Lithium secondary battery overcharge protection electrolyte and lithium secondary battery

A lithium secondary battery and overcharging technology, which is applied in secondary batteries, secondary battery repair/maintenance, lithium batteries, etc., can solve the problems affecting the long cycle life of the battery, the battery cannot be used continuously, and the internal resistance of the battery is increased. Achieve the effects of improving kinetic properties, reducing reactivity, and avoiding combustion and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

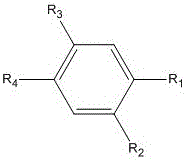

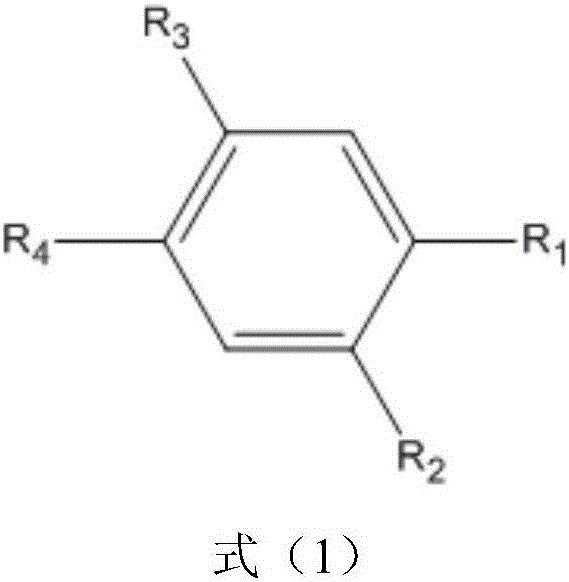

Method used

Image

Examples

Embodiment 1

[0024] Electrolyte preparation steps: In a glove box filled with argon, mix ethylene carbonate, diethyl carbonate and ethyl methyl carbonate at a mass ratio of EC: DEC: EMC = 3: 2: 5, and then add to the mixed solution Slowly add 1.0mol / L lithium hexafluorophosphate, 0.02mol / L lithium difluorophosphate and 0.02mol / L lithium bisfluorosulfonimide, and finally add 0.5wt% of tris(trimethylsilane) based on the total weight of the electrolyte Phosphoric acid ester (TMSP), 1wt% vinyl sulfate (DTD), 0.2wt% vinylene carbonate (VC) and 2wt% 2,4-difluoroanisole were stirred uniformly to obtain the lithium secondary battery of Example 1 Electrolyte.

[0025] Inject the prepared lithium secondary battery electrolyte into the fully dried silicon-carbon composite / LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 In the power battery, after the battery is placed at 45°C, formed into a high-temperature clamp, and sealed again, it is conventionally divided.

[0026] 1) Normal temperature cycle performance test: At 25℃, ...

Embodiment 2~8

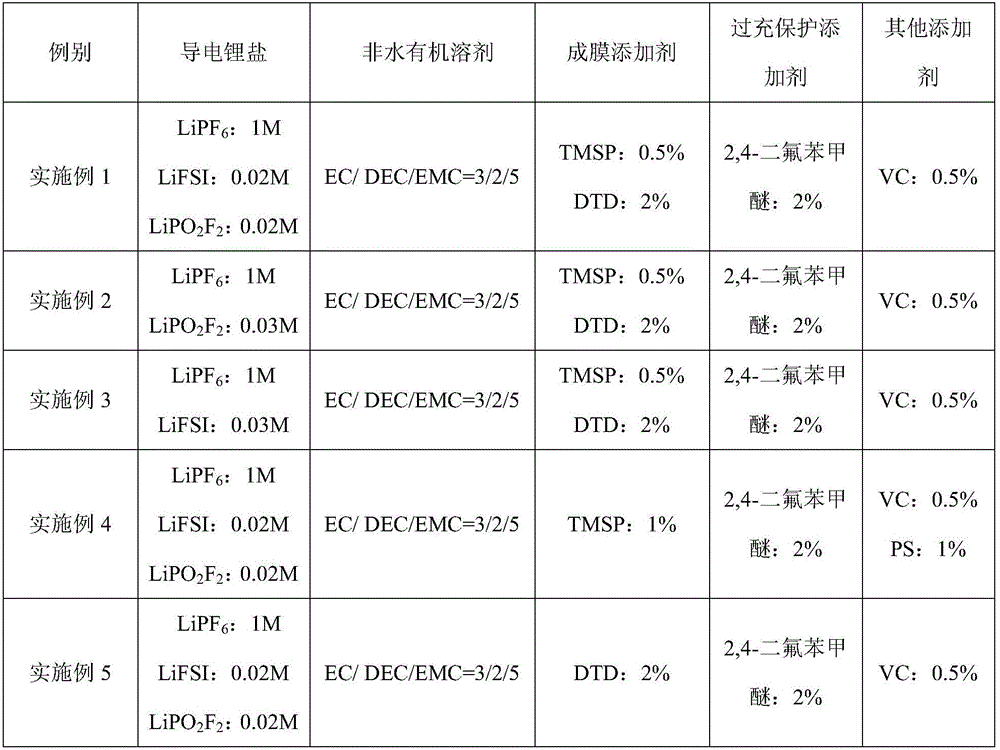

[0032] Examples 2 to 8 and Comparative Examples 1 to 4

[0033] In Examples 2 to 8 and Comparative Examples 1 to 4, except that the composition ratio of each component of the electrolyte is added as shown in Table 1, the others are the same as in Example 1. Table 1 shows the composition ratios of the electrolyte components of Examples 1-8 and Comparative Examples 1-4:

[0034]

[0035]

[0036] Table 1

[0037] In Table 1 above, the abbreviations / chemical formula corresponding names of each chemical substance are as follows:

[0038] LiPF 6 (Lithium hexafluorophosphate), LiPO 2 F 2 (Lithium difluorophosphate), LiFSI (lithium bisfluorosulfonimide), EC (ethylene carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), DMC (dimethyl carbonate), PC (Propylene carbonate), DTD (vinyl sulfate), TMSP (tris(trimethylsilane) phosphate), VC (vinylene carbonate), PS (1,3-propane sultone).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com