1,000 MPa-level high-aluminum hot-dip-galvanized dual-phase steel and preparation method thereof

A dual-phase steel and hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as missed plating, deterioration of spot weldability of galvanized sheet, and reduction of galvanized wettability , to achieve the effect of strong weldability and platability, high work hardening rate and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

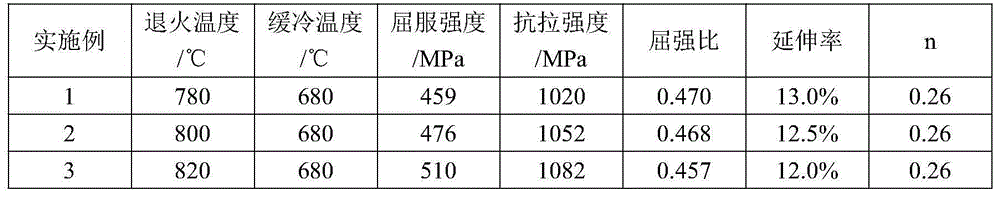

[0025] The chemical composition of the embodiment of the present invention is as shown in Table 1. After smelting, the billet forging size is 30mm (thickness) × 90mm (width) × 90mm (length) billet. After forging, the billet is soaked at 1250°C for 1 hour, hot rolled to 3.5mm, the rolling start temperature is ≥1150°C, and the final rolling temperature is controlled at about 850°C, then water cooled to the coiling temperature of 650°C, put into the holding furnace to cool with the furnace, Simulate the coiling process. The hot-rolled sheet is cold-rolled after pickling, and the cold-rolled reduction rate is about 70%.

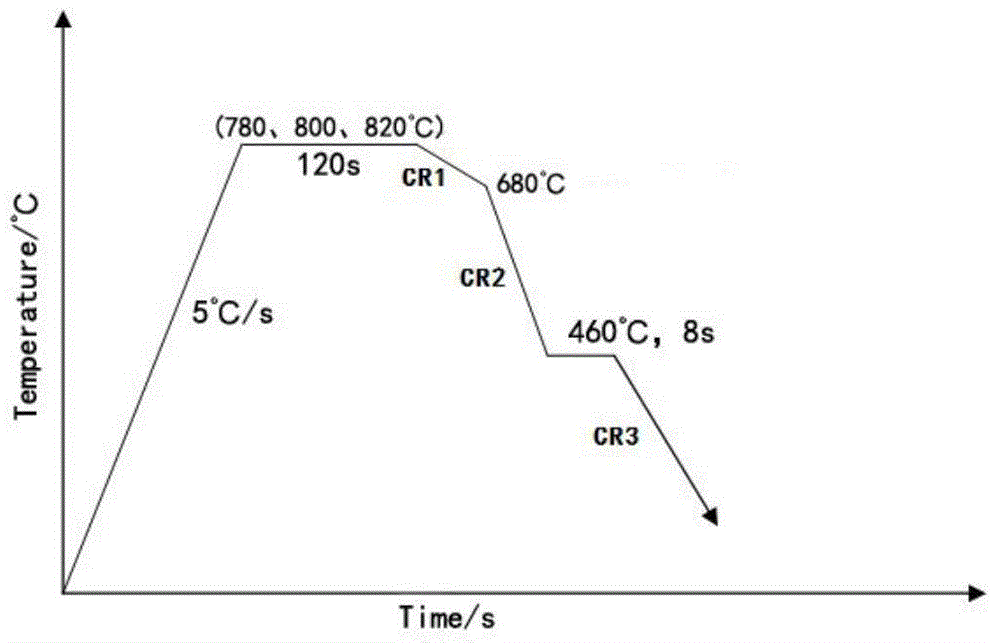

[0026] Schematic diagram of hot-dip galvanizing annealing process figure 1As shown, the cold-rolled sheet was heated to the two-phase region at a rate of 5°C / s for annealing, respectively 780°C, 800°C, and 820°C, kept for 120s, and then slowly cooled to 680°C at 7°C / s, followed by 22°C The cooling rate of ℃ / s is quickly cooled to 460 ℃ and enters the zinc pot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com