High-strength cold-rolled steel sheet excellent in coating film adhesion

a cold-rolled steel sheet, excellent technology, applied in the direction of heat treatment apparatus, furnaces, manufacturing tools, etc., can solve the problems of poor chemical treatability of steel sheets, cracks, adverse affecting ductility, etc., to achieve good chemical treatability, good weldability, good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0090] The invention will be described in more detail with reference to the following examples, which are not intended to restrict the scope thereof, and various changes and modifications may be made in the invention without departing from the spirit and scope thereof.

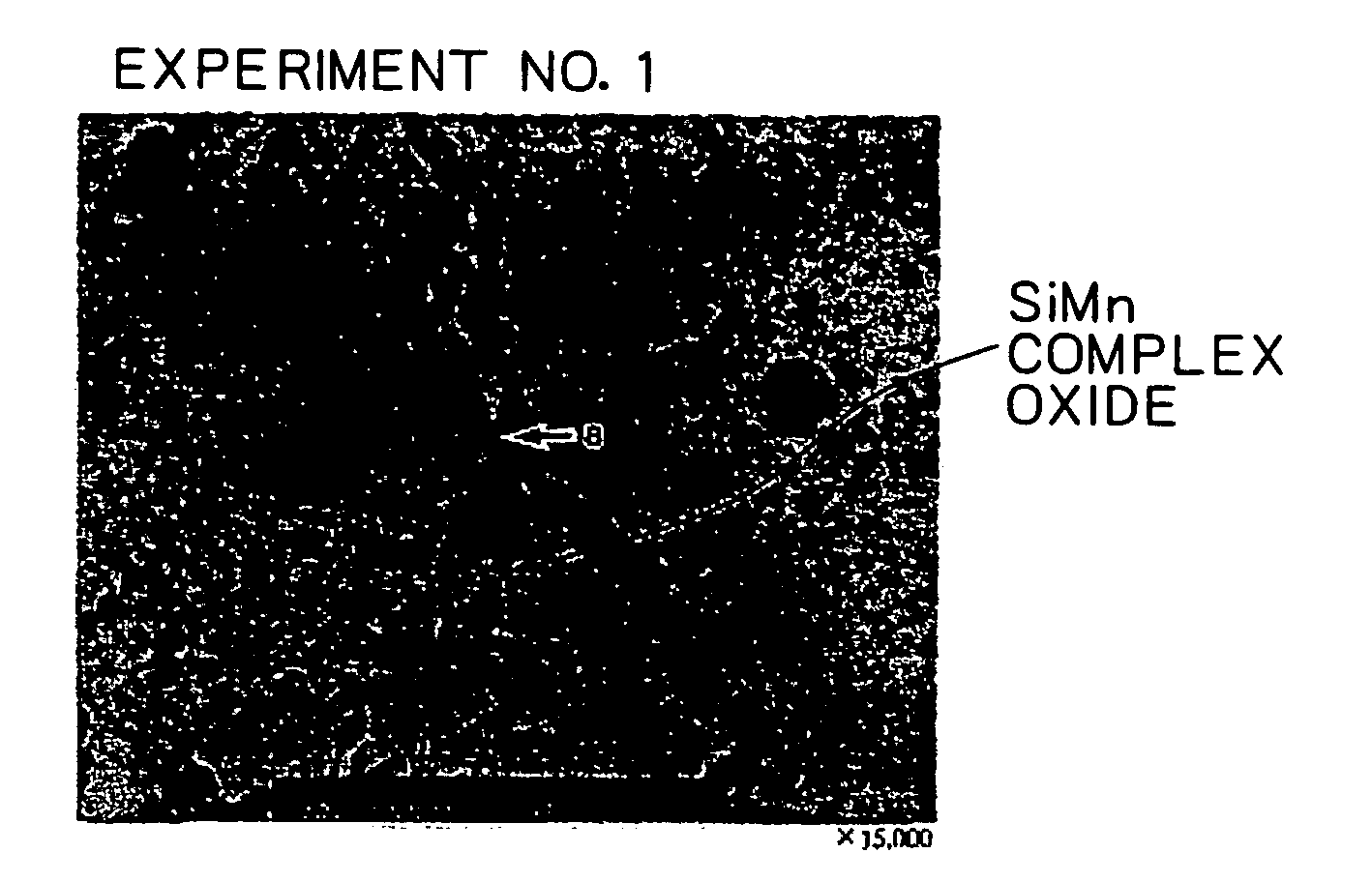

[0091] In each example, a steel with the chemical composition shown in Table 1 was prepared by melting, and the resulting steel was cast into a slab, which underwent hot rolling, followed by pickling. Winding and pickling were performed under the conditions shown in Tables 2 and 3. Pickling involved an aqueous solution of hydrochloric acid (1 to 18 mass %) at 70 to 90° C. Pickling was followed by cold rolling, which gave a 1.4 mm thick steel sheet.

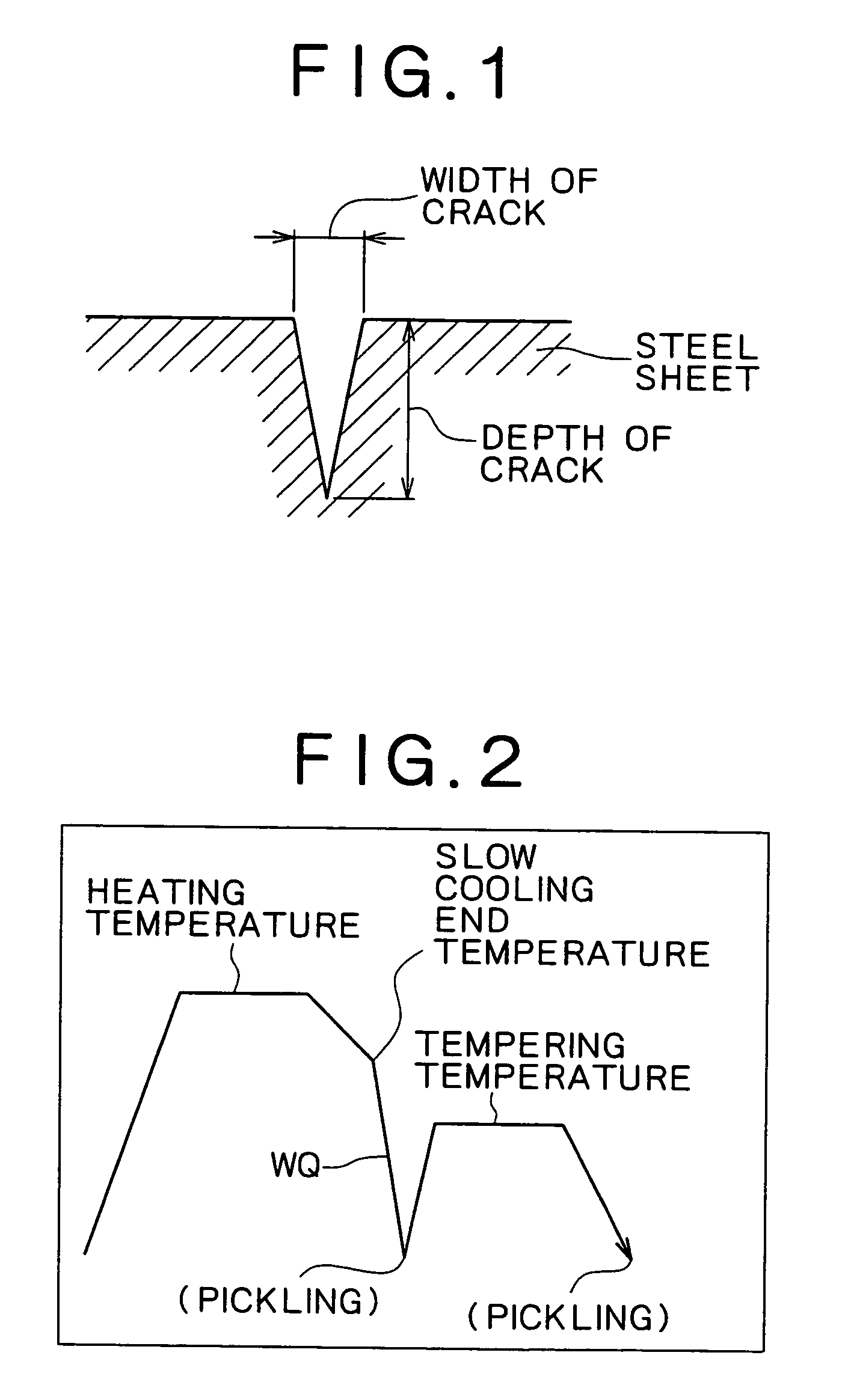

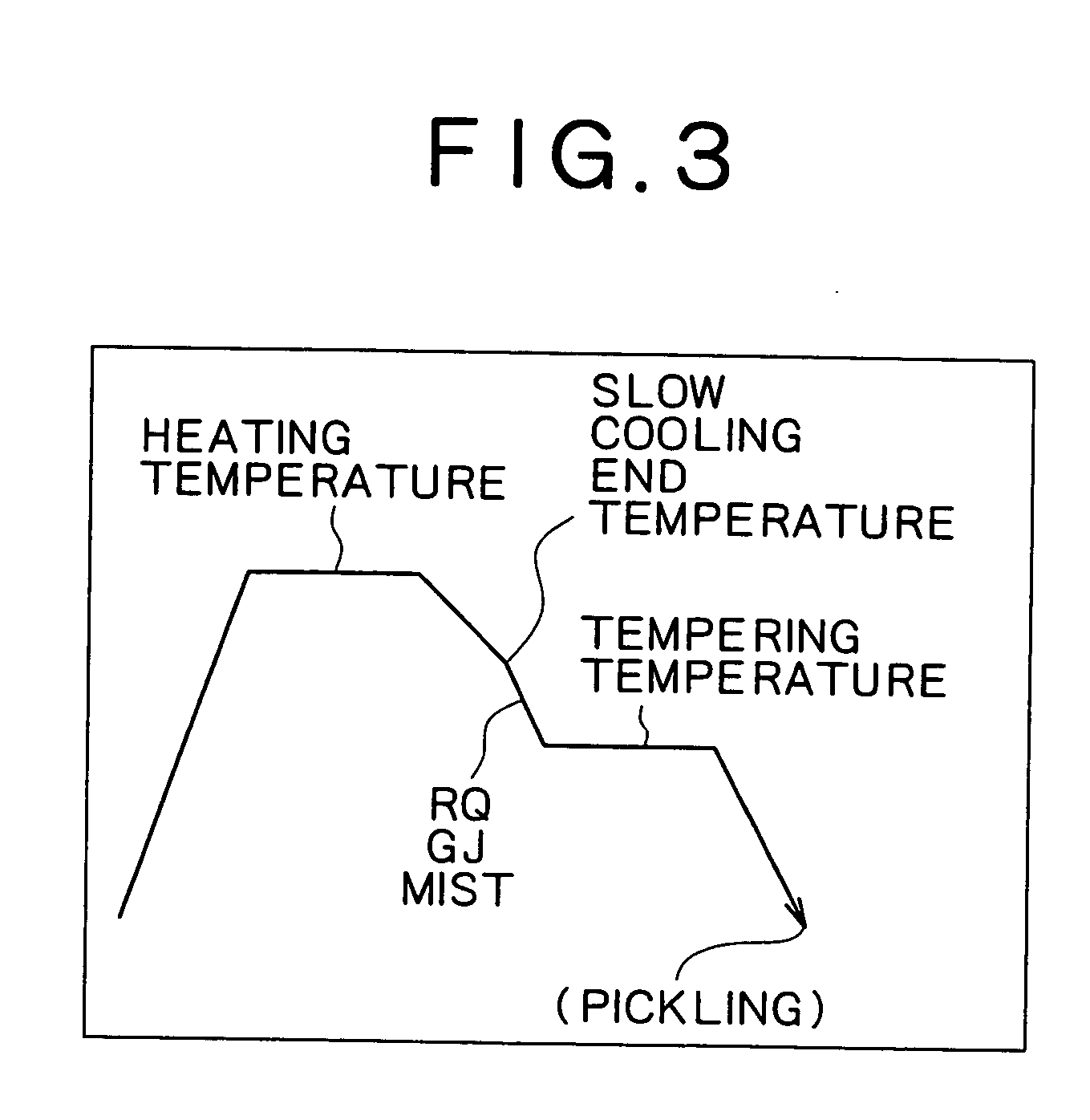

[0092] The steel sheet underwent continuous annealing by either of the processes shown in FIGS. 2 and 3. The process shown in FIG. 2 involves cooling with water quenching (WQ) that follows soaking and slow cooling. The process shown in FIG. 3 involves cooling with mist, gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com