Ultrafine crystal bainite high-strength steel and manufacturing method thereof

A technology of bainite steel and manufacturing method, which is applied in the field of high-strength structural steel, can solve the problems of reduced finish rolling temperature, reduced strength, and reduced hardenability of deformed austenite, and achieves reduced C content, good weldability, and alloy The effect of low element content

Inactive Publication Date: 2010-08-25

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 36 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It was found in the factory production that the strength of the finishing rolling temperature decreased and the strength also decreased, which may be due to the decrease of the hardenability of deformed austenite at low temperature; ⑧Development of cooling equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

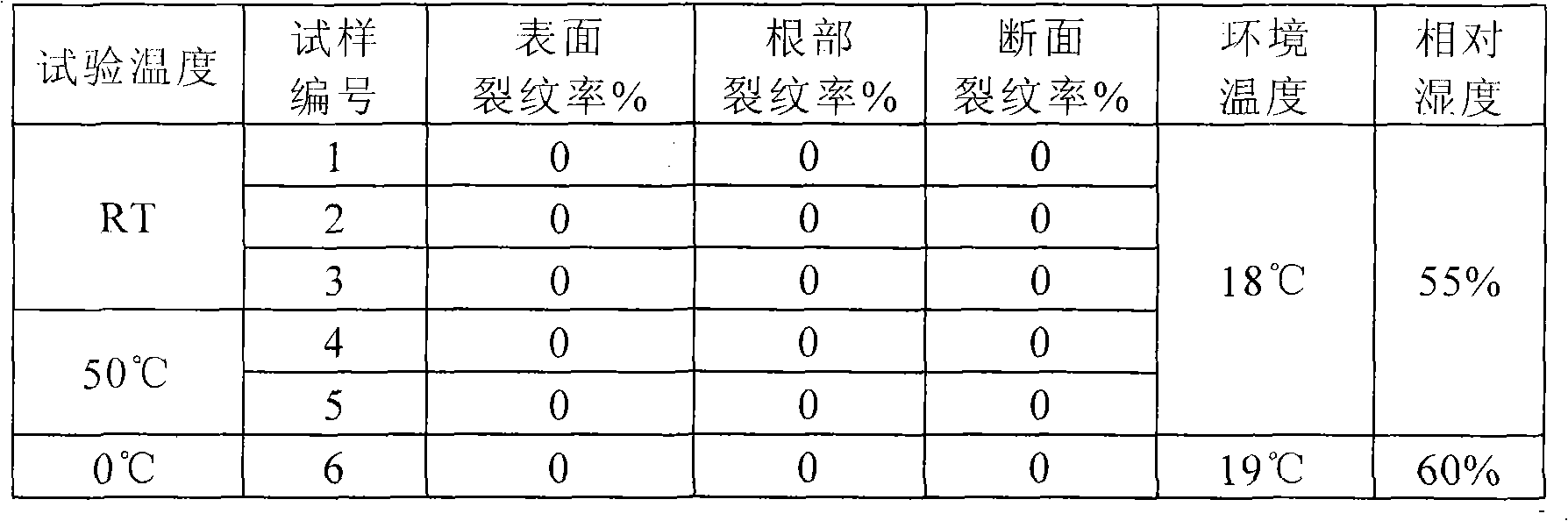

Abstract

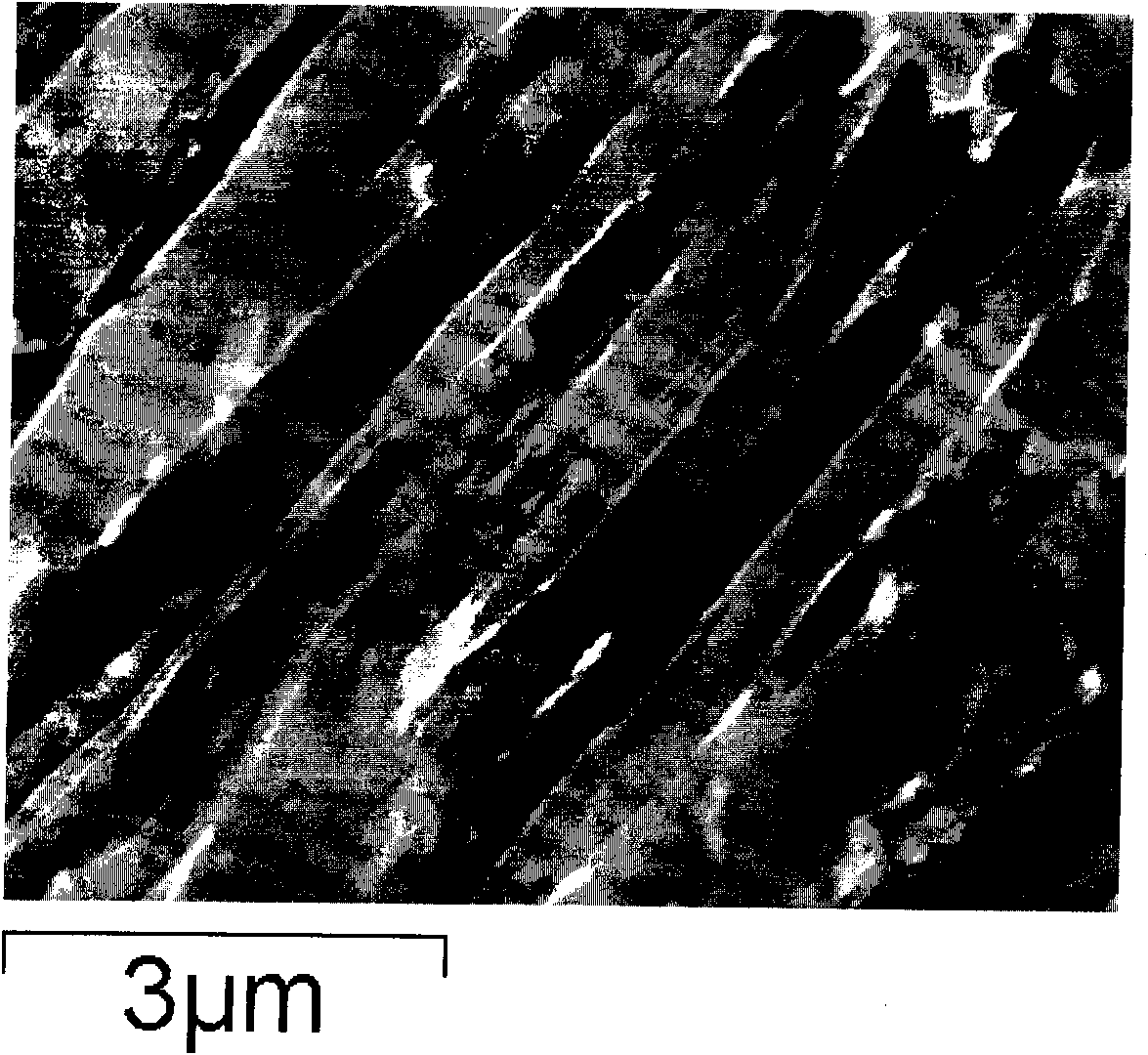

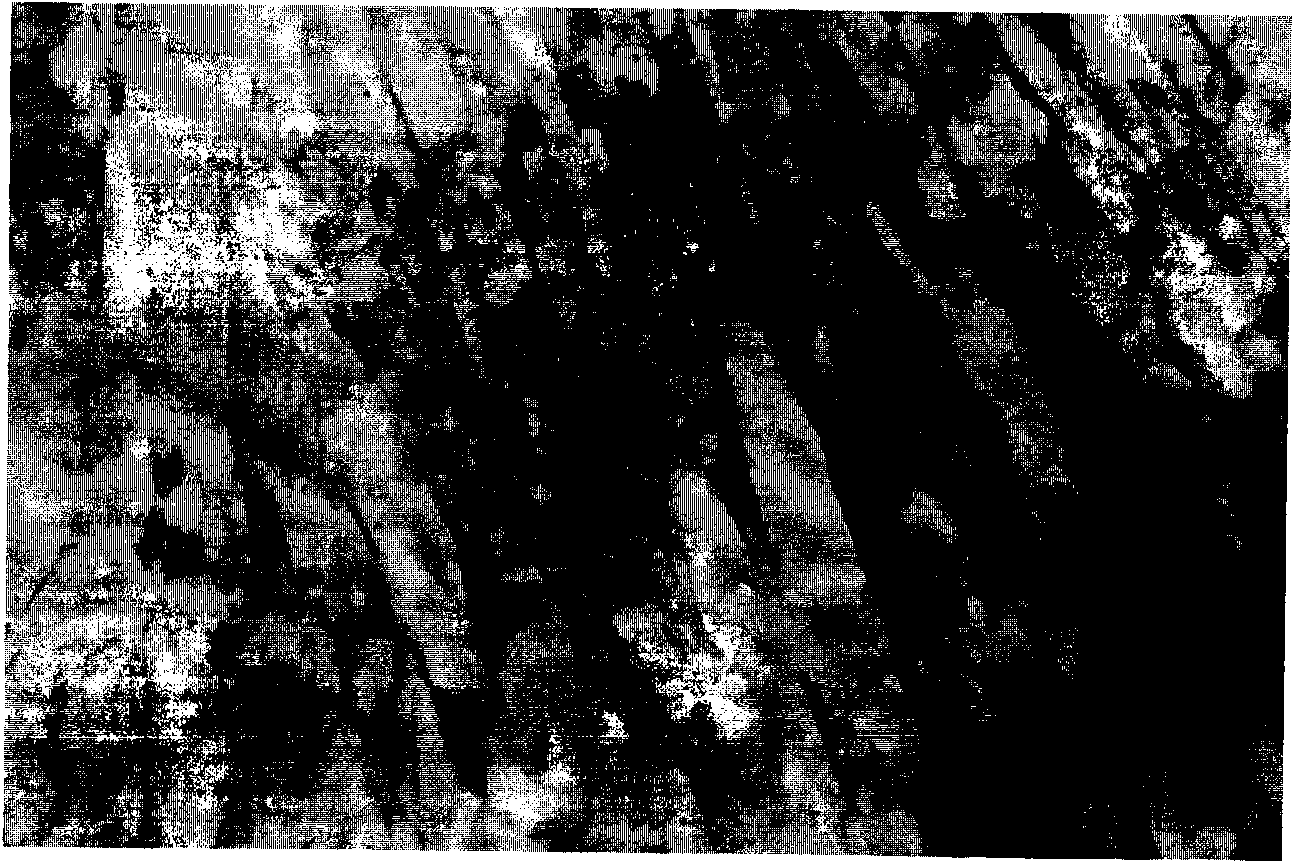

