Macromolecular gypsum retarder and preparation method and application thereof

A gypsum retarder and polymer technology, which is applied in the field of polymer gypsum retarder and its preparation, can solve the problems of gypsum strength reduction and achieve the effects of reducing growth rate, reducing strength loss and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Present embodiment provides a kind of polymer gypsum retarder, its preparation method comprises:

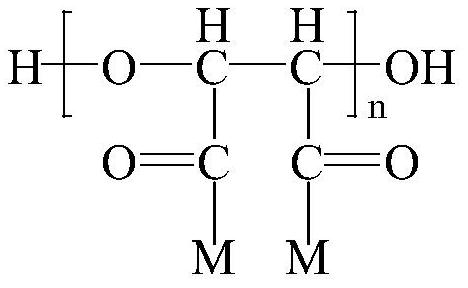

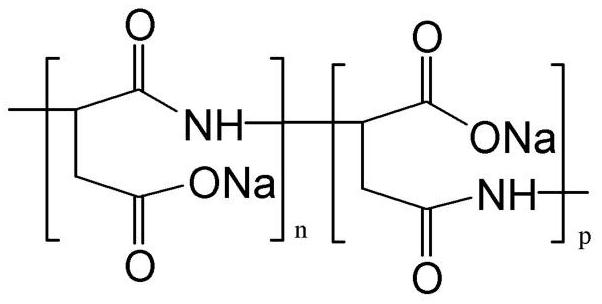

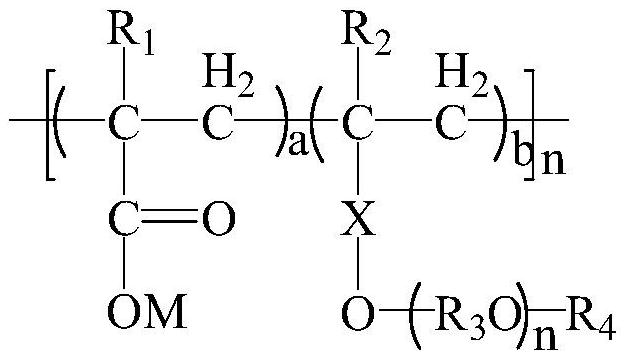

[0057] Put 60 parts of polyepoxysuccinic acid, 20 parts of polyaspartic acid, and 20 parts of polycarboxylate water-reducer, all according to the weight of dry matter, into a mixer, mix well, and spray dry to make powder. A polymer gypsum retarder is obtained.

[0058] Add the retarder prepared in this embodiment to the building gypsum, the amount of the retarder added is 0.01% of the total weight of the gypsum, and the setting time and strength performance tests are carried out under the water consumption of standard consistency.

Embodiment 2

[0064] Present embodiment provides a kind of polymer gypsum retarder, its preparation method comprises:

[0065] Put 20 parts of polyepoxysuccinic acid, 40 parts of polyaspartic acid, and 40 parts of polycarboxylate water reducer, all according to the weight of dry matter, into a mixer, mix well, and spray dry to make powder. A polymer gypsum retarder is obtained.

[0066] Add the retarder prepared in this embodiment to the building gypsum, the amount of the retarder added is 0.05% of the total weight of the gypsum, and the setting time and strength performance test are carried out under the water consumption of the standard consistency. plaster of construction for comparison.

[0067] Table 2 Embodiment 2 Performance Test Results Comparison

[0068]

Embodiment 3

[0070] Present embodiment provides a kind of polymer gypsum retarder, its preparation method comprises:

[0071] Put 40 parts of polyepoxysuccinic acid, 30 parts of polyaspartic acid, and 30 parts of polycarboxylate superplasticizer into a mixer according to the weight of dry matter, mix well, and spray dry to make powder. A polymer gypsum retarder is obtained.

[0072] Add the setting retarder prepared in this embodiment to building gypsum, the adding amount of retarder is 0.5% of the total weight of gypsum, and carry out setting time and strength performance test under the standard consistency water consumption, simultaneously with no adding retarder plaster of construction for comparison.

[0073] Table 3 Embodiment 3 Performance Test Results Comparison

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com