Composite structure type high tensile strength steel plate, plated plate of composite structure type high tensile strength steel and method for their production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

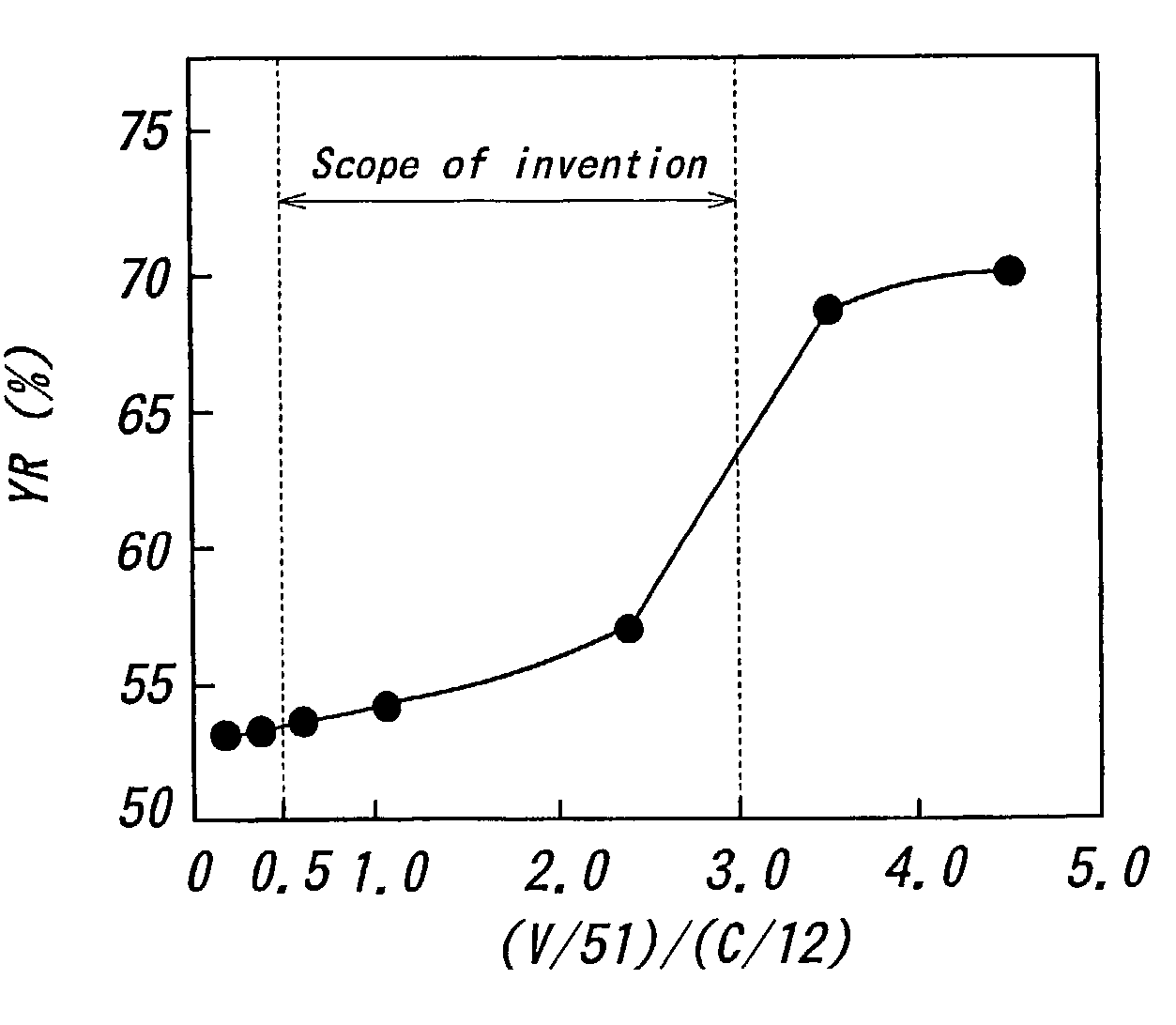

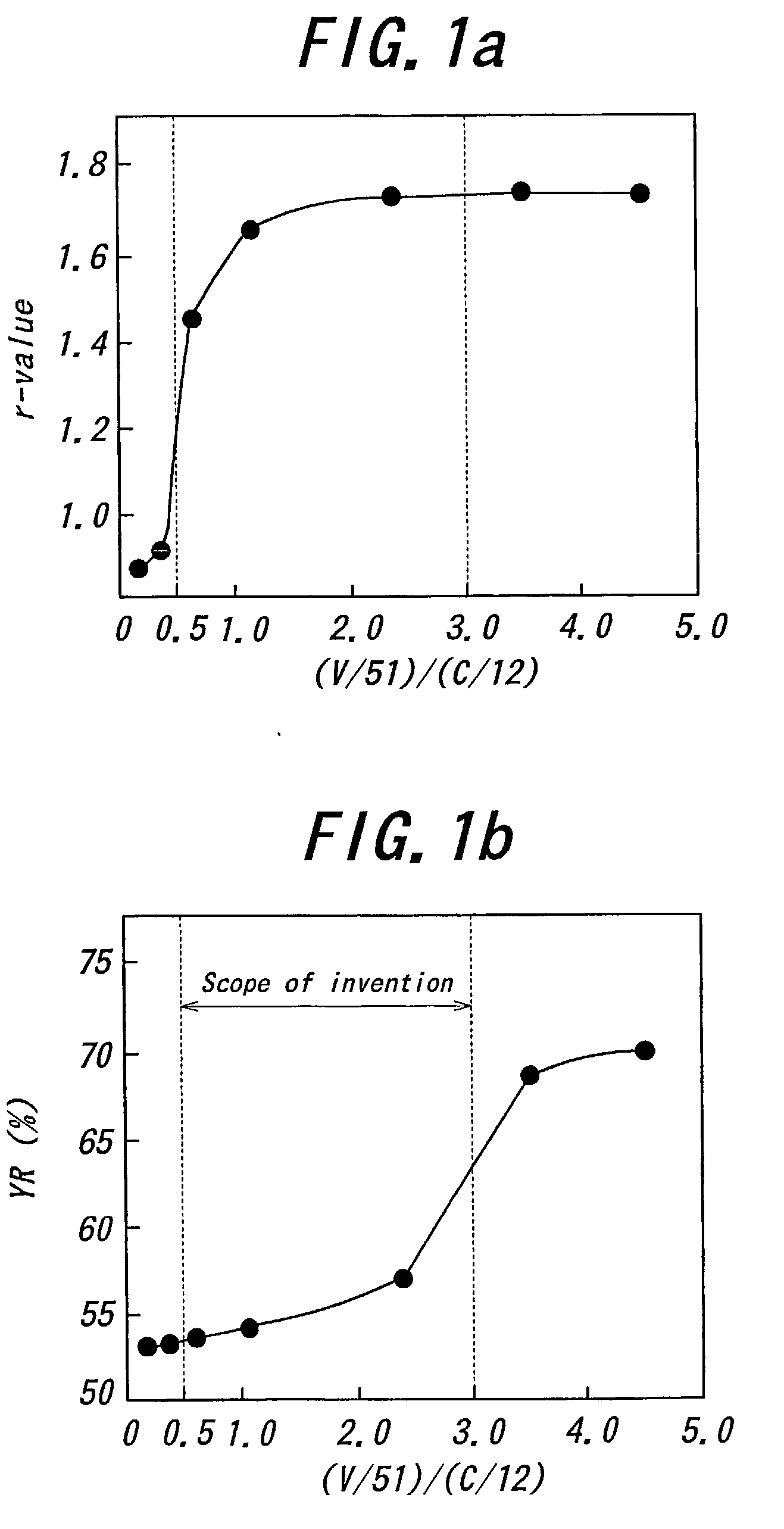

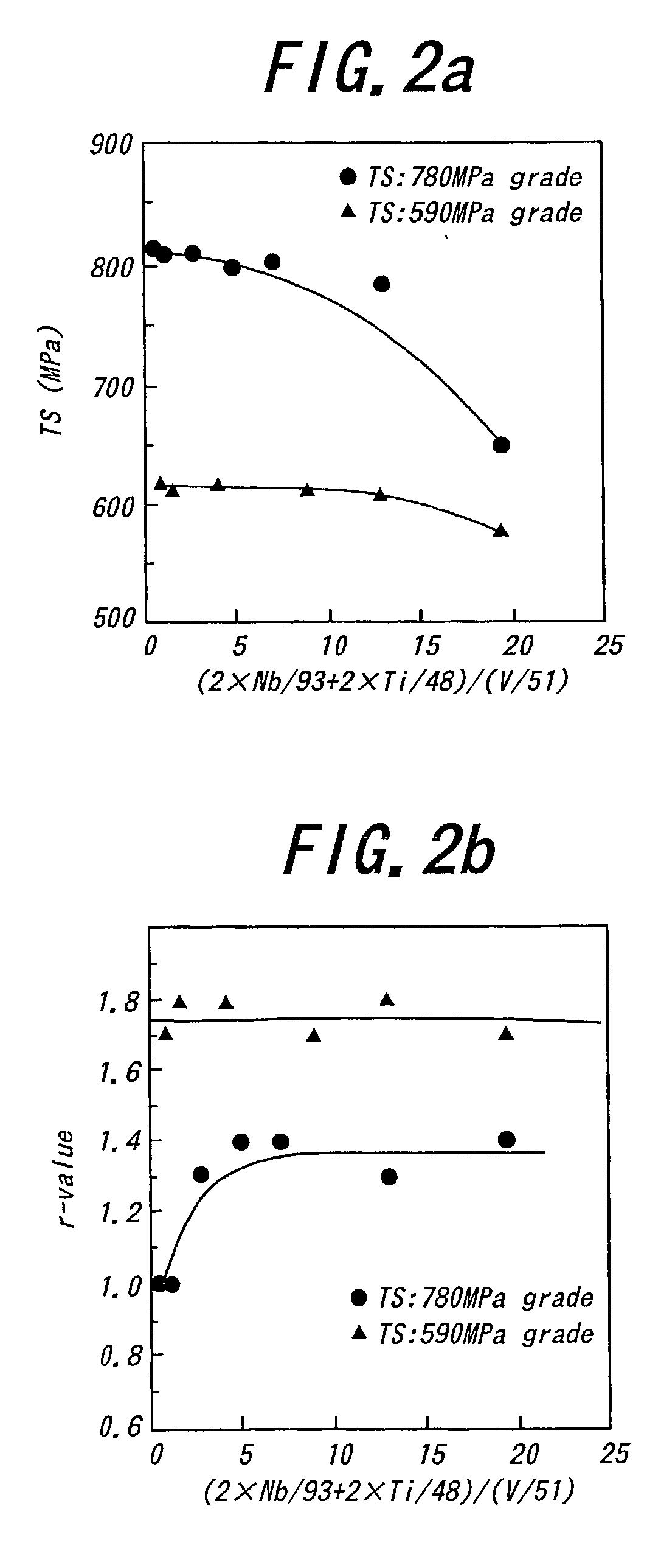

Image

Examples

Embodiment Construction

1-C 830 92 M 8 8 340 600 31 57 1.8 Invention example 6 1-D 830 90 M 10 10 330 610 30 54 1.4 Invention example 7 1-E 830 92 M 8 8 310 570 33 54 1.7 Invention example 8 1-F 830 100 -- 0 0 510 600 27 85 1.8 Comparative example 9 1-G 830 93 M 7 7 330 610 31 54 0.8 Comparative example 10 1-H 850 92 M 8 8 350 630 29 56 1.9 Invention example 11 1-I 850 93 M 7 7 330 620 30 53 1.9 Invention example 12 1-J 850 92 M 8 8 330 610 33 54 1.8 Invention example 13 1-K 830 92 M 8 8 245 450 38 54 1.9 Invention example 14 1-L 830 93 M 7 7 330 605 30 55 1.8 Invention example (Note) *.sup.1F is abbreviation of ferrite phase, M is abbreviation of matensite phase, P is abbreviation of perlite phase and B is abbreviation of beinite phase.

[0133]

8TABLE 5(b) Cold rolling Annealing Microstructure Mechanical properties of temperature in Ferrite Second phase cold rolled steel sheet Steel continuous phase Area ratio of Area ratio Tensile properties sheet Steel annealing line Area martensite of second YS TS El YR N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com