The invention relates to ultrafine crystal bainite high-strength steel and a manufacturing method thereof. The ultrafine crystal bainite high strength steel comprises the components by mass percent: 0.03-0.06% of C, 0.05-0.90% of Si, 1.00-2.00% of Mn, 0.05-0.25% of Cr, 0.03-0.08% of Nb, 0.02-0.04% of Al, 0.004-0.020% of Ti, 0.0010-0.0020% of B, 0.01-0.03% of Zr as well as balance of Fe and inevitable impurities, and P cm is<=0.20%. 13.14C+14.21Nb+6.32Cr+680B-1.98Mn<(Si)<12.22C+9.87Nb+8.11Cr+1210B-1.25Mn. By adopting control thermal mechanical rolling and accelerated cooling technology, the invention can obtain an ultrafine bainite ferrite lath and structure with mahaud components distributed along the interface of the lath; and the yield strength is more than 690MPa, the tensile strength is more than 780MPa, and the Charpy impact power Akv (-20 DEG C) is>=120J. A steel plate has good welding performance, is welded at the room temperature and has no welding cold crack after being placed for 48h.

Description

A kind of ultra-fine-grained bainitic high-strength steel and its manufacturing method technical field The invention relates to high-strength structural steel, in particular to an ultra-fine-grained bainite high-strength steel and a manufacturing method thereof. Background technique Controlled rolling technology has developed rapidly in recent years and has become popular all over the world. This period has many technical characteristics. ①Application of rolling technology, developed a system that can be applied to all rolling mills; ②Consciously applied rolling in the two-phase region to improve performance; ③Using the recrystallization of austenite fine grains in the middle temperature region, proposed the theory of recrystallization controlled rolling (Recrystallization Controlled Rolling RCR ); ④Utilization of Ti, Nb, and V composites, Ti can inhibit austenite recrystallization, form TiN to inhibit grain growth and control the shape of sulfidic inclusions; ⑤The applic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/32C22C38/38C22C33/04C21D8/02

Inventor 姚连登李红斌赵小婷

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com