A battery casting and welding mold

A technology of casting and welding molds and batteries, which is applied in the field of batteries, can solve problems such as mold breakage, and achieve the effect of making up for the loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

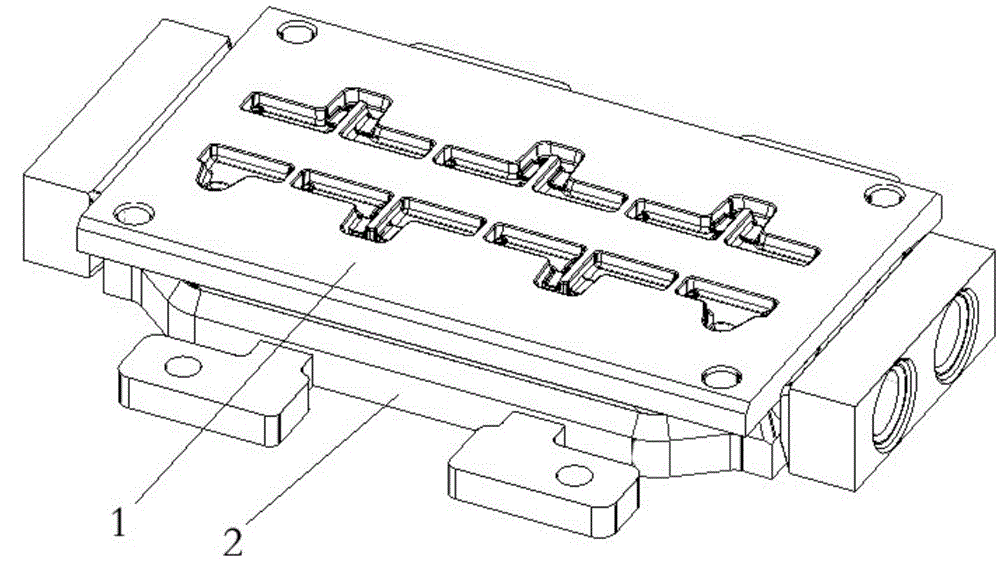

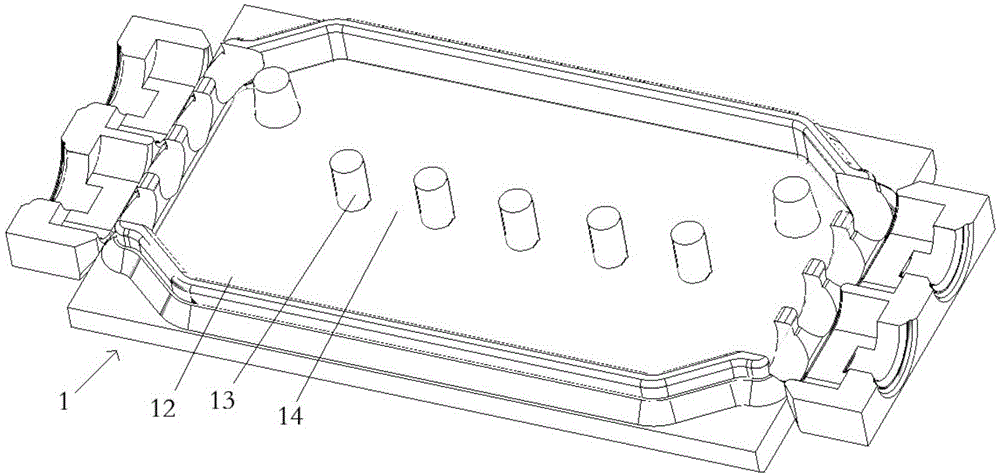

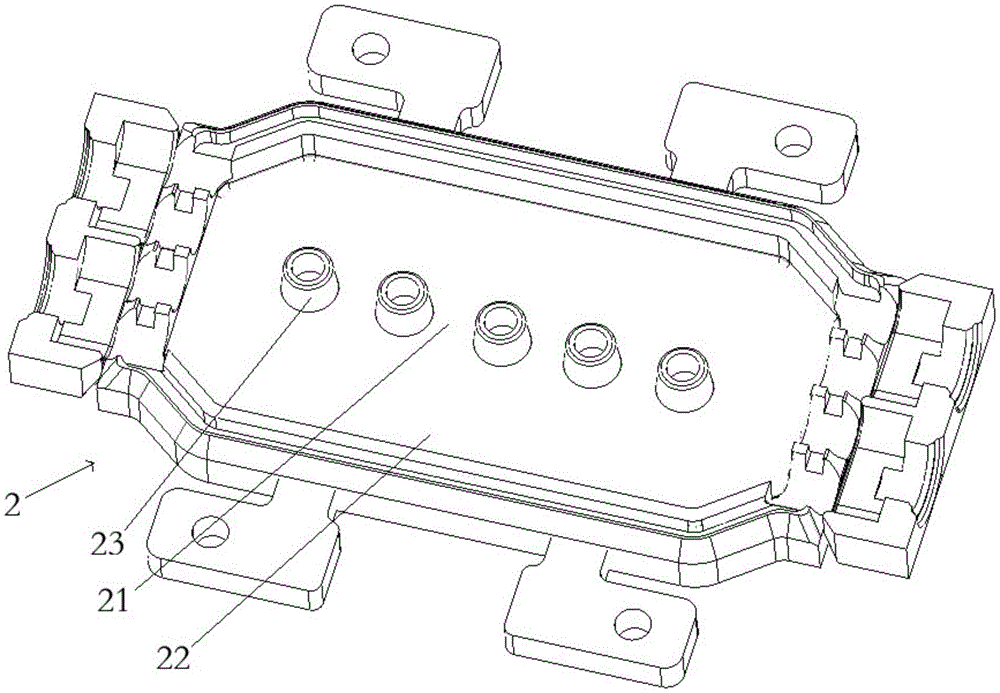

[0014] Figure 1-4 One embodiment of the invention is shown.

[0015] A battery casting and welding mold, including an upper plate and a lower plate, the upper surface of the upper plate is provided with a number of forming units for casting collectors, the upper plate can be buckled with the lower plate, and the upper plate and the lower plate are buckled together and then put up The lower surface of the plate and the upper surface of the lower plate form an inner cavity; an upper reinforcement part is provided on both sides of the upper plate, and the upper reinforcement part and the upper plate are integrally structured, the lower surface of the upper plate is smooth, and the two sides of the lower plate are respectively There is a lower reinforcing part, the lower reinforcing part and the lower plate are integrally structured, the upper surface of the lower plate is smooth; the lower surface of the upper plate is provided with a number of mounting columns, and the upper su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com