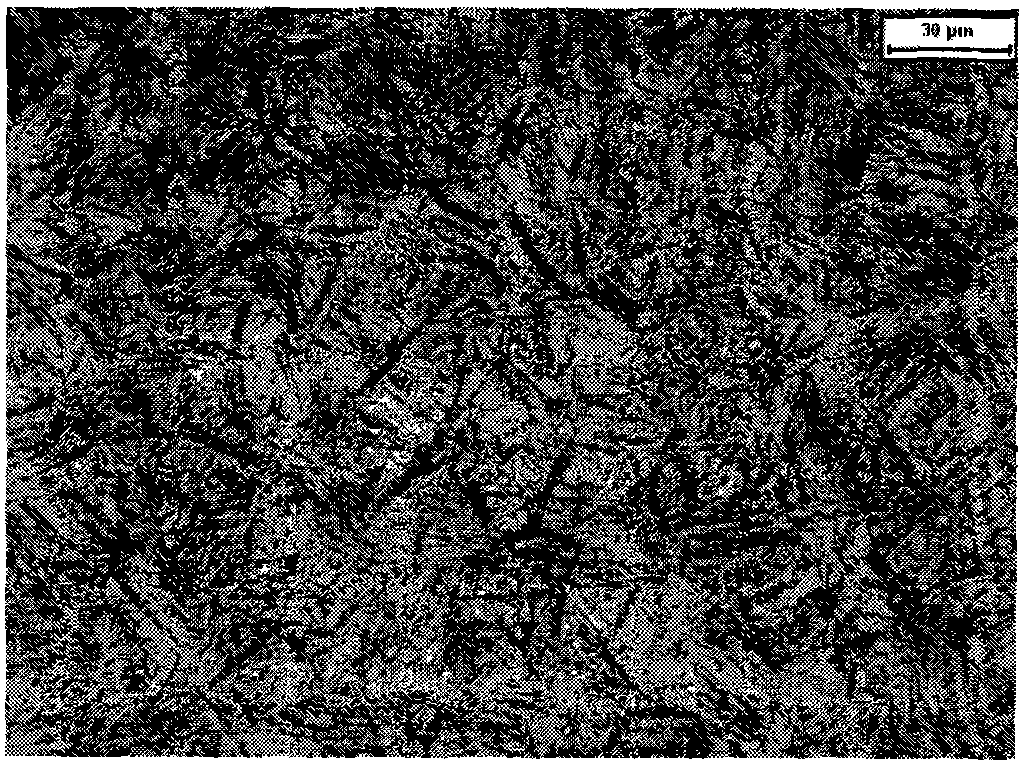

Low-alloy high-strength high-toughness wear-resistant steel plate and manufacturing method thereof

