A kind of permeable foam concrete

A foam concrete, water permeability technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

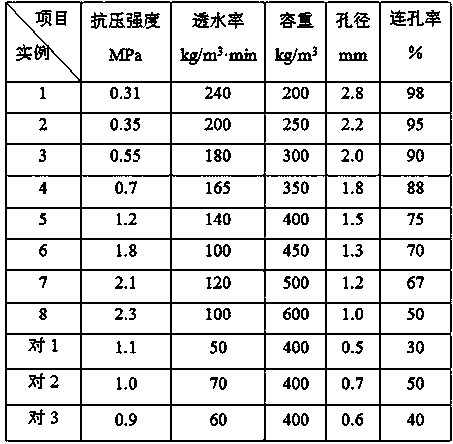

Examples

Embodiment 1

[0024] A water-permeable foam concrete is prepared from the following raw materials in parts by weight: 160 parts of cement, 0.2 parts of a foaming agent, 2 parts of a water reducing agent, 1 part of an expanding agent, 1 part of a plasticizer and 90 parts of water.

[0025] The water-cement ratio of the permeable foam concrete is 0.56.

[0026] The cement is PO42.5 grade cement.

[0027] The water reducer is sodium lignosulfonate.

[0028] The swelling agent is ammonium nitrate.

[0029] Described plasticizer is phthalate.

[0030] The foaming agent comprises the following raw materials in parts by weight: 200 parts of foaming agent, 20 parts of foam stabilizer, 3 parts of flocculant, 1 part of thickener, 1.5 parts of preservative and 420 parts of water.

[0031] The foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate AES; the foam stabilizer is coconut oil fatty acid diethanolamide 6501; the flocculant is polyethylene oxide; the thickener is hydroxypropyl ...

Embodiment 2

[0038] A water-permeable foam concrete is prepared from the following raw materials in parts by weight: 190 parts of cement, 0.25 parts of foaming agent, 2.5 parts of water reducing agent, 2 parts of expanding agent, 2 parts of plasticizer and 100 parts of water.

[0039] The water-cement ratio of the permeable foam concrete is 0.53.

[0040] Described cement is PO325 grade cement.

[0041] The water reducing agent is β-naphthalenesulfonate formaldehyde condensation product.

[0042] Described bulking agent is ammonium bicarbonate.

[0043] Described plasticizer is terephthalate.

[0044] The foaming agent comprises the following raw materials in parts by weight: 210 parts of foaming agent, 23 parts of foam stabilizer, 3.5 parts of flocculant, 1.5 parts of thickener, 2 parts of preservative and 430 parts of water.

[0045] The foaming agent is sodium lauryl sulfate K12; the foam stabilizer is coconut oil fatty acid diethanolamide 6501; the flocculant is polyacrylamide; and ...

Embodiment 3

[0051] A water-permeable foam concrete is made from the following raw materials in parts by weight: 200 parts of cement, 0.28 parts of foaming agent, 2.6 parts of water reducing agent, 2.5 parts of expanding agent, 2.5 parts of plasticizer and 100 parts of water.

[0052] The water-cement ratio of the permeable foam concrete is 0.5.

[0053] The cement is PO42.5 grade cement.

[0054] The water reducer is a water-soluble sulfonated acetone-formaldehyde polycondensate.

[0055] The swelling agent is ammonium nitrate.

[0056] Described plasticizer is benzoate.

[0057] The foaming agent comprises the following raw materials in parts by weight: 220 parts of foaming agent, 25 parts of foam stabilizer, 5 parts of flocculant, 1.5 parts of thickener, 2 parts of preservative and 450 parts of water.

[0058] The foaming agent is fatty alcohol polyoxyethylene ether sodium sulfate AES; the foam stabilizer is coconut oil fatty acid diethanolamide 6501; the flocculant is polyethylene oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com