Framework and bogie comprising same

A bogie and frame technology, which is applied in the field of rail transit, can solve the problems of poor welding performance and large load burden of the frame, and achieve the effects of reducing load burden, reducing the structure of a series of springs, simplifying the structure and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

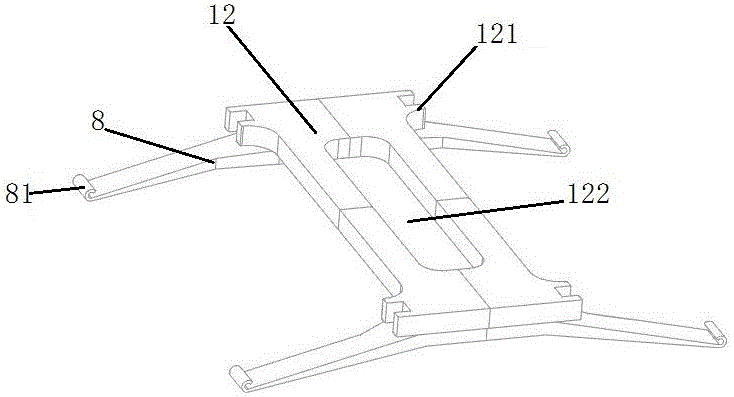

[0036] like figure 1 As shown, a frame includes beams 12 and side beams 8 made of carbon fiber composite materials. The side beam 8 is a sheet structure, and the middle part is arched in the longitudinal direction. The beam 12 is connected to the arched top of the side beam 8 and is detachably connected to the side beam 8 .

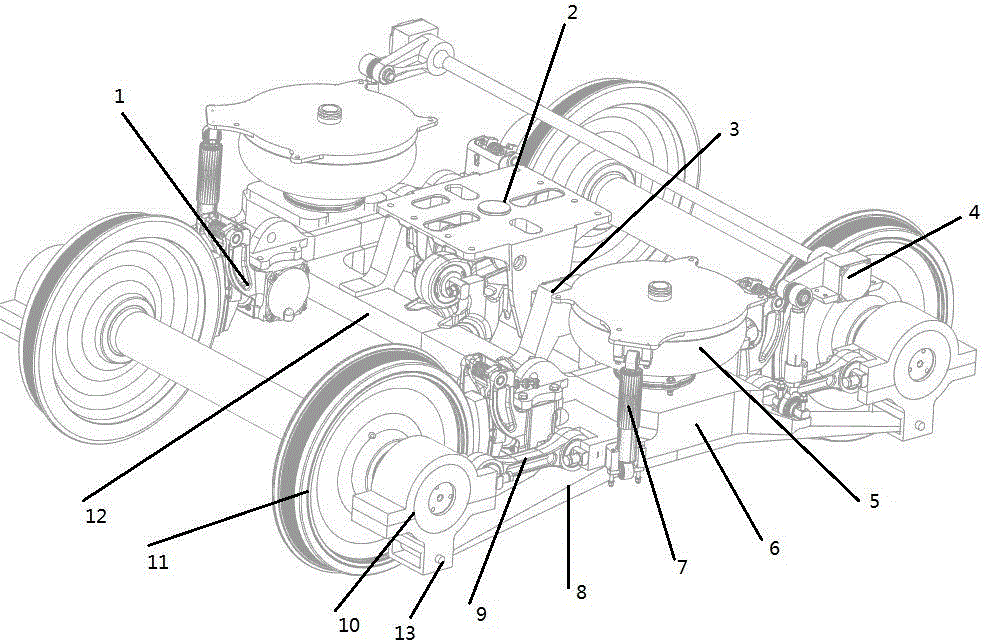

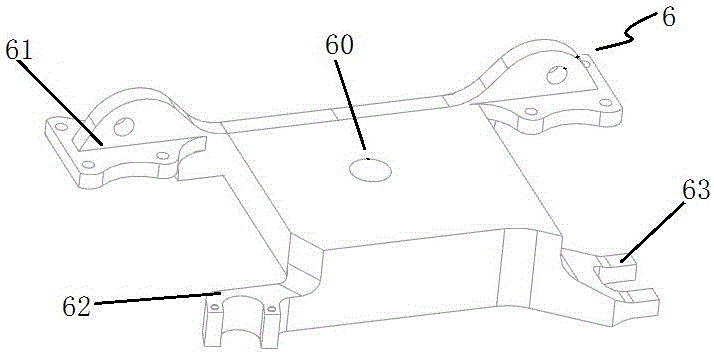

[0037] like Figure 2-4 As shown, a bogie includes the frame described in the above solution. Integrated mounts 6 are respectively installed on the upper surfaces of the transverse ends of the beam 12. The integrated mounts 6 include a base 60, a pair of brake mounts 61 arranged back-to-back along the same straight line on one side of the base 60, and a pair of brake mounts 61 on the base 60. A vertical shock absorber seat 62 is provided at one end of the other side and an anti-roll device mounting seat 63 is provided at the other end. In the middle of the beam 12 is provided a rectangular through hole 122 for installing the fifth wheel 2 and the fift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com