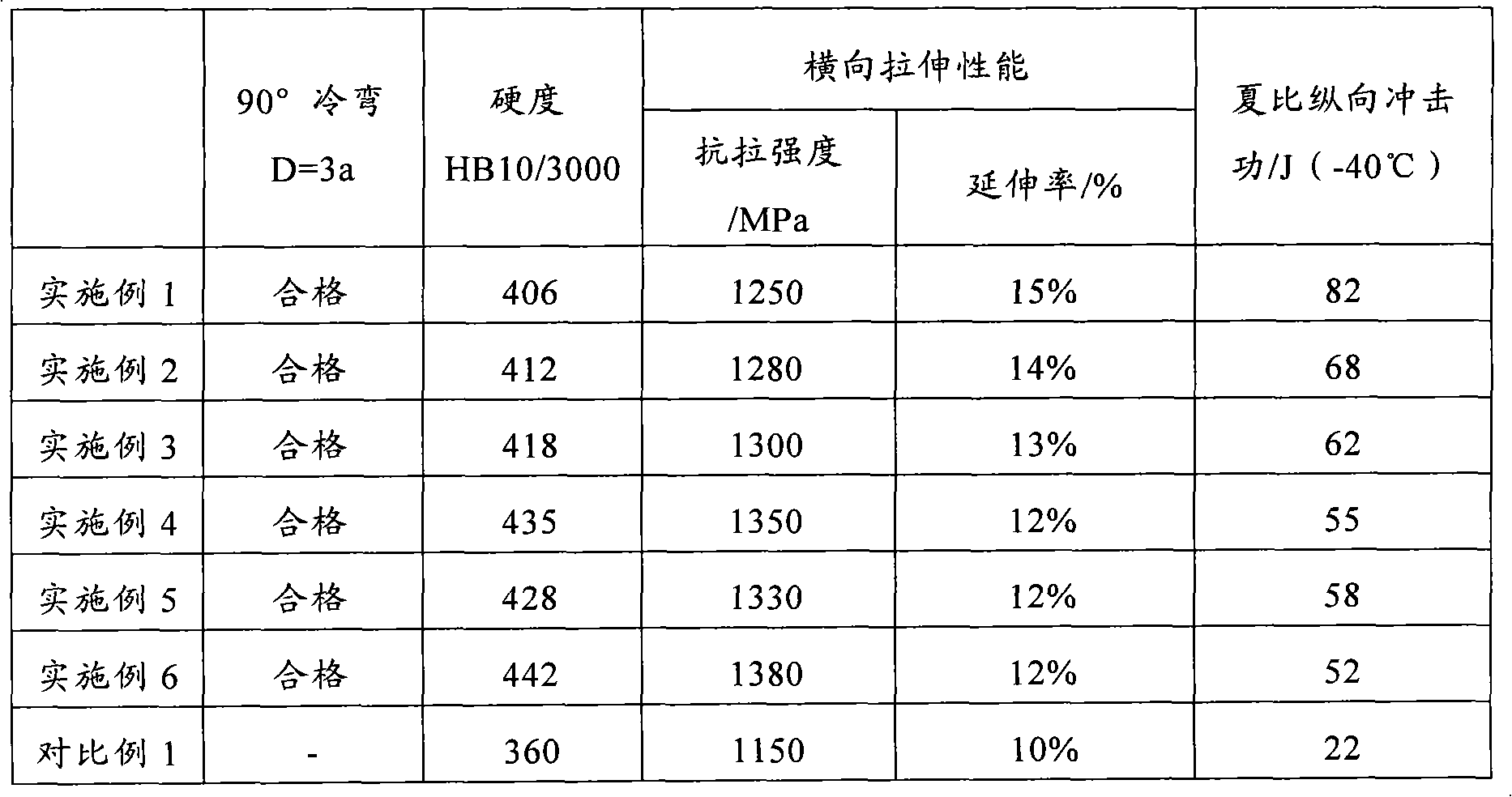

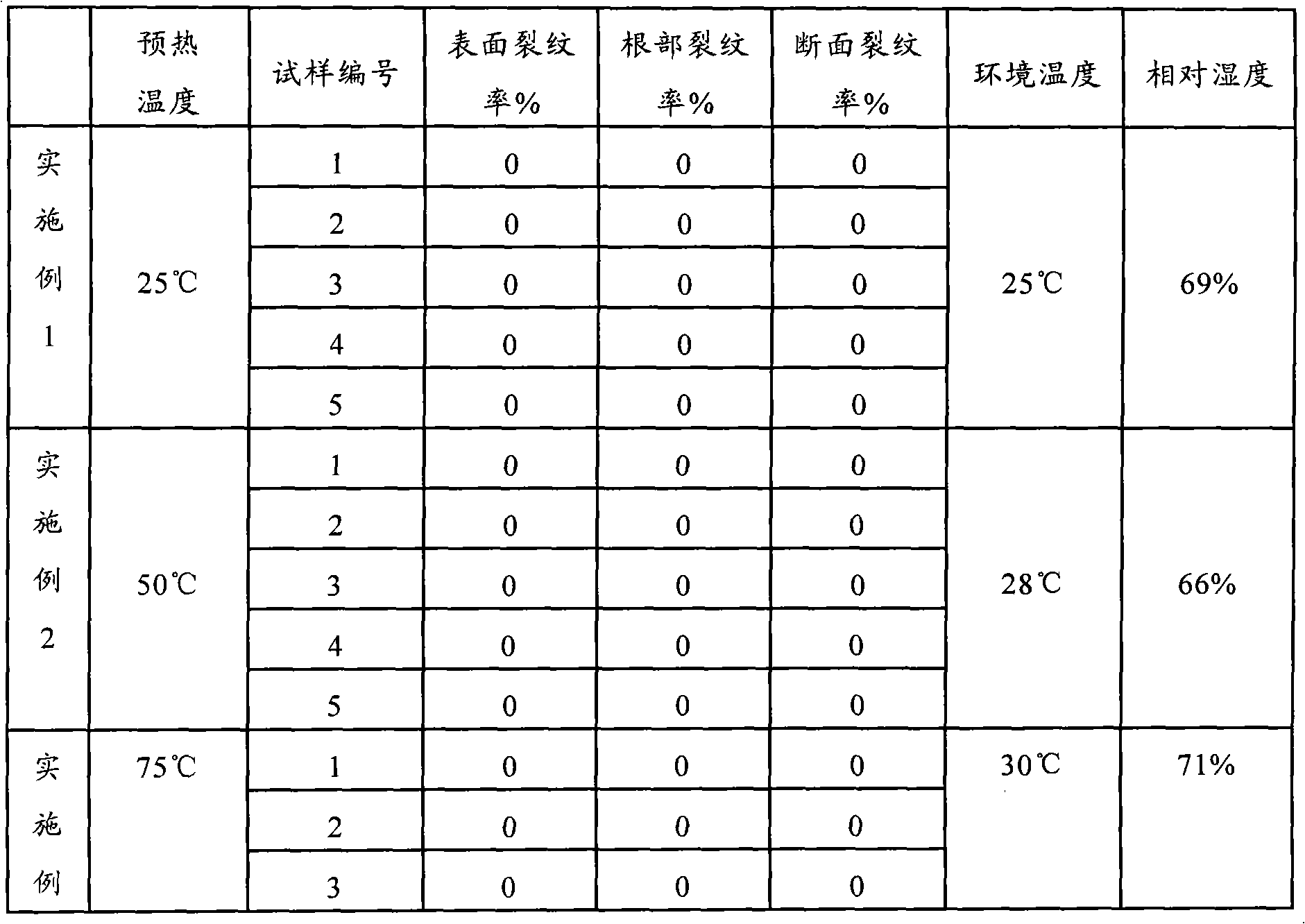

The invention provides a low-alloy high-strength high-toughness wear-resistant steel plate which is characterized in that the low-alloy high-strength high-toughness wear-resistant steel plate comprises the following chemical compositions in percentage by weight: 0.15-0.27 wt% of C, 0.20-1.0 wt% of Si, 0.80-1.8 wt% of Mn, less than 0.030 wt% of P, less than 0.010 wt% of S, 0.20-1.0 wt% of Cr, 0.10-0.40 wt% of Mo, 0.010-0.040 wt% of Nb, 0.0005-0.0040 wt% of B, 0.020-0.060 wt% of Al, 0.004-0.030 wt% of Ti and balance of Fe and inevitable impurities; and in addition, the contents of Cr, Mo and Nbsatisfy the condition: Cr+Mo+Nb is more than or equal to 0.35 wt%, and the contents of Cr and Mo satisfy the condition: Cr / Mo is more than or equal to 1.2. The low-alloy high-strength high-toughness wear-resistant steel plate of the invention has the charateristics that the hardness is more than 450 HB, the tensile strength is more than 1500 MPa, the yield strength is more than 1200 MPa, the elongation ratio is more than 15%, the impact energy is more than 80 J, the plate thickness can reach 80 mm, and fine texture can be martensite or martensite and retained austenite. The steel has low production cost, simple and easily mastered production process, high strength and hardness and favorable toughness and weldability.

Owner:BAOSHAN IRON & STEEL CO LTD

Hot rolling wire rod for mechanical structure of 1600 Mpa level and manufacture method thereof

The invention provides a hot rolling wire rod for a mechanical structure of 1600 Mpa level and a manufacture method thereof. The hot rolling wire rod for the mechanical structure comprises the following chemical components by weight percent: 0.20 to 0.30 wt percent of C, 1.5 to 3.0 wt percent of Si, 2.0 to 4.0 wt percent of Mn, 0.20 to 0.30 wt percent of Mo, and the balance of Fe and unavoidable impurities. The invention adopts Mn-Si-Mo line components, and obtains the hot rolling wire rod taking an acicular martensite as a main tissue and containing a bainite of 5 percent to 10 percent as the characteristics at the same time through production procedures such as smelting, rough rolling, finish rolling and the like. The hot rolling wire rod has higher strength, excellent toughness and ductility, the yield strength no less than 1300 Mpa, the tensile strength no less than1600 Mpa, the yield ratio no less than 0.70 percent, the elongation no less than 10.0 percent and the reduction of area no less than 50 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

