Electrolyte solution for improving swelling of lithium ion battery

An electrolyte solution, lithium-ion battery technology, applied in electrical components, secondary batteries, circuits, etc., can solve problems such as increased internal resistance of batteries, decreased battery charge-discharge cycle performance, etc., to reduce gas problems and achieve superior electrochemical performance. The effect of exerting and reducing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

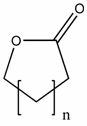

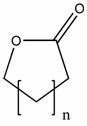

Image

Examples

Embodiment 1

[0017] Prepare the 503048 square aluminum case battery of 750mAh, wherein the positive electrode of the battery is Li 1.05 Ni 0.8 co 0.17 al 0.03 o 2 , the negative electrode is artificial graphite, and the separator is polypropylene (PP) / polyethylene (PE) / polypropylene (PP); respectively pouring different electrolytes, storing them at 85 degrees for 4 hours and 60 degrees for 30 days, and testing their thickness Variety. After high temperature storage, the thickness change is required to be no more than 5%.

[0018] This embodiment is specifically shown in the following table:

[0019] test electrolyte 85 degrees storage for 4 hours thickness change Store at 60 degrees for 30 days thickness change Example 1-1 1M LiBF 4 EC-EMC (30 / 70, v / v), VC (1wt%)+PS (2wt%)+SN (1wt%) 13.1% 14.7% Example 1-2 1M LiBF 4 EC-EMC-GBL (30 / 40 / 30, v / v), VC (1wt%)+PS (2wt%)+SN (1wt%) 4.3% 4.5% Example 1-3 1M LiBF 4 EC-EMC-GBL (30 / 30 / 40, v / v)...

Embodiment 2

[0024] Prepare 523550 soft-pack lithium-ion batteries of 1000mAh, wherein the positive electrode of the battery is Li 1.05 Ni 0.8 co 0.17 al 0.03 o 2 , the negative electrode is artificial graphite, and the separator is polypropylene (PP) / polyethylene (PE) / polypropylene (PP); respectively pouring different electrolytes, storing them at 85 degrees for 4 hours and 60 degrees for 30 days, and testing their thickness Variety. After high temperature storage, the thickness change is required to be no more than 10%.

[0025] This embodiment is specifically shown in the following table:

[0026] Electrolyte 85 degrees storage for 4 hours thickness change Store at 60 degrees for 30 days thickness change Example 2-1 1M LiBF4 EC-EMC-GBL (30 / 20 / 50, v / v), VC (1.5wt%) 23.1% 24.7% Example 2-2 1M LiBF4 EC-EMC-GBL (30 / 20 / 50, v / v), VC (1.5wt%)+PS (1.5wt%) 8.3% 8.5% Example 2-3 1M LiBF4 EC-EMC-GBL (30 / 20 / 50, v / v), VC (1.5wt%)+SN (1wt%) 6.8% 7.1% ...

Embodiment 3

[0030] Prepare 523550 soft-pack lithium-ion batteries of 1000mAh, wherein the positive electrode of the battery is Li 1.05 Ni 0.8 co 0.17 al 0.03 o 2 , the negative electrode is artificial graphite, and the separator is polypropylene (PP) / polyethylene (PE) / polypropylene (PP); according to the experimental results of Example 2, ethylene carbonate (EC)-ethyl methyl carbonate (EMC) was selected - Butyrolactone (GBL) (30 / 20 / 50, v / v) solvent system and vinylene carbonate (VC) (1wt%) + 1,3 propane sultone (PS) (2wt%) + butane Dinitrile (SN) (1wt%) is a composite additive, LiB(C 2 o 4 ) 2 Salt, inject its electrolyte into the battery to be tested, and test the thickness change of the battery after high-temperature storage (85 degrees for 4 hours).

[0031] This embodiment is specifically shown in the following table:

[0032] Electrolyte Thickness change after storage at 85 degrees for 4 hours Example 3-1 0.7M LiB(C 2 o 4 ) 2 EC-EMC-GBL (30 / 20 / 50,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com