Active natto hot and spicy sauce and processing method thereof

A technology for spicy sauce and natto, which is applied in the field of food processing, can solve the problems of peculiar smell and sticky thread, which affects consumption and promotion, and is expensive, and achieves the effects of prolonging the shelf life, shortening the fermentation period and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of active natto spicy sauce of the present invention, it is mixed by natto, biological preservative and spicy sauce, and the composition ratio of natto, biological preservative, spicy sauce is: 100: 0.05~0.1 : 20-120.

[0036] The present invention also has the following technical characteristics:

[0037] The natto is made by fermenting and maturing soybeans or black soybeans with Bacillus natto and adding biological preservatives.

[0038] The spicy sauce is made of bright red chili or dried red chili with ingredients.

[0039] The ingredients of the bright red pepper are: bright red pepper, cooked sesame, ginger, Chinese prickly ash, fine salt, sugar, 20 ° Be' salt water, bright red pepper, cooked sesame, ginger, Chinese pepper, fine salt, sugar, 20 ° Be' salt water The proportioning ratio is: 100:5~35:5~10:0.4:6:6:27.

[0040] The added ingredients of the dried red pepper are: dried red pepper, cooked sesame, ginger, pepper powder, fine salt,...

Embodiment 2

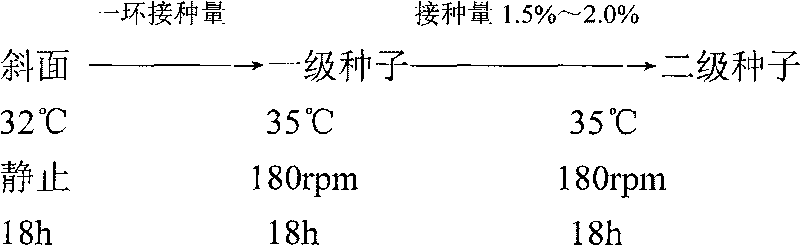

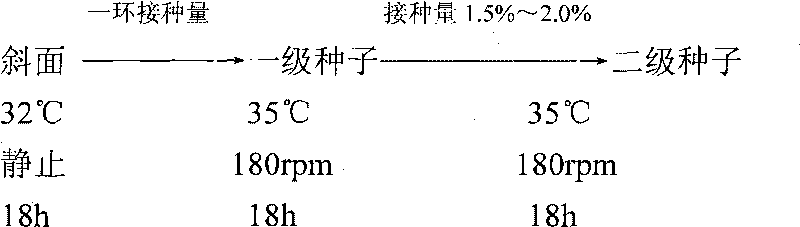

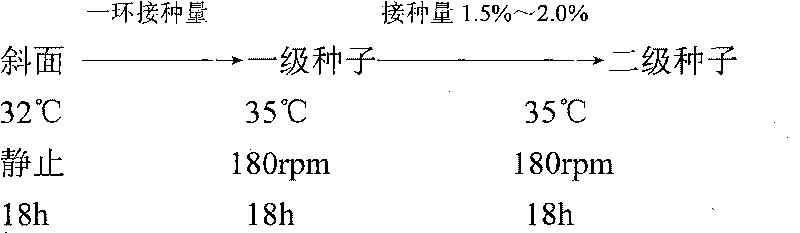

[0063] Embodiment 2: the technical process of the present invention is as follows: get 100kg of soybeans screened, add water to wash clean, soak in clear water then, soak at room temperature about 24 ℃ for 20 hours, until soybeans have no hard core, drain; (wet Beans are about 200kg) Put the soaked soybeans into a sterilization tank for heat sterilization, the sterilization temperature is 121°C; the sterilization time is 45min. Strain culture:

[0064]

[0065] Slope seed medium formula (100ml): beef extract 0.8g, peptone 1.0g, sodium chloride 0.3g, pH 7.0, sterilization temperature 121°C; sterilization time 20min. Culture conditions: temperature 32°C, static culture, time 18h; primary seed and secondary seed medium: primary seed medium (100ml): glucose 1g, corn steep liquor 2g, sodium chloride 0.3g, molasses 0.1g; Grade seed medium (3000ml): glucose 30g, corn steep liquor 60g, sodium chloride 9g, molasses 3g, pH7.0, sterilization temperature 121°C; sterilization time 20mi...

Embodiment 3

[0066] Embodiment 3: making of spicy sauce: get 100 kg of fresh red pepper, remove the stalk, wash, drain, and pulverize; get 10 kg of sesame, remove impurities, fry it, and pulverize it; get 5 kg of ginger, wash it, and pulverize it; get 0.4 kg of Chinese prickly ash Pulverize; mix and grind crushed chili, cooked sesame, ginger, Chinese prickly ash, 6kg of fine salt, 6kg of sugar, and 27kg of brine at 20°Be', heat and sterilize; mix the finished product: 200kg of natto fermented for 18 hours and biological Preservative 0.1kg, spicy sauce 100kg, stir and mix evenly in the sterilized finished product mixing tank; the mixed finished product is automatically packed into packaging boxes by the packaging machine, 30g per box;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com