2000MPa grade superhigh intensity high tenacity steel plate and manufacturing method thereof

ActiveCN101376945BCommon typeReduce dosageRoll mill control devicesHeat treatment process controlMetallurgyYield ratio

The invention provides a 2000MPa super high-strength and high-toughness steel sheet and a manufacturing method thereof. The 2000MPa super high-strength and high-toughness steel sheet comprises the following chemical components: 0.20 percent to 0.60 percent of C, 1.0 percent to 3.0 percent of Si, 1.0 percent to 5.0 percent of Mn, 0.10 percent to 0.60 percent of Mo, and the rest are Fe and inevitable impurities. In the invention, Mn-Si-Mo series components are adopted, and the steel sheet with bainite / martensite duplex phase as the tissue characteristic is obtained through a controlled rolling and cooling technology. The yield strength of the steel sheet is more than or equal to 1000Mpa, the tensile strength is more than or equal to 2000Mpa, the yield ratio is more than or equal to 0.75, the charpy impact power Akv (-40DEG C) is more than 50J, and the 50 percent ductile-brittle transition temperature FATT is lower than -40 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

S275JR thick borated steel plate and production method thereof

The invention discloses a S275JR thick borated steel plate which comprises the following chemical components in percentage by weight: 0.13-0.15% of C, 0.2-0.4% of Si, 1.0-1.2% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.0015-0.003% of Ca, 0.017-0.027% of Als, 0.0011-0.0016% of B and the balance of Fe and impurities. The invention further discloses a production method of the S275JR thick borated steel plate. By adopting a low cost component design, the steel plate with good surface quality can be produced through proper continuous casting, heating, controlled rolling and cold controlling processed by taking cheap silicon and manganese as main alloy elements. The steel plate is simple in production process, short in production period and low in manufacturing cost.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Wear resistant steel plate

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com