High-durability concrete product with gradient structure and preparation method thereof

A technology of concrete products and gradient structures, applied in the field of building materials, can solve the problems of unfavorable early strength, insufficient durability, easy peeling, etc., and achieve the effect of improving anti-erosion performance, improving mechanical properties, and improving anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

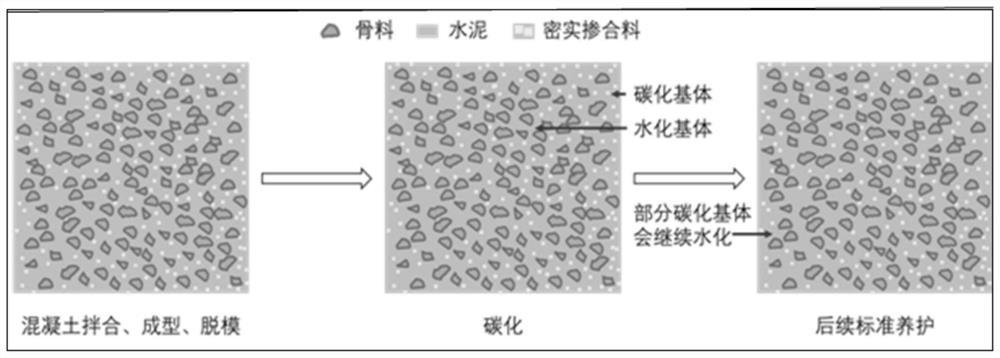

Method used

Image

Examples

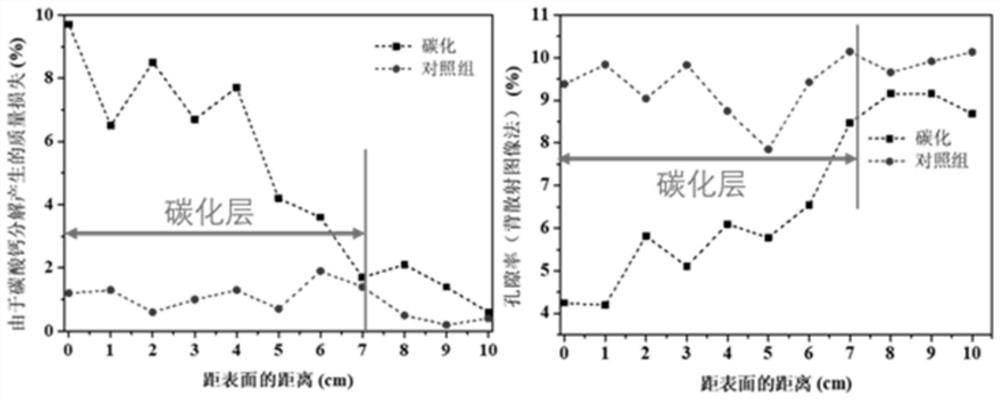

Embodiment 1

[0029] A highly durable concrete product with a gradient structure, the preparation method comprising the following steps:

[0030] (1) Select ordinary portland cement to prepare the formula of C40 concrete, use calcium olivine powder (Bretts specific surface area 6800cm 2 g -1 ) as a dense admixture to replace 15% of the cement component, according to the national standard for mixing and molding process molding, curing in a standard curing room with a humidity of >95% and a temperature of 20±2°C for 1 day to demould to obtain a concrete specimen ;

[0031] (2) Place the concrete specimen obtained in step (1) in a drying oven at 50° C. and a relative humidity of 20% to dry for 24 hours, and then place it in an autoclave to carry out carbonation curing under a carbon dioxide atmosphere. The curing conditions are temperature 10° C., The carbon dioxide concentration is 90%, the relative humidity is 70%, the carbonization curing time is 12h, and the pressure in the autoclave is ...

Embodiment 2

[0037] A highly durable concrete product with a gradient structure, the preparation method comprising the following steps:

[0038] (1) Select fly ash Portland cement to prepare C50 concrete formula, and use wollastonite powder and calcium olivine powder as a dense admixture in a mass ratio of 5:5 (the Blaine specific surface area is 5410cm 2 g -1 ) to replace 15% of the cement component, and molded according to the mixing and molding process specified in the national standard, and cured in a standard curing room with a humidity >95% and a temperature of 20±2°C for 1 day to demould to obtain a concrete specimen;

[0039](2) Place the concrete specimen obtained in step (1) in a drying oven at 50° C. and a relative humidity of 20% to dry for 24 hours, and then place it in an autoclave for carbonation curing under a carbon dioxide atmosphere. The curing conditions are 30° C., The carbon dioxide concentration is 99%, the relative humidity is 90%, the carbonization curing time is ...

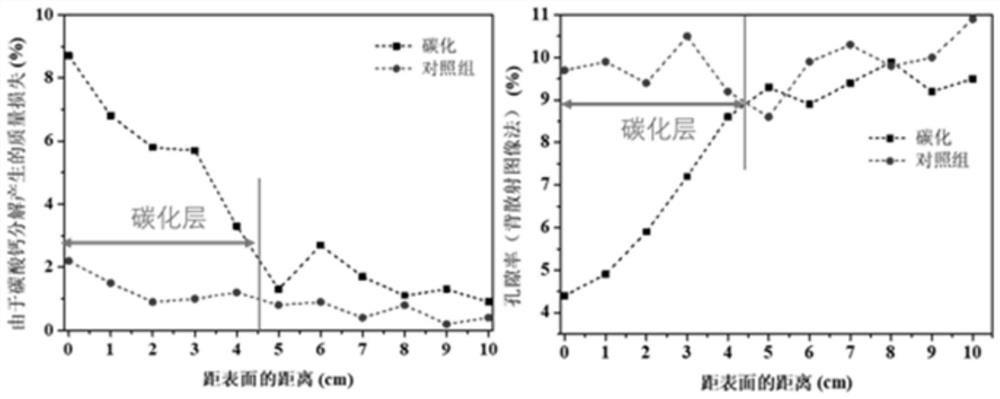

Embodiment 3

[0045] A highly durable concrete product with a gradient structure, the preparation method comprising the following steps:

[0046] (1) Select slag Portland cement to prepare C50 concrete formula, and use wollastonite powder and calcium olivine powder in a mass ratio of 2:8 as a dense admixture (the Blaine specific surface area is 5000cm 2 g -1 ) to replace 30% of the cement component, according to the national standard for mixing and molding process molding, curing in a standard curing room with humidity >95% and temperature 20±2°C for 1 day to demould to obtain concrete specimens;

[0047] (2) Place the concrete specimen obtained in step (1) in a drying oven at 50° C. and a relative humidity of 20% to dry for 24 hours, and then place it in an autoclave for carbonation curing under a carbon dioxide atmosphere. The curing conditions are 20° C., The carbon dioxide concentration is 95%, the relative humidity is 90%, the carbonization curing time is 8h, and the pressure in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com