Aluminium alloy profile for building template, and preparation method thereof

A technology for aluminum alloy profiles and building formwork, which is applied in the field of aluminum alloy profiles for building formwork and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

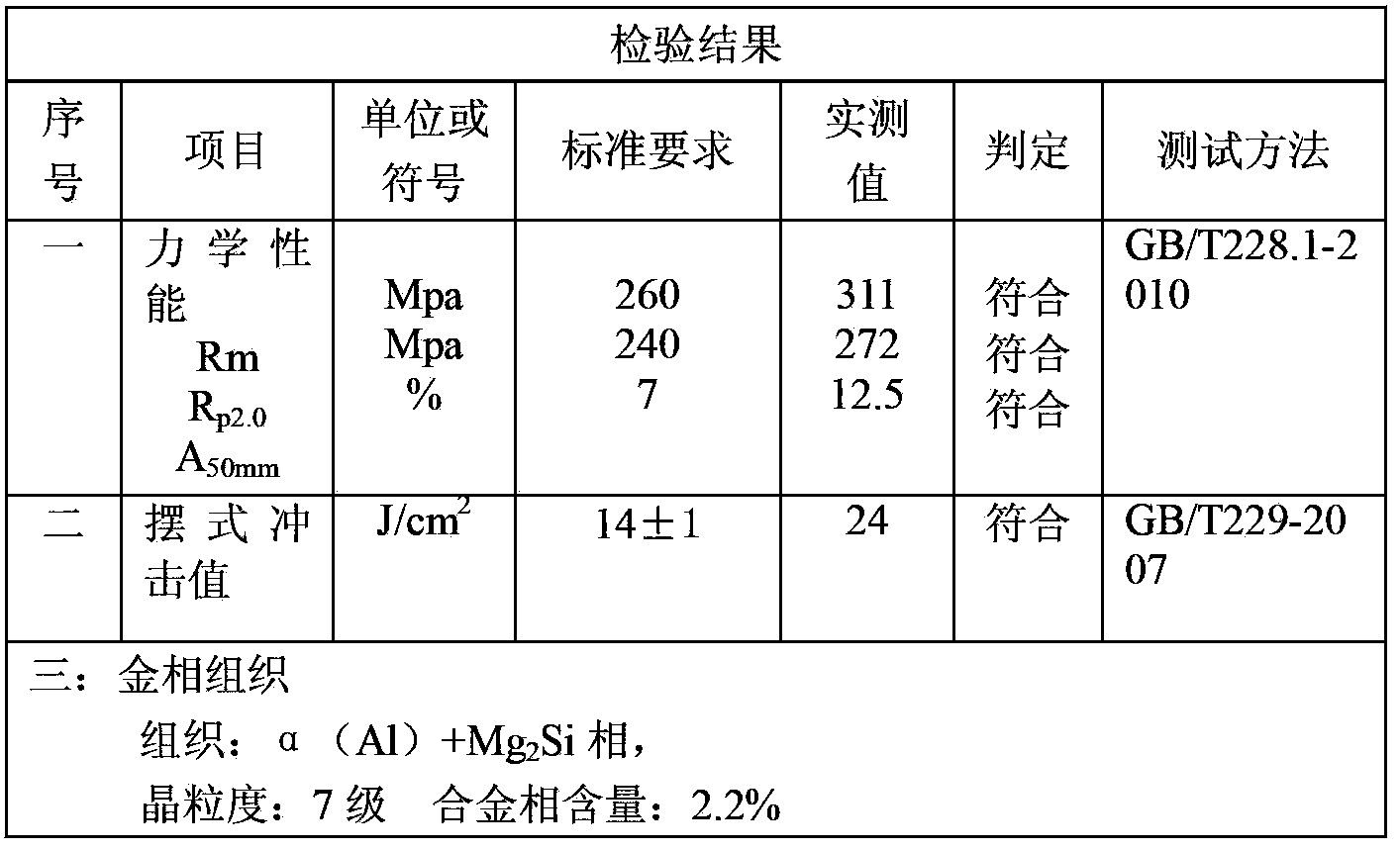

specific Embodiment 1

[0037] A preparation method of aluminum alloy profiles for building templates:

[0038] 1) Prepare the aluminum alloy of the present invention according to the conventional method, the weight percentage of each component is 100%, and the weight percentage is (sampled and analyzed in the casting flow plate for chemical composition): 0.92% magnesium, 0.63% silicon, 0.19% copper, 0.05% manganese, 0.05% zirconium, 0.04% chromium, 0.008% titanium, 0.19% iron, 0.09% zinc, and the balance of aluminum is cast into an aluminum alloy ingot, and the balance is aluminum in aluminum Contains 0.15% of impurities, which are the same as those contained in existing aluminum, and the ingot is a cast rod with a diameter of Φ260mm;

[0039] 2) The aluminum alloy ingot is subjected to high-temperature homogenization treatment at 560°C, heated for 7 hours, then cooled by strong wind or water mist to 150°C, then moved to the atmosphere and continued to air-cool to room temperature;

[0040] 3) Cut th...

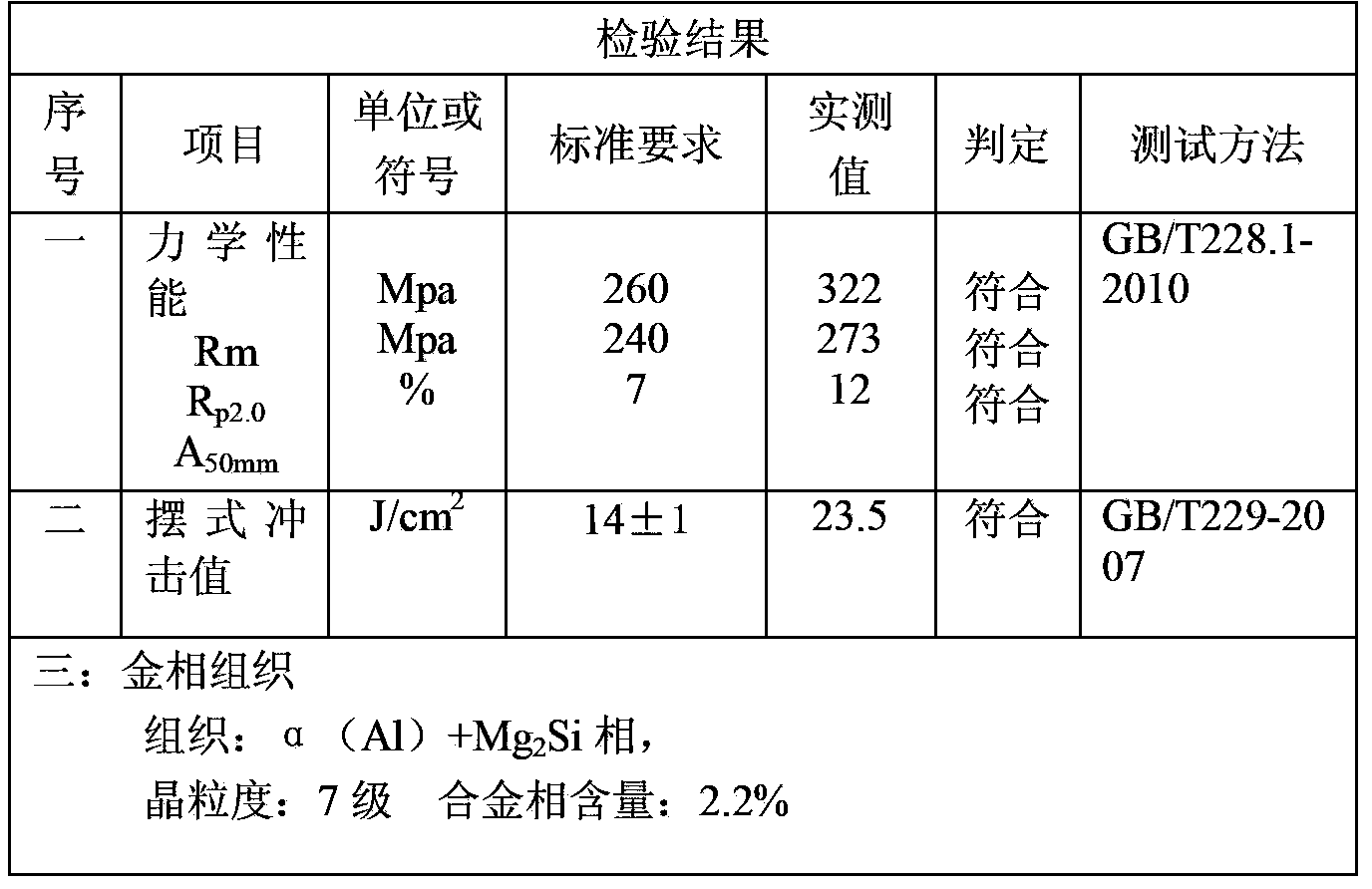

specific Embodiment 2

[0045] A preparation method of aluminum alloy profiles for building templates:

[0046] 1) Prepare the aluminum alloy of the present invention according to the conventional method, the total weight percentage of each component is 100%, and the weight percentage is (sampling and analyzing the chemical composition in the casting flow plate): magnesium 0.87%, silicon 0.60%, copper 0.17%, 0.05% manganese, 0.04% zirconium, 0.05% chromium, 0.007% titanium, 0.17% iron, 0.05% zinc, and the balance of aluminum is cast into an aluminum alloy ingot, and the balance is aluminum in aluminum Contains 0.1% impurities, which are the same as those contained in existing aluminum, and the cast ingot is a cast rod with a diameter of Φ260mm;

[0047] 2) The aluminum alloy ingot is subjected to high-temperature homogenization treatment at 560°C, heated for 9 hours, then cooled by strong wind or water mist to 150°C, then moved to the atmosphere and continued to air-cool to room temperature;

[0048...

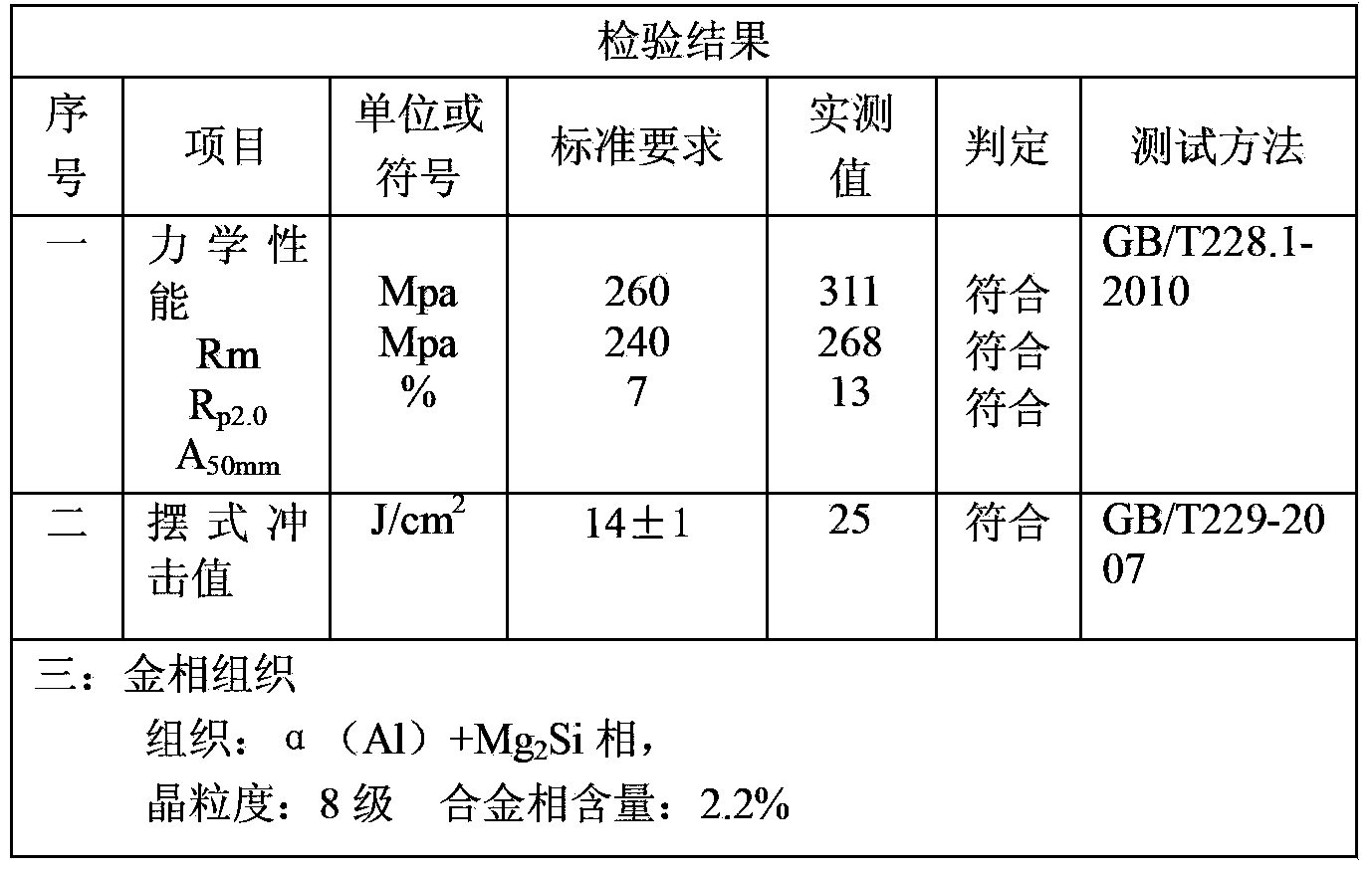

specific Embodiment 3

[0053] A preparation method of aluminum alloy profiles for building templates:

[0054] 1) Prepare the aluminum alloy of the present invention according to the conventional method, the total weight percentage of each component is 100%, and the weight percentage is (sampling and analyzing the chemical composition in the casting flow plate): magnesium 0.90%, silicon 0.62%, copper 0.16%, 0.05% manganese, 0.08% zirconium, 0.008% titanium, 0.02% iron, 0.03% zinc, and the aluminum alloy composition with the balance of aluminum is cast into an aluminum alloy ingot, and the balance is that the aluminum in the aluminum contains 0.08% of impurities , and the impurities contained in the existing aluminum are the same, and the ingot is a cast rod with a diameter of Φ260mm;

[0055] 2) The aluminum alloy ingot is subjected to high-temperature homogenization treatment at 560°C, heated for 9 hours, then cooled by strong wind or water mist to 150°C, then moved to the atmosphere and continued ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com