600HB-grade wear resistant steel plate and its manufacturing method

A technology of wear-resistant steel plate and manufacturing method, which is applied in the field of wear-resistant steel, can solve the problems of deterioration of wear-resistant steel welding and processing performance, and achieve the effects of eliminating internal stress, loose process system, and reasonable composition and process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

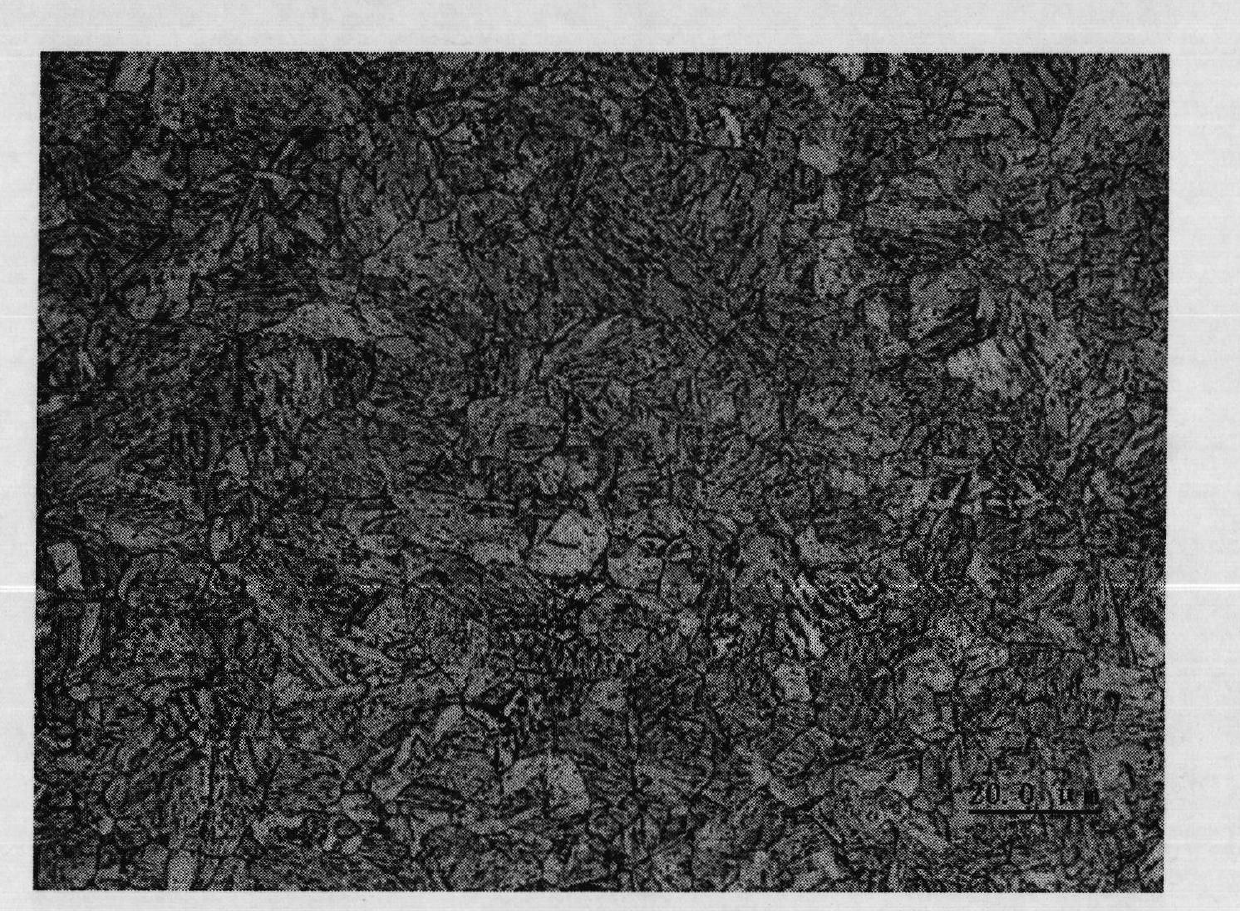

Image

Examples

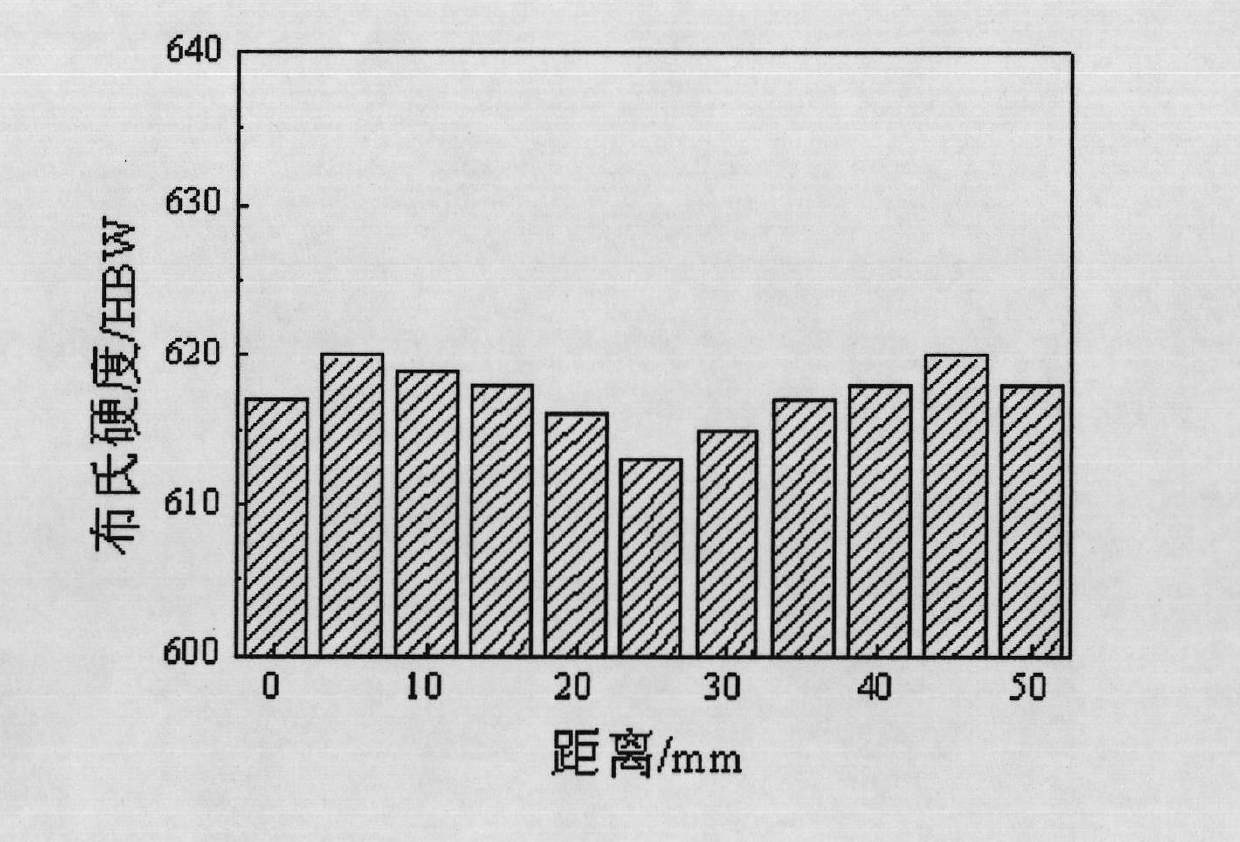

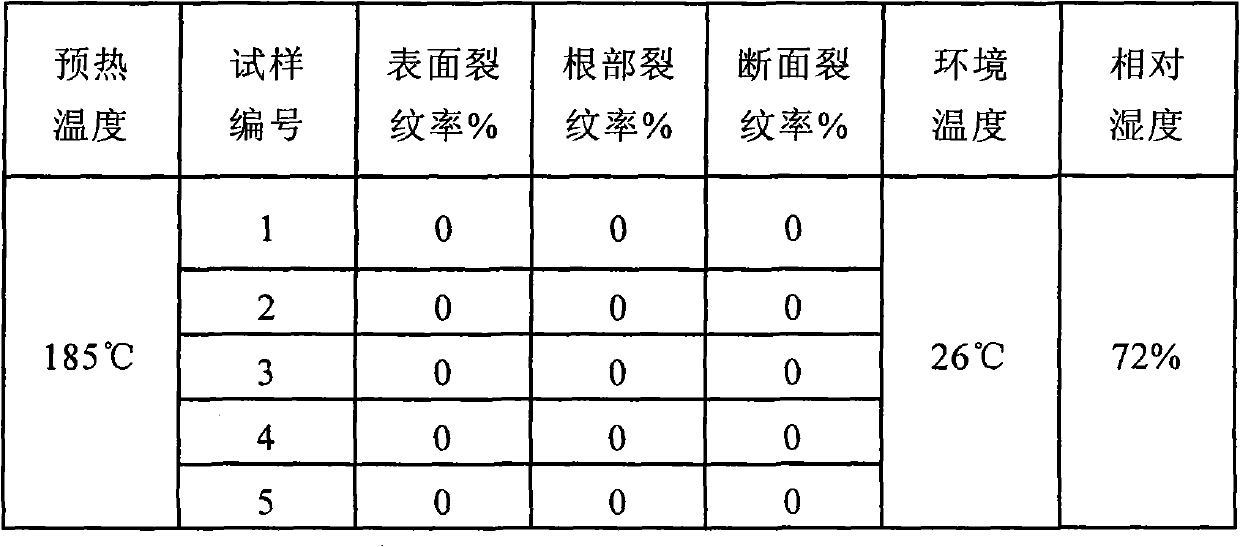

Embodiment 1

[0045] The chemical composition of the 600HB wear-resistant steel plate of the present invention is shown in Table 2. According to the chemical composition shown in Table 2, it is smelted in an electric furnace or a converter. After refining, it is cast into a continuous casting billet or ingot. The continuous casting billet or steel ingot is heated to 1250 ° C, the rolling temperature is 1200 ° C, and the thickness of the finished steel plate is 6mm. After rolling Air cooling, quenching heating temperature is Ac 3 +80°C, tempering temperature is 300°C, after tempering, stacking or cooling bed cooling.

Embodiment 2

[0047] The implementation is the same as in Example 1, wherein the heating temperature is 1230°C, the rolling start temperature is 1180°C, the thickness of the finished steel plate is 12mm, and the quenching heating temperature is Ac 3 +60°C, tempering temperature is 250°C, after tempering, stack or cool down in a cooling bed.

Embodiment 3

[0049] The implementation method is the same as in Example 1, wherein the heating temperature is 1200°C, the rolling start temperature is 1150°C, the thickness of the finished steel plate is 20mm, and the quenching heating temperature is Ac 3 +50°C, tempering temperature is 220°C, after tempering, stack or cool down in a cooling bed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com