Manufacturing method of ultra-soft state photovoltaic welding belt

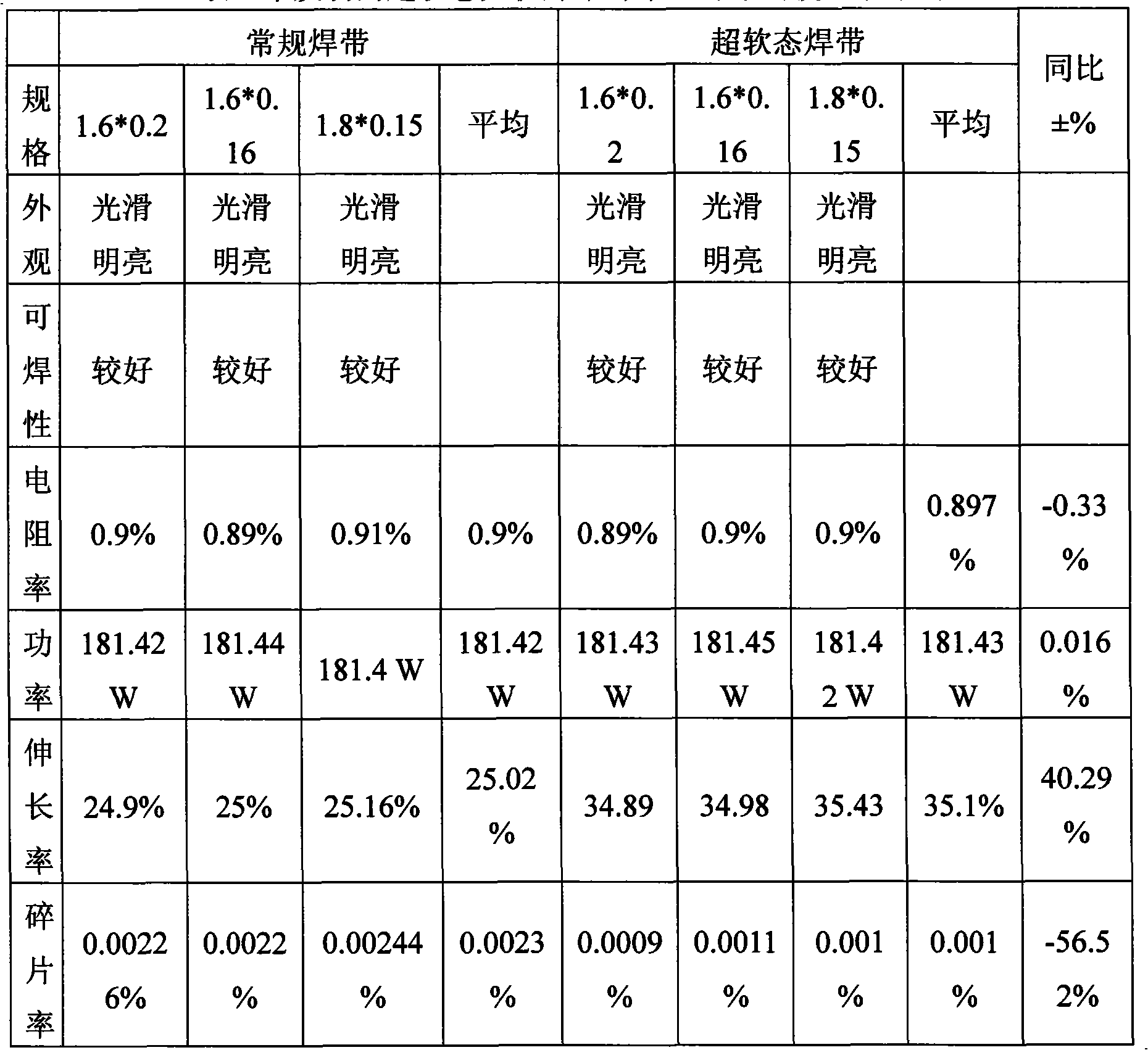

A photovoltaic ribbon and manufacturing method technology, applied in the field of ribbon manufacturing, can solve the problems of weldability and elongation that are difficult to adapt to the rapid development of photovoltaic modules, high fragmentation rate, and economic losses of photovoltaic module manufacturers. Strong weldability, reduced chipping rate, and improved elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Example: finish rolling the oxygen-free copper wire and undergo continuous tubular annealing, the temperature is controlled at 500-550 °C, and the speed is 2 m / min; the annealed oxygen-free copper wire is ultrasonically cleaned with clean water, and the temperature is 40-500 °C. 60℃, the frequency is 15-40KHz, the speed is 2m / min, the cleaned copper strip is soaked with NCF no-cleaning environment-friendly flux, and enters the tin furnace to coat tin, the temperature is controlled at 200-220℃, and the speed is 2 m / min, the solder ribbon comes out of the tin furnace, and is rapidly cooled and shaped by the automatic speed-regulating induced draft fan, and then the solder ribbon is finished by the automatic drawing machine and the automatic wire take-up machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com