Enzymolysis, phosphorylation and heat treatment method for corn flour

A heat treatment method and technology of corn flour, applied in the field of grain processing, to achieve the effect of fine and smooth taste, simple equipment, and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of enzymolysis phosphorylation heat treatment method of cornflour, comprises the following steps:

[0029] Select common commercially available corn flour with a particle size of 70 mesh, add water, the mass ratio of water to corn flour is 1.3:1, fully mix to form a paste-like viscous fluid, add 0.5% of the mass of corn flour to neutral protease, and the enzyme activity is 2.38× 10 4 U / g, enzymatic hydrolysis at 55°C for 3.5h, then heated to 75°C for 10 minutes to inactivate the enzyme, freeze-dried and pulverized the corn flour after enzyme inactivation to obtain enzymatic corn flour; The reagent is fully mixed with the enzymatic corn flour by spraying, sealed with plastic wrap, left at room temperature for 10 hours, and then placed in an oven at 60°C to reduce the moisture content of the enzymatic corn flour to 10%, and then placed in The heating reaction was carried out in a drying oven at 150° C. for 2 hours, wherein the amount of the phosphoryl...

Embodiment 2

[0031] Embodiment 2 A kind of enzymolysis phosphorylation heat treatment method of cornflour, comprises the following steps:

[0032] Select ordinary commercially available corn flour with a particle size of 75 mesh, add water, the mass ratio of water to corn flour is 1.2:1, mix well to form a paste-like viscous fluid, add 0.4% of the mass of corn flour to neutral protease, and the enzyme activity is 2.38× 10 4 U / g, enzymatic hydrolysis at 52°C for 3 hours, then heated to 70°C for 10 minutes to inactivate the enzyme, freeze-dried and pulverized the corn flour after enzyme inactivation to obtain enzymatic corn flour; Mix well with enzymatic corn flour by spraying, seal it with plastic wrap, let it stand at room temperature for 12 hours, then place it in an oven at 45°C to reduce the moisture content of corn flour to 9%, and then place it at 125°C The reaction was heated for 2.8 hours in an electric blast drying oven, wherein the amount of phosphorylation reagent added was 1.5%...

Embodiment 3

[0034] Embodiment 3 A kind of enzymolysis phosphorylation heat treatment method of corn flour, comprises the following steps:

[0035] Select ordinary corn flour with a particle size of 80 mesh, add water and mix thoroughly, the mass ratio of water to corn flour is 1.3:1, add 0.4% neutral protease of corn flour mass, and the enzyme activity is 2.38×10 4 U / g, enzymatic hydrolysis at 50°C for 3 hours, then heated to 75°C for 10 minutes to inactivate the enzyme, freeze-dried and pulverized the corn flour after enzyme inactivation to obtain enzymatic corn flour; Mix well with enzymatic corn flour by spraying, seal with plastic wrap, let it stand at room temperature for 12 hours, and then place it in an oven at 50°C to reduce the moisture content of corn flour to 10%, and then place it at 130 The reaction was heated in an electric blast drying oven at ℃ for 2 hours, and the amount of phosphorylation reagent added was 1.2% of the mass of enzymatically hydrolyzed corn flour.

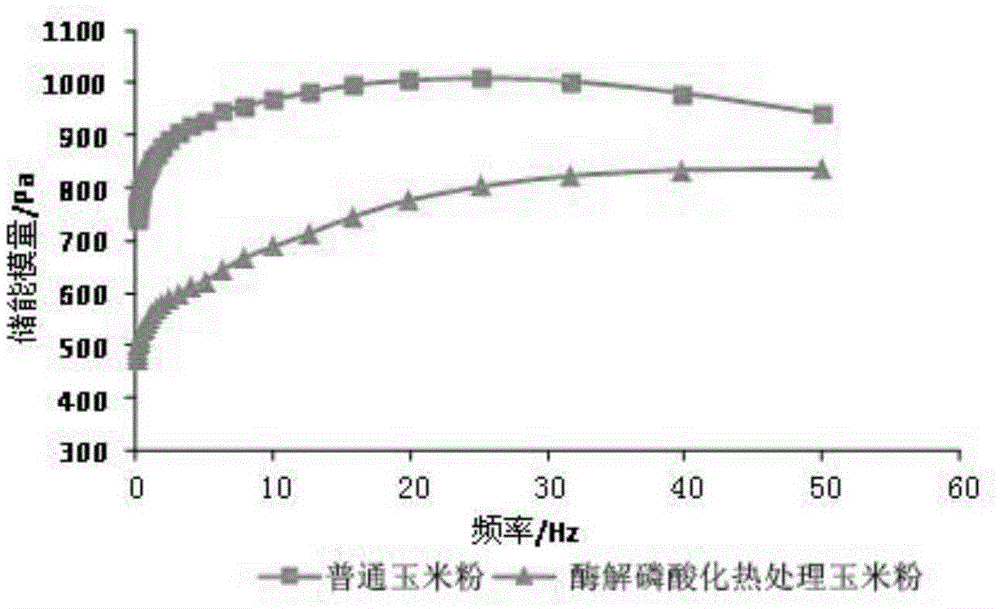

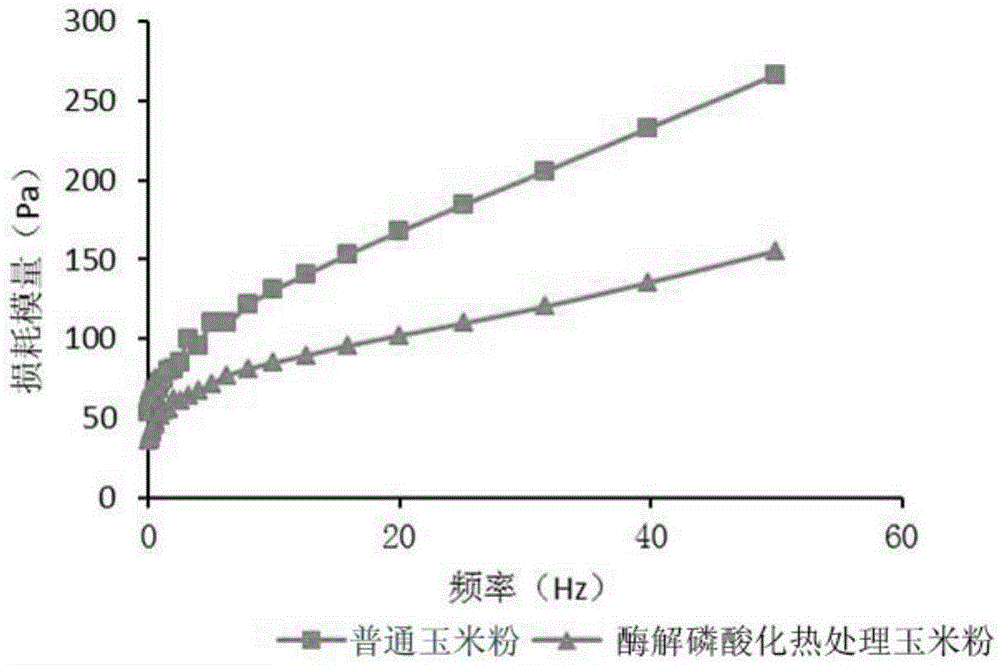

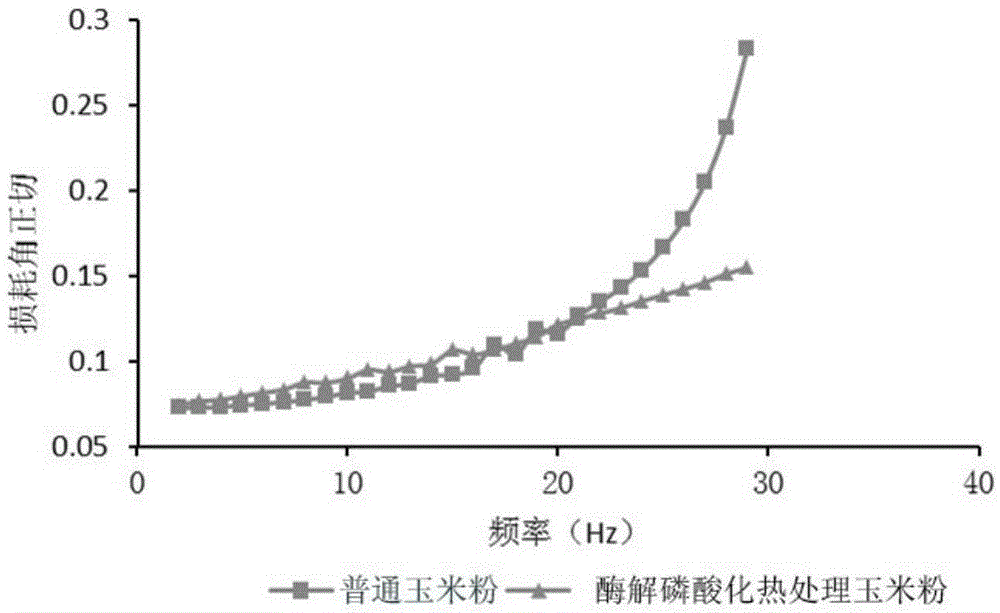

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com