Patents

Literature

566results about How to "Good weldability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

InactiveUS20030129444A1Lower yield stressImprove ductilityHot-dipping/immersion processesThin material handlingSheet steelHigh intensity

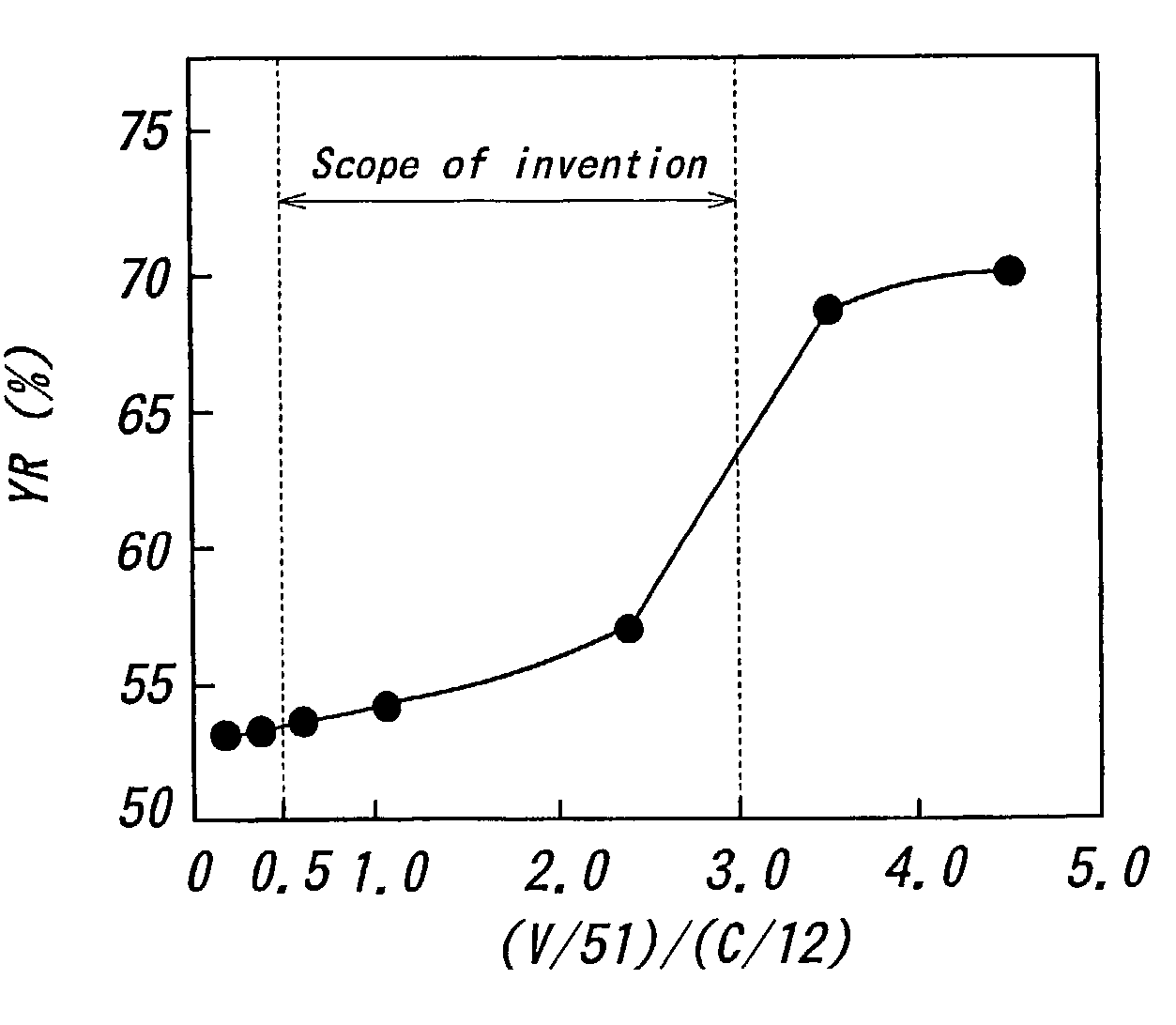

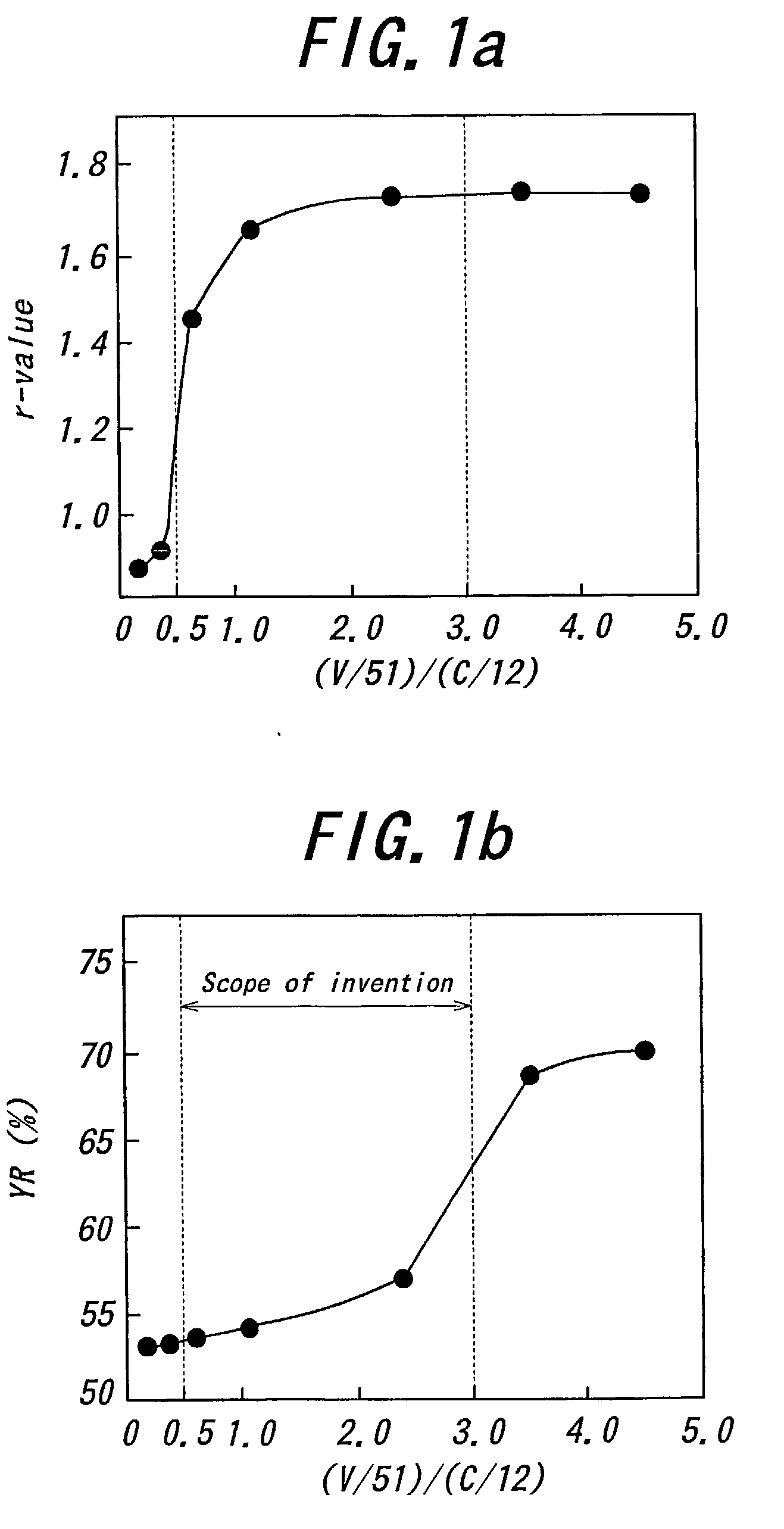

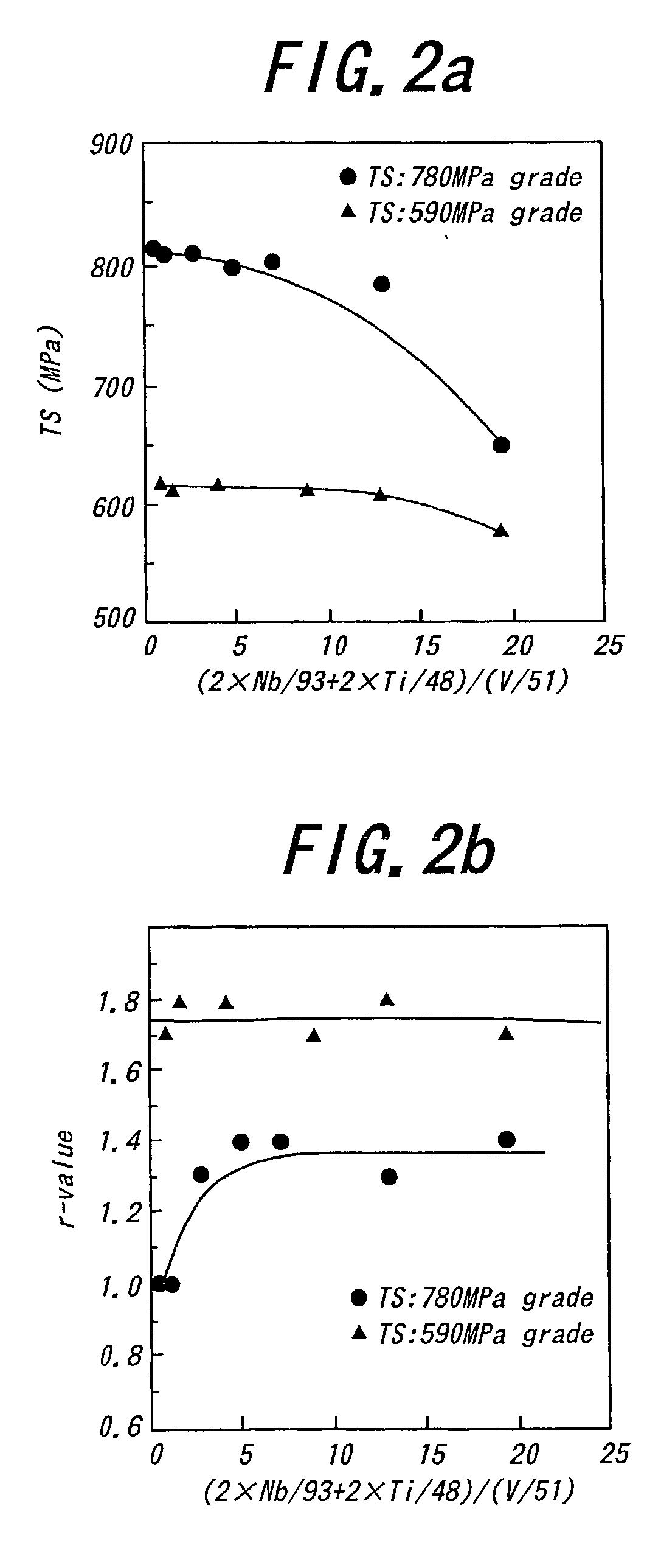

The invention proposes a high-strength dual-phase cold rolled steel sheet having an excellent deep drawability, wherein the steel sheet has a composition comprising C: 0.01-0.08 mass %, Si: not more than 2.0 mass %, Mn: not more than 3.0 mass %, P: not more than 0.10 mass %, S: not more than 0.02 mass %, A1: 0.005-0.20 mass %, N: not more than 0.02 mass % and V: 0.01-0.5 mass %, provided that V and C satisfy a relationship of 0.5xC / 12<=V / 51<=3xC / 12, and the remainder being Fe and inevitable impurities, and has a microstructure consisting of a ferrite phase as a primary phase and a secondary phase including martensite phase at an area ratio of not less than 1% to a whole of the microstructure and a high-strength dual-phase galvanized steel sheet comprising a galvanized coating on the above steel sheet as well as a method of producing the same.

Owner:JFE STEEL CORP

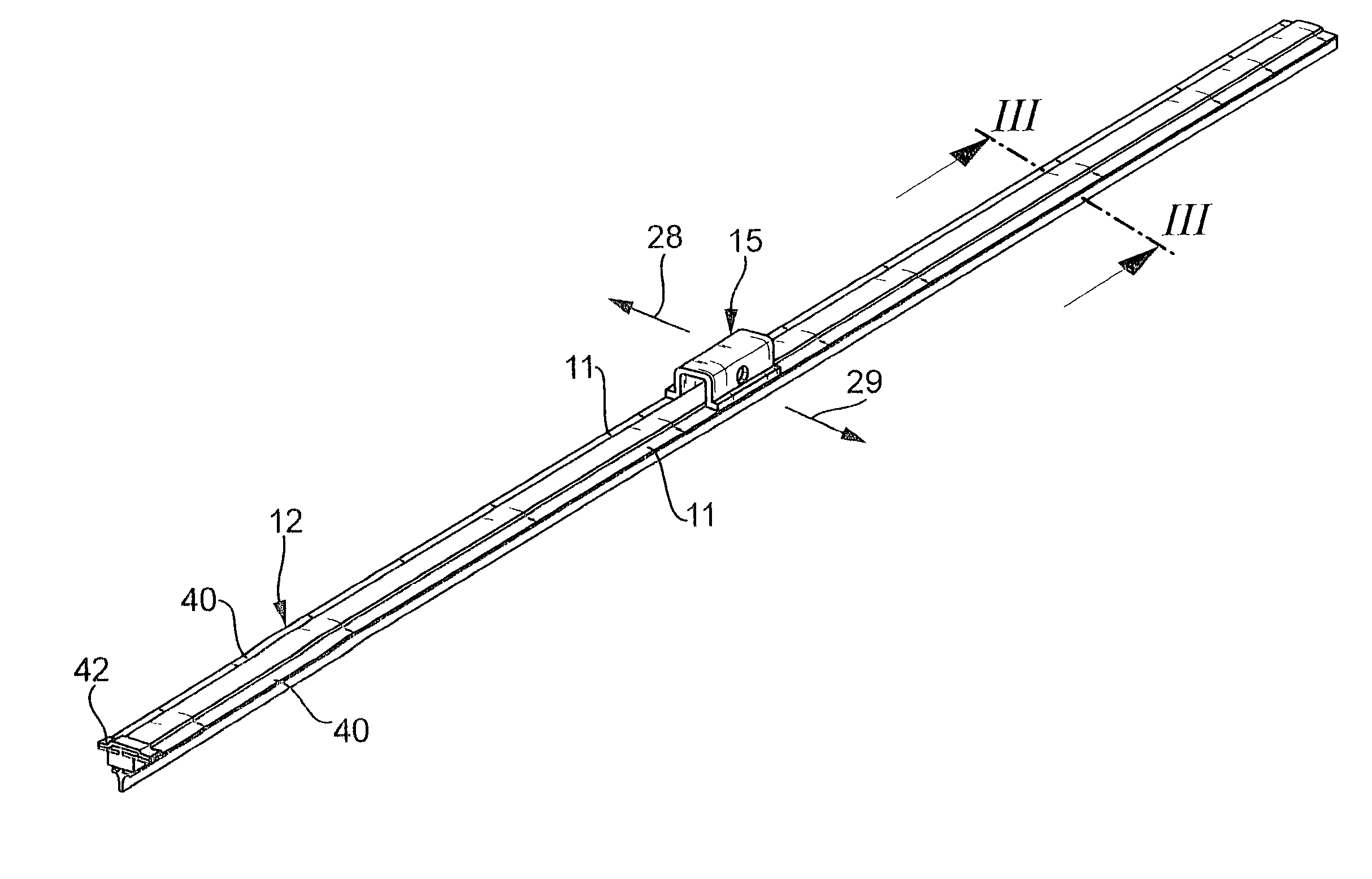

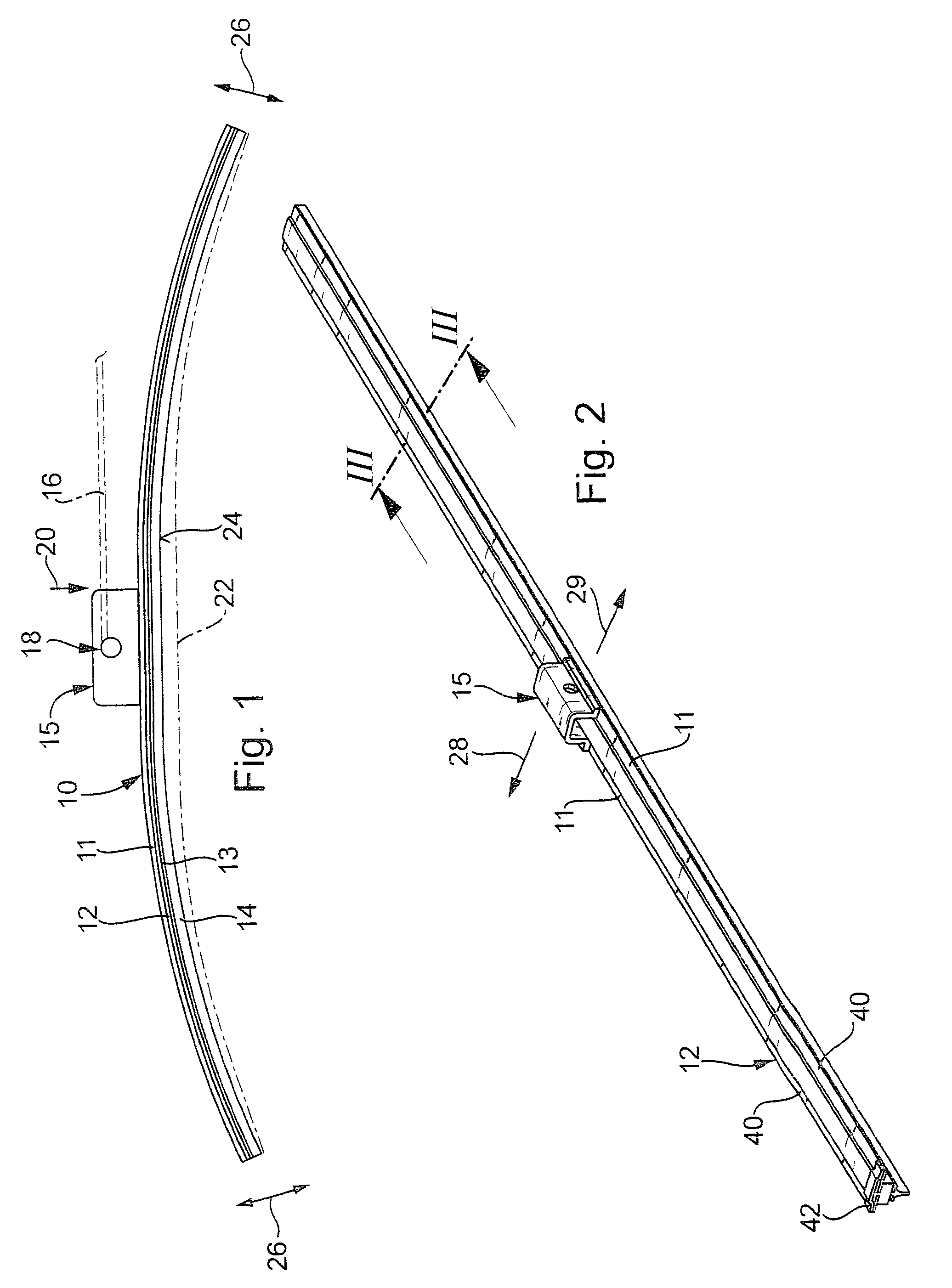

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

Ni-base heat resistant alloy and welded joint thereof

InactiveUS20030005981A1Improve carburization resistanceImprove solubilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthEthylene

A Ni-base heat resistant alloy excellent in weldability and strength at elevated temperatures and suited for use in manufacturing cracking furnace tubes and reformer furnace tubes to be used in ethylene plants as well as a welded joint therefor is provided. The alloy of the invention is a Ni-base heat-resistant alloy, which comprises C: not more than 0.1%, Si: not more than 2%, Mn: not more than 2%, P: not more than 0.025%, S: not more than 0.005%, N: not more than 0.04%, Cr: 10 to 30%, Al: 2.1 to less than 4.5%, and Mo: 2.5 to 15% or W: 2.5 to 9% or Mo and W: 2.5 to 15% in total, and satisfies the relation (1) given below:<paragraph lvl="0"><in-line-formula>(104Si+1980P+1980S+9Al+15Ti+11Nb+1.8W+11600B)<={1.1(240-20000S-1900P-30Al-10Ti-9W+17000B) (1)< / in-line-formula>In the welded joint of the invention, both of the base metal and weld metal are made of the alloy having the above composition, and the ST value of the weld metal as calculated according to the following formula (2) or (3) is larger by not less than 3 than the ST value of the base metal:<paragraph lvl="0"><in-line-formula>in the case of Ti<=4C; ST-Mo+1.5W+100Ti (2)< / in-line-formula><paragraph lvl="0"><in-line-formula>in the case of Ti>4C; ST=Mo+1.5W+400C (3).< / in-line-formula>

Owner:NIPPON STEEL CORP

Nickel-base alloy

Owner:ATI PROPERTIES

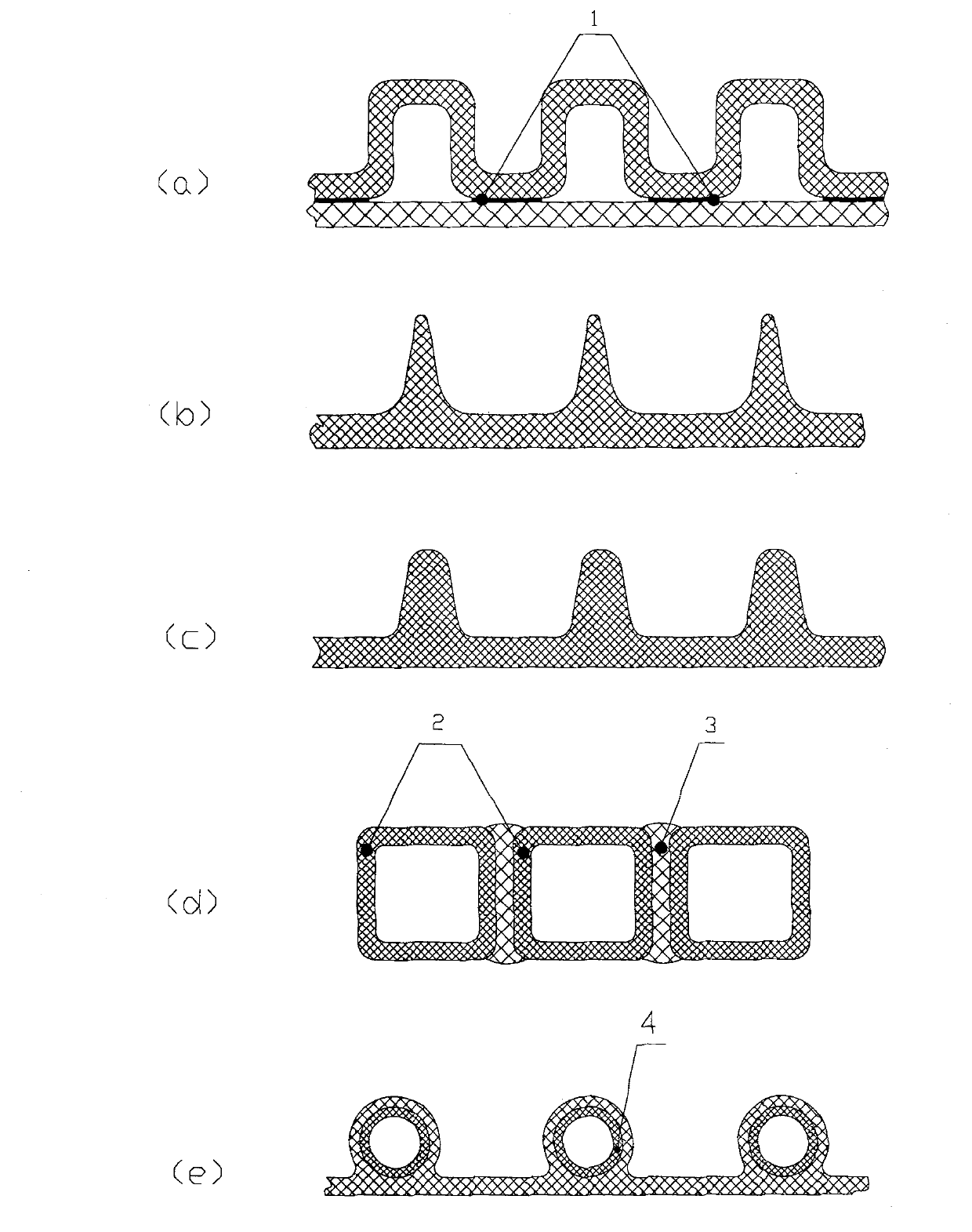

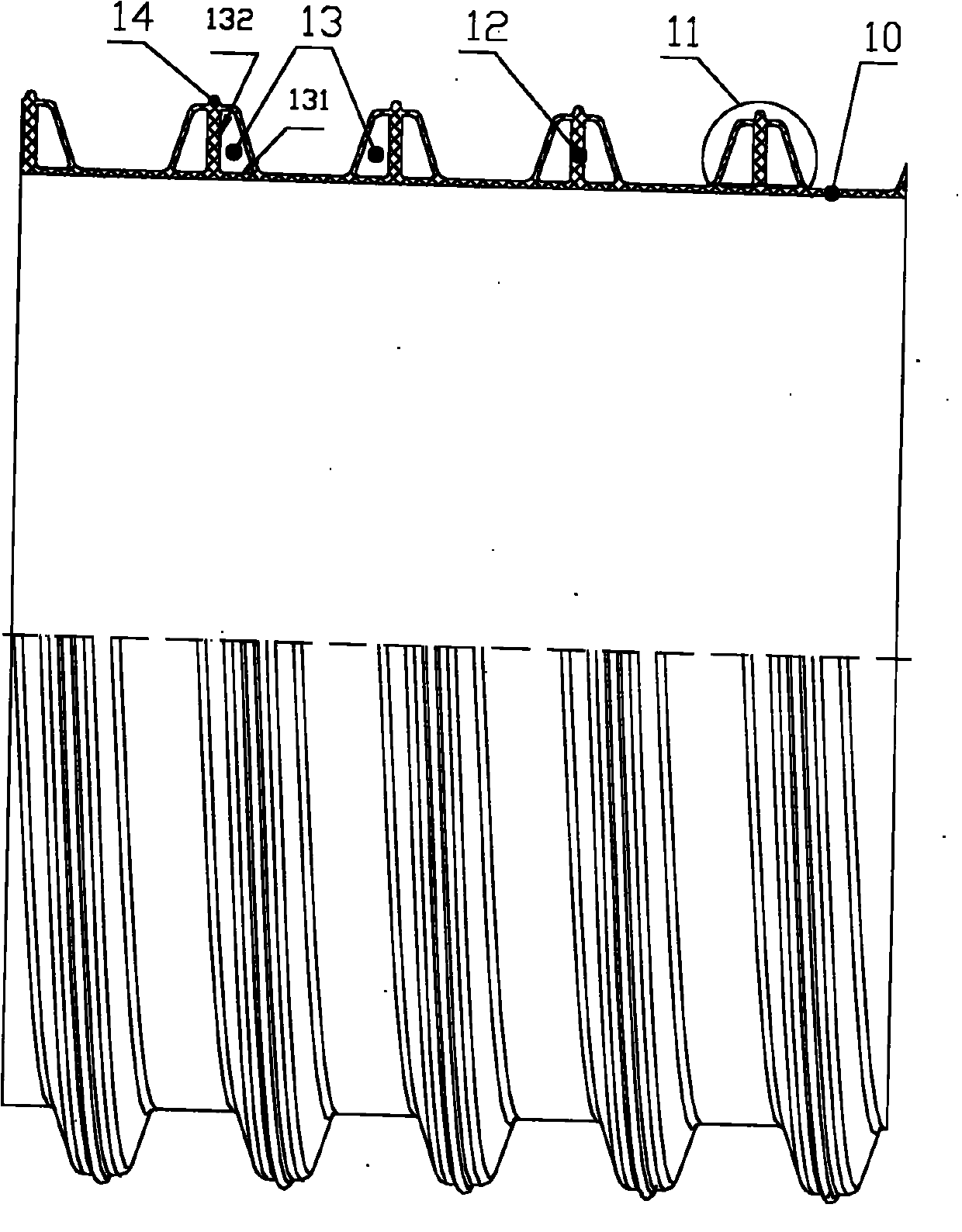

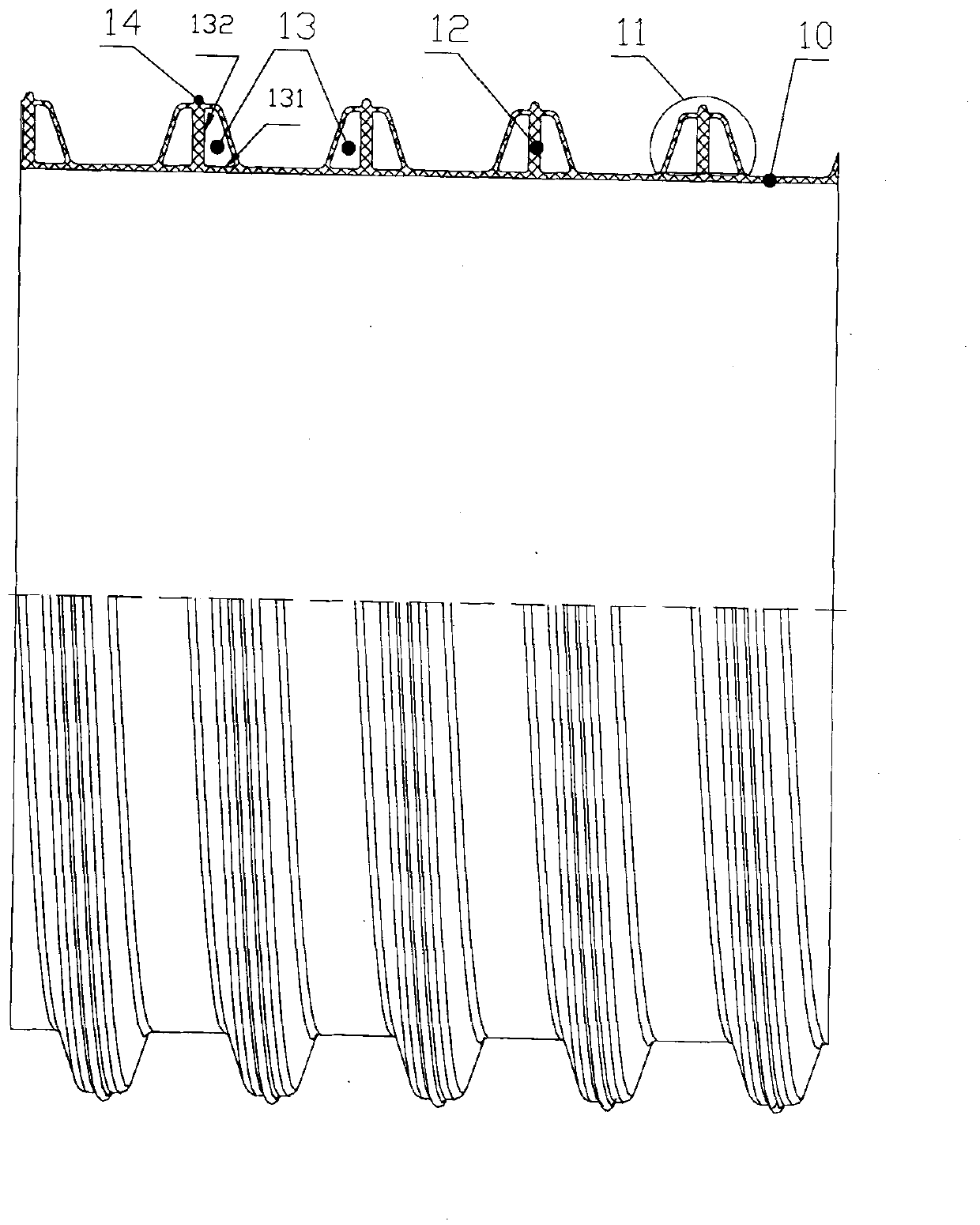

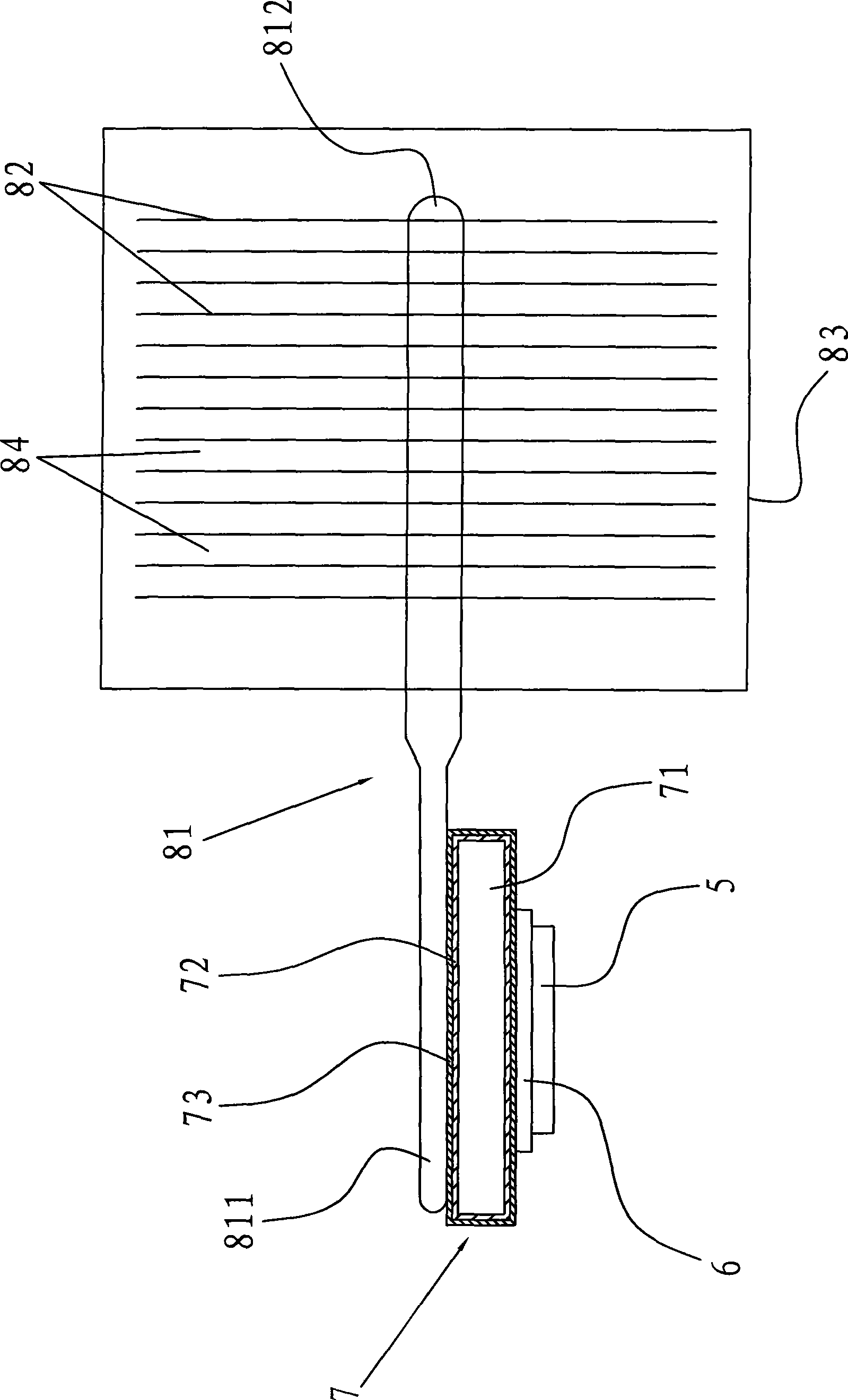

Internal rib reinforcing outer ripple type plastic twining structured wall pipe and manufacturing method thereof

InactiveCN101907207AIncrease the outer surface areaGood synergyRigid pipesTubular articlesMechanical engineeringHot-melt adhesive

The invention relates to an internal rib reinforcing outer ripple type plastic spirally twining structured wall pipe, which comprises a cylindrical surfaced pipe main body and a reinforcing rib wound outside of the pipe main body. The reinforcing rib contains an inner reinforcing rib vertical to the pipe wall, wherein the inner rib divides the reinforcing rib into two parallel hollow cavities. The upper part of the reinforcing rib and the top of the inner rib are both provided with a solid bulge. A method for manufacturing the plastic reinforcing pipe of the invention comprises the steps of: continuously extruding a plastic abnormal strip with two tubular bulges and containing a hollow cavity inside through a first plastic extruder, continuously, regularly, spirally twining the plastic abnormal strip on a formed roller in parallel, at the same time, extruding fused plastic gel in a clearance between adjacent side walls of the spirally wound plastic abnormal strip through a second plastic extruder, rolling two projected tubular cavities corresponding to two sides of the clearances connected by fusing the adjacent plastic abnormal pipe through a rolling wheel which is arranged at the corresponding part on the periphery of the formed roller with a slot structure, forming an outer projected reinforcing rib of the pipe outer wall by fusing the two tubular bulges, and extruding the residual fused gel in the clearance by the rolling wheel so as to form the solid bulge.

Owner:戴爱清

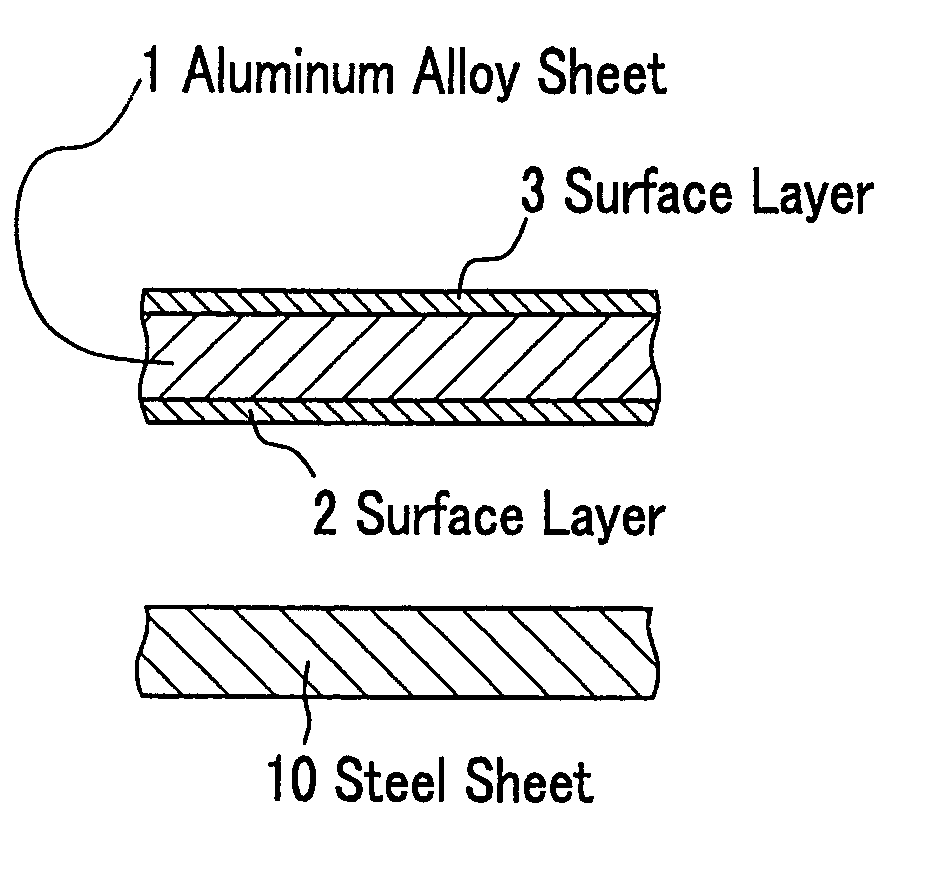

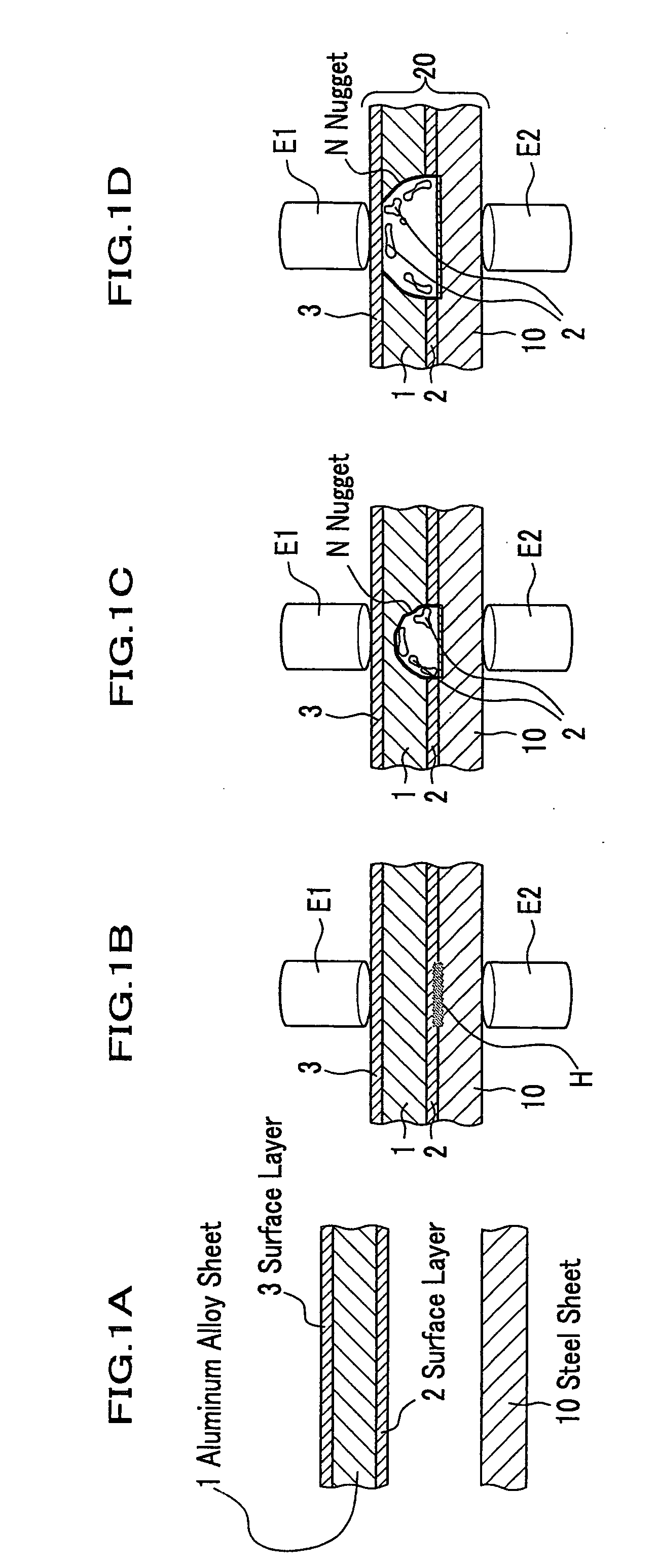

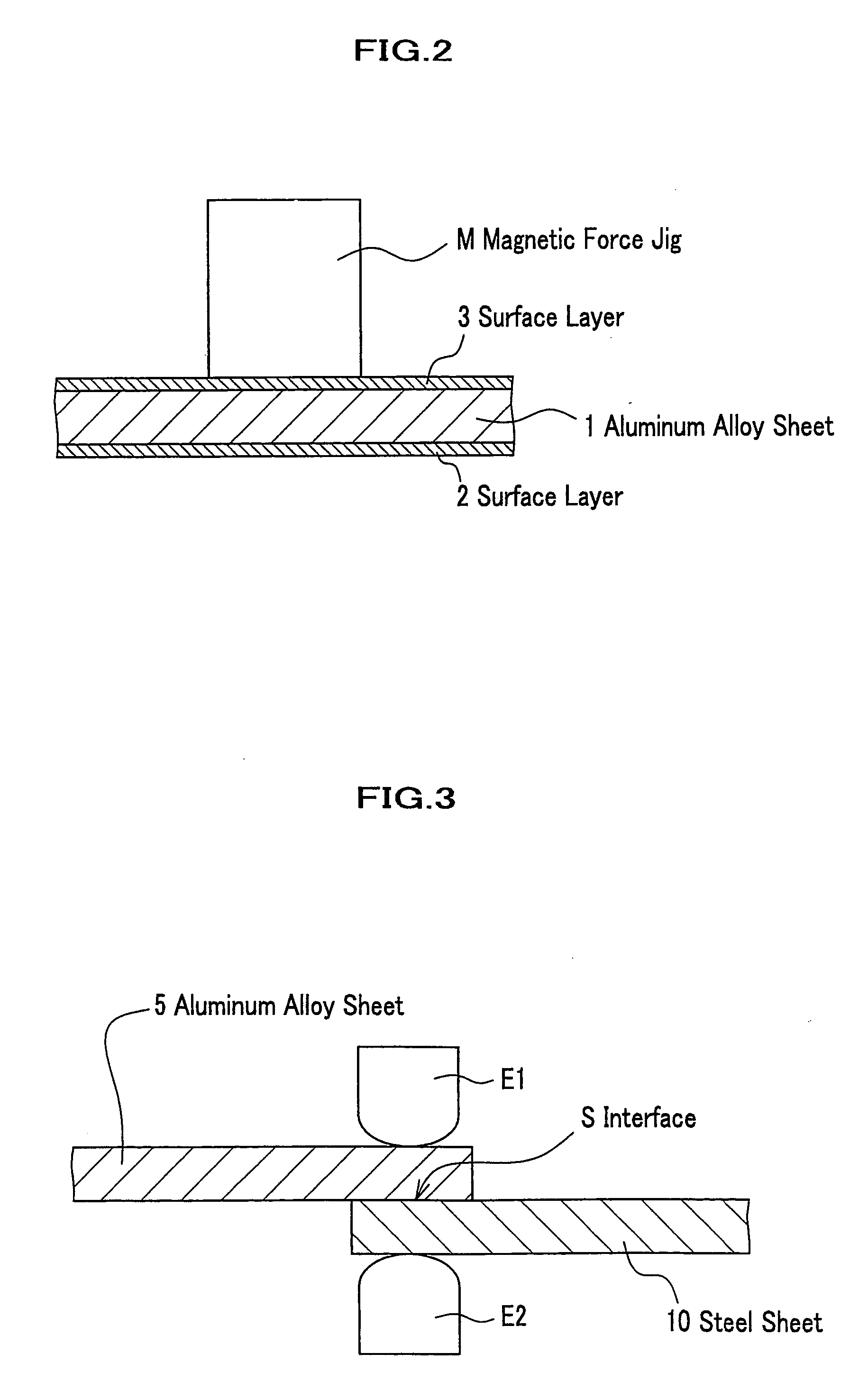

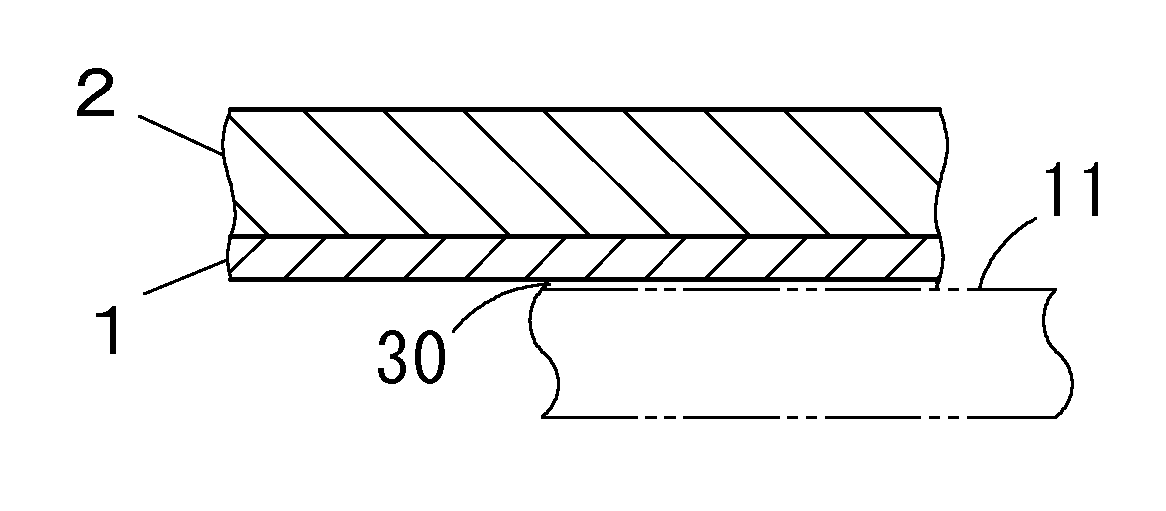

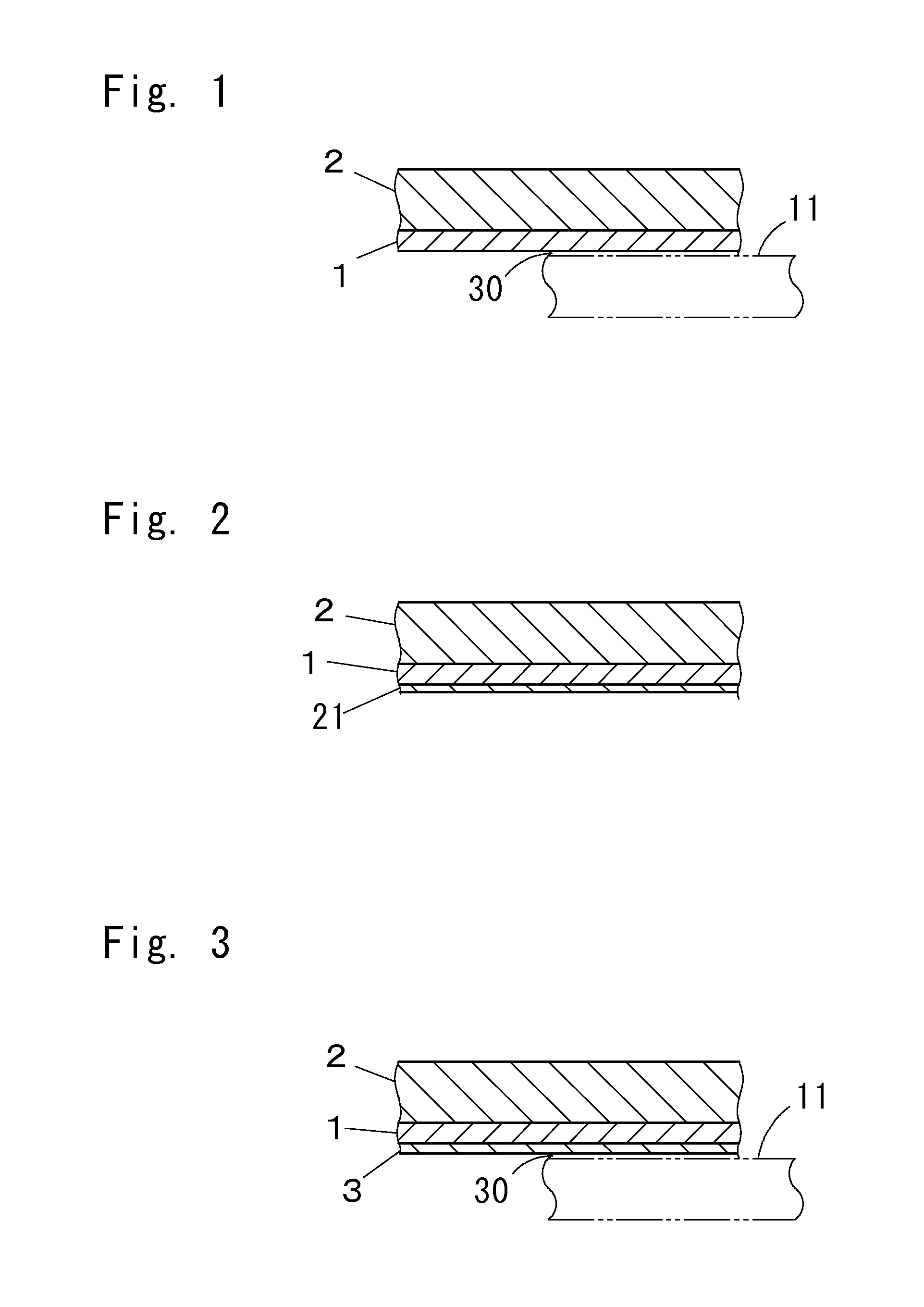

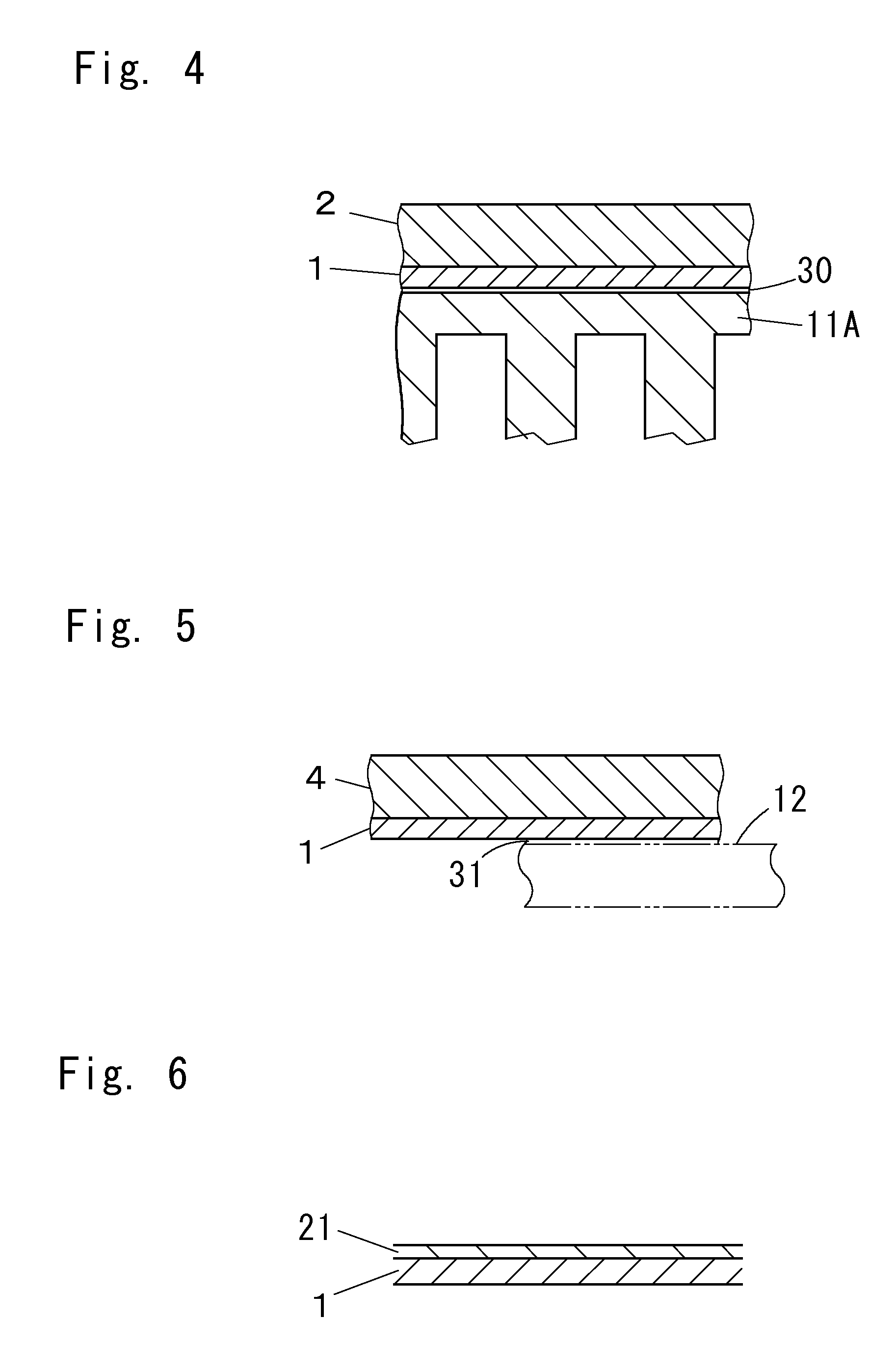

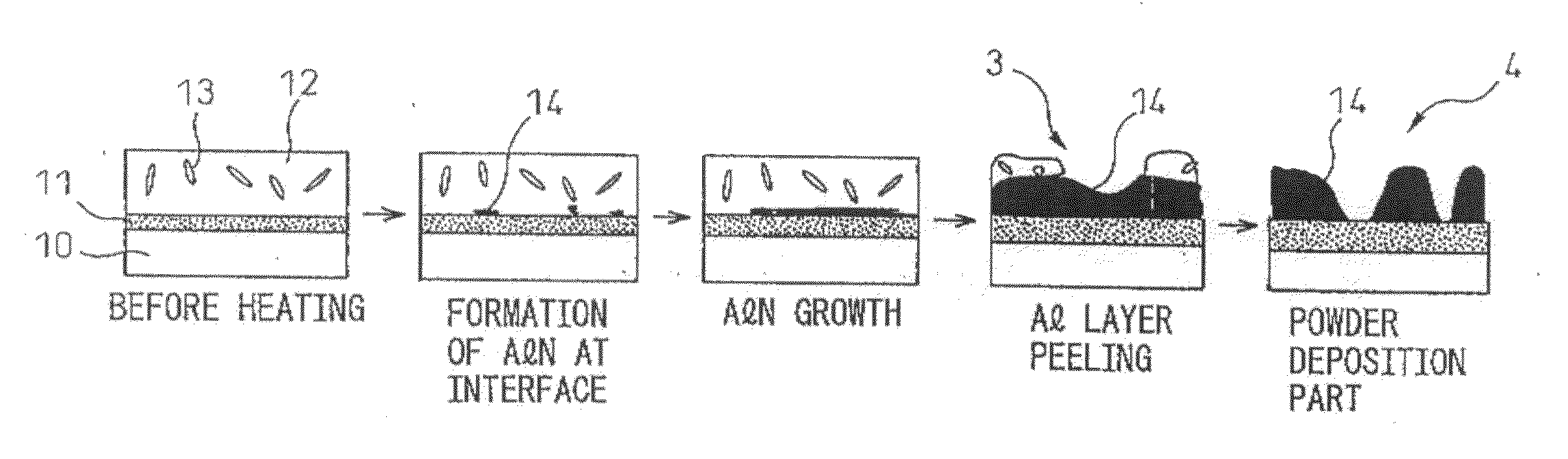

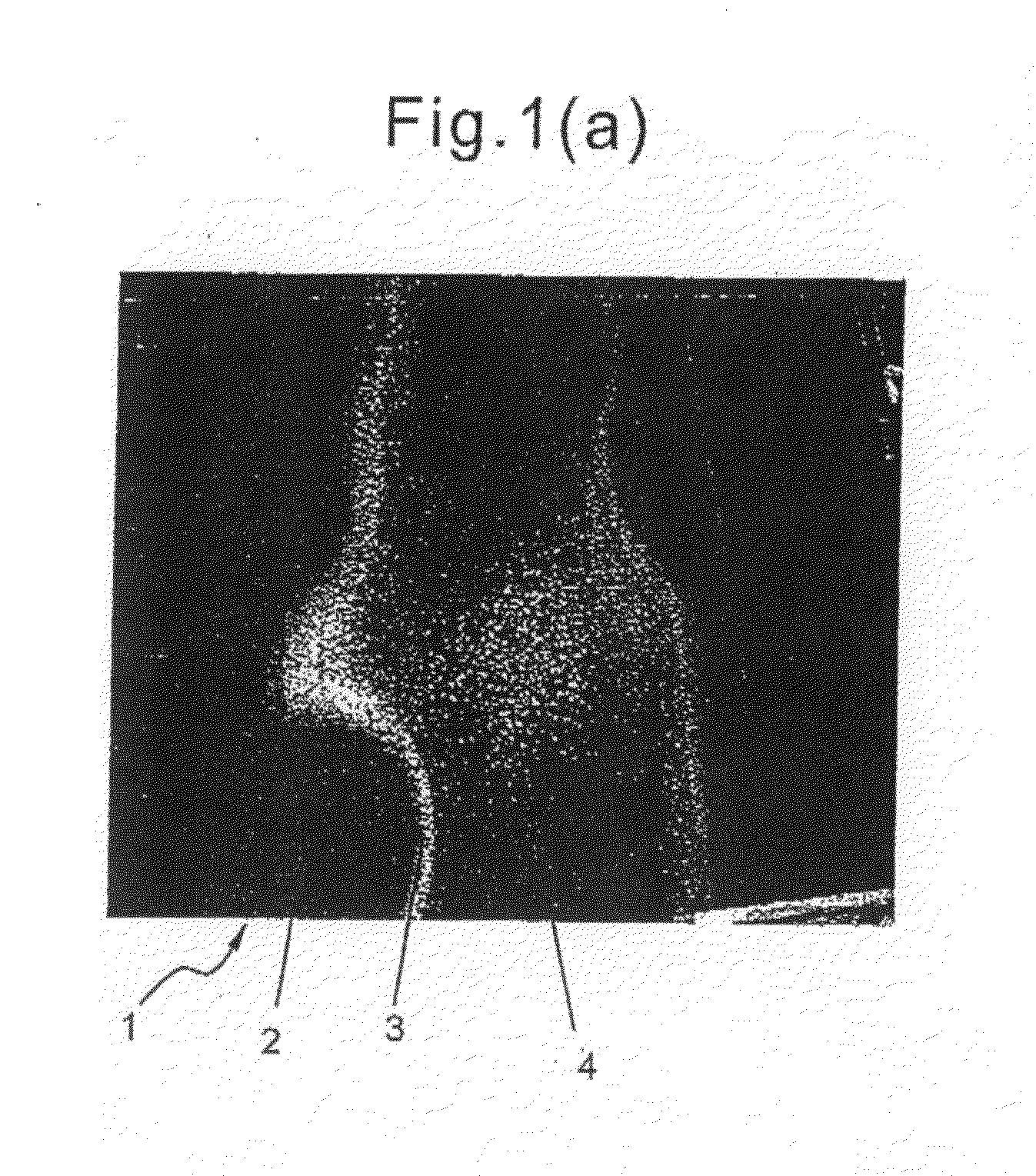

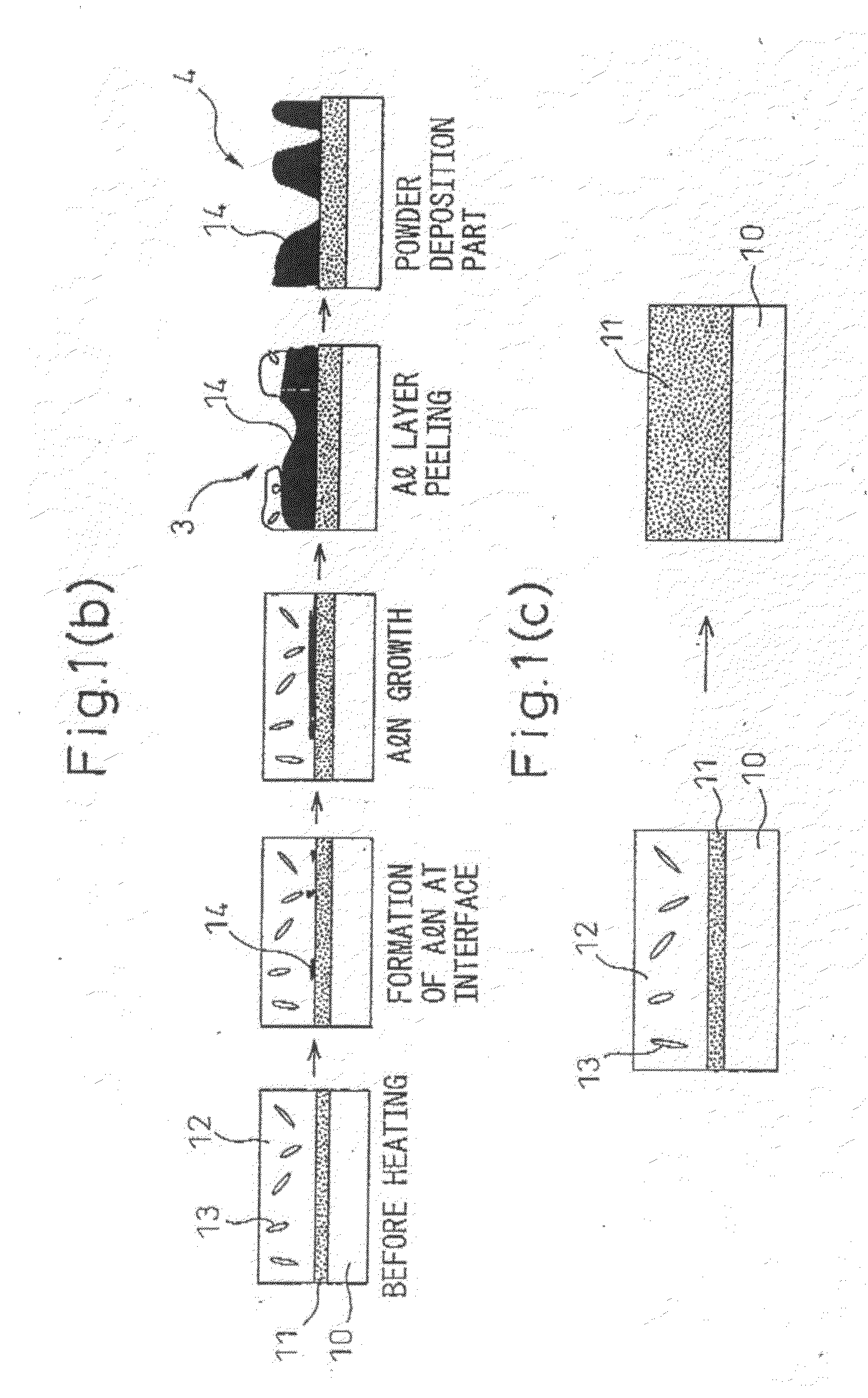

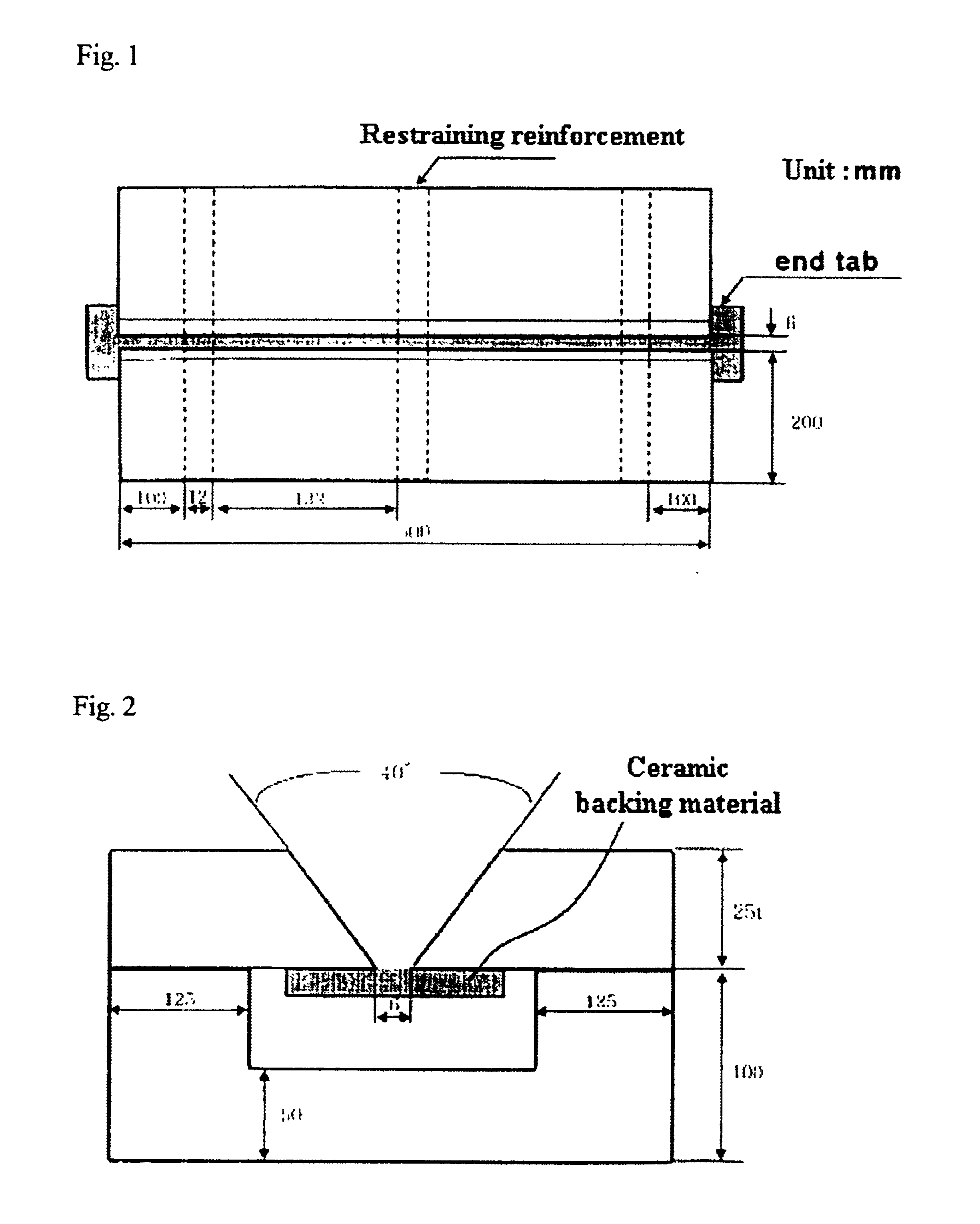

Resistance welding method of different kinds of materials, and resistance welding member of aluminum alloy material and different kind of material

InactiveUS20050218121A1Improve solderabilityEfficiency of manufacturing can not be realizedHot-dipping/immersion processesArc welding apparatusSurface layerSpot welding

The resistance welding method of different kinds of materials is the method for welding an iron material and an aluminum alloy material, and comprises the steps of: performing in advance a coating treatment at least to a portion of the aluminum alloy material, where resistance welding is performed, with any of iron and iron-base alloy and forming a surface layer; and performing resistance welding of the iron material and the aluminum alloy material through the surface layer, and the resistance welding may be any of spot welding and projection welding.

Owner:HONDA MOTOR CO LTD +1

Ni-base heat resistant alloy and welded joint thereof

InactiveUS6702906B2Improve the immunityHigh strengthWelding/cutting media/materialsSoldering mediaEthyleneMetal

Owner:NIPPON STEEL CORP

Coated metal material capable of being welded which is excellent in corrosion resistance of worked zone

ActiveUS7390564B2Improve conductivityGood formabilityLiquid surface applicatorsSynthetic resin layered productsMetallic materialsMetal sheet

Owner:NIPPON STEEL CORP

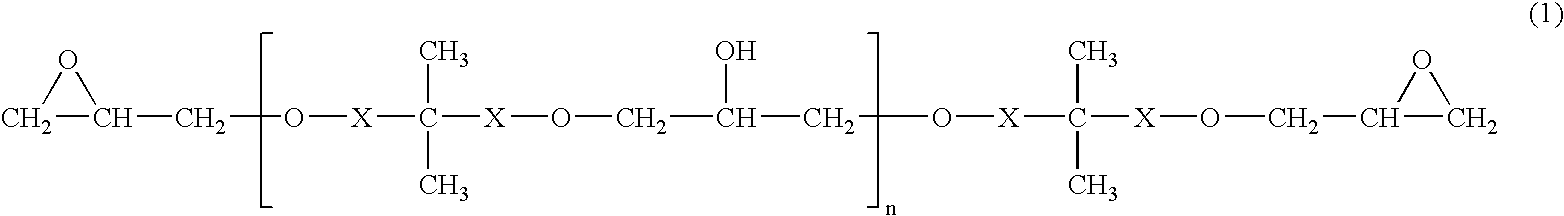

Coating composition and resin-coated metal sheets

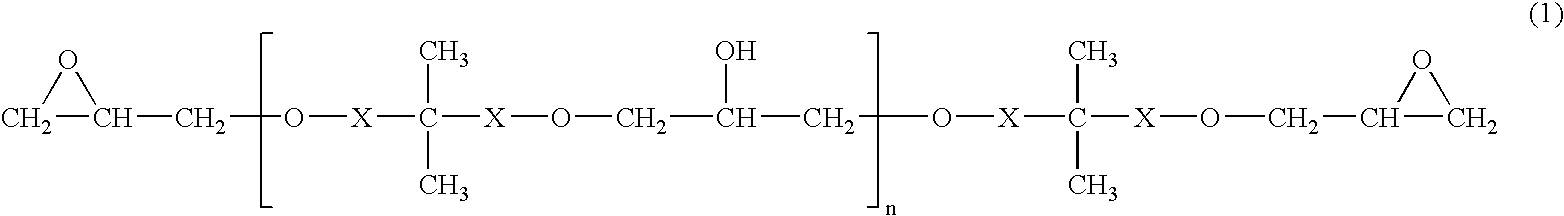

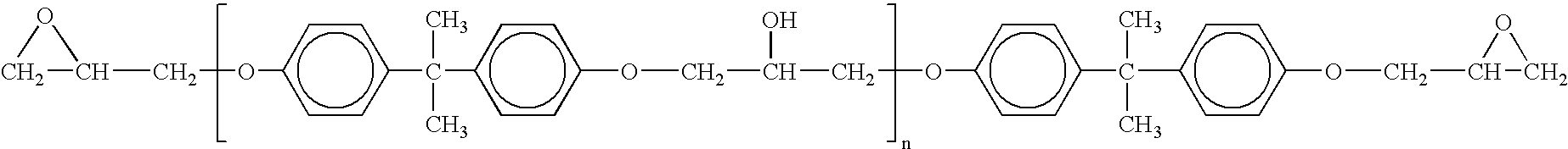

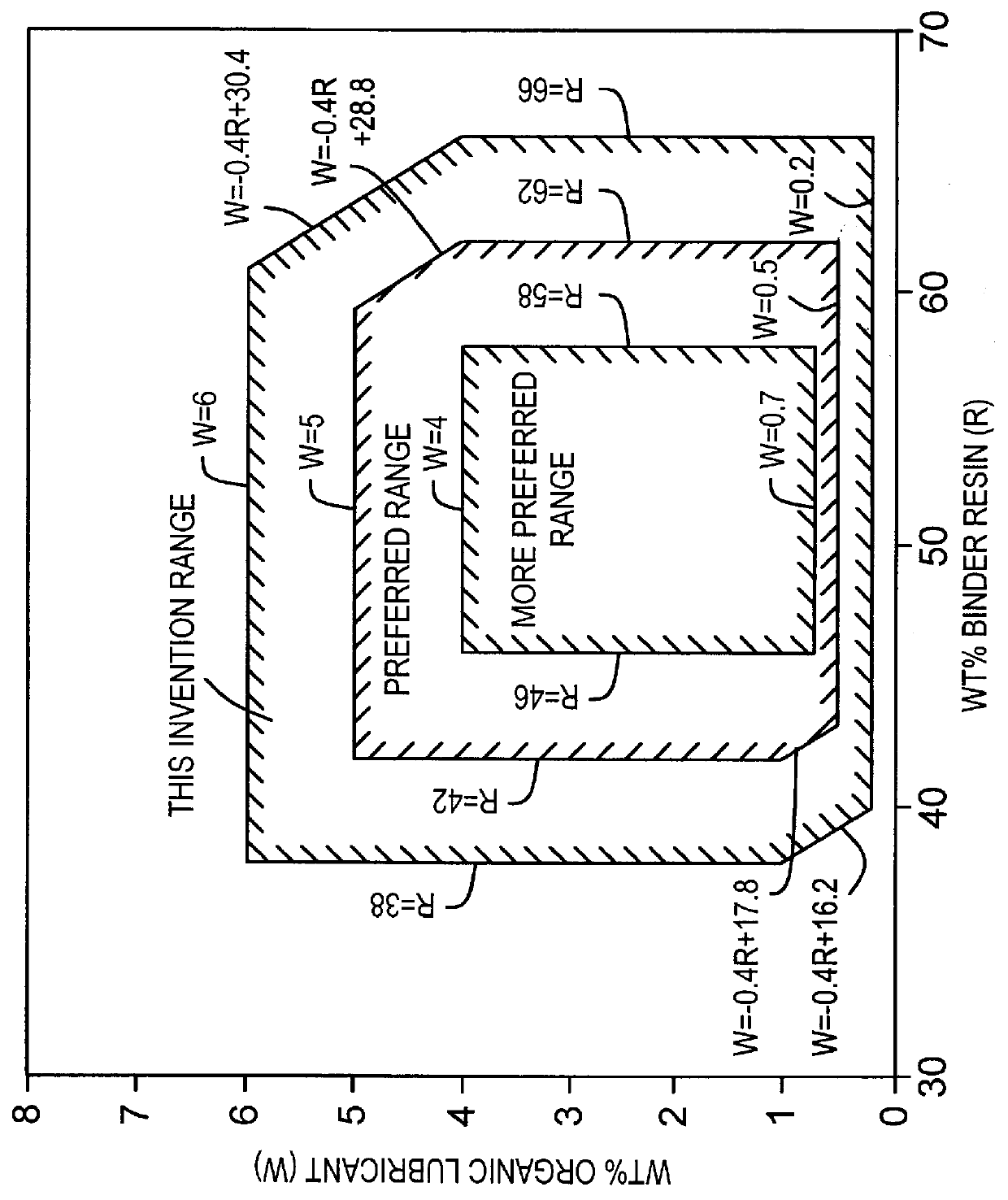

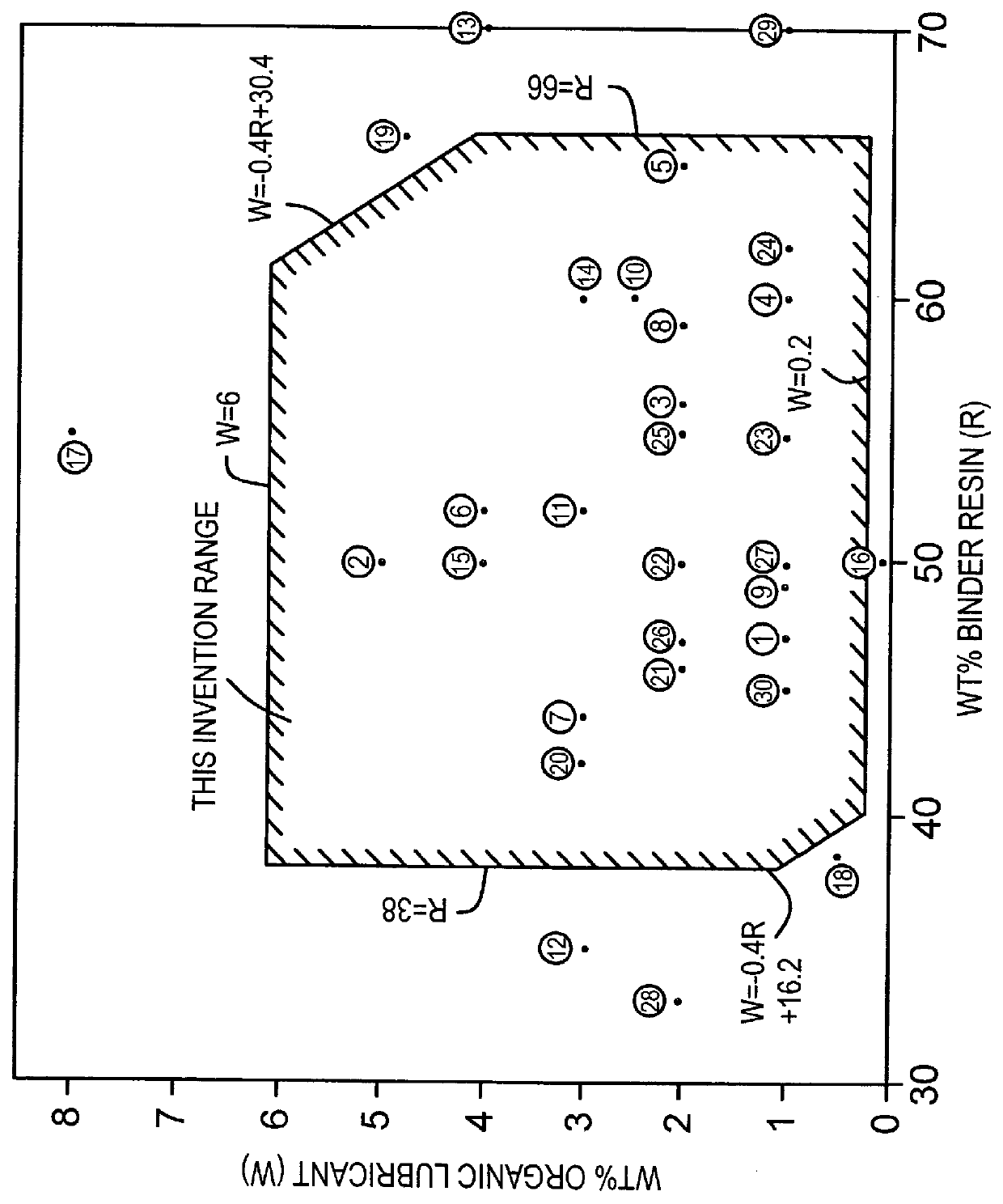

InactiveUS6126730AImprove solderabilityImprove adhesionLiquid surface applicatorsConductive materialInorganic pigmentsChemical conversion

A coating composition comprising 38%-66% of a binder resin (including a curing agent), 0.2%-6% of an organic lubricant, 20%-50% of an iron phosphide-based electrically conductive pigment, and 3%-25% of one or more other inorganic pigments including anticorrosive pigments (the total content of these pigments being between 31% and 56%), wherein the content of the binder resin (including a curing agent) (R) and that of the organic lubricant (W) satisfy the following inequality: -0.4R+16.2< / =W< / =-0.4R+30.4, and wherein the coating composition further comprises a curing catalyst in an amount of from 0.7% to 10% based on the solids of the binder resin (including a curing agent). The coating composition can be applied to a plated metal sheet having a zinc- or aluminum-based plated coating after the plated metal sheet has been subjected to chemical conversion treatment such as chromating treatment, to form a resinous coating thereon having a thickness of 2-9 mu m, thereby resulting in the production of a resin-coated metal sheet having improved overcoat adhesion, weldability, edge face corrosion resistance, and formability, which is suitable for use as a material for automotive repair parts.

Owner:SUMITOMO METAL IND LTD +1

Basic flux cored wire with excellent weldability

InactiveUS20030116550A1Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaMn oxideAlloy steel

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

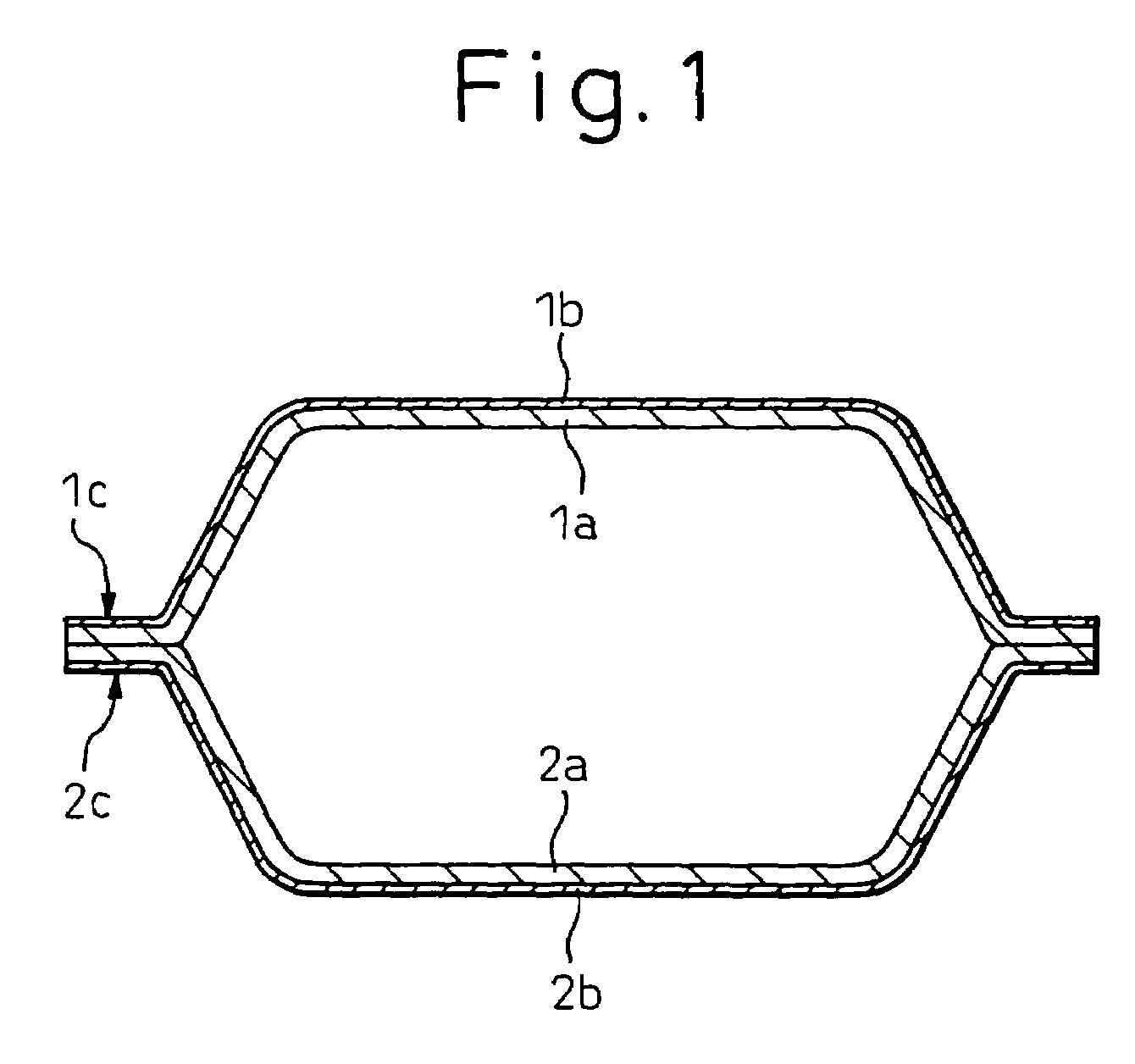

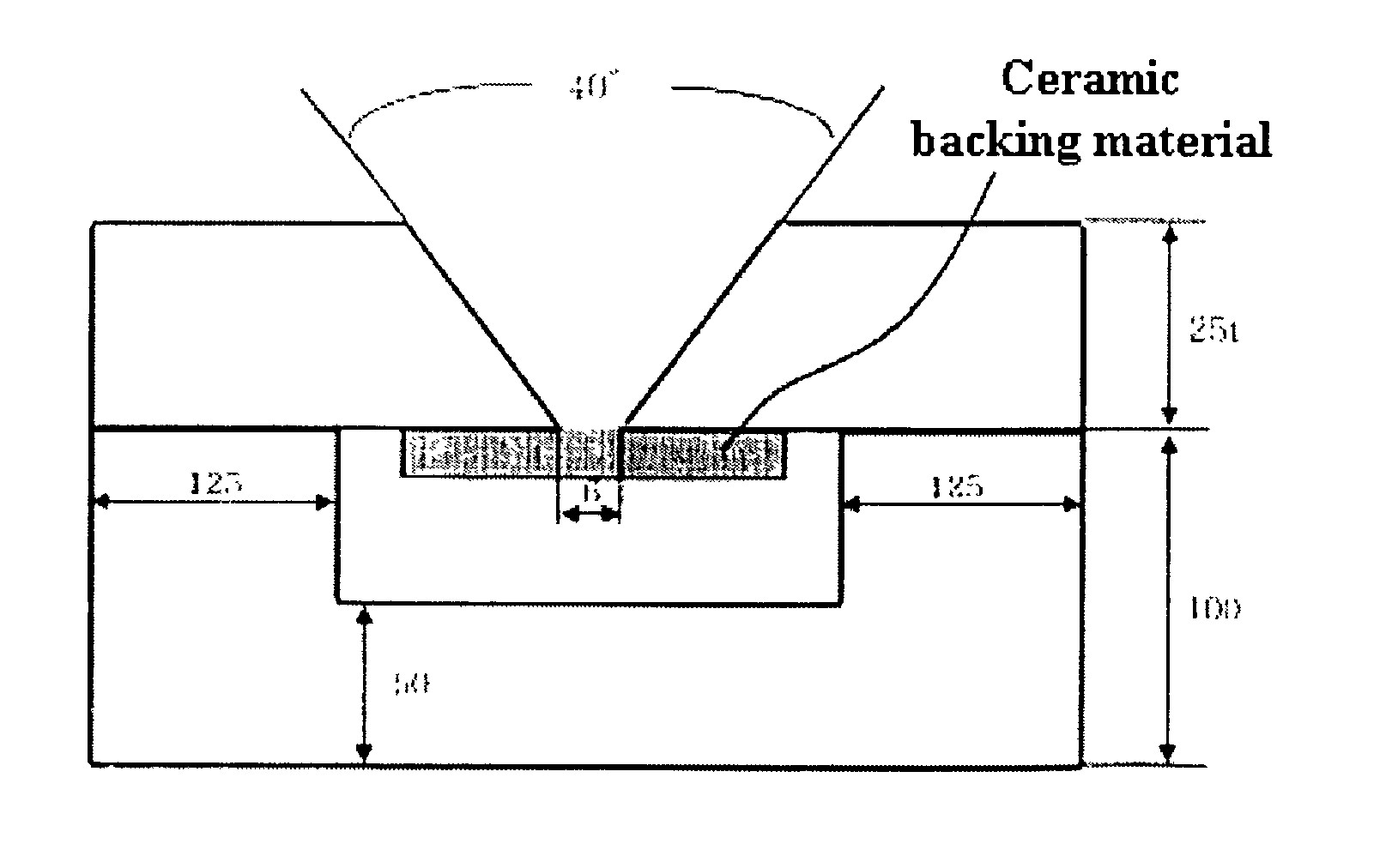

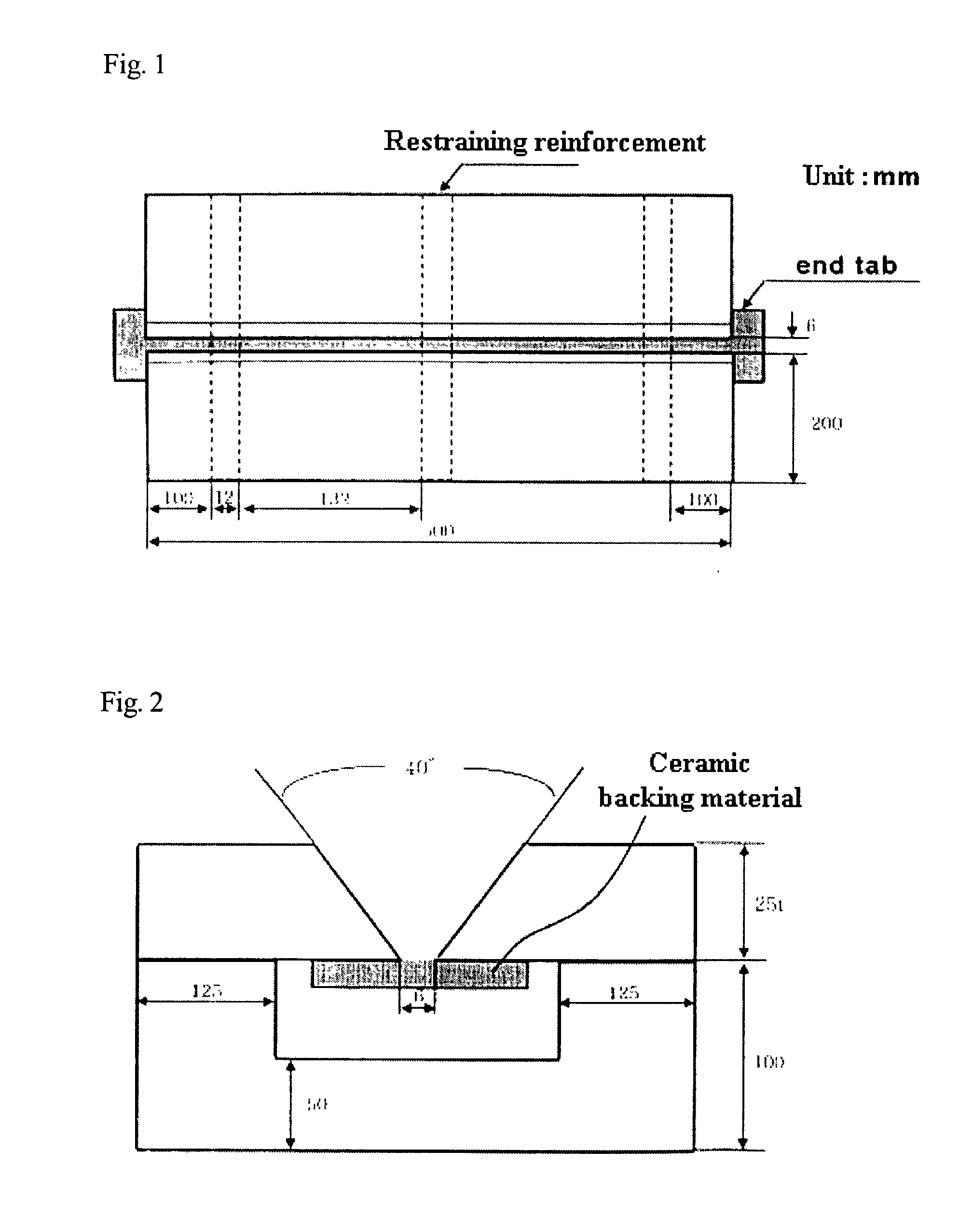

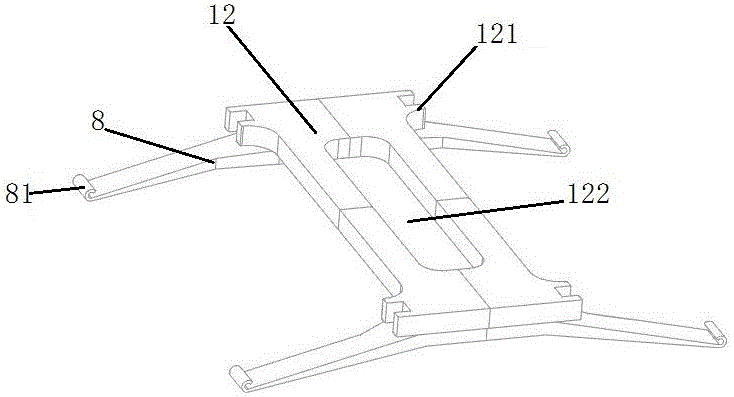

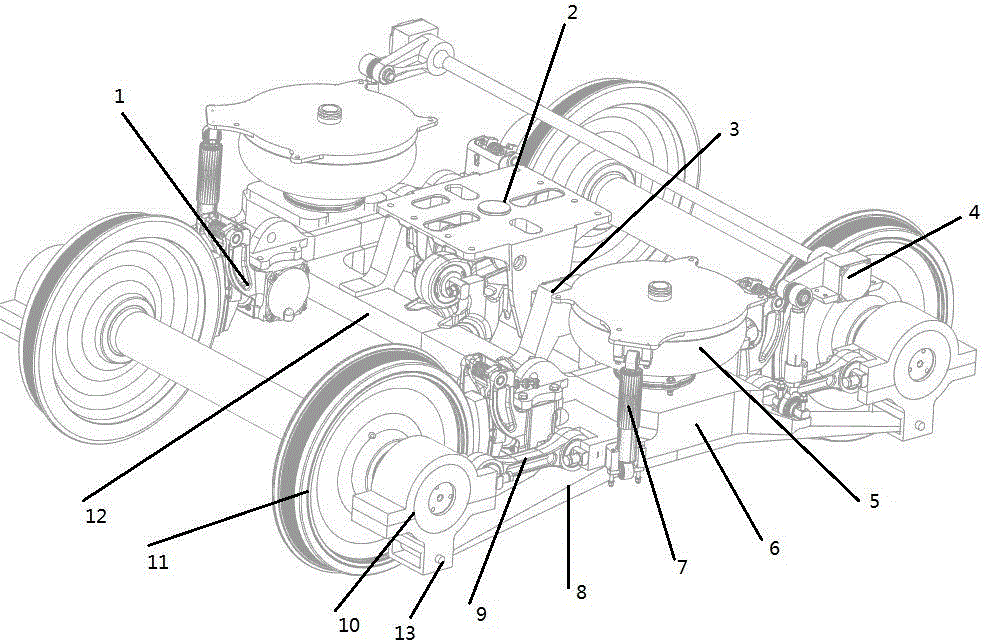

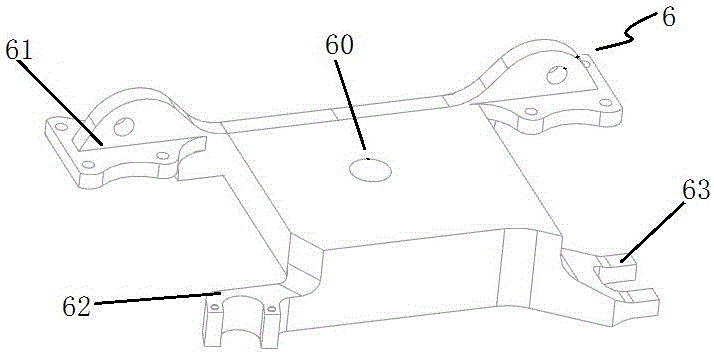

Framework and bogie comprising same

ActiveCN105905126AGood weldabilityAchieve decouplingRailway braking systemsRailway transportBogieEngineering

The invention discloses a framework. The framework comprises a cross beam and a side beam, wherein the side beam is of a sheet structure and hunches up in the center in the longitudinal direction; and the cross beam is connected to the hunching-up top of the side beam and detachably connected with the side beam. The invention further provides a bogie at the same time. The bogie comprises the framework; integration mounting bases are installed on the upper surfaces of the transverse two ends of the cross beam correspondingly; each integration mounting base comprises a foundation seat, a pair of brake mounting seats, a vertical absorber seat and an antiroll device mounting seat, wherein the brake mounting seats are arranged on one side of the foundation seat in the same straight line in a back-to-back mode, the vertical absorber seat is arranged at one end of the other lateral side of the foundation seat, and the antiroll device mounting seat is arranged on the other end of the other lateral side of the foundation seat; and the side beam, the cross beam and the integration mounting bases are in series connection sequentially through fasteners. The problem that a framework made from carbon fiber composite materials is poor in welding property is solved. The longitudinal, transverse and vertical rigidity decoupling of the side beam and the cross beam is achieved. The framework and the bogie have the advantages that the structure and assembling process of the bogie are simplified, and the loading burden of the framework is relieved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Coated metal material capable of being welded which is excellent in corrosion resistance of worked zone

ActiveUS20050244660A1Improve conductivityImprove corrosion resistanceLiquid surface applicatorsSynthetic resin layered productsMetallic materialsMetal sheet

A weldable coated metal material excellent in the corrosion resistance of the formed part, comprising a metal sheet having formed on at least one surface thereof a coat layer containing electrically conducting particles, wherein the number distribution of the electrically conducting particle has a mode value in the particle size range from 0.05 to 1.0 μm and the total content of electrically conducting particles in the coat layer is from 15 to 60 vol %.

Owner:NIPPON STEEL CORP

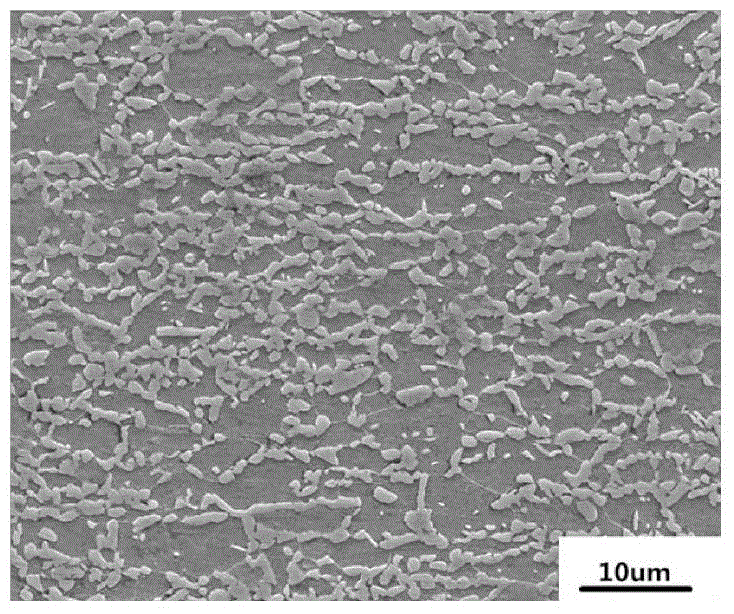

Hot stamped high strength part excellent in post painting anticorrosion property and method of production of same

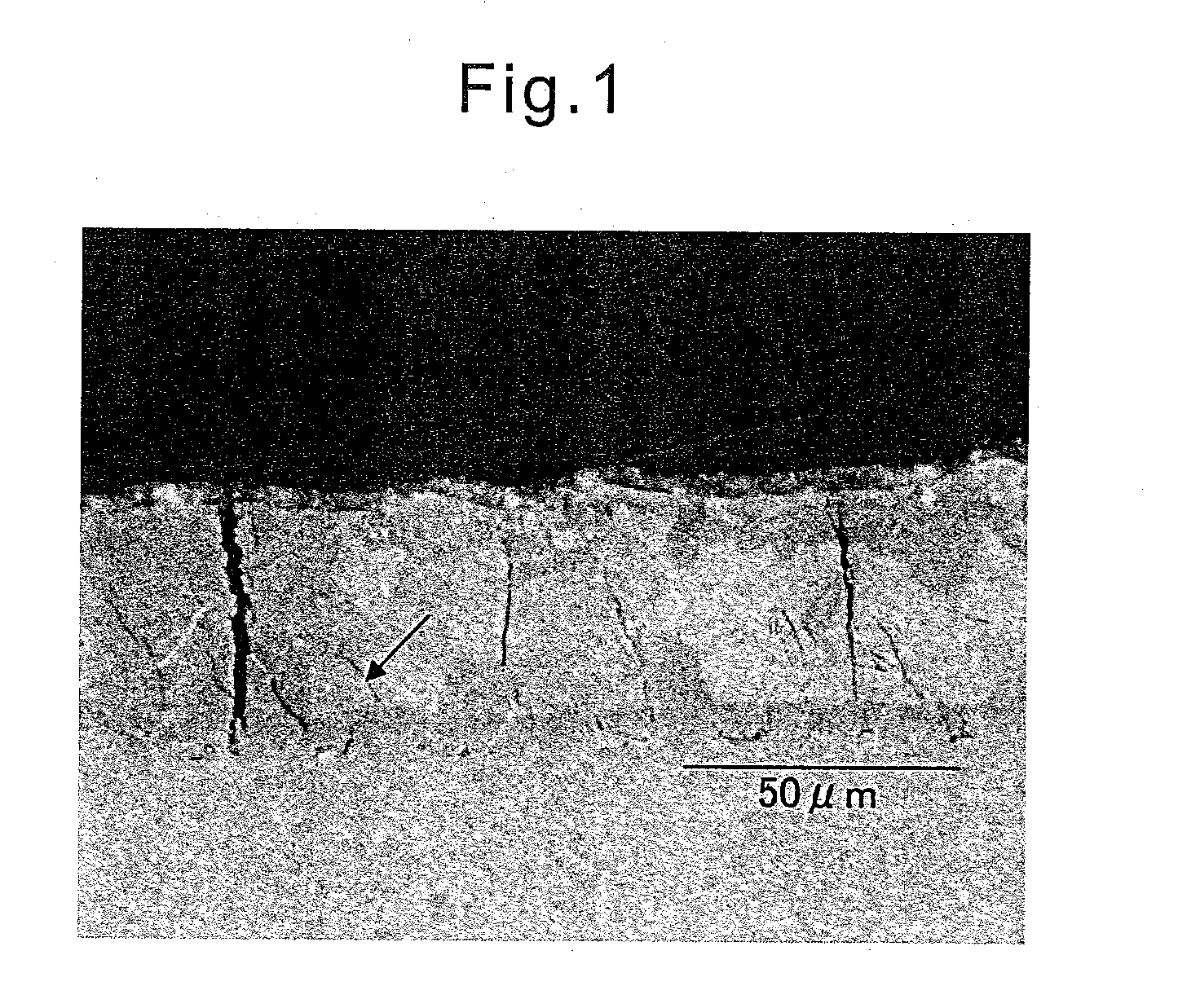

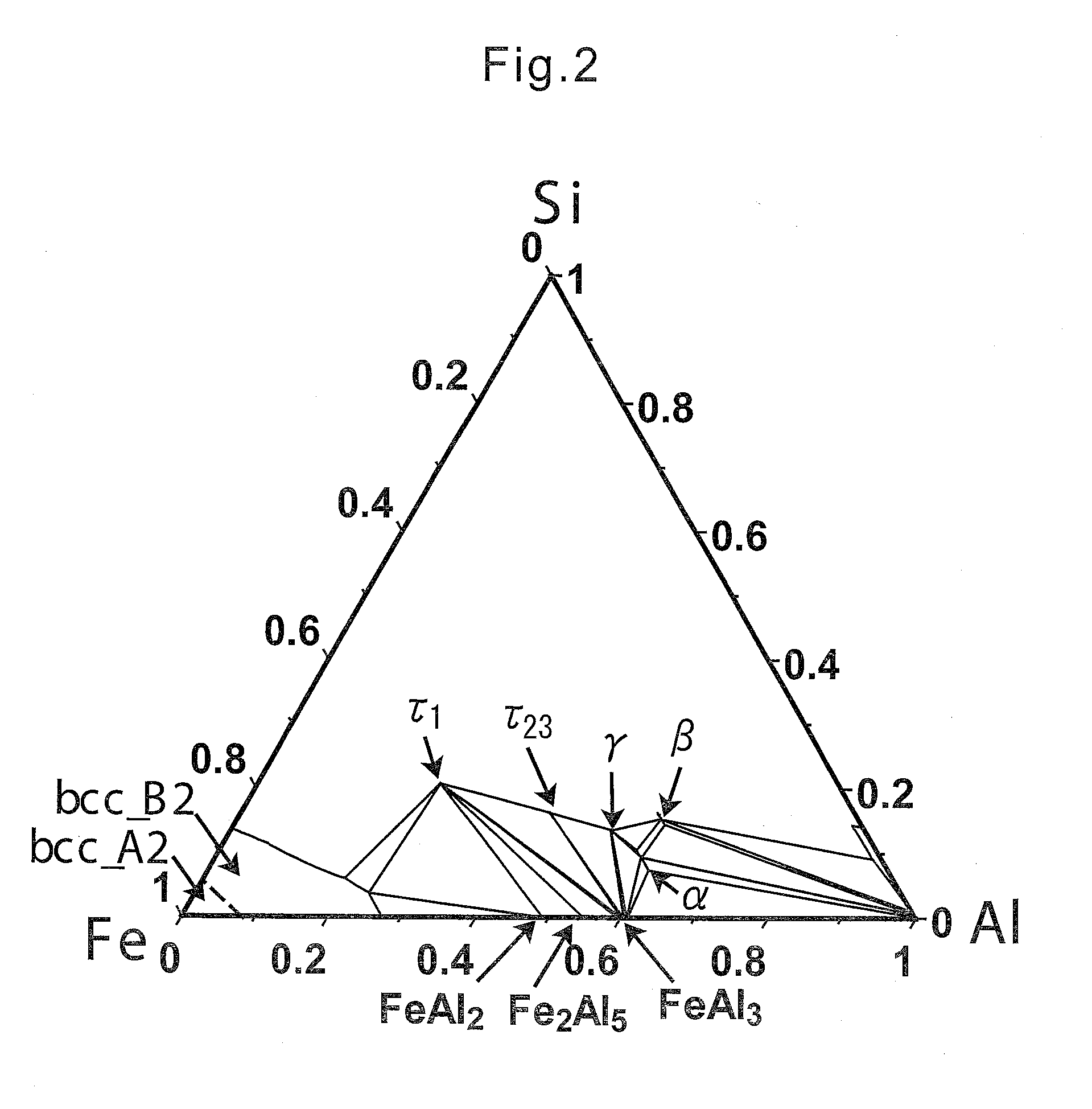

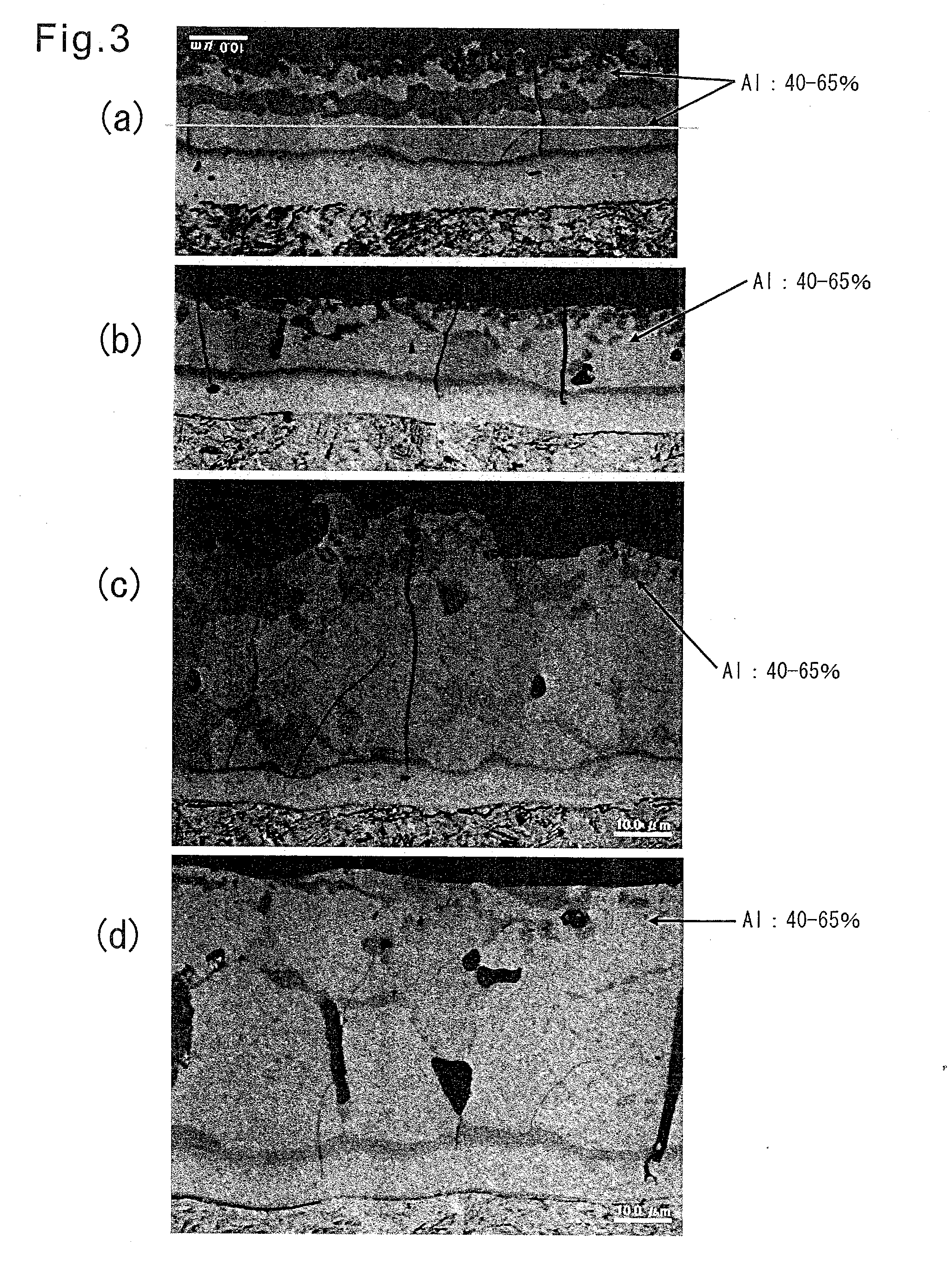

ActiveUS20140030544A1Inhibits the formation of cracksHigh strengthHot-dipping/immersion processesFurnace typesHot stampingCrazing

A hot stamped high strength part in which the propagation of cracks which form at the plating layer at the time of hot stamping when hot stamping aluminum plated steel sheet is suppressed and the post painting anticorrosion property is excellent even without adding special ingredient elements which suppress formation of cracks in an aluminum plating layer is provided.A hot stamped high strength part which is excellent in post painting anticorrosion property, which hot stamped high strength part has an alloy plating layer which includes an Al—Fe intermetallic compound phase on the surface of the steel sheet, wherein the alloy plating layer is comprised from phases of a plurality of intermetallic compounds, a mean linear intercept length of crystal grains of a phase containing Al: 40 to 65 mass % among the phases of the plurality of intermetallic compounds is 3 to 20 μm, an average value of thickness of the Al—Fe alloy plating layer is 10 to 50 μm, and a ratio of the average value of thickness to the standard deviation of thickness of the Al—Fe alloy plating layer satisfies the following relationship:0<standard deviation of thickness / average value of thickness≦0.15.

Owner:NIPPON STEEL CORP

Aluminum bonding alloy, and clad material and aluminum bonding composite material each having bonding alloy layer made of the alloy

ActiveUS20120202090A1Improve corrosion resistanceImprove workabilityHot-dipping/immersion processesWelding/cutting media/materialsTitaniumAluminum metal

An aluminum bonding alloy is an Ni—Mg alloy for bonding aluminum and a non-aluminum metal selected from steel, copper, nickel or titanium. The Ni—Mg alloy consists essentially of 0.08-0.90 mass % Mg, and the balance of Ni and inevitable impurities. A clad material includes a non-aluminum metal layer made of the non-aluminum metal and a bonding alloy layer made of the aluminum bonding alloy. The non-aluminum metal layer and the bonding alloy layer are bonded together by pressure welding and diffusion bonding.

Owner:NEOMAX MATERIALS

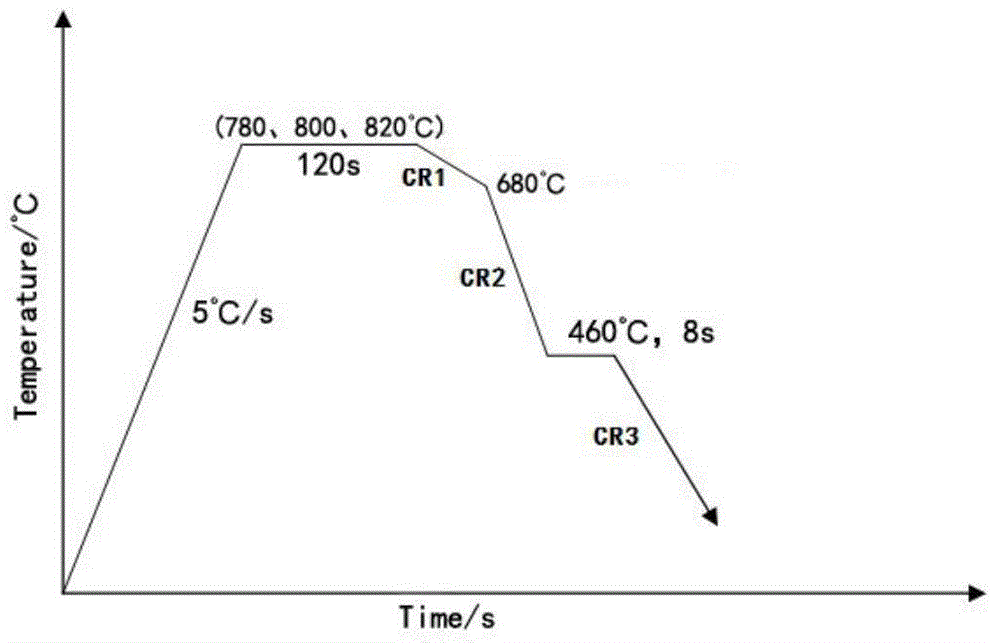

1,000 MPa-level high-aluminum hot-dip-galvanized dual-phase steel and preparation method thereof

InactiveCN104561812AHigh tensile strengthLow yield ratioHot-dipping/immersion processesSteel platesCompound (substance)

The invention belongs to the technical field of cold-rolled high-aluminum hot-dip-galvanized super-high-strength steel plates for automobiles, and relates to 1,000 MPa-level high-aluminum hot-dip-galvanized dual-phase steel and a preparation method thereof. The 1,000 MPa-level high-aluminum hot-dip-galvanized dual-phase steel comprises the following chemical components by mass percent: 0.10%-0.18% of C, 1.4%-1.9% of Mn, 0.20%-0.60% of Cr, 0.10%-0.40% of Mo, not more than 0.050% of Si, 0.50%-0.90% of Al, not more than 0.0030% of S, not more than 0.0090% of P, not more than 0.0050% of N and the balance of Fe and inevitable impurity elements. Si is replaced with Al, so that the galvanizing defects such as plating leakage caused by enrichment oxidation of Si on the surface of a steel plate are overcome; meanwhile, the strength and the tenacity of the steel are improved by adding Mn, Cr and Mo, so that the steel is good in strength-toughness ratio and usability, and the strength level can reach more than 1,000 MPa.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy sheet for spot welding

InactiveUS6369347B1Good weldabilityLittle likelihoodArc welding apparatusResistance welding apparatusElectrical resistance and conductanceSurface layer

An aluminum alloy sheet for automotive use is provided which comprises a starting aluminum alloy sheet which has an alloy composition containing from 2 to 6% by weight of Mg, 0.15 to 1.0% by weight of Fe and from 0.03 to 2.0% by weight Mn, and a surface layer disposed over one surface of the starting alloy sheet to be pressed against electrodes for use in welding, the surface layer containing a particulate intermetallic compound has a particle diameter of 0.5 mum or more and a density of 4,000 pieces of particles per one mm2 or more. The product alloy sheet ensure least deformation of an electrode and stable weldability by means of continuous resistance spot welding.

Owner:NIPPON LIGHT METAL CO LTD +2

High strength steel pipe for an air bag and a process for its manufacture

InactiveUS6878219B2High strengthGood weldabilityPedestrian/occupant safety arrangementFurnace typesRare-earth elementHigh intensity

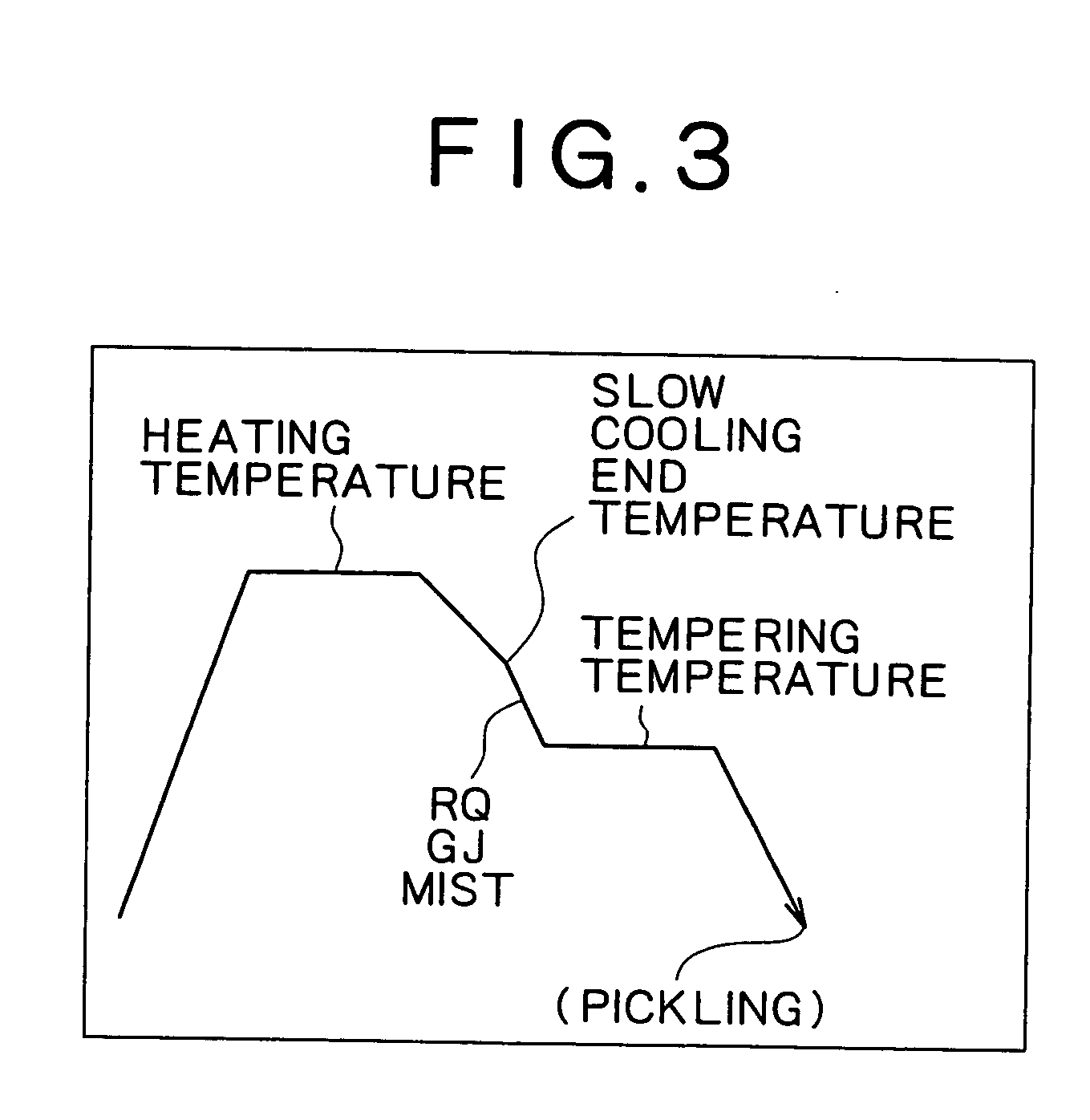

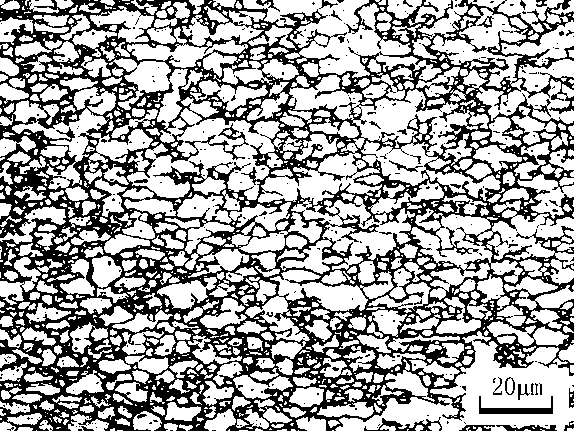

In order to manufacture a steel pipe for an air bag which can cope with increase in the pressure of gas blown into an air bag and decreases in the wall thickness of an accumulator, a steel having a composition, mass %, of:C: 0.05-0.20%,Si: 0.1-1.0%,Mn: 0.20-2.0%,P: at most 0.025%,S: at most 0.010%,Cr: 0.05-1.0%,Al: at most 0.10%,if necessary at least one of Mo: at most 0.50%, Ni: at most 1.5%, Cu: at most 0.5%, V: at most 0.2%, Ti: at most 0.1%, Nb: at most 0.1%, and B: at most 0.005%, andalso if necessary, at least one of Ca: at most 0.01%, Mg: at most 0.01%, and REM (rare earth elements): at most 0.01%,and a remainder of Fe and impurities is used to produce a steel pipe, and the pipe is then subjected to cold working to predetermined dimensions, then to heating to a temperature of at least the Ac1 transformation temperature followed by quenching, and then to tempering at a temperature no higher than the Ac1 transformation temperature.

Owner:NIPPON STEEL CORP

Aluminum plated steel sheet for rapid heating hot-stamping, production method of the same and rapid heating hot-stamping method by using this steel sheet

ActiveUS20110174418A1Eliminate generationReduce riskShaping toolsHot-dipping/immersion processesHot stampingHydrogen

The present invention solves the problem of melting of Al in heating before hot-stamping, which had been a problem in the past in applying hot-stamping to Al-plated steel sheet, and provides Al-plated steel sheet for hot-stamping and a method of hot-stamping using that Al-plated steel sheet to solve the problem of delayed fracture due to residual hydrogen, and, furthermore, a method of a rapid heating hot-stamping using that Al-plated steel sheet.The Al-plated steel sheet of the present invention is produced by annealing the Al-plated steel sheet as coiled in a box-anneal furnace for the time and at the temperature indicated in FIG. 5, and alloying of a plated Al and a steel sheet.Further, a method of rapid heating hot-stamping in the present invention is characterized by cutting out a stamping blank of an Al-plated steel sheet, and heating that blank in heating before hot-stamping by an average temperature with a rising rate of 40° C. / sec or more and a time of exposure to an environment of 700° C. or more of 20 seconds or less, and then hot-stamping it.

Owner:NIPPON STEEL CORP

High-grade wear-resistant steel plate and production method thereof

InactiveCN101748346AGuaranteed hardenabilitySolve the coarse and uneven grain sizeRoll mill control devicesElectric furnaceWear resistantQuenching

The invention discloses a high-grade wear-resistant steel plate. The steel plate comprises the following components in percentage by mass: less than or equal to 0.26 percent of C, less than or equal to 0.50 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.30 percent of Ni, less than or equal to 1.50 percent of Cr, less than or equal to 0.06 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.03 percent of Ti, less than or equal to 0.50 percent of Mo, less than or equal to 0.08 percent of V, less than or equal to 0.004 percent of B, and the balance of Fe and inevitable impurities. A method for producing the steel plate comprises smelting, casting, heating, rolling, straightening, shot blasting, quenching, heat treatment, cutting and other process steps. The steel plate has the advantages of steel purity, high strength, high hardness, good low temperature toughness, good weldability, good processability, good cold bending property, large steel plate thickness, good plate cut, little noble metal added to the steel plate and low cost. The steel plate can be widely used in the industry of manufacturing mining, engineering, metallurgical and other machinery with broad application prospects.

Owner:WUYANG IRON & STEEL +1

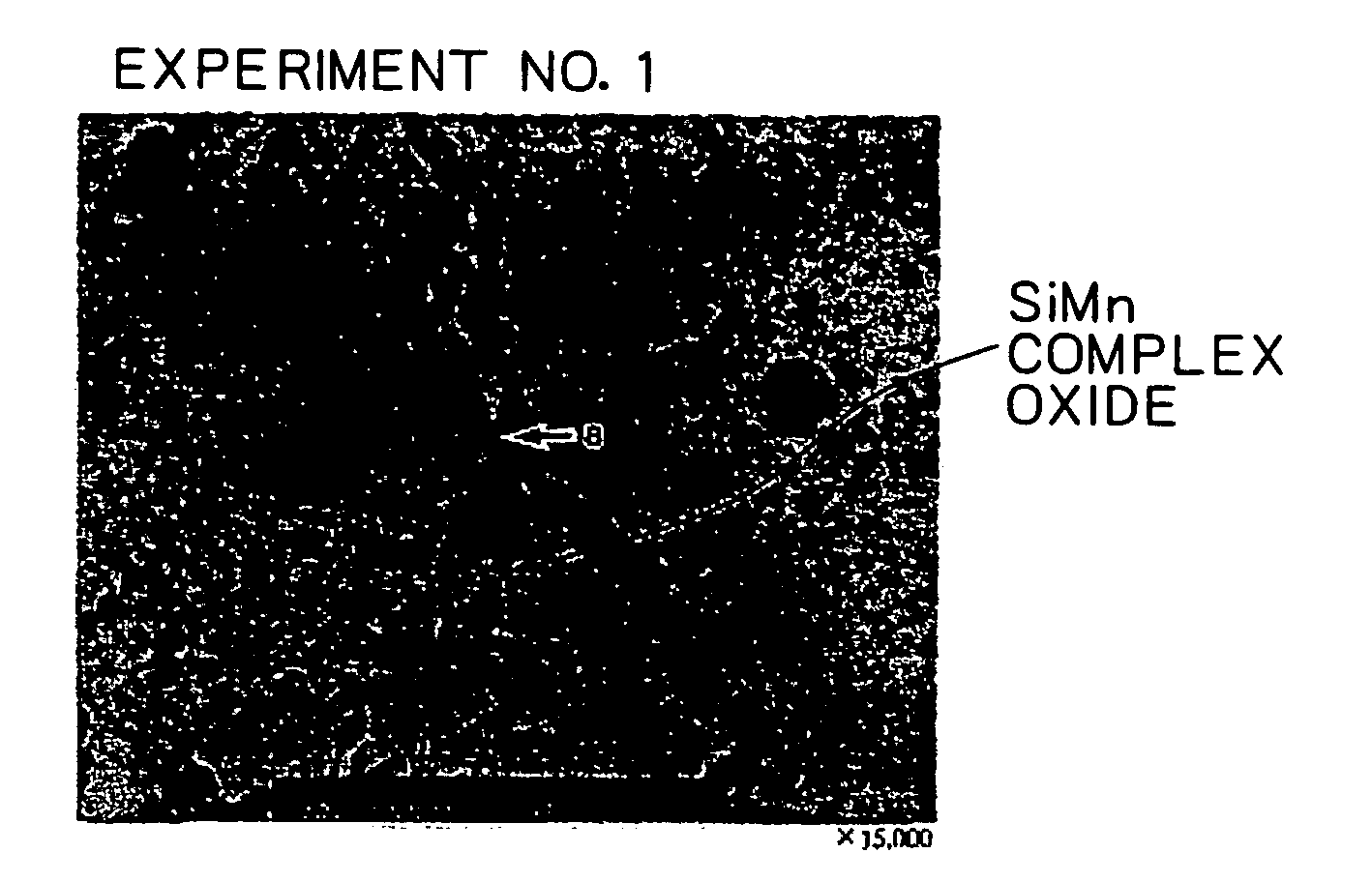

High-strength cold-rolled steel sheet excellent in coating film adhesion

InactiveUS20050139293A1Improve solderabilityHigh strengthHot-dipping/immersion processesFurnace typesComplex oxideComposite material

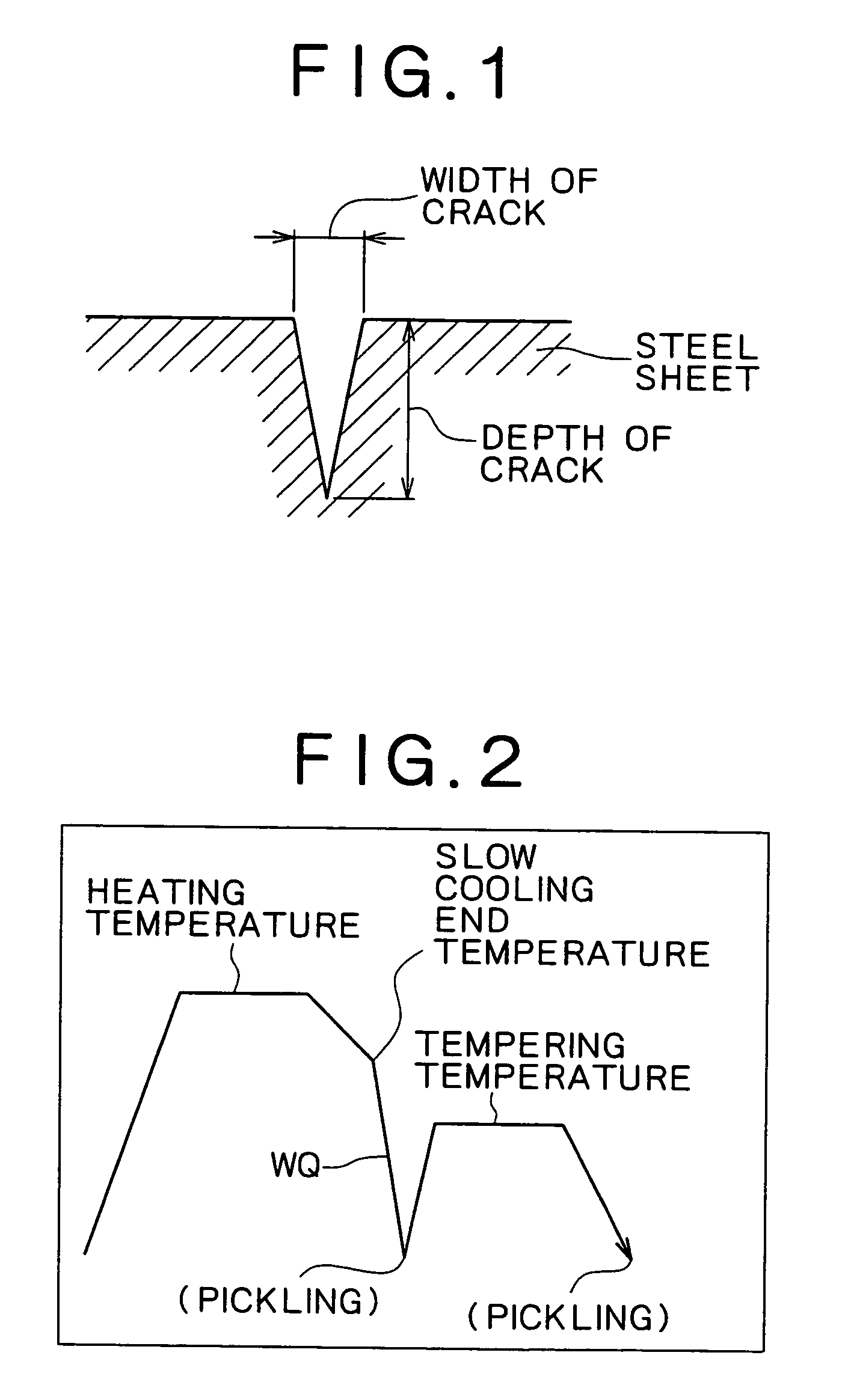

A cold-rolled steel sheet of DP (Dual Phase) type with a specific composition meets the requirements: [0001](I) In the surface of the steel sheet, there exist Si—Mn complex oxides no larger than 5 μm in diameter of the equivalent circle as many as 10 or more per 100 μm2 and the coverage of oxides composed mainly of Si on the surface of steel sheet is no more than 10% of surface area, and / or (II) The cross section near the surface of the steel sheet does not show cracks with a width no larger than 3 μm and a depth no smaller than 5 μm in arbitrary ten fields of observation under an SEM with a magnification of 2000. A high-strength cold-rolled steel sheet excellent in coating film adhesion and having a tensile strength no lower than 550 MPa is provided.

Owner:KOBE STEEL LTD

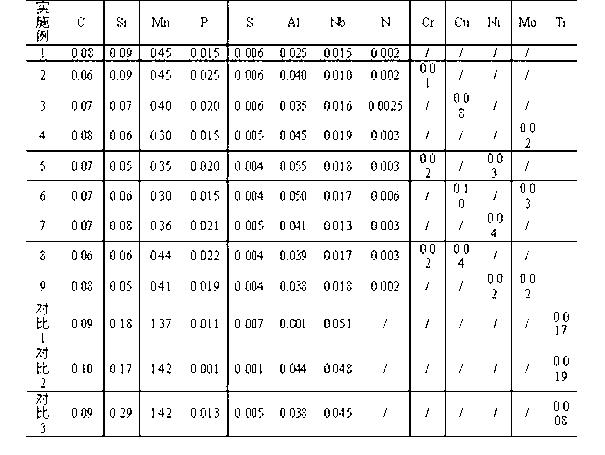

Steel for 300MPa-grade automobile structural part and production method for steel

The invention relates to steel for a 300MPa-grade automobile structural part and a production method for the steel. The steel comprises the following main components in percentage by weight: 0.06-0.08 percent of C, 0.05-0.09 percent of Si, 0.30-0.45 percent of Mn, 0.025-0.055 percent of Al, 0.015-0.025 percent of P, less than or equal to 0.006 percent of S, 0.010-0.019 percent of Nb, less than or equal to 0.006 percent of N and the balance of Fe and impurities. The production method comprises the production steps of molten iron desulfurization, converter smelting, ladle argon blowing, continuous casting, heating of a casting blank, hot rolling, winding, conventional pickling, cold rolling, continuous operation and flattening for later use. The production method disclosed by the invention has the advantages of short process flow, lower energy consumption and stable mechanical property; and in addition, on the premise that the yield strength of 300-340MPa and the tensile strength of 390-445MPa are met, the elongation percentage is not lower than 31 percent, the plastic strain ratio r is 1.45-1.80, a strain hardening index n is 0.16-0.20, a wide-cold test bending is 180 degrees and a bending diameter d is equal to 0; and in a metallographic structure, an equiaxed ferrite is 85-90 percent and a granular pearlite is 10-15 percent.

Owner:武汉钢铁有限公司

Steel in use for fire resistant, heat insulated oil line, and preparation method

ActiveCN1873041AHigh yield strengthImprove durabilityDrilling rodsFurnace typesGasolineRoom temperature

This invention discloses a method for manufacturing steel for high-temperature-resistant and heat-insulating oil pipes. The steel comprises: C 0.05-0.25 wt.%, Si 0.10-0.6 wt.%, Mn 0.10-1.0 wt.%, Cr 0.5-2.0 wt.%, Mo 0.10-1.0 wt.%, W 0.1-1.0 wt.%, Fe and inevitable impurities. The method comprises: (1) smelting, casting and hot-rolling seamless steel pipes; (2) performing austenite treatment in 920-1000 deg.C temperature zone; (3) quenching and tempering at 620-720 deg.C. The yield strength of the pipes at room temperature is greater than 650 MPa. After thermal treatment, the pipes can be combined with suitable solder and welded under CO2 protection to obtain heat-insulating oil pipes with increased high temperature strength (30%), and can be used for gasoline-driving thick oil extraction.

Owner:BAOSHAN IRON & STEEL CO LTD

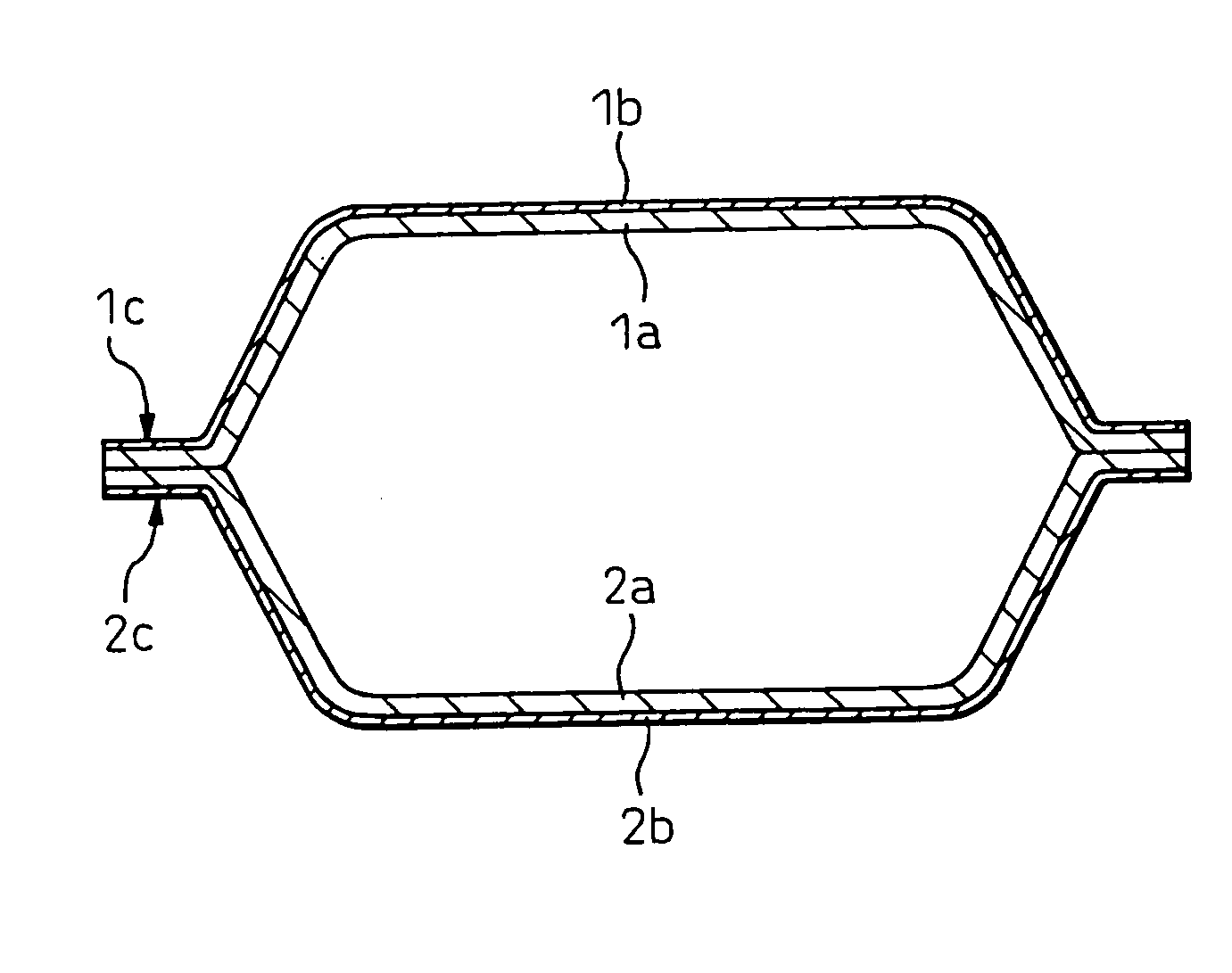

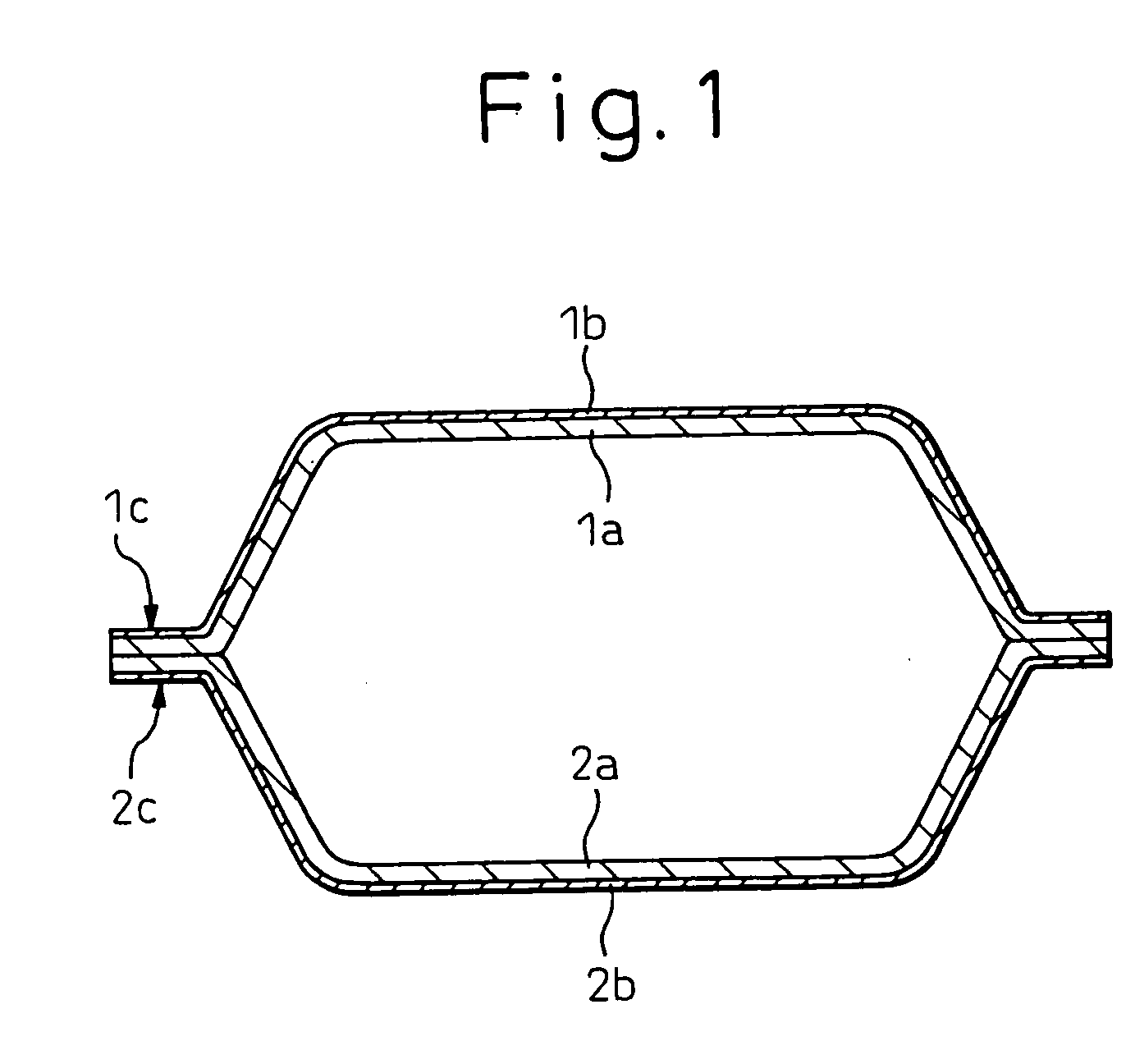

Sealed type cell manufacturing method

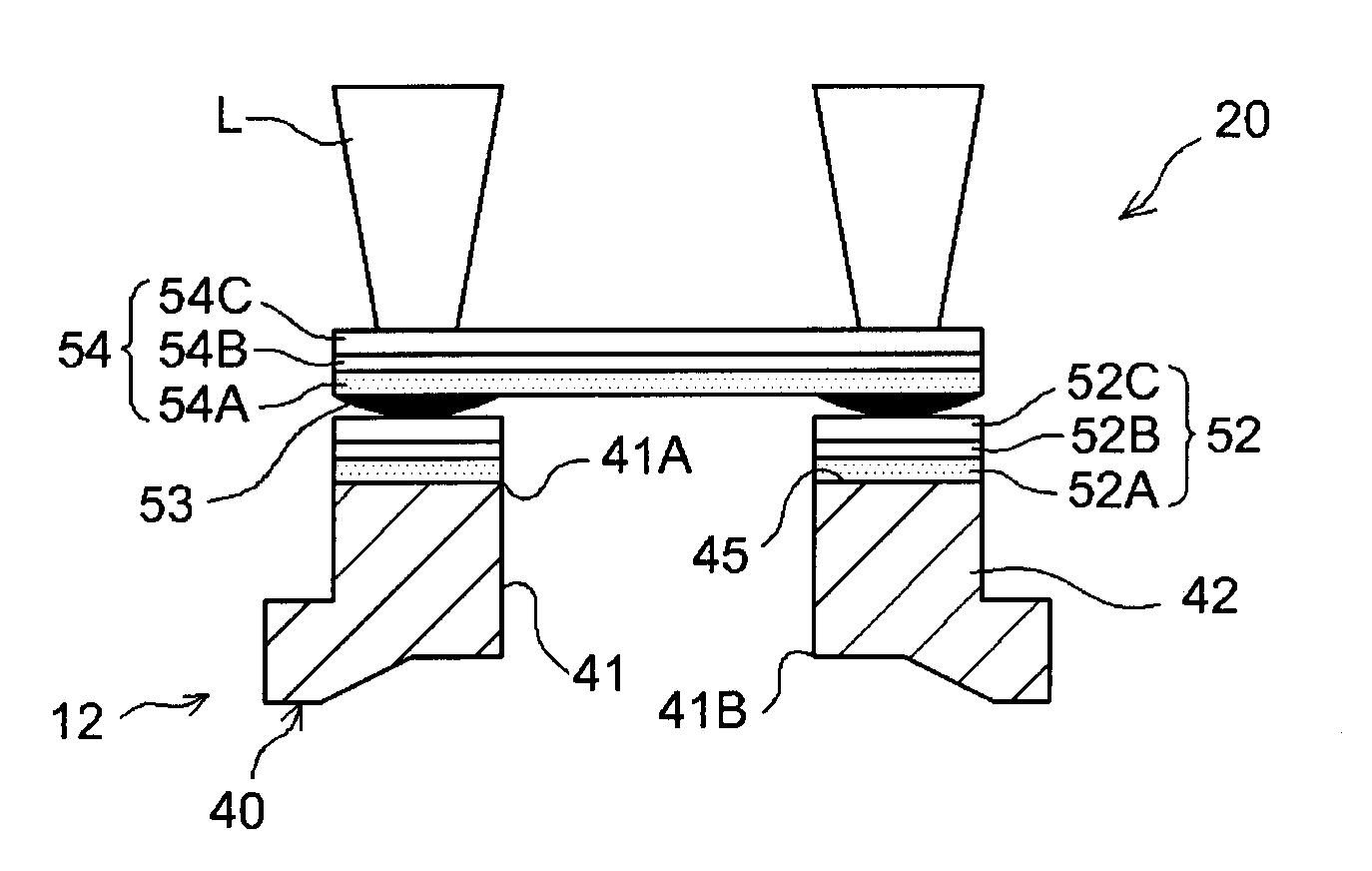

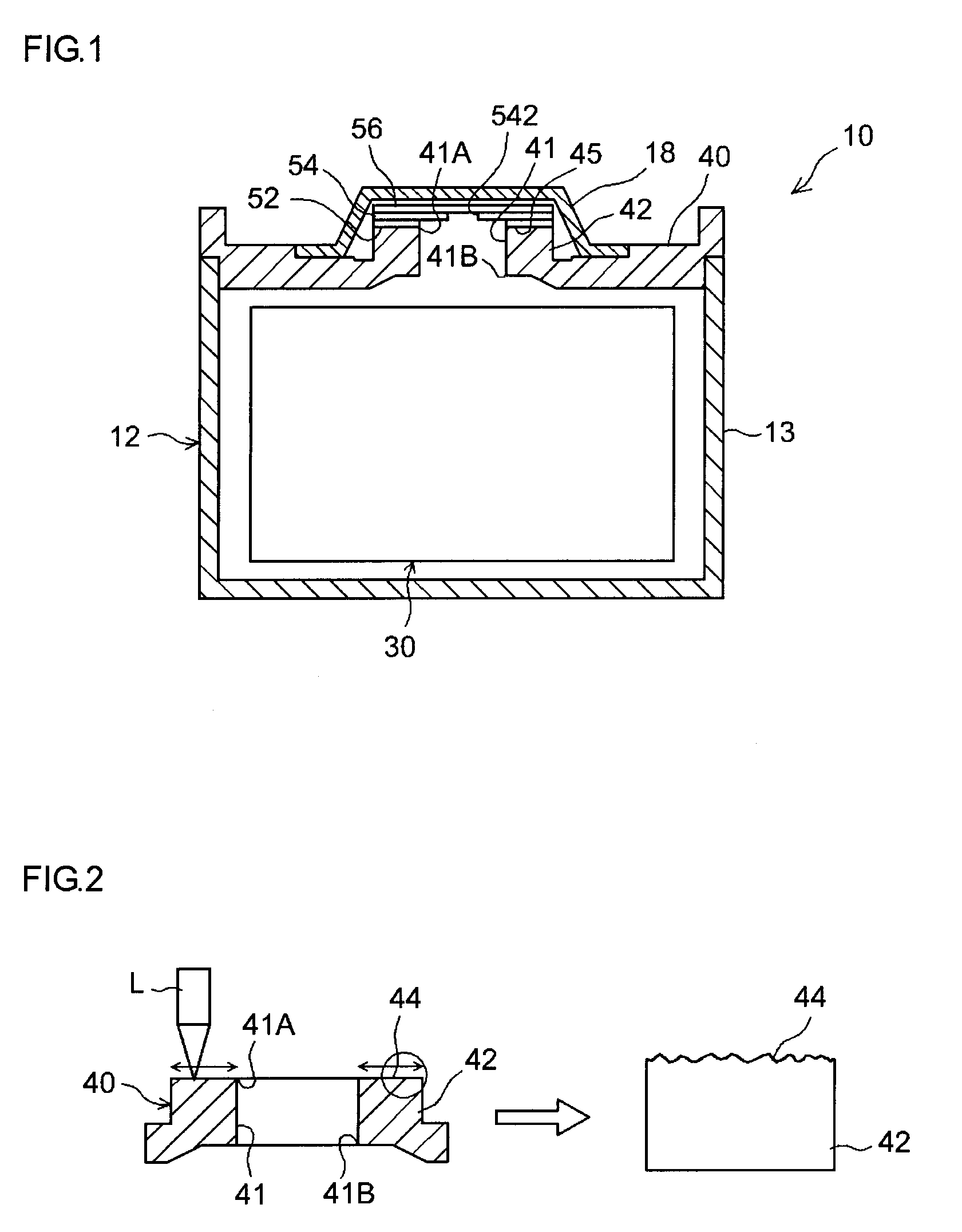

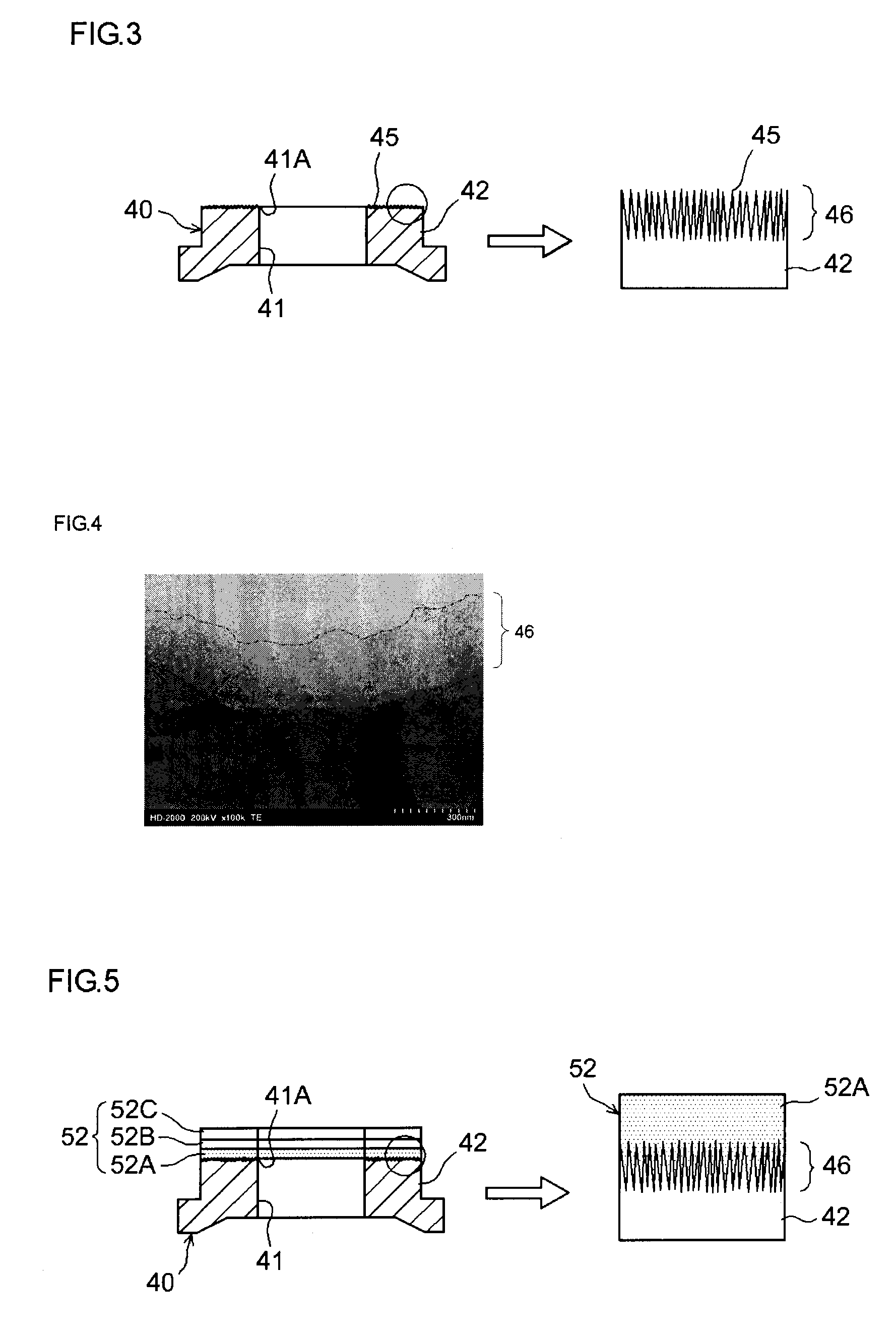

ActiveUS20110027645A1Improve solderabilityGood weldabilityLarge-sized flat cells/batteriesFinal product manufactureEngineeringAlloy

A cell assembly (20) is formed by arranging an electrode body and electrolyte in an external case (12) having a through hole (41). A laser is applied to an annular portion (formed by Al or Al-based alloy) surrounding an opening end (41A) of the through hole (41) toward outside the case so as to form a welded base (45). A sealing film (54) is welded to the surface of the welded base directly or via a base film (52) welded in advance, so as to temporarily seal the through hole (41). The cell assembly (20) in the temporarily sealed state is subjected to initial charge and then a hole is opened through the film (54) so as to form a gas discharge passage for communication between inside and outside of the case (12), thereby discharging an excessive gas from the case (12) outside.

Owner:TOYOTA JIDOSHA KK

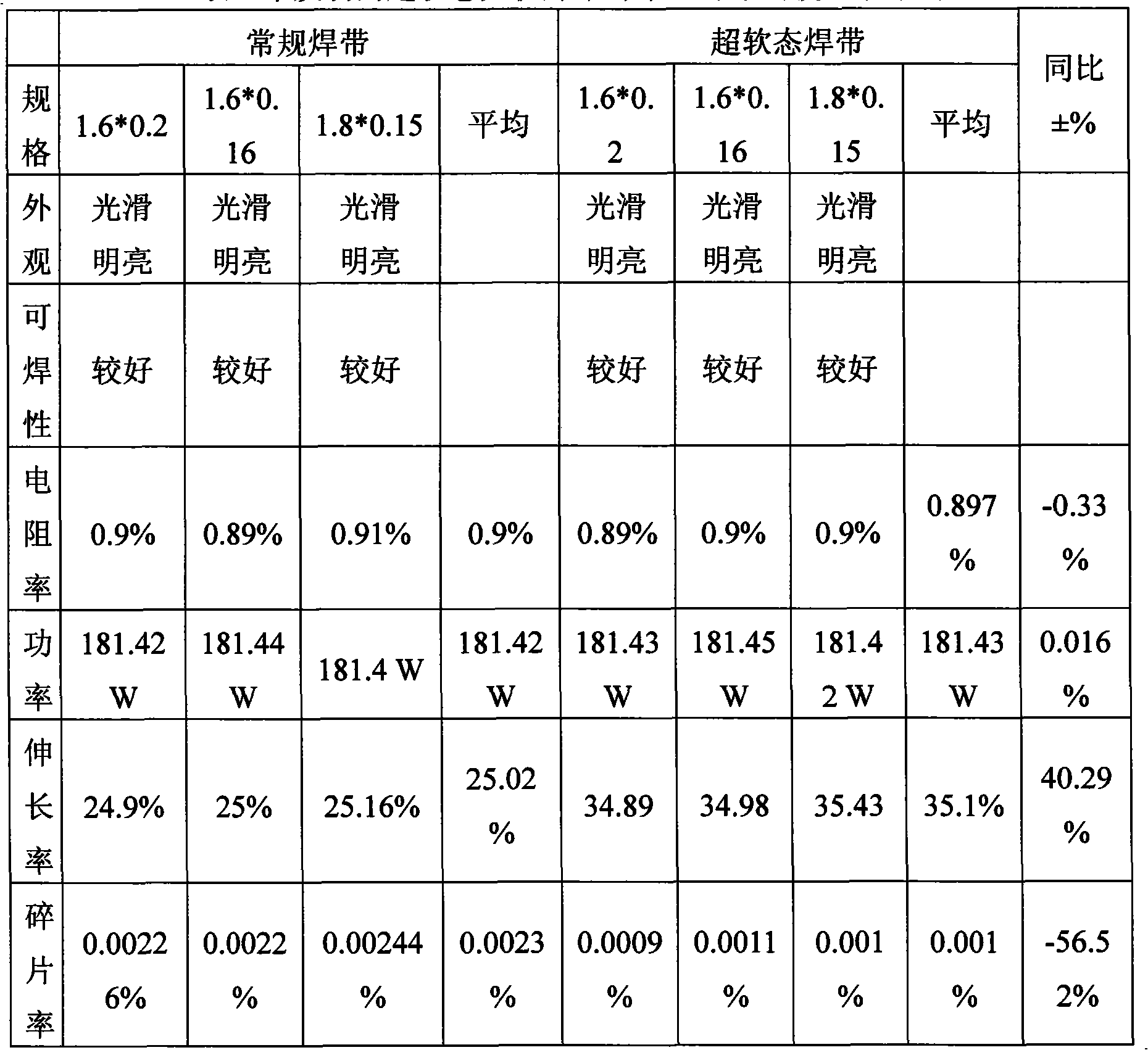

Manufacturing method of ultra-soft state photovoltaic welding belt

InactiveCN101621090AStrong weldabilityHigh conductivityFinal product manufactureSemiconductor devicesSolderabilityMegasonic cleaning

The invention discloses a manufacturing method of an ultra-soft state photovoltaic welding belt. The method comprises the following steps: oxygen-free copper wires are firstly planished and are annealed in a continuous pipe mode; clear water is then used for carrying out ultrasonic cleaning on the annealed oxygen-free copper wires; copper belts are then soaked by a welding flux and are led to a tin furnace for plating tin, and an automatic speed-regulating draught fan is finally arranged at an outlet of the tin furnace; after coming out from the tin furnace, the copper belts plated with tin firstly pass through the draught fan, and then pass through an automatic capstan and an automatic wire-rewinding machine for hanging, and a finished product of the welding belt is formed. The invention adopts a continuous working procedure so that material loss is reduced, labor capacity is increased, and meanwhile, strong weldability and high conductivity of the welding belt are ensured. Compared with a conventional photovoltaic welding belt manufactured by a traditional method, the tensile stretch is increased by 40%, and the fragmentation rate in the process of welding is greatly reduced.

Owner:无锡市耀普科技有限公司

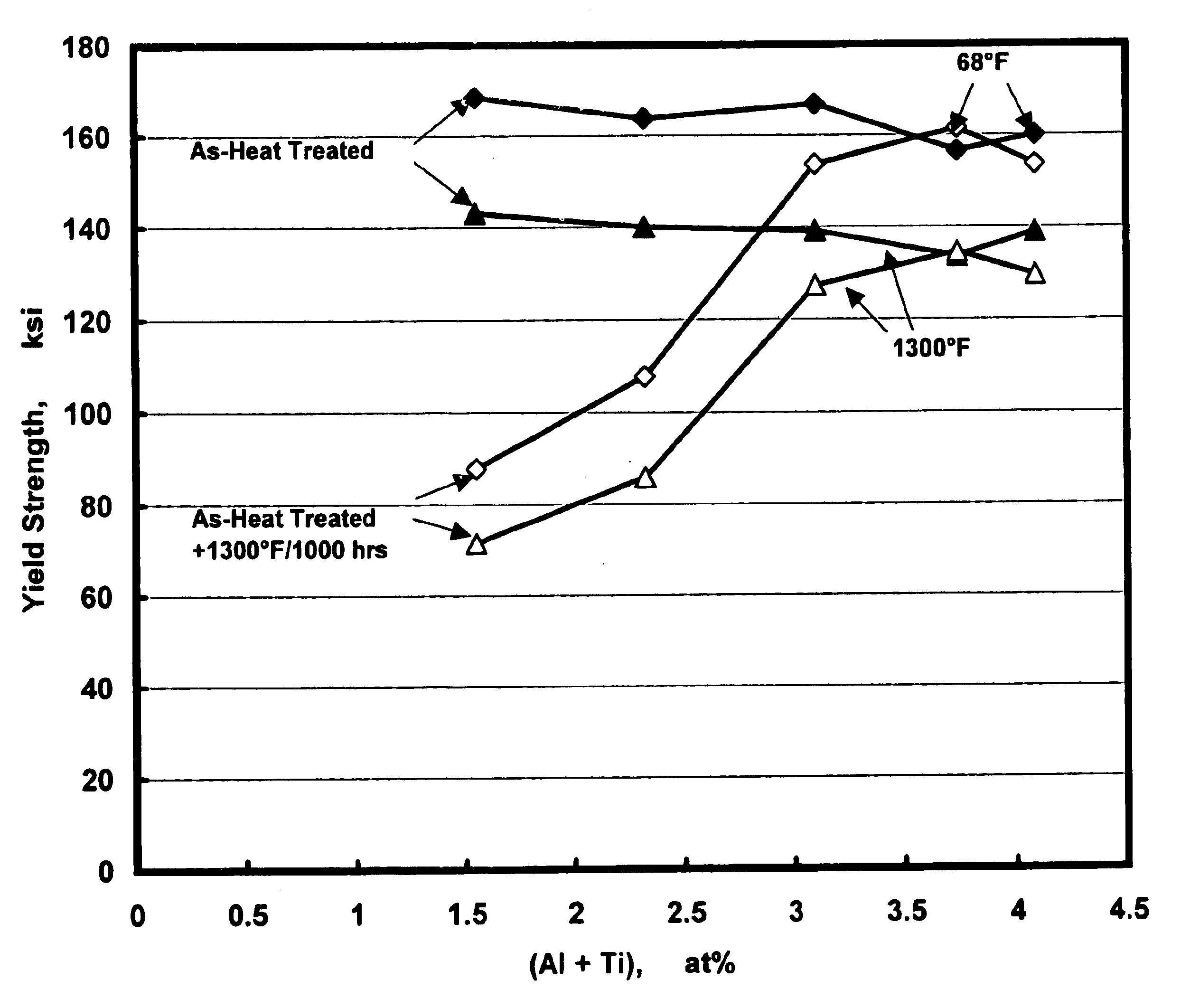

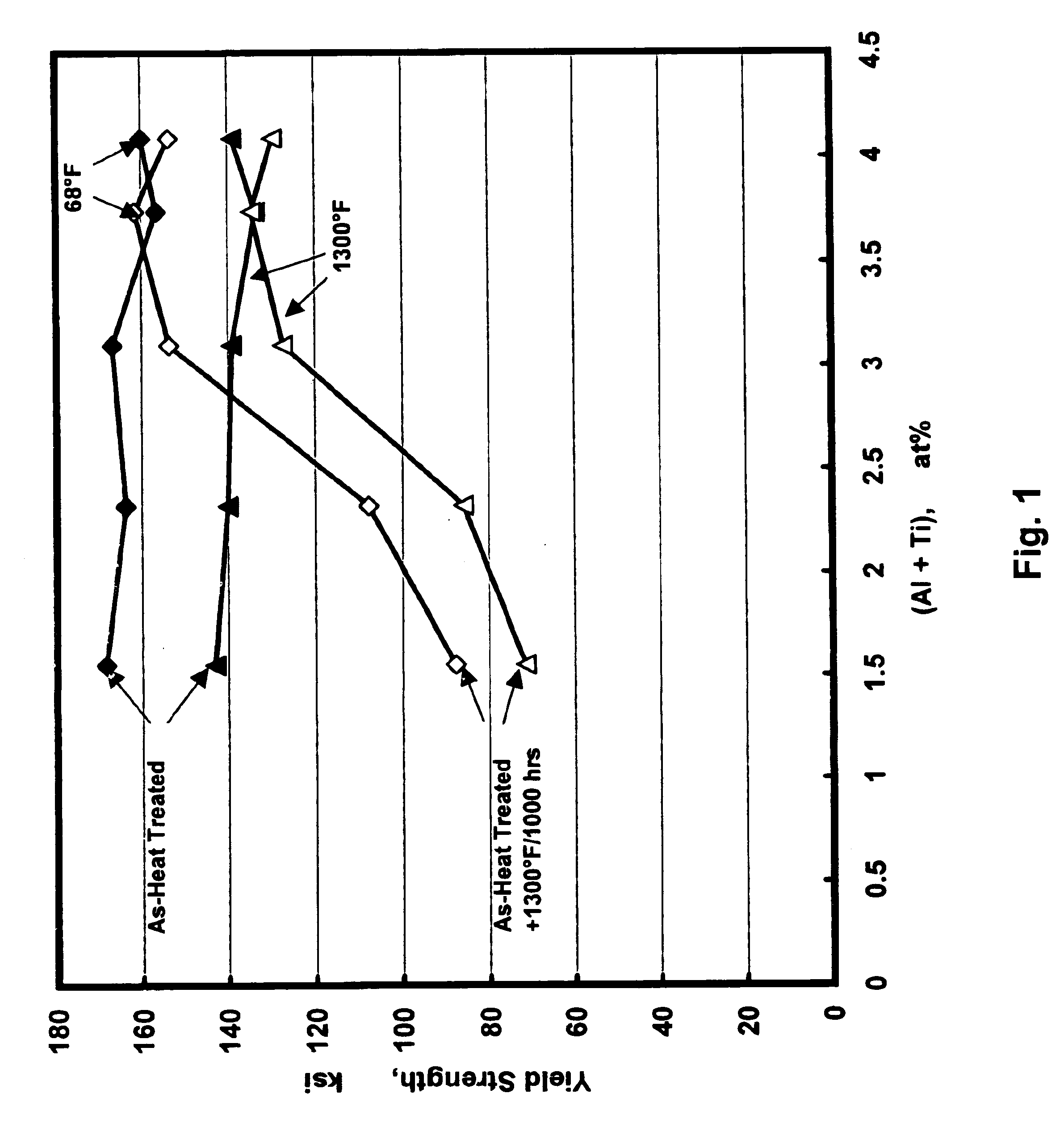

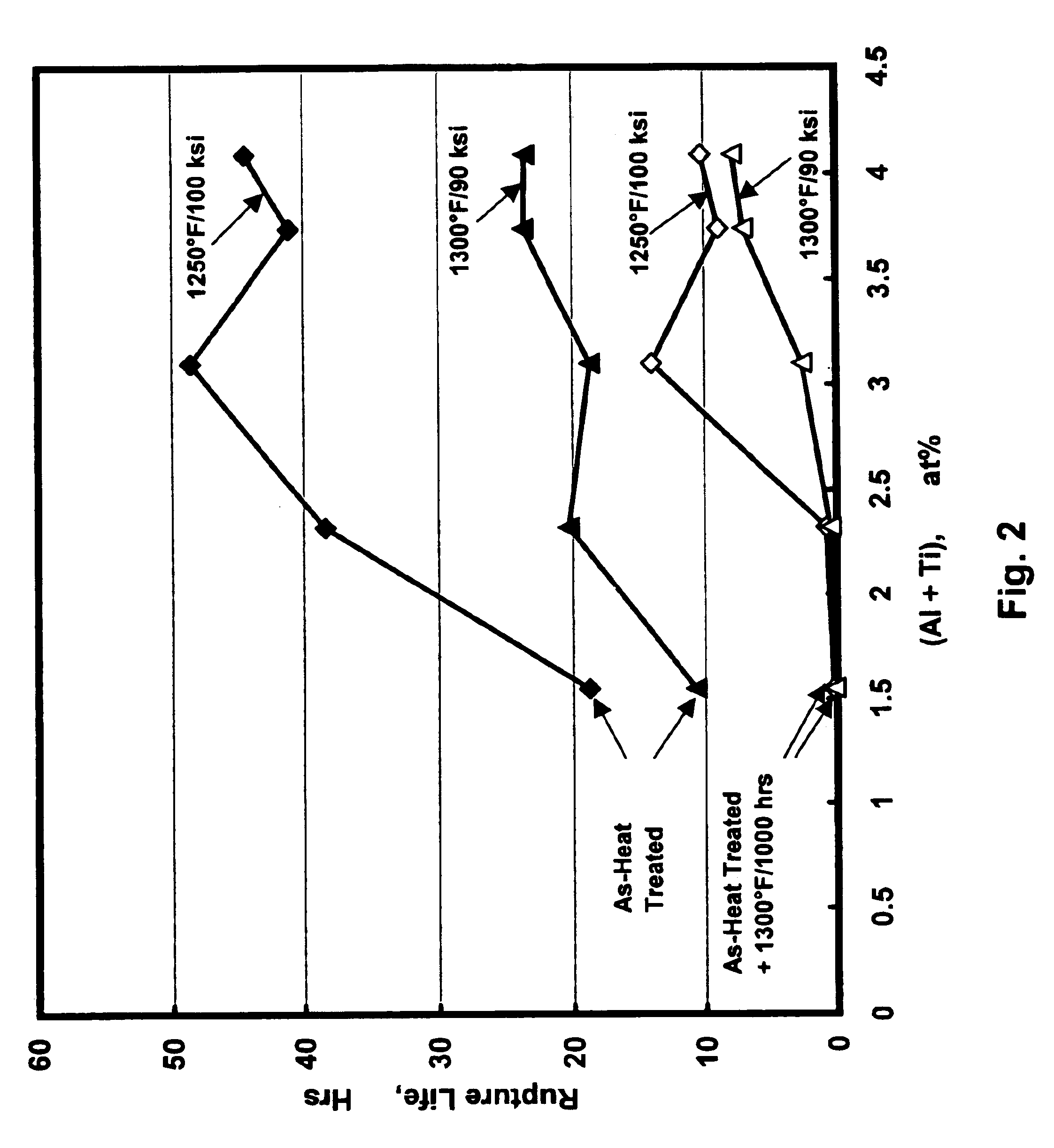

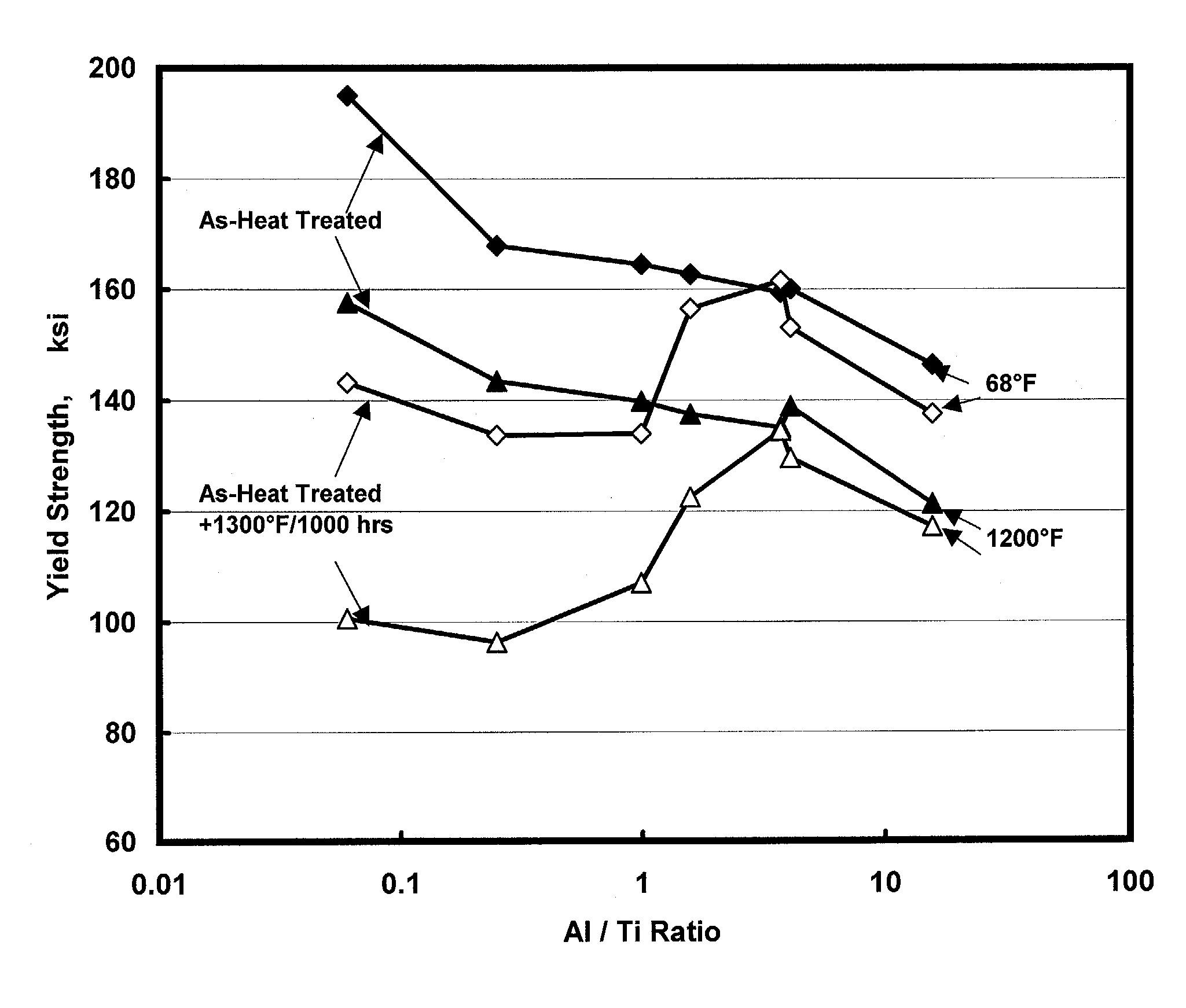

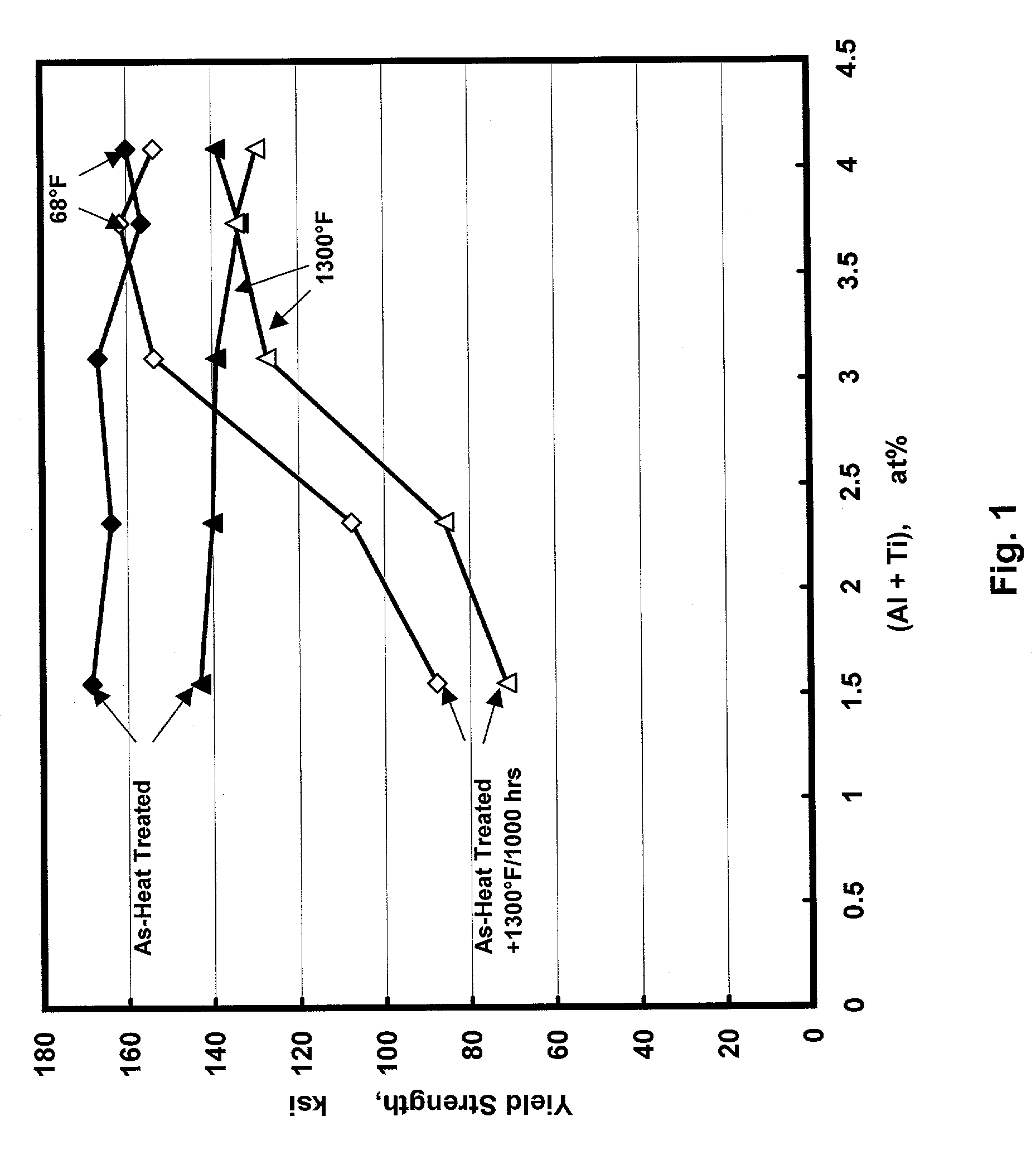

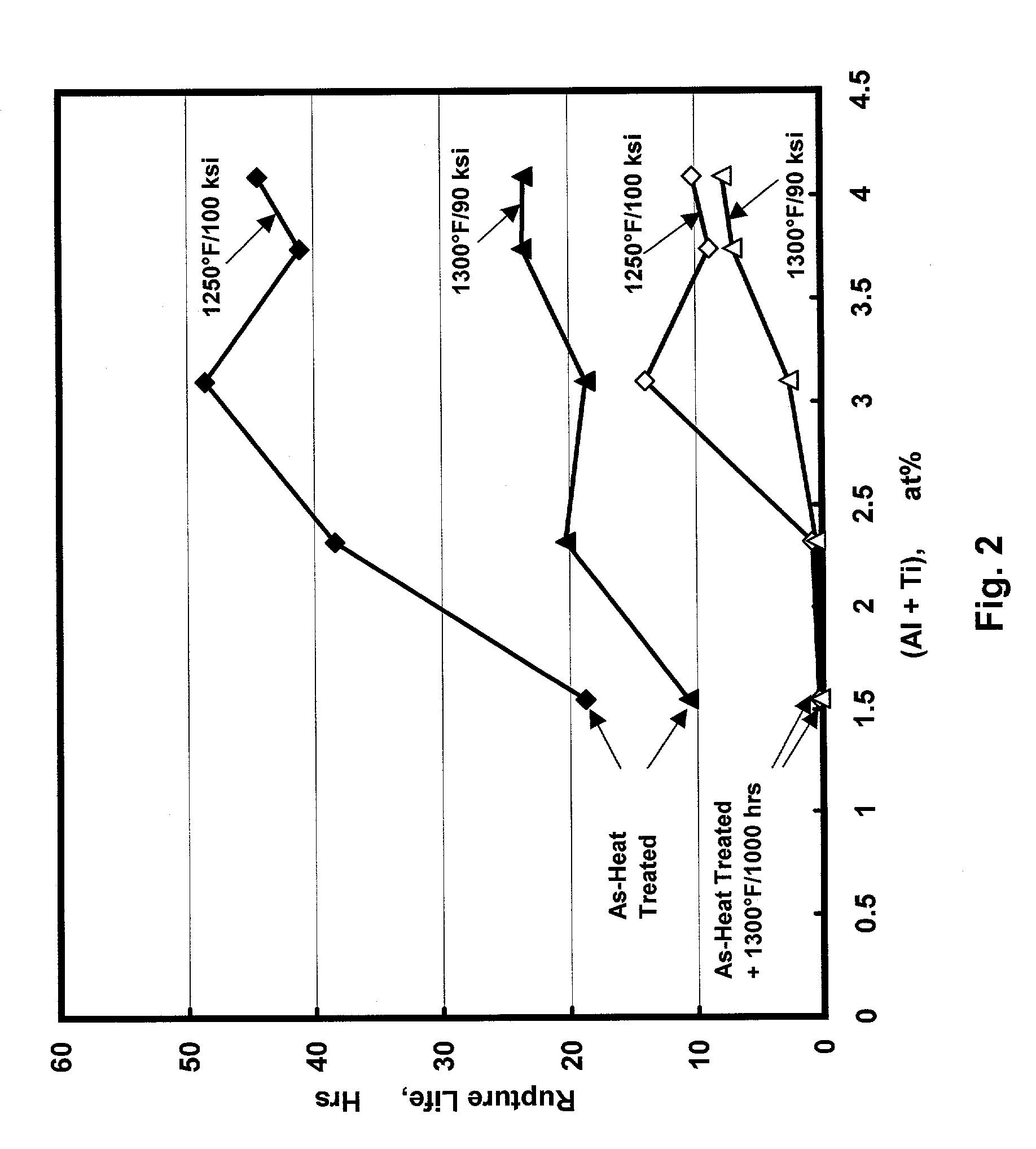

Nickel-base alloy

A nickel-base alloy includes, in weight percent, up to about 0.10 percent carbon; about 12 up to about 20 percent chromium; up to about 4 percent molybdenum; up to about 6 percent tungsten, wherein the sum of molybdenum and tungsten is at least about 2 percent and not more than about 8 percent; about 5 up to about 12 percent cobalt; up to about 14 percent iron; about 4 percent up to about 8 percent niobium; about 0.6 percent up to about 2.6 percent aluminum; about 0.4 percent up to about 1.4 percent titanium; about 0.003 percent up to about 0.03 percent phosphorous; about 0.003 percent up to about 0.015 percent boron; nickel; and incidental impurities. The sum of atomic percent aluminum and atomic percent titanium is from about 2 to about 6 percent, the ratio of atomic percent aluminum to atomic percent titanium is at least about 1.5, and the atomic percent of aluminum plus titanium divided by the atomic percent of niobium equals about 0.8 to about 1.3. The nickel-base alloy may be provided in the form of an article of manufacture, such as, for example, a disk, a blade, a fastener, a case, or a shaft. A method for making a nickel-base alloy also is disclosed. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:ATI PROPERTIES

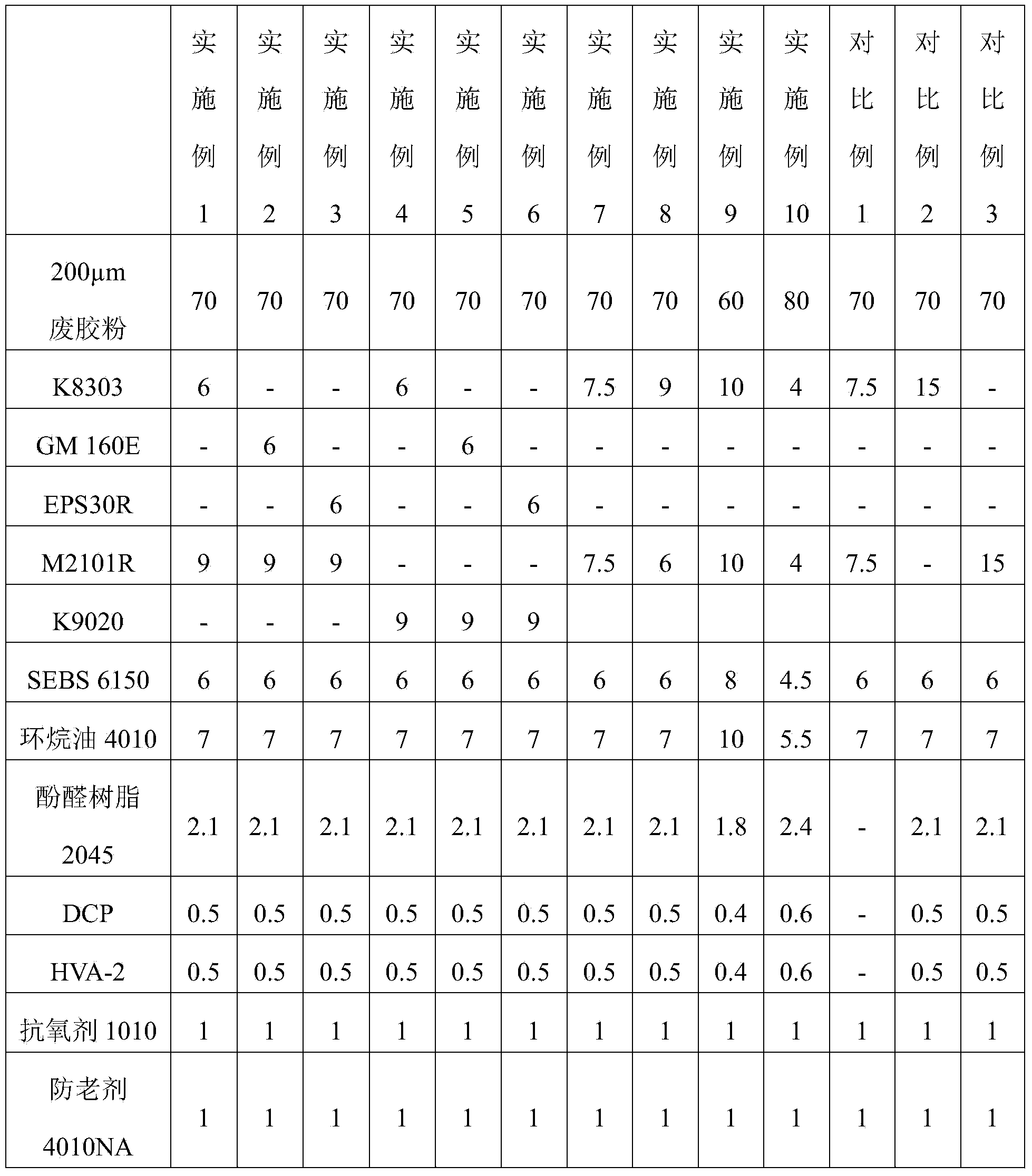

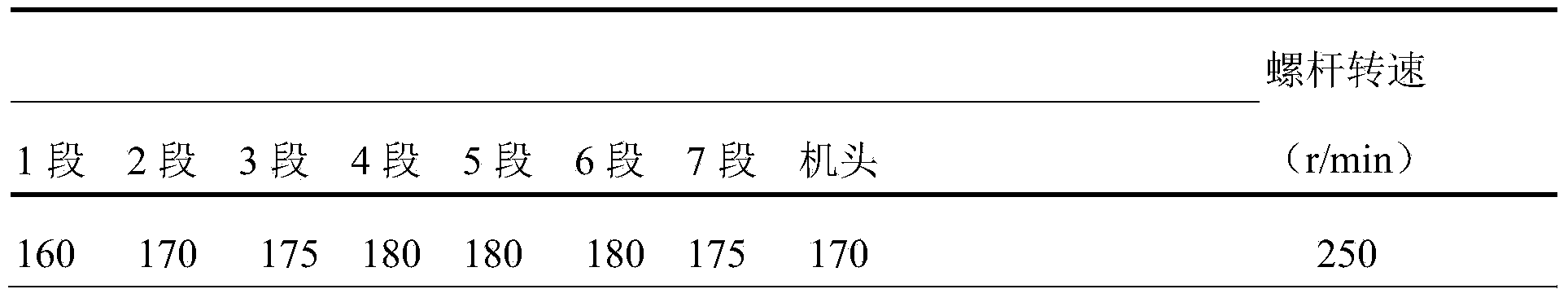

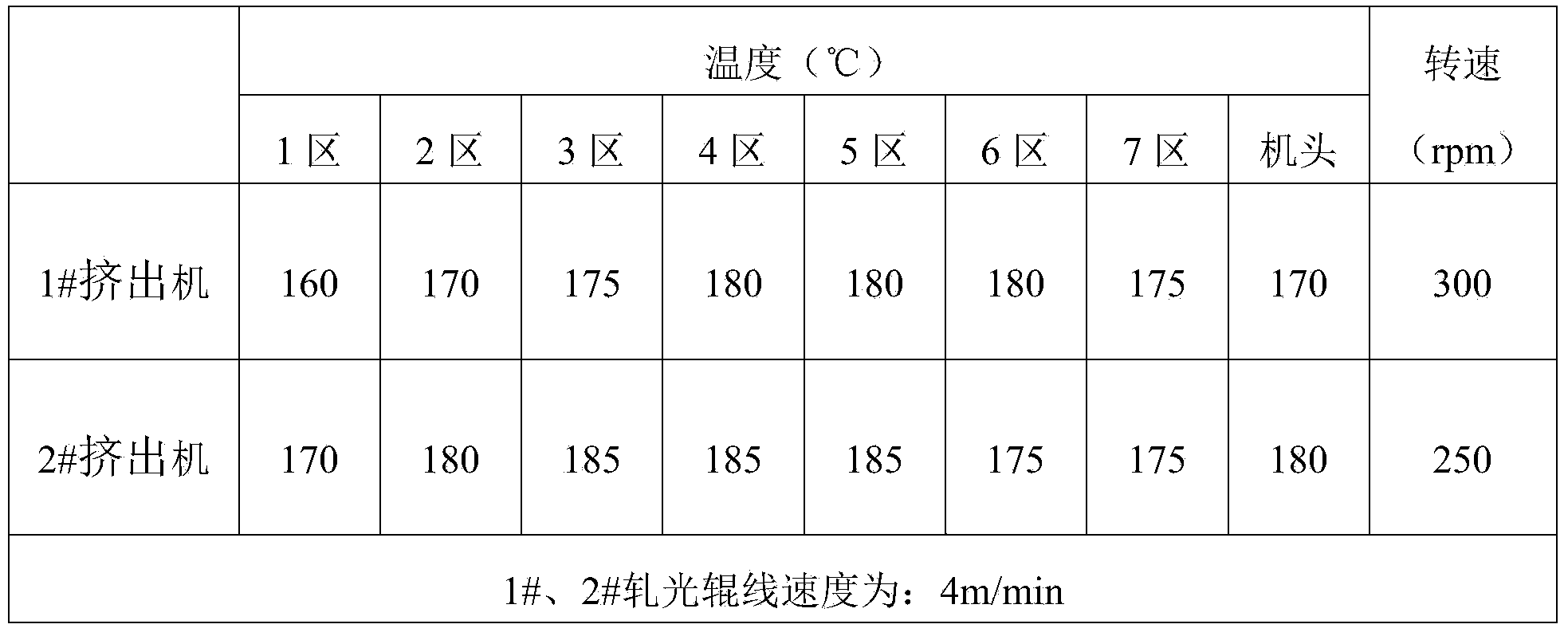

High-performance thermoplastic polyolefin waterproof coiled material with high scrap rubber powder doping amount

ActiveCN104260504AWide variety of sourcesLow priceSynthetic resin layered productsConstructions elementsThermoplasticPolymer science

The invention relates to a high-performance thermoplastic polyolefin waterproof coiled material with a high scrap rubber powder doping amount. The high-performance thermoplastic polyolefin waterproof coiled material is formed by compounding an upper surface thermoplastic polyolefin (TPO) coiled material layer, an intermediate fiber fabric enhancement layer and a lower surface scarp rubber powder-based thermoplastic elastomer (WRTPE) coiled material layer. The composite waterproof coiled material disclosed by the invention is high in tensile strength and high in breakage ductility; all the coiled material layers are tightly combined, and all properties are higher than the indexes of enhancement coiled materials in a fabric GB 27789-2011; the composite coiled material is convenient to construct, and the cost of the composite coiled material is lowered by 20-30 percent when compared with the cost of a TPO enhanced coiled material with the same thickness; the high-performance thermoplastic polyolefin waterproof coiled material has a wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Basic flux cored wire with excellent weldability

InactiveUS6713723B2Improve crack resistanceLow toughnessWelding/cutting media/materialsSoldering mediaCrack resistanceShielding gas

Disclosed is a basic flux cored wire having a mild steel or an alloy steel sheath filled with flux, characterized in that the flux essentially consists of, with respect to the total weight of the wire: 0.3 to 3.0% Ti and Ti oxide (TiO2-converted value); 1.0 to 2.5% Si and Si oxide (SiO2-converted value); 0.1 to 1.5% Mg and Mg oxide (MgO-converted value); 1.5 to 4.0% Mn and Mn oxide (MnO-converted value); 0.2 to 1.5% Al and Al oxide (Al2O3-converted value); 0.1 to 1.0% Zr and Zr oxide (ZrO2-converted value); 0.2 to 3.5% CaF2; and 0.01 to 0.5% K2O, with the proviso that the components satisfy the basicity of 0.5 to 4.5 in the basicity equation (1) defined as B=(CaF2+MgO+MnO+K2O) / (TiO2+SiO2+Al2O3+ZrO2). The basic flux cored wire of the present invention is excellent in crack resistance and low temperature toughness, and exhibits excellent welding workability in all welding positions, ensuring an improvement in the efficiency of welding work. Furthermore, the basic flux cored wire according to the present invention exhibits excellent welding workability even under a shield gas of 100% CO2.

Owner:KISWEL LTD

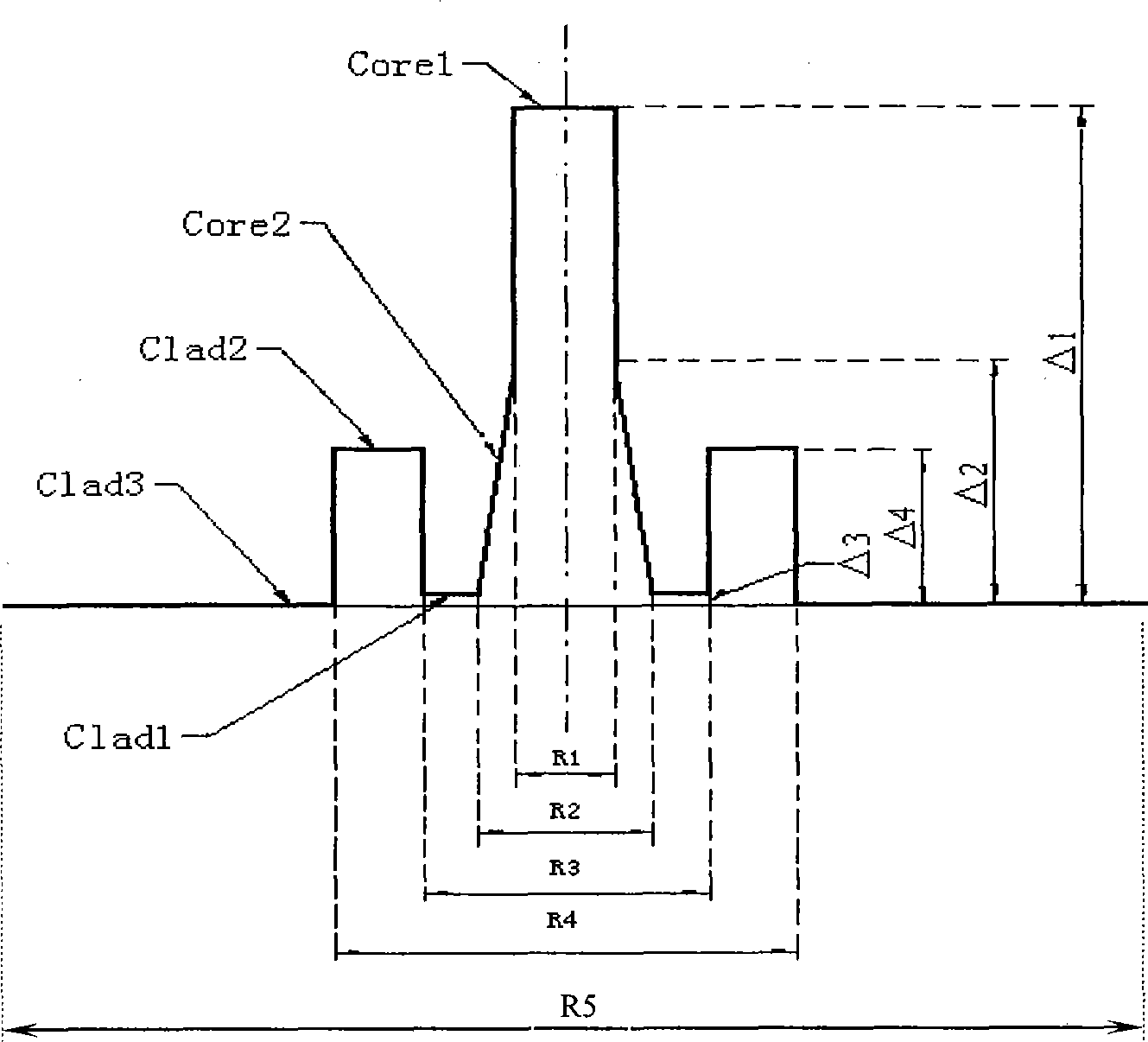

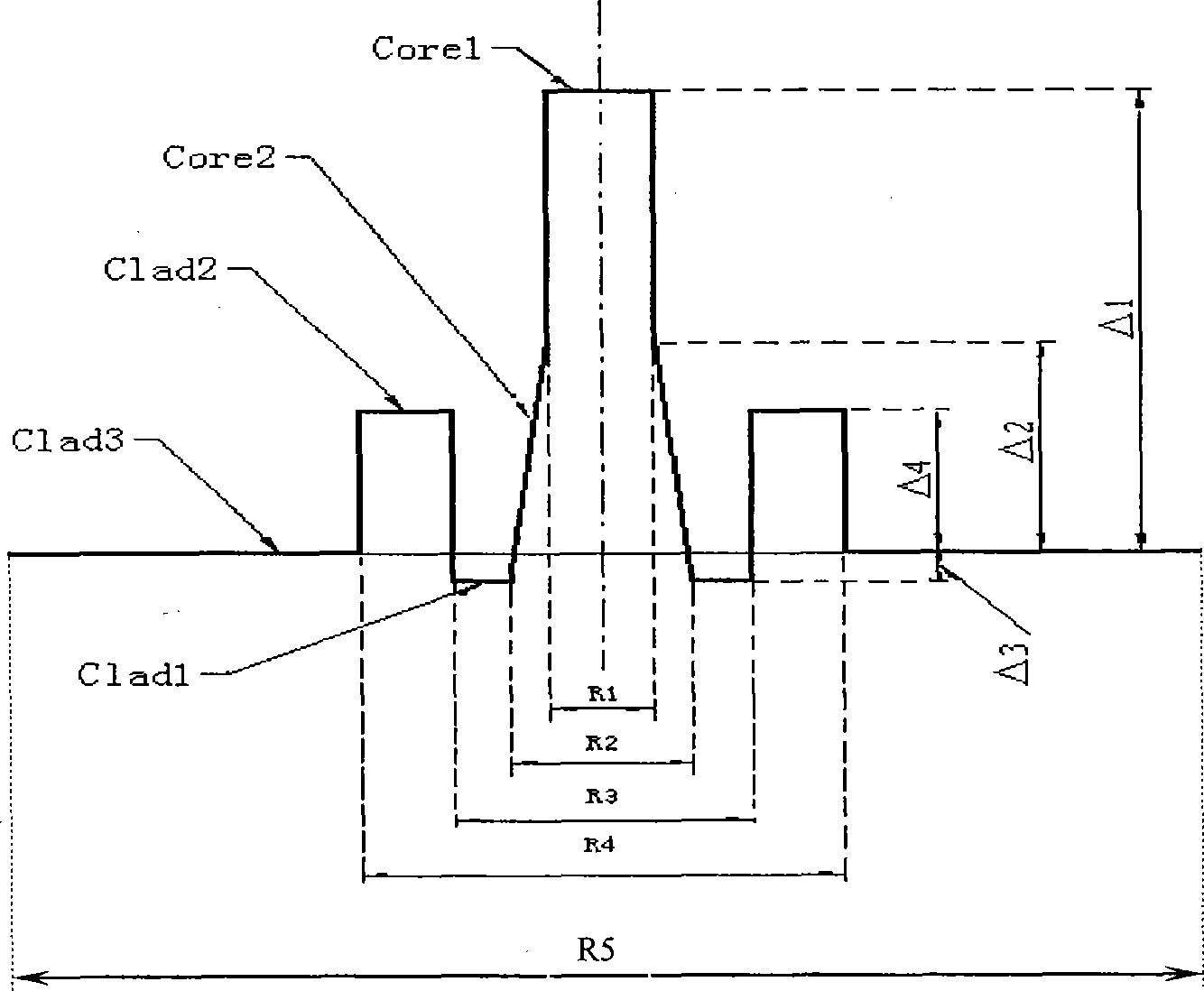

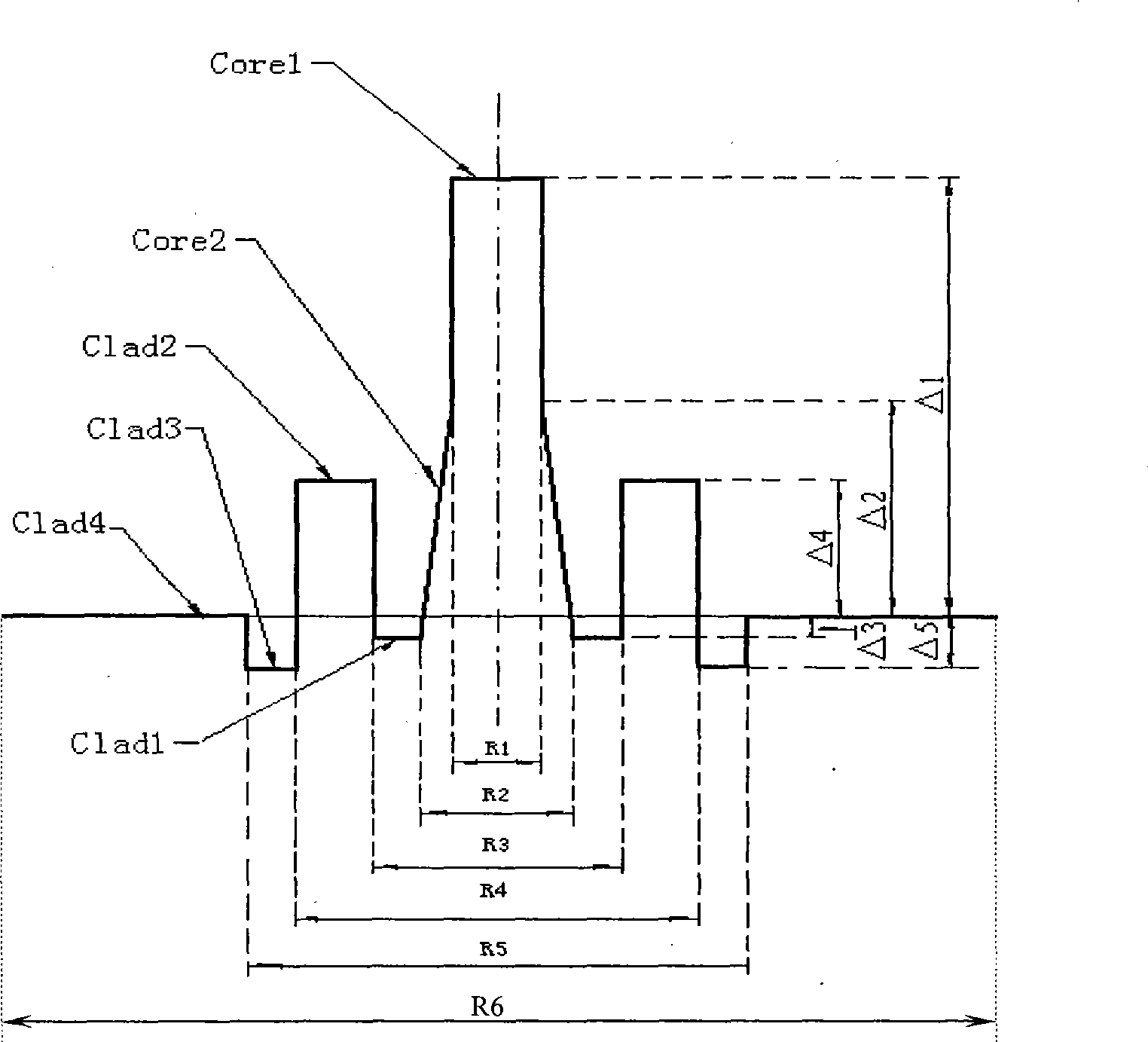

Improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution

ActiveCN101446663ASimple structureEasy to getOptical fibre with multilayer core/claddingOptical waveguide light guideColor effectPolarization mode dispersion

The invention provides an improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution, comprising an optical fiber core layer, and a cladding covered on the optical fiber core layer; wherein, the optical fiber core layer comprises an internal core layer and an external core layer enclosing the internal core, both of which have different refractive indexes; the refractive index of the external core layer is gradually distributed; the cladding comprises an internal cladding, a ring-core cladding and an external cladding which are sequentially arranged from interior to exterior and have different refractive indexes; the external cladding layer is a pure SiO2 glass layer; the refractive index distribution of the optical fiber core layer meets the formula that n1 is more than n2 which is more than nc; the refractive index distribution of the cladding meets the formula that n4 is more than n3 which is more than nc or n4 is more than nc which is more than n3. The improved nonzero dispersion-shifted single-mode optical fiber has low nonlinear color-effect characteristic (namely large effective area), optimum dispersion and low dispersion efficiency, effectively solves the nonlinearity problem and polarization mode dispersion problem of high-speed communication, reduces the dispersion management cost and has low fusing loss, thus being applicable to large-capacity high-speed long-distance transmission system.

Owner:HANGZHOU FUTONG COMM TECH CO LTD +1

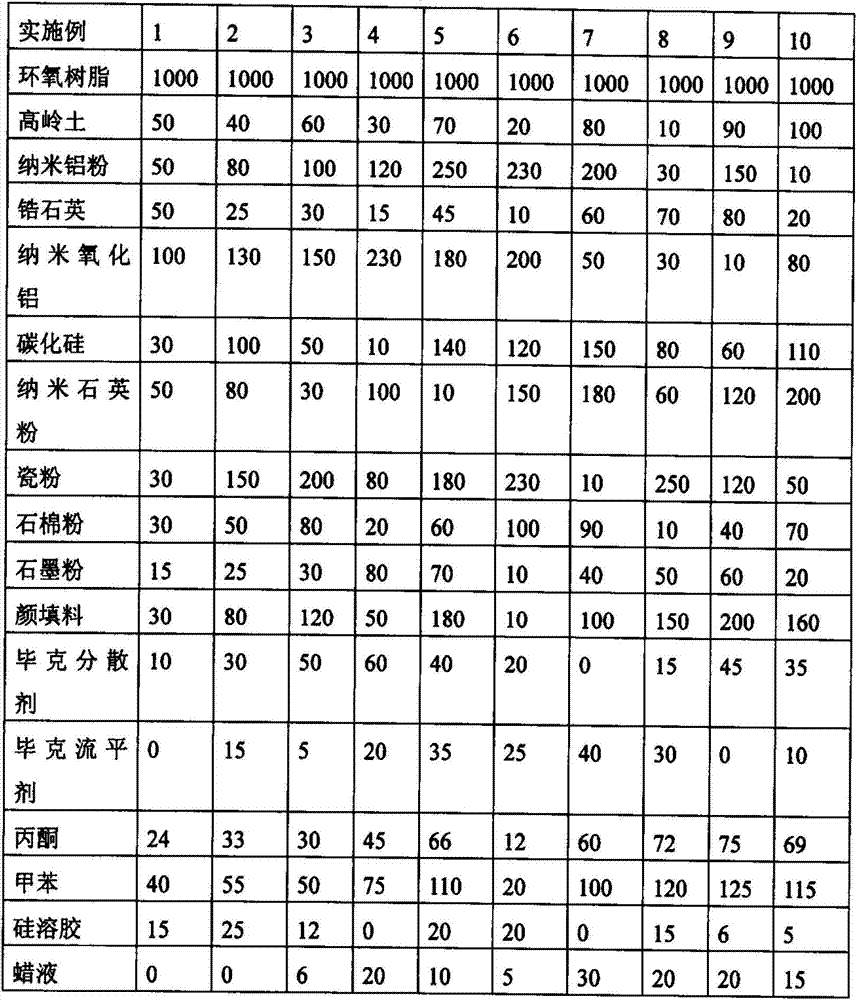

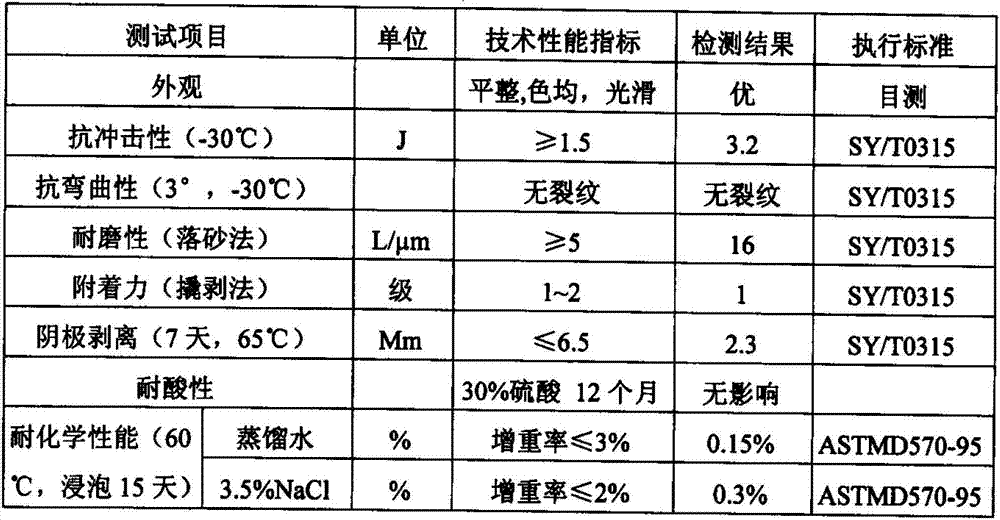

Manufacturing method of metal ceramic anticorrosive paint

ActiveCN103589273AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNano al2o3

A metal ceramic anticorrosive paint mainly includes kaolin, nanometer aluminium powder, nano alumina, silicon carbide, nano quartz powder, ceramic powder, asbestos powder, graphite powder, a pigment, a filler, epoxy resin, an additive and a mixed organic solvent. The solid powders are subjected to nano ultrafine treatment to reach a granularity of 20-200 nm. The paint provided by the invention is a single-component paint, which is simple in manufacturing process, economical and environment-friendly. The coating of the paint does not require a primer and can be used alone without adding special finish. The coating has excellent wear resistance, corrosion resistance, impact resistance, stability, strong adhesion, compactness and stability, and can effectively prevent erosion by acid, alkali, salt and seawater. In addition, the paint can be widely applied to oil pipeline, oil storage tank, chemical equipment, ships, bridges, offshore platforms and other steel structure buildings.

Owner:SHANGHAI JIANYE TECH ENG

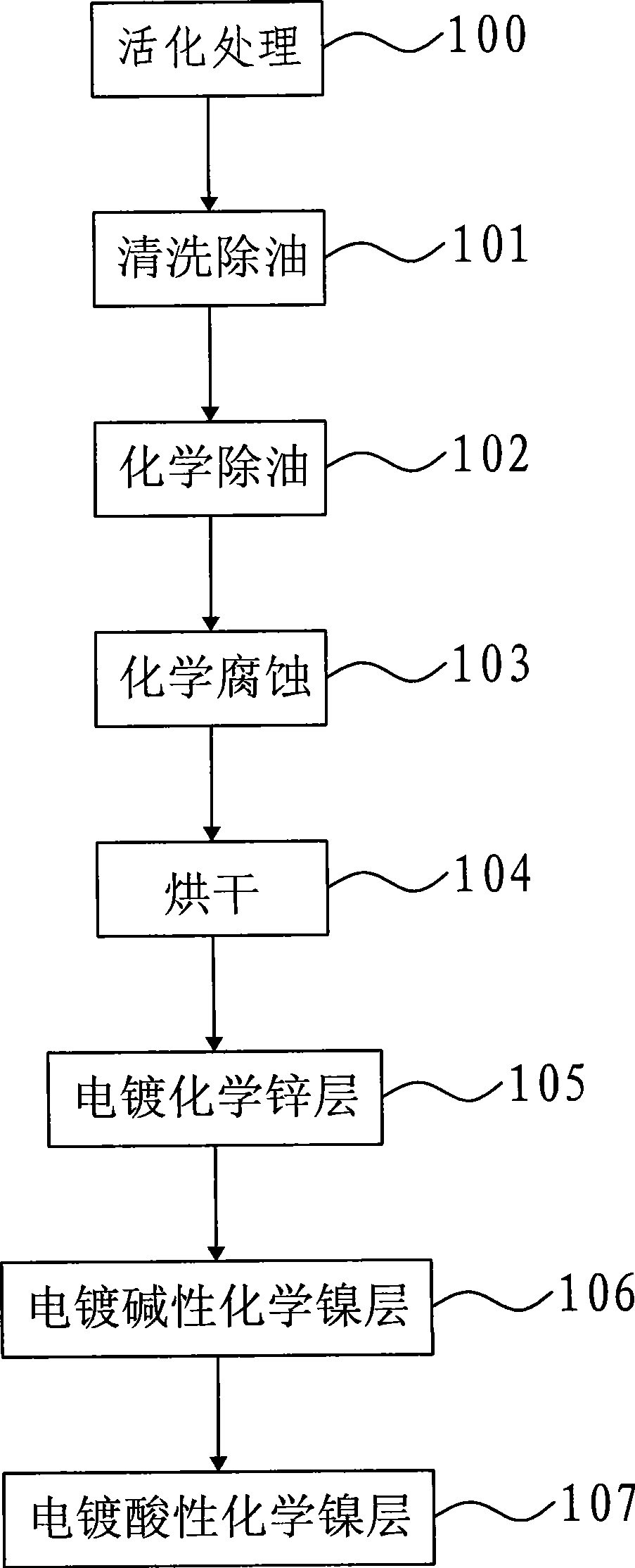

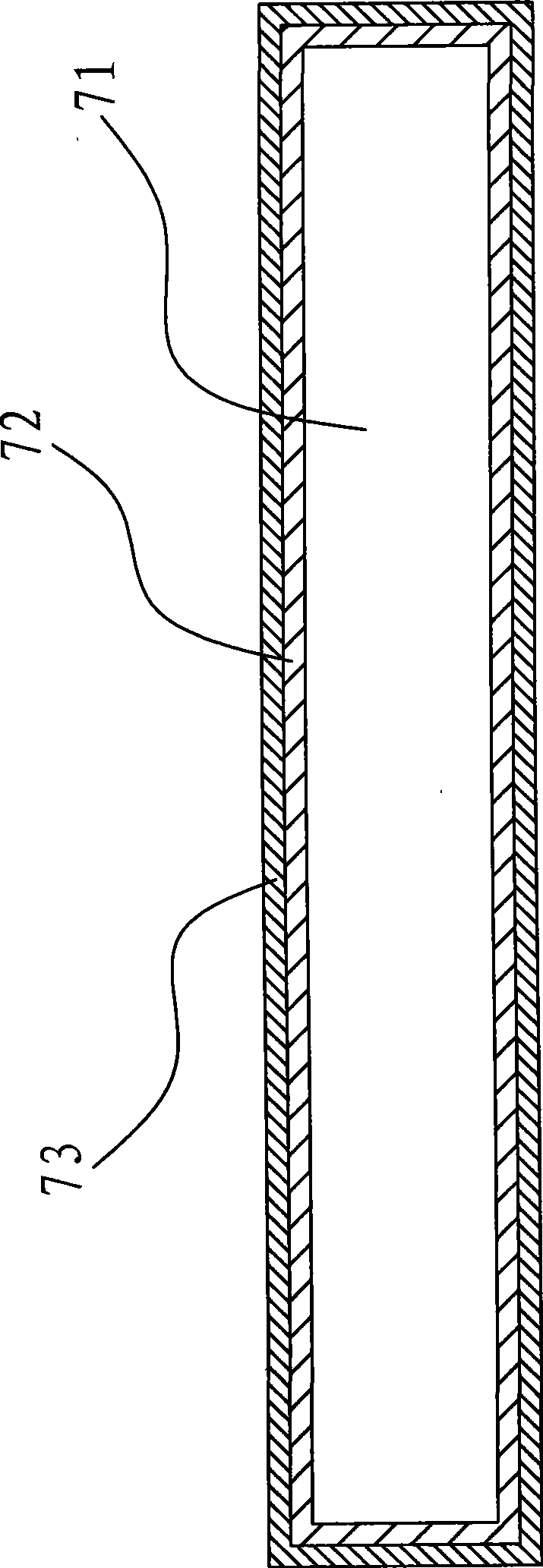

High power LED lamp heat conducting and heat radiating device, heat conducting base and producing technique

InactiveCN101509650AGood weldabilityGood wear resistancePoint-like light sourceSemiconductor/solid-state device detailsZincHardness

The invention discloses a heat-conduction and heat-dissipation device for a large-power LED luminaire, a heat-conduction base and a preparation process. The invention provides a graphite heat-conduction base which comprises a graphite product; the surface of the graphite product is electroplated by a chemical zinc layer; and the surface of the chemical zinc layer is electroplated by a chemical nickel layer. When the graphite heat-conduction base is being produced or applied, the chemical nickel layer of the outermost layer can protect the surface of the graphite product, thus leading the graphite product not easy to be damaged by pressure or abraded. The invention also provides a heat-conduction and heat-dissipation device for the large-power LED luminaire, comprising the graphite heat-conduction base and a heat dissipation device; the graphite heat-conduction base is fixedly arranged on the top end of the heat-conduction substrate of the large-power LED luminaire; and the heat dissipation device is fixedly arranged on the top end of the graphite heat-conduction base. The heat-conduction and heat-dissipation device for the large-power LED luminaire has the advantages of small volume, light weight, low cost, good heat-dissipation effect, good welding performance, good wearability, higher hardness, high electric-conduction and heat-conduction and the like.

Owner:DONGGUAN XIANGLONG